The Mechanical Behavior and Enhancement Mechanism of Short Carbon Fiber Reinforced AFS Interface

Abstract

1. Introduction

2. Experimental Method

2.1. Materials

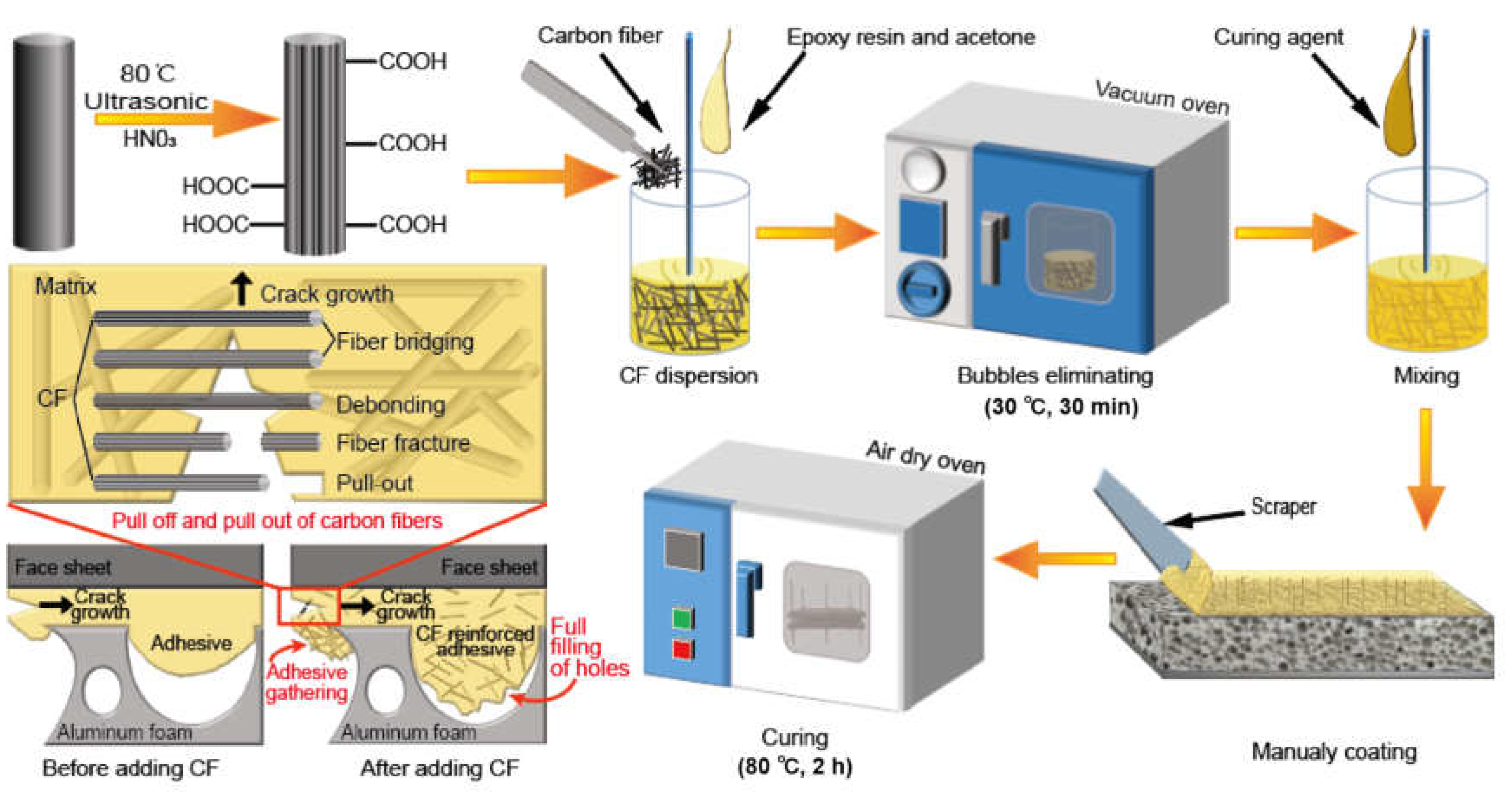

2.2. Fabrication of Single Lap Joints (SLJs) and Aluminum Foam Sandwich Structures (AFSs)

