Mechanical Properties, Dry Shrinkage, and Water Penetration of Reusing Fine and Ultrafine Recycled Concrete Aggregate

Abstract

1. Introduction

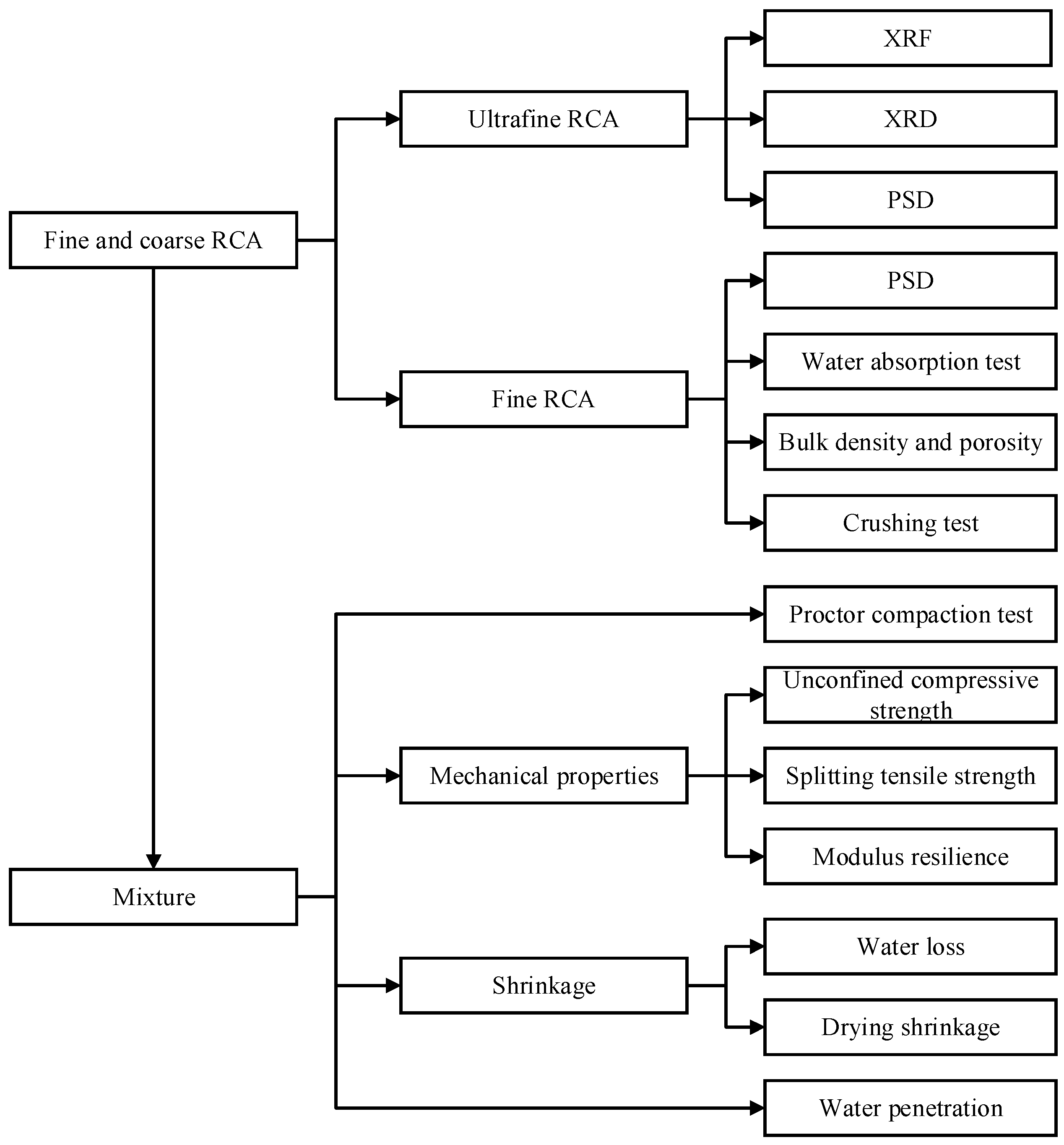

2. Experimental Program

2.1. Starting Materials

2.2. Sample Preparations

2.3. Test Methods

