Nanometers-Thick Ferromagnetic Surface Produced by Laser Cutting of Diamond

Abstract

1. Introduction

2. Samples and Methods

2.1. Laser Cutting and After-Cutting Processes of Diamond Crystals

2.2. Samples Characteristics

2.2.1. Natural Diamond Samples

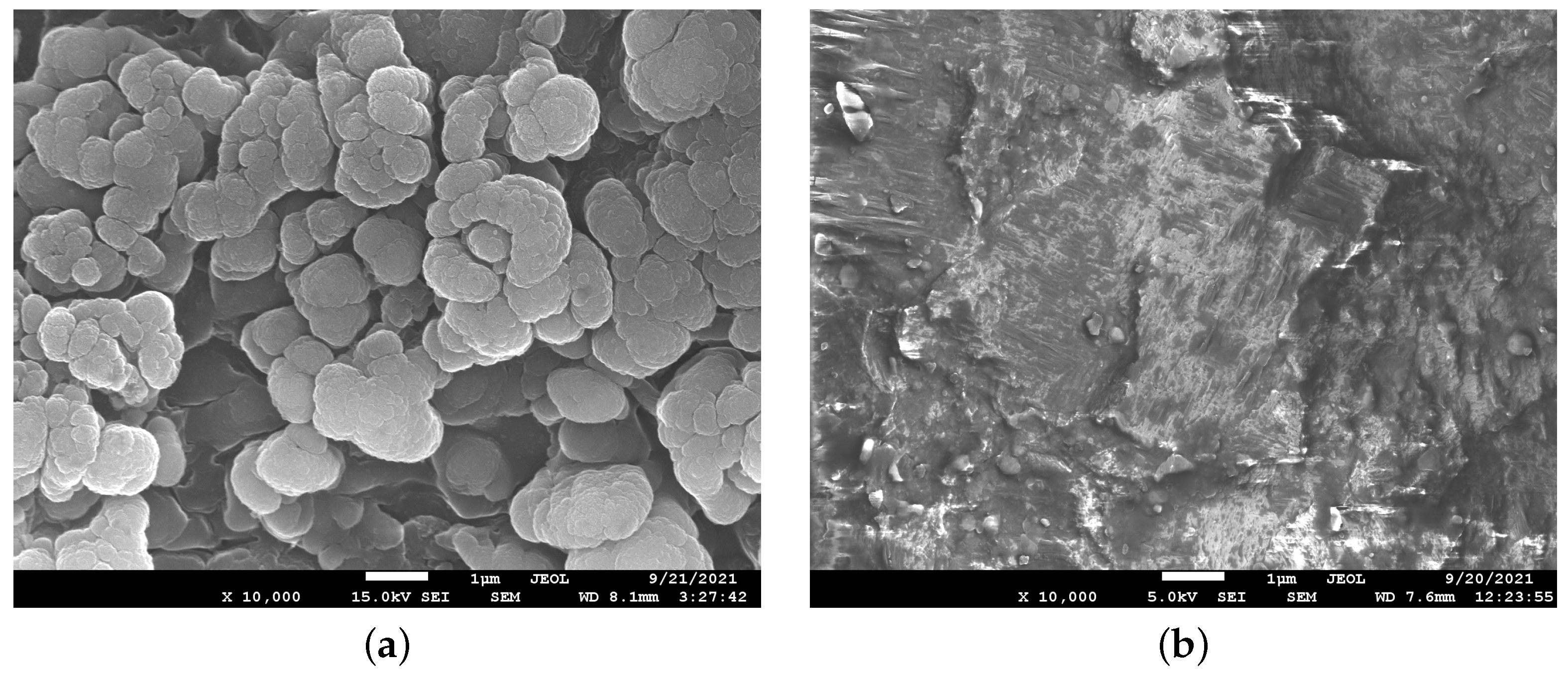

2.2.2. CVD Diamond Samples