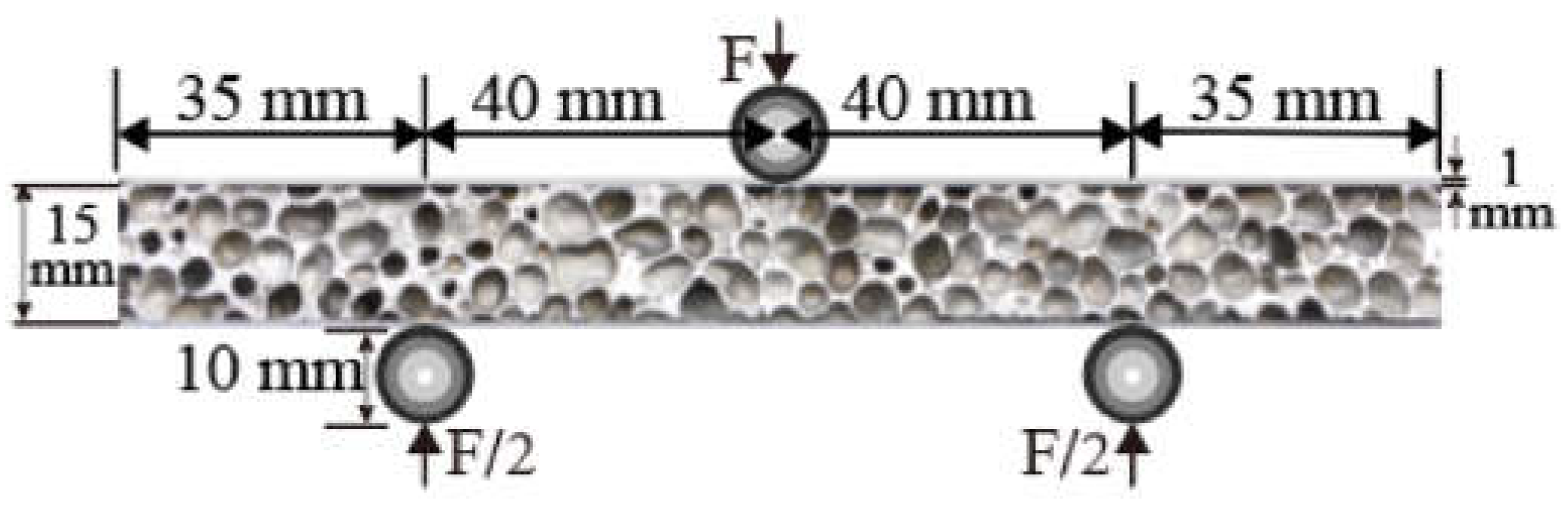

2.3. Single Lap Shear Test and Three-Point Bending Test

3. Result and Discussion

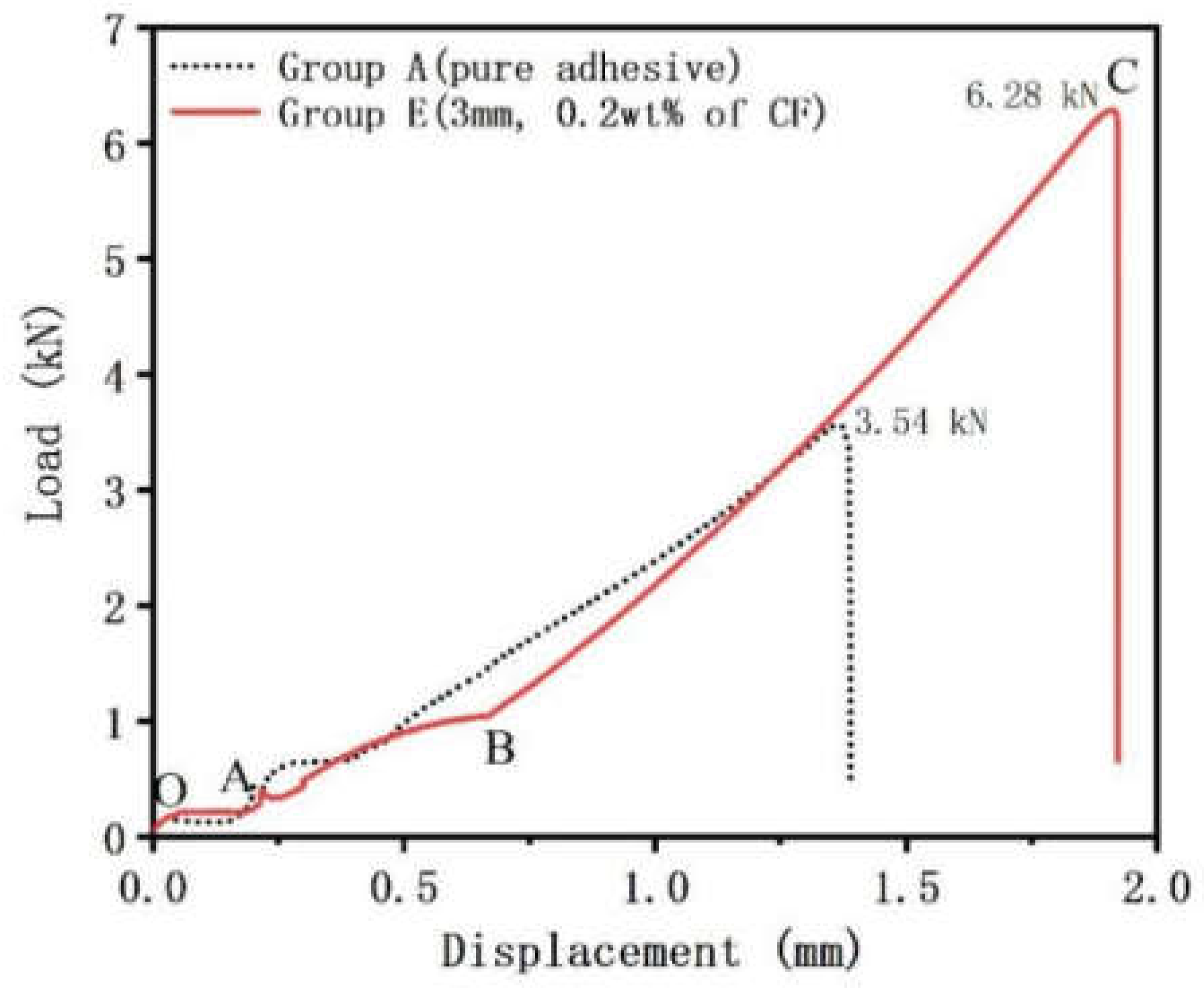

3.1. Single-Lap Shear Behavior of the Reinforced Interface

3.1.1. The Load-Displacement

