An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study

Abstract

1. Introduction

2. Experiment

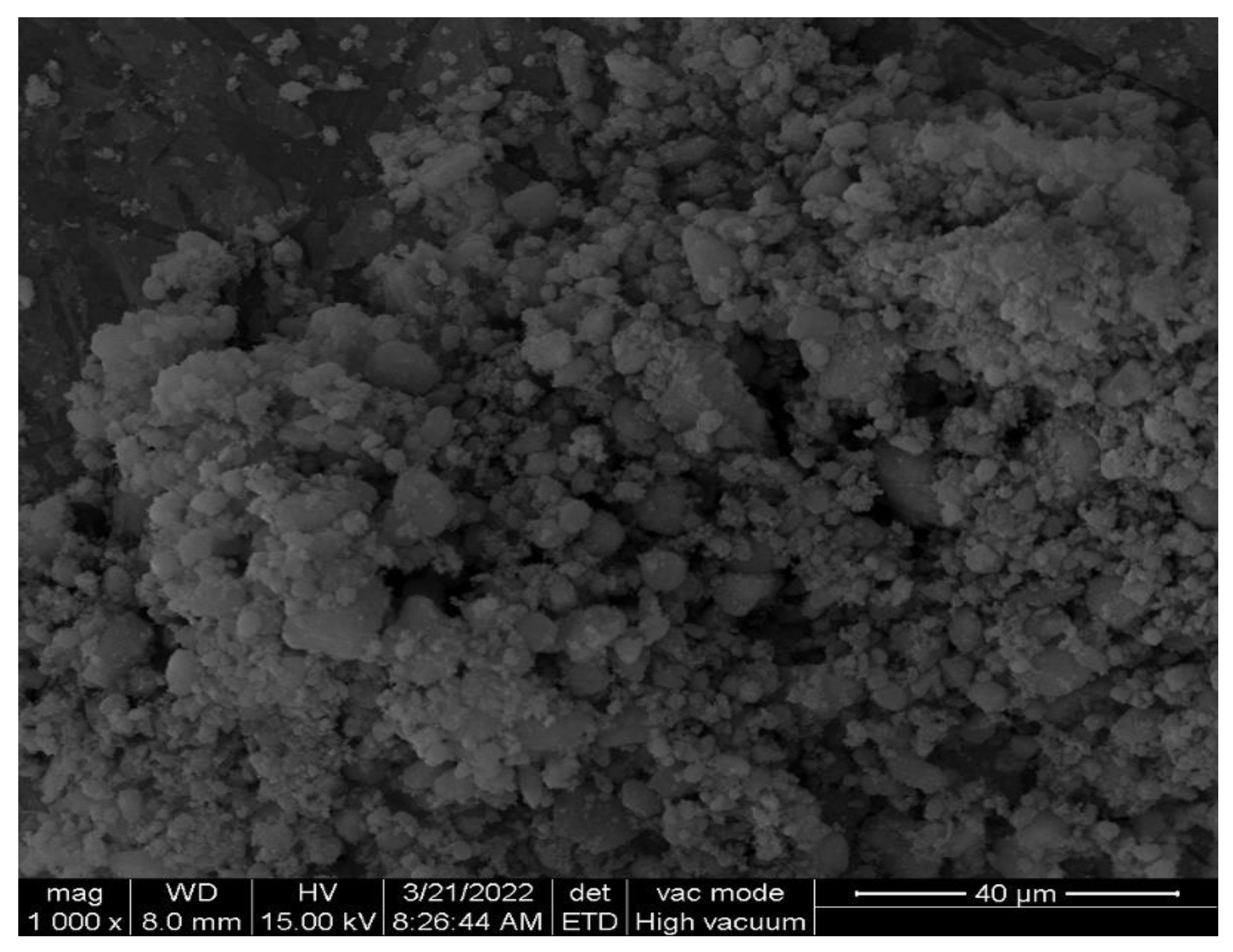

2.1. Experimental Materials

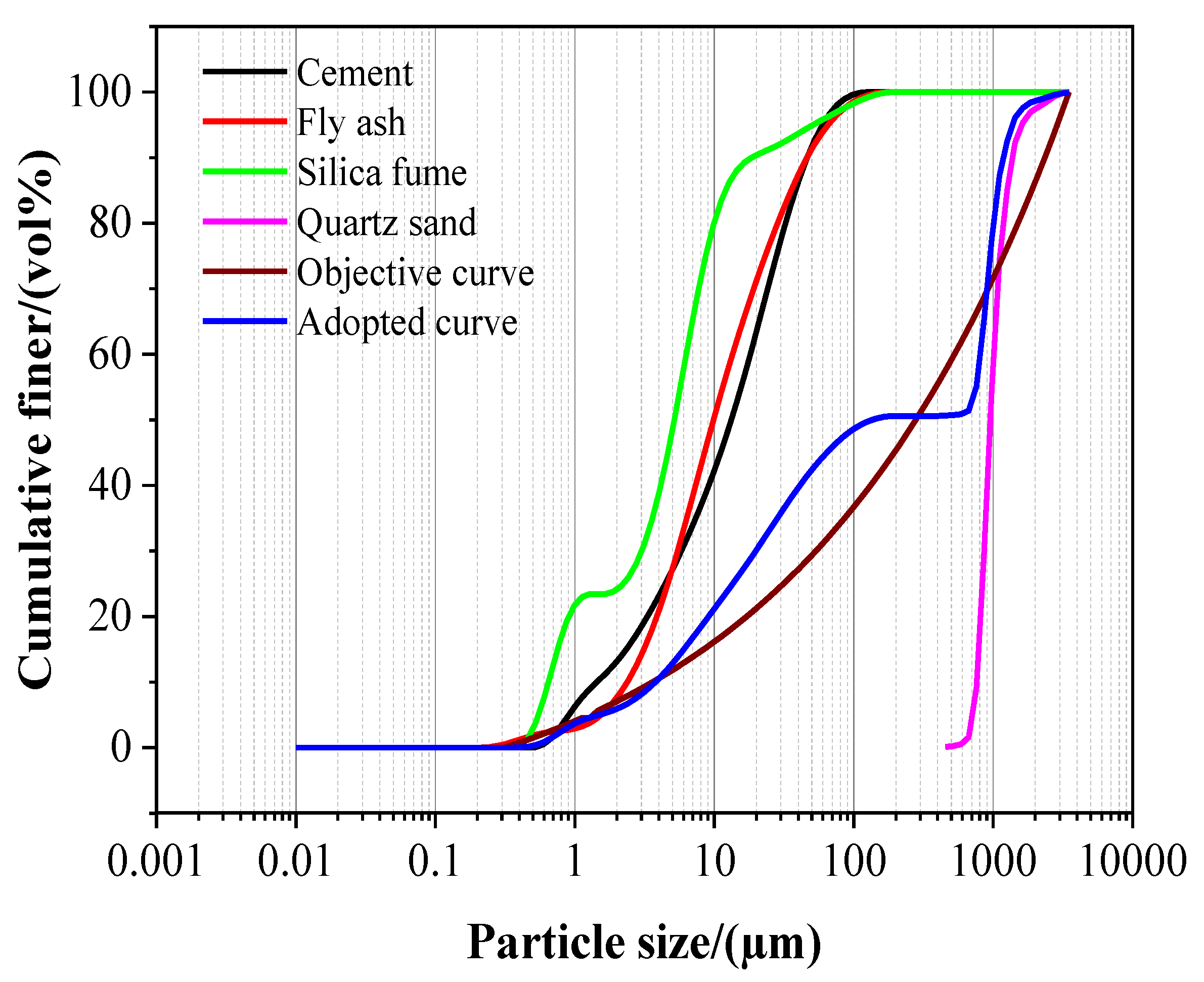

