Gradient Structure Design and Welding-Hammering Hybrid Remanufacturing Process of Continuous Casting Rollers

Abstract

1. Introduction

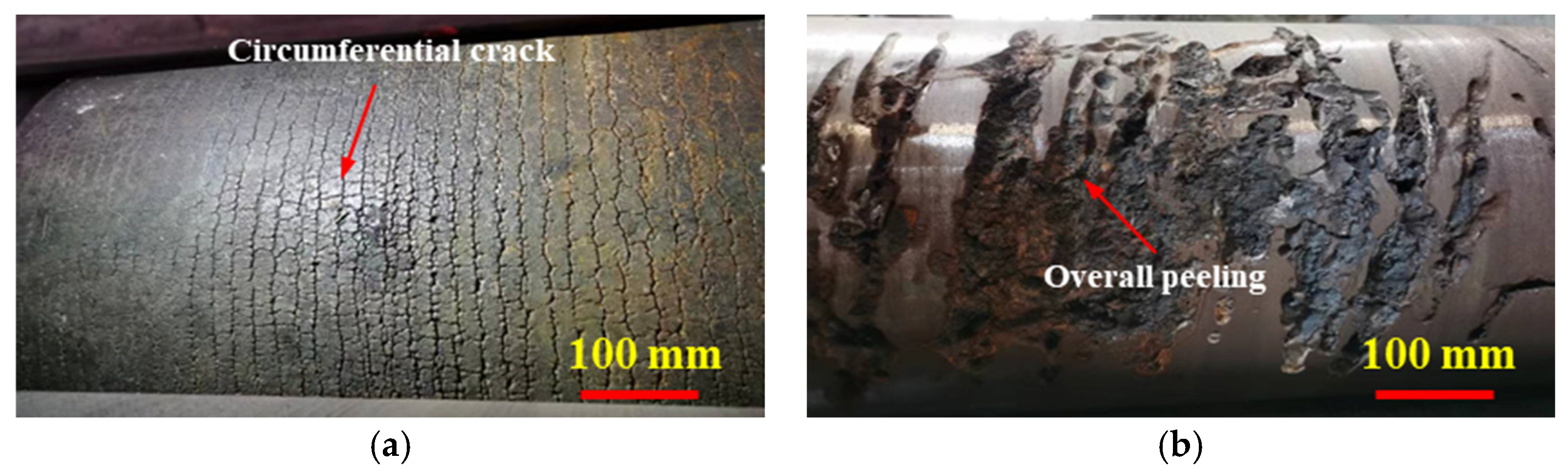