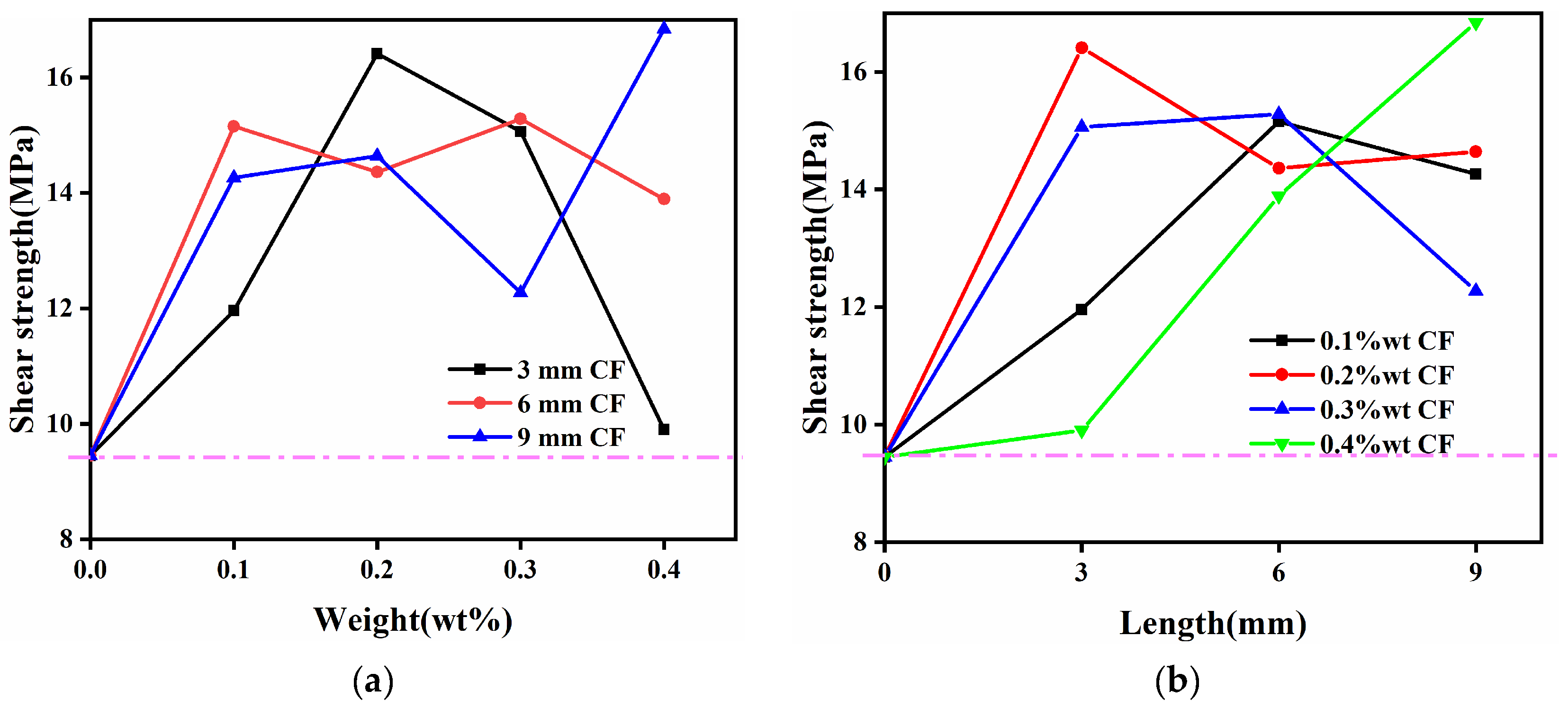

3.1.2. Effects of Carbon-Fiber Length and Content on the Mechanical Behavior of the Gluing Joint

3.2. Three-Point Bending Behavior of the AFS with Short Fiber Reinforced Interface

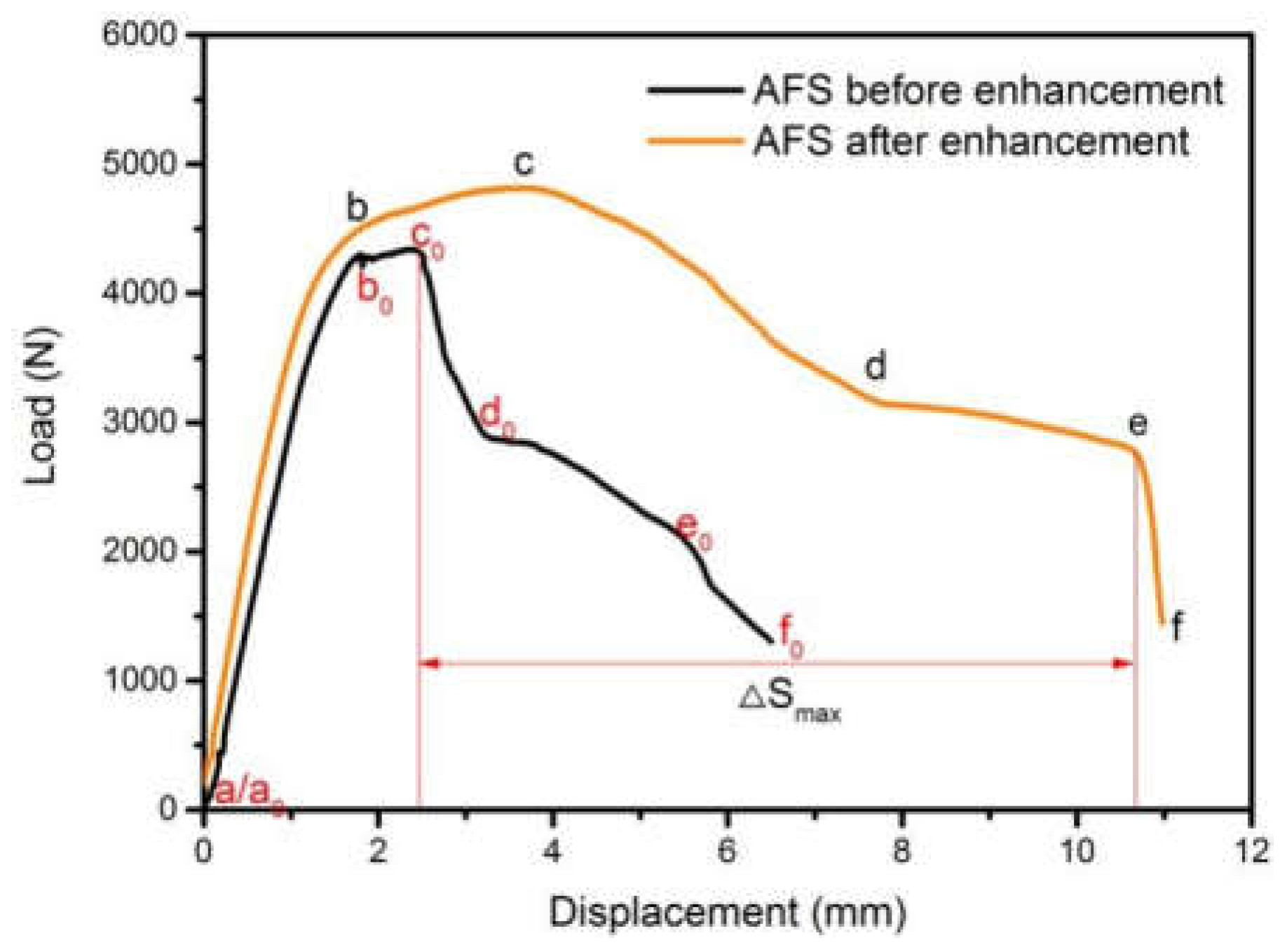

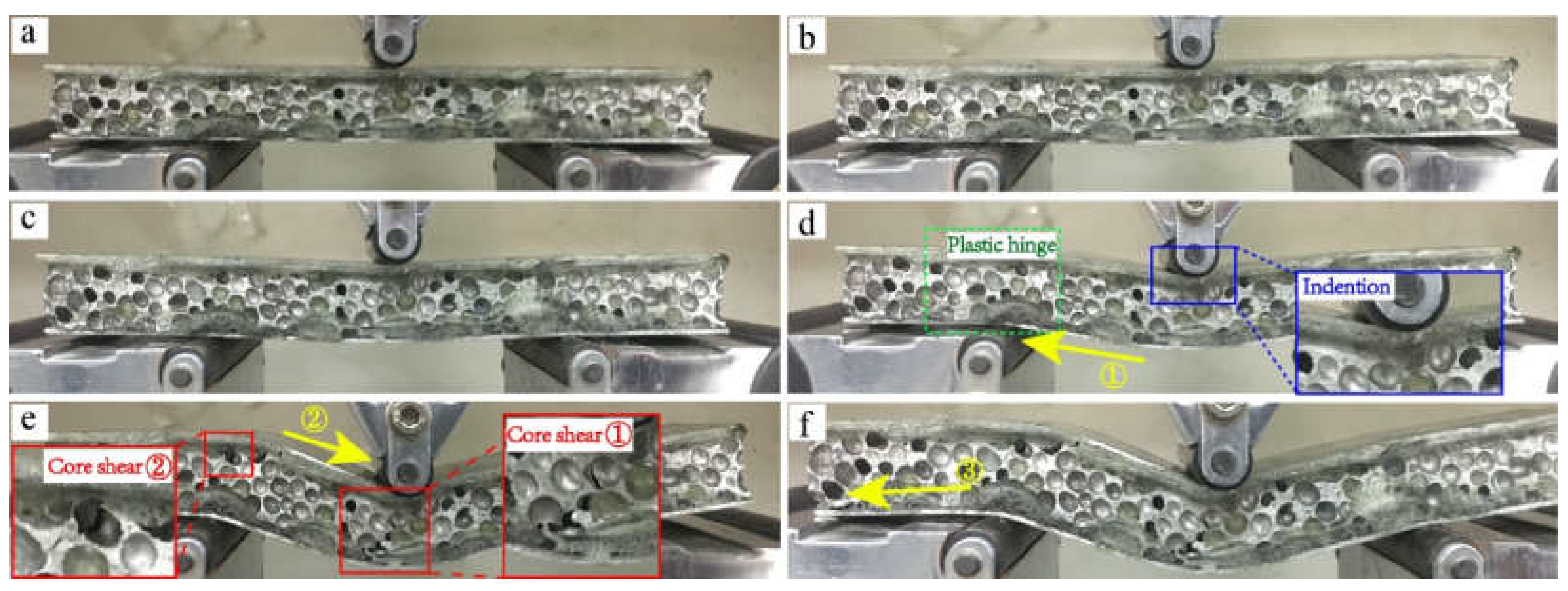