2.2. Mix Design of UHPC

2.3. Specimen Preparation and Curing

2.4. Experimental Methods

3. Results and Discussion

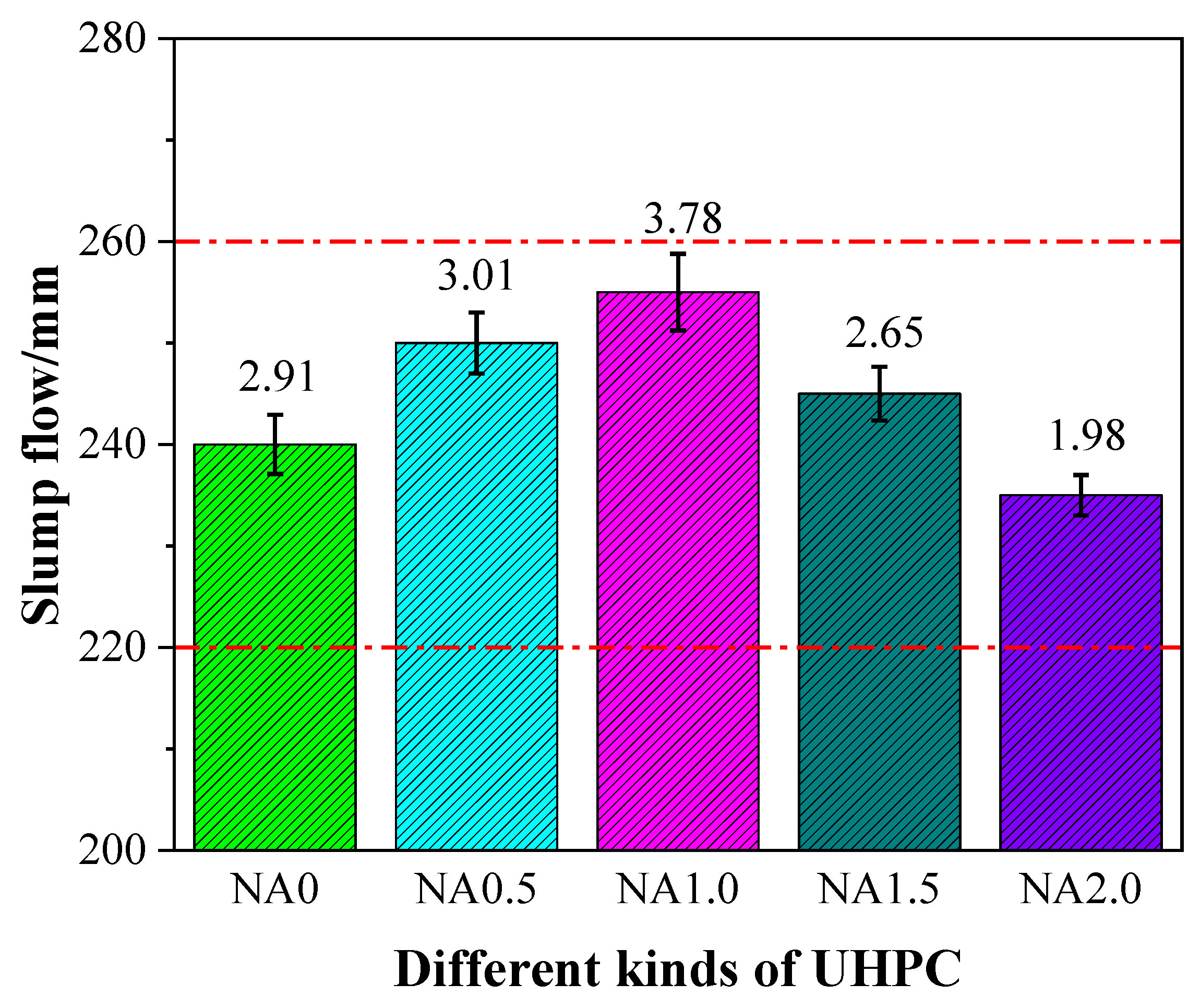

3.1. Fluidity

3.2. Flexural Strength

