The Fabrication and Characterization of BaTiO3 Piezoceramics Using SLA 3D Printing at 465 nm Wavelength

Abstract

:1. Introduction

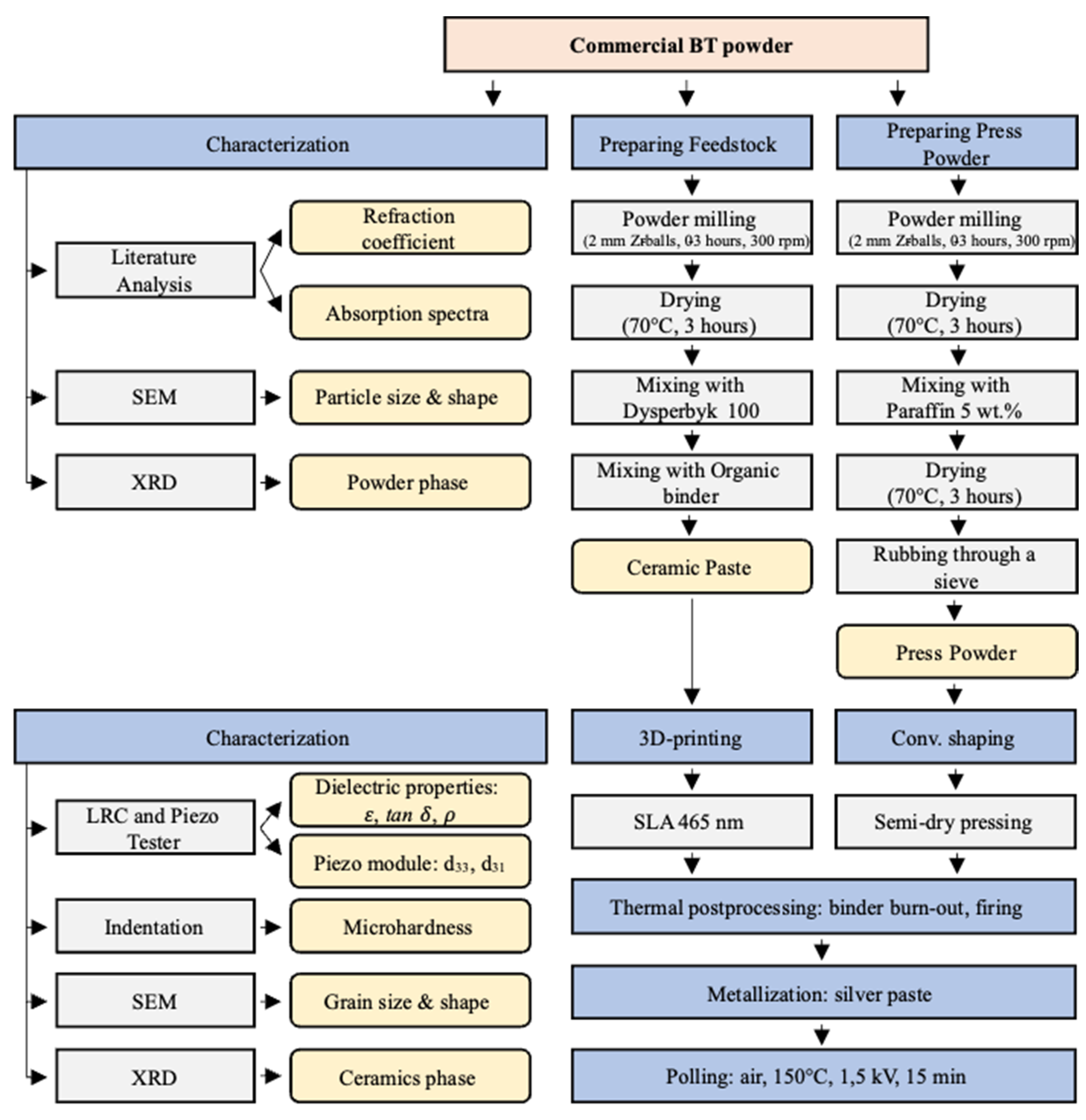

2. Materials and Methods

2.1. Materials

2.2. SLA 465 nm 3D Printing

2.3. Semi-Dry Pressing

2.4. Post-Processing: Thermal Treatment, Metallization, Polling

2.5. Measurement of Powder and Samples Properties

3. Results

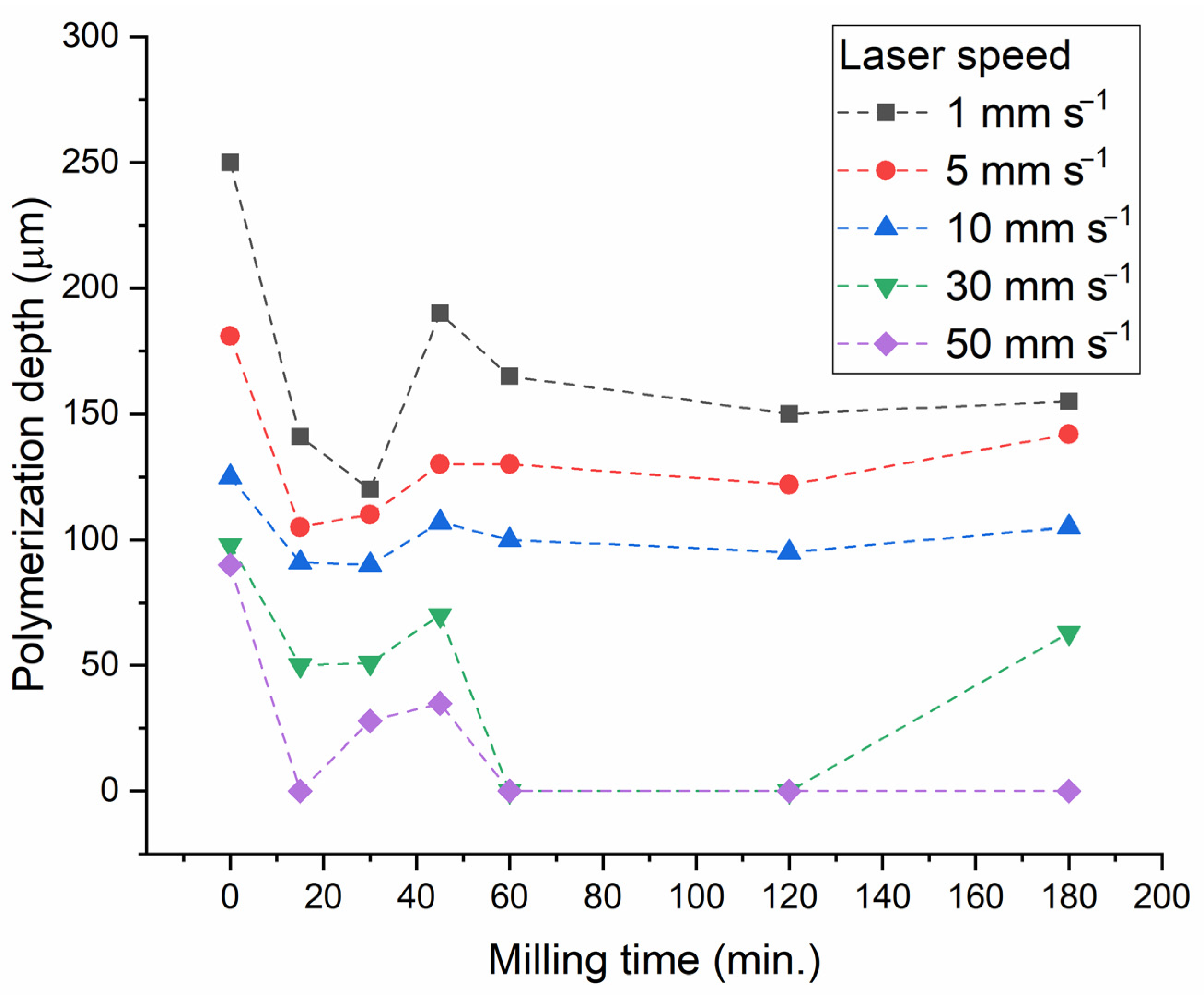

3.1. Photopolymerization

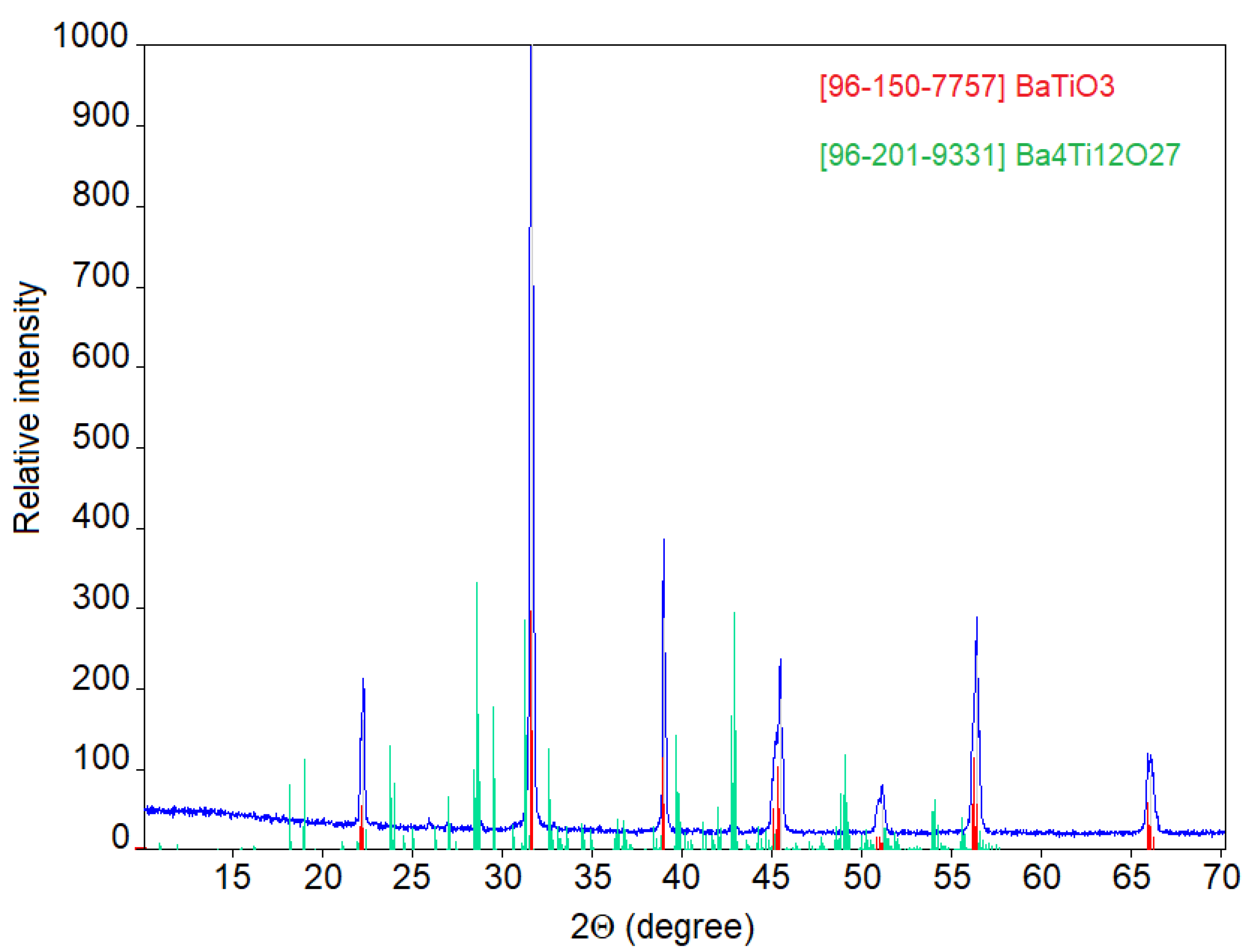

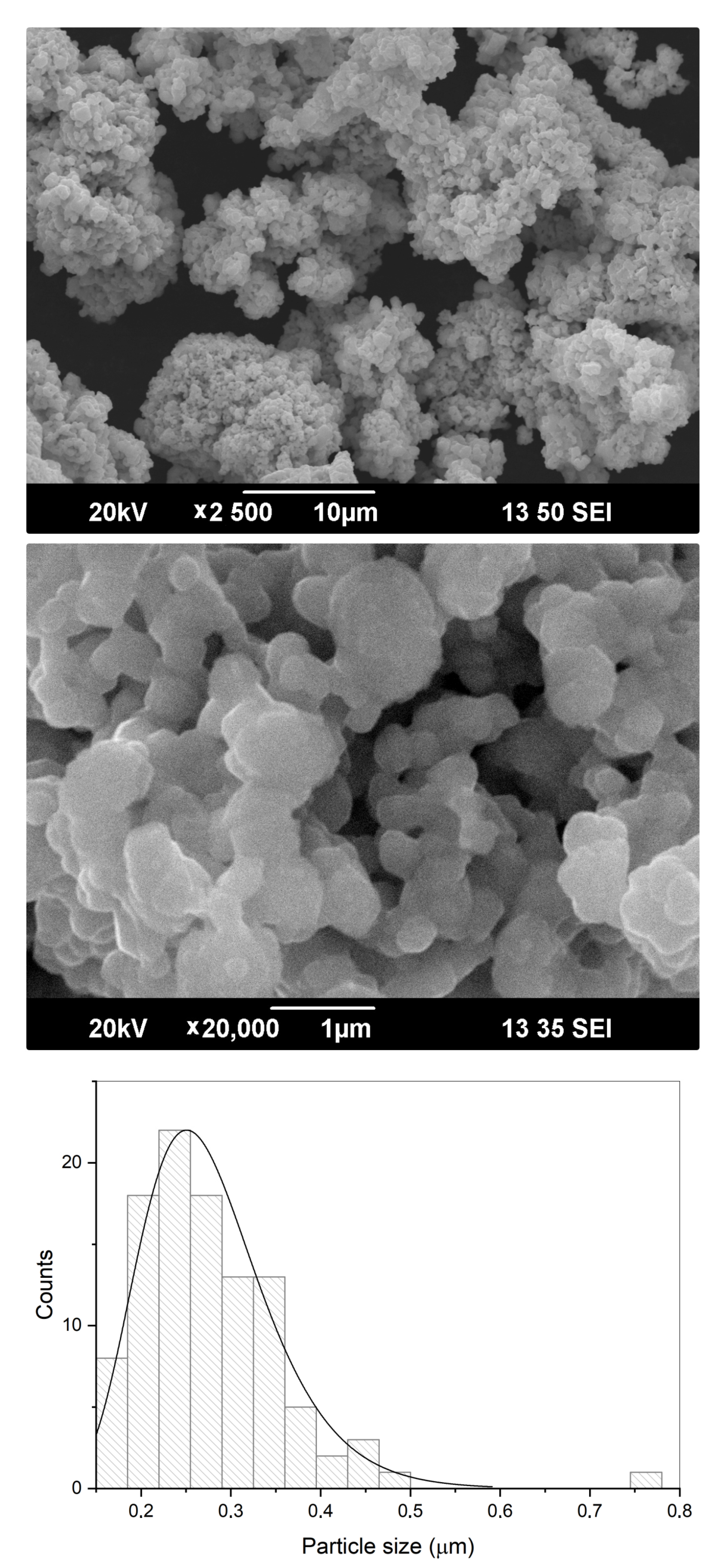

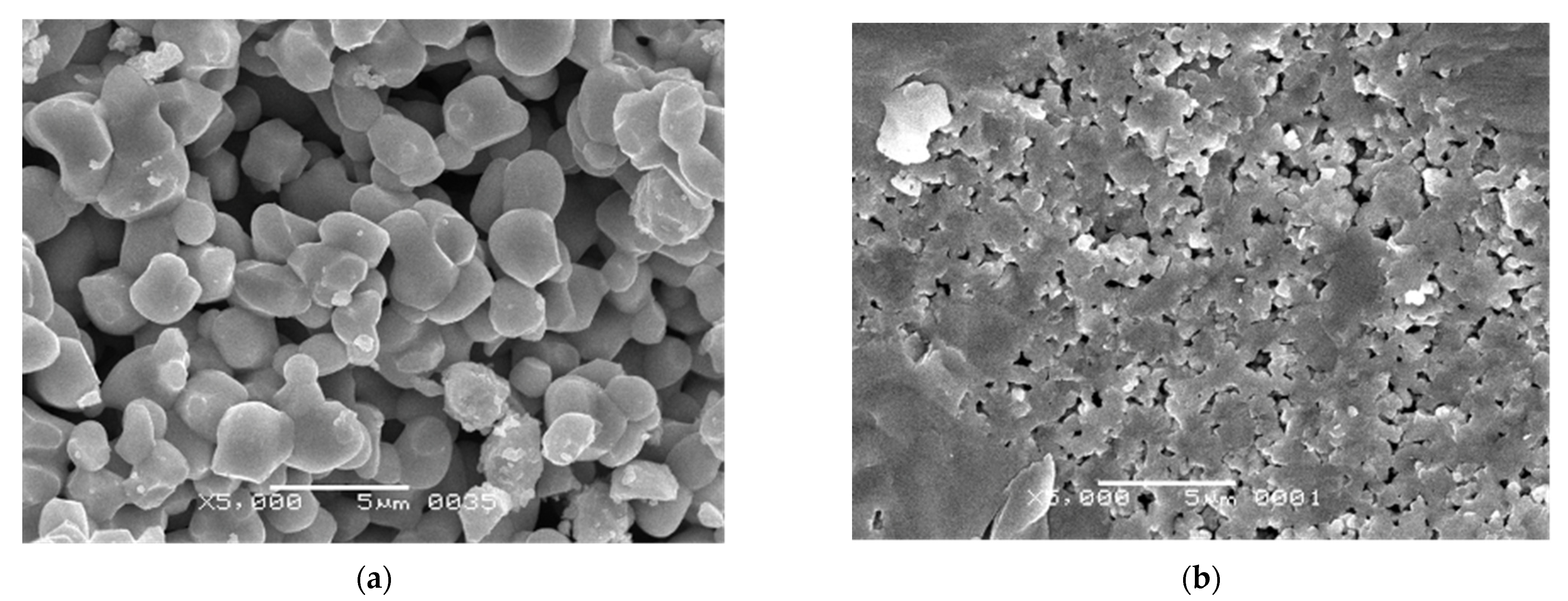

3.2. Materials Characterization

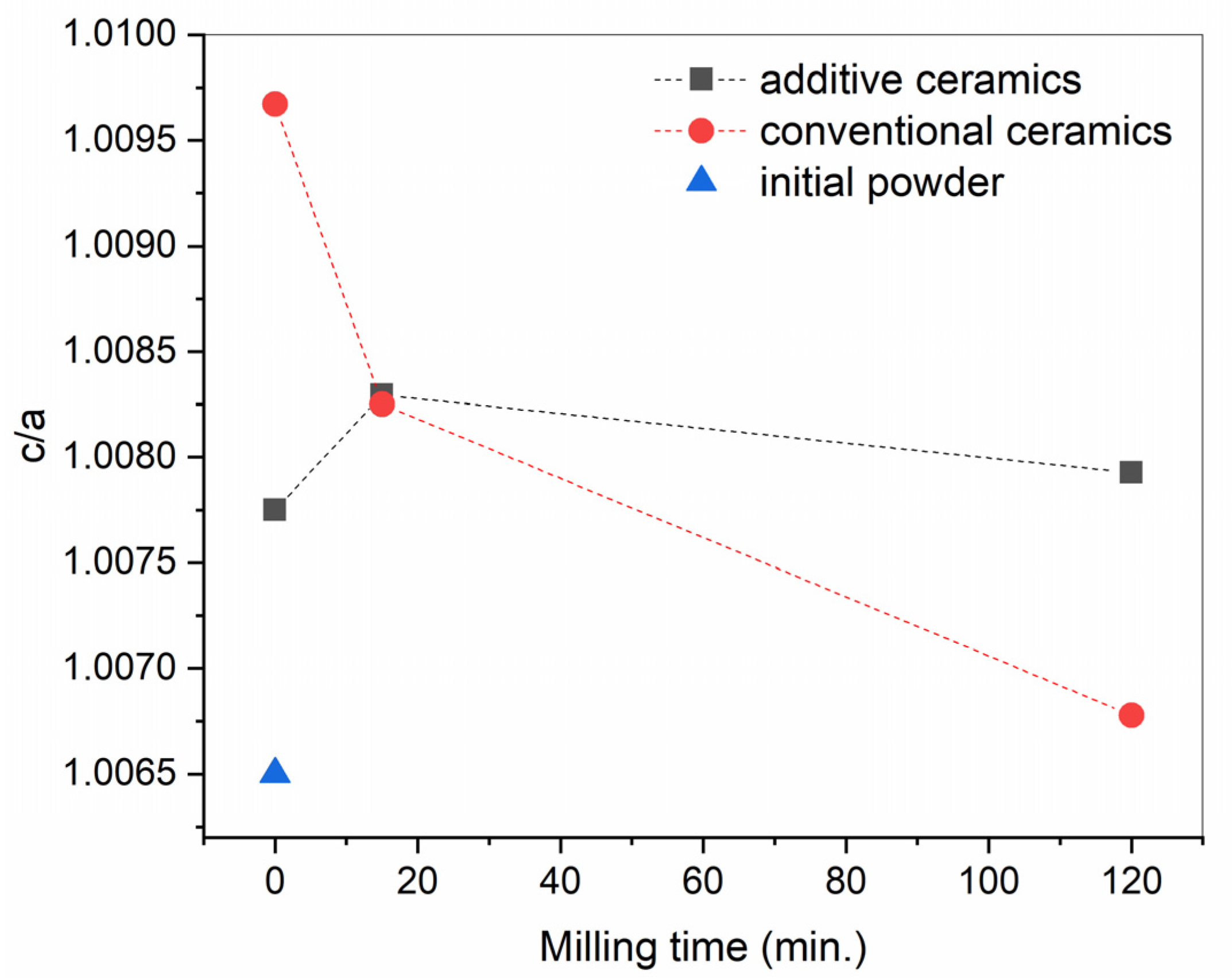

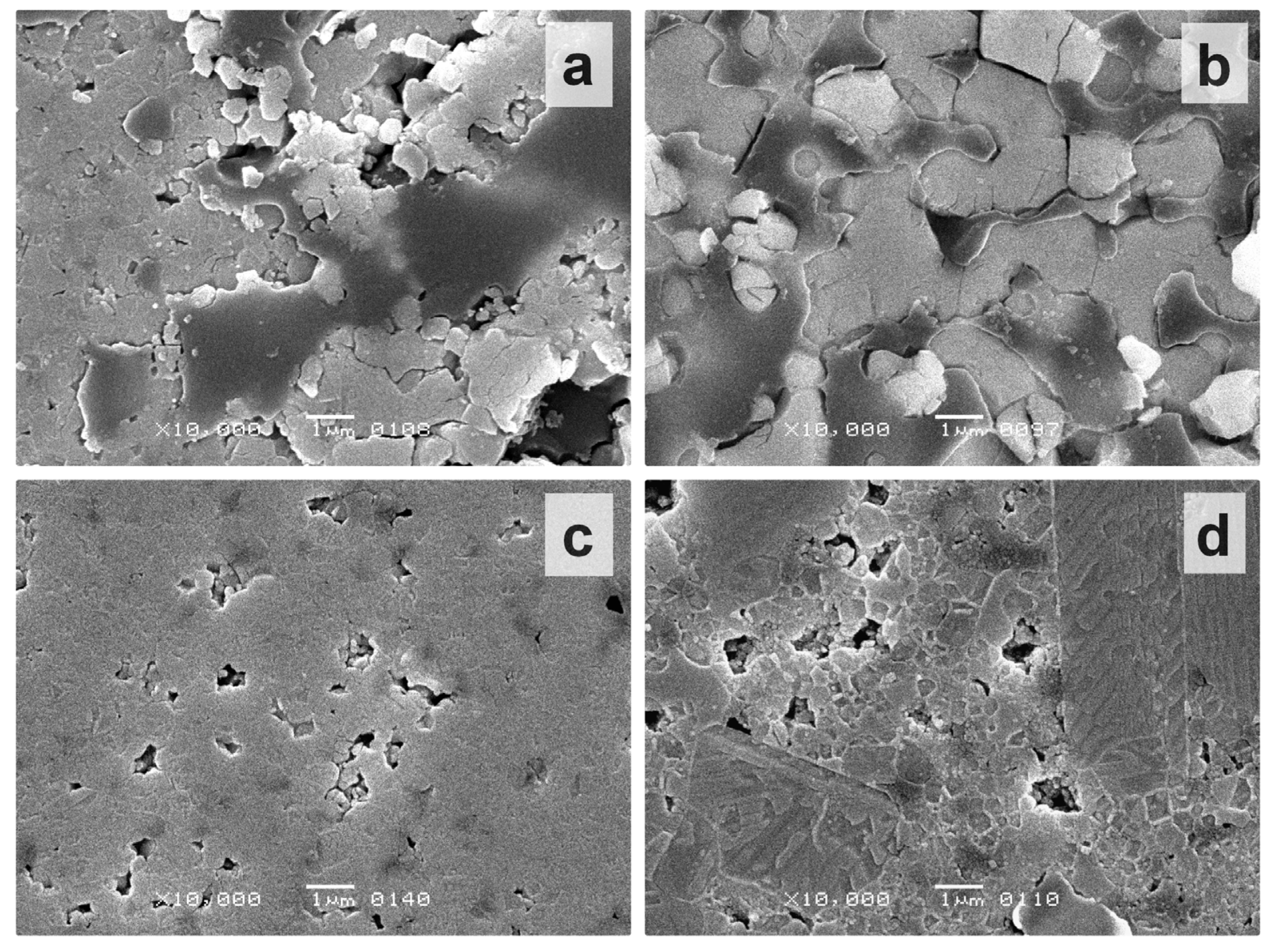

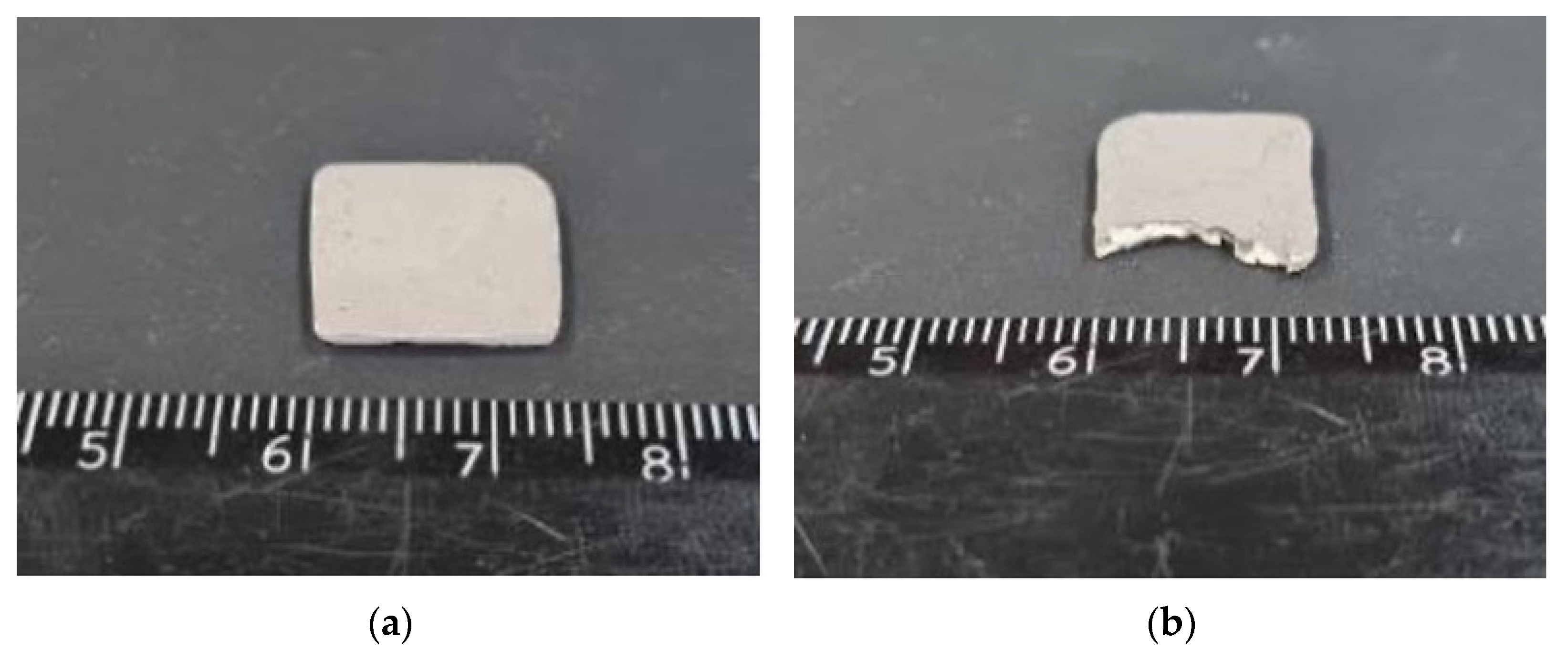

3.3. Ceramics Properties

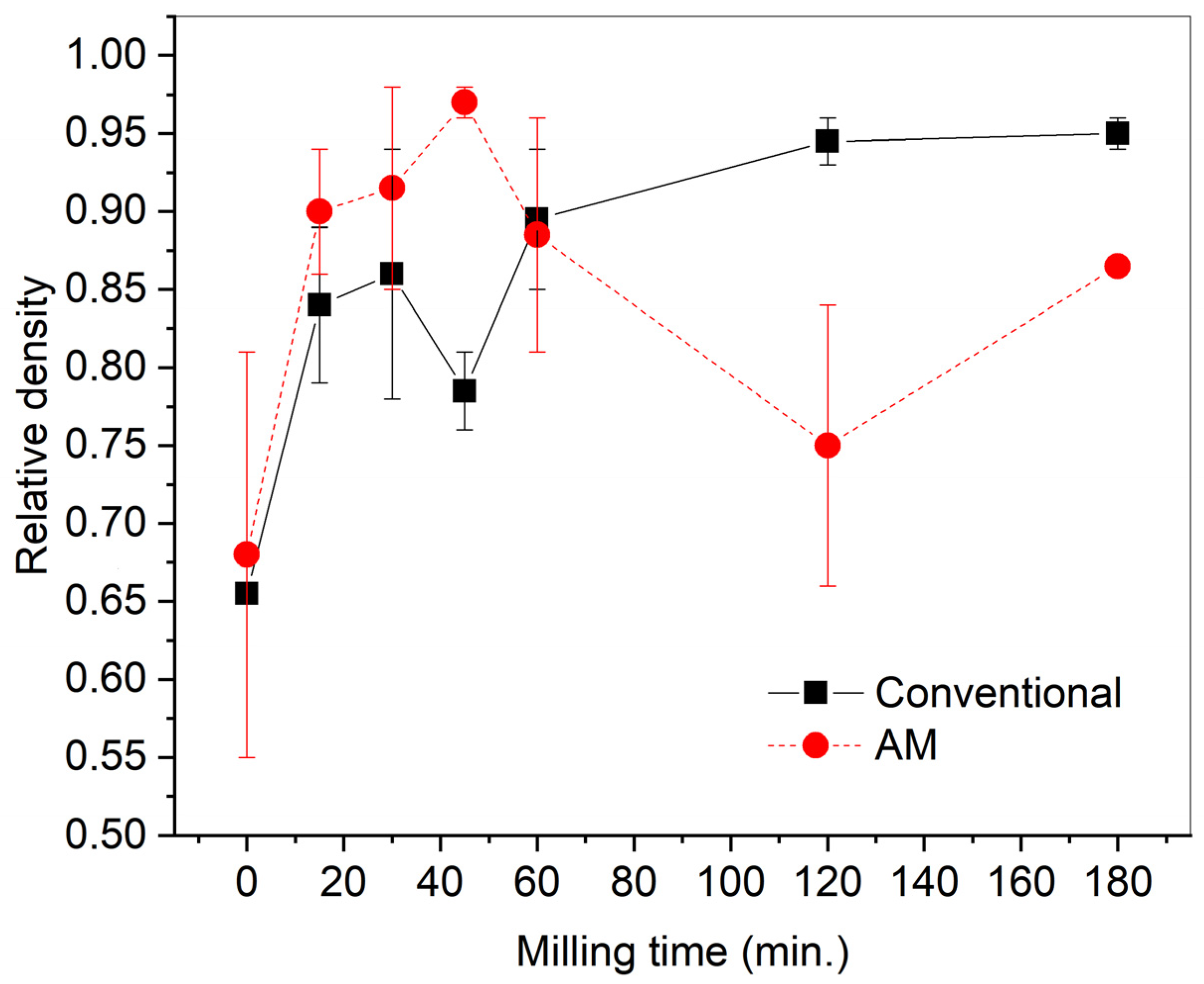

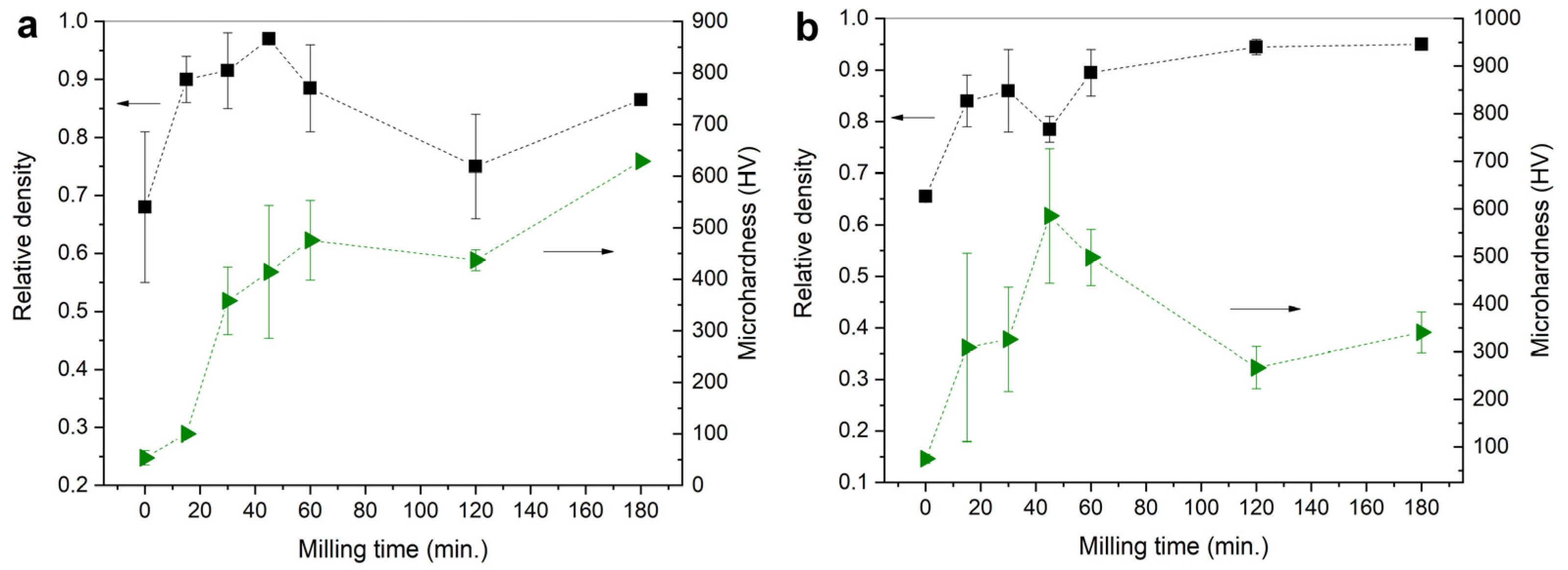

3.3.1. Relative Density

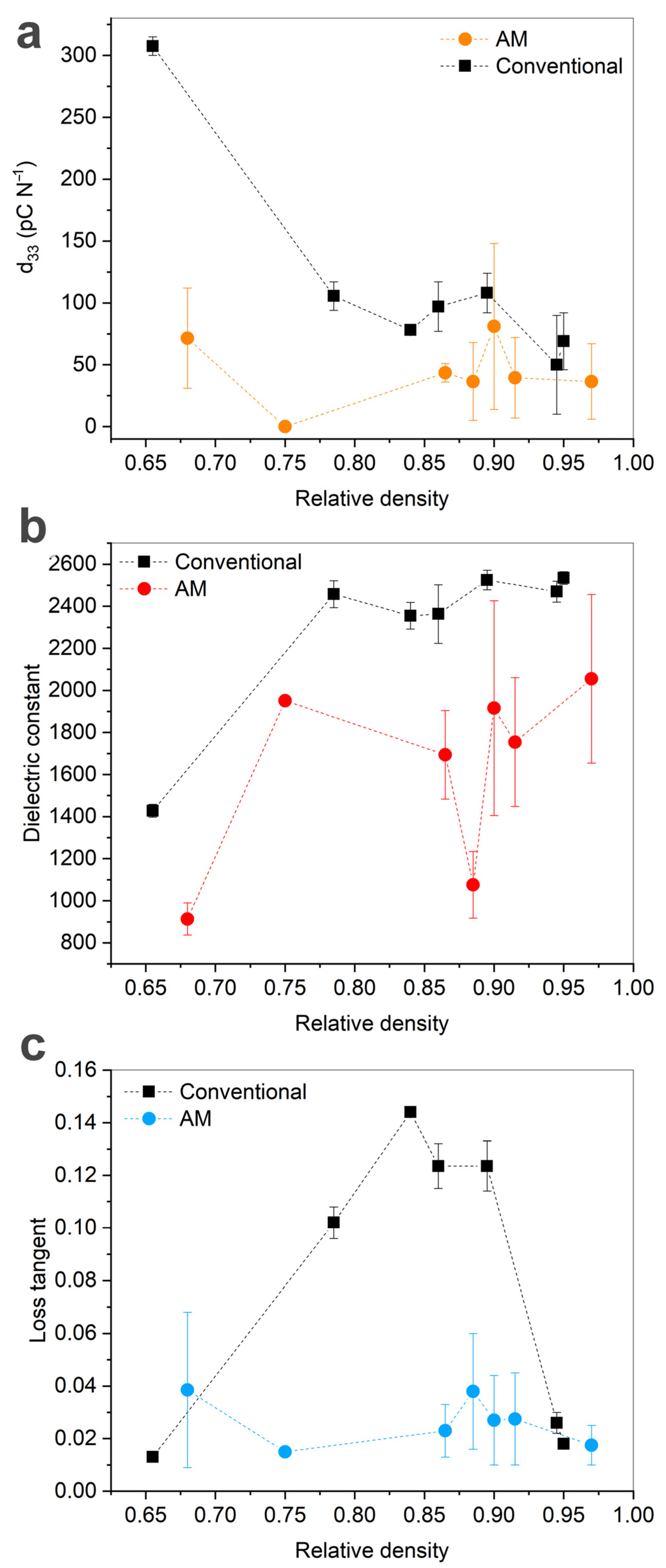

3.3.2. Piezoelectric Properties

3.3.3. Microhardness