2.3. Methods: PIXE, Raman and SQUID Characterization

3. Results

3.1. Magnetic Impurities Measurements

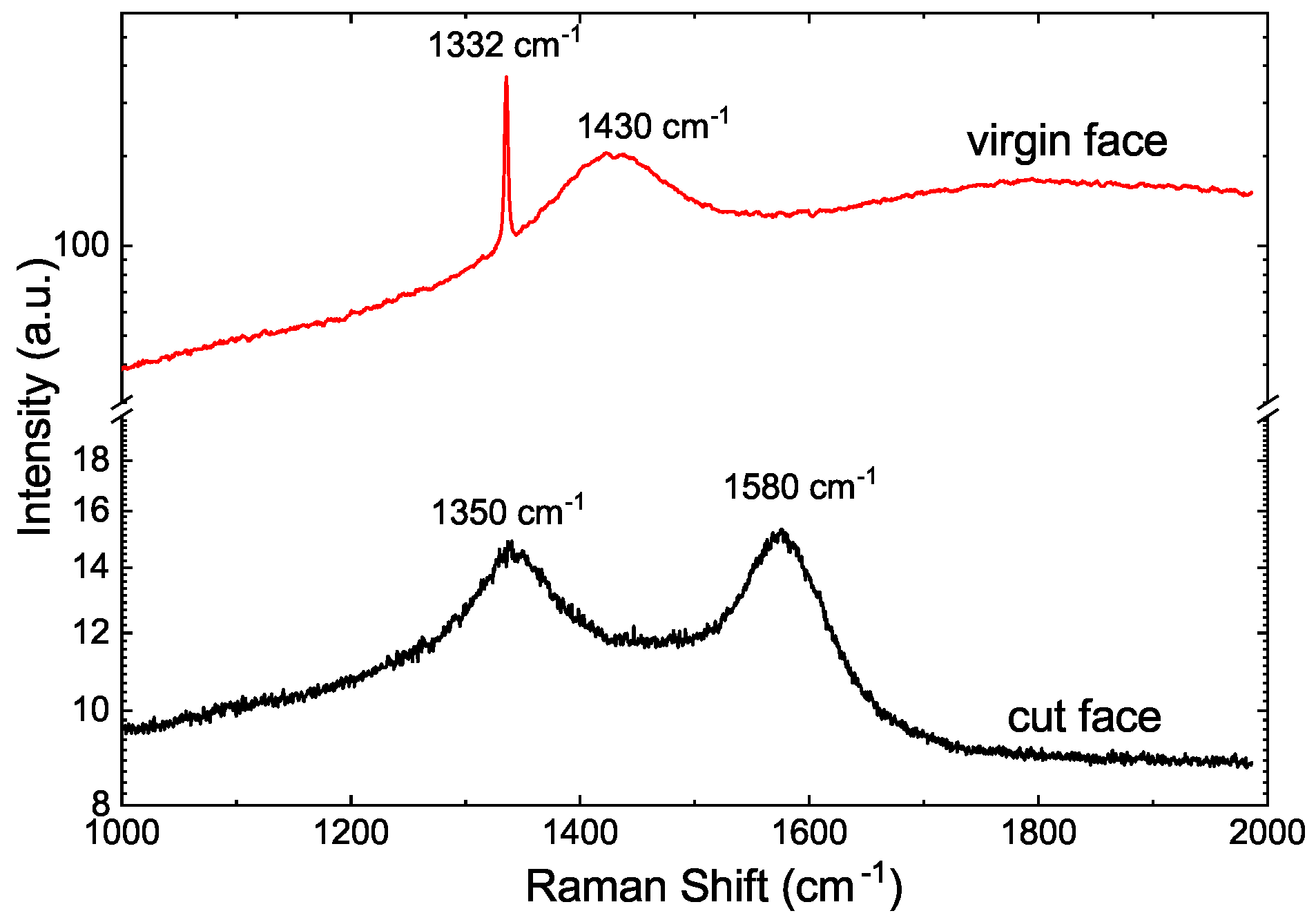

3.2. Raman

3.3. Magnetization Measurements

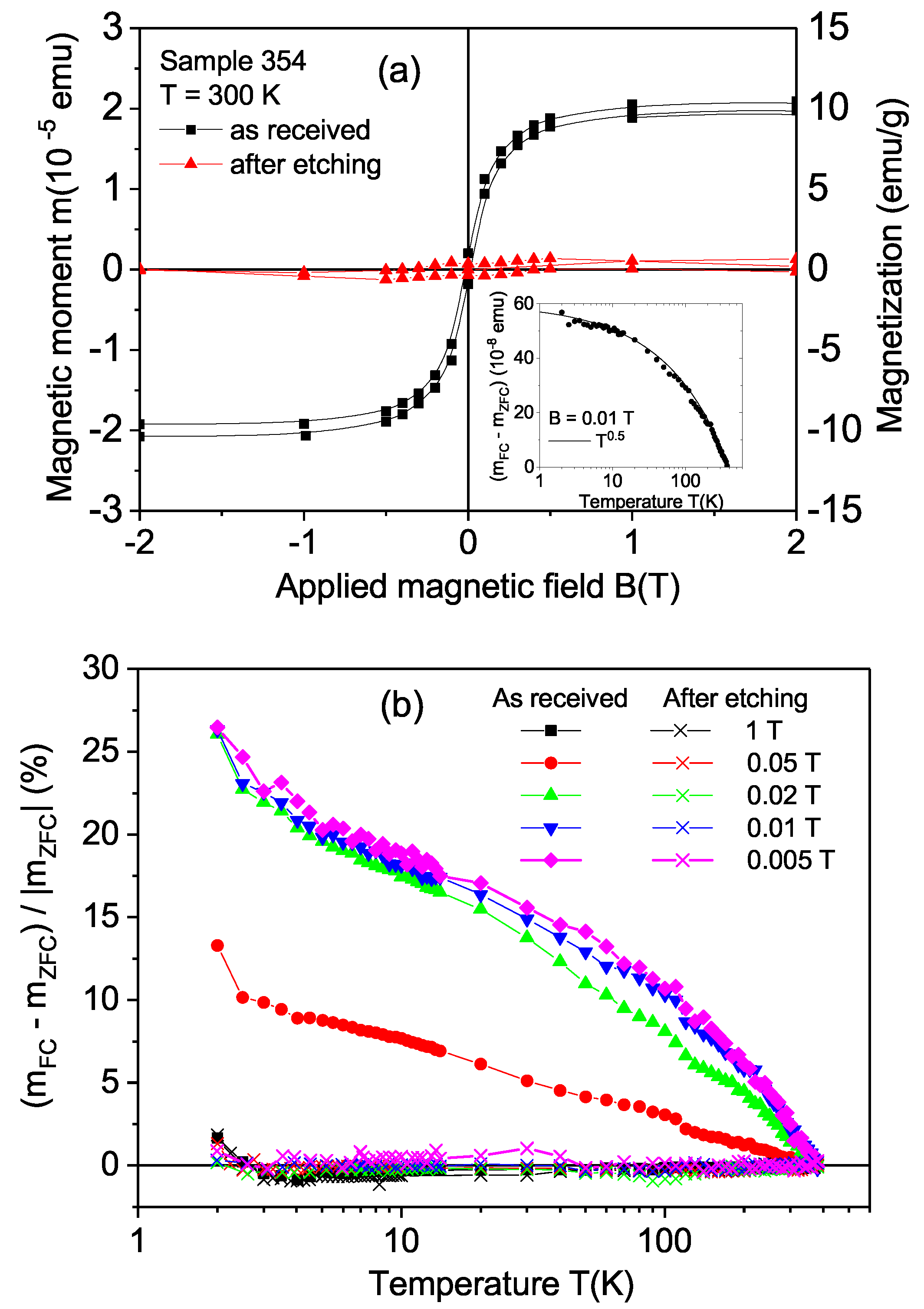

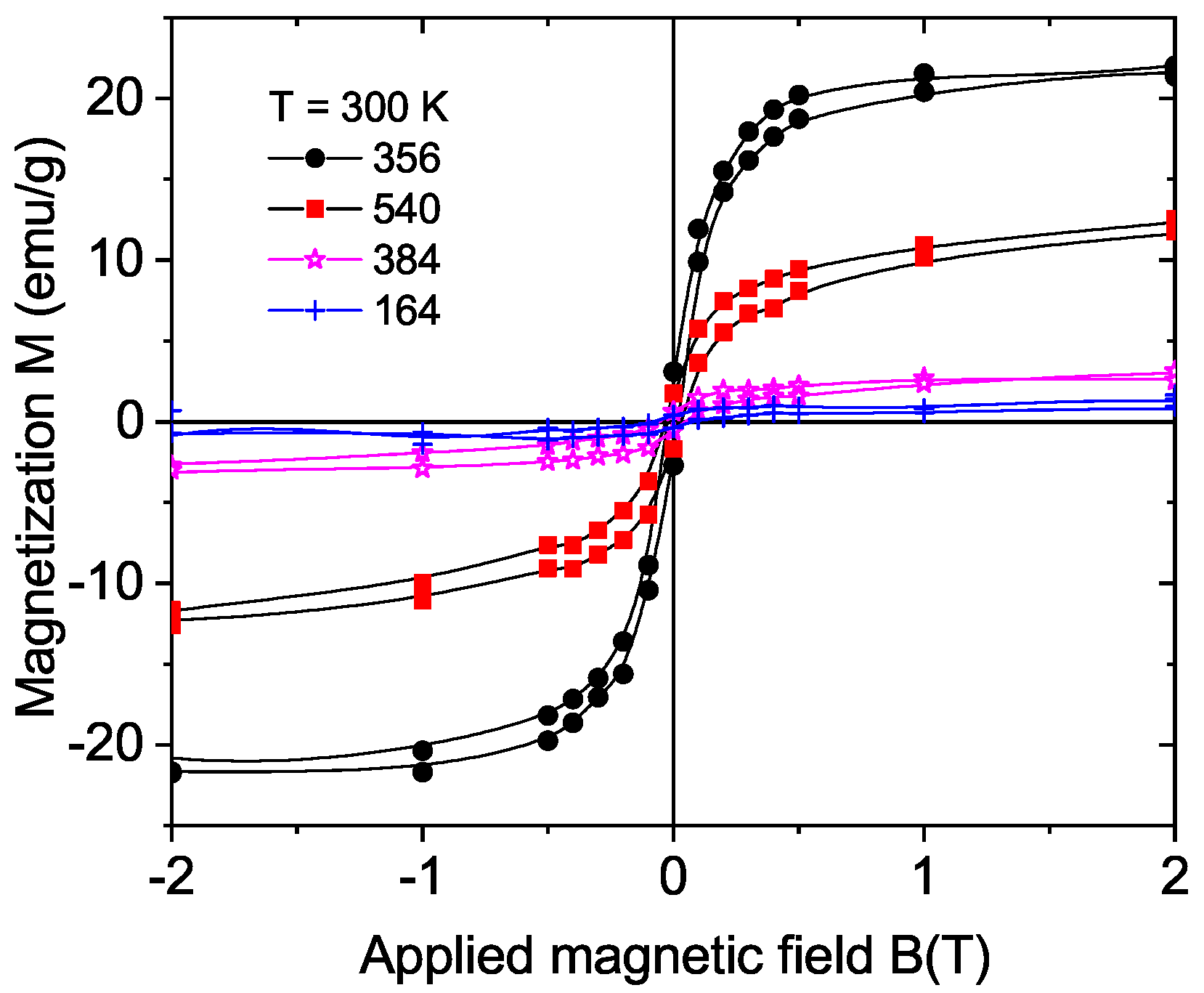

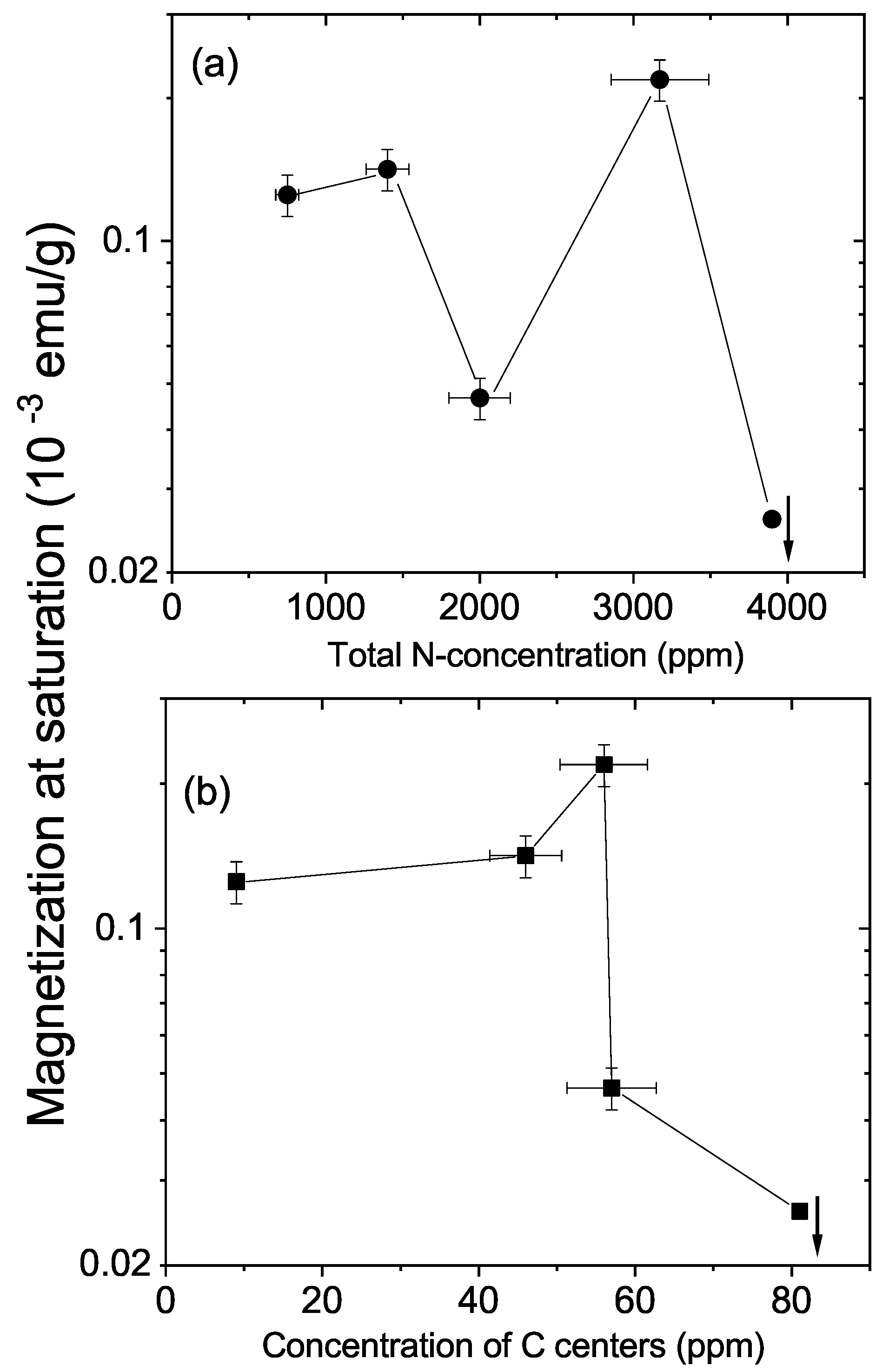

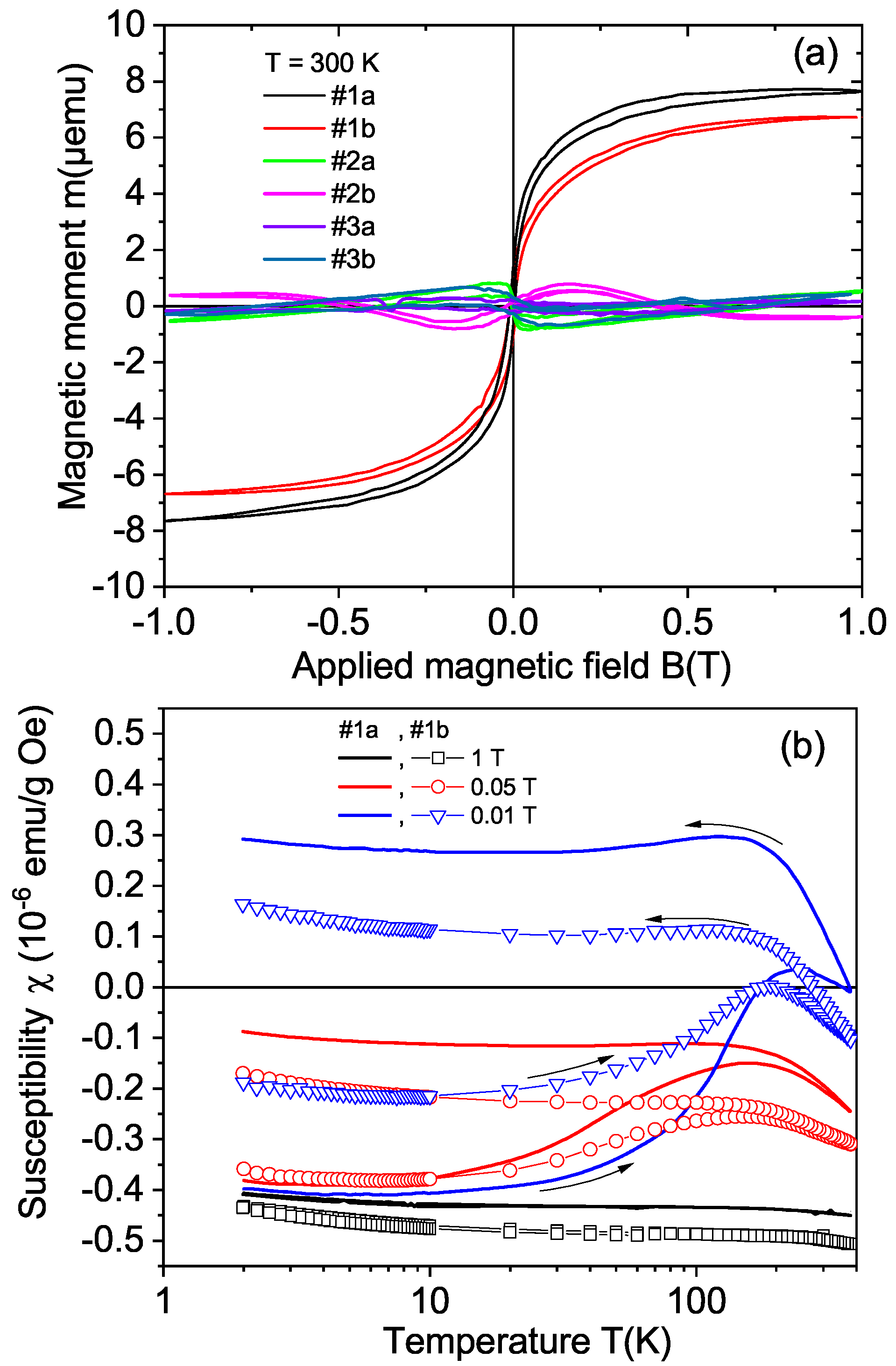

