Behavior of Silica Nanoparticles Synthesized from Rice Husk Ash by the Sol–Gel Method as a Photocatalytic and Antibacterial Agent

Abstract

1. Introduction

| Chemical Constituents | Percentage Composition (%) | |||

|---|---|---|---|---|

| Raheem et al. [34] | Jongpradist et al. [35] | Rambo et al. [36] | Rama Subbarao et al. [37] | |

| SiO2 | 86.51 | 93.00 | 91.40 | 91.10 |

| Al2O3 | 0.61 | 0.17 | 0.48 | 0.40 |

| Fe2O3 | 0.60 | 0.35 | 0.02 | 0.40 |

| CaO | 0.71 | 0.91 | 0.50 | 0.40 |

| MgO | 1.53 | 0.42 | 0.35 | 0.50 |

| SO3 | 0.02 | 0.11 | --- | 0.10 |

| Na2O | 0.05 | 0.63 | 0.00 | 0.10 |

| K2O | 1.89 | 2.82 | 1.50 | 2.20 |

| P2O5 | 4.20 | --- | 0.18 | --- |

| TiO2 | --- | --- | 0.00 | --- |

| MnO | --- | --- | 0.37 | --- |

| Loss of ignition (L.O.I) | 3.88 | 4.70 | 5.63 | 4.80 |

| SiO2 + Al2O3 + Fe2O3 | 87.72 | 93.50 | 91.90 | 91.90 |

2. Experimental Work

2.1. Materials

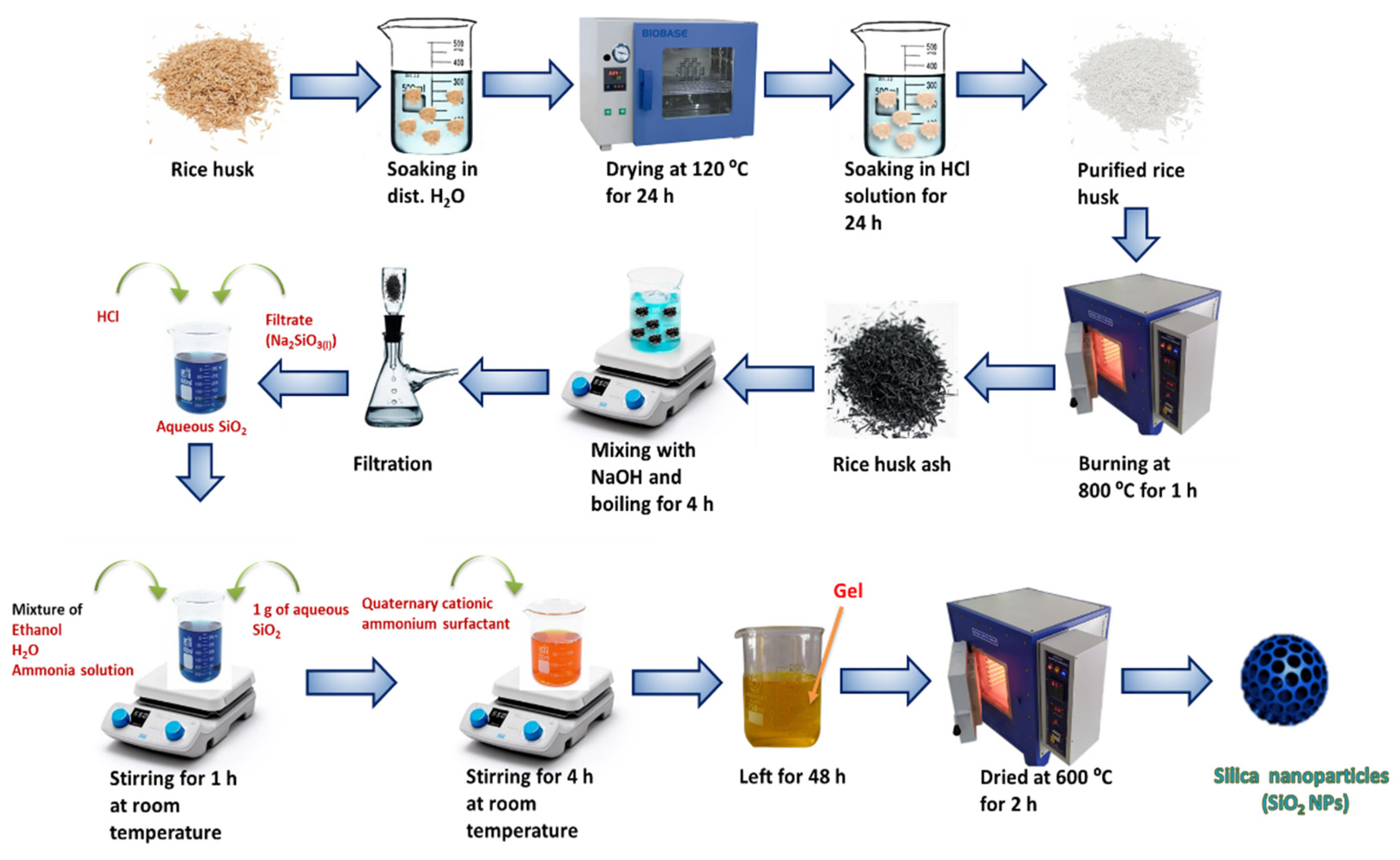