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Yunus, D.E.; He, R.; Shi, W.; Kaya, O.; Liu, Y. Short Fiber Reinforced 3d Printed Ceramic Composite with Shear Induced Alignment. Ceram. Int. 2017, 43, 11766–11772. [Google Scholar] [CrossRef]

- Koruza, J.; Bell, A.J.; Frömling, T.; Webber, K.G.; Wang, K.; Rödel, J. Requirements for the Transfer of Lead-Free Piezoceramics into Application. J. Mater. 2018, 4, 13–26. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, Y.; Wu, J.-W.; Ji, X.-R.; Wu, S.-H. 3D Printing of BaTiO3 Piezoelectric Ceramics for a Focused Ultrasonic Array. Sensors 2019, 19, 4078. [Google Scholar] [CrossRef] [Green Version]

- Giberti, H.; Strano, M.; Annoni, M. An Innovative Machine for Fused Deposition Modeling of Metals and Advanced Ceramics. MATEC Web Conf. 2016, 43, 03003. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Sun, H.; Tan, Y.; Shi, Y.; Liu, J.; Zhang, S.; Huang, S. Additive Manufacturing of Traditional Ceramic Powder via Selective Laser Sintering with Cold Isostatic Pressing. Int. J. Adv. Manuf. Technol. 2017, 90, 945–952. [Google Scholar] [CrossRef]