3.3.1. Natural Diamond Samples

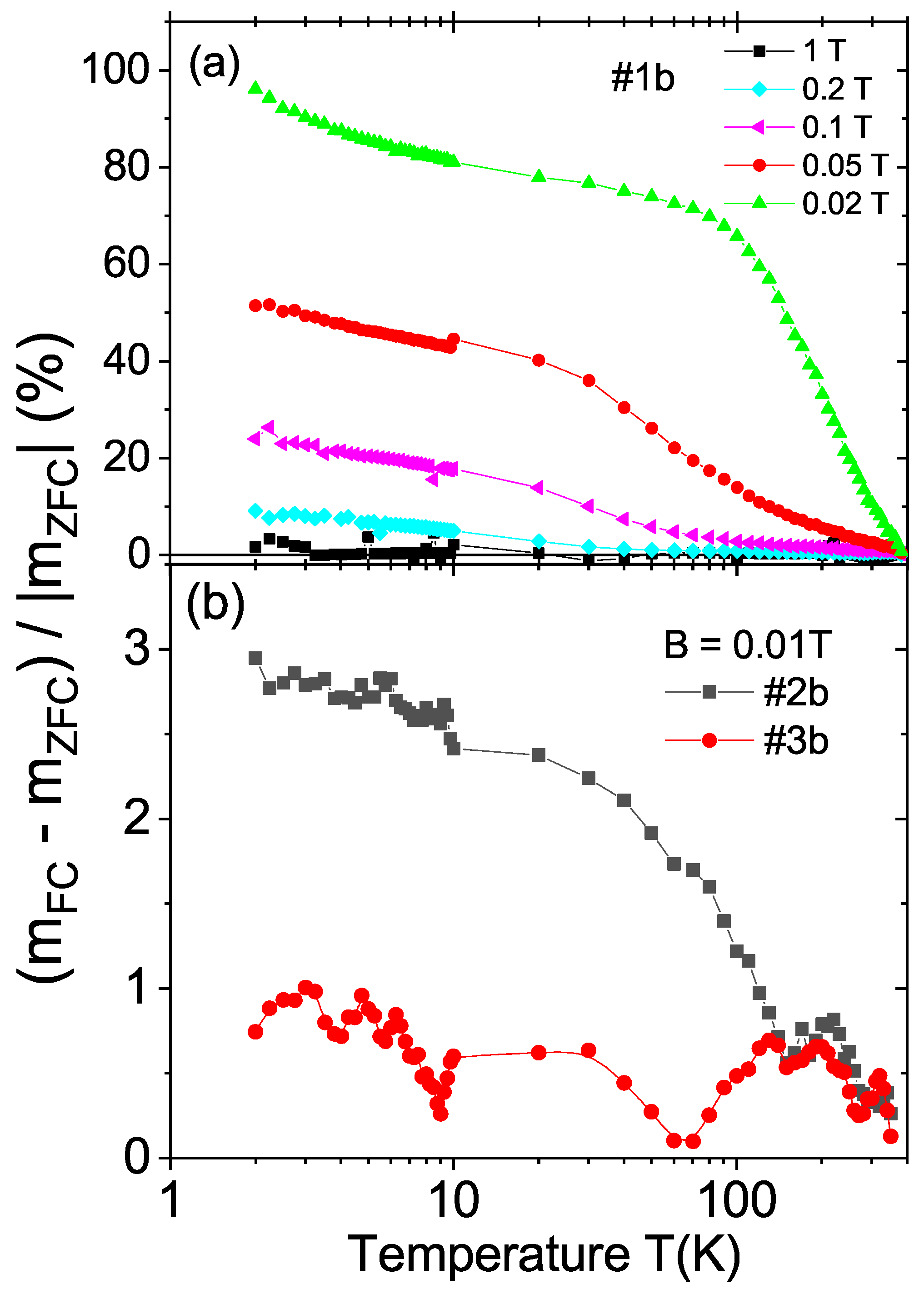

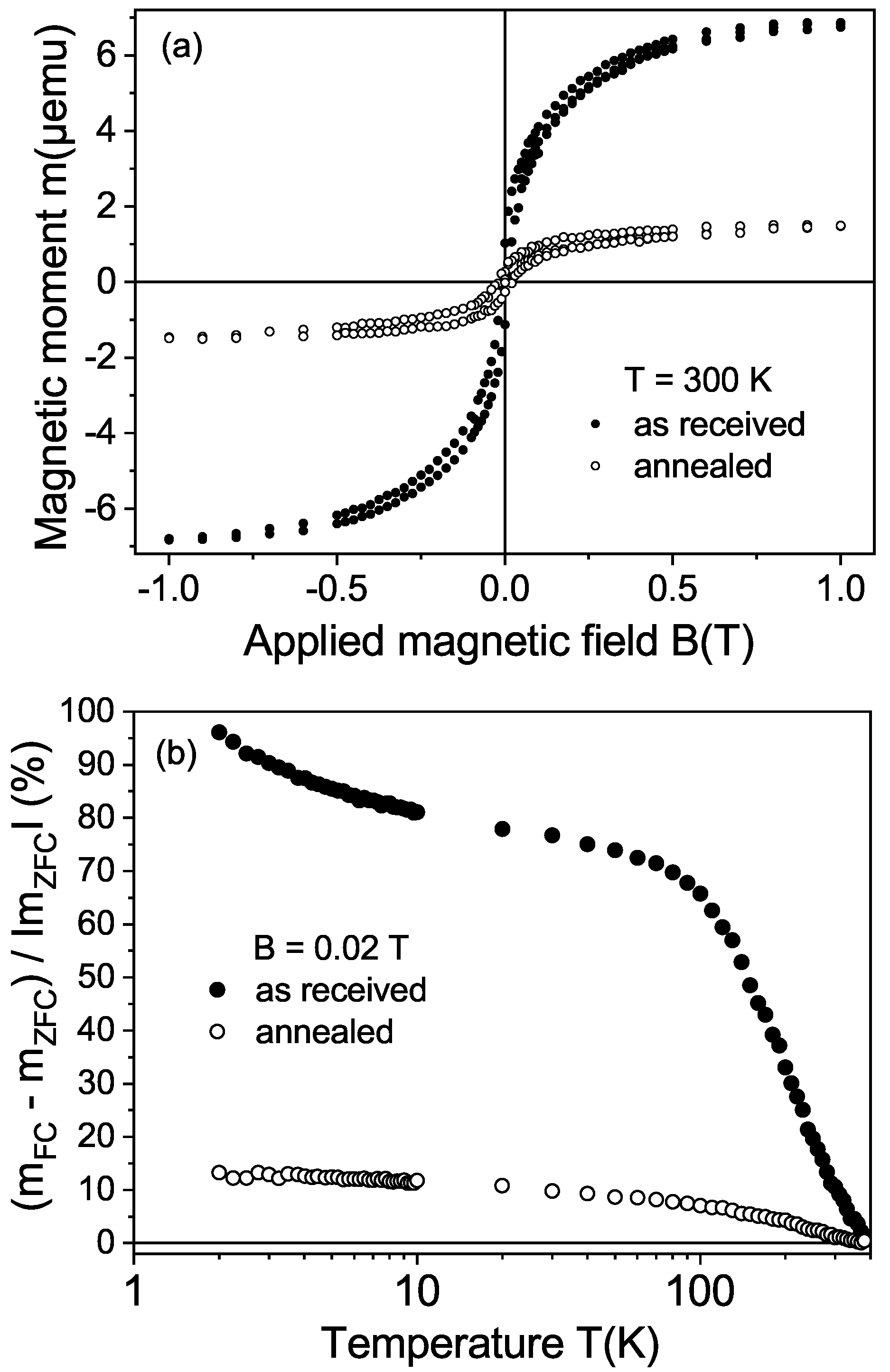

3.3.2. CVD Diamond Samples

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CVD | Chemical vapor deposition |

| SQUID | Superconducting quantum interference device |

| PIXE | Particle-induced X-ray emission |

References

