Setting Time, Microstructure, and Durability Properties of Low Calcium Fly Ash/Slag Geopolymer: A Review

Abstract

:1. Introduction

2. Research Significance

3. Research Methodology

4. Setting and Hardened Characteristics

4.1. Setting Time

4.2. Microstructural Properties

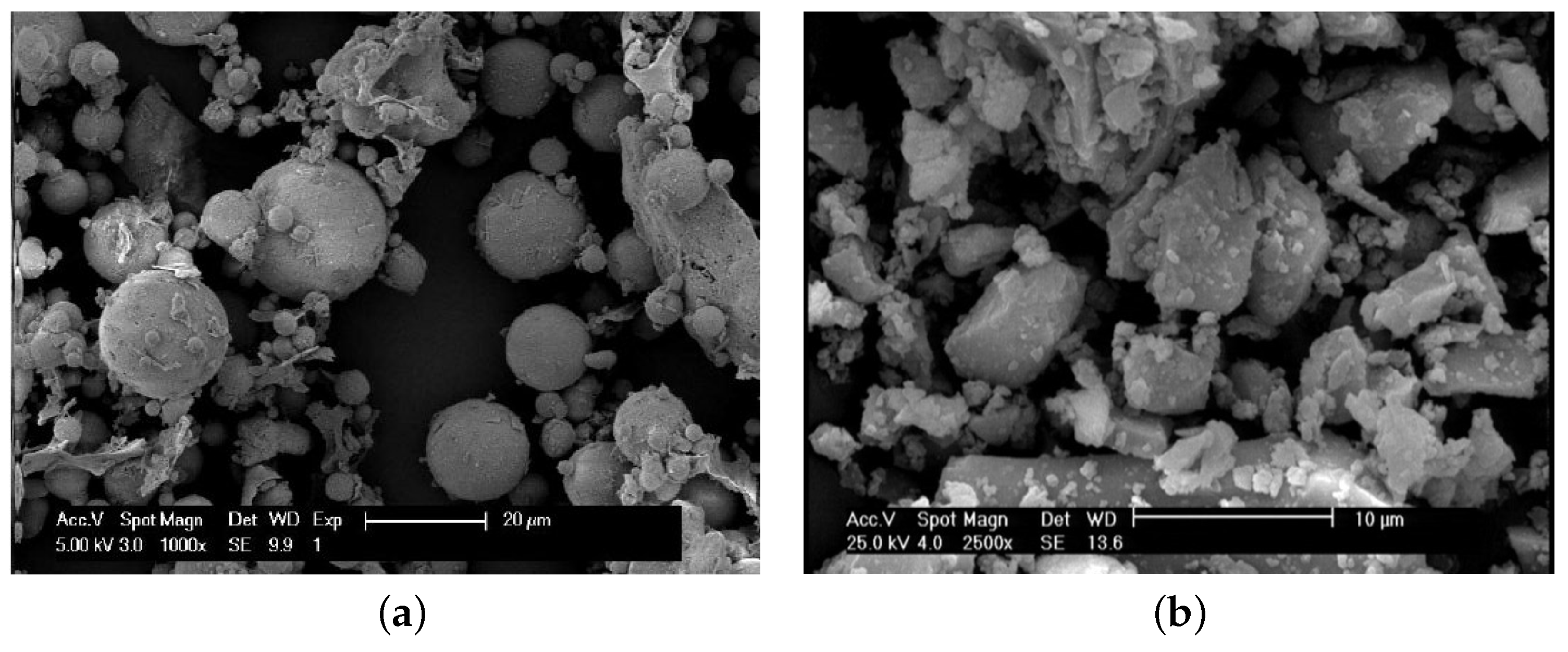

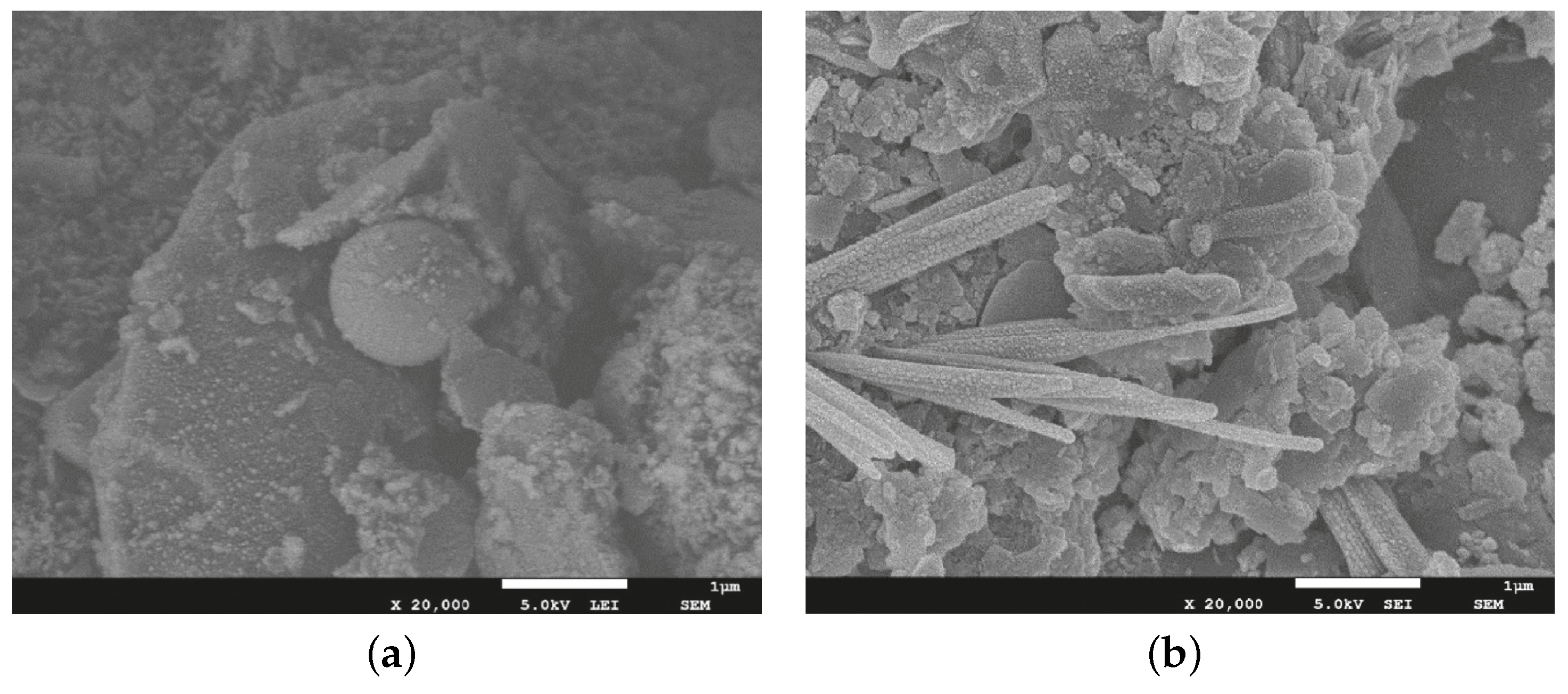

4.2.1. Reaction Developments and Gel Phases

4.2.2. Permeability Properties

4.2.3. Shrinkage Behavior

4.3. Durability Properties

4.3.1. Chloride Resistance

4.3.2. Sulfate Attack

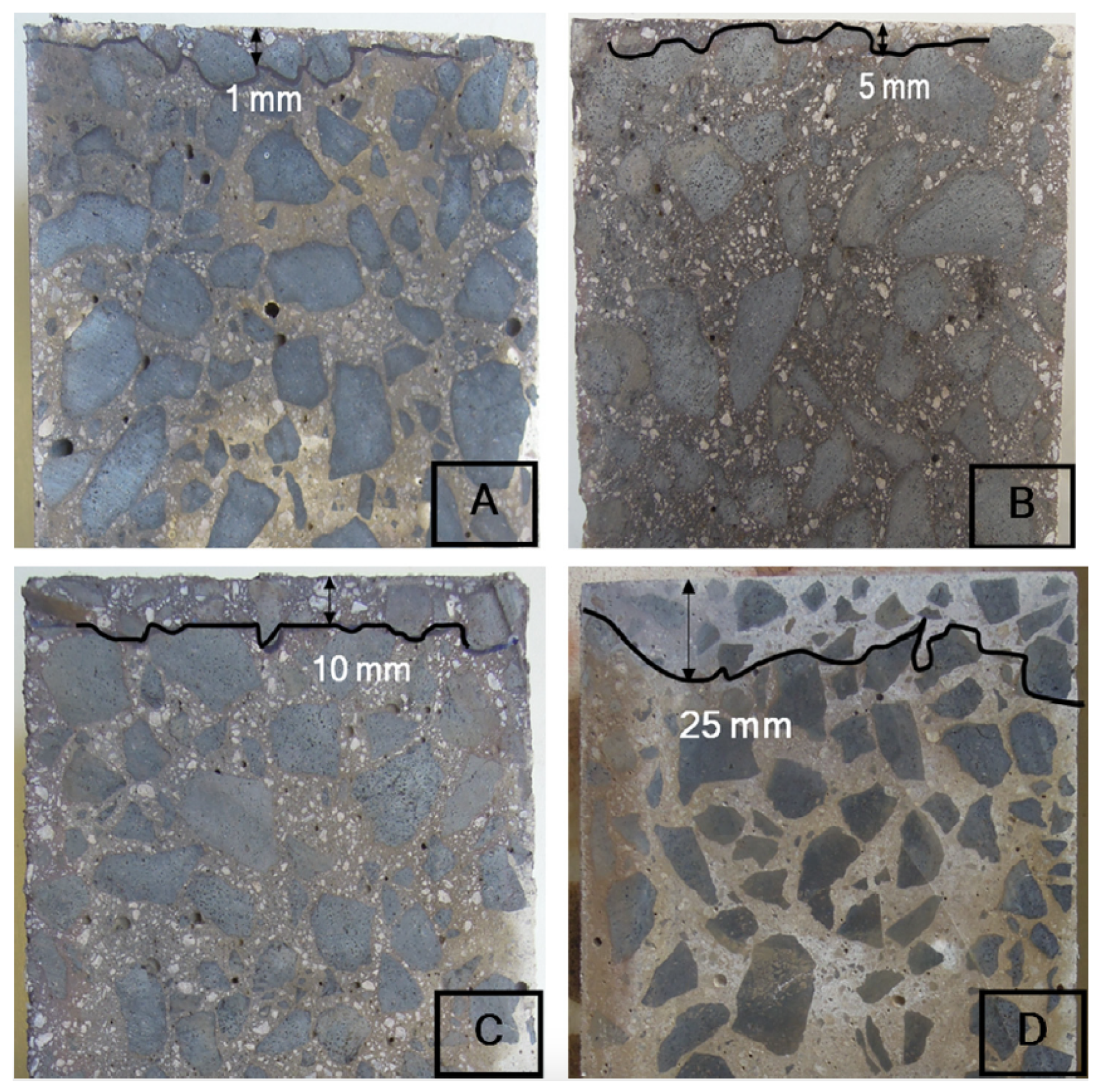

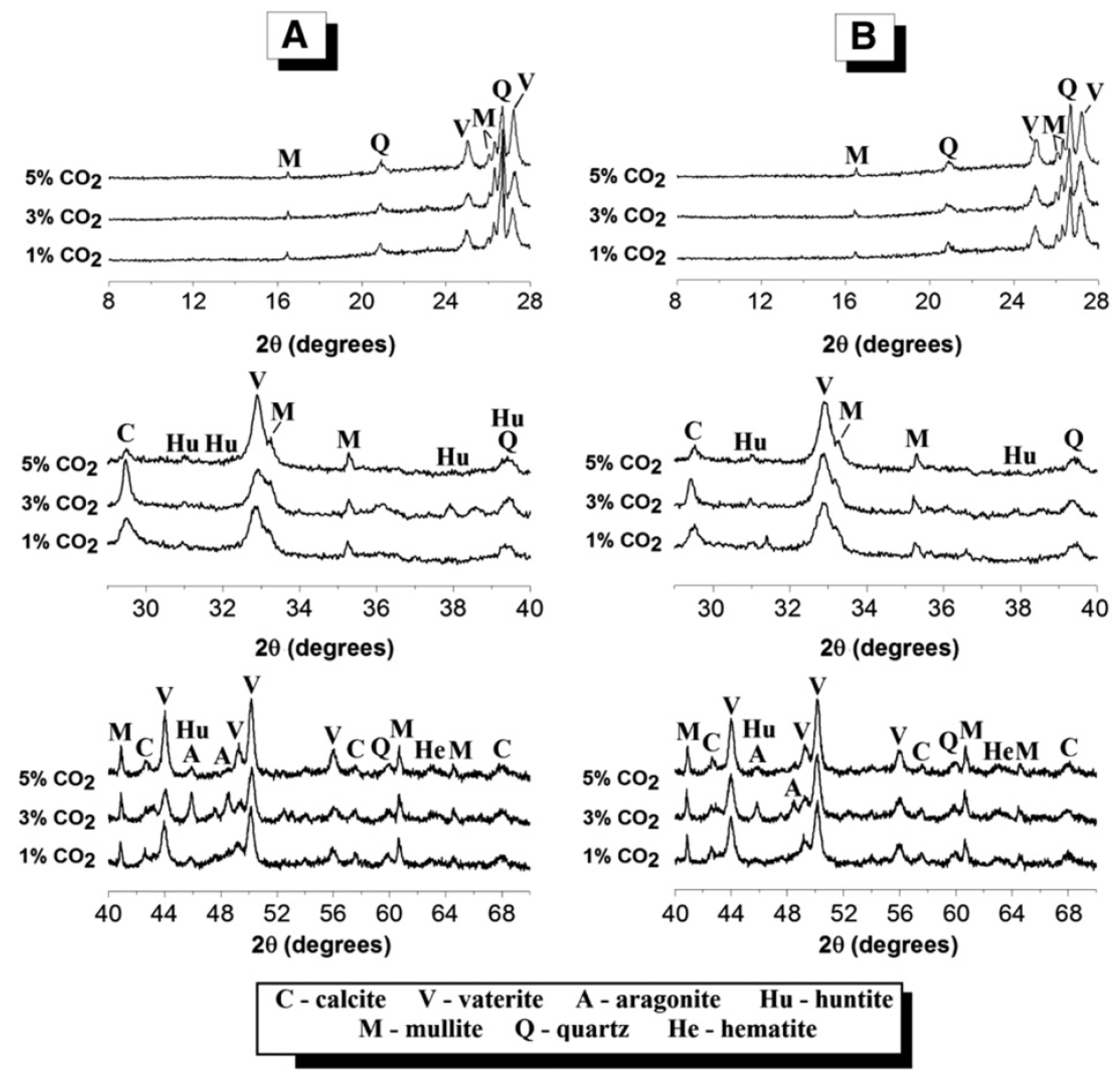

4.3.3. Carbonatation

5. Discussion

6. Conclusions