2.2. Preparation of Silica Nanoparticles (SiO2 NPs)

2.3. Characterization Techniques

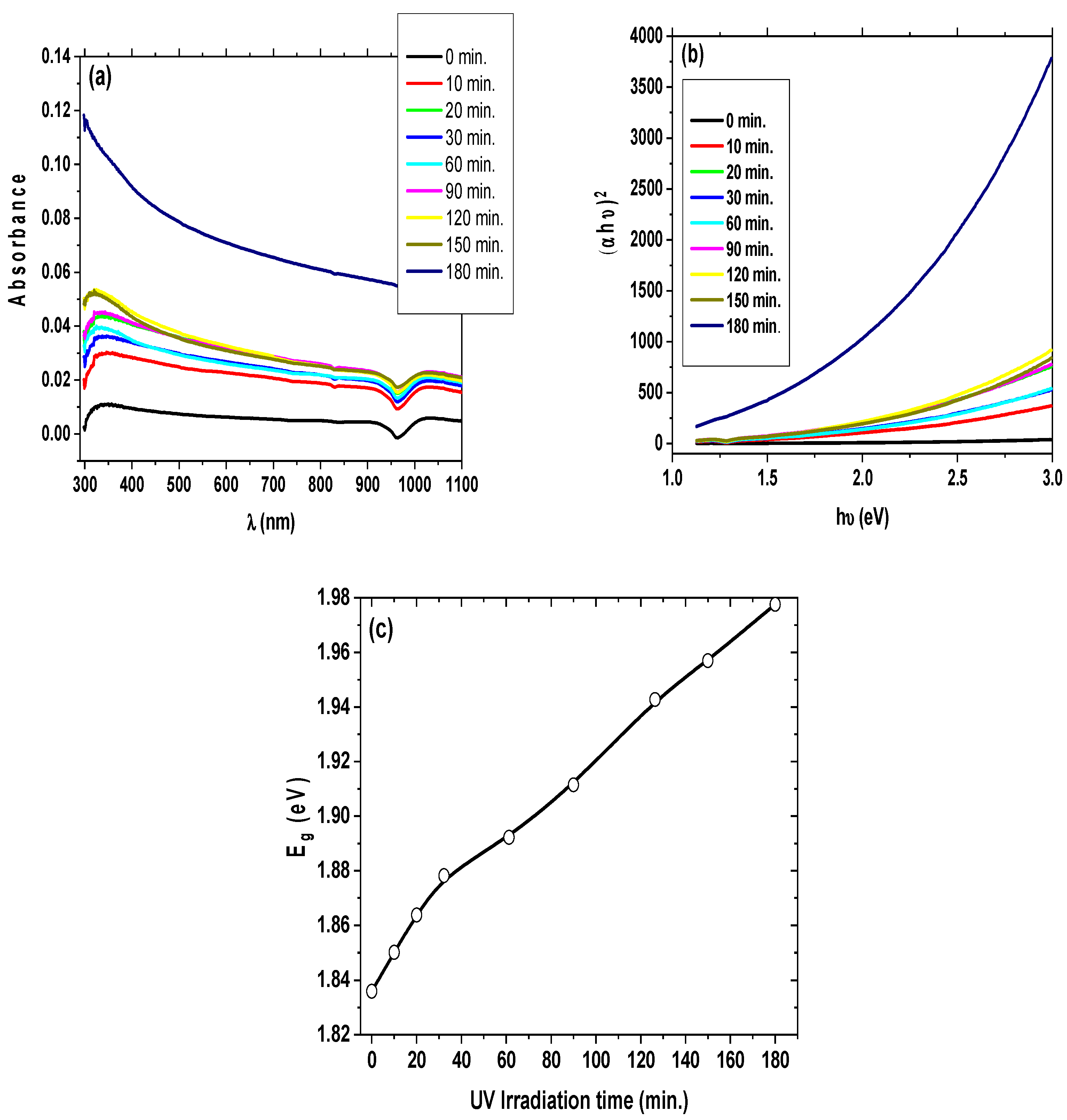

2.4. Optical Study of Synthesized SiO2 NPs

2.5. Photocatalytic Study of Synthesized SiO2 NPs

2.6. Microbial Study of Synthesized SiO2 NPs

3. Results and Discussion

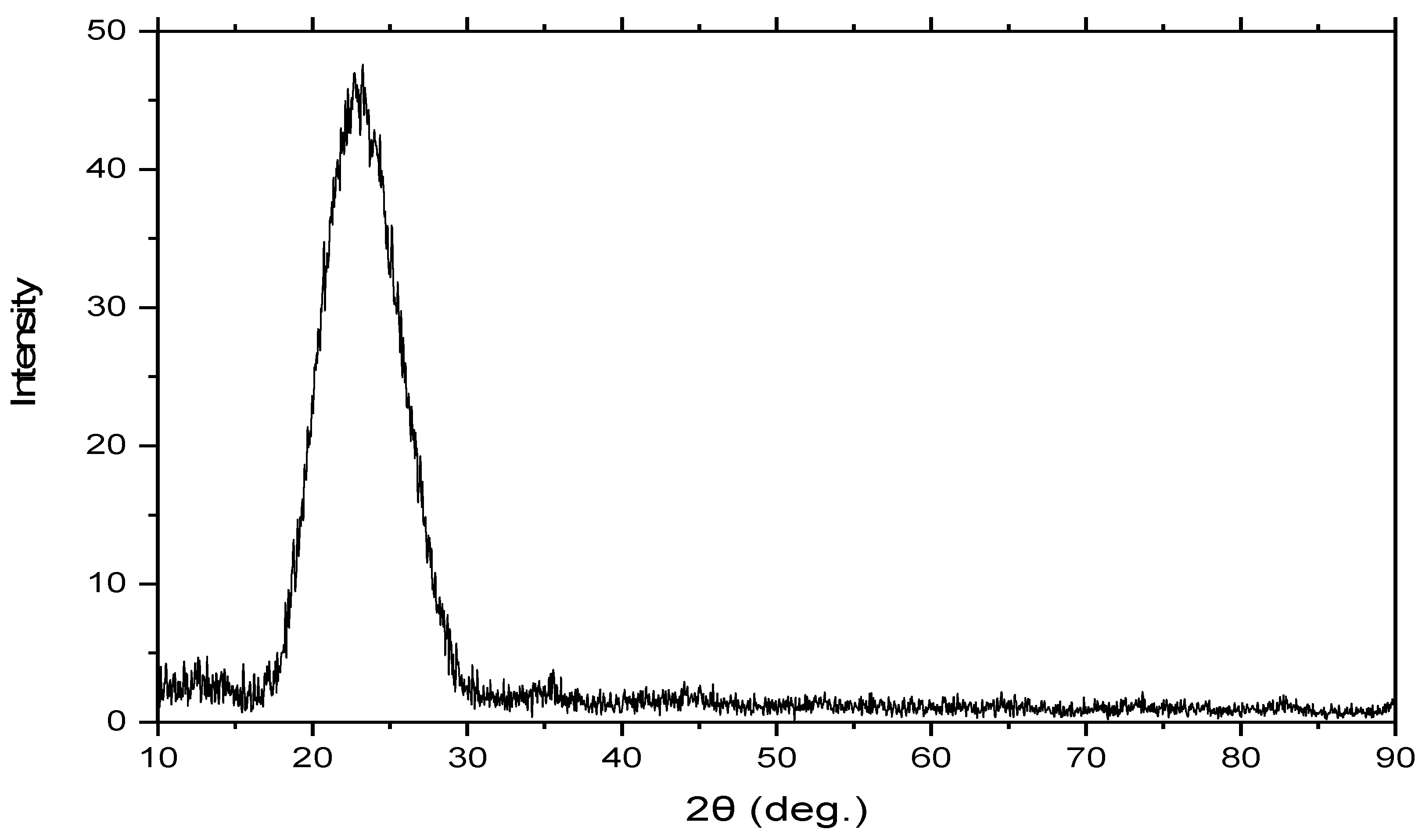

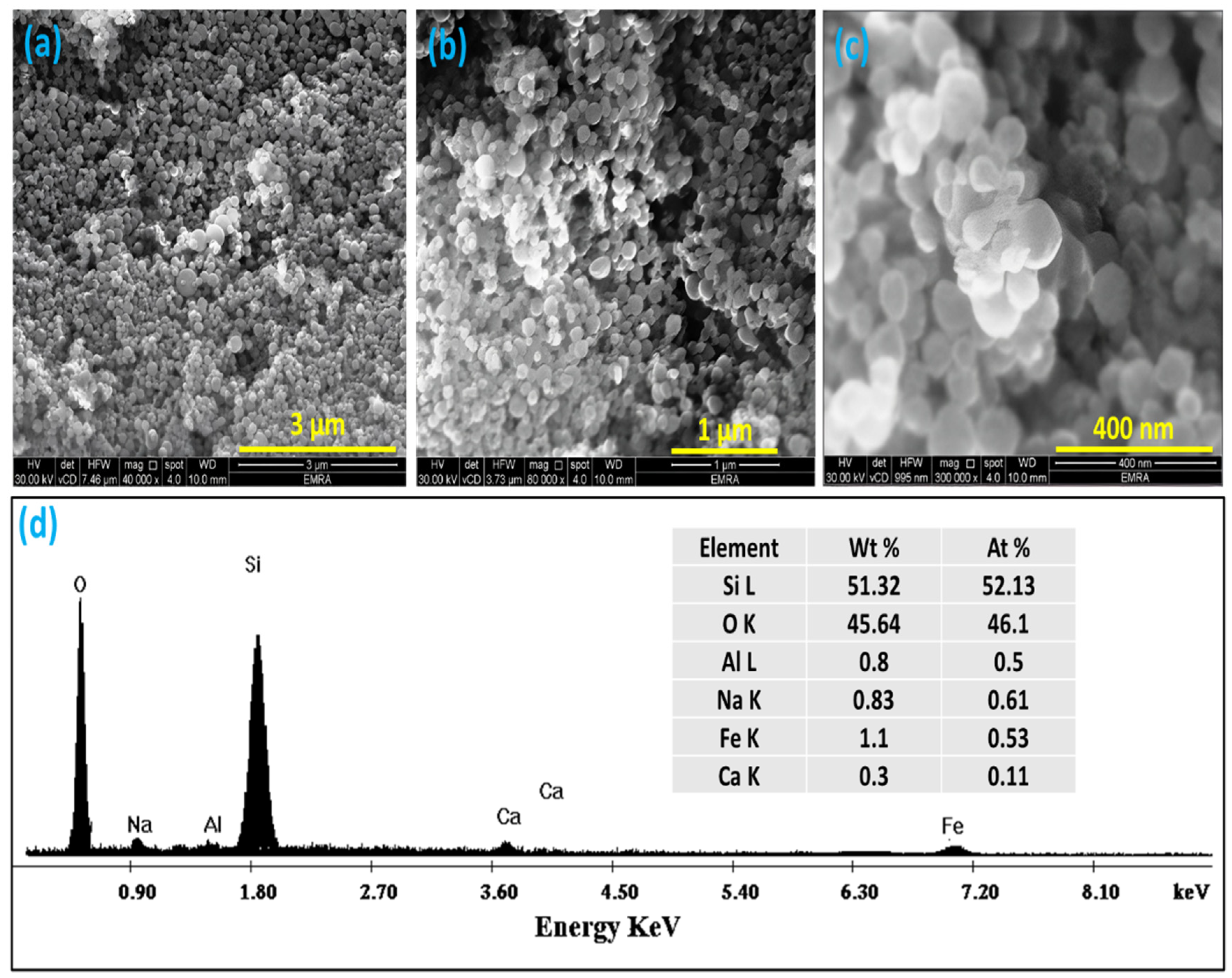

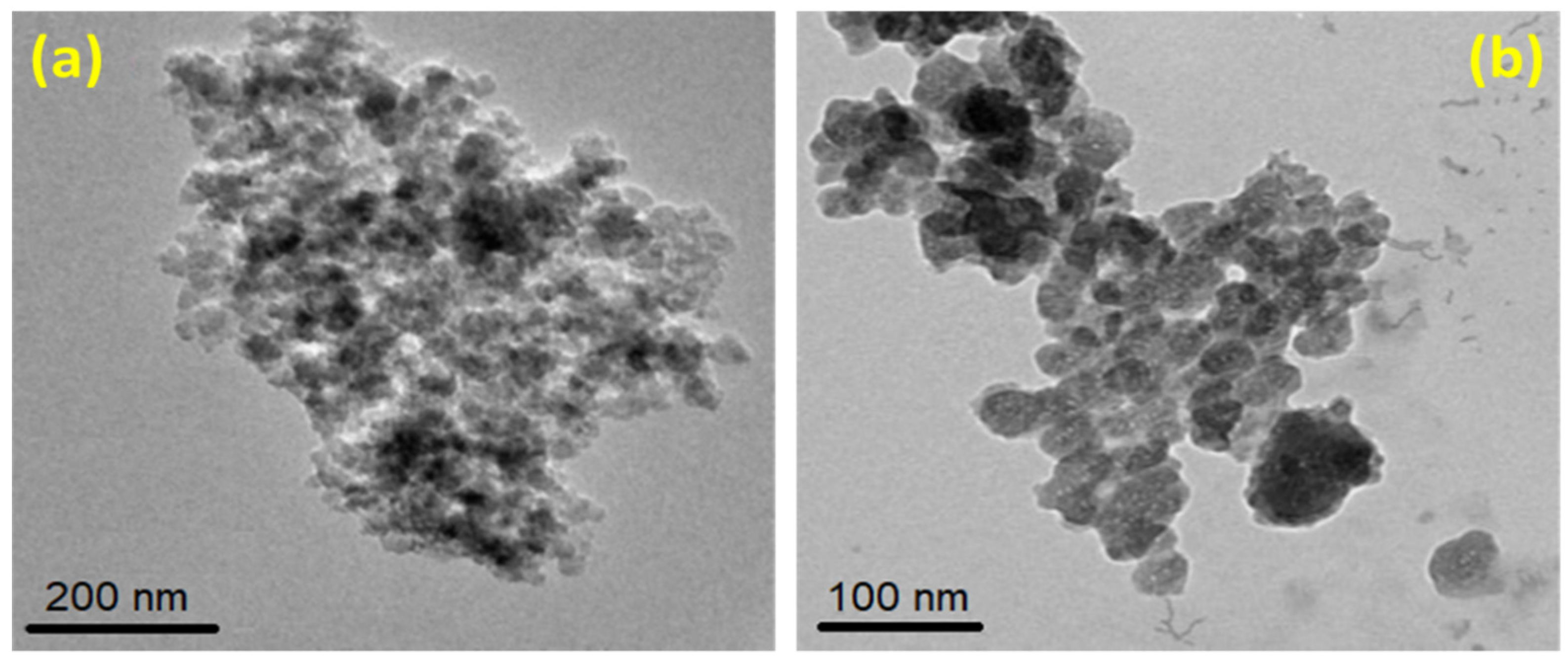

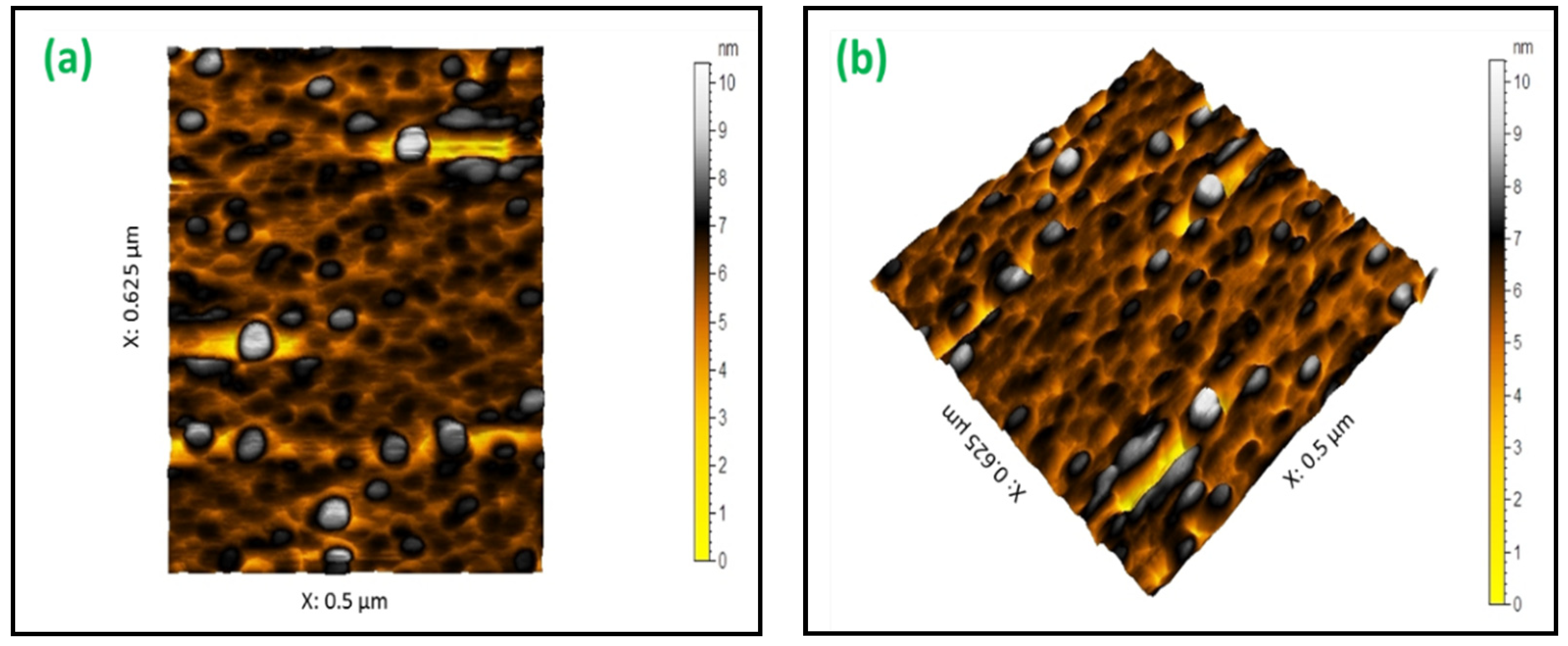

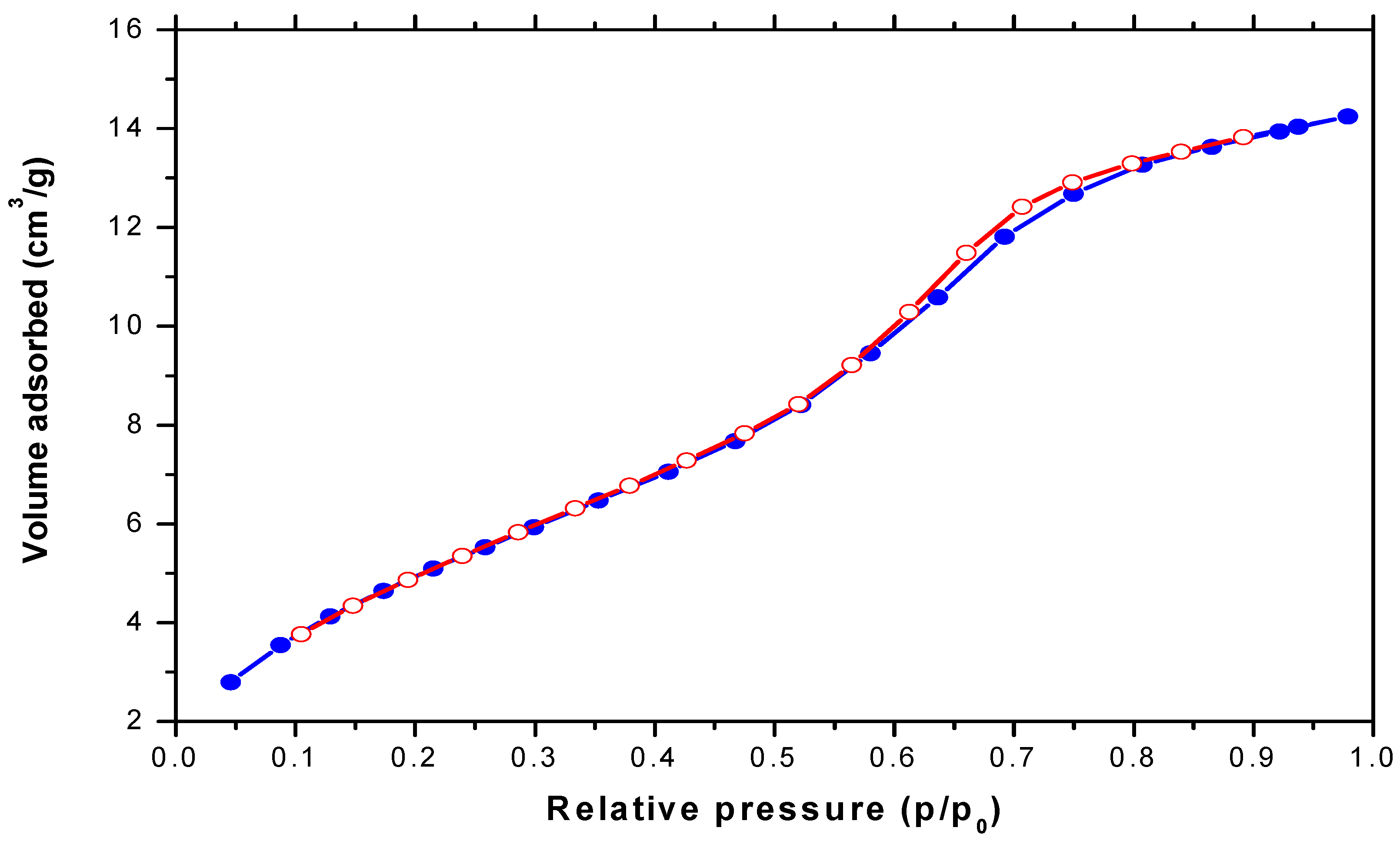

