3.2. VTI Method

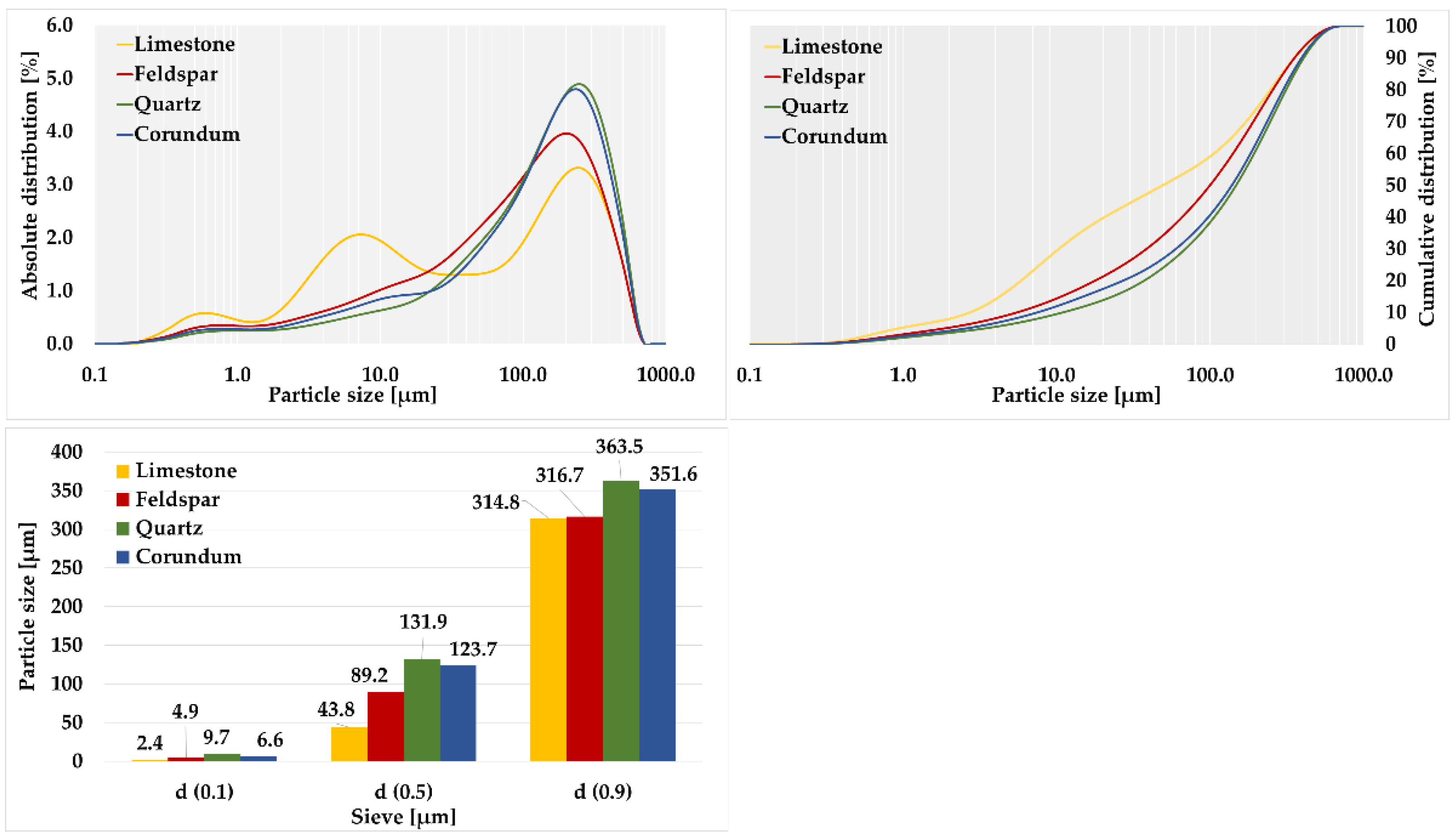

Five sieve analyses were performed for each material and the average over-sieve shares fractions were calculated.

Based on the over-sieve share, see

Table 8, the grinding indexes k

VTI for each material were determined, see

Table 9, as shown in

Figure 3.

For corundum, the highest average value of over-sieve share per 0.090 mm mesh was observed, 85.14%. The lowest average value of over-sieve share fraction was observed for limestone, at only 48.80%. The average value of over-sieve share was 61.38% for feldspar and 69.08% for silica.

Based on the calculated grindability indexes and their average values, the individual materials were grouped into appropriate classes. Corundum was the only representative in the category of not easy to grind due to its average value of kVTI 0.090 = 0.59. The other materials were categorized as medium grindable materials. Limestone had an average grindability index kVTI 0.090 = 1.60, which was close to the threshold for easily grindable materials. For feldspar, an average value of kVTI 0.090 = 1.24 was found, while for quartz, an average value of kVTI 0.090 = 1.03 was calculated.

Subsequently, laser granulometry was performed to calculate grindability indexes for comparison with the results of sieve analysis, see

Table 10 and

Table 11.

A high proportion (39.68%) of grains below 0.020 mm was observed in limestone. Quartz had the lowest proportion of 13.89% in this area. For corundum, the content of grains below 0.020 mm was 17.42%, while for feldspar, the value was determined to be 21.29%.

The over-sieve shares fractions that were used to calculate the grindability indexes of each material by laser granulometry were evaluated. For corundum, the highest average over-sieve share per 0.090 mm grid was observed at 86.22%. The lowest observed value of over-sieve share was found for limestone, only 49.72%. The average value of over-sieve share was found to be 62.38% for feldspar and 71.76% for quartz.

According to the calculated grindability indexes, the individual materials were again grouped into the appropriate classes. The classification was identical to the sieve analysis. Corundum was the only representative classified in the category of not easy to grind and the other materials fell into the group of moderately grindable materials.