- The setting times of fly ash/slag-based systems are affected by multiple factors that include the fly ash/slag ratio, the type and amount of superplasticizers, activator concentration, and available soluble silica. Among these factors, the fly ash/slag ratio and the available silica content in the activator are the dominant parameters that impact the setting time. However, polycarboxylate-based superplasticizers are effective when used for the evaluated combined systems and effectively retard the initial and final setting time.

- Incorporating higher slag quantities increases the microstructure density and reduces the number of unreacted particles due to the formation of calcium-rich phases that include C-S-H (similar reaction products to those found in OPC systems) and C-A-S-H (the main reaction product in slag-based geopolymers, with a higher aluminum content).

- The coexistence of geopolymeric and calcium-rich gel phases results in substantially reduced permeability, and substituting high percentages or excessive amounts of slag may lead to shrinkage and produce micro-cracks.

- The ratio of fly ash to slag and the maturity of the reaction products substantially affect the chloride penetration depths due to the change in permeable voids. However, chloride penetration does not only depend on the amount of pores as the permeability is also affected by the pore geometry (tortuosity).

- For fly ash/slag geopolymers, the ingression of magnesium sulfate ions is more aggressive than that of sodium sulfate ions. Fly ash/slag-based systems in magnesium sulfate environments form gypsum and/or ettringite products, whereas the effect of sodium sulfates is negligible or positively affects these binary geopolymer systems.

- Curing conditions and the gel maturity of fly ash/slag-based geopolymer are the dominant factors that determine the carbonatation resistance, which needs to be properly controlled because the carbonatation of fly ash/sag systems may form undesirable compounds such as natron, huntite, and calcium carbonate.