3.3. Compressive Strength

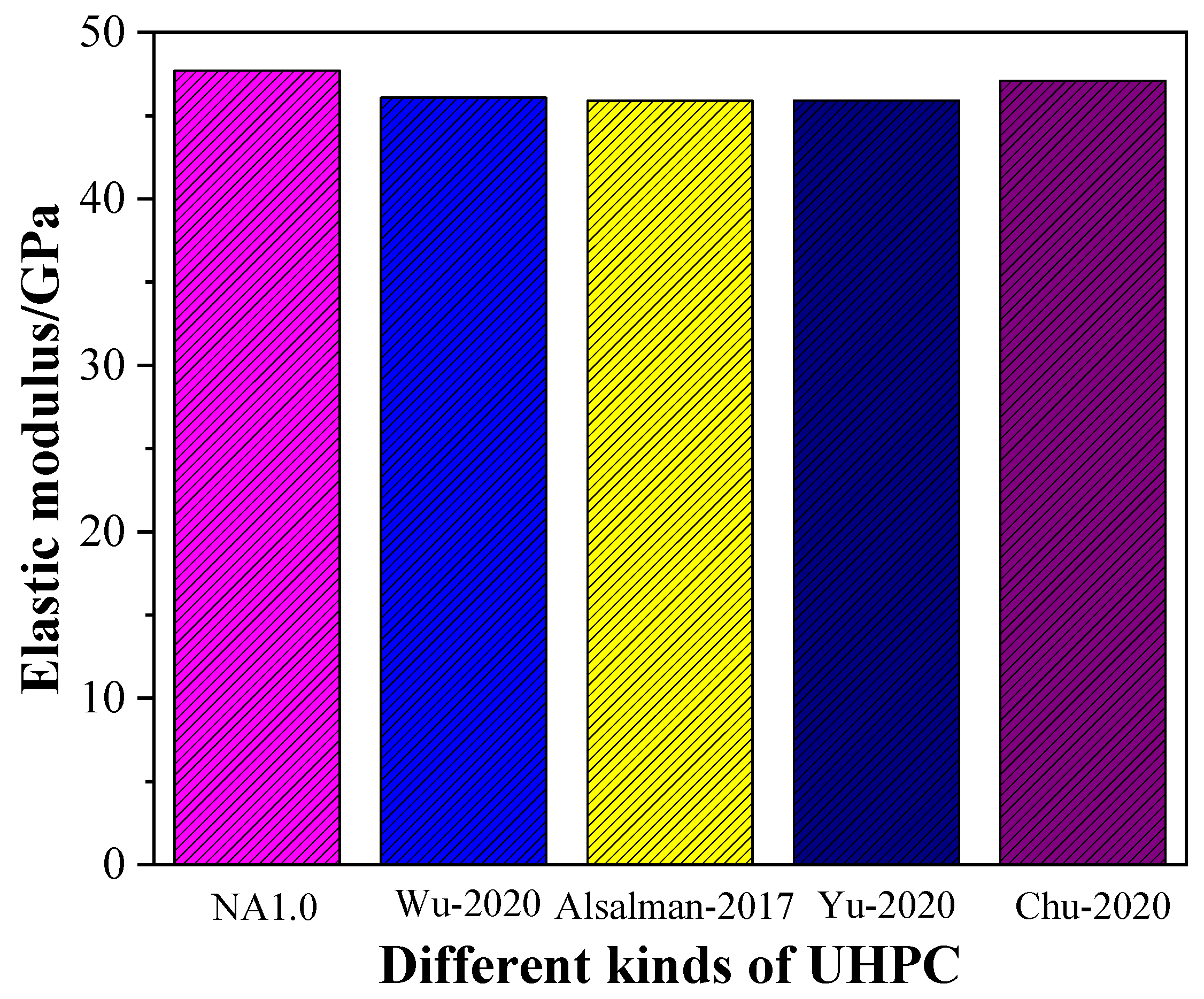

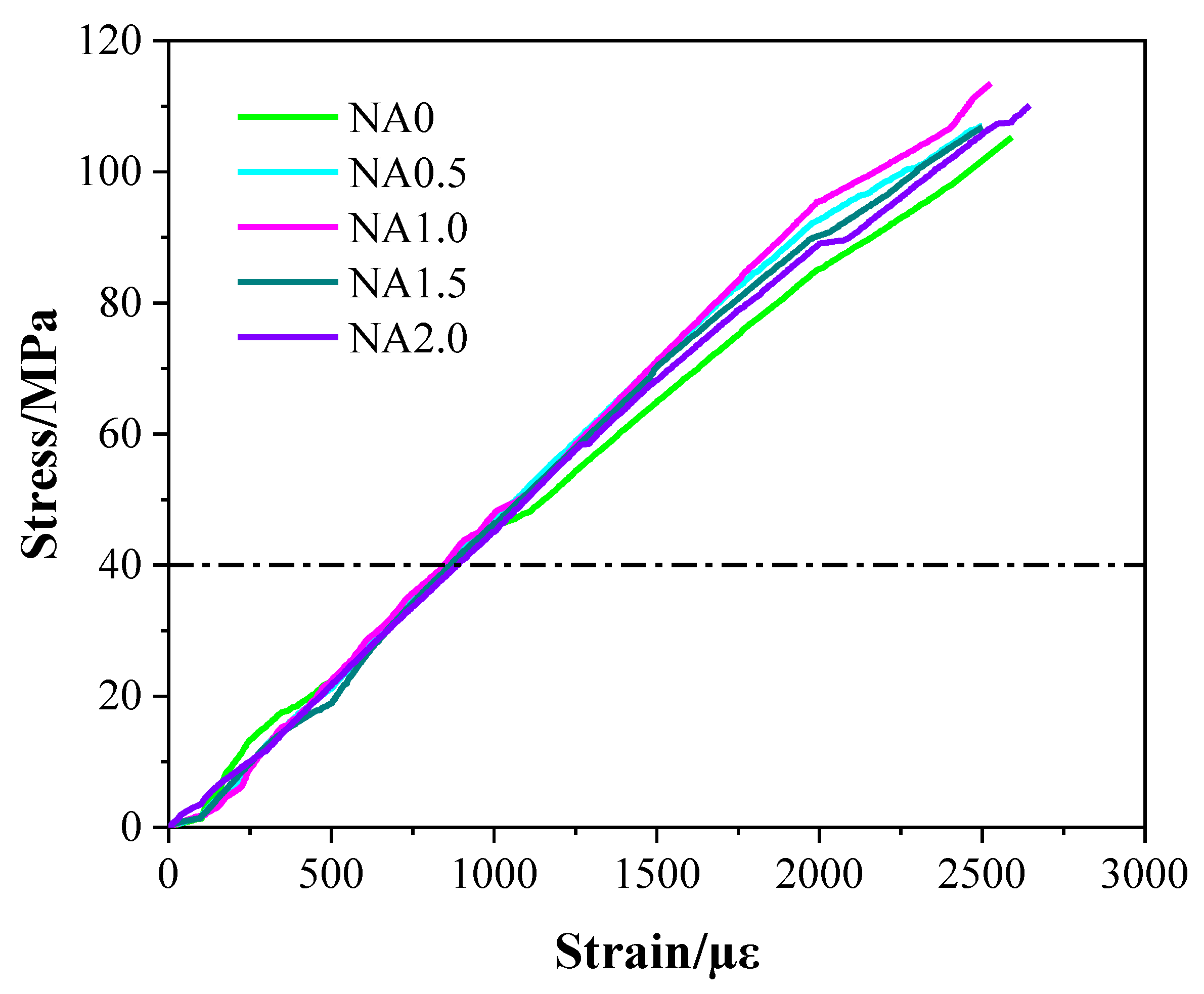

3.4. Elastic Modulus

3.5. Ultrasonic Pulse Velocity

3.6. Relationship between Compressive Strength and Elastic Modulus