- Lee, J.-H.; Hwang, H.-J.; Kim, J.-H.; Hwang, K.-T.; Han, K.-S. Ceramic Ink-Jet Printing on Glass Substrate Using Oleophobic Surface Treatment. J. Korean Ceram. Soc. 2016, 53, 75–80. [Google Scholar] [CrossRef] [Green Version]

- Feilden, E.; Ferraro, C.; Zhang, Q.; García-Tuñón, E.; D’Elia, E.; Giuliani, F.; Vandeperre, L.; Saiz, E. 3D Printing Bioinspired Ceramic Composites. Sci. Rep. 2017, 7, 13759. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic Stereolithography: Additive Manufacturing for Ceramics by Photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Jacobs, P.F. Rapid Prototyping & Manufacturing—Fundamentals of Stereolithography. J. Manuf. Syst. 1993, 12, 430–433. [Google Scholar] [CrossRef]

- Smirnov, A.; Chugunov, S.; Kholodkova, A.; Isachenkov, M.; Vasin, A.; Shishkovsky, I. Progress and Challenges of 3D-Printing Technologies in the Manufacturing of Piezoceramics. Ceram. Int. 2021, 47, 10478–10511. [Google Scholar] [CrossRef]

- Gentry, S.P.; Halloran, J.W. Depth and Width of Cured Lines in Photopolymerizable Ceramic Suspensions. J. Eur. Ceram. Soc. 2013, 33, 1981–1988. [Google Scholar] [CrossRef]

- Song, X.; Chen, Y.; Lee, T.W.; Wu, S.; Cheng, L. Ceramic Fabrication Using Mask-Image-Projection-Based Stereolithography Integrated with Tape-Casting. J. Manuf. Process. 2015, 20, 456–464. [Google Scholar] [CrossRef] [Green Version]

- Jang, J.H.; Wang, S.; Pilgrim, S.M.; Schulze, W.A. Preparation and Characterization of Barium Titanate Suspensions for Stereolithography. J. Am. Ceram. Soc. 2004, 83, 1804–1806. [Google Scholar] [CrossRef]

- Chen, Z.; Song, X.; Lei, L.; Chen, X.; Fei, C.; Chiu, C.T.; Qian, X.; Ma, T.; Yang, Y.; Shung, K.; et al. 3D Printing of Piezoelectric Element for Energy Focusing and Ultrasonic Sensing. Nano Energy 2016, 27, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Song, X.; Chen, Z.; Lei, L.; Shung, K.; Zhou, Q.; Chen, Y. Piezoelectric Component Fabrication Using Projection-Based Stereolithography of Barium Titanate Ceramic Suspensions. Rapid Prototyp. J. 2017, 23, 44–53. [Google Scholar] [CrossRef]