3.1. Characterization of Synthesized SiO2 NPs

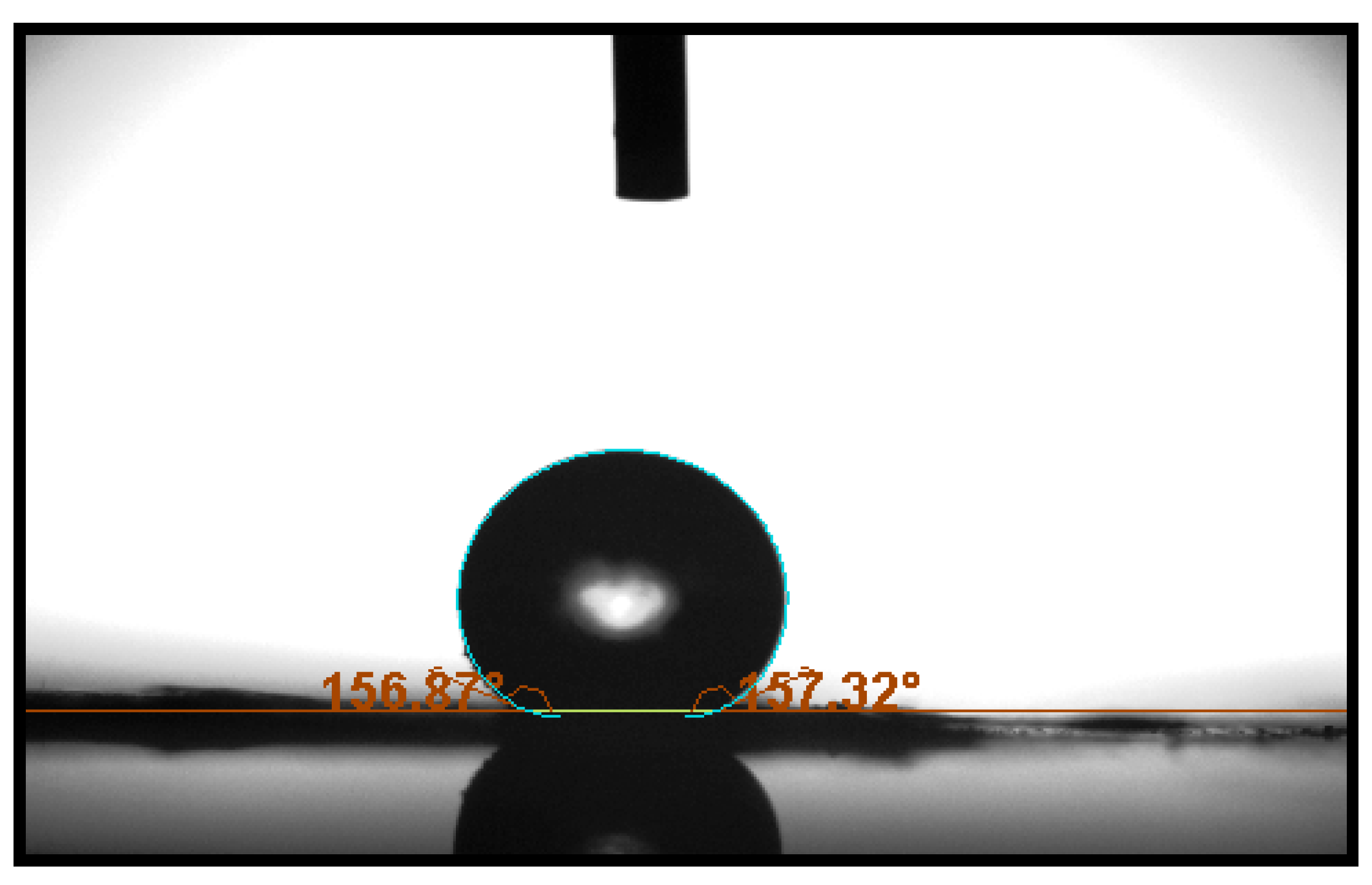

3.2. Wettability of Synthesized SiO2 NPs

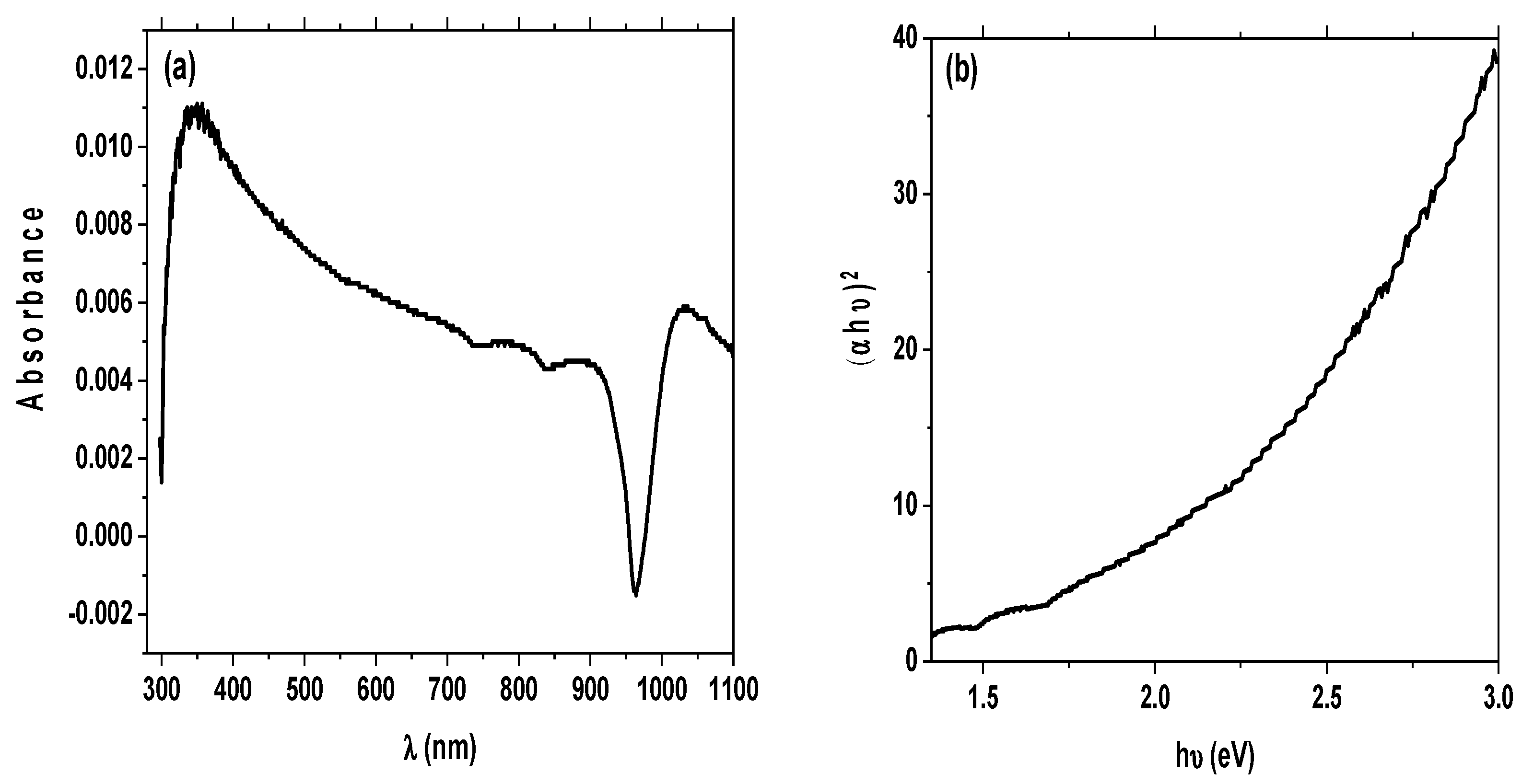

3.3. Optical Properties

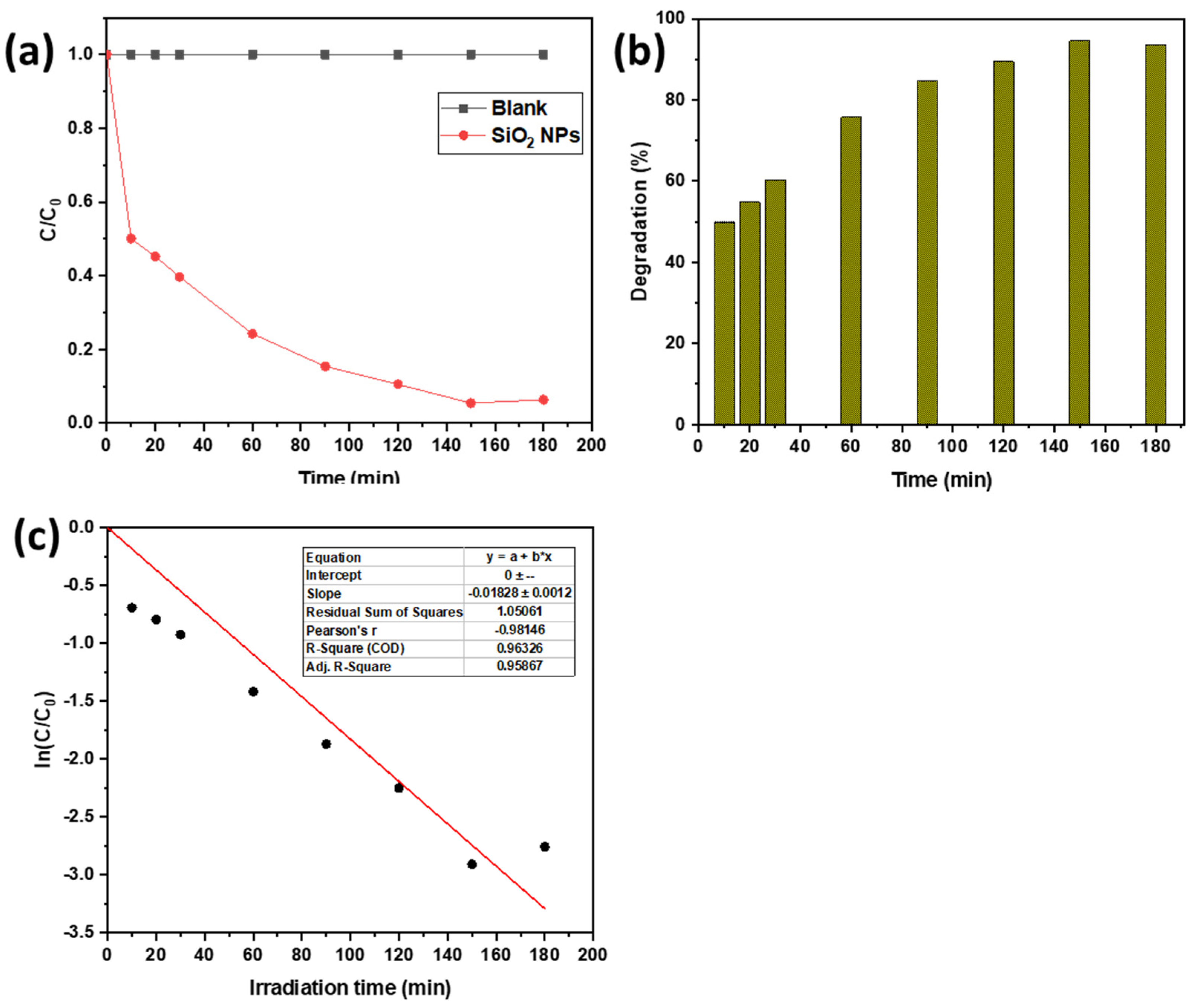

3.4. UV Photocatalysis Properties

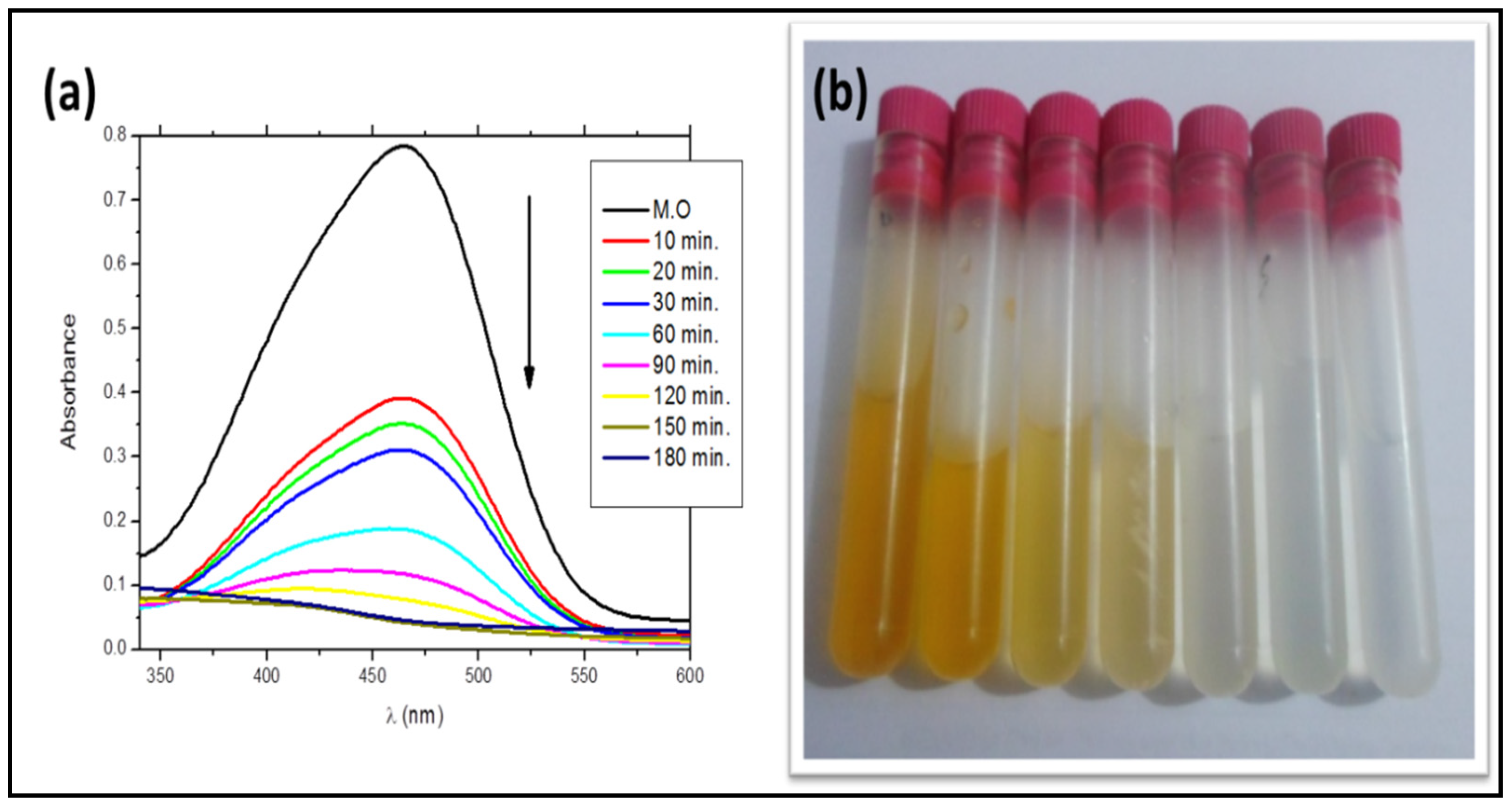

3.5. Photodegradation Performance

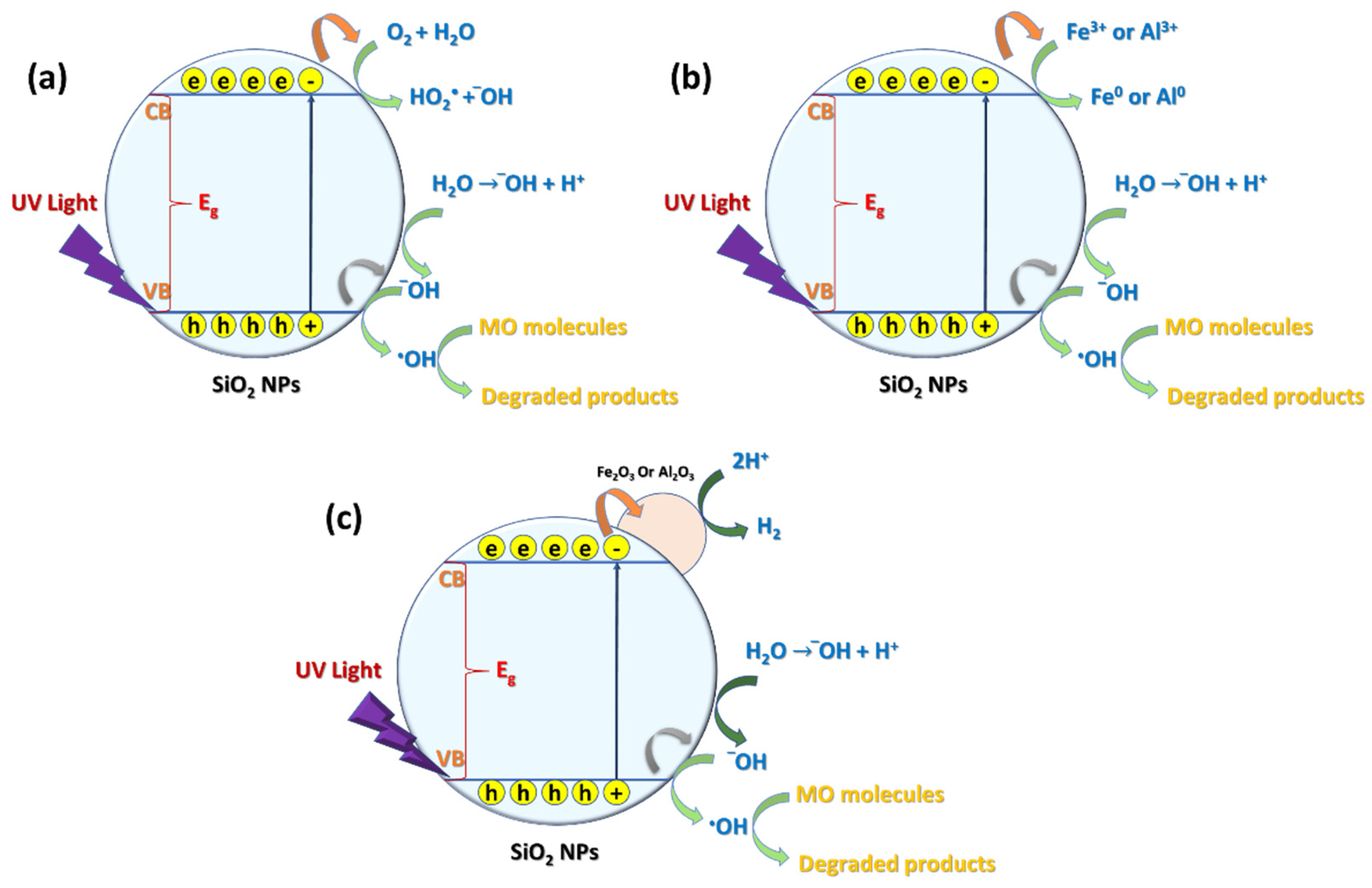

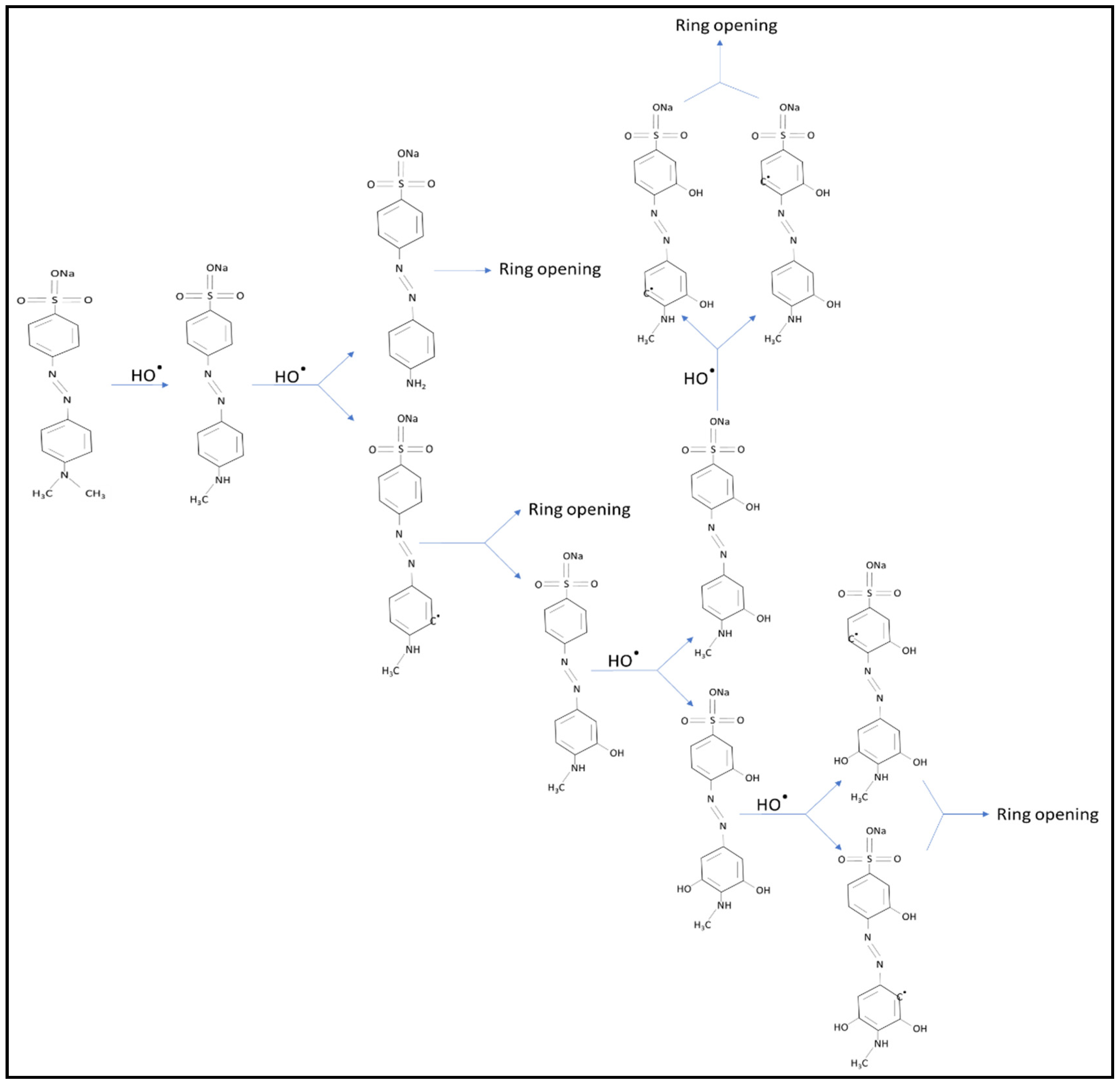

3.6. Probable Mechanism for Photocatalytic Degradation of MO Dye

