The Influence of Abrasive and Acidic Aggressions on the Surface Condition of Flowable Composite Resin

Abstract

:1. Introduction

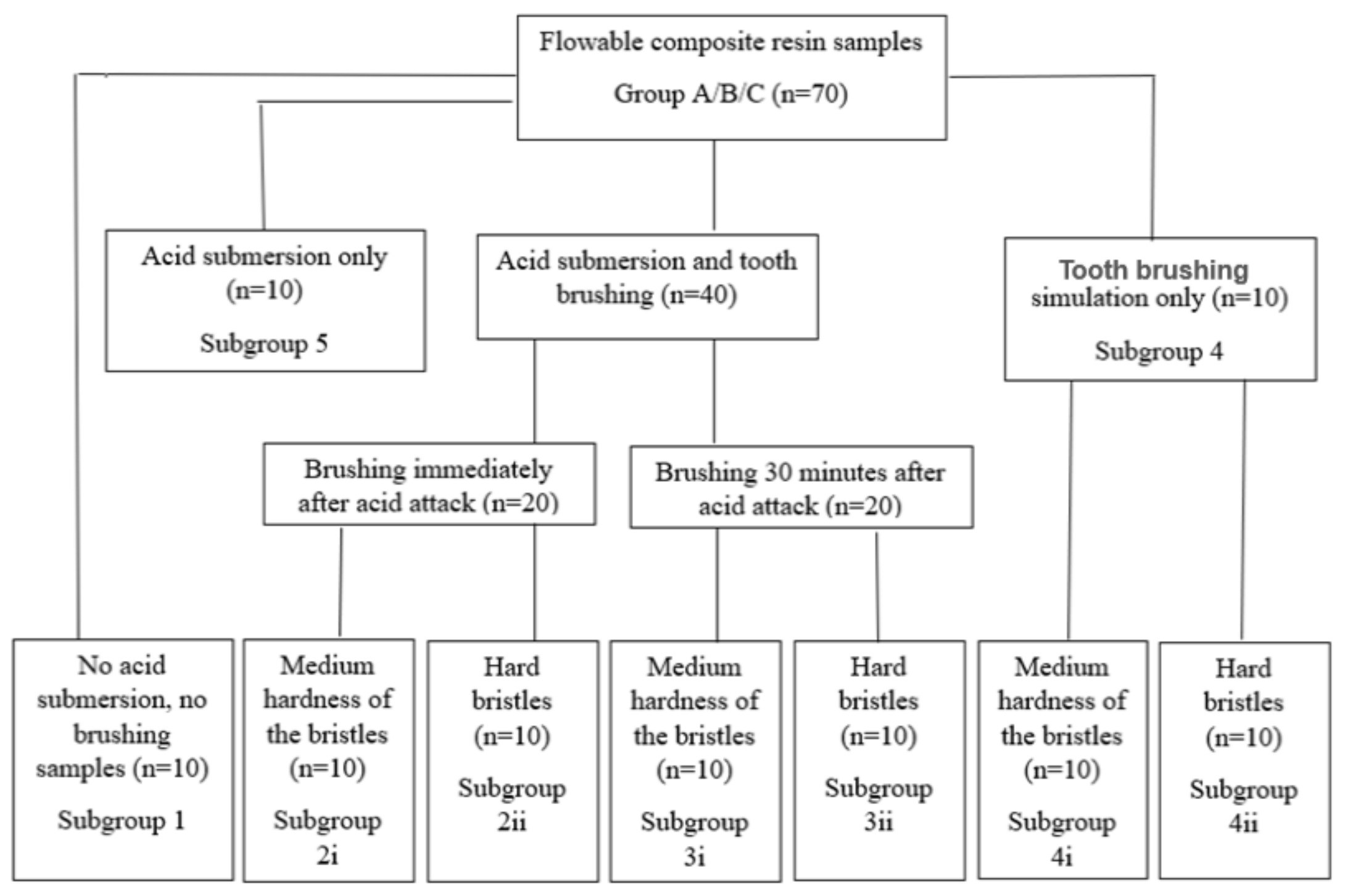

2. Materials and Methods

2.1. Sample Preparation

2.2. Finishing and Polishing Procedure

2.3. Simulation of Acid Attack

2.4. Brushing Simulation

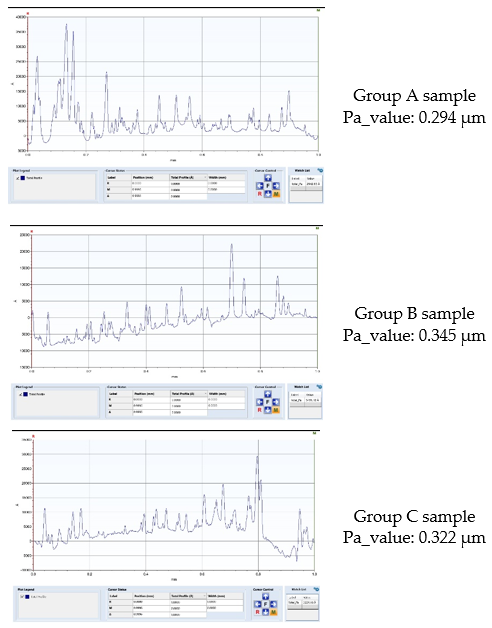

2.5. Profilometry

2.6. Statistical Analysis

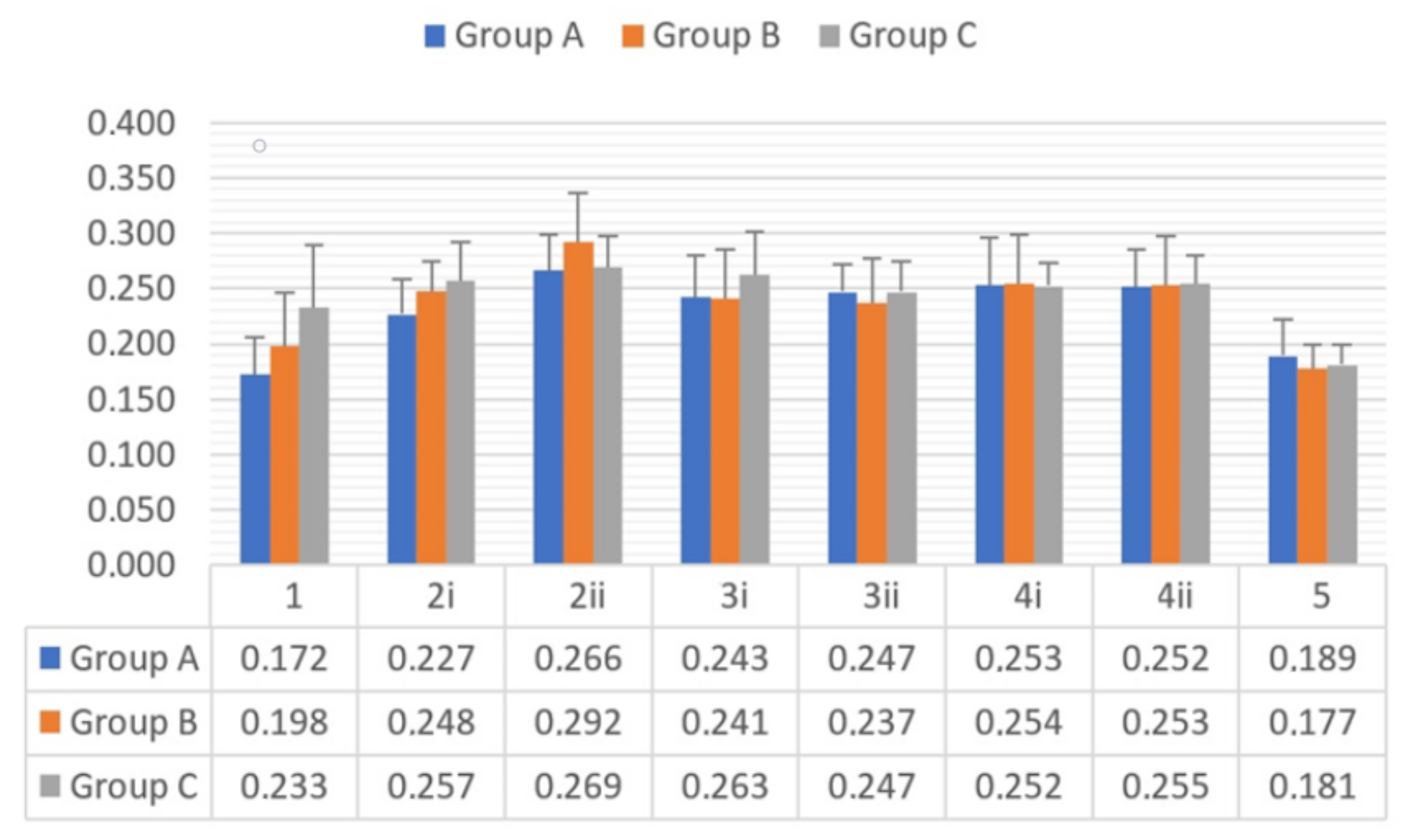

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Han, L.; Okamoto, A.; Fukushima, M.; Okiji, T. Evaluation of Flowable Resin Composite Surfaces Eroded by Acidic and Alcoholic Drinks. Dent. Mater. J. 2008, 27, 455–465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lai, G.; Zhao, L.; Wang, J.; Kunzelmann, K.-H. Surface properties and color stability of dental flowable composites influenced by simulated toothbrushing. Dent. Mater. J. 2018, 37, 717–724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garcia, F.C.P.; Wang, L.; D’Alpino, P.H.P.; De Souza, J.B.; De Araújo, P.A.; Mondelli, R.F.D.L. Evaluation of the roughness and mass loss of the flowable composites after simulated toothbrushing abrasion. Braz. Oral Res. 2004, 18, 156–161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferracane, J.; Moser, J.; Greener, E. Rheology of Composite Restoratives. J. Dent. Res. 1981, 60, 1678–1685. [Google Scholar] [CrossRef] [PubMed]