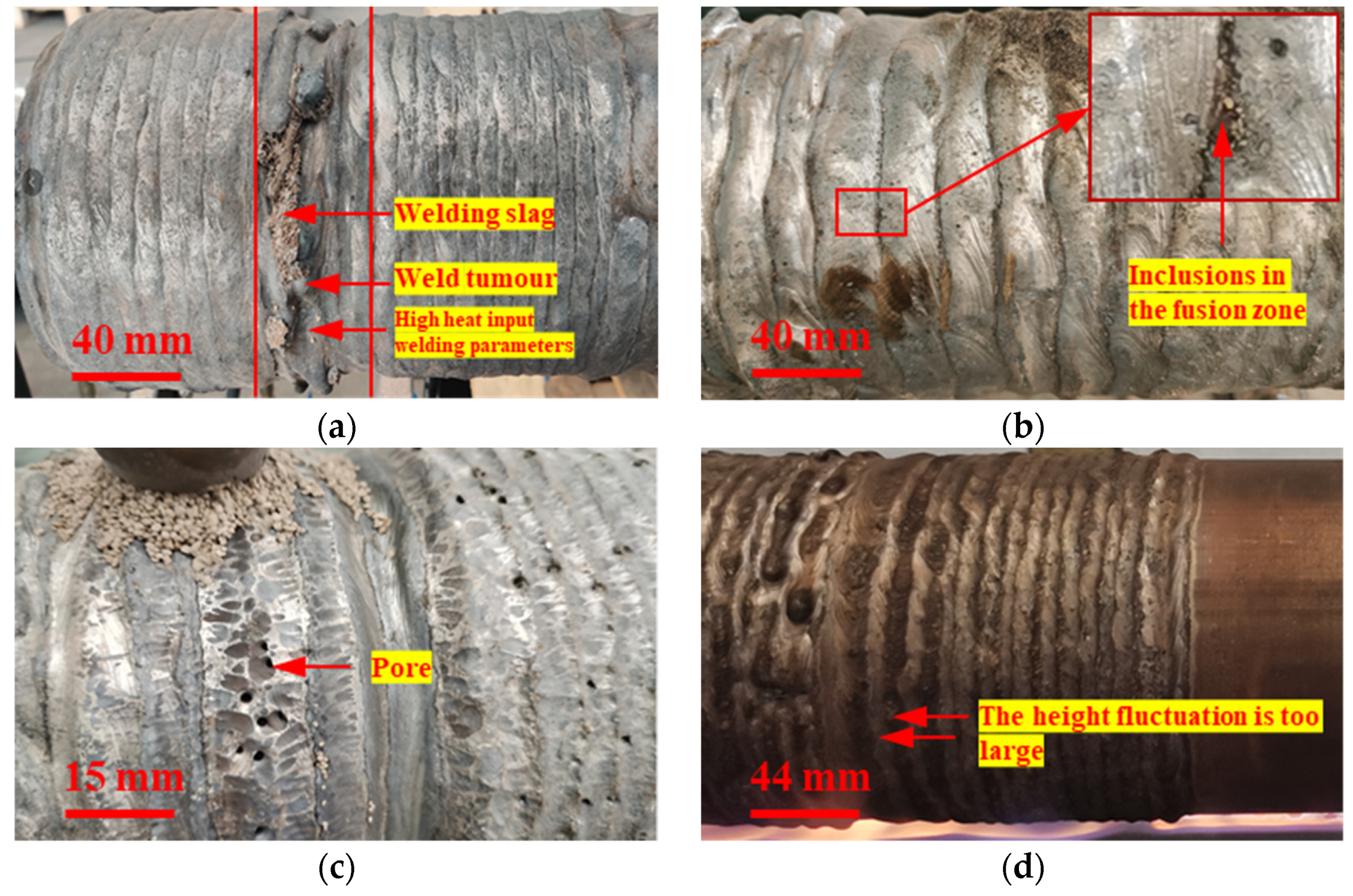

2. Failure Analysis of Continuous Casting Rollers

3. Remanufacturing Process Design

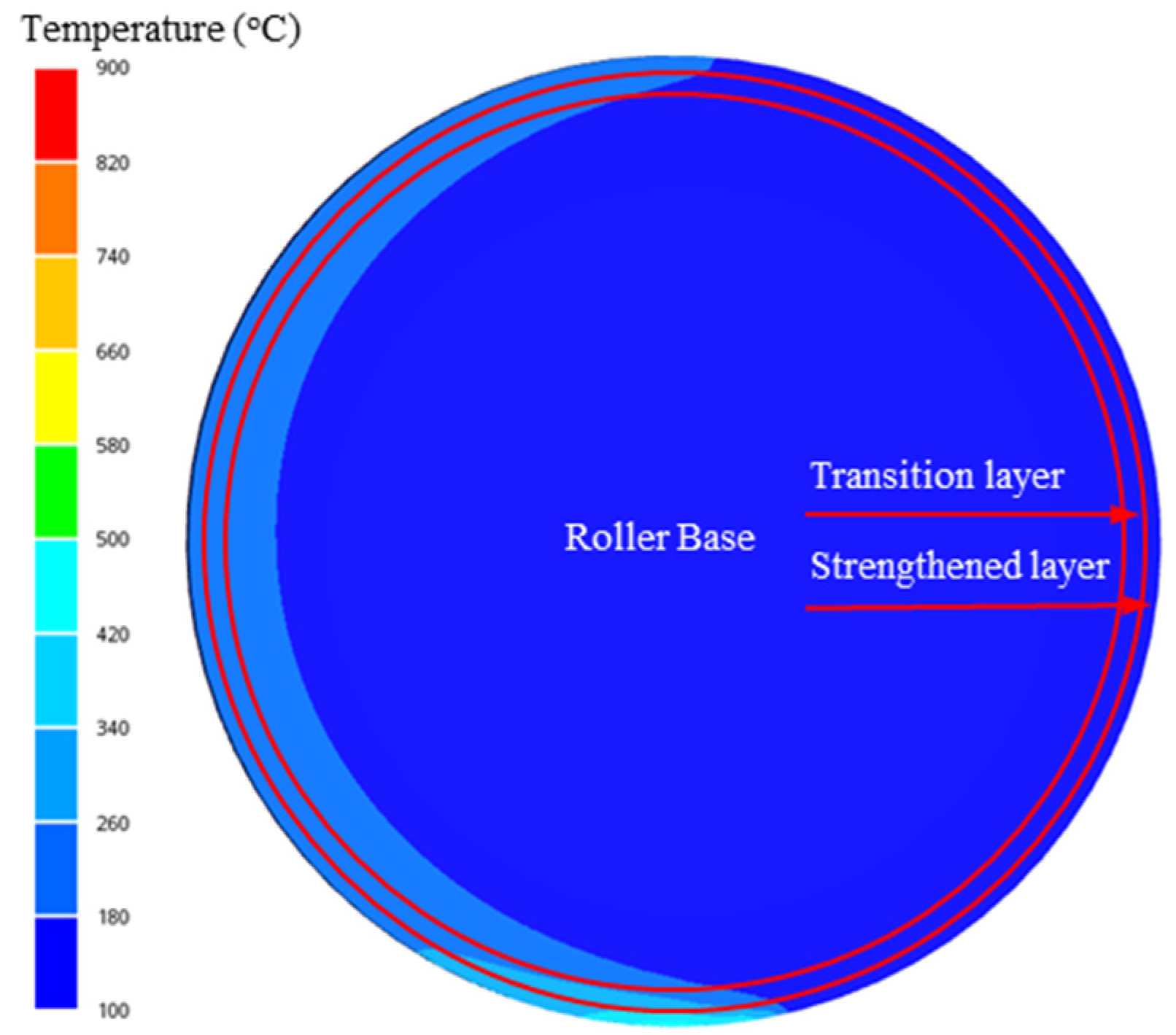