3.7. Comparative Study of Photocatalytic Degradation of Synthesized SiO2 NPs with Those from the Literature

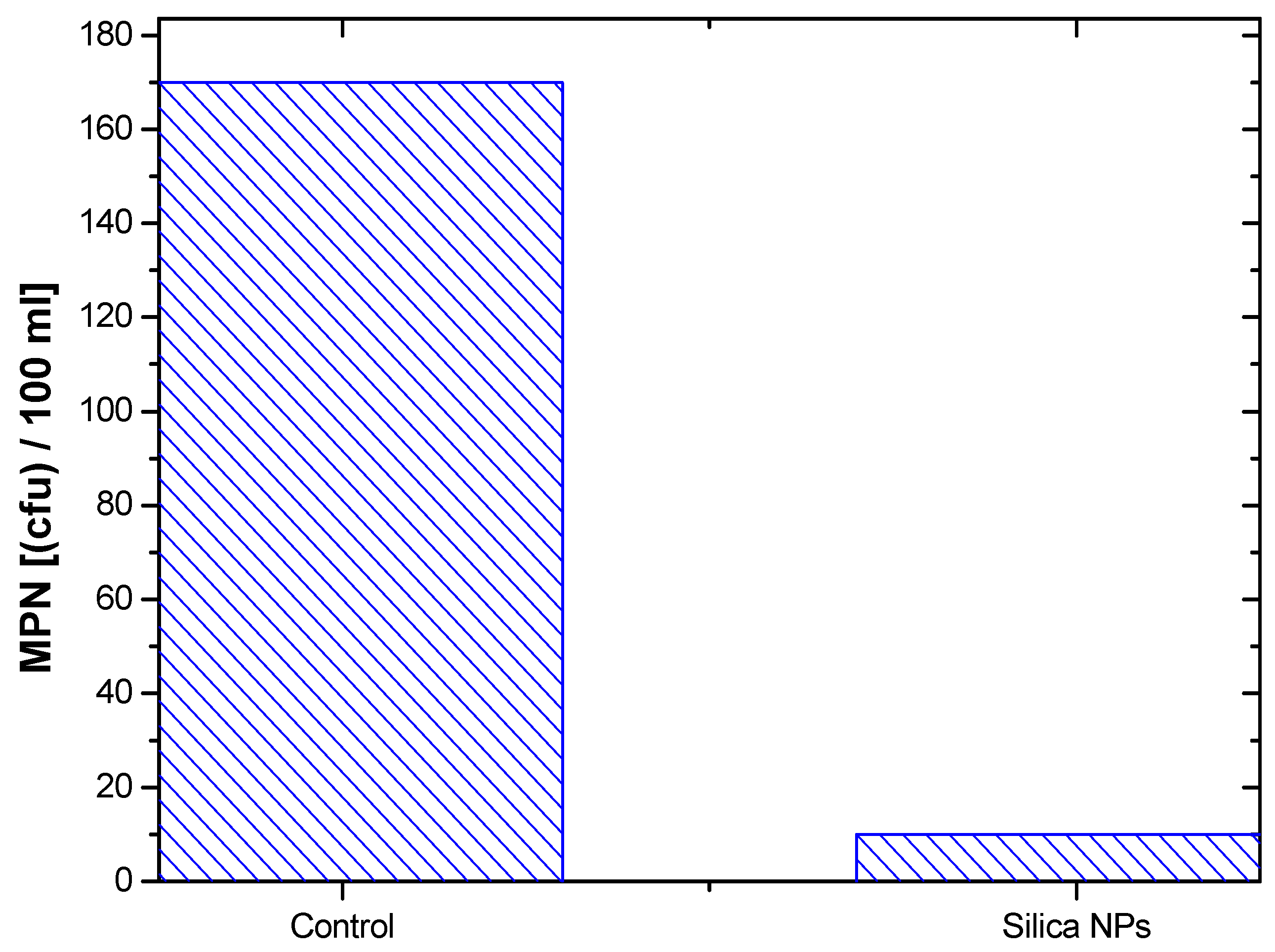

3.8. Antibacterial Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamdy, A.; Mostafa, M.K.; Nasr, M. Regression analysis and artificial intelligence for removal of methylene blue from aqueous solutions using nanoscale zero-valent iron. Int. J. Environ. Sci. Technol. 2018, 16, 357–372. [Google Scholar] [CrossRef]