- Esquinazi, P. (Ed.) Basic Physics of Functionalized Graphite; Springer Series in Materials Science 244; Springer International Publishing AG: Cham, Switzerland, 2016. [Google Scholar]

- Talapatra, S.; Ganesan, P.G.; Kim, T.; Vajtai, R.; Huang, M.; Shina, M.; Ramanath, G.; Srivastava, D.; Deevi, S.C.; Ajayan, P.M. Irradiation-induced magnetism in carbon nanostructures. Phys. Rev. Lett. 2005, 95, 097201. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Samuely, T.; Xu, Z.; Jochum, J.K.; Volodin, A.; Zhou, S.; May, P.W.; Onufriienko, O.; Kačmarčík, J.; Steele, J.A.; et al. Superconducting Ferromagnetic Nanodiamond. ACS Nano 2017, 11, 5358–5366. [Google Scholar] [CrossRef] [PubMed]

- Narayan, J.; Bhaumik, A. Novel phase of carbon, ferromagnetism, and conversion into diamond. J. Appl. Phys. 2015, 118, 215303. [Google Scholar] [CrossRef]

- Kenmochi, K.; Sato, K.; Yanase, A.; Katayama-Yoshida, H. Materials Design of Ferromagnetic Diamond. Jpn. J. Appl. Phys. 2004, 44, L51–L53. [Google Scholar] [CrossRef]