3.1. Gradient Structure Design

3.2. Materials Design

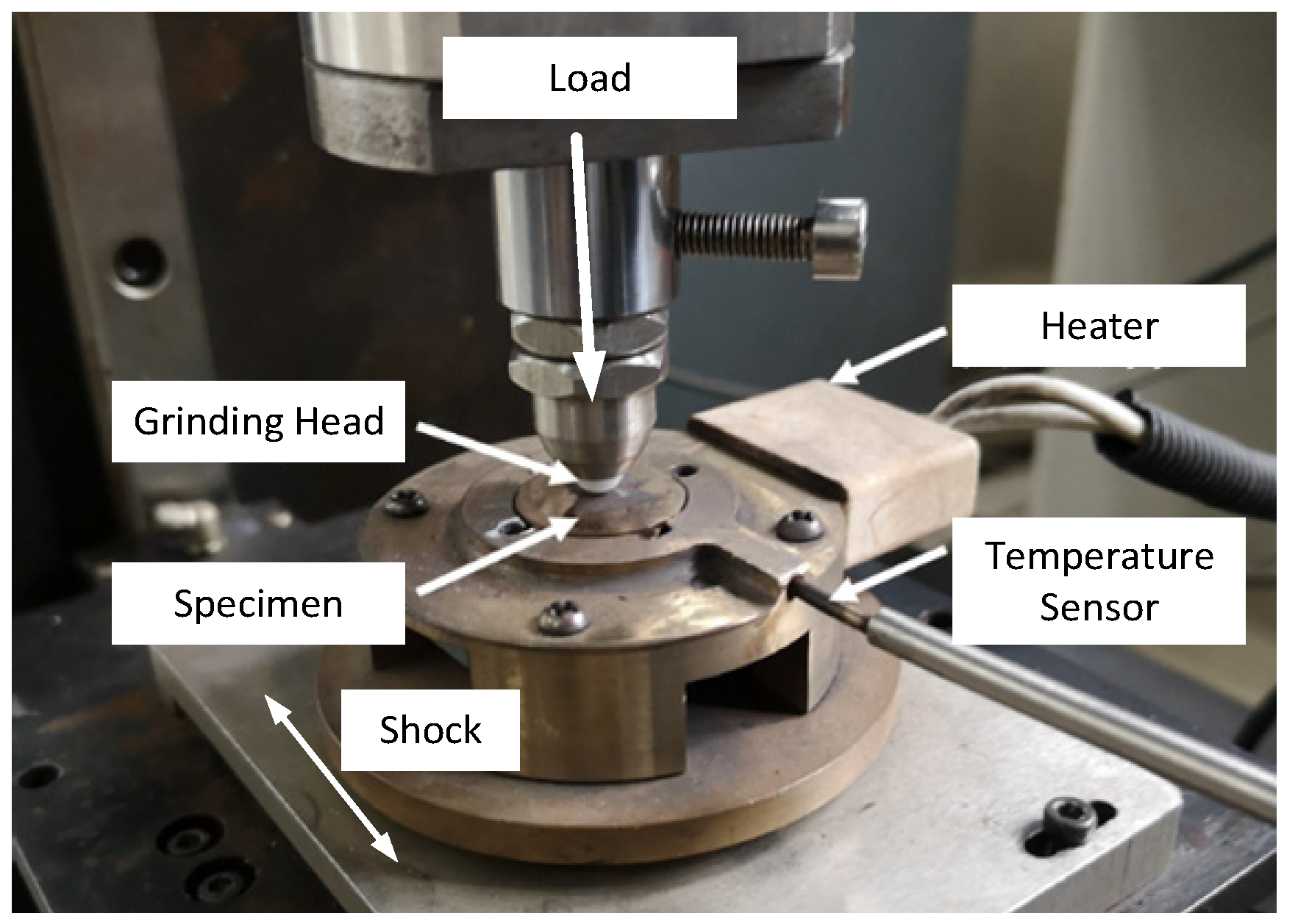

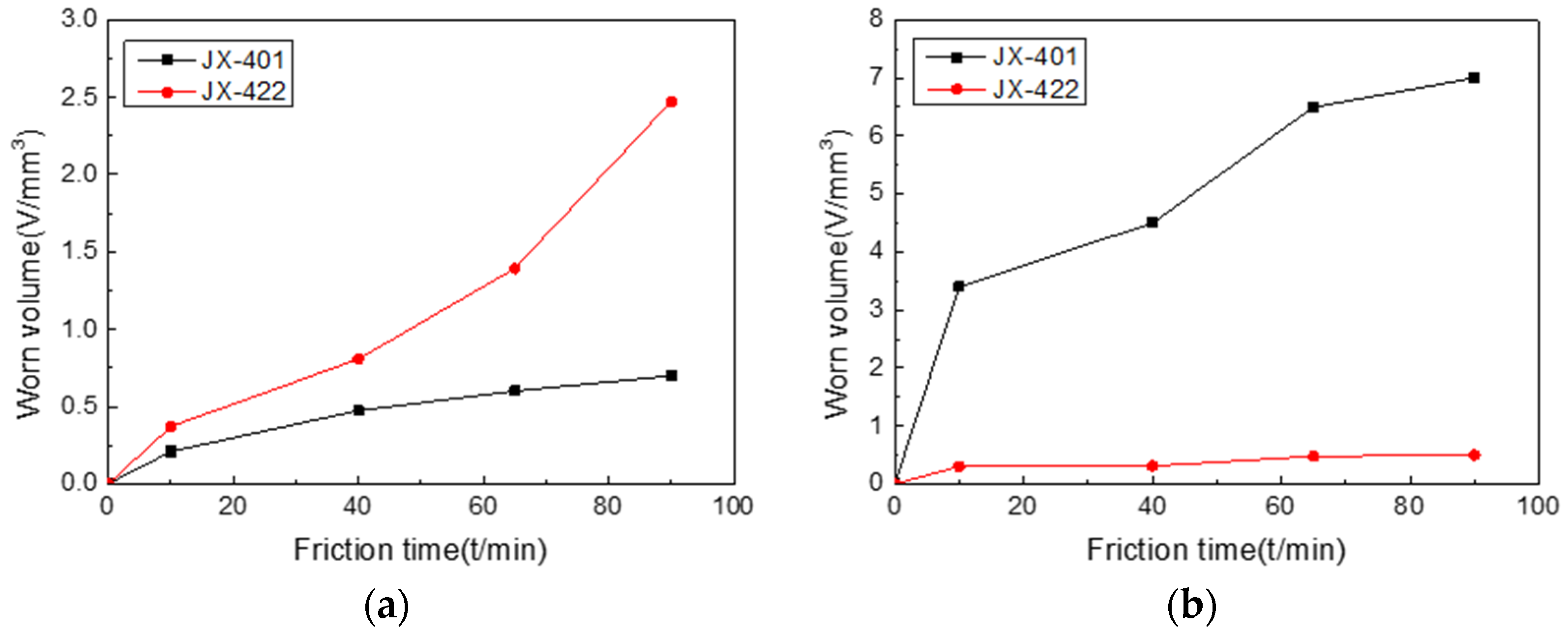

