Low-Temperature Dielectric Response of Strontium Titanate Thin Films Manipulated by Zn Doping

Abstract

:1. Introduction

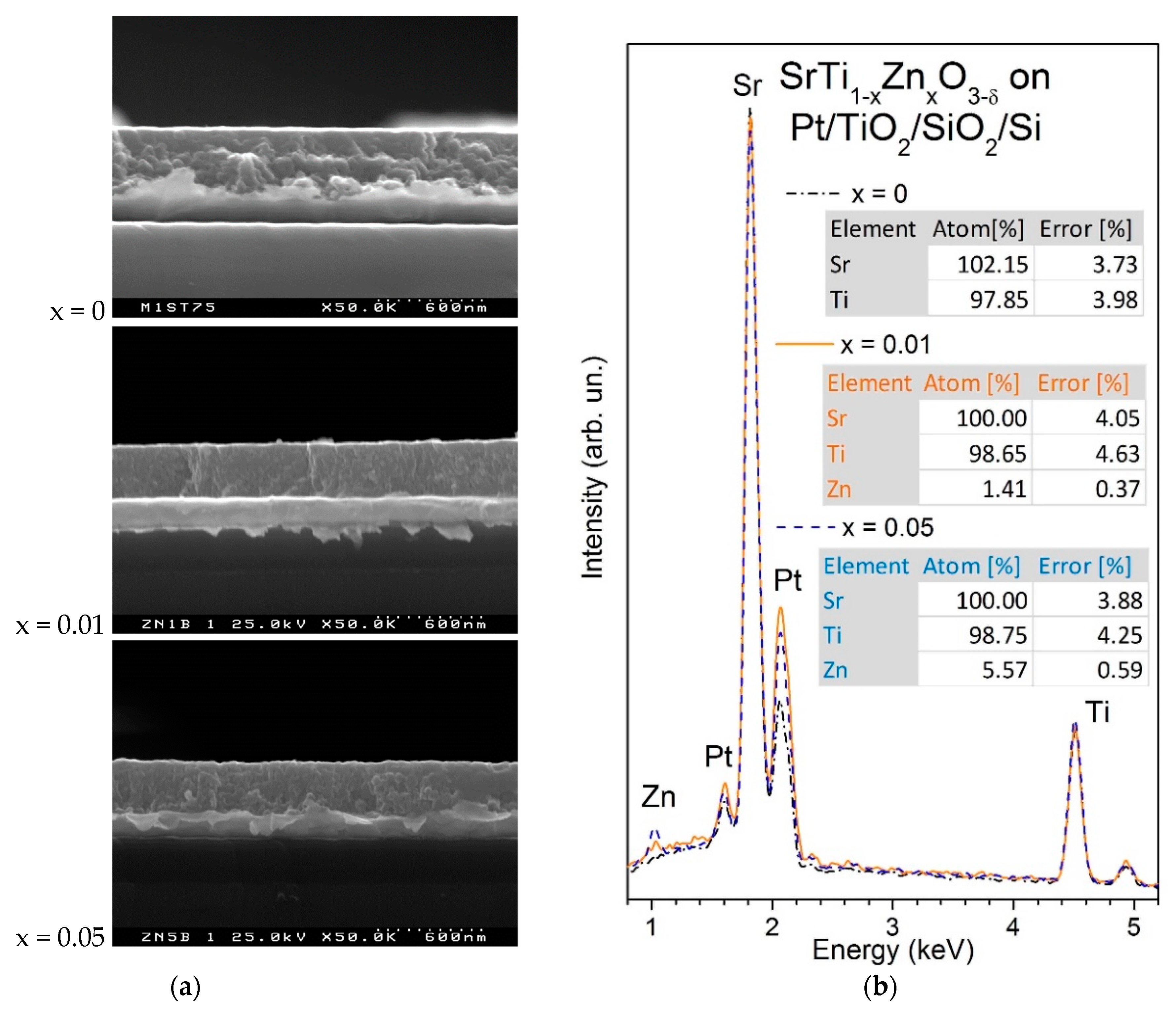

2. Materials and Methods

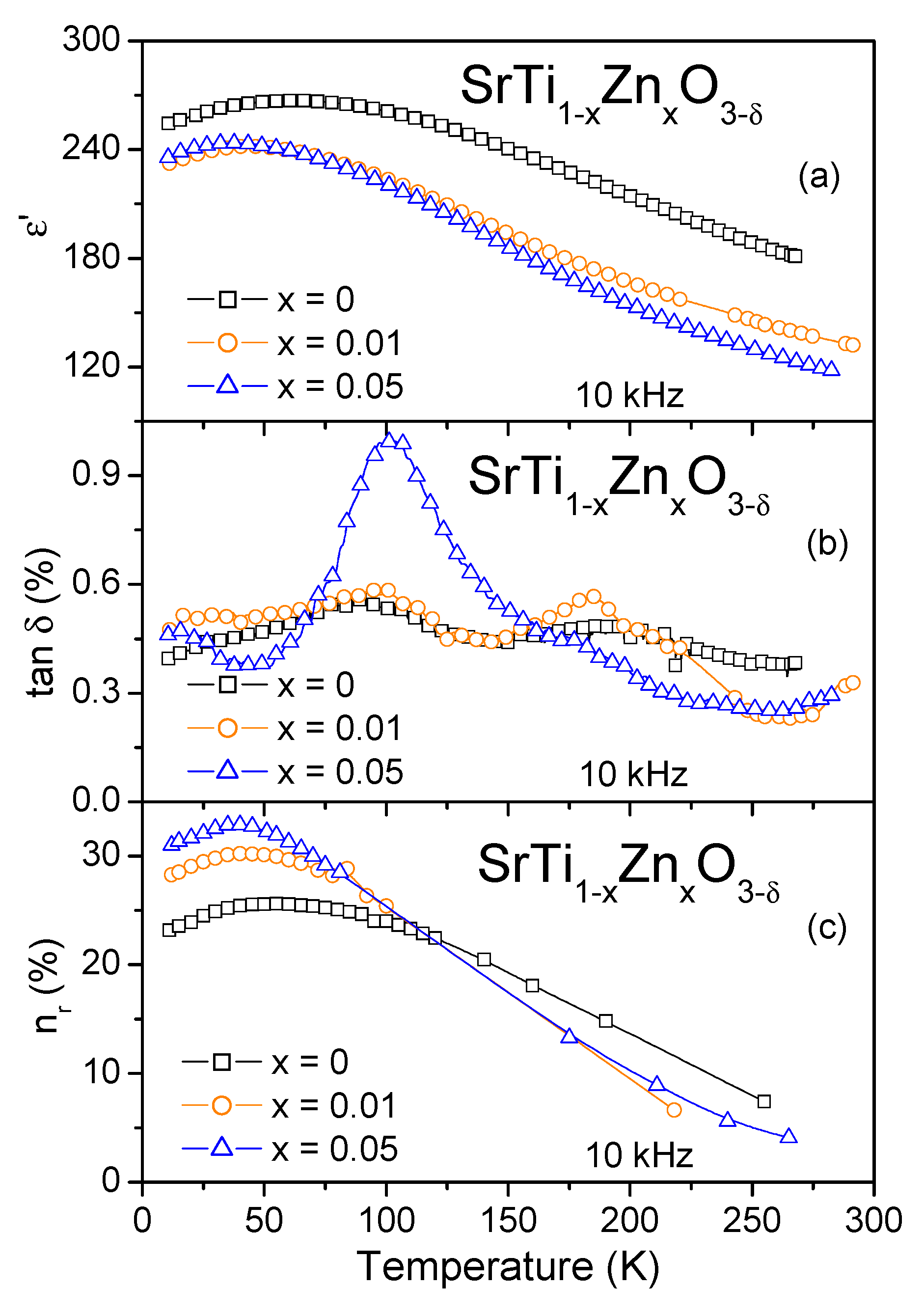

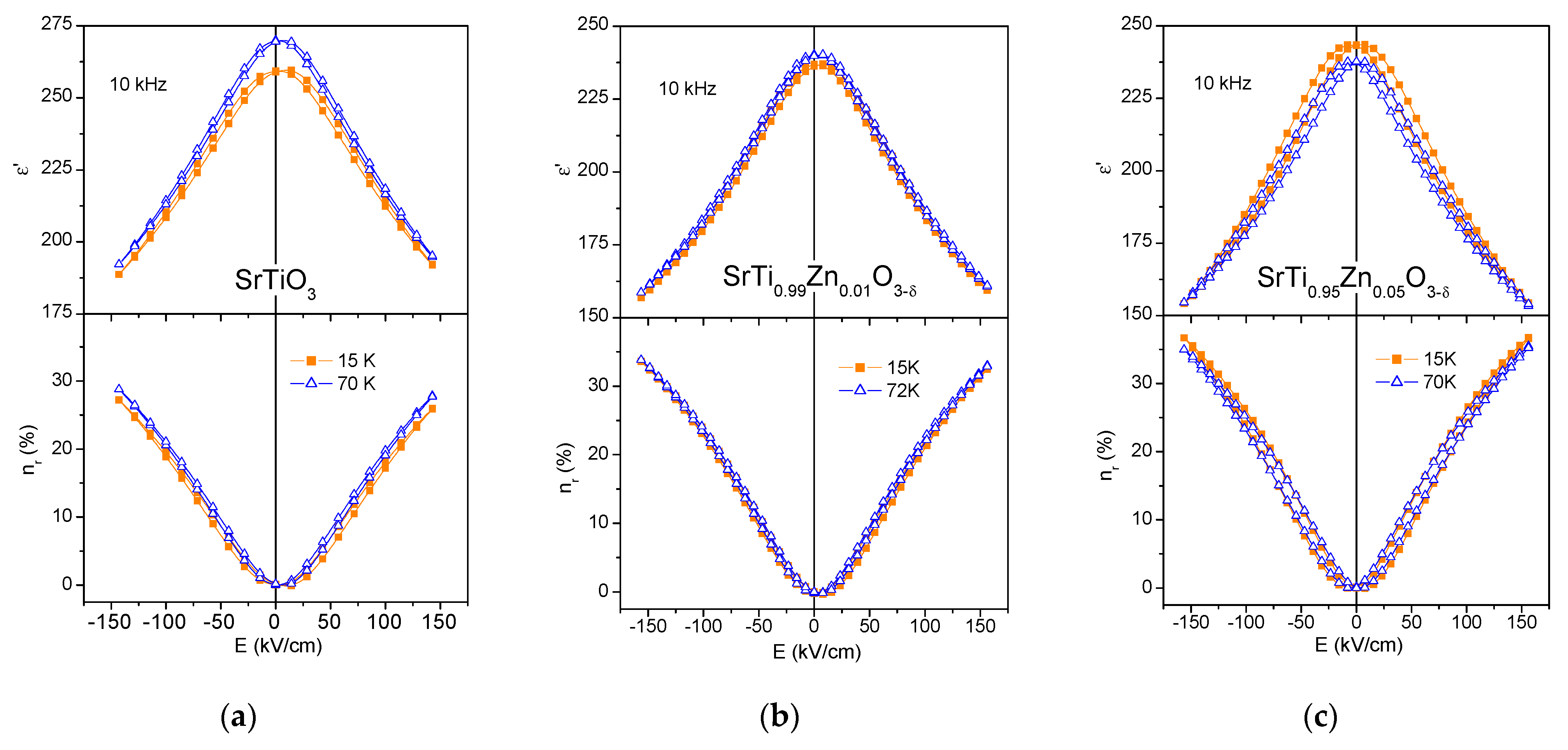

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Korn, D.S.; Wu, H.-D. A Comprehensive Review of Microwave System Requirements on Thin-Film Ferroelectrics. Integr. Ferroelectr. 1999, 24, 215–237. [Google Scholar] [CrossRef]