- Chan, J.A.; Montanari, B.; Gale, J.D.; Bennington, S.M.; Taylor, J.W.; Harrison, N.M. Magnetic properties of polymerized C60: The influence of defects and hydrogen. Phys. Rev. B 2004, 70, 041403. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Fukui, K.I.; Enoki, T.; Kusakabe, K. Edge state on hydrogen-terminated graphite edges investigated by scanning tunneling microscopy. Phys. Rev. B 2006, 73, 125415. [Google Scholar] [CrossRef]

- Ma, Y.; Lehtinen, P.O.; Foster, A.S.; Nieminen, R.M. Hydrogen-induced magnetism in carbon nanotubes. Phys. Rev. B 2005, 72, 085451. [Google Scholar] [CrossRef]

- Saito, T.; Ozeki, T.; Terashima, K. Hydrogen-induced magnetism in carbon nanotubes. Solid State Commun. 2005, 136, 546–549. [Google Scholar] [CrossRef]

- Lee, K.W.; Lee, Y.H.; Kim, I.M.; Lee, C.E. Magnetic Moment in Proton-Irradiated Graphite. J. Korean Phys. Soc. 2005, 47, 337–338. [Google Scholar]

- Ohldag, H.; Esquinazi, P.; Arenholz, E.; Spemann, D.; Rothermel, M.; Setzer, A.; Butz, T. The role of hydrogen in room-temperature ferromagnetism at graphite surfaces. New J. Phys. 2010, 12, 123012. [Google Scholar] [CrossRef]

- Makarova, T.L.; Shelankov, A.L.; Serenkov, I.T.; Sakharov, V.I.; Boukhvalov, D.W. Anisotropic magnetism of graphite irradiated with medium-energy hydrogen and helium ions. Phys. Rev. B 2011, 83, 085417. [Google Scholar] [CrossRef]

- Friedman, A.L.; Chun, H.; Jung, Y.J.; Heiman, D.; Glaser, E.R.; Menon, L. Possible room-temperature ferromagnetism in hydrogenated carbon nanotubes. Phys. Rev. B 2010, 81, 115461. [Google Scholar] [CrossRef]

- García, N.; Esquinazi, P.; Barzola-Quiquia, J.; Dusari, S. Evidence for semiconducting behavior with a narrow band gap of Bernal graphite. New J. Phys. 2012, 14, 053015. [Google Scholar] [CrossRef]

- Ariskina, R.; Schnedler, M.; Esquinazi, P.D.; Champi, A.; Stiller, M.; Hergert, W.; Dunin-Borkowski, R.E.; Ebert, P.; Venus, T.; Estrela-Lopis, I. Influence of surface band bending on a narrow band gap semiconductor: Tunneling atomic force studies of graphite with Bernal and rhombohedral stacking orders. Phys. Rev. Mater. 2021, 5, 044601. [Google Scholar] [CrossRef]

- Wang, C.Z.; Ho, K.M.; Shirk, M.D.; Molian, P.A. Laser-Induced Graphitization on a Diamond (111) Surface. Phys. Rev. Lett. 2000, 85, 4092–4095. [Google Scholar] [CrossRef] [PubMed]

- Jeschke, H.O.; Garcia, M.E.; Bennemann, K.H. Microscopic analysis of the laser-induced femtosecond graphitization of diamond. Phys. Rev. B 1999, 60, R3701–R3704. [Google Scholar] [CrossRef]

- Takesada, M.; Vanagas, E.; Tuzhilin, D.; Kudryashov, I.; Suruga, S.; Murakami, H.; Sarukura, N.; Matsuda, K.; Mononobe, S.; Saiki, T.; et al. Micro-Character Printing on a Diamond Plate by Femtosecond Infrared Optical Pulses. Jpn. J. Appl. Phys. 2003, 42, 4613–4616. [Google Scholar] [CrossRef]

- Mouhamadali, F.; Equis, S.; Saeidi, F.; Best, J.; Cantoni, M.; Hoffmann, P.; Wasmer, K. Nanosecond pulsed laser-processing of CVD diamond. Opt. Lasers Eng. 2020, 126, 105917. [Google Scholar] [CrossRef]

- Hermani, J.P.; Emonts, M.; Brecher, C. Nanosecond Laser Processing of Diamond Materials. In Proceedings of the Lasers in Manufacturing Conference, Munich, Germany, 22–25 June 2015; Available online: https://www.wlt.de/lim/Proceedings2015/Stick/PDF/Contribution299_final.pdf (accessed on 5 December 2021).

- Sasaki, Y.; Takeda, A.; Li, K.; Ohshio, S.; Akasaka, H.; Nakano, M.; Saitoh, H. Evaluation of etching on amorphous carbon films in nitric acid. Diam. Relat. Mater. 2012, 24, 104–106. [Google Scholar] [CrossRef]

- Polushin, N.I.; Ovchinnikova, M.S.; Sorokin, M.N. Reducing the Metal Content in PCD Polycrystalline Diamond Layer by Chemical and Electrochemical Etching. Russ. J. Non-Ferr. Met. 2018, 59, 557–562. [Google Scholar] [CrossRef]

- Babich, Y.; Feigelson, B. Distribution of N+ centers in synthetic diamond single crystals. Inorg. Mater. 2009, 45, 616–619. [Google Scholar] [CrossRef]

- Woods, G.S. Infrared absorption studies of the annealing of irradiated diamonds. Philos. Mag. B 1984, 50, 673–688. [Google Scholar] [CrossRef]