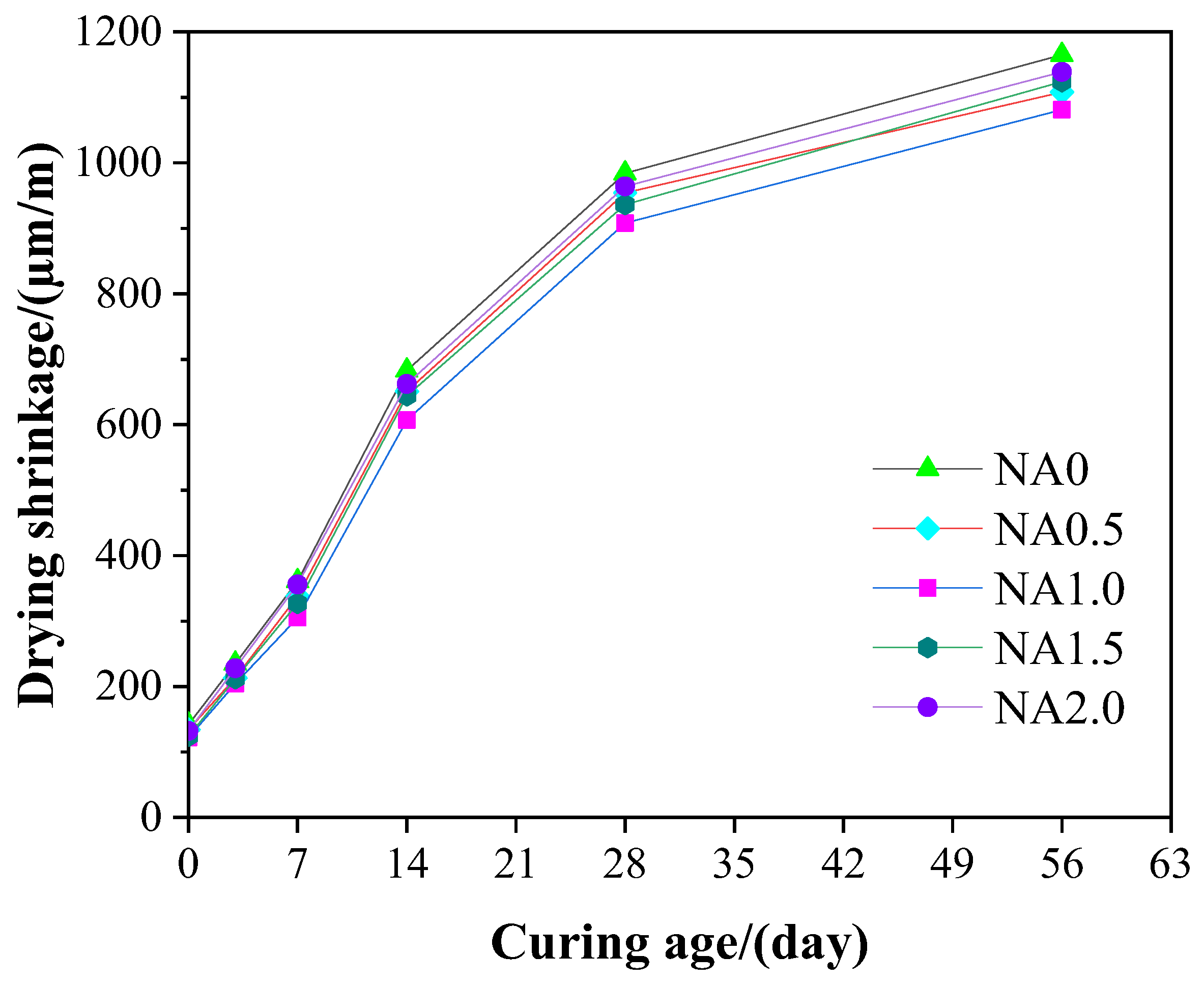

3.7. Drying Shrinkage

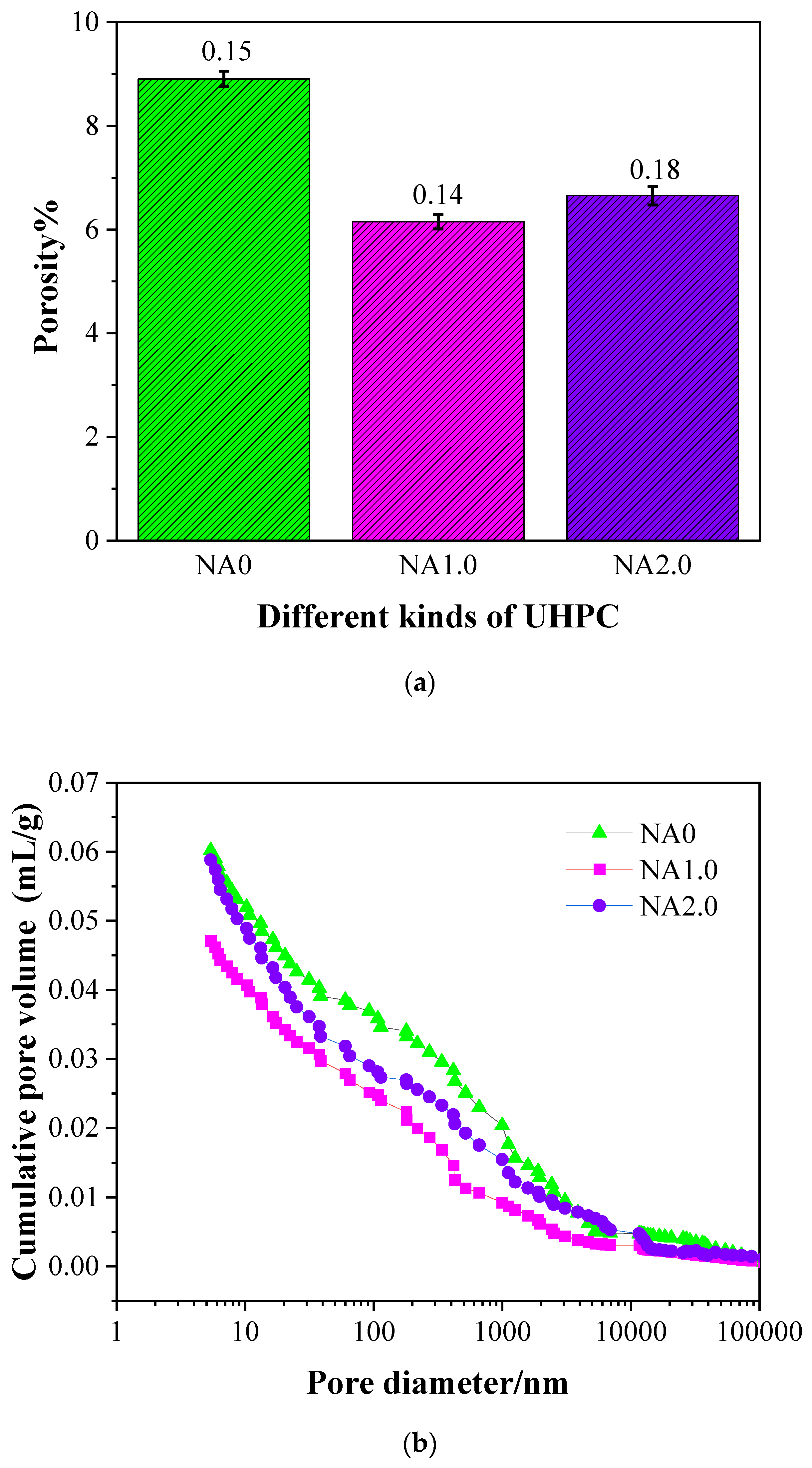

3.8. Porosity and Pore Size Distribution

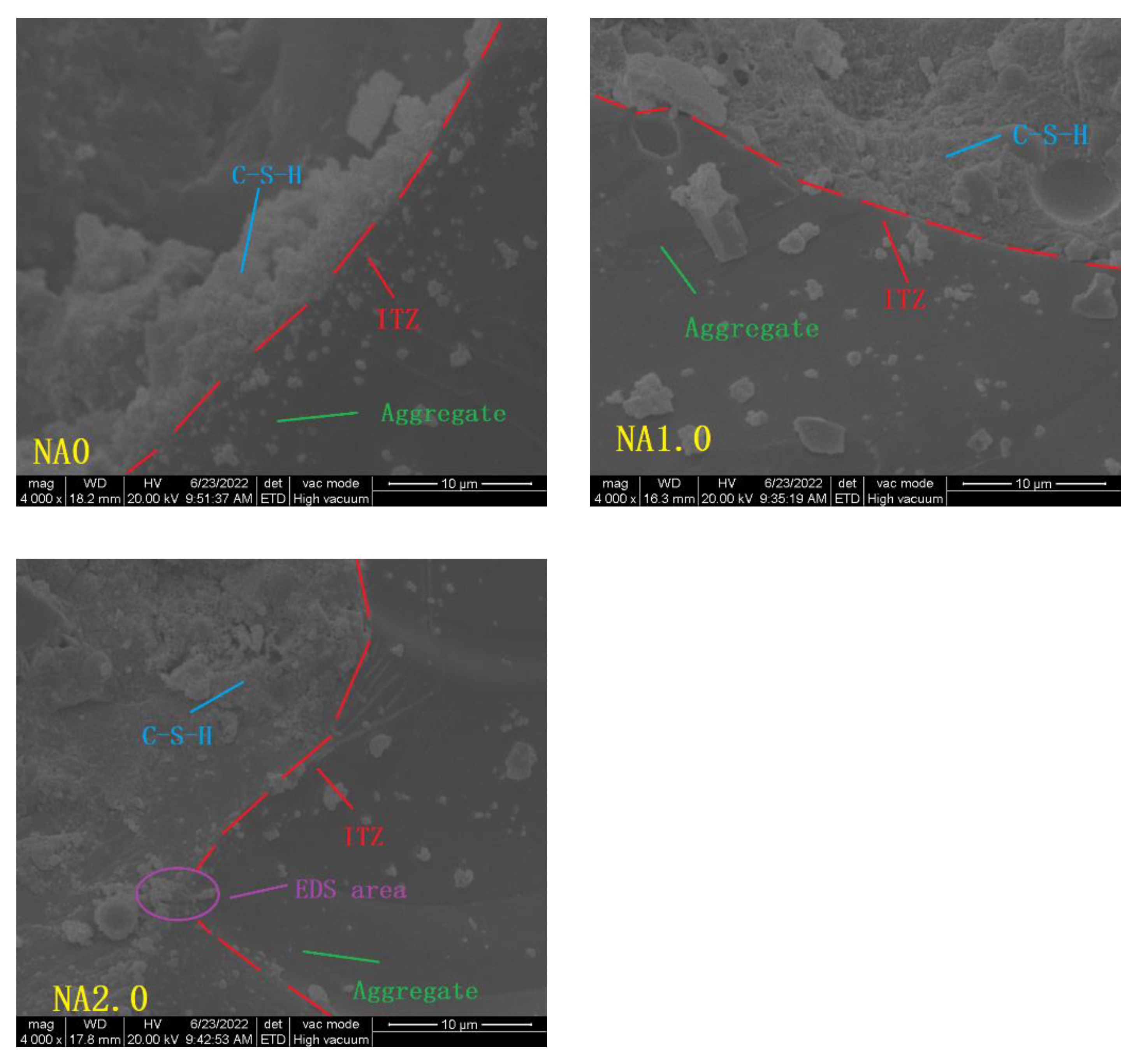

3.9. Microstructure

4. Conclusions

- The UHPC specimens made herein had a slump flow ranging from 235 to 255 mm. The incorporation of NA in a proper amount could improve the fluidity of UHPC.