- Chen, X.; Sun, J.; Guo, B.; Wang, Y.; Yu, S.; Wang, W.; Bai, J. Effect of the Particle Size on the Performance of BaTiO3 Piezoelectric Ceramics Produced by Additive Manufacturing. Ceram. Int. 2021, 48, 1285–1292. [Google Scholar] [CrossRef]

- Sotov, A.; Kantyukov, A.; Popovich, A.; Sufiiarov, V. LCD-SLA 3D Printing of BaTiO3 Piezoelectric Ceramics. Ceram. Int. 2021, 47, 30358–30366. [Google Scholar] [CrossRef]

- Wang, W.; Sun, J.; Guo, B.; Chen, X.; Ananth, K.P.; Bai, J. Fabrication of Piezoelectric Nano-Ceramics via Stereolithography of Low Viscous and Non-Aqueous Suspensions. J. Eur. Ceram. Soc. 2020, 40, 682–688. [Google Scholar] [CrossRef]

- Chugunov, S.; Smirnov, A.; Kholodkova, A.; Tikhonov, A.; Dubinin, O.; Shishkovsky, I. Evaluation of Stereolithography-Based Additive Manufacturing Technology for BaTiO3 Ceramics at 465 nm. Appl. Sci. 2022, 12, 412. [Google Scholar] [CrossRef]