- Vendik, O.G.; Hollmann, E.K.; Kozyrev, A.B.; Prudan, A.M. Ferroelectric Tuning of Planar and Bulk Microwave Devices. J. Supercond. 1999, 12, 325–338. [Google Scholar] [CrossRef]

- Miranda, F.A.; Subramanyam, G.; Van Keuls, F.W.; Romanofsky, R.R.; Warner, J.D.; Mueller, C.H. Design and development of ferroelectric tunable microwave components for Ku- and K-band satellite communication systems. IEEE Trans. Microw. Theory Tech. 2000, 48, 1181–1189. [Google Scholar] [CrossRef]

- Tombak, A.; Maria, J.-P.; Ayguavives, F.T.; Jin, Z.; Stauf, G.T.; Kingon, A.I.; Mortazawi, A. Voltage-controlled RF filters employing thin-film barium-strontium-titanate tunable capacitors. IEEE Trans. Microw. Theory Tech. 2003, 51, 462–467. [Google Scholar] [CrossRef]

- Nath, J.; Ghosh, D.; Fathelbab, W.; Maria, J.-P.; Kingon, A.I.; Franzon, P.D.; Steer, M.B. An electronically tunable microstrip bandpass filter using thin-film Barium-Strontium-Titanate (BST) varactors. IEEE Trans. Microw. Theory Tech. 2005, 53, 2707–2712. [Google Scholar] [CrossRef]