- Stiegler, J.; von Kaenel, Y.; Cans, M.; Blank, E. Space filling by nucleation and growth in chemical vapor deposition of diamond. J. Mater. Res. 1996, 11, 716–726. [Google Scholar] [CrossRef][Green Version]

- Badzian, A.; Badzian, T. Recent developments in hard materials. Int. J. Refract. Met. Hard Mater. 1997, 15, 3–12. [Google Scholar] [CrossRef]

- Zaitsev, A. Optical Properties of Diamond; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Esquinazi, P.; Barzola-Quiquia, J.; Spemann, D.; Rothermel, M.; Ohldag, H.; García, N.; Setzer, A.; Butz, T. Magnetic order in graphite: Experimental evidence, intrinsic and extrinsic difficulties. J. Magn. Magn. Mater. 2010, 322, 1156–1161. [Google Scholar] [CrossRef]

- Barzola-Quiquia, J.; Stiller, M.; Esquinazi, P.; Molle, A.; Wunderlich, R.; Pezzagna, S.; Meijer, J.; Kossack, W.; Buga, S. Unconventional Magnetization below 25 K in Nitrogen-doped Diamond provides hints for the existence of Superconductivity and Superparamagnetism. Sci. Rep. 2019, 9, 8743. [Google Scholar] [CrossRef]

- Setzer, A.; Esquinazi, P.D.; Daikos, O.; Scherzer, T.; Pöppl, A.; Staacke, R.; Lühmann, T.; Pezzagna, S.; Knolle, W.; Buga, S.; et al. Weak Electron Irradiation Suppresses the Anomalous Magnetization of N-Doped Diamond Crystals. Phys. Status Solidi 2021, 258, 2100395. [Google Scholar] [CrossRef]

| Name | Orientation | Mass | Cut Area | N | N Centers |

|---|---|---|---|---|---|

| (mg) | (mm2) | (ppm) | (ppm) (A, B, C) | ||

| 354 | (100) | 96.0 | 3170 | 195, 681, 56 | |

| 356 | (100) | 106.0 | 1400 | 522, 78, 46 | |

| 540 | (100) | 96.0 | 750 | 240, 66, 9 | |

| 164 | (111) | 38.6 | 3900 | 605, 656, 81 | |

| 384 | (111) | 120.0 | 2000 | 696, 132, 57 |

| Name | Orientation | Laser Treatment | Mass | Cut Area |

|---|---|---|---|---|

| (mg) | (mm2) | |||

| 1a | (100) | cut | 32.5 | |

| 1b | (100) | polish | 33.6 | |

| 2a | (110) | cut | 35.6 | |

| 2b | (110) | polish | 33.3 | |

| 3a | (111) | cut | 39.5 | |

| 3b | (111) | polish | 65.7 |

| Sample | Analyzed Area | Concentration | MDL | ||||

|---|---|---|---|---|---|---|---|

| Fe | Co | Ni | Fe | Co | Ni | ||

| 354 | mm) | 0.17 | 0.046 | 0.16 | 0.03 | 0.03 | 0.03 |

| m) | 0.08 | < | < | 0.05 | 0.04 | 0.05 | |

| 356 | spot | 1.99 | - | 0.12 | 0.07 | 0.04 | 0.05 |

| 540 | spot | 0.57 | - | 0.11 | 0.06 | 0.04 | 0.04 |

| 164 | mm) | 2.6 | 0.038 | 0.098 | 0.04 | 0.03 | 0.03 |

| m) | 0.32 | - | < | 0.2 | 0.2 | 0.2 | |

| 384 | (1 mm) | 0.84 | 0.28 | 0.35 | 0.08 | 0.08 | 0.07 |

| m) | 0.8 | < | 0.2 | 0.2 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Setzer, A.; Esquinazi, P.D.; Buga, S.; Georgieva, M.T.; Reinert, T.; Venus, T.; Estrela-Lopis, I.; Ivashenko, A.; Bondarenko, M.; Böhlmann, W.; et al. Nanometers-Thick Ferromagnetic Surface Produced by Laser Cutting of Diamond. Materials 2022, 15, 1014. https://doi.org/10.3390/ma15031014

Setzer A, Esquinazi PD, Buga S, Georgieva MT, Reinert T, Venus T, Estrela-Lopis I, Ivashenko A, Bondarenko M, Böhlmann W, et al. Nanometers-Thick Ferromagnetic Surface Produced by Laser Cutting of Diamond. Materials. 2022; 15(3):1014. https://doi.org/10.3390/ma15031014

Chicago/Turabian StyleSetzer, Annette, Pablo D. Esquinazi, Sergei Buga, Milena T. Georgieva, Tilo Reinert, Tom Venus, Irina Estrela-Lopis, Andrei Ivashenko, Maria Bondarenko, Winfried Böhlmann, and et al. 2022. "Nanometers-Thick Ferromagnetic Surface Produced by Laser Cutting of Diamond" Materials 15, no. 3: 1014. https://doi.org/10.3390/ma15031014

APA StyleSetzer, A., Esquinazi, P. D., Buga, S., Georgieva, M. T., Reinert, T., Venus, T., Estrela-Lopis, I., Ivashenko, A., Bondarenko, M., Böhlmann, W., & Meijer, J. (2022). Nanometers-Thick Ferromagnetic Surface Produced by Laser Cutting of Diamond. Materials, 15(3), 1014. https://doi.org/10.3390/ma15031014