- The flexural strength, compressive strength, and elastic modulus of UHPC were 22.84–24.86 MPa, 131.25–152.06 MPa, and 43.03–47.71 GPa, respectively. The mechanical properties of UHPC could be improved by NA.

- The UPV propagated in UHPC ranged from 4.47 to 4.69 km/s. The addition of NA led to an increase of 1.3%-4.9% in the UPV of UHPC.

- The porosity of UHPC was between 6.15% and 8.91%. The addition of NA had a prohibiting impact on the threshold pore diameter and porosity of UHPC.

- The incorporation of NA led to a decline of 2.9–11.76% in the dry shrinkage of UHPC.

- The optimal amount of NA in UHPC was 1.0% whether the explained variable used to examine NA was workability, mechanical properties, microstructure, or durability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chu, H.Y.; Gao, L.; Qian, J.J.; Jiang, J.Y.; Wang, D.Q. Mechanical properties and microstructure of ultra-high-performance concrete with high elastic modulus. Constr. Build. Mater. 2022, 335, 127385. [Google Scholar] [CrossRef]

- Chu, H.; Zhang, Y.; Wang, F.; Feng, T.; Wang, L.; Wang, D. Effect of Graphene Oxide on Mechanical Properties and Durability of Ultra-High-Performance Concrete Prepared from Recycled Sand. Nanomaterials 2020, 10, 1718. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.J.; Wu, Z.M.; Xiao, J.F.; Wang, D.H.; Huang, Z.Y.; Fang, Z. A review on ultra-high-performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Wang, D.H.; Shi, C.J.; Wu, Z.M.; Xiao, J.F.; Huang, Z.Y.; Fang, Z. A review on ultra-high-performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Hannawi, K.; Bian, H.; Prince-Agbodjan, W.; Raghavan, B. Effect of different types of fibers on the microstructure and the mechanical behavior of Ultra-High-Performance Fiber-Reinforced Concretes. Compos. Part B Eng. 2016, 86, 214–220. [Google Scholar] [CrossRef]

- Piasta, W.; Góra, J.; Budzynski, W. Stress-strain relationships and elastic modulus of rocks and of ordinary and high performance concretes. Constr. Build. Mater. 2017, 153, 728–739. [Google Scholar] [CrossRef]

- Wu, F.H.; Xu, L.H.; Chi, Y.; Zeng, Y.Q.; Deng, F.Q.; Chen, Q. Compressive and flexural properties of ultra-high-performance fiber-reinforced cementitious composite: The effect of coarse aggregate. Compos. Struct. 2020, 236, 11810. [Google Scholar] [CrossRef]

- Ouyang, X.; Shi, C.J.; Wu, Z.M. Experimental investigation and prediction of elastic modulus of ultra-high-performance concrete (UHPC) based on its composition. Cem. Concr. Res. 2020, 138, 106241. [Google Scholar] [CrossRef]

- Jindal, B.B.; Sharma, R. The effect of nanomaterials on properties of geopolymers derived from industrial by-products: A state-of-the-art review. Constr. Build. Mater. 2020, 252, 119028. [Google Scholar] [CrossRef]

- Norhasri, M.S.M.; Hamidah, M.S.; Fadzil, A.M. Applications of using nano material in concrete: A review. Constr. Build. Mater. 2017, 133, 91–97. [Google Scholar] [CrossRef]

- Zhang, A.; Ge, Y.; Yang, W.C.; Cai, X.P.; Du, Y.B. Comparative study on the effects of nano-SiO2, nano-Fe2O3 and nano-NiO on hydration and microscopic properties of white cement. Constr. Build. Mater. 2019, 218, 116767. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Sui, S.Y.; Wang, L.G.; Feng, T.T.; Gao, Y.; Mu, S.; Tang, L.P.; Jiang, J.Y. Improving the chloride binding capacity of cement paste by adding nano-Al2O3: The cases of blended cement pastes. Constr. Build. Mater. 2020, 232, 177219. [Google Scholar] [CrossRef]

- Chu, H.; Qin, J.; Gao, L.; Jiang, J.; Wang, F.; Wang, D. Effects of graphene oxide on mechanical properties and microstructure of ultra-high-performance lightweight concrete. J. Sustain. Cem. Based Mater. 2022, 11, 2104757. [Google Scholar] [CrossRef]

- Peng, Y.M.; Ma, K.L.; Long, G.C.; Xie, Y.J. Influence of Nano-SiO2, Nano-CaCO3 and Nano-Al2O3 on Rheological Properties of Cement–Fly Ash Paste. Materials 2019, 12, 2598. [Google Scholar] [CrossRef]

- Xu, Z.H.; Gao, J.M.; Zhou, Z.H.; Zhao, Y.S.; Chen, X.M. Hydration and microstructure of tricalcium silicate incorporating nano-TiO2. Constr. Build. Mater. 2020, 262, 120805. [Google Scholar] [CrossRef]

- Shao, Q.Y.; Zheng, K.R.; Zhou, X.J.; Zhou, J.; Zeng, X.H. Enhancement of nano-alumina on long-term strength of Portland cement and the relation to its influences on compositional and microstructural aspects. Cem. Concr. Compos. 2019, 98, 39–48. [Google Scholar] [CrossRef]

- Feng, H.; Shen, S.H.; Pang, Y.Y.; Gao, D.Y.; Wang, Z.Y.; Sheikh, M.N. Mechanical properties of fiber and nano-Al2O3 reinforced magnesium phosphate cement composite. Constr. Build. Mater. 2021, 270, 121861. [Google Scholar] [CrossRef]