2.3.1. X-ray Diffractometry

2.3.2. X-ray Fluorescence

2.3.3. Particle Size Distribution

2.3.4. Aggregate Water Absorption Test

2.3.5. Bulk Density and Aggregate Porosity Test

2.3.6. Aggregate Crushing Test

2.3.7. Proctor Compaction Test

2.3.8. Unconfined Compressive Strength

2.3.9. Splitting Tensile Strength

2.3.10. Resilient Modulus

2.3.11. Water Loss and Drying Shrinkage

2.3.12. Water Penetration

3. Results and Discussion

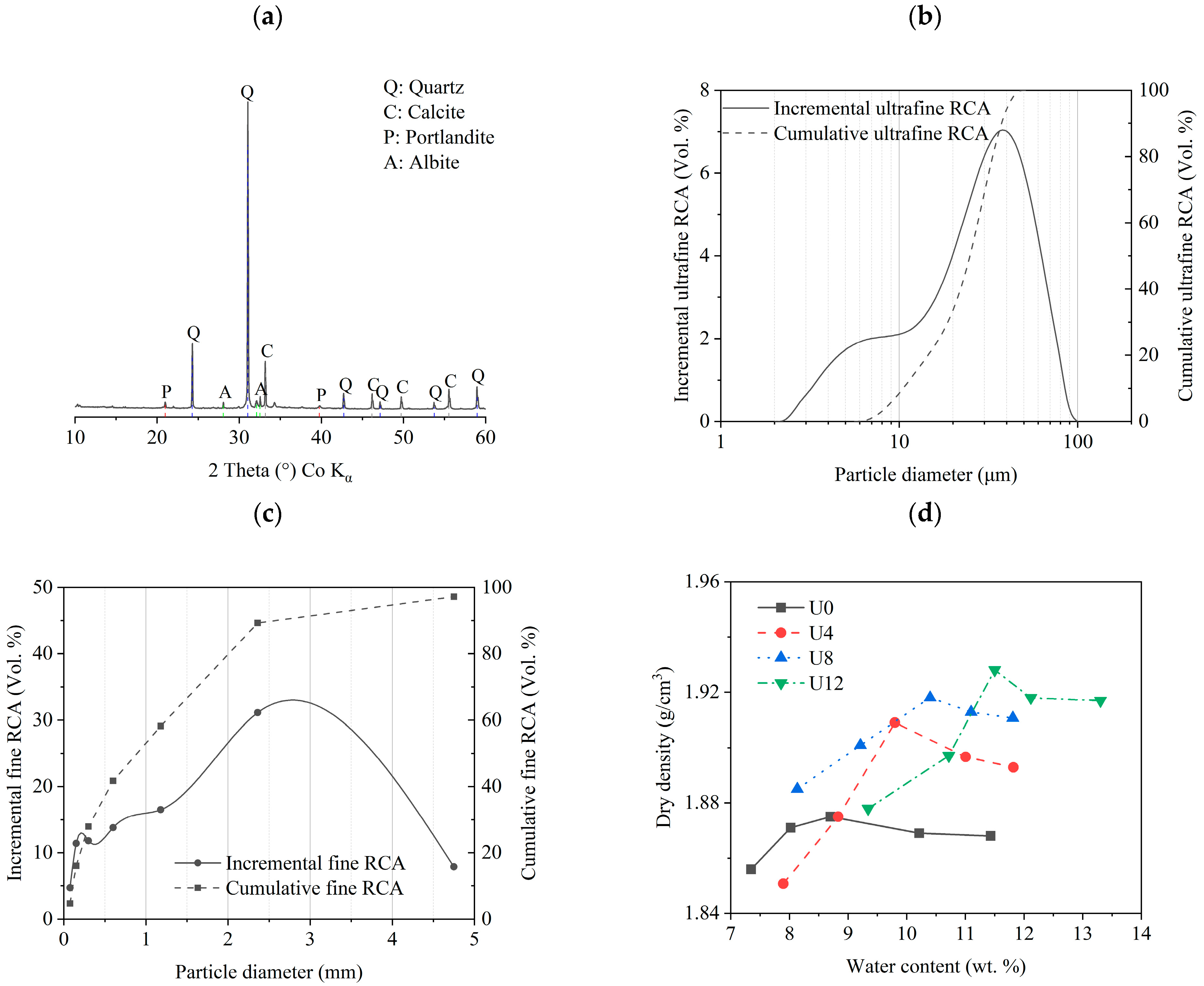

3.1. Characterization of RCA and Its Mixture

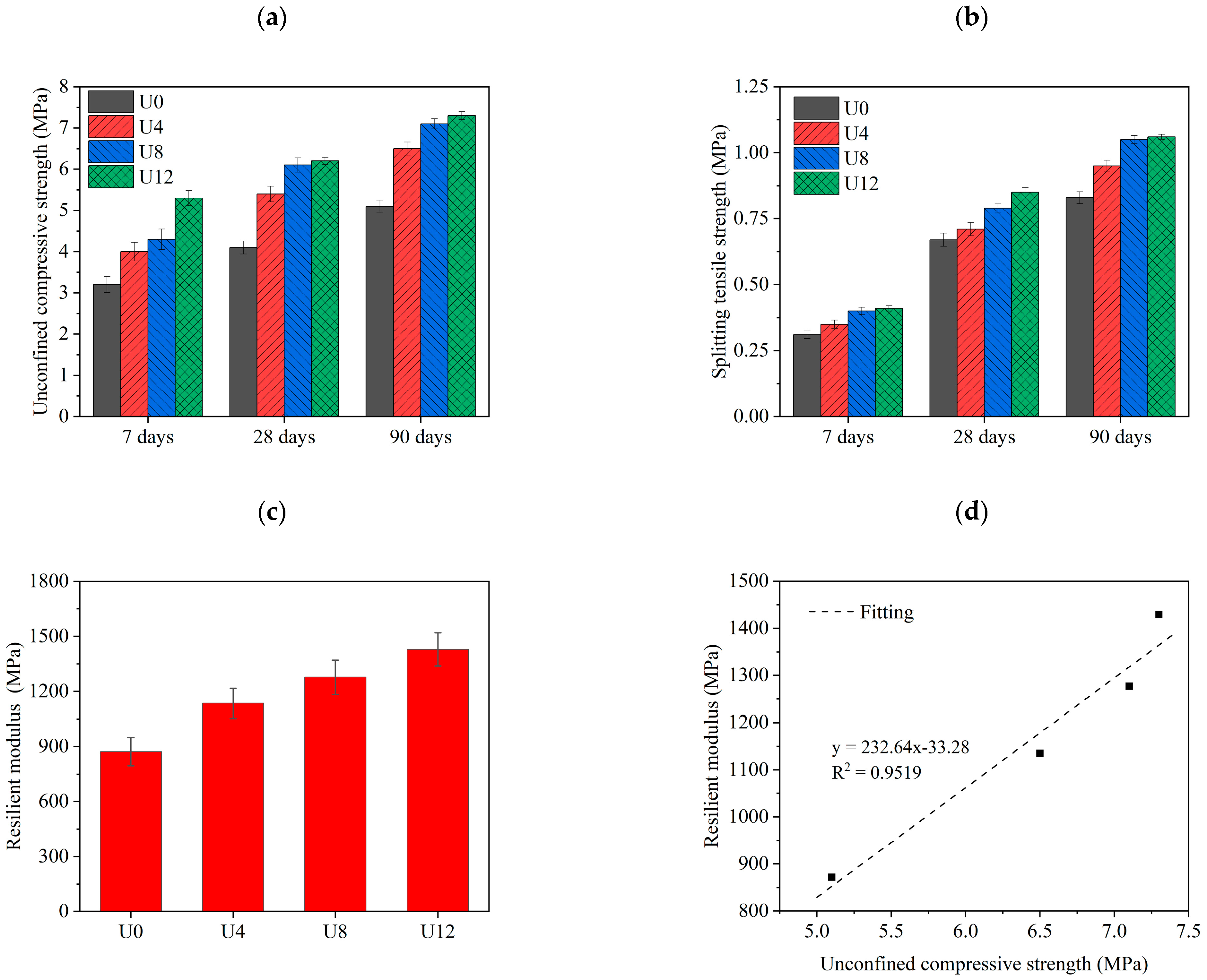

3.2. Mechanical Properties