- The interaction of low-calcium fly ash and slag with an alkaline solution produces multiple phases and introduces complex mechanisms (multi-gel phase structures, elemental compositions, pore structures) that are still not fully understood and require further investigation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Cement. A Review; Technical Papers; Geopolymer Institute: Saint-Quentin, France, 2013; pp. 1–11. [Google Scholar]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef] [Green Version]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymeric reactions in archaeological cements and in modern blended cements. Concr. Int. 1987, 9, 23–29. [Google Scholar]

- Davidovits, J. Chemistry of geopolymeric systems, terminology. Geopolymer 1999, 99, 9–39. [Google Scholar]

- Motorwala, A.; Shah, V.; Kammula, R.; Nannapaneni, P.; Raijiwala, D. ALKALI activated FLY-ASH based geopolymer concrete. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 159–166. [Google Scholar]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, Z.; Zhu, Y.; Tian, L. Durability of alkali-activated fly ash concrete: Chloride penetration in pastes and mortars. Constr. Build. Mater. 2014, 65, 51–59. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. (1980–2015) 2014, 62, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Brice, D.G.; Kilcullen, A.R.; Hamdan, S.; van Deventer, J.S. Influence of fly ash on the water and chloride permeability of alkali-activated slag mortars and concretes. Constr. Build. Mater. 2013, 48, 1187–1201. [Google Scholar] [CrossRef]

- Shang, J.; Dai, J.G.; Zhao, T.J.; Guo, S.Y.; Zhang, P.; Mu, B. Alternation of traditional cement mortars using fly ash-based geopolymer mortars modified by slag. J. Clean. Prod. 2018, 203, 746–756. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G. Effect of elevated temperatures on geopolymer paste, mortar and concrete. Cem. Concr. Res. 2010, 40, 334–339. [Google Scholar] [CrossRef]

- Van Deventer, J.S.; Provis, J.L.; Duxson, P.; Brice, D.G. Chemical research and climate change as drivers in the commercial adoption of alkali activated materials. Waste Biomass Valoriz. 2010, 1, 145–155. [Google Scholar] [CrossRef]

- ASTM C294-19; Standard Terminology Relating to Concrete and Concrete Aggregates. ASTM-International: West Conshohocken, PA, USA, 2019.

- Hardjito, D. Studies of Fly Ash-Based Geopolymer Concrete. Ph.D. Thesis, Curtin University, Bentley, WA, Australia, 2005. [Google Scholar]

- Snellings, R.; Mertens, G.; Elsen, J. Supplementary cementitious materials. Rev. Mineral. Geochem. 2012, 74, 211–278. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Moeini, M.A. Mechanical and durability properties of alkali activated slag coating mortars containing nanosilica and silica fume. Constr. Build. Mater. 2018, 163, 611–621. [Google Scholar] [CrossRef]

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM-International: West Conshohocken, PA, USA, 2019.

- Shi, C. Steel slag—Its production, processing, characteristics, and cementitious properties. J. Mater. Civ. Eng. 2004, 16, 230–236. [Google Scholar] [CrossRef]

- Hogan, F.; Meusel, J. Evaluation for durability and strength development of a ground granulated blast furnace slag. Cem. Concr. Aggreg. 1981, 3, 40–52. [Google Scholar]

- Škvára, F.; Kopeckỳ, L.; Nemecek, J.; Bittnar, Z. Microstructure of geopolymer materials based on fly ash. Ceramics-Silikaty 2006, 50, 208–215. [Google Scholar]

- Hadi, M.N.; Zhang, H.; Parkinson, S. Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J. Build. Eng. 2019, 23, 301–313. [Google Scholar] [CrossRef]

- Jang, J.G.; Lee, N.; Lee, H.K. Fresh and hardened properties of alkali-activated fly ash/slag pastes with superplasticizers. Constr. Build. Mater. 2014, 50, 169–176. [Google Scholar] [CrossRef]

- Saha, S.; Rajasekaran, C. Enhancement of the properties of fly ash based geopolymer paste by incorporating ground granulated blast furnace slag. Constr. Build. Mater. 2017, 146, 615–620. [Google Scholar] [CrossRef]

- Li, Z.; Liu, S. Influence of slag as additive on compressive strength of fly ash-based geopolymer. J. Mater. Civ. Eng. 2007, 19, 470–474. [Google Scholar] [CrossRef]

- Deb, P.; Nath, P.; Sarker, P. Properties of fly ash and slag blended geopolymer concrete cured at ambient temperature. In New Developments in Structural Engineering and Construction; University of Hawaii: Manoa, HI, USA, 2013; pp. 571–576. [Google Scholar]