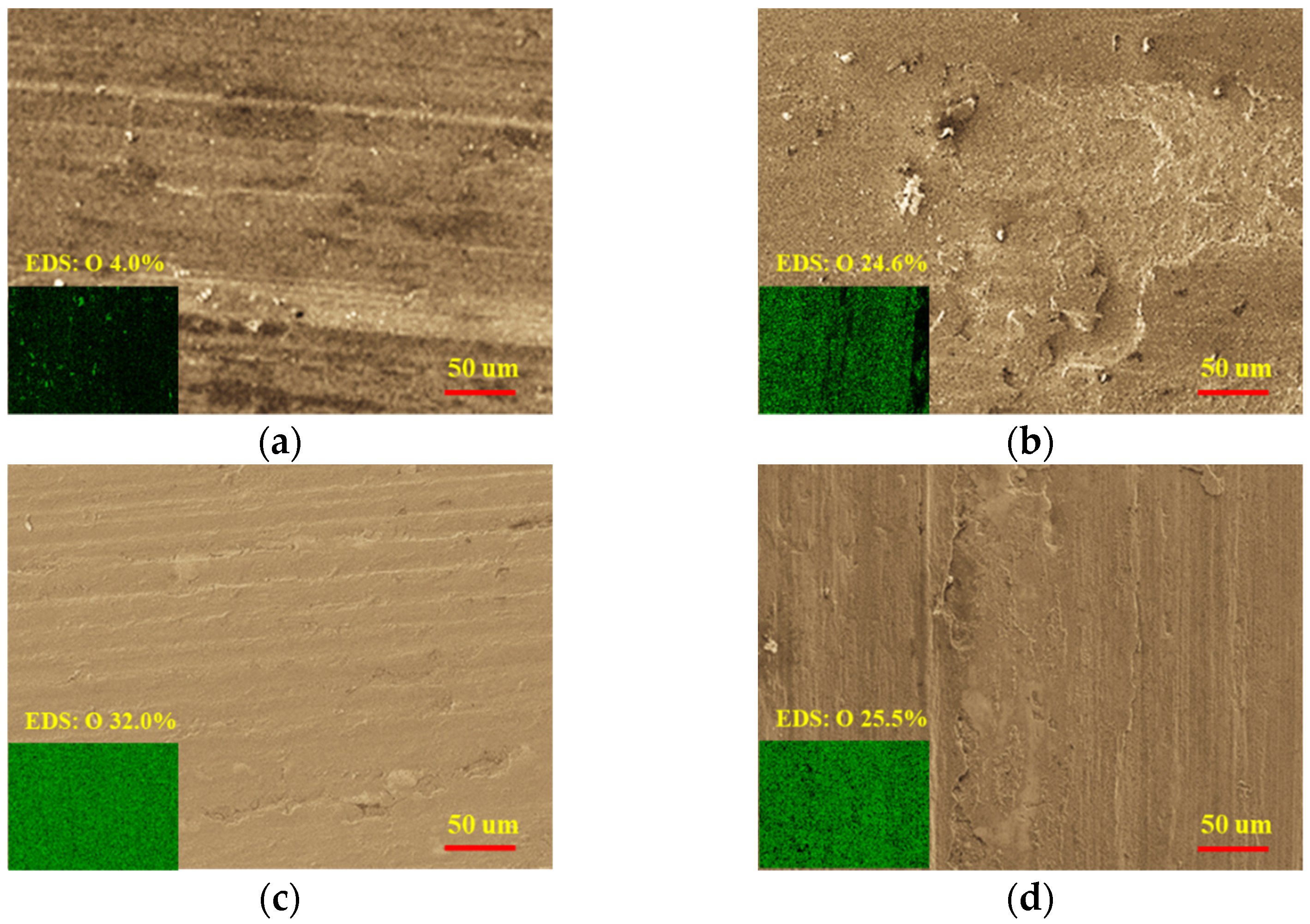

3.3. Wear Test

4. Welding-Hammering Hybrid Process and Application

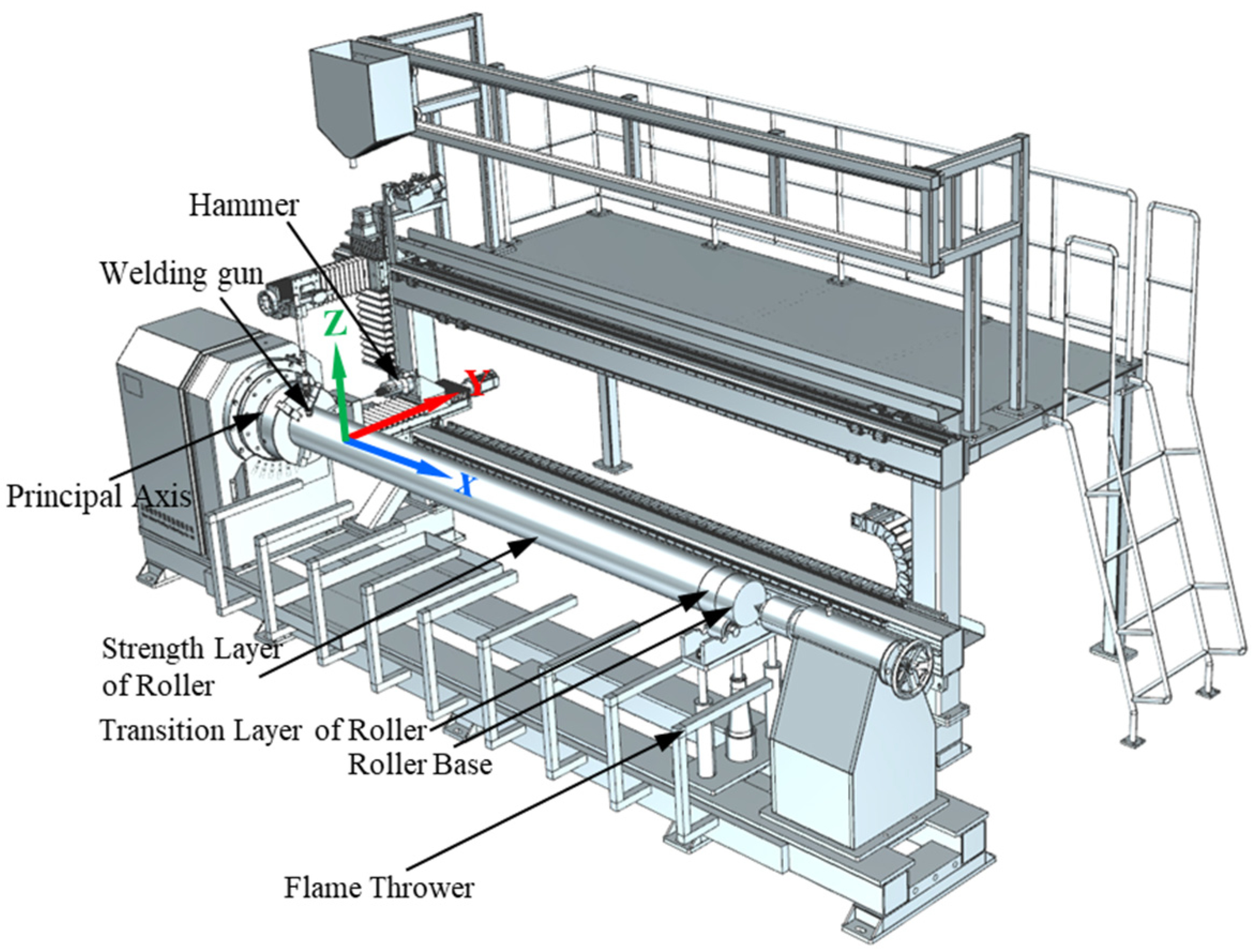