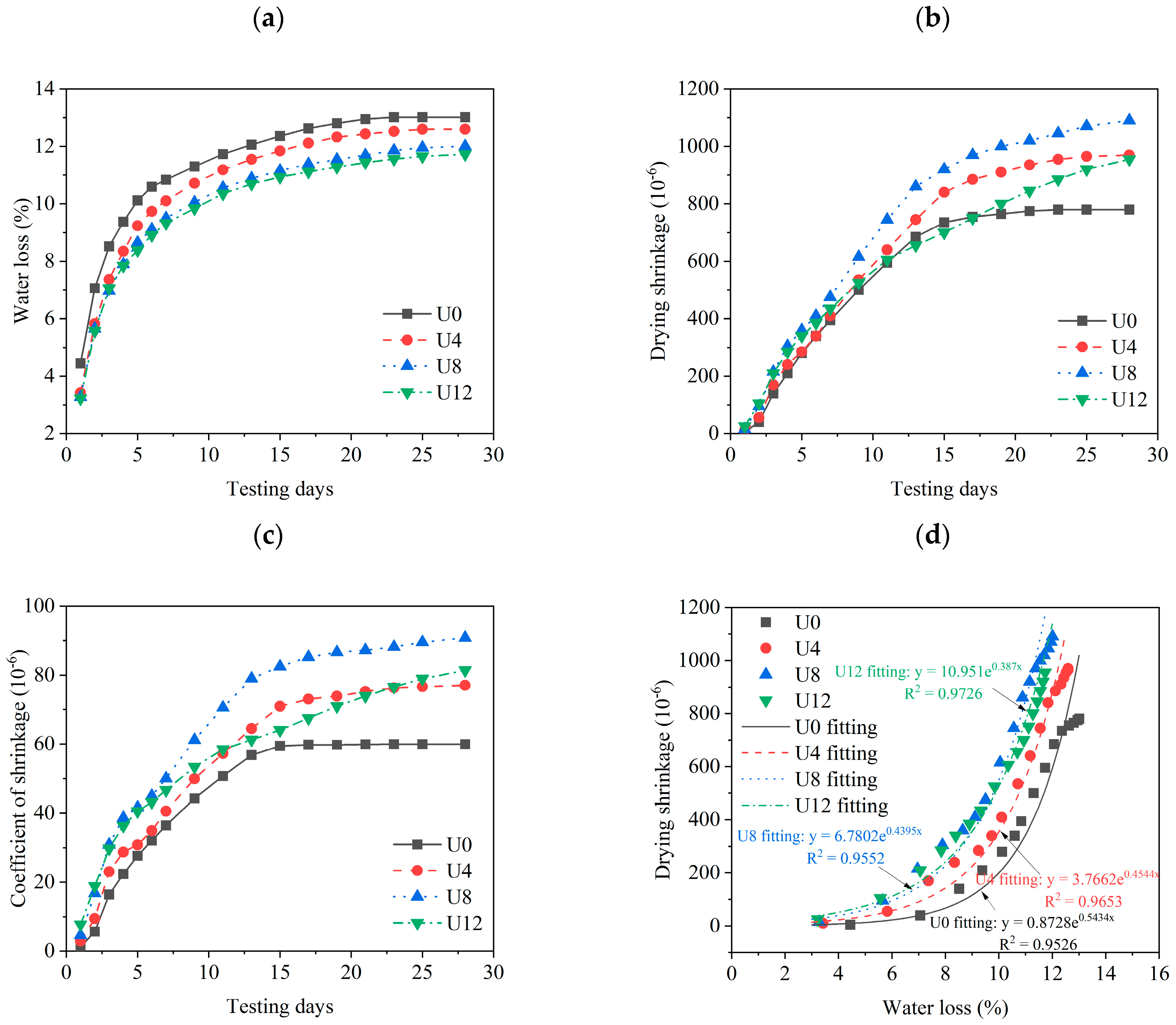

3.3. Shrinkage Properties

3.4. Resistance of Water Penetration

4. Conclusions

- The particle size distribution indicates the fine RCA belonging to coarse sand. Meanwhile, RCA shows low density, high porosity, and high water absorption.