- Lovat, G.; Burghignoli, P.; Celozzi, S. A tunable ferroelectric antenna for fixed-frequency scanning applications. IEEE Antennas Wirel. Propag. Lett. 2006, 5, 353–356. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, D.; Lancaster, M.J.; Button, T.W.; Su, B. Investigation of ferroelectric thick-film varactors for microwave phase shifters. IEEE Trans. Microw. Theory Tech. 2007, 55, 418–424. [Google Scholar] [CrossRef]

- Courreges, S.; Li, Y.; Zhao, Z.; Choi, K.; Hunt, A.; Horst, S.; Cressler, J.D.; Papapolymerou, J. A Ka-band electronically tunable ferroelectric filter. IEEE Microw. Wirel. Compon. Lett. 2009, 19, 356–358. [Google Scholar] [CrossRef]

- Kong, C.; Li, H.; Chen, X.; Jiang, S.; Zhou, J.; Chen, C. A monolithic AlGaN/GaN HEMT VCO using BST thin-film varactor. IEEE Trans. Microw. Theory Tech. 2012, 60, 3413–3419. [Google Scholar] [CrossRef]

- Cure, D.; Weller, T.M.; Price, T.; Miranda, F.A.; Van Keuls, F.W. Low-profile tunable dipole antenna using barium strontium titanate varactors. IEEE Trans. Antennas Propag. 2013, 62, 1185–1193. [Google Scholar] [CrossRef]

- Haghzadeh, M.; Armiento, C.; Akyurtlu, A. All-printed flexible microwave varactors and phase shifters based on a tunable BST/polymer. IEEE Trans. Microw. Theory Tech. 2017, 65, 2030–2042. [Google Scholar] [CrossRef]

- Haskou, A.; Sharaiha, A.; Collardey, S.; Borderon, C.; Ginestar, S.; Renoud, R.; Gundel, H.W. A reconfigurable miniaturized planar inverted-F antenna with integrated BaSrTiO3 capacitor. Microw. Opt. Technol. Lett. 2018, 60, 1511–1515. [Google Scholar] [CrossRef]

- Crunteanu, A.; Muzzupapa, V.; Ghalem, A.; Huitema, L.; Passerieux, D.; Borderon, C.; Renoud, R.; Gundel, H.W. Characterization and performance analysis of BST-based ferroelectric varactors in the millimeter-wave domain. Crystals 2021, 11, 277. [Google Scholar] [CrossRef]

- Subramanyam, G.; Cole, M.W.; Sun, N.X.; Kalkur, T.S.; Sbrockey, N.M.; Tompa, G.S.; Guo, X.; Chen, C.; Alpay, S.P.; Rossetti, G.A., Jr.; et al. Challenges and opportunities for multifunctional oxide thin films for voltage tunable radio frequency/microwave components. J. Appl. Phys. 2013, 114, 191301. [Google Scholar] [CrossRef] [Green Version]

- Tagantsev, A.K.; Sherman, V.O.; Astafiev, K.F.; Venkatesh, J.; Setter, N. Ferroelectric Materials for Microwave Tunable Applications. J. Electroceram. 2003, 11, 5–66. [Google Scholar] [CrossRef]

- Ahmed, A.; Goldthorpe, I.A.; Khandani, A.K. Electrically tunable materials for microwave applications. Appl. Phys. Rev. 2015, 2, 011302. [Google Scholar] [CrossRef]

- Falmbigl, M.; Golovina, I.S.; Hawley, C.J.; Plokhikh, A.V.; Shafir, O.; Grinberg, I.; Spanier, J.E. Ultrahigh anharmonicity low-permittivity tunable nanocrystalline thin-film BaTi2O5. Acta Mater. 2021, 208, 116712. [Google Scholar] [CrossRef]

- Bouça, P.; Figueiredo, R.; Wlodarkiewicz, A.; Tkach, A.; Matos, J.N.; Vilarinho, P.M.; Borges de Carvalho, N. Design and Characterization of Novel Barium Strontium Titanate Thick Films for Sub-6 GHz RF Applications. IEEE Trans. Microw. Theory Tech. 2022, 70, 611–621. [Google Scholar] [CrossRef]

- Li, H.-C.; Si, W.; West, A.D.; Xi, X.X. Thickness dependence of dielectric loss in SrTiO3 thin films. Appl. Phys. Lett. 1998, 73, 464–466. [Google Scholar] [CrossRef]