- Kholodkova, A.A.; Danchevskaya, M.N.; Ivakin, Y.D.; Muravieva, G.P.; Smirnov, A.D.; Tarasovskii, V.P.; Ponomarev, S.G.; Fionov, A.S.; Kolesov, V.V. Properties of Barium Titanate Ceramics Based on Powder Synthesized in Supercritical Water. Ceram. Int. 2018, 44, 13129–13138. [Google Scholar] [CrossRef]

- Gražulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quirós, M.; Lutterotti, L.; Manakova, E.; Butkus, J.; Moeck, P.; Le Bail, A. Crystallography Open Database—An Open-Access Collection of Crystal Structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef] [PubMed]

- Larson, A.C.; Von Dreele, R.B. General Structure Analysis System (GSAS); Los Alamos National Laboratory: Los Alamos, NM, USA, 2000; pp. 86–748. [Google Scholar]

- Toby, B.H. EXPGUI, a Graphical User Interface for GSAS. J. Appl. Crystallogr. 2001, 34, 210–213. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.-H.; Lu, S.-C.; Tuan, W.-H.; Chen, C.-Y. Microstructure Transition from Normal to Abnormal Grains for BaTiO3. J. Eur. Ceram. Soc. 2009, 29, 3243–3248. [Google Scholar] [CrossRef]