- More ultrafine RCA leads to an increase in optimum moisture content and maximum dry density of the mixture, which is due to its higher water absorption than the fine RCA.

- Elevated ultrafine RCA contents result in higher compressive strength (up to 43.14%), splitting tensile strength (up to 27.71%), and resilient modulus (up to 63.88%) at 90 days. It is associated with the higher reactivity of ultrafine RCA than fine RCA.

- More ultrafine RCA increases the drying shrinkage during its high water absorption and more water loss during the curing period. Simultaneously, the drying shrinkage is highly correlated with water loss (R2 > 0.9 in all cases).

- Higher ultrafine RCA contents show higher resistance to water penetration because ultrafine RCA promotes gel formation, which improves the microstructure of the matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balaguera, A.; Carvajal, G.I.; Albertí, J.; Fullana-i-Palmer, P. Life cycle assessment of road construction alternative materials: A literature review. Resour. Conserv. Recycl. 2018, 132, 37–48. [Google Scholar] [CrossRef]

- Kumar, S.; Patil, C.B. Estimation of resource savings due to fly ash utilization in road construction. Resour. Conserv. Recycl. 2006, 48, 125–140. [Google Scholar] [CrossRef]

- Liu, T.; Fan, J.; Peng, Z. Central Load-Bearing Control in the Construction Process of the Concrete Spherical Joint Nandu River Swing Bridge: A Case Study. Buildings 2022, 12, 511. [Google Scholar] [CrossRef]

- Liu, T.; Yu, Q.; Fan, J.; Peng, Z.; Wang, E. Concrete spherical joint contact stress distribution and overturning moment of swing bridge. Structures 2020, 28, 1187–1195. [Google Scholar] [CrossRef]

- Kedir, F.; Hall, D.M. Resource efficiency in industrialized housing construction—A systematic review of current performance and future opportunities. J. Clean. Prod. 2021, 286, 5443. [Google Scholar] [CrossRef]

- Teizer, J.; Neve, H.; Li, H.; Wandahl, S.; König, J.; Ochner, B.; König, M.; Lerche, J. Construction resource efficiency improvement by Long Range Wide Area Network tracking and monitoring. Autom. Constr. 2020, 116, 3245. [Google Scholar] [CrossRef]

- Geng, J.; Sun, J. Characteristics of the carbonation resistance of recycled fine aggregate concrete. Constr. Build. Mater. 2013, 49, 814–820. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Characterization of eco-friendly steel fiber-reinforced concrete containing waste coconut shell as coarse aggregates and fly ash as partial cement replacement. Struct. Concr. 2020, 21, 437–447. [Google Scholar] [CrossRef]

- Divyah, N.; Prakash, R.; Srividhya, S.; Sivakumar, A. Parametric study on lightweight concrete-encased short columns under axial compression-Comparison of design codes. Struct. Eng. Mech. 2022, 83, 387–400. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Fan, Y.; Huang, X. An overview of study on recycled aggregate concrete in China (1996-2011). Constr. Build. Mater. 2012, 31, 364–383. [Google Scholar] [CrossRef]

- Liu, K.; Yan, J.; Alam, M.S.; Zou, C. Seismic fragility analysis of deteriorating recycled aggregate concrete bridge columns subjected to freeze-thaw cycles. Eng. Struct. 2019, 187, 1–15. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Thomas, C.; Kirgiz, M.S. The structural integrity of recycled aggregate concrete produced with fillers and pozzolans. Struct. Integr. Recycl. Aggreg. Concr. Prod. Fill. Pozzolans 2021, 1–477. [Google Scholar] [CrossRef]

- Ulsen, C.; Tseng, E.; Angulo, S.C.; Landmann, M.; Contessotto, R.; Balbo, J.T.; Kahn, H. Concrete aggregates properties crushed by jaw and impact secondary crushing. J. Mater. Res. Technol. 2019, 8, 494–502. [Google Scholar] [CrossRef]