- Somacal, D.C.; Manfroi, F.B.; Monteiro, M.; Oliveira, S.D.; Bittencourt, H.R.; Borges, A.G.; Spohr, A.M. Effect of pH Cycling Followed by Simulated Toothbrushing on the Surface Roughness and Bacterial Adhesion of Bulk-fill Composite Resins. Oper. Dent. 2020, 45, 209–218. [Google Scholar] [CrossRef]

- Jones, D.W.; Jones, P.; Wilson, H. A simple abrasion test for composites. J. Dent. 1972, 1, 28–34. [Google Scholar] [CrossRef]

- Al Khuraif, A.A. Anin vitroevaluation of wear and surface roughness of particulate filler composite resin after tooth brushing. Acta Odontol. Scand. 2014, 72, 977–983. [Google Scholar] [CrossRef]

- De Oliveira, G.U.; Mondelli, R.; Rodrigues, M.C.; Franco, E.B.; Ishikiriama, S.; Wang, L. Impact of filler size and distribution on roughness and wear of composite resin after simulated toothbrushing. J. Appl. Oral Sci. 2012, 20, 510–516. [Google Scholar] [CrossRef]

- Bollenl, C.M.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef]

- Komandla, D.R.; Acharya, S.R.; Pentapati, K.C. Comparative Evaluation of Surface Roughness of Resin- Modified Glass Ionomer and Glass Hybrid Restorative Materials Simulated by Tooth Brushing: An in-Vitro Study. Pesqui. Bras. Odontopediatria Clínica Integr. 2021, 21, 1–8. [Google Scholar] [CrossRef]

- Walter, R. Bulk-Fill Flowable Composite Resins. J. Esthet. Restor. Dent. 2013, 25, 72–76. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Wang, X.; Gao, X.; Chen, F.; Liang, X.; Li, D. Effects of surface properties of polymer-based restorative materials on early adhesion of Streptococcus mutans in vitro. J. Dent. 2016, 54, 33–40. [Google Scholar] [CrossRef] [PubMed]

- Ionescu, A.; Wutscher, E.; Brambilla, E.; Schneider-Feyrer, S.; Giessibl, F.J.; Hahnel, S. Influence of surface properties of resin-based composites on in vitro Streptococcus mutans biofilm development. Eur. J. Oral Sci. 2012, 120, 458–465. [Google Scholar] [CrossRef] [PubMed]

- Alali, M.; Silikas, N.; Satterthwaite, J. The Effects of Toothbrush Wear on the Surface Roughness and Gloss of Resin Composites with Various Types of Matrices. Dent. J. 2021, 9, 8. [Google Scholar] [CrossRef] [PubMed]

- Vasudeva, G. Monomer systems for dental composites and their future: A review. J. Calif. Dent. Assoc. 2009, 37, 389–398. [Google Scholar] [PubMed]