- Hamdy, A.; Mostafa, M.; Nasr, M. Zero-valent iron nanoparticles for methylene blue removal from aqueous solutions and textile wastewater treatment, with cost estimation. Water Sci. Technol. 2018, 78, 367–378. [Google Scholar] [CrossRef] [PubMed]

- Hamdy, A.; Ismail, S.H.; Ebnalwaled, A.A.; Mohamed, G.G. Characterization of Superparamagnetic/Monodisperse PEG-Coated Magnetite Nanoparticles Sonochemically Prepared from the Hematite Ore for Cd(II) Removal from Aqueous Solutions. J. Inorg. Organomet. Polym. Mater. 2020, 31, 397–414. [Google Scholar] [CrossRef]

- Hamdy, A.; Mostafa, M.K.; Nasr, M. Techno-economic estimation of electroplating wastewater treatment using zero-valent iron nanoparticles: Batch optimization, continuous feed, and scaling up studies. Environ. Sci. Pollut. Res. 2019, 26, 25372–25385. [Google Scholar] [CrossRef]

- Dey, P.C.; Das, R. Enhanced photocatalytic degradation of methyl orange dye on interaction with synthesized ligand free CdS nanocrystals under visible light illumination. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 231, 118122. [Google Scholar] [CrossRef]

- Chen, D.; Ray, A.K. Removal of toxic metal ions from wastewater by semiconductor photocatalysis. Chem. Eng. Sci. 2001, 56, 1561–1570. [Google Scholar] [CrossRef]

- Regraguy, B.; Rahmani, M.; Mabrouki, J.; Drhimer, F.; Ellouzi, I.; Mahmou, C.; Dahchour, A.; El Mrabet, M.; El Hajjaji, S. Photocatalytic degradation of methyl orange in the presence of nanoparticles NiSO4/TiO2. Nanotechnol. Environ. Eng. 2022, 7, 157–171. [Google Scholar] [CrossRef]

- Muscetta, M.; Russo, D. Photocatalytic Applications in Wastewater and Air Treatment: A Patent Review (2010–2020). Catalysts 2021, 11, 834. [Google Scholar] [CrossRef]

- Elawwad, A.; Ragab, M.; Hamdy, A.; Husein, D.Z. Enhancing the performance of microbial desalination cells using δMnO2/graphene nanocomposite as a cathode catalyst. J. Water Reuse Desalination 2020, 10, 214–226. [Google Scholar] [CrossRef]

- Sadek, A.H.; Asker, M.S.; Abdelhamid, S.A. Bacteriostatic impact of nanoscale zero-valent iron against pathogenic bacteria in the municipal wastewater. Biologia 2021, 76, 2785–2809. [Google Scholar] [CrossRef]

- Hamdy, A. Experimental Study of the Relationship Between Dissolved Iron, Turbidity, and Removal of Cu(II) Ion From Aqueous Solutions Using Zero-Valent Iron Nanoparticles. Arab. J. Sci. Eng. 2020, 46, 5543–5565. [Google Scholar] [CrossRef]

- Mourdikoudis, S.; Pallares, R.M.; Thanh, N.T.K. Characterization techniques for nanoparticles: Comparison and complementarity upon studying nanoparticle properties. Nanoscale 2018, 10, 12871–12934. [Google Scholar] [CrossRef]

- Al-Qasmi, N.; Al-Gethami, W.; Alhashmialameer, D.; Ismail, S.H.; Sadek, A.H. Evaluation of Green-Synthesized Cuprospinel Nanoparticles as a Nanosensor for Detection of Low-Concentration Cd(II) Ion in the Aqueous Solutions by the Quartz Crystal Microbalance Method. Materials 2022, 15, 6240. [Google Scholar] [CrossRef]

- Elshayb, O.M.; Nada, A.M.; Sadek, A.H.; Ismail, S.H.; Shami, A.; Alharbi, B.M.; Alhammad, B.A.; Seleiman, M.F. The Integrative Effects of Biochar and ZnO Nanoparticles for Enhancing Rice Productivity and Water Use Efficiency under Irrigation Deficit Conditions. Plants 2022, 11, 1416. [Google Scholar] [CrossRef]

- Abdelmigeed, M.O.; Sadek, A.H.; Ahmed, T.S. Novel easily separable core–shell Fe3O4/PVP/ZIF-8 nanostructure adsorbent: Optimization of phosphorus removal from Fosfomycin pharmaceutical wastewater. RSC Adv. 2022, 12, 12823–12842. [Google Scholar] [CrossRef]

- Ismail, S.H.; Hamdy, A.; Ismail, T.A.; Mahboub, H.H.; Mahmoud, W.H.; Daoush, W.M. Synthesis and Characterization of Antibacterial Carbopol/ZnO Hybrid Nanoparticles Gel. Crystals 2021, 11, 1092. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on nanoparticles and nanostructured materials: History, sources, toxicity and regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef]

- Farag, R.; El-Shafei, M.M.; Mahmoud, A.S.; Mostafa, M.; Peters, R. Green synthesis of nano iron carbide: Preparation, characterization and application for removal of phosphate from aqueous solutions. In Proceedings of the 2018 AIChE Annual Meeting, Pittsburgh, PA, USA, 28 October–2 November 2018. [Google Scholar]

- Navya, P.N.; Daima, H.K. Rational engineering of physicochemical properties of nanomaterials for biomedical applications with nanotoxicological perspectives. Nano Converg. 2016, 3, 1. [Google Scholar] [CrossRef]

- Kumar, A.; Bera, S.; Singh, M.; Mondal, D. Molecular Interactions of Silica Nanoparticles and Biomolecule-Functionalized Silica Nanoparticles with Bixa orellana L. Plant DNA. Silicon 2021, 14, 1407–1419. [Google Scholar] [CrossRef]

- El-Shamy, A.G. Novel in-situ synthesis of nano-silica (SiO2) embedded into polyvinyl alcohol for dye removal: Adsorption and photo-degradation under visible light. Polymer 2022, 242, 124579. [Google Scholar] [CrossRef]

- Yadav, V.K.; Fulekar, M. Green synthesis and characterization of amorphous silica nanoparticles from fly ash. Mater. Today Proc. 2019, 18, 4351–4359. [Google Scholar] [CrossRef]

- Ebnalwaled, A.A.; Sadek, A.H.; Ismail, S.H.; Mohamed, G.G. Structural, optical, dielectric, and surface properties of polyimide hybrid nanocomposites films embedded mesoporous silica nanoparticles synthesized from rice husk ash for optoelectronic applications. Opt. Quantum Electron. 2022, 54, 690. [Google Scholar] [CrossRef]

- Badr, Y.; El-Wahed, M.A.; Mahmoud, M. Photocatalytic degradation of methyl red dye by silica nanoparticles. J. Hazard. Mater. 2008, 154, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Jiang, W.; Chen, L.; Xu, P.; Wang, H. Treatment of Produced Water with Photocatalysis: Recent Advances, Affecting Factors and Future Research Prospects. Catalysts 2020, 10, 924. [Google Scholar] [CrossRef]

- Regmi, C.; Joshi, B.; Ray, S.K.; Gyawali, G.; Pandey, R.P. Understanding Mechanism of Photocatalytic Microbial Decontamination of Environmental Wastewater. Front. Chem. 2018, 6, 33. [Google Scholar] [CrossRef]

- Worasuwannarak, N.; Sonobe, T.; Tanthapanichakoon, W. (2007) Pyrolysis behaviors of rice straw, rice husk, and corncob by TG-MS technique. J. Anal. Appl. Pyrolysis 2007, 78, 265–271. [Google Scholar] [CrossRef]

- Yadav, V.K.; Gnanamoorthy, G.; Yadav, K.K.; Ali, I.H.; Bagabas, A.A.; Choudhary, N.; Yadav, S.; Suriyaprabha, R.; Islam, S.; Modi, S.; et al. Utilization of Incense Stick Ash in Hydrometallurgy Methods for Extracting Oxides of Fe, Al, Si, and Ca. Materials 2022, 15, 1879. [Google Scholar] [CrossRef]

- Hossain, S.S.; Mathur, L.; Roy, P.K. Rice husk/rice husk ash as an alternative source of silica in ceramics: A review. J. Asian Ceram. Soc. 2018, 6, 299–313. [Google Scholar] [CrossRef]

- Verma, M.; Godbout, S.; Brar, S.K.; Solomatnikova, O.; Lemay, S.P.; Larouche, J.P. Biofuels Production from Biomass by Thermochemical Conversion Technologies. Int. J. Chem. Eng. 2012, 2012, 542426. [Google Scholar] [CrossRef]

- Vamvuka, D. Bio-oil, solid and gaseous biofuels from biomass pyrolysis processes-An overview. Int. J. Energy Res. 2011, 35, 835–862. [Google Scholar] [CrossRef]

- Della, V.; Kühn, I.; Hotza, D. Rice husk ash as an alternate source for active silica production. Mater. Lett. 2002, 57, 818–821. [Google Scholar] [CrossRef]

- Yadav, V.K.; Fulekar, M.H. Advances in Methods for Recovery of Ferrous, Alumina, and Silica Nanoparticles from Fly Ash Waste. Ceramics 2020, 3, 384–420. [Google Scholar] [CrossRef]

- Raheem, A.A.; Kareem, M.A. Chemical Composition and Physical Characteristics of Rice Husk Ash Blended Cement. Int. J. Eng. Res. Afr. 2017, 32, 25–35. [Google Scholar] [CrossRef]

- Jongpradist, P.; Homtragoon, W.; Sukkarak, R.; Kongkitkul, W.; Jamsawang, P. Efficiency of Rice Husk Ash as Cementitious Material in High-Strength Cement-Admixed Clay. Adv. Civ. Eng. 2018, 2018, 8346319. [Google Scholar] [CrossRef]

- Rambo, M.K.; Cardoso, A.L.; Bevilaqua, D.B.; Rizzetti, T.M.; Ramos, L.A.; Korndorfer, G.H.; Martins, A.F. Silica from Rice Husk Ash as an Additive for Rice Plant. J. Agron. 2011, 10, 99–104. [Google Scholar] [CrossRef]