- Torben, C.H.; Henrik, N. Strength of Recycled Concrete Made from Crushed Concrete Coarse Aggregate. Concr. Int. 1983, 5, 79–83. [Google Scholar]

- Gómez-Soberón, J.M.V. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Zheng, J.; Ling, T.C. Carbon dioxide sequestration on recycled aggregates. Carbon Dioxide Sequestration Cem. Constr. Mater. 2018, 247–277. [Google Scholar] [CrossRef]

- Hansen, T.C.; Boegh, E. Elasticity and Drying Shrinkage Concrete of Recycled-Aggregate. J. Proc. 1985, 82, 648–652. [Google Scholar]

- Kox, S.; Vanroelen, G.; Van Herck, J.; de Krem, H.; Vandoren, B. Experimental evaluation of the high-grade properties of recycled concrete aggregates and their application in concrete road pavement construction. Case Stud. Constr. Mater. 2019, 11, 282. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Samali, B. Experimental and correlational study on the utilisation of RCA as an alternative coarse aggregate in asphalt mixtures. Aust. J. Civ. Eng. 2017, 15, 80–92. [Google Scholar] [CrossRef]

- Gebremariam, A.T.; Vahidi, A.; Di Maio, F.; Moreno-Juez, J.; Vegas-Ramiro, I.; Łagosz, A.; Mróz, R.; Rem, P. Comprehensive study on the most sustainable concrete design made of recycled concrete, glass and mineral wool from C&D wastes. Constr. Build. Mater. 2021, 273, 1697. [Google Scholar] [CrossRef]

- Poon, C.S.; Qiao, X.C.; Chan, D. The cause and influence of self-cementing properties of fine recycled concrete aggregates on the properties of unbound sub-base. Waste Manag. 2006, 26, 1166–1172. [Google Scholar] [CrossRef] [PubMed]

- Radević, A.; Isailović, I.; Wistuba, M.P.; Zakić, D.; Orešković, M.; Mladenović, G. The impact of recycled concrete aggregate on the stiffness, fatigue, and low-temperature performance of asphalt mixtures for road construction. Sustainability 2020, 12, 3949. [Google Scholar] [CrossRef]

- Ulsen, C.; Kahn, H.; Hawlitschek, G.; Masini, E.A.; Angulo, S.C.; John, V.M. Production of recycled sand from construction and demolition waste. Constr. Build. Mater. 2013, 40, 1168–1173. [Google Scholar] [CrossRef]

- Grabiec, A.M.; Klama, J.; Zawal, D.; Krupa, D. Modification of recycled concrete aggregate by calcium carbonate biodeposition. Constr. Build. Mater. 2012, 34, 145–150. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Tsujino, M.; Noguchi, T.; Tamura, M.; Kanematsu, M.; Maruyama, I. Application of conventionally recycled coarse aggregate to concrete structure by surface modification treatment. J. Adv. Concr. Technol. 2007, 5, 13–25. [Google Scholar] [CrossRef]

- Zhu, L.; Ning, Q.; Han, W.; Bai, L. Compressive strength and microstructural analysis of recycled coarse aggregate concrete treated with silica fume. Constr. Build. Mater. 2022, 334, 7453. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.; Tang, Y.; Deng, Q.; Wang, D.; Poon, C. sun Fully utilizing carbonated recycled aggregates in concrete: Strength, drying shrinkage and carbon emissions analysis. J. Clean. Prod. 2022, 377, 4520. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez de Juan, M. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Ferreira, R.L.S.; Anjos, M.A.S.; Nóbrega, A.K.C.; Pereira, J.E.S.; Ledesma, E.F. The role of powder content of the recycled aggregates of CDW in the behaviour of rendering mortars. Constr. Build. Mater. 2019, 208, 601–612. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Huang, J.; Wang, Z.; Ma, S.; Liu, Y. Relationship between internal humidity and drying shrinkage of recycled aggregate thermal insulation concrete considering recycled aggregate content. Constr. Build. Mater. 2022, 355, 129224. [Google Scholar] [CrossRef]