- Fang, G.; Bahrami, H.; Zhang, M. Mechanisms of autogenous shrinkage of alkali-activated fly ash-slag pastes cured at ambient temperature within 24 h. Constr. Build. Mater. 2018, 171, 377–387. [Google Scholar] [CrossRef]

- Nedeljković, M.; Li, Z.; Ye, G. Setting, strength, and autogenous shrinkage of alkali-activated fly ash and slag pastes: Effect of slag content. Materials 2018, 11, 2121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, N.; Lee, H.K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef] [Green Version]

- Kurtoglu, A.E.; Alzeebaree, R.; Aljumaili, O.; Nis, A.; Gulsan, M.E.; Humur, G.; Cevik, A. Mechanical and durability properties of fly ash and slag based geopolymer concrete. Adv. Concr. Constr. 2018, 6, 345. [Google Scholar]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Mehrotra, S. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer. J. Mater. Sci. 2010, 45, 607–615. [Google Scholar] [CrossRef]

- Krishnaraja, A.; Sathishkumar, N.; Kumar, T.S.; Kumar, P.D. Mechanical behaviour of geopolymer concrete under ambient curing. Int. J. Sci. Eng. Technol. 2014, 3, 130–132. [Google Scholar]

- Puertas, F.; Martinez-Ramirez, S.; Alonso, S.; Vazquez, T. Alkali-activated fly ash/slag cements: Strength behaviour and hydration products. Cem. Concr. Res. 2000, 30, 1625–1632. [Google Scholar] [CrossRef]

- Wardhono, A.; Law, D.W.; Strano, A. The strength of alkali-activated slag/fly ash mortar blends at ambient temperature. Procedia Eng. 2015, 125, 650–656. [Google Scholar] [CrossRef] [Green Version]

- Qiu, J.; Zhao, Y.; Xing, J.; Sun, X. Fly Ash/Blast Furnace Slag-Based Geopolymer as a Potential Binder for Mine Backfilling: Effect of Binder Type and Activator Concentration. Adv. Mater. Sci. Eng. 2019, 2019, 2028109. [Google Scholar] [CrossRef] [Green Version]

- Gopalakrishnan, R.; Chinnaraju, K. Durability of ambient cured alumina silicate concrete based on slag/fly ash blends against sulfate environment. Constr. Build. Mater. 2019, 204, 70–83. [Google Scholar] [CrossRef]

- Hardjito, D.; Cheak, C.C.; Ing, C.H.L. Strength and setting times of low calcium fly ash-based geopolymer mortar. Mod. Appl. Sci. 2008, 2, 3–11. [Google Scholar] [CrossRef] [Green Version]

- Criado, M.; Fernández-Jiménez, A.; Palomo, A. Alkali activation of fly ash: Effect of the SiO2/Na2O ratio: Part I: FTIR study. Microporous Mesoporous Mater. 2007, 106, 180–191. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Lee, W.; Van Deventer, J. The effect of ionic contaminants on the early-age properties of alkali-activated fly ash-based cements. Cem. Concr. Res. 2002, 32, 577–584. [Google Scholar] [CrossRef]

- Wardhono, A.; Gunasekara, C.; Law, D.W.; Setunge, S. Comparison of long term performance between alkali activated slag and fly ash geopolymer concretes. Constr. Build. Mater. 2017, 143, 272–279. [Google Scholar] [CrossRef]

- Tan, K.; Pu, X. Strengthening effects of finely ground fly ash, granulated blast furnace slag, and their combination. Cem. Concr. Res. 1998, 28, 1819–1825. [Google Scholar] [CrossRef]

- Puligilla, S.; Mondal, P. Role of slag in microstructural development and hardening of fly ash-slag geopolymer. Cem. Concr. Res. 2013, 43, 70–80. [Google Scholar] [CrossRef]

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM-International: West Conshohocken, PA, USA, 2013.