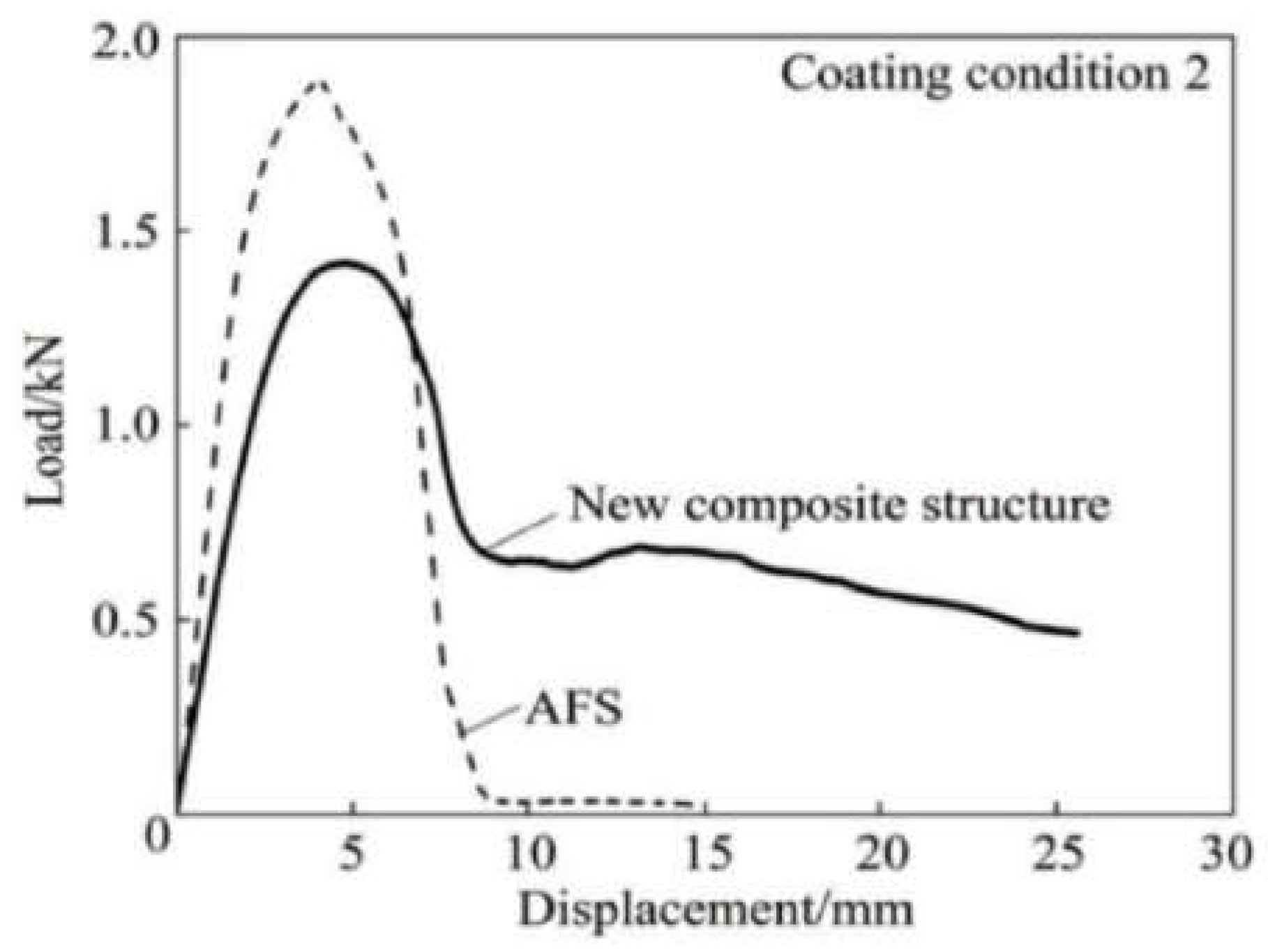

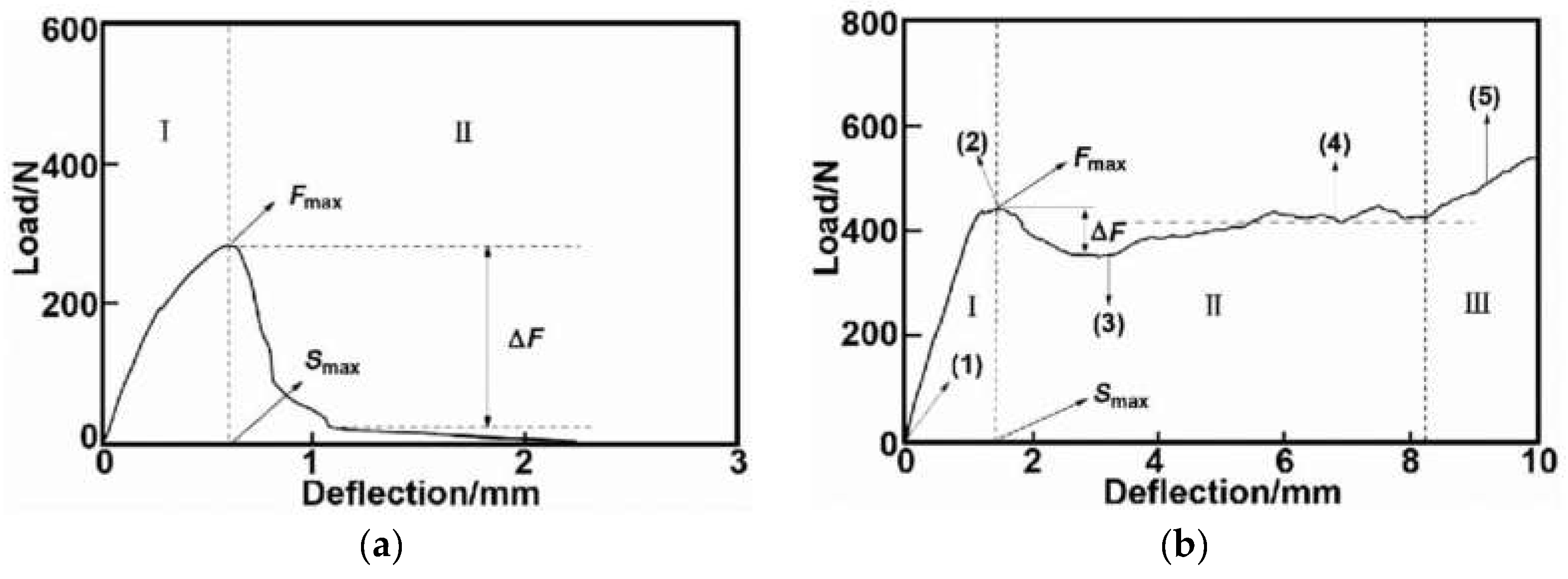

3.2.1. The Load-Displacement Curve and Deformation Process

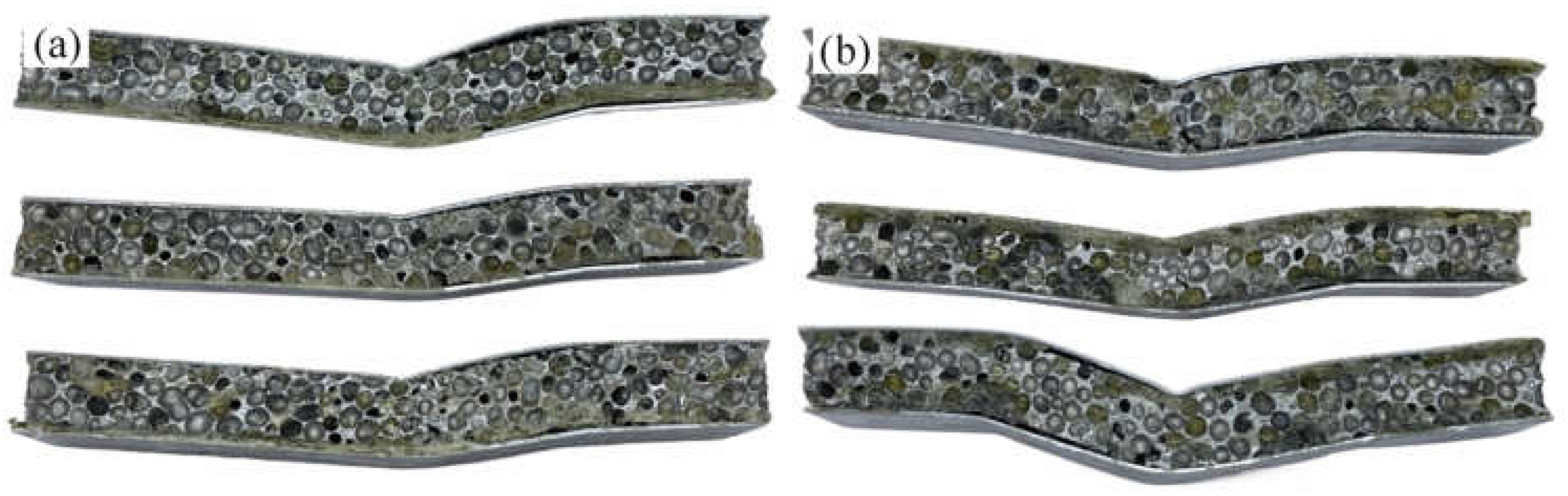

3.2.2. The Failure Mode

3.3. Enhancement Mechanism of the Interface

4. Conclusions

- The result of the single lap shear test indicated that the modified carbon fiber had a positive effect on the shear strength of the interface of AFS. The single lap shear reinforced with 3 mm length and 0.2 wt% content carbon fiber showed the highest enhancement, increasing by 73.65%.