- Tran, D.L.; Mouret, M.; Cassagnabère, F.; Phung, Q.T. Effects of Intrinsic Granular Porosity and Mineral Admixtures on Durability and Transport Properties of Recycled Aggregate Concretes. Mater. Today Commun. J. 2022, 33. [Google Scholar] [CrossRef]

- Gao, D.; Zhu, W.; Fang, D.; Tang, J.; Zhu, H. Shear behavior analysis and capacity prediction for the steel fiber reinforced concrete beam with recycled fine aggregate and recycled coarse aggregate. Structures 2022, 37, 44–55. [Google Scholar] [CrossRef]

- GB175-2007; Common Portland Cement. Standardization Administration of China: Beijing, China, 2007.

- Xu, D.; Zhang, Z.; Qin, Y.; Yang, Y. Effect of particle size on the failure behavior of cemented coral sand under impact loading. Soil Dyn. Earthq. Eng. 2021, 149, 6884. [Google Scholar] [CrossRef]

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. China Communications Press: Beijing, China, 2014.

- GB 5009.227-2016; Method for Analysis of Hygienic Standard of Edible Oils. Standardization Administration of China: Beijing, China, 2016.

- IS:2386; (Part l) Methods of Test for Aggregates for Concrete. Bureau of Indian Standards: Delhi, India, 2002.

- DIN EN 13286-2:2013-02; Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction. Deutsches Institut für Normung: Berlin, Germany, 2013.

- JTG E51-2009; Highway & Transportation Industry Standard Test Methods of Materials Stabilized with Inorganic Binders for Highway Engineering. Ministry of Transportation Highway Research Institute: Beijing, China, 2009.

- JTG-E30-2005; Test Methods of Cement and Concrete for Highway Engineering. Ministry of Communications Highway Science Research Institute: Nanjing, China, 2005.

- Liu, C.; Zhang, W.; Liu, H.; Zhu, C.; Wu, Y.; He, C.; Wang, Z. Recycled aggregate concrete with the incorporation of rice husk ash: Mechanical properties and microstructure. Constr. Build. Mater. 2022, 351, 8934. [Google Scholar] [CrossRef]

- Nam, B.H.; An, J.; Youn, H. Accelerated calcite precipitation (ACP) method for recycled concrete aggregate (RCA). Constr. Build. Mater. 2016, 125, 749–756. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Zhao, W.; Duan, Z.; Xu, Y. Combined use of recycled concrete aggregate and glass cullet in mortar: Strength, alkali expansion and chemical compositions. J. Build. Eng. 2022, 55, 4721. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 2196. [Google Scholar] [CrossRef]

- Zhang, H. Concrete. In Building Materials in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2011; pp. 81–423. [Google Scholar]

- Gencel, O.; Balci, B.; Bayraktar, O.Y.; Nodehi, M.; Sarı, A.; Kaplan, G.; Hekimoğlu, G.; Gholampour, A.; Benli, A.; Ozbakkaloglu, T. The effect of limestone and bottom ash sand with recycled fine aggregate in foam concrete. J. Build. Eng. 2022, 54, 4689. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Xiao, J.; Zhong, P. A method to determine water absorption of recycled fine aggregate in paste for design and quality control of fresh mortar. Constr. Build. Mater. 2019, 197, 30–41. [Google Scholar] [CrossRef]

- Htet, P.; Chen, W.; Hao, H.; Shaikh, F. Physical and mechanical properties of quaternary blended concrete with recycled coarse aggregates and crushed waste glass. Constr. Build. Mater. 2022, 353, 9016. [Google Scholar] [CrossRef]

- Ayan, V.; Limbachiya, M.C.; Omer, J.R.; Azadani, S.M.N. Compaction assessment of recycled aggregates for use in unbound subbase application. J. Civ. Eng. Manag. 2014, 20, 169–174. [Google Scholar] [CrossRef]

- Likes, L.; Markandeya, A.; Haider, M.M.; Bollinger, D.; McCloy, J.S.; Nassiri, S. Recycled concrete and brick powders as supplements to Portland cement for more sustainable concrete. J. Clean. Prod. 2022, 364, 2651. [Google Scholar] [CrossRef]