- Tazawa, E.i.; Miyazawa, S.; Kasai, T. Chemical shrinkage and autogenous shrinkage of hydrating cement paste. Cem. Concr. Res. 1995, 25, 288–292. [Google Scholar] [CrossRef]

- Lee, N.; Jang, J.G.; Lee, H.K. Shrinkage characteristics of alkali-activated fly ash/slag paste and mortar at early ages. Cem. Concr. Compos. 2014, 53, 239–248. [Google Scholar] [CrossRef]

- Hojati, M.; Radlińska, A. Shrinkage and strength development of alkali-activated fly ash-slag binary cements. Constr. Build. Mater. 2017, 150, 808–816. [Google Scholar] [CrossRef]

- Castel, A.; Foster, S.; Ng, T.; Sanjayan, J.; Gilbert, R. Creep and drying shrinkage of a blended slag and low calcium fly ash geopolymer Concrete. Mater. Struct. 2016, 49, 1619–1628. [Google Scholar] [CrossRef] [Green Version]

- Singh, B.; Rahman, M.; Paswan, R.; Bhattacharyya, S. Effect of activator concentration on the strength, ITZ and drying shrinkage of fly ash/slag geopolymer concrete. Constr. Build. Mater. 2016, 118, 171–179. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Corrosion performance of embedded steel in fly ash geopolymer concrete by impressed voltage method. In Proceedings of the 21st Australian Conference on the Mechanics of Structures and Materials, Melbourne, Australia, 7–10 December 2010; pp. 781–786. [Google Scholar]

- Noushini, A.; Castel, A.; Aldred, J.; Rawal, A. Chloride diffusion resistance and chloride binding capacity of fly ash-based geopolymer concrete. Cem. Concr. Compos. 2020, 105, 103290. [Google Scholar] [CrossRef]

- Yuan, Q.; Shi, C.; De Schutter, G.; Audenaert, K.; Deng, D. Chloride binding of cement-based materials subjected to external chloride environment—A review. Constr. Build. Mater. 2009, 23, 1–13. [Google Scholar] [CrossRef]

- ASTM C1543-10; Standard Test Method for Determining the Penetration of Chloride Ion into Concrete by Ponding (Withdrawn 2019). ASTM-International: West Conshohocken, PA, USA, 2019.

- Nordtest, N. BUILD 492. Chloride Migration Coefficient from Non-Steady-State Migration Experiments; NORDTEST: Espoo, Finland, 1999. [Google Scholar]

- Bear, J. Dynamics of Fluids in Porous Media Dover Publications; INC: New York, NY, USA, 1988. [Google Scholar]

- Rajagopalan, G. Durability of alumina silicate concrete based on slag/fly ash blends against corrosion. Eng. Constr. Archit. Manag. 2019, 26, 1641–1651. [Google Scholar] [CrossRef]

- Florida, D. Florida method of test for an accelerated laboratory method for corrosion testing of reinforced concrete using impressed current. FM 2000, 5, 522. [Google Scholar]

- Yang, T.; Yao, X.; Zhang, Z. Quantification of chloride diffusion in fly ash–slag-based geopolymers by X-ray fluorescence (XRF). Constr. Build. Mater. 2014, 69, 109–115. [Google Scholar] [CrossRef]

- Albitar, M.; Ali, M.M.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Arbi, K.; Nedeljkovic, M.; Zuo, Y.; Ye, G. A review on the durability of alkali-activated fly ash/slag systems: Advances, issues, and perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–5453. [Google Scholar] [CrossRef] [Green Version]

- Karthik, A.; Sudalaimani, K.; Vijayakumar, C. Durability study on coal fly ash-blast furnace slag geopolymer concretes with bio-additives. Ceram. Int. 2017, 43, 11935–11943. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; Hamdan, S.; van Deventer, J.S. Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure. Mater. Struct. 2013, 46, 361–373. [Google Scholar] [CrossRef]

- Džunuzović, N.; Komljenović, M.; Nikolić, V.; Ivanović, T. External sulfate attack on alkali-activated fly ash-blast furnace slag composite. Constr. Build. Mater. 2017, 157, 737–747. [Google Scholar] [CrossRef]

- Morandeau, A.; Thiery, M.; Dangla, P. Investigation of the carbonation mechanism of CH and CSH in terms of kinetics, microstructure changes and moisture properties. Cem. Concr. Res. 2014, 56, 153–170. [Google Scholar] [CrossRef] [Green Version]

- Pasupathy, K.; Berndt, M.; Castel, A.; Sanjayan, J.; Pathmanathan, R. Carbonation of a blended slag-fly ash geopolymer concrete in field conditions after 8 years. Constr. Build. Mater. 2016, 125, 661–669. [Google Scholar] [CrossRef]

- Chang, C.F.; Chen, J.W. The experimental investigation of concrete carbonation depth. Cem. Concr. Res. 2006, 36, 1760–1767. [Google Scholar] [CrossRef]