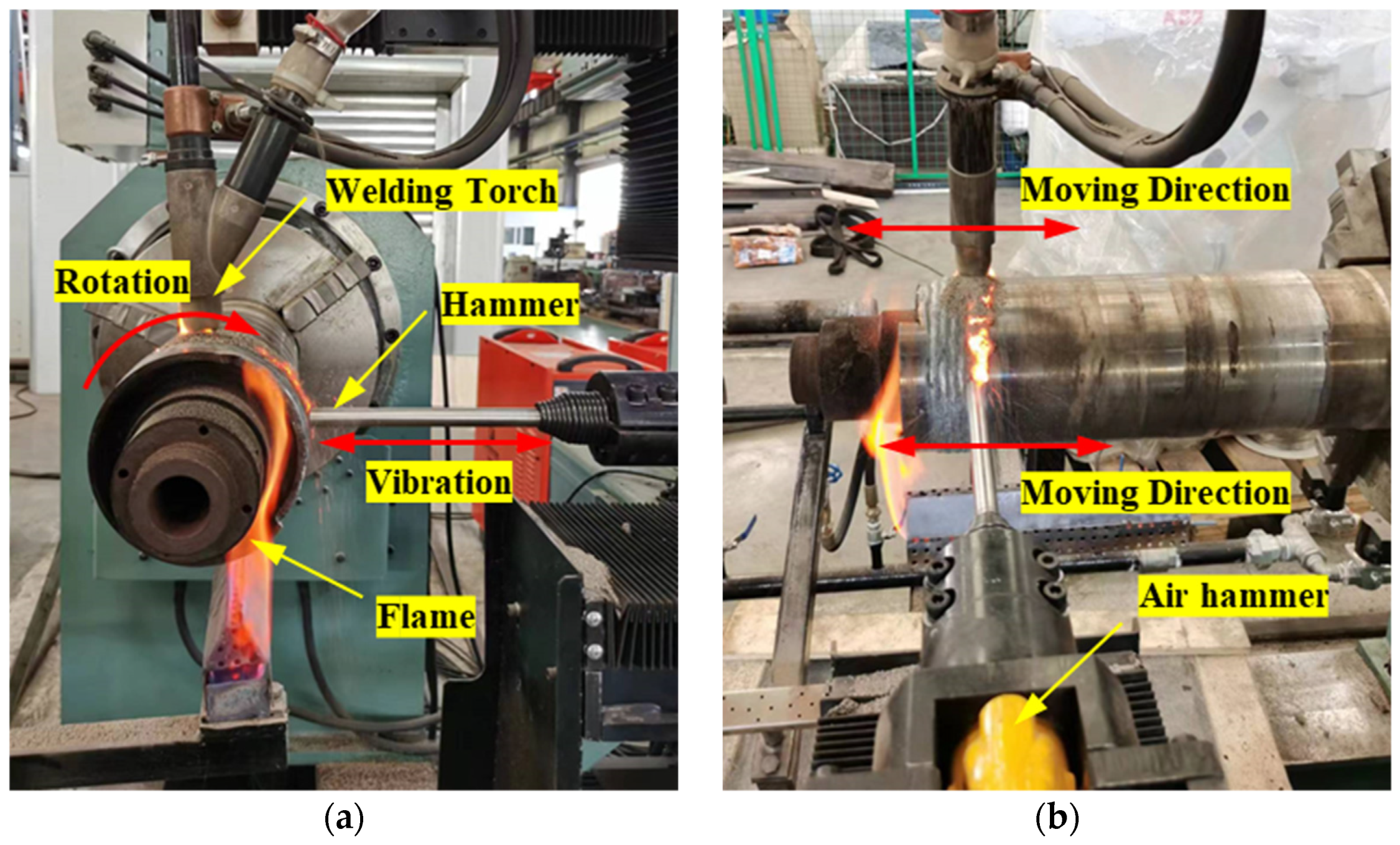

4.1. Repair Equipment with Welding-Hammering Hybrid Function

4.2. Welding Process Parameters Analysis

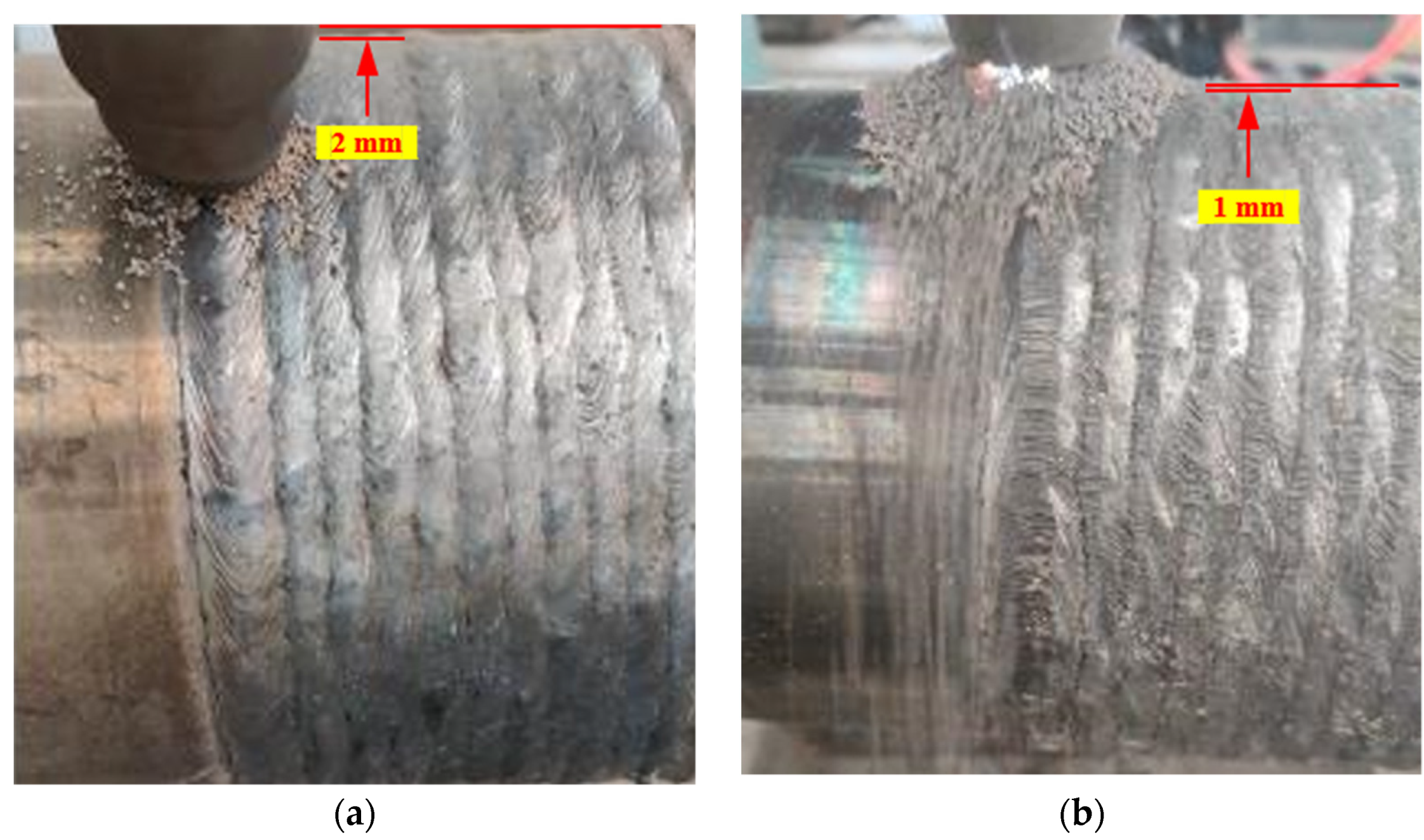