- Zheng, S.J.; Ma, X.L.; Yamamoto, T.; Ikuhara, Y. Atomistic Study of Abnormal Grain Growth Structure in BaTiO3 by Transmission Electron Microscopy and Scanning Transmission Electron Microscopy. Acta Mater. 2013, 61, 2298–2307. [Google Scholar] [CrossRef]

- Bäurer, M.; Shih, S.-J.; Bishop, C.; Harmer, M.P.; Cockayne, D.; Hoffmann, M.J. Abnormal Grain Growth in Undoped Strontium and Barium Titanate. Acta Mater. 2010, 58, 290–300. [Google Scholar] [CrossRef]

- Fisher, J.G.; Lee, B.-K.; Choi, S.-Y.; Wang, S.-M.; Kang, S.-J.L. Inhibition of Abnormal Grain Growth in BaTiO3 by Addition of Al2O3. J. Eur. Ceram. Soc. 2006, 26, 1619–1628. [Google Scholar] [CrossRef]

- Uyar, F.; Wilson, S.; Winning, M.; Rollett, A.D. Simulation of Grain Growth under the Effect of Stress. Mater. Sci. Forum 2012, 715–716, 197–202. [Google Scholar] [CrossRef]

- Moriyama, M.; Matsunaga, K.; Morita, T.; Tsukimoto, S.; Murakami, M. The Effect of Strain Distribution on Abnormal Grain Growth in Cu Thin Films. Mater. Trans. 2004, 45, 3033–3038. [Google Scholar] [CrossRef] [Green Version]

- Kabirova, D.B.; Pavlova, V.V.; Imayev, M.F. Abnormal Grain Growth in YBa2Cu3O7−x High-Tc Superconducting Ceramics during High-Temperature Deformation. Lett. Mater. 2016, 6, 338–342. [Google Scholar] [CrossRef]

- Shvetsova, N.A.; Shvetsov, I.A.; Lugovaya, M.A.; Petrova, E.I.; Rybyanets, A.N. Microstructure Characterization and Properties of Porous Piezoceramics. J. Adv. Dielectr. 2021, 11, 2160006. [Google Scholar] [CrossRef]

- DeAngelis, D.A.; Schulze, G.W. The Effects of Piezoelectric Ceramic Dissipation Factor on the Performance of Ultrasonic Transducers. Phys. Procedia 2015, 63, 28–36. [Google Scholar] [CrossRef] [Green Version]

- Morel, A.; Pillonnet, G.; Wanderoild, Y.; Badel, A. Dielectric Losses Considerations for Piezoelectric Energy Harvesting. J. Low Power Electron. 2018, 14, 244–254. [Google Scholar] [CrossRef]

- Shen, Z.-Y.; Li, J.-F. Enhancement of Piezoelectric Constant D33 in BaTiO3 Ceramics Due to Nano-Domain Structure. J. Ceram. Soc. Jpn. 2010, 118, 940–943. [Google Scholar] [CrossRef] [Green Version]

| Powder Sample | Milling Time, Min | Powder Volume Fraction, % |

|---|---|---|

| BT-1 | 0 | 37.14 |

| BT-2 | 15 | 52.33 |

| BT-3 | 30 | 51.24 |

| BT-4 | 45 | 50.10 |

| BT-5 | 60 | 49.83 |

| BT-6 | 120 | 42.38 |

| BT-7 | 180 | 51.82 |

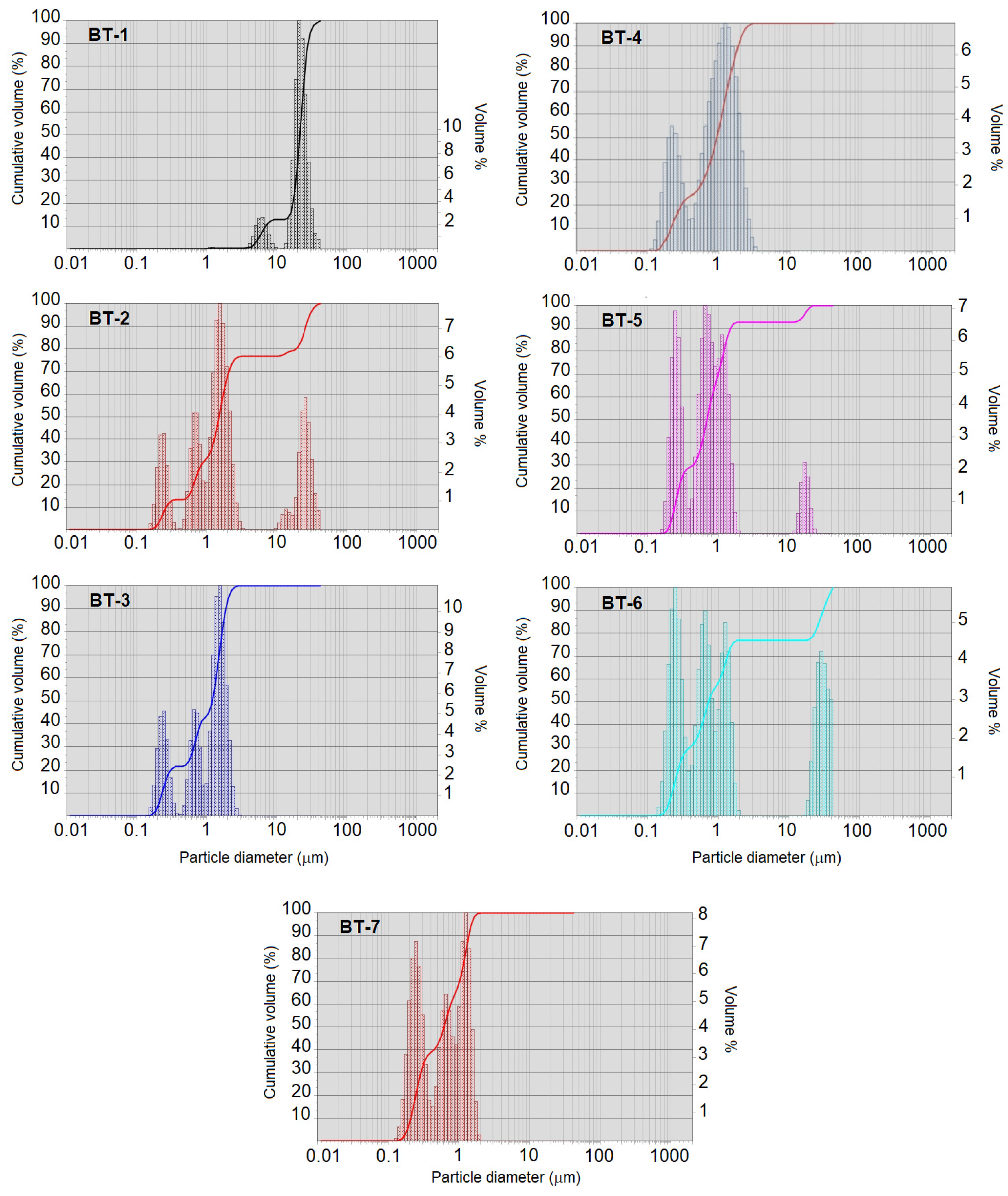

| Powder Sample | Milling Time, Min | Modal Diameter, μm | d90, μm | d50, μm | d10, μm | Specific Surface Area, cm²/cm³ |