- Vilarinho, P.M.; Fu, Z.; Kingon, A.I.; Tkach, A. Low loss tunable dielectric BaNd2Ti5O14-(Ba0.5Sr0.5)TiO3 composite thick films. Scr. Mater. 2018, 155, 160–163. [Google Scholar] [CrossRef]

- Hofman, W.; Hoffmann, S.; Waser, R. Dopant influence on dielectric losses, leakage behaviour, and resistance degradation of SrTiO3 thin films. Thin Solid Film. 1997, 305, 66–73. [Google Scholar] [CrossRef]

- Joshi, P.C.; Cole, M.W. Mg-doped Ba0.6Sr0.4TiO3 thin films for tunable microwave applications. Appl. Phys. Lett. 2000, 77, 289–291. [Google Scholar] [CrossRef]

- Tkach, A.; Vilarinho, P.M.; Kholkin, A.L.; Pashkin, A.; Samoukhina, P.; Pokorny, J.; Veljko, S.; Petzelt, J. Lattice dynamics and dielectric response of Mg-doped SrTiO3 ceramics in a wide frequency range. J. Appl. Phys. 2005, 97, 044104. [Google Scholar] [CrossRef]

- Guo, Y.Y.; Guo, Y.J.; Liu, J.-M. Zn doping-induced enhanced dielectric response of quantum paraelectric SrTiO3. J. Appl. Phys. 2012, 111, 074108. [Google Scholar] [CrossRef]

- Pan, W.; Cao, M.; Hao, H.; Yao, Z.; Yu, Z.; Liu, H. Defect engineering toward the structures and dielectric behaviors of (Nb,Zn) co-doped SrTiO3 ceramics. J. Eur. Ceram. Soc. 2020, 40, 49–55. [Google Scholar] [CrossRef]

- Tkach, A.; Okhay, O. Giant dielectric response in (Nb + Zn) co-doped strontium titanate ceramics tailored by atmosphere. Scr. Mater. 2020, 185, 19–20. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Li, Y.; Xu, B.; Xia, S.; Shi, P. Microwave dielectric properties and optical transmittance of SrTiO3/ZnTiO3 heterolayer thin films fabricated by sol–gel processing. J. Adv. Dielectr. 2020, 10, 2050027. [Google Scholar] [CrossRef]

- Tkach, A.; Okhay, O.; Reaney, I.; Vilarinho, P.M. Mechanical strain engineering of dielectric tunability in polycrystalline SrTiO3 thin films. J. Mater. Chem. C 2018, 6, 2467–2475. [Google Scholar] [CrossRef] [Green Version]

- Tkach, A.; Vilarinho, P.M.; Kholkin, A. Effect of Mg doping on the structural and dielectric properties of strontium titanate ceramics. Appl. Phys. A Mater. 2004, 79, 2013–2020. [Google Scholar] [CrossRef]

- Okhay, O.; Wu, A.; Vilarinho, P.M.; Tkach, A. Low temperature dielectric characterization of Mg-doped SrTiO3 thin films prepared by sol-gel. Appl. Phys. Lett. 2010, 96, 152906. [Google Scholar] [CrossRef]

- Tkach, A.; Vilarinho, P.M.; Kholkin, A. Structural and dielectric properties of Mn-doped strontium titanate ceramics. Ferroelectrics 2004, 304, 87–90. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okhay, O.; Vilarinho, P.M.; Tkach, A. Low-Temperature Dielectric Response of Strontium Titanate Thin Films Manipulated by Zn Doping. Materials 2022, 15, 859. https://doi.org/10.3390/ma15030859

Okhay O, Vilarinho PM, Tkach A. Low-Temperature Dielectric Response of Strontium Titanate Thin Films Manipulated by Zn Doping. Materials. 2022; 15(3):859. https://doi.org/10.3390/ma15030859

Chicago/Turabian StyleOkhay, Olena, Paula M. Vilarinho, and Alexander Tkach. 2022. "Low-Temperature Dielectric Response of Strontium Titanate Thin Films Manipulated by Zn Doping" Materials 15, no. 3: 859. https://doi.org/10.3390/ma15030859

APA StyleOkhay, O., Vilarinho, P. M., & Tkach, A. (2022). Low-Temperature Dielectric Response of Strontium Titanate Thin Films Manipulated by Zn Doping. Materials, 15(3), 859. https://doi.org/10.3390/ma15030859