- Chimello, D.; Dibb, R.; Corona, S.; Lara, E. Assessing wear and surface roughness of different composite resins after toothbrushing. Mater. Res. 2001, 4, 285–289. [Google Scholar] [CrossRef] [Green Version]

- Rada, E.R. The versatility of flowable composites. Dent. Today 1998, 17, 78–82. [Google Scholar]

- Condon, J.R.; Ferracane, J.L. Evaluation of composite wear with a new multi-mode oral wear simulator. Dent. Mater. 1996, 12, 218–226. [Google Scholar] [CrossRef]

- Sulong, M.Z.A.M.; Aziz, R.A. Wear of materials used in dentistry: A review of the literature. J. Prosthet. Dent. 1990, 63, 342–349. [Google Scholar] [CrossRef]

- Suzuki, S.; Leinfelder, K.F.; Kawai, K.; Tsuchitani, Y. Effect of particle variation on wear rates of posterior composites. Am. J. Dent. 1995, 8, 173–178. [Google Scholar]

- Hashemikamangar, S.S.; Meymand, M.Z.; Kharazifard, M.-J.; Valizadeh, S. Surface microhardness of a self-adhesive composite in comparison with conventional composite resins. Dent. Med. Probl. 2020, 57, 247–253. [Google Scholar] [CrossRef] [PubMed]

- Salama, F.; Abdelmegid, F.; Alhomaidhi, L.; Alswayyed, S.; Alfarraj, S. Effect of Whitening Toothpastes and Brushing on Microhardness of Esthetic Restorative Materials. J. Clin. Pediatr. Dent. 2020, 44, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Göpferich, A. Mechanisms of polymer degradation and erosion. Biomaterials 1996, 17, 103–114. [Google Scholar] [CrossRef]

- Lepri, C.P.; Ribeiro, M.V.M.; Dibb, A.; Palma-Dibb, R.G. Influence of mouth rinse solutions on the color stability and microhardness of a composite resin. Int. J. Esthet. Dent. 2014, 9, 238–246. [Google Scholar]

- Lee, E.-H.; Ahn, J.-S.; Lim, Y.-J.; Kwon, H.-B.; Kim, M.-J. Effect of post-curing time on the color stability and related properties of a tooth-colored 3D-printed resin material. J. Mech. Behav. Biomed. Mater. 2021, 126, 104993. [Google Scholar] [CrossRef]

- Chin, A.; Ikeda, M.; Takagaki, T.; Nikaido, T.; Sadr, A.; Shimada, Y.; Tagami, J. Effects of Immediate and Delayed Cementations for CAD/CAM Resin Block after Alumina Air Abrasion on Adhesion to Newly Developed Resin Cement. Materials 2021, 14, 7058. [Google Scholar] [CrossRef]

- Li, Y.; Guan, H.; Bao, Y.; Guo, S.; Lei, D.; Zhao, T.; Zhong, B.; Li, Z. Ni0.6Zn0.4Fe2O4/Ti3C2Tx nanocomposite modified epoxy resin coating for improved microwave absorption and impermeability on cement mortar. Constr. Build. Mater. 2021, 310, 125213. [Google Scholar] [CrossRef]

- Carvalho, F.; Sampaio, C.; Fucio, S.; Carlo, H.; Correr-Sobrinho, L.; Puppin-Rontani, R. Effect of Chemical and Mechanical Degradation on Surface Roughness of Three Glass Ionomers and a Nanofilled Resin Composite. Oper. Dent. 2012, 37, 509–517. [Google Scholar] [CrossRef]

- Sexson, J.C.; Phillips, R.W. Studies on the effects of abrasives on acrylic resins. J. Prosthet. Dent. 1951, 1, 454–471. [Google Scholar] [CrossRef]

- Barbieri, G.M.; Mota, E.G.; Rodrigues-Junior, S.A.; Burnett, L.H.B., Jr. Effect of Whitening Dentifrices on the Surface Roughness of Commercial Composites. J. Esthet. Restor. Dent. 2011, 23, 338–345. [Google Scholar] [CrossRef]

- Monteiro, B.; Spohr, A.M. Surface Roughness of Composite Resins after Simulated Toothbrushing with Different Dentifrices. J. Int. Oral Heal. 2015, 7, 1–5. [Google Scholar]