- Rama Subbarao, G.V.; Siddartha, D.; Muralikrishna, T.; Sailaja, K.; Sowmya, T. Industrial wastes in soil improvement. Int. Sch. Res. Not. 2011, 2011, 138149. [Google Scholar] [CrossRef]

- Sapawe, N.; Osman, N.S.; Zakaria, M.Z.; Fikry, S.A.S.S.M.; Aris, M.A.M. Synthesis of green silica from agricultural waste by sol-gel method. Mater. Today Proc. 2018, 5, 21861–21866. [Google Scholar] [CrossRef]

- Usgodaarachchi, L.; Thambiliyagodage, C.; Wijesekera, R.; Bakker, M.G. Synthesis of mesoporous silica nanoparticles derived from rice husk and surface-controlled amine functionalization for efficient adsorption of methylene blue from aqueous solution. Curr. Res. Green Sustain. Chem. 2021, 4, 100116. [Google Scholar] [CrossRef]

- Sankar, S.; Kaur, N.; Lee, S.; Kim, D.Y. Rapid sonochemical synthesis of spherical silica nanoparticles derived from brown rice husk. Ceram. Int. 2018, 44, 8720–8724. [Google Scholar] [CrossRef]

- Iler, K.R. The Chemistry of Silica: Solubility, Polymerization, Colloid and Surface Properties and Biochemistry of Silica; Wiley: Hoboken, NJ, USA, 1979. [Google Scholar]

- Colomban, P. Gel technology in ceramics, glass-ceramics and ceramic-ceramic composites. Ceram. Int. 1989, 15, 23–50. [Google Scholar] [CrossRef]

- Rovani, S.; Santos, J.; Corio, P.; Fungaro, D. An Alternative and Simple Method for the Preparation of Bare Silica Nanoparticles Using Sugarcane Waste Ash, an Abundant and Despised Residue in the Brazilian Industry. J. Braz. Chem. Soc. 2019, 30, 1524–1533. [Google Scholar] [CrossRef]

- Alkaykh, S.; Mbarek, A.; Ali-Shattle, E.E. Photocatalytic degradation of methylene blue dye in aqueous solution by MnTiO3 nanoparticles under sunlight irradiation. Heliyon 2020, 6, e03663. [Google Scholar] [CrossRef] [PubMed]

- Baird, R.B.; Eaton, A.D.; Rice, E.W.; Bridgewater, L. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2017; Volume 23. [Google Scholar]

- Cotruvo, J.A. 2017 WHO guidelines for drinking water quality: First addendum to the fourth edition. J. Am. Water Work. Assoc. 2017, 109, 44–51. [Google Scholar] [CrossRef]

- Primo, J.D.O.; Horsth, D.F.; Correa, J.d.S.; Das, A.; Bittencourt, C.; Umek, P.; Buzanich, A.G.; Radtke, M.; Yusenko, K.V.; Zanette, C.; et al. Synthesis and Characterization of Ag/ZnO Nanoparticles for Bacteria Disinfection in Water. Nanomaterials 2022, 12, 1764. [Google Scholar] [CrossRef] [PubMed]

- De Matteis, V.; Rizzello, L.; Ingrosso, C.; Liatsi-Douvitsa, E.; De Giorgi, M.L.; De Matteis, G.; Rinaldi, R. Cultivar-Dependent Anticancer and Antibacterial Properties of Silver Nanoparticles Synthesized Using Leaves of Different Olea Europaea Trees. Nanomaterials 2019, 9, 1544. [Google Scholar] [CrossRef]

- Khouchaf, L.; Boulahya, K.; Das, P.P.; Nicolopoulos, S.; Kis, V.K.; Lábár, J.L. Study of the Microstructure of Amorphous Silica Nanostructures Using High-Resolution Electron Microscopy, Electron Energy Loss Spectroscopy, X-ray Powder Diffraction, and Electron Pair Distribution Function. Materials 2020, 13, 4393. [Google Scholar] [CrossRef]

- Sun, J.; Xu, Z.; Li, W.; Shen, X. Effect of Nano-SiO2 on the Early Hydration of Alite-Sulphoaluminate Cement. Nanomaterials 2017, 7, 102. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Ab Wab, H.A.; Razak, K.A.; Shamsuddin, S. In Vitro Evaluation of Cytotoxicity of Colloidal Amorphous Silica Nanoparticles Designed for Drug Delivery on Human Cell Lines. J. Nanomater. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

- Thu, K.; Chakraborty, A.; Saha, B.; Ng, K.C. Thermo-physical properties of silica gel for adsorption desalination cycle. Appl. Therm. Eng. 2013, 50, 1596–1602. [Google Scholar] [CrossRef]

- Bharti, C.; Nagaich, U.; Pal, A.K.; Gulati, N. Mesoporous silica nanoparticles in target drug delivery system: A review. Int. J. Pharm. Investig. 2015, 5, 124–133. [Google Scholar] [CrossRef]

- Cendrowski, K.; Chen, X.; Zielinska, B.; Kalenczuk, R.J.; Rümmeli, M.H.; Büchner, B.; Klingeler, R.; Borowiak-Palen, E. Synthesis, characterization, and photocatalytic properties of core/shell mesoporous silica nanospheres supporting nanocrystalline titania. J. Nanoparticle Res. 2011, 13, 5899–5908. [Google Scholar] [CrossRef]

- Le, V.H.; Thuc, C.N.H.; Thuc, H.H. Synthesis of silica nanoparticles from Vietnamese rice husk by sol–gel method. Nanoscale Res. Lett. 2013, 8, 58. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, K.; Guo, X.; Zhou, W.; Song, G.; Cheng, S. Mesoporous silica nanoparticles as high performance anode materials for lithium-ion batteries. New J. Chem. 2016, 40, 8202–8205. [Google Scholar] [CrossRef]

- Bchellaoui, N.; Hayat, Z.; Mami, M.; Dorbez-Sridi, R.; El Abed, A.I. Microfluidic-assisted formation of highly monodisperse and mesoporous silica soft microcapsules. Sci. Rep. 2017, 7, 16326. [Google Scholar] [CrossRef]

- Hanif, H.; Nazir, S.; Mazhar, K.; Waseem, M.; Bano, S.; Rashid, U. Targeted delivery of mesoporous silica nanoparticles loaded monastrol into cancer cells: An in vitro study. Appl. Nanosci. 2017, 7, 549–555. [Google Scholar] [CrossRef]

- Selvaggi, R.; Tarpani, L.; Santuari, A.; Giovagnoli, S.; Latterini, L. Silica nanoparticles assisted photodegradation of acridine orange in aqueous suspensions. Appl. Catal. B Environ. 2015, 168–169, 363–369. [Google Scholar] [CrossRef]

- Romolini, G.; Gambucci, M.; Ricciarelli, D.; Tarpani, L.; Zampini, G.; Latterini, L. Photocatalytic activity of silica and silica-silver nanocolloids based on photo-induced formation of reactive oxygen species. Photochem. Photobiol. Sci. 2021, 20, 1161–1172. [Google Scholar] [CrossRef]

- Rahman, I.A.; Vejayakumaran, P.; Sipaut, C.S.; Ismail, J.; Chee, C.K. Size-dependent physicochemical and optical properties of silica nanoparticles. Mater. Chem. Phys. 2009, 114, 328–332. [Google Scholar] [CrossRef]

- Skuja, L. Optically active oxygen-deficiency-related centers in amorphous silicon dioxide. J. Non-Crystalline Solids 1998, 239, 16–48. [Google Scholar] [CrossRef]

- Jafarzadeh, M.; Rahman, I.; Sipaut, C. Optical properties of amorphous organo-modified silica nanoparticles produced via co-condensation method. Ceram. Int. 2010, 36, 333–338. [Google Scholar] [CrossRef]

- Ab Rahman, I.; Padavettan, V. Synthesis of Silica Nanoparticles by Sol-Gel: Size-Dependent Properties, Surface Modification, and Applications in Silica-Polymer Nanocomposites—A Review. J. Nanomater. 2012, 2012, 132424. [Google Scholar] [CrossRef]

- Mehta, S.K.; Kumar, S.; Chaudhary, S.; Bhasin, K.K. Nucleation and growth of surfactant-passivated CdS and HgS nanoparticles: Time-dependent absorption and luminescence profiles. Nanoscale 2009, 2, 145–152. [Google Scholar] [CrossRef]

- Stamplecoskie, K.G.; Scaiano, J.C. Light Emitting Diode Irradiation Can Control the Morphology and Optical Properties of Silver Nanoparticles. J. Am. Chem. Soc. 2010, 132, 1825–1827. [Google Scholar] [CrossRef] [PubMed]

- Lalitha, B.; Mohan, D.K.; Ramananda, R.D. Effect of microwave irradiation time on structural and optical properties of ZnS nanoparticles. Inorg. Chem. Commun. 2022, 140, 109460. [Google Scholar] [CrossRef]

- Kamoun, O.; Gassoumi, A.; Kouass, S.; Alhalaili, B.; Vidu, R.; Turki-Kamoun, N. An Investigation on the Synthesis of Molybdenum Oxide and Its Silica Nanoparticle Composites for Dye Degradation. Nanomaterials 2020, 10, 2409. [Google Scholar] [CrossRef] [PubMed]

- Biradar, A.I.; Sarvalkar, P.D.; Teli, S.B.; Pawar, C.; Patil, P.; Prasad, N.R. Photocatalytic degradation of dyes using one-step synthesized silica nanoparticles. Mater. Today Proc. 2021, 43, 2832–2838. [Google Scholar] [CrossRef]

- Sareshkeh, A.T.; Some-Saraee, R.B.; Rasoulifard, M.H.; Seyed-Dorraji, M.-S.; Hosseini, S.F. P and C co-modified g-C3N4/SiO2/ZnO Z-scheme based heterogeneous nanocomposite as a highly boosted visible-light-driven photocatalytic system. J. Alloy. Compd. 2022, 923, 166392. [Google Scholar] [CrossRef]

- Rohilla, S.; Gupta, A.; Kumar, V.; Kumari, S.; Petru, M.; Amor, N.; Noman, M.T.; Dalal, J. Excellent UV-light triggered photocatalytic performance of ZnO. SiO2 nanocomposite for water pollutant compound methyl orange dye. Nanomaterials 2021, 11, 2548. [Google Scholar] [CrossRef]

- Nosaka, Y.; Nosaka, A.Y. Generation and Detection of Reactive Oxygen Species in Photocatalysis. Chem. Rev. 2017, 117, 11302–11336. [Google Scholar] [CrossRef]