4.3. Welding-Hammering Hybrid Process

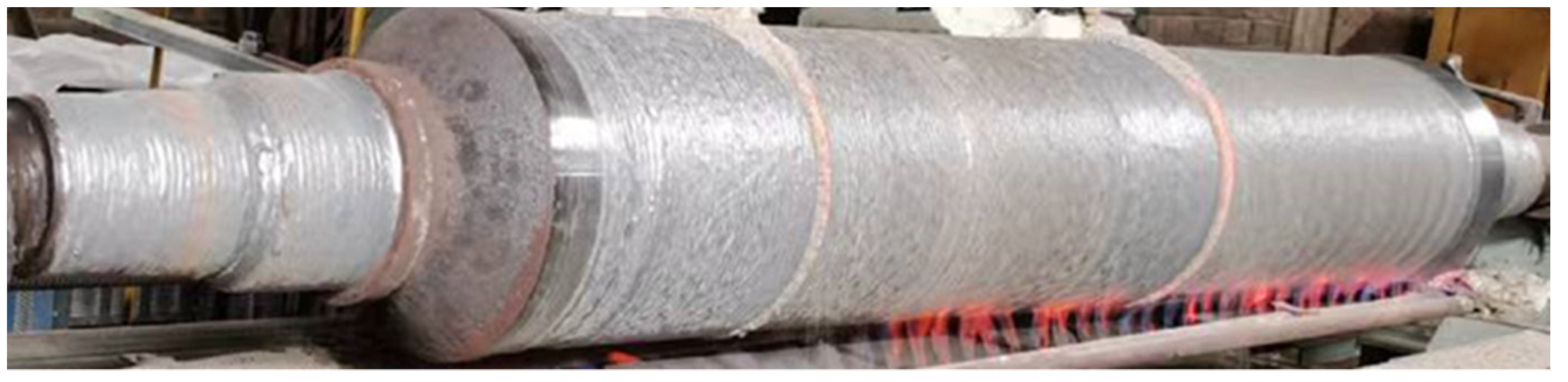

4.4. Application in Continuous Casting Roller Repair

5. Conclusions

- (1)