- Three-point bending tests proved that the strength of the short fiber reinforced AFS was higher than the unreinforced AFS. There was a giant improvement in energy absorption. The numerical value was from 17.49 (kN × mm) to 39.51 (kN × mm) whose growth rate reached 125.95%. The problem of failure of AFS due to degumming was improved.

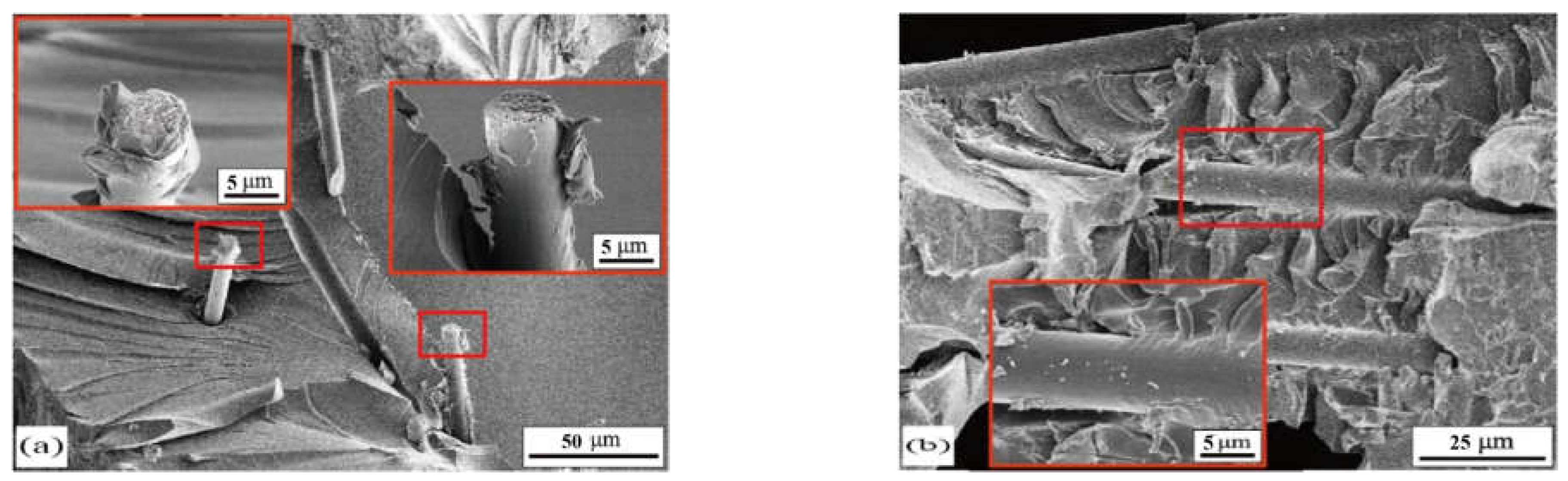

- The reinforcement mechanism of the carbon fiber reinforced interface for AFS was due to the influence of the carbon fiber on adhesive interface shear failure. Three categories of reinforcement mechanisms were discovered in this study: (a) the pull off and pull mechanism: the modified carbon fiber performed as the bridge, the bonding strength improved because of the pull off, and pull out of fibers; (b) the adhesion effect: the carbon fiber gathered in the hole edge resulted in epoxy resins being gathered in there too, which increased the effective bonding area of the interface; (c) the mechanical self-locking effect: the carbon fiber enhanced the adhesive filling performance of aluminum foam holes, which improved the mechanical self-locking effect of the bonding interface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, S.; Li, Q.; Long, S.; Yang, X.; Li, W. Crashworthiness design for foam filled thin-wall structures. Mater. Des. 2009, 30, 2024–2032. [Google Scholar] [CrossRef]

- Islam, M.A.; Brown, A.D.; Hazell, P.J.; Kader, M.A.; Escobedo, J.P.; Saadatfar, M.; Xu, S.; Ruan, D.; Turner, M. Mechanical response and dynamic deformation mechanisms of closed-cell aluminium alloy foams under dynamic loading. Int. J. Impact Eng. 2018, 114, 111–122. [Google Scholar] [CrossRef]

- Sun, G.; Wang, E.; Zhang, J.; Li, S.; Zhang, Y.; Li, Q. Experimental study on the dynamic responses of foam sandwich panels with different facesheets and core gradients subjected to blast impulse. Int. J. Impact Eng. 2020, 135, 20. [Google Scholar] [CrossRef]

- Singh, S.; Bhatnagar, N. A survey of fabrication and application of metallic foams (1925–2017). J. Porous Mater. 2018, 25, 537–554. [Google Scholar] [CrossRef]

- Schwingel, D.; Seeliger, H.-W.; Vecchionacci, C.; Alwes, D.; Dittrich, J. Aluminium foam sandwich structures for space applications. Acta Astronaut. 2007, 61, 326–330. [Google Scholar] [CrossRef]

- Banhart, J. Light-Metal Foams—History of Innovation and Technological Challenges. Adv. Eng. Mater. 2013, 15, 82–111. [Google Scholar] [CrossRef]

- Santhosh, S.; Saravanan, C.; Rajaguru, K.; Kumar, B.S.; Sathish, T. Fabrication and analysis of aluminium foam with glass fiber based on PMC for helmet applications. Mater. Today Proc. 2021, 37, 1286–1288. [Google Scholar] [CrossRef]

- Shang, J.; He, D. Deformation of sandwich beams with Al foam cores in three-point bending. Chin. J. Mater. Res. 2003, 17, 31–38. [Google Scholar]

- Raza, M.S.; Datta, S.; Saha, P. Micro-mechanical and X-Ray micro-computed tomographical analysis of quasi-static three-point loading behaviour of closed-cell aluminium foam with and without epoxy-bonded aluminium face-sheet. Mater. Sci. Eng. A 2021, 809, 140907. [Google Scholar] [CrossRef]

- Zu, G.; Song, B.; Zhong, Z.; Li, X.; Mu, Y.; Yao, G. Static three-point bending behavior of aluminum foam sandwich. J. Alloy. Compd. 2012, 540, 275–278. [Google Scholar] [CrossRef]