- Kandi, D.; Martha, S.; Thirumurugan, A.; Parida, K.M. Modification of BiOI Microplates with CdS QDs for Enhancing Stability, Optical Property, Electronic Behavior toward Rhodamine B Decolorization, and Photocatalytic Hydrogen Evolution. J. Phys. Chem. C 2017, 121, 4834–4849. [Google Scholar] [CrossRef]

- Yang, Z.-Y.; Shen, G.-Y.; He, Y.-P.; Liu, X.-X.; Yang, S.-J. Preparation of TiO2/SiO2 composite oxide and its photocatalytic degradation of rhodamine B. J. Porous Mater. 2016, 23, 589–599. [Google Scholar] [CrossRef]

- Sun, R.; Chen, Z.; Yang, Y.; Peng, J.; Zheng, T. Effects and mechanism of SiO2 on photocatalysis and super hydrophilicity of TiO2 films prepared by sol-gel method. Mater. Res. Express 2018, 6, 046409. [Google Scholar] [CrossRef]

- Fatimah, I.; Said, A.; Hasanah, U.A. Preparation of TiO2-SiO2 using Rice Husk Ash as Silica Source and The Kinetics Study as Photocatalyst in Methyl Violet Decolorization. Bull. Chem. React. Eng. Catal. 2015, 10, 43–49. [Google Scholar] [CrossRef]

- Chong, W.-K.; Ng, B.-J.; Tan, L.-L.; Chai, S.-P. Recent Advances in Nanoscale Engineering of Ternary Metal Sulfide-Based Heterostructures for Photocatalytic Water Splitting Applications. Energy Fuels 2022, 36, 4250–4267. [Google Scholar] [CrossRef]

- Luo, J.; Zhou, X.; Ning, X.; Zhan, L.; Ma, L.; Xu, X.; Li, S.; Sun, S. Utilization of LaCoO3 as an efficient co-catalyst to boost the visible light photocatalytic performance of g-C3N4. Sep. Purif. Technol. 2018, 201, 309–317. [Google Scholar] [CrossRef]

- Mandari, K.K.; Son, N.; Kim, T.; Kang, M. Highly efficient SnS2@Ag/AgVO3 heterostructures for improved charge carriers in photocatalytic H2 production. J. Alloy. Compd. 2022, 927, 166886. [Google Scholar] [CrossRef]

- Lubis, S.; Mustafa, I.; Ermanda, Y.; Ramadhani, M. Preparation of SiO2/α-Fe2O3 Composite from Rice Husk and Iron Sand as a Photocatalyst for Degradation of Acid Black 1 Dye. In Proceedings of the Journal of Physics: Conference Series, North Sumatera Province, Indonesia, 17 November 2020. [Google Scholar]

- Mandal, S.; Adhikari, S.; Pu, S.; Wang, X.; Kim, D.-H.; Patel, R.K. Interactive Fe2O3/porous SiO2 nanospheres for photocatalytic degradation of organic pollutants: Kinetic and mechanistic approach. Chemosphere 2019, 234, 596–607. [Google Scholar] [CrossRef]

- Vinoda, B.M.; Vinuth, M.; Bodke, Y.D.; Manjanna, J. Photocatalytic Degradation of Toxic Methyl Red Dye Using Silica Nanoparticles Synthesized from Rice Husk Ash. J. Environ. Anal. Toxicol. 2015, 5, 1000336. [Google Scholar]

- Badr, Y.; Mahmoud, M. Photocatalytic degradation of methyl orange by gold silver nano-core/silica nano-shell. J. Phys. Chem. Solids 2007, 68, 413–419. [Google Scholar] [CrossRef]

- Mayilsamy, M.; Palanisamy, S. Photocatalytic Degradation Of Methyl Orange From Aqueous Solution By Using Chitosan Silica Composite. Lett. Appl. NanoBioScience 2021, 10, 2320–2330. [Google Scholar]

- Naikwade, A.G.; Jagadale, M.B.; Kale, D.P.; Gophane, A.D.; Garadkar, K.M.; Rashinkar, G.S. Photocatalytic Degradation of Methyl Orange by Magnetically Retrievable Supported Ionic Liquid Phase Photocatalyst. ACS Omega 2020, 5, 131–144. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Mittal, H.; Reddy, L.; Nair, P.; Ngila, J.C.; Parashar, V. Morphogenesis of ZnO nanostructures: Role of acetate (COOH−) and nitrate (NO3−) ligand donors from zinc salt precursors in synthesis and morphology dependent photocatalytic properties. RSC Adv. 2015, 5, 38801–38809. [Google Scholar] [CrossRef]

- Kaur, J.; Bansal, S.; Singhal, S. Photocatalytic degradation of methyl orange using ZnO nanopowders synthesized via thermal decomposition of oxalate precursor method. Phys. B Condens. Matter 2013, 416, 33–38. [Google Scholar] [CrossRef]

- Oyewo, O.A.; Ramaila, S.; Mavuru, L.; Onwudiwe, D.C. Enhanced photocatalytic degradation of methyl orange using Sn-ZnO/GO nanocomposite. J. Photochem. Photobiol. 2022, 11, 100131. [Google Scholar] [CrossRef]

- Dhanalakshmi, J.; Padiyan, D.P. Photocatalytic degradation of methyl orange and bromophenol blue dyes in water using sol–gel synthesized TiO2 nanoparticles. Mater. Res. Express 2017, 4, 095020. [Google Scholar] [CrossRef]

- Subha, P.; Jayaraj, M. Solar photocatalytic degradation of methyl orange dye using TiO2 nanoparticles synthesised by sol–gel method in neutral medium. J. Exp. Nanosci. 2014, 10, 1106–1115. [Google Scholar] [CrossRef]

- Naraginti, S.; Stephen, F.B.; Radhakrishnan, A.; Sivakumar, A. Zirconium and silver co-doped TiO2 nanoparticles as visible light catalyst for reduction of 4-nitrophenol, degradation of methyl orange and methylene blue. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 135, 814–819. [Google Scholar] [CrossRef]

| Parameter | SiO2 NPs |

|---|---|

| BET surface area (m2/g) | 78.52 |

| BJH adsorption cumulative surface area (m2/g) | 40.63 |

| BJH desorption cumulative surface area (m2/g) | 38.48 |

| Total pore volume (cm3/g) | 0.062 |

| Average pore diameter (nm) | 3.158 |

| Statistics | Time [s] | CA Left [°] | CA Right [°] | CA Mean [°] | ST [mN/m] | Y-L β | Y-L r [mm] |

|---|---|---|---|---|---|---|---|

| Mean | 5.00318 | 159.15092 | 157.67678 | 158.41385 | 76.633084 | −0.3450381 | 1.6443942 |

| Std deviation | 2.91972 | 2.5912125 | 0.2020522 | 1.3742527 | 1.3486686 | 0.0065737 | 0.0014165 |

| Min | 0 | 156.24350 | 157.23423 | 156.80051 | 71.624433 | −0.3690024 | 1.6402470 |

| Max | 10.0059 | 175.76149 | 158.23625 | 166.99887 | 79.423913 | −0.3313800 | 1.6515908 |

| Sr. No. | Photocatalyst | Pollutant | Light Source | Degradation Time | Photocatalytic Activity | Ref. |

|---|---|---|---|---|---|---|

| 1 | SiO2 Ag NPs@SiO2 NPs Au NPs@SiO2 NPs Au NPs&Ag NPs@SiO2 NPs Ag+@SiO2 NPs Au3+@SiO2 NPs | Methyl red | Xe Lamp | 120 min 40 min 40 min 35 min 35 min 10 min | 100% | [24] |

| 2 | SiO2 | Methylene blue, Methyl orange | Hg Lamp | 90 min | 99.51% | [69] |

| 3 | SiO2 NPs (RHA) | Methyl red | Sunlight | 120 min | 95% | [82] |

| 4 | SiO2 NPs SiO2@Ag NPs SiO2@Au NPs | Methyl orange | Xe Lamp | 120 min 65 min 85 min | 100% | [83] |

| 5 | Chitosan Silica Composite | Methyl orange | Sunlight | 70 min | 94.01% | [84] |

| 6 | [FemIL@SiO2@ Mag]2MoO4 | Methyl orange | Hg Lamp | 30 min | 99% | [85] |

| 7 | SiO2 (RHA) | Methyl orange | Hg Lamp | 150 min | ~95% | Present work |

| 8 | ZnO nanorod ZnO nanospindle ZnO nanoflower | Methyl orange | Hg Lamp | 180 min | 89% 80% 69% | [86] |

| 9 | ZnO nanoparticle | Methyl orange | Hg Lamp | 80 min | 100% | [87] |

| 10 | ZnO-Sn/GO nanocomposites | Methyl orange | Xe Lamp | 120 min | 96.2% | [88] |

| 11 | TiO2 nanoparticles | Methyl orange | Xe Lamp | 240 min | 67.12% | [89] |

| 12 | TiO2 nanoparticles | Methyl orange | Sunlight | 30 min | 60% | [90] |

| 13 | Zr and Ag codoped TiO2 nanoparticles | Methyl orange | Tungsten lamp | 7 min | 100% | [91] |

| 14 | TiO2 Sachtopore (NiSO4/TiO2 = 0.2%) nanoparticles Pure TiO2 Sachtopore TiO2 Sachtopore (NiSO4/TiO2 = 0.1%) nanoparticles | Methyl orange | UV Lamp | 120 min | 45% 38% 20% | [7] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhadhrami, A.; Mohamed, G.G.; Sadek, A.H.; Ismail, S.H.; Ebnalwaled, A.A.; Almalki, A.S.A. Behavior of Silica Nanoparticles Synthesized from Rice Husk Ash by the Sol–Gel Method as a Photocatalytic and Antibacterial Agent. Materials 2022, 15, 8211. https://doi.org/10.3390/ma15228211

Alhadhrami A, Mohamed GG, Sadek AH, Ismail SH, Ebnalwaled AA, Almalki ASA. Behavior of Silica Nanoparticles Synthesized from Rice Husk Ash by the Sol–Gel Method as a Photocatalytic and Antibacterial Agent. Materials. 2022; 15(22):8211. https://doi.org/10.3390/ma15228211

Chicago/Turabian StyleAlhadhrami, A., Gehad G. Mohamed, Ahmed H. Sadek, Sameh H. Ismail, A. A. Ebnalwaled, and Abdulraheem S. A. Almalki. 2022. "Behavior of Silica Nanoparticles Synthesized from Rice Husk Ash by the Sol–Gel Method as a Photocatalytic and Antibacterial Agent" Materials 15, no. 22: 8211. https://doi.org/10.3390/ma15228211

APA StyleAlhadhrami, A., Mohamed, G. G., Sadek, A. H., Ismail, S. H., Ebnalwaled, A. A., & Almalki, A. S. A. (2022). Behavior of Silica Nanoparticles Synthesized from Rice Husk Ash by the Sol–Gel Method as a Photocatalytic and Antibacterial Agent. Materials, 15(22), 8211. https://doi.org/10.3390/ma15228211