- Carvalho, F.G.; Fucio, S.B.P.; Paula, A.B.; Correr, G.M.; Sinhoreti, M.A.C.; Puppin-Rontani, R.M. Child toothbrush abrasion effect on ionomeric materials. J. Dent. Child. 2008, 75, 112–116. [Google Scholar]

- Barucci-Pfister, N.; Göhring, T.N. Subjective and objective perceptions of specular gloss and surface roughness of esthetic resin composites before and after artificial aging. Am. J. Dent. 2009, 22, 102–110. [Google Scholar] [CrossRef] [PubMed]

| The Name of Flowable Composite Resin | Manufacturer | Batch No. | Composition | Filler wt%/vol% |

|---|---|---|---|---|

| Grandio Flow | VOCO GmbH, Cuxhaven, Germany | 2036127 | Bis-GMA, TEGDMA, HEDMA, glass ceramic, nanoparticle | 65.6 wt%/80 vol% |

| Filtek Ultimate Flow | 3M-ESPE, St. Paul, MN, USA | 3930A2 | Bis-GMA, UDMA, Bis-EMA, Zirconia/silica, zirconia, silica | 78.5 wt%/63.3 vol% |

| G-aenial Flo X | GC Europe | 1910162 | UDMA, Bis-MEPP, TEGDMA, silicon, dioxide, strontium glass | 69 wt%/50 vol% |

| Toothbrush Name | Bristle Hardness | Bristle Material | Bristle Length | Bristle Thickness |

|---|---|---|---|---|

| R.O.C.S. ”Professional” Medium | medium | nylon | 0.8/1.3 | 0.18/0.2 |

| R.O.C.S. ”Professional” Firm | hard | nylon | Not provided by the producer | Not provided by the producer |

| Subgroups | 1 | 2i | 2ii | 3i | 3ii | 4i | 4ii | 5 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Groups | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | A | B | C |

| A | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * |

| B | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * |

| C | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - | * | * | - |

| Group A | Group B | Group C | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2i | 2ii | 3i | 3ii | 4i | 4ii | 5 | 1 | 2i | 2ii | 3i | 3ii | 4i | 4ii | 5 | 1 | 2i | 2ii | 3i | 3ii | 4i | 4ii | 5 | |

| 1 | - | * | ** | * | ** | ** | ** | * | - | * | ** | * | * | * | * | * | - | * | * | * | * | * | * | * |

| 2i | * | - | * | * | * | * | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * | * | * | ** |

| 2ii | ** | * | - | * | * | * | * | ** | ** | * | - | * | * | * | * | ** | * | * | - | * | * | * | * | ** |

| 3i | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * | ** |

| 3ii | ** | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * |

| 4i | ** | * | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * | * | * | * | * | - | * | * |

| 4ii | ** | * | * | * | * | - | * | * | * | * | * | * | * | - | * | * | * | * | * | * | * | - | ** | |

| 5 | * | * | ** | * | * | * | * | - | * | * | ** | * | * | * | * | - | * | ** | ** | ** | * | * | ** | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tărăboanță, I.; Stoleriu, S.; Gurlui, S.; Nica, I.; Tărăboanță-Gamen, A.C.; Iovan, A.; Andrian, S. The Influence of Abrasive and Acidic Aggressions on the Surface Condition of Flowable Composite Resin. Materials 2022, 15, 1000. https://doi.org/10.3390/ma15031000

Tărăboanță I, Stoleriu S, Gurlui S, Nica I, Tărăboanță-Gamen AC, Iovan A, Andrian S. The Influence of Abrasive and Acidic Aggressions on the Surface Condition of Flowable Composite Resin. Materials. 2022; 15(3):1000. https://doi.org/10.3390/ma15031000

Chicago/Turabian StyleTărăboanță, Ionuț, Simona Stoleriu, Silviu Gurlui, Irina Nica, Andra Claudia Tărăboanță-Gamen, Alexandru Iovan, and Sorin Andrian. 2022. "The Influence of Abrasive and Acidic Aggressions on the Surface Condition of Flowable Composite Resin" Materials 15, no. 3: 1000. https://doi.org/10.3390/ma15031000

APA StyleTărăboanță, I., Stoleriu, S., Gurlui, S., Nica, I., Tărăboanță-Gamen, A. C., Iovan, A., & Andrian, S. (2022). The Influence of Abrasive and Acidic Aggressions on the Surface Condition of Flowable Composite Resin. Materials, 15(3), 1000. https://doi.org/10.3390/ma15031000