- Zu, G.-Y.; Lu, R.-H.; Li, X.-B.; Zhong, Z.-Y.; Ma, X.-J.; Han, M.-B.; Yao, G.-C. Three-point bending behavior of aluminum foam sandwich with steel panel. Trans. Nonferrous Met. Soc. China 2013, 23, 2491–2495. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Pergamon Press: Oxford, UK, 1998. [Google Scholar]

- Zhu, X.; Ai, S.; Lu, X.; Cheng, K.; Ling, X.; Zhu, L.; Liu, B. Collapse models of aluminum foam sandwiches under static three-point bending based on 3D geometrical reconstruction. Comput. Mater. Sci. 2014, 85, 38–45. [Google Scholar] [CrossRef]

- Latour, M.; D’Aniello, M.; Landolfo, R.; Rizzano, G. Experimental and numerical study of double-skin aluminium foam sandwich panels in bending. Thin-Walled Struct. 2021, 164, 107894. [Google Scholar] [CrossRef]

- Yu, J.; Wang, E.; Li, J.; Zheng, Z. Static and low-velocity impact behavior of sandwich beams with closed-cell aluminum-foam core in three-point bending. Int. J. Impact Eng. 2008, 35, 885–894. [Google Scholar] [CrossRef]

- Zou, G.; Chang, Z.; Ming, R.; Xia, P.; Wang, Q. Study on Impact performance of sandwich panel with foam aluminum foam. Acta Armamentarii 2009, 30, 276–279. [Google Scholar]

- Liu, C.; Zhang, Y.X.; Ye, L. High velocity impact responses of sandwich panels with metal fibre laminate skins and aluminium foam core. Int. J. Impact Eng. 2017, 100, 139–153. [Google Scholar] [CrossRef]

- Liu, H.; Cao, Z.; Yao, G.; Luo, H.; Zu, G. Performance of aluminum foam-steel panel sandwich composites subjected to blast loading. Mater. Des. 2013, 47, 483–488. [Google Scholar] [CrossRef]

- Jing, L.; Wang, Z.; Zhao, L. The dynamic response of sandwich panels with cellular metal cores to localized impulsive loading. Compos. Part B Eng. 2016, 94, 52–63. [Google Scholar] [CrossRef]

- Harte, A.M.; Fleck, N.A.; Ashby, M.F. The fatigue strength of sandwich beams with an aluminium alloy foam core. Int. J. Fatigue 2001, 23, 499–507. [Google Scholar] [CrossRef]

- Yan, C.; Wang, J.; Song, X. Fatigue behavior and damage mechanism of aluminum foam sandwich with carbon-fiber face-sheets. J. Mech. Sci. Technol. 2020, 34, 1119–1127. [Google Scholar] [CrossRef]

- Wan, L.; Huang, Y.; Huang, T.; Lv, S.; Feng, J. Novel method of fluxless soldering with self-abrasion for fabricating aluminum foam sandwich. J. Alloy. Compd. 2015, 640, 1–7. [Google Scholar] [CrossRef]

- Baumgārtner, F.; Duarte, I.; Banhart, J. Industrialization of Powder Compact Foaming Process. Adv. Eng. Mater. 2000, 2, 168. [Google Scholar] [CrossRef]

- Banhart, J.; Stanzick, H.; Helfen, L.; Baumbach, T.; Nijhof, K. Real-time X-ray Investigation of Aluminum Foam Sandwich Production. Adv. Eng. Mater. 2001, 3, 507. [Google Scholar] [CrossRef]

- Lin, H.; Luo, H.; Huang, W.; Zhang, X.; Yao, G. Diffusion bonding in fabrication of aluminum foam sandwich panels. J. Mater. Process. Technol. 2016, 230, 35–41. [Google Scholar] [CrossRef]

- Cederqvist, L.; Reynolds, A.P. Factors affecting the properties of friction stir welded aluminum lap joints. Weld. J. 2001, 80, 588–594. [Google Scholar]

- Hangai, Y.; Koyama, S.; Hasegawa, M.; Utsunomiya, T. Fabrication of Aluminum Foam/Dense Steel Composite by Friction Stir Welding. Metall. Mater. Trans. A 2010, 41, 2184–2186. [Google Scholar] [CrossRef]

- Hangai, Y.; Kamada, H.; Utsunomiya, T.; Kitahara, S.; Kuwazuru, O.; Yoshikawa, N. Aluminum alloy foam core sandwich panels fabricated from die casting aluminum alloy by friction stir welding route. J. Mater. Process. Technol. 2014, 214, 1928–1934. [Google Scholar] [CrossRef]

- Hao, Q.X.; Qiu, S.W.; Hu, Y.B. Development on Preparation Technology of Aluminum Foam Sandwich Panels. Rare Met. Mater. Eng. 2015, 44, 548–552. [Google Scholar]

- Ruan, D.; Lu, G.; Wong, Y.C. Quasi-static indentation tests on aluminium foam sandwich panels. Compos. Struct. 2010, 92, 2039–2046. [Google Scholar] [CrossRef]

- Baştürk, S.B.; Tanoğlu, M. Development and Mechanical Behavior of FML/Aluminium Foam Sandwiches. Appl. Compos. Mater. 2013, 20, 789–802. [Google Scholar] [CrossRef]

- Kwon, Y.J.; Shigematsu, I.; Saito, N. Development of New Production Technology for Metallic Foam Core Sandwich Panel Using Friction Phenomena. Mater. Trans. 2009, 50, 879–884. [Google Scholar] [CrossRef]

- Shi, X.; Xu, Y.-J.; Long, J.-W.; Zhao, Q.; Ding, X.-M.; Chen, L.; Wang, Y.-Z. Layer-by-layer assembled flame-retardant architecture toward high-performance carbon fiber composite. Chem. Eng. J. 2018, 353, 550–558. [Google Scholar] [CrossRef]

- Greenfeld, I.; Zhang, W.; Sui, X.; Wagner, H.D. Intermittent beading in fiber composites. Compos. Sci. Technol. 2018, 160, 21–31. [Google Scholar] [CrossRef]

- Cai, S.; Li, Y.; Liu, H.-Y.; Mai, Y.-W. Effect of electrospun polysulfone/cellulose nanocrystals interleaves on the interlaminar fracture toughness of carbon fiber/epoxy composites. Compos. Sci. Technol. 2019, 181, 107673. [Google Scholar] [CrossRef]