- Heikal, M.; Ismail, M.N.; Ibrahim, N.S. Physico-mechanical, microstructure characteristics and fire resistance of cement pastes containing Al2O3 nano-particles. Constr. Build. Mater. 2015, 91, 232–242. [Google Scholar] [CrossRef]

- Bahareh, M.; Soheil, J.; Kirk, V.; Hania, M.; Haleh, R.; Bijan, S. Fresh, Mechanical, and Durability Properties of Self-Compacting Mortar Incorporating Alumina Nanoparticles and Rice Husk Ash. Materials 2021, 14, 6778. [Google Scholar]

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): An experimental study. Constr. Build. Mater. 2020, 245, 118444. [Google Scholar] [CrossRef]

- Meddah, M.S.; Praveenkumar, T.R.; Vijayalakshmi, M.M.; Manigandan, S.; Arunachalam, R. Mechanical and microstructural characterization of rice husk ash and Al2O3 nanoparticles modified cement concrete. Constr. Build. Mater. 2020, 255, 119358. [Google Scholar] [CrossRef]

- Popova, A.I.; Lushchikb, A.; Shabloninb, E.; Vasil’chenkob, E.; Kotomina, E.A.; Moskinaa, A.M.; Kuzovkova, V.N. Comparison of the F-type center thermal annealing in heavy-ion and neutron irradiated Al2O3 single crystals. Nucl. Instrum. Method Phys. Res. B 2018, 433, 93–97. [Google Scholar] [CrossRef]

- Qi, S.; Popotnikova, N.M.; Ananyev, M.V.; Kuzmin, A.V.; Eremin, V.A.; Pankratov, A.A.; Molchanova, N.G.; Reznitskikh, O.G.; Farlenkov, A.S.; Vovkotrub, E.G.; et al. High-temperature glassy-ceramic sealants SiO2-Al2O3-BaO-MgO and SiO2-Al2O3-ZrO2-CaO-Na2O for solid oxide electrochemical devices. Trans. Nonferrous Met. Soc. China 2016, 26, 2916–2924. [Google Scholar] [CrossRef]

- de Larrard, F. Ultra fine particles for the making of very high strength concretes. Cem. Concr. Res. 1989, 19, 161–172. [Google Scholar] [CrossRef]

- de Larrard, F.; Sedran, T. Mixture-proportioning of high-performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Fuller, W.B.; Thompson, S.E. The laws of proportioning concrete. Trans. Am. Soc. Civ. Eng. 1907, 33, 222–298. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of nano-silica on the hydration and microstructure development of ultra-high performance concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Fan, D.Q.; Yu, R.; Shui, Z.H.; Wu, C.F.; Song, Q.L.; Liu, Z.J.; Sun, Y.; Gao, X.; He, Y.J. A new design approach of steel fibre reinforced ultra-high performance concrete composites: Experiments and modeling. Cem. Concr. Res. 2020, 110, 103597. [Google Scholar] [CrossRef]

- Brouwers, H.J.H.; Radix, H.J. Erratum to “Self-Compacting Concrete: Theoretical and experimental study”. Cem. Concr. Res. 2007, 37, 1376. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.H.; Gao, X.; Xiao, X.G.; Fan, D.Q.; Chen, Z.A.; Cai, J.J.; Li, X.S.; He, R.J. Feasibility analysis of treating recycled rock dust as an environmentally friendly alternative material in ultra-high performance concrete (UHPC). J. Clean. Prod. 2020, 258, 120673. [Google Scholar] [CrossRef]

- Li, P.P.; Yu, Q.L.; Brouwers, H.J.H. Effect of coarse basalt aggregates on the properties of ultra-high-performance concrete (UHPC). Constr. Build. Mater. 2018, 170, 649–659. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Shui, Z.; Song, Q.; Liu, Z.; Bao, M.; Liu, Z.J.; Wu, S. Optimized treatment of recycled construction and demolition waste in developing sustainable ultra-high performance concrete. J. Clean. Prod. 2019, 221, 805–816. [Google Scholar] [CrossRef]

- Karim, R.; Najimi, M.; Shafei, B. Assessment of transport properties, volume stability, and frost resistance of non-proprietary ultra-high-performance concrete. Constr. Build. Mater. 2019, 227, 117031. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions; Springer: Boston, MA, USA, 1994. [Google Scholar]

- Hunger, M. An Integral Design Concept for Ecological Self-Compacting Concrete. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- GB/T 2419; Test Method for Fluidity of Cement Mortar. Standards Press of China: Beijing, China, 2005.

- GB/T 17671; Method of Testing Cements-Determination of Strength. Standards Press of China: Beijing, China, 1999.

- GB/T 50081; Test Methods of Concrete Physical and Mechanical Properties. China Architecture & Building Press: Beijing, China, 2019.

- Zhang, W.H.; Zhang, Z.X.; Liu, P.Y.; Zhang, Y.S.; Zhang, C.X.; She, W. Uniaxial tensile and compressive stress-strain behavior of multi-scale fiber-reinforced ultra-high performance concrete. J. Chin. Ceram. Soc. 2020, 48, 1155–1167. (In Chinese) [Google Scholar]

- CECS 02:2005; Technical Specification for Detecting Strength of Concrete by Ultrasonic-Rebound Combined Method. China Planning Press: Beijing, China, 2005.