|---|---|---|---|---|---|---|

| BT-1 | 0 | 20.82 | 26.94 | 19.96 | 9.42 | 3855 |

| BT-2 | 15 | 1.53 | 26.21 | 1.5 | 0.26 | 68,591 |

| BT-3 | 30 | 1.49 | 1.89 | 1.2 | 0.23 | 97,836 |

| BT-4 | 45 | 1.27 | 1.85 | 0.93 | 0.21 | 110,538 |

| BT-5 | 60 | 0.67 | 1.48 | 0.68 | 0.23 | 118,969 |

| BT-6 | 120 | 0.24 | 1.67 | 0.72 | 0.22 | 112,420 |

| BT-7 | 180 | 1.23 | 1.37 | 0.61 | 0.21 | 141,825 |

| Duration of the Initial BT Powder Milling, Min | Length of Abnormal Grain, μm | Mean Length to Width Ratio | ||

|---|---|---|---|---|

| Minimum | Maximum | Mean | ||

| 30 | 2.7 | 50.8 | 9.3 ± 5.1 | 2.0 ± 1.0 |

| 45 | 4.4 | 21.5 | 11.0 ± 3.7 | 2.3 ± 1.3 |

| 80 | 5.0 | 25.8 | 13.6 ± 4.7 | 1.7 ± 0.5 |

| Powder Sample | Piezoceramic Sample Code | ε (1 kHz) | tgδ (1 kHz) | d33, pC/N | Microhardness, HV | Relative Density |

|---|---|---|---|---|---|---|

| BT-1 | BT-1-AM1 | 837 | 0.061 | 31 | 39.77 | 0.62 |

| BT-1-AM2 | 857 | 0.068 | 37 | 44.63 | 0.55 | |

| BT-1-AM3 | 990 | 0.009 | 112 | 67.79 | 0.81 | |

| BT-2 | BT-2-AM1 | 2006 | 0.037 | 52 | 104.05 | 0.88 |

| BT-2-AM2 | 1405 | 0.044 | 148 | 96.11 | 0.86 | |

| BT-2-AM3 | 2426 | 0.01 | 14 | - | 0.94 | |

| BT-3 | BT-3-AM1 | 1499 | 0.045 | 72 | 292.24 | 0.85 |

| BT-3-AM2 | 2061 | 0.033 | 7 | 357.01 | 0.98 | |

| BT-3-AM3 | 1448 | 0.01 | 8 | 424.04 | 0.94 | |

| BT-4 | BT-4-AM1 | 1654 | 0.025 | 67 | 285.42 | 0.97 |

| BT-4-AM2 | 0 | - | 0 | 317.78 | 0.98 | |

| BT-4-AM3 | 2456 | 0.01 | 6 | 543.26 | 0.96 | |

| BT-5 | BT-5-AM1 | 1234 | 0.06 | 68 | 420.26 | 0.81 |

| BT-5-AM2 | 0 | - | 0 | 398.30 | 0.96 | |

| BT-5-AM3 | 918 | 0.016 | 5 | 552.66 | 0.95 | |

| BT-6 | BT-6-AM1 | 0 | - | 0 | 416.94 | 0.84 |

| BT-6-AM2 | 0 | - | 0 | 442.75 | 0.66 | |

| BT-6-AM3 | 1951 | 0.015 | 0 | 456.94 | 0.80 | |

| BT-7 | BT-7-AM1 | 1531 | 0.033 | 51 | - | 0.86 |

| BT-7-AM2 | 1905 | 0.013 | 0 | 628.84 | 0.87 | |

| BT-7-AM3 | 1484 | 0.026 | 36 | - | 0.86 |

| Powder Sample | Piezoceramic Sample Code | ε (1 kHz) | tgδ (1 kHz) | d33, pC/N | Microhardness, HV | Relative Density |

|---|---|---|---|---|---|---|

| BT-1 | BT-1-P1 | 1459 | 0.013 | 315 | 65.59 | 0.66 |

| BT-1-P2 | 1397 | 0.013 | 300 | 84.99 | 0.65 | |

| BT-1-P3 | 1324 | 0.012 | 280 | 78.73 | 0.62 | |

| BT-2 | BT-2-P1 | 2418 | 0.143 | 81 | 194.88 | 0.79 |

| BT-2-P2 | 2394 | 0.145 | 80 | 507.01 | 0.89 | |

| BT-2-P3 | 2292 | 0.144 | 75 | 110.68 | 0.83 | |

| BT-3 | BT-3-P1 | 2387 | 0.119 | 117 | 215.99 | 0.94 |

| BT-3-P2 | 2502 | 0.132 | 77 | 430.89 | 0.93 | |

| BT-3-P3 | 2224 | 0.115 | 78 | 435.76 | 0.78 | |

| BT-4 | BT-4-P1 | 2394 | 0.096 | 94 | 444.21 | 0.80 |

| BT-4-P2 | 2423 | 0.098 | 105 | 726.51 | 0.81 | |

| BT-4-P3 | 2521 | 0.108 | 117 | 493.99 | 0.76 | |

| BT-5 | BT-5-P1 | 2478 | 0.114 | 124 | 438.74 | 0.94 |

| BT-5-P2 | 2516 | 0.117 | 92 | 556.91 | 0.85 | |

| BT-5-P3 | 2571 | 0.133 | 117 | 538.61 | 0.94 | |

| BT-6 | BT-6-P1 | 2420 | 0.022 | 90 | 222.06 | 0.96 |

| BT-6-P2 | 2519 | 0.025 | 11 | 310.85 | 0.93 | |

| BT-6-P3 | 2484 | 0.030 | 10 | 297.34 | 0.95 | |

| BT-7 | BT-7-P1 | 2534 | 0.019 | 92 | 297.95 | 0.94 |

| BT-7-P2 | 2504 | 0.018 | 60 | 336.99 | 0.96 | |

| BT-7-P3 | 2565 | 0.017 | 46 | 383.54 | 0.95 |

| # | Mean Powder Particle Size, μm | Light Wavelength, nm | Photopolymerization Depth, μm | d33, pC/N | tan δ | ε | Micro Hardness, HV | Reference |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.5 | - | - | 166 | 0.036 | 2177 | - | [4] |

| 2 | 0.428 | 405 | 90 (40 vol.% BT) | 163 | 0.016 | 2762 | - | [19] |

| 3 | 1.5 | 465 | >120 (52 vol.% BT) | 148 | 0.044 | 1405 | 96.11 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smirnov, A.; Chugunov, S.; Kholodkova, A.; Isachenkov, M.; Tikhonov, A.; Dubinin, O.; Shishkovsky, I. The Fabrication and Characterization of BaTiO3 Piezoceramics Using SLA 3D Printing at 465 nm Wavelength. Materials 2022, 15, 960. https://doi.org/10.3390/ma15030960

Smirnov A, Chugunov S, Kholodkova A, Isachenkov M, Tikhonov A, Dubinin O, Shishkovsky I. The Fabrication and Characterization of BaTiO3 Piezoceramics Using SLA 3D Printing at 465 nm Wavelength. Materials. 2022; 15(3):960. https://doi.org/10.3390/ma15030960

Chicago/Turabian StyleSmirnov, Andrey, Svyatoslav Chugunov, Anastasia Kholodkova, Maxim Isachenkov, Andrey Tikhonov, Oleg Dubinin, and Igor Shishkovsky. 2022. "The Fabrication and Characterization of BaTiO3 Piezoceramics Using SLA 3D Printing at 465 nm Wavelength" Materials 15, no. 3: 960. https://doi.org/10.3390/ma15030960

APA StyleSmirnov, A., Chugunov, S., Kholodkova, A., Isachenkov, M., Tikhonov, A., Dubinin, O., & Shishkovsky, I. (2022). The Fabrication and Characterization of BaTiO3 Piezoceramics Using SLA 3D Printing at 465 nm Wavelength. Materials, 15(3), 960. https://doi.org/10.3390/ma15030960