- Shokrian, M.D.; Shelesh-Nezhad, K.; Najjar, R. The effects of Al surface treatment, adhesive thickness and microcapsule inclusion on the shear strength of bonded joints. Int. J. Adhes. Adhes. 2019, 89, 139–147. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, S.; Hu, X.; Guo, X.; Chen, J.; Chen, H. Short-aramid-fiber toughening of epoxy adhesive joint between carbon fiber composites and metal substrates with different surface morphology. Compos. Part B Eng. 2015, 77, 38–45. [Google Scholar] [CrossRef]

- Wang, N.-Z.; Chen, X.; Li, A.; Li, Y.-X.; Zhang, H.-W.; Liu, Y. Three-point bending performance of a new aluminum foam composite structure. Trans. Nonferrous Met. Soc. China 2016, 26, 359–368. [Google Scholar] [CrossRef]

- Zu, G.; Lu, R.; Liu, J.; Ma, X.; Han, M.; Peng, F. Failure mode of aluminum foam sandwich panels. Funct. Mater. 2014, 45, 84–87. [Google Scholar]

- Yan, C.; Song, X.D. Effects of foam core density and face-sheet thickness on the mechanical properties of aluminum foam sandwich. Steel Compos. Struct. 2016, 21, 1145–1156. [Google Scholar] [CrossRef]

| Material | Density | Average Pore Size /mm | Pore Size Range /mm | Tensile Strength /MPa | Yield Strength /MPa | Elongation /% | Tensile Modulus/MPa |

|---|---|---|---|---|---|---|---|

| Aluminum foam | 0.60 g/cm3 | 3.77 | 1.66~6.67 | - | 4.4 | - | - |

| 6061 aluminum alloy | 2.75 g/cm3 | - | - | 333 | 300 | - | - |

| Carbon fiber bundle | 297.1 g/m2 | - | - | 3298.9 | - | 1.5 | 2.5 × 105 |

| Length | 0 mm | 3 mm | 6 mm | 9 mm | |

|---|---|---|---|---|---|

| Content | |||||

| 0.0%wt | A | -- | -- | -- | |

| 0.1%wt | -- | B | C | D | |

| 0.2%wt | -- | E | F | G | |

| 0.3%wt | -- | H | I | J | |

| 0.4%wt | -- | K | L | M | |

| Number | 1 /MPa | 2 /MPa | 3 /MPa | Average /MPa | Max /MPa | Standard Deviation/MPa | Enhance Degree/% | |

|---|---|---|---|---|---|---|---|---|

| Group | ||||||||

| A (pure adhesive) | 9.48 | 9.43 | 9.45 | 9.45 | 9.48 | 0.025 | - | |

| B (0.1 wt% & 3 mm CF) | 10.18 | 12.59 | 13.10 | 11.96 | 13.10 | 1.56 | 26.56 | |

| C (0.1 wt% & 6 mm CF) | 15.46 | 15.46 | 14.52 | 15.15 | 15.46 | 0.54 | 60.32 | |

| D (0.1 wt% & 9 mm CF) | 15.04 | 13.21 | 14.54 | 14.26 | 15.04 | 0.95 | 50.90 | |

| E (0.2 wt% & 3 mm CF) | 16.75 | 16.02 | 16.46 | 16.41 | 16.75 | 0.37 | 73.65 | |

| F (0.2 wt% & 6 mm CF) | 13.34 | 15.42 | 14.33 | 14.36 | 15.42 | 1.04 | 51.96 | |

| G (0.2 wt% & 9 mm CF) | 14.08 | 14.13 | 15.72 | 14.64 | 15.72 | 0.93 | 54.92 | |

| H (0.3 wt% & 3 mm CF) | 14.15 | 16.39 | 14.63 | 15.06 | 16.39 | 1.18 | 59.37 | |

| I (0.3 wt% & 6 mm CF) | 14.74 | 16.54 | 14.55 | 15.28 | 16.54 | 1.10 | 61.69 | |

| J (0.3 wt% & 9 mm CF) | 12.63 | 12.57 | 11.61 | 12.27 | 12.63 | 0.57 | 29.84 | |

| K (0.4 wt% & 3 mm CF) | 10.69 | 9.45 | 9.55 | 9.90 | 10.69 | 0.69 | 4.76 | |

| L (0.4 wt% & 6 mm CF) | 15.15 | 13.83 | 12.70 | 13.89 | 15.15 | 1.22 | 46.98 | |

| M (0.4 wt% & 9 mm CF) | 17.11 | 19.25 | 14.15 | 16.84 | 19.25 | 2.56 | 78.20 | |

| Specimen Name | Peak Load /kN | Displacement of Peak Load/mm | Effective Displacement/mm | Energy Absorption /kN × mm |

|---|---|---|---|---|

| Unreinforced AFS | 4.34 | 2.40 | 5.77 | 17.49 |

| Reinforced AFS | 4.82 | 3.59 | 10.68 | 39.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Cai, J.; Xiang, K.; Zhao, J.; Lei, W.; Fang, C. The Mechanical Behavior and Enhancement Mechanism of Short Carbon Fiber Reinforced AFS Interface. Materials 2022, 15, 9012. https://doi.org/10.3390/ma15249012

Yan C, Cai J, Xiang K, Zhao J, Lei W, Fang C. The Mechanical Behavior and Enhancement Mechanism of Short Carbon Fiber Reinforced AFS Interface. Materials. 2022; 15(24):9012. https://doi.org/10.3390/ma15249012

Chicago/Turabian StyleYan, Chang, Jiaxu Cai, Kun Xiang, Jinfeng Zhao, Wanqing Lei, and Changqing Fang. 2022. "The Mechanical Behavior and Enhancement Mechanism of Short Carbon Fiber Reinforced AFS Interface" Materials 15, no. 24: 9012. https://doi.org/10.3390/ma15249012

APA StyleYan, C., Cai, J., Xiang, K., Zhao, J., Lei, W., & Fang, C. (2022). The Mechanical Behavior and Enhancement Mechanism of Short Carbon Fiber Reinforced AFS Interface. Materials, 15(24), 9012. https://doi.org/10.3390/ma15249012