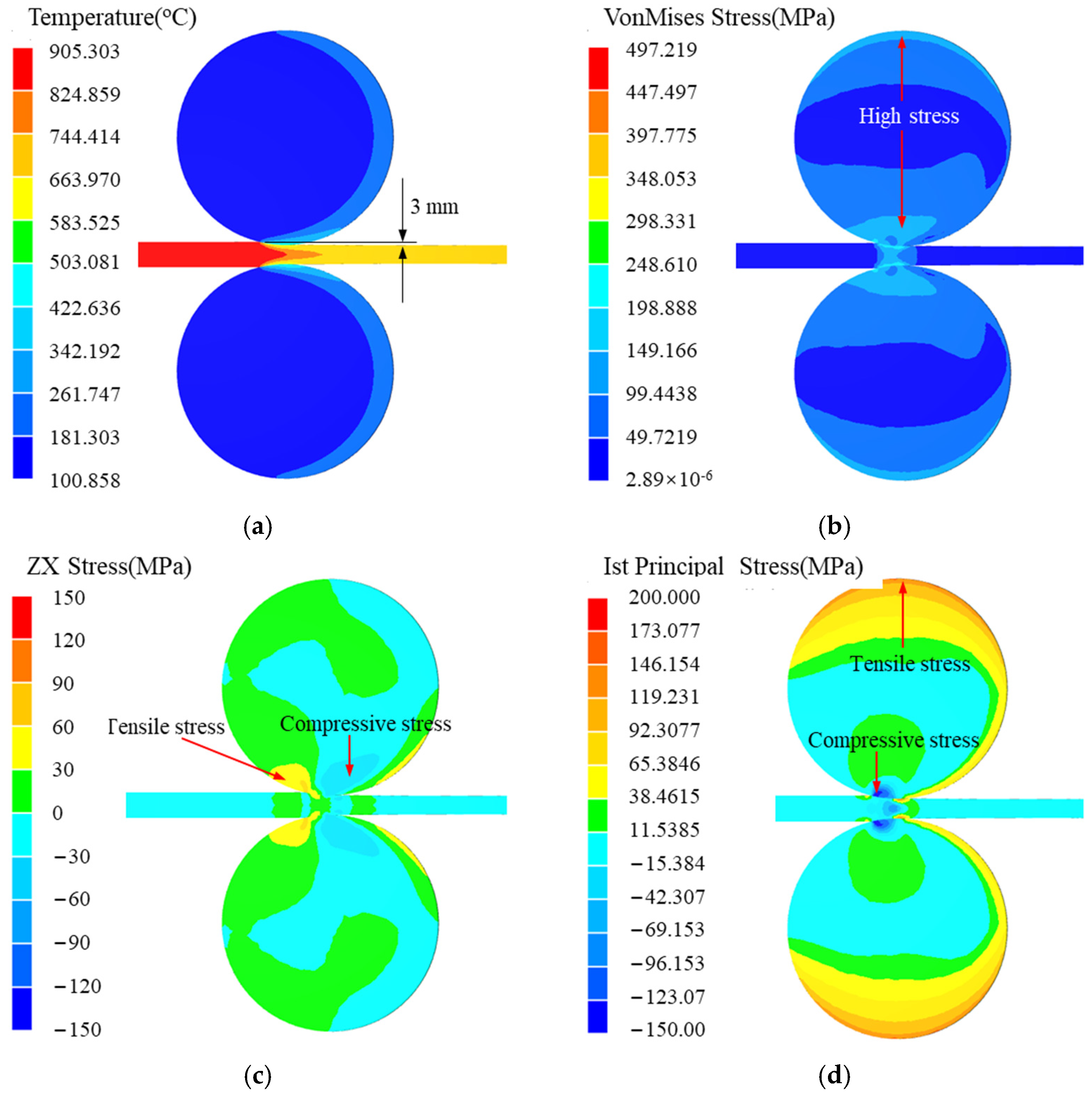

- The failure modes of continuous steel casting rollers were studied, and the general approximate state of stress was specified by numerical simulation. The results showed that cyclic tension–compression shear stress, cyclic tension–compression normal stress, thermal cycle, and a highly corrosive environment cause the fatigue cracking and overall peeling of the roller surface.

- (2)

- According to the simulation results of a roller under service conditions, a three-layer gradient structure composed of a base layer, transition layer, and strengthened layer was proposed. The strengthened layer of the roller needs high-temperature wear resistance, which is usually found in high-nickel and high-cobalt alloy materials. Then, weld materials JX-401, containing large amounts of Ni and Cr elements, and JX-422, containing large amounts of Cr element, were designed for the strengthened layer and transition layer, respectively. At high temperature, the wear mechanisms of JX-401 are mainly oxidation wear and abrasive wear, and the wear mechanisms of JX-422 are mainly oxidation wear and adhesive wear, accompanied by slight fatigue wear. The wear resistance of JX-422 is significantly higher than that of JX-401 at high temperature.

- (3)

- The new welding-hammering hybrid process was applied to repair a continuous casting roller. The microscopic analysis of the specimens showed that the welding-hammering hybrid process can defragment the crystal, eliminate the welding pores, and improve the toughness of the material. The repair process without hammering can only produce an as-cast structure, but the welding-hammering hybrid process can produce a forged structure. The new welding-hammering hybrid process can significantly improve the service life of a repaired roller by about 100% compared with traditional methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, J.; Huang, P.; He, F. Research of Surfacing Technology on Continuous Casting Roller. Adv. Mat. Res. 2011, 189–193, 3370–3376. [Google Scholar] [CrossRef]

- Leino, M.; Pekkarinen, J.; Soukka, R. The Role of Laser Additive Manufacturing Methods of Metals in Repair, Refurbishment and Remanufacturing–Enabling Circular Economy. Phys. Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Liyanage, T.; Fisher, G.; Gerlich, A.P. Microstructures and abrasive wear performance of PTAW deposited Ni–WC overlays using different Ni-alloy chemistries. Wear 2012, 274–275, 345–354. [Google Scholar] [CrossRef]

- Guoqing, C.; Xuesong, F.; Yanhui, W.; Shan, L.; Wenlong, Z. Microstructure and wear properties of nickel-based surfacing deposited by plasma transferred arc welding. Surf. Coat. Technol. 2013, 228 (Suppl. S1), 276–282. [Google Scholar] [CrossRef]

- Badisch, E.; Kirchgaßner, M. Influence of welding parameters on microstructure and wear behaviour of a typical NiCrBSi hardfacing alloy reinforced with tungsten carbide. Surf. Coat. Technol. 2008, 202, 6016–6022. [Google Scholar] [CrossRef]

- Baldridge, T.; Poling, G.; Foroozmehr, E.; Kovacevic, R.; Metz, T.; Kadekar, V.; Gupta, M.C. Laser cladding of Inconel 690 on Inconel 600 superalloy for corrosion protection in nuclear applications. Opt. Lasers Eng. 2013, 51, 180–184. [Google Scholar] [CrossRef]

- Buchanan, V.E.; McCartney, D.G.; Shipway, P.H. A comparison of the abrasive wear behaviour of iron-chromium based hardfaced coatings deposited by SMAW and electric arc spraying. Wear 2008, 264, 542–549. [Google Scholar] [CrossRef]

- Chen, H.; Zi, X.; Han, Y.; Dong, G.; Liu, S.; Chen, C. Microstructure and mechanical properties of additive manufactured W-Ni-Fe-Co composite produced by selective laser melting. Int. J. Refract. Met. Hard Mater. 2020, 86, 105111. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Golański, D.; Chmielewski, T.; Chmielewski, M. Microstructure of Rhenium Doped Ni-Cr Deposits Produced by Laser Cladding. Materials 2021, 14, 2745. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Bober, M.; Chmielewski, T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Appl. Sci. 2022, 12, 4568. [Google Scholar] [CrossRef]

- Tian, L.; Xing, S.; Liu, G.; Luo, Y. Numerical Simulation of Hardfacing Remanufacturing for Large-Scale Damaged Grinding Roller. Int. J. Adv. Manuf. Technol. 2021, 118, 2613–2649. [Google Scholar] [CrossRef]

- Deng, H.-X.; Shi, H.-J.; Tsuruoka, S.-J.; Yu, H.-C.; Zhong, B. Influence of welding technique and temperature on fatigue properties of steel deposited with Co-based alloy hardfacing coating. Surf. Coat. Technol. 2012, 35, 63–70. [Google Scholar] [CrossRef]

- Amushahi, M.H.; Ashrafizadeh, F.; Shamanian, M. Characterization of boride-rich hardfacing on carbon steel by arc spray and GMAW processes. Surf. Coat. Technol. 2010, 204, 2723–2728. [Google Scholar] [CrossRef]

- Chatterjee, S.; Pal, T.K. Weld procedural effect on the performance of iron based hardfacing deposits on cast iron substrate. J. Mater. Process. Technol. 2006, 173, 61–69. [Google Scholar] [CrossRef]

- Kesavan, D.; Kamaraj, M. Influence of aging treatment on microstructure, wear and corrosion behavior of a nickel base hardfaced coating. Wear 2011, 272, 7–17. [Google Scholar] [CrossRef]

- Wang, Y.; Gou, J.; Chu, R.; Zhen, D.; Liu, S. The effect of nano-additives containing rare earth oxides on sliding wear behavior of high chromium cast iron hardfacing alloys. Tribol. Int. 2016, 103, 102–112. [Google Scholar] [CrossRef]