- Horsakulthai, V. Effect of recycled concrete powder on strength, electrical resistivity, and water absorption of self-compacting mortars. Case Stud. Constr. Mater. 2021, 15, 725. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Meyer, C.; Herfellner, S. Effects of internal curing on the strength, drying shrinkage and freeze-thaw resistance of concrete containing recycled concrete aggregates. Constr. Build. Mater. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Muthuraman, U.; Raja, M.A.; Sophia, M.; Ganesh Babu, O. Influence of silane treatment on the mechanical strength and durability of reactive powder concrete containing recycled fine aggregate. Mater. Today Proc. 2022, 62, 5444–5451. [Google Scholar] [CrossRef]

- Tao, Z.; Zhang, Y.; Chen, X.; Gu, X. Effects of freeze-thaw cycles on the mechanical properties of cement-fiber composite treated silty clay. Constr. Build. Mater. 2022, 316, 5867. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Evangelista, L.; de Brito, J.; Skaf, M.; Manso, J.M. Shrinkage prediction of recycled aggregate structural concrete with alternative binders through partial correction coefficients. Cem. Concr. Compos. 2022, 129, 4506. [Google Scholar] [CrossRef]

- Tang, Q.; Ma, Z.; Wu, H.; Wang, W. The utilization of eco-friendly recycled powder from concrete and brick waste in new concrete: A critical review. Cem. Concr. Compos. 2020, 114, 3807. [Google Scholar] [CrossRef]

| Sample ID | Cement | Ultrafine Aggregate | Fine Aggregate |

|---|---|---|---|

| U0 | 5 | 0 | 100 |

| U4 | 4 | 96 | |

| U8 | 8 | 92 | |

| U12 | 12 | 88 |

| Testing | Sample Size |

|---|---|

| Unconfined compressive strength | Φ50 mm × 50 mm |

| Splitting tensile strength | |

| Resilient modulus | Φ100 mm × 100 mm |

| Shrinkage testing | 50 mm × 50 mm × 200 mm |

| Water penetration | Φ150 mm × 150 mm |

| SiO2 | CaO | Al2O3 | Fe2O3 | Na2O | K2O | SO3 | MgO | Cl | |

|---|---|---|---|---|---|---|---|---|---|

| Ultrafine RCA | 49.75 | 22.31 | 10.66 | 4.12 | 2.10 | 1.97 | 1.88 | 1.62 | 0.07 |

| Coefficient of Water Absorption | Bulk Density | Loose Bulk Density | Compacted Bulk Density | Loose Porosity | Compacted Porosity | Crushing Value | |

|---|---|---|---|---|---|---|---|

| Unit | wt. % | kg/m3 | kg/m3 | kg/m3 | % | % | % |

| Fine RCA | 9.69 | 2430 | 1245 | 1380 | 48.7 | 43.2 | 22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Fan, J.; Peng, Z. Mechanical Properties, Dry Shrinkage, and Water Penetration of Reusing Fine and Ultrafine Recycled Concrete Aggregate. Materials 2022, 15, 8947. https://doi.org/10.3390/ma15248947

Liu T, Fan J, Peng Z. Mechanical Properties, Dry Shrinkage, and Water Penetration of Reusing Fine and Ultrafine Recycled Concrete Aggregate. Materials. 2022; 15(24):8947. https://doi.org/10.3390/ma15248947

Chicago/Turabian StyleLiu, Tao, Jianfeng Fan, and Ziqiang Peng. 2022. "Mechanical Properties, Dry Shrinkage, and Water Penetration of Reusing Fine and Ultrafine Recycled Concrete Aggregate" Materials 15, no. 24: 8947. https://doi.org/10.3390/ma15248947

APA StyleLiu, T., Fan, J., & Peng, Z. (2022). Mechanical Properties, Dry Shrinkage, and Water Penetration of Reusing Fine and Ultrafine Recycled Concrete Aggregate. Materials, 15(24), 8947. https://doi.org/10.3390/ma15248947