- Khan, M.; Castel, A.; Noushini, A. Carbonation of a low-calcium fly ash geopolymer concrete. Mag. Concr. Res. 2017, 69, 24–34. [Google Scholar] [CrossRef]

- Zhuguo, L.; Sha, L. Carbonation resistance of fly ash and blast furnace slag based geopolymer concrete. Constr. Build. Mater. 2018, 163, 668–680. [Google Scholar]

- Bernal, S.A.; Provis, J.L.; Walkley, B.; San Nicolas, R.; Gehman, J.D.; Brice, D.G.; Kilcullen, A.R.; Duxson, P.; van Deventer, J.S. Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation. Cem. Concr. Res. 2013, 53, 127–144. [Google Scholar] [CrossRef]

- Puertas, F.; Palacios, M.; Manzano, H.; Dolado, J.; Rico, A.; Rodríguez, J. A model for the CASH gel formed in alkali-activated slag cements. J. Eur. Ceram. Soc. 2011, 31, 2043–2056. [Google Scholar] [CrossRef]

- ASTM C1556; Standard Test Method for Determining the Apparent Chloride Diffusion Coefficient of Cementitious Mixtures by Bulk Diffusion. ASTM-International: West Conshohocken, PA, USA, 2011.

- Garcia-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A.; Macphee, D. Compatibility studies between NASH and CASH gels. Study in the ternary diagram Na2O–CaO–Al2O3–SiO2–H2O. Cem. Concr. Res. 2011, 41, 923–931. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Fly ash-slag interaction during alkaline activation: Influence of activators on phase assemblage and microstructure formation. Constr. Build. Mater. 2016, 122, 594–606. [Google Scholar] [CrossRef] [Green Version]

- Walkley, B.; San Nicolas, R.; Sani, M.A.; Rees, G.J.; Hanna, J.V.; van Deventer, J.S.; Provis, J.L. Phase evolution of C-(N)-ASH/NASH gel blends investigated via alkali-activation of synthetic calcium aluminosilicate precursors. Cem. Concr. Res. 2016, 89, 120–135. [Google Scholar] [CrossRef] [Green Version]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

| Reference | GGBFS * | (SS/SH) ** | Molarity | Notes |

|---|---|---|---|---|

| [31] |

|

|

|

|

|

|

|

| |

|

| |||

| ||||

| [32] |

|

|

|

|

|

|

| ||

| [24] |

|

|

|

|

|

|

| ||

| ||||

| [25] |

|

|

|

|

|

| |||

| ||||

| [35] |

|

|

|

|

| ||||

| [26] |

|

|

|

|

|

| |||

| [29] |

|

|

|

|

|

|

| Reference | Binders and activators | Conditions | Notes |

|---|---|---|---|

| [67] |

|

|

|

|

|

| |

|

|

| |

| [66] |

|

|

|

|

|

| |

|

|

| |

|

| ||

| |||

| [65] |

|

|

|

|

|

| |

|

|

| |

|

| ||

| |||

| [40] |

|

|

|

|

|

| |

|

|

| |

|

|

| |

| |||

| [63] |

|

|

|

|

|

| |

|

|

| |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aldawsari, S.; Kampmann, R.; Harnisch, J.; Rohde, C. Setting Time, Microstructure, and Durability Properties of Low Calcium Fly Ash/Slag Geopolymer: A Review. Materials 2022, 15, 876. https://doi.org/10.3390/ma15030876

Aldawsari S, Kampmann R, Harnisch J, Rohde C. Setting Time, Microstructure, and Durability Properties of Low Calcium Fly Ash/Slag Geopolymer: A Review. Materials. 2022; 15(3):876. https://doi.org/10.3390/ma15030876

Chicago/Turabian StyleAldawsari, Salem, Raphael Kampmann, Jörg Harnisch, and Catharina Rohde. 2022. "Setting Time, Microstructure, and Durability Properties of Low Calcium Fly Ash/Slag Geopolymer: A Review" Materials 15, no. 3: 876. https://doi.org/10.3390/ma15030876

APA StyleAldawsari, S., Kampmann, R., Harnisch, J., & Rohde, C. (2022). Setting Time, Microstructure, and Durability Properties of Low Calcium Fly Ash/Slag Geopolymer: A Review. Materials, 15(3), 876. https://doi.org/10.3390/ma15030876