- Wang, J.; Liu, T.; Zhou, Y.; Xing, X.; Liu, S.; Yang, Y.; Yang, Q. Effect of nitrogen alloying on the microstructure and abrasive impact wear resistance of Fe-Cr-C-Ti-Nb hardfacing alloy. Surf. Coat. Technol. 2017, 309, 1072–1080. [Google Scholar] [CrossRef]

- Gou, J.; Wang, Y.; Wang, C.; Chu, R.; Liu, S. Effect of rare earth oxide nano-additives on micro-mechanical properties and erosion behavior of Fe-Cr-C-B hardfacing alloys. J. Alloy. Compd. 2017, 691, 800–810. [Google Scholar] [CrossRef]

- Zhou, Y.F.; Yang, Y.L.; Jiang, Y.W.; Yang, J.; Ren, X.J.; Yang, Q.X. Fe–24 wt.%Cr–4.1 wt.%C hardfacing alloy: Microstructure and carbide refinement mechanisms with ceria additive. Mater. Charact. 2012, 72, 77–86. [Google Scholar] [CrossRef]

- Lesiuk, G.; Smolnicki, M.; Rozumek, D.; Krechkovska, H.; Student, O.; Correia, J.; Mech, R.; De Jesus, A. Study of the fatigue crack growth in long-term operated mild steel under mixed-mode (I+II, I+III) loading conditions. Materials 2020, 13, 160. [Google Scholar] [CrossRef]

- Woo, W.; Em, V.; Hubbard, C.R.; Lee, H.-J.; Park, K.S. Residual stress determination in a dissimilar weld overlay pipe by neutron diffraction. Mater. Sci. Eng. A 2011, 528, 8021–8027. [Google Scholar] [CrossRef]

- Wang, X.-L.; Payzant, E.A.; Taljat, B.; Hubbard, C.R.; Keiser, J.R.; Jirinec, M.J. Experimental determination of the residual stresses in a spiral weld overlay tube. Mater. Sci. Eng. A 1997, 232, 31–38. [Google Scholar] [CrossRef]

- Viňáš, J.; Brezinová, J.; Guzanová, A.; Svetlík, J. Degradation of renovation layers deposited on continuous steel casting rollers by submerged arc welding. Proc. Inst. Mech. Eng. Part B 2013, 227, 1841–1848. [Google Scholar] [CrossRef]

- Zhang, K.; Zhou, J.; Zhang, M.; Peng, S.; Su, Z.; Zhang, J. A comparison study on wear characteristics of Ni-based, Co-based and Fe-based alloys for heated hot stamping tools manufactured by surfacing technology. Int. J. Adv. Manuf. Technol. 2020, 106, 3659–3668. [Google Scholar] [CrossRef]

- Edwards, L.; Bouchard, P.J.; Dutta, M.; Wang, D.Q.; Santisteban, J.R.; Hiller, S.; Fizpatrick, M.E. Direct measurement of the residual stresses near a ‘boat-shaped’ repair in a 20 mm thick stainless steel tube butt weld. Int. J. Press. Vessel. Pip. 2005, 82, 288–298. [Google Scholar] [CrossRef]

| Roller Diameter(mm) | Initial Temperature (°C) | Number of Mesh | Friction Model | Heat Transfer Coefficient (W/m2K) | |||

|---|---|---|---|---|---|---|---|

| Blank | Roller | Blank | Roller | Coulomb | Shear | ||

| 170 | 1000 | 100 | 200,000 | 10,000 | 0.15 | 0.3 | 20,000 |

| Material | C | Si | Mn | Cr | Mo | W | V | Ni | Co | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| JX-401 (Transition Layer) | 0.06 | 0.7 | 1.20 | 17.0 | 2.42 | 1.79 | 0.35 | - | - | Bal. |

| JX-422 (Strengthened Layer) | 0.03 | 2.0 | 2.00 | 21.0 | 3.50 | - | 0.35 | 11.00 | 0.35 | Bal. |

| Cr5 (Roller Base) | 0.52 | 0.46 | 0.55 | 5.10 | 0.60 | - | 0.11 | 0.43 | - | Bal. |

| Parameter | Value |

|---|---|

| Load (F/N) | 200 |

| Temperature (T/°C) | 200, 500 |

| Moving Frequency (f/Hz) | 4 |

| Moving Stroke (L/mm) | 8 |

| Wear Time (t/min) | 10, 40, 65, 90 |

| SiO2 + TiO2 | MnO + A12O3 | CaO + MgO | CaF2 | S | P | H2O | Impurity |

|---|---|---|---|---|---|---|---|

| 19.7 | 24.2 | 31.7 | 20.5 | 0.013 | 0.017 | 0.02 | 0.02 |

| Service Conditions of Roller | New Roller Service Results | Repaired Roller Service Results (with Hammering) | |||||

|---|---|---|---|---|---|---|---|

| Roller Surface Temperature (°C) | Roller Diameter (mm) | Rotation Speed (r/min) | Rolling Reduction (mm) | Rolling Capacity (T) | Service Time (Month) | Rolling Capacity (T) | Service Time (Month) |

| 500~600 | 170 | 700 | 10 | 150,000 | 6 | 300,000 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Xiao, G.; Peng, J.; Yu, Y.; Zhou, J. Gradient Structure Design and Welding-Hammering Hybrid Remanufacturing Process of Continuous Casting Rollers. Materials 2022, 15, 8588. https://doi.org/10.3390/ma15238588

Zhang J, Xiao G, Peng J, Yu Y, Zhou J. Gradient Structure Design and Welding-Hammering Hybrid Remanufacturing Process of Continuous Casting Rollers. Materials. 2022; 15(23):8588. https://doi.org/10.3390/ma15238588

Chicago/Turabian StyleZhang, Jiansheng, Guiqian Xiao, Jie Peng, Yingyan Yu, and Jie Zhou. 2022. "Gradient Structure Design and Welding-Hammering Hybrid Remanufacturing Process of Continuous Casting Rollers" Materials 15, no. 23: 8588. https://doi.org/10.3390/ma15238588

APA StyleZhang, J., Xiao, G., Peng, J., Yu, Y., & Zhou, J. (2022). Gradient Structure Design and Welding-Hammering Hybrid Remanufacturing Process of Continuous Casting Rollers. Materials, 15(23), 8588. https://doi.org/10.3390/ma15238588