- European Project Group. Specification and Guidelines for Self-Compacting Concrete; EFNARC: Hamshire, UK, 2002. [Google Scholar]

- Stefancic, M.; Mladenovic, A.; Bellotto, M.; Jereb, V.; Zavrsnik, L. Particle packing and rheology of cement pastes at different replacement levels of cement by α-Al2O3 submicron particles. Constr. Build. Mater. 2017, 139, 256–266. [Google Scholar] [CrossRef]

- Mostafa, S.; Shaira, M.; Aydin, B. A Comparative Study on the Influence of Nano and Micro Particles on the Workability and Mechanical Properties of Mortar Supplemented with Fly Ash. Buildings 2021, 11, 60. [Google Scholar]

- Mo, Z.Y.; Wang, R.; Gao, X.J. Hydration and mechanical properties of UHPC matrix containing limestone and different levels of metakaolin. Constr. Build. Mater. 2020, 256, 119454. [Google Scholar] [CrossRef]

- Rad, T.A.; Tanzadeh, J.; Pourdada, A. Laboratory evaluation of self-compacting fiber-reinforced concrete modified with hybrid of nanomaterials. Constr. Build. Mater. 2020, 232, 117211. [Google Scholar]

- Li, W.G.; Huang, Z.Y.; Cao, F.L.; Sun, Z.H.; Shah, S.P. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Yu, L.Z.; Wu, R.X. Using graphene oxide to improve the properties of ultra-high-performance concrete with fine recycled aggregate. Constr. Build. Mater. 2020, 259, 120657. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Geng, Y.; Wang, Q.; Zhang, S. Prediction of the elastic modulus and the splitting tensile strength of concrete incorporating both fine and coarse recycled aggregate. Constr. Build. Mater. 2019, 215, 332–346. [Google Scholar] [CrossRef]

- Alsalman, A.; Dang, C.N.; Prinz, G.S.; Hale, W.M. Evaluation of elastic modulus of ultra-high-performance concrete. Constr. Build. Mater. 2017, 153, 918–928. [Google Scholar] [CrossRef]

- Chu, H.Y.; Shi, W.F.; Wang, Q.; Gao, L.; Wang, D.Q. Feasibility of manufacturing self-compacting mortar with high elastic modulus by Al2O3 micro powder: A preliminary study. Constr. Build. Mater. 2022, 340, 127736. [Google Scholar] [CrossRef]

- Sanchayan, S.; Foster, S.J. High temperature behaviour of hybrid steel-PVA fibre reinforced reactive powder concrete. Mater. Struct. 2016, 49, 769–782. [Google Scholar] [CrossRef]

- Hoang, A.L.; Fehling, E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra-high-performance concrete. Constr. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Jurowski, K.; Grzeszczyk, S. Influence of selected factors on the relationship between the dynamic elastic modulus and compressive strength of concrete. Materials 2018, 11, 477. [Google Scholar] [CrossRef]

- Lozano-Lunar, A.; da Silva, P.R.; de Brito, J.; Alvarez, J.I.; Fernández, J.M.; Jiménez, J.R. Performance and durability properties of self-compacting mortars withelectric arc furnace dust as filler. J. Clean. Prod. 2019, 219, 818–832. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jimenez, J.R.; Ayuso, J.; Fernandez, J.M.; de Brito, J. Maximum feasible use of recycled sand from construction and demolition waste for eco-mortar production-part-I: Ceramic masonry waste. J. Clean. Prod. 2015, 87, 692–706. [Google Scholar] [CrossRef]

- Das, B.B.; Kondraivendhan, B. Implication of pore size distribution parameters on compressive strength, permeability and hydraulic diffusivity of concrete. Constr. Build. Mater. 2012, 28, 382–386. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Partial substitution of silica fume with fine glass powder in UHPC: Filling the micro gap. Constr. Build. Mater. 2017, 139, 374–383. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Effect of graphite nanoplatelets and carbon nanofibers on rheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC. Cem. Concr. Res. 2018, 105, 64–71. [Google Scholar] [CrossRef]

| Chemical Composition | Cement | Fly Ash | Silica Fume | Quartz Sand |

|---|---|---|---|---|

| CaO | 56.214 | 4.656 | 0.895 | 0.036 |

| SiO2 | 23.839 | 54.708 | 97.515 | 96.469 |

| Al2O3 | 8.155 | 35.081 | 0.736 | 2.520 |

| Fe2O3 | 3.600 | 4.429 | 0.188 | 0.316 |

| MgO | 4.252 | 0.235 | 0.238 | 0.235 |

| SO3 | 3.317 | 0.65 | 0.057 | - |

| K2O | 0.446 | 0.112 | 0.213 | 0.363 |

| Na2O | 0.177 | 0.129 | 0.158 | 0.061 |

| Specific gravity (kg/m3) | 3050 | 2300 | 2150 | 2650 |

| Specific surface (m2/kg) | 434.2 | 283.9 | 1324 | - |

| Mixture | NA0 | NA0.5 | NA1.0 | NA1.5 | NA2.0 |

|---|---|---|---|---|---|

| Cement | 649.65 | 646.4 | 643.15 | 639.90 | 636.66 |

| Fly ash | 299 | 299 | 299 | 299 | 299 |

| Silica fume | 120.4 | 120.4 | 120.4 | 120.4 | 120.4 |

| NA | 0 | 3.25 | 6.5 | 9.75 | 12.99 |

| Quartz sand | 1062.65 | 1062.65 | 1062.65 | 1062.65 | 1062.65 |

| Water | 200.0 | 200.0 | 200.0 | 200.0 | 200.0 |

| Steel fiber | 156.8 | 156.8 | 156.8 | 156.8 | 156.8 |

| Water-reducing agent | 10.69 | 10.69 | 10.69 | 10.69 | 10.69 |

| Mixture | NA0 | NA1.0 | NA2.0 |

|---|---|---|---|

| Macro-pores | 40.48 | 32.43 | 37.76 |

| Capillary pores | 51.19 | 58.11 | 53.81 |

| Gel micro-pores | 8.33 | 9.46 | 8.43 |

| Element | Weight % | Atomic % |

|---|---|---|

| O K | 51.29 | 63.98 |

| Al K | 48.71 | 36.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, H.; Wang, Q.; Gao, L.; Jiang, J.; Wang, F. An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study. Materials 2022, 15, 8118. https://doi.org/10.3390/ma15228118

Chu H, Wang Q, Gao L, Jiang J, Wang F. An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study. Materials. 2022; 15(22):8118. https://doi.org/10.3390/ma15228118

Chicago/Turabian StyleChu, Hongyan, Qun Wang, Li Gao, Jinyang Jiang, and Fengjuan Wang. 2022. "An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study" Materials 15, no. 22: 8118. https://doi.org/10.3390/ma15228118

APA StyleChu, H., Wang, Q., Gao, L., Jiang, J., & Wang, F. (2022). An Approach of Producing Ultra-High-Performance Concrete with High Elastic Modulus by Nano-Al2O3: A Preliminary Study. Materials, 15(22), 8118. https://doi.org/10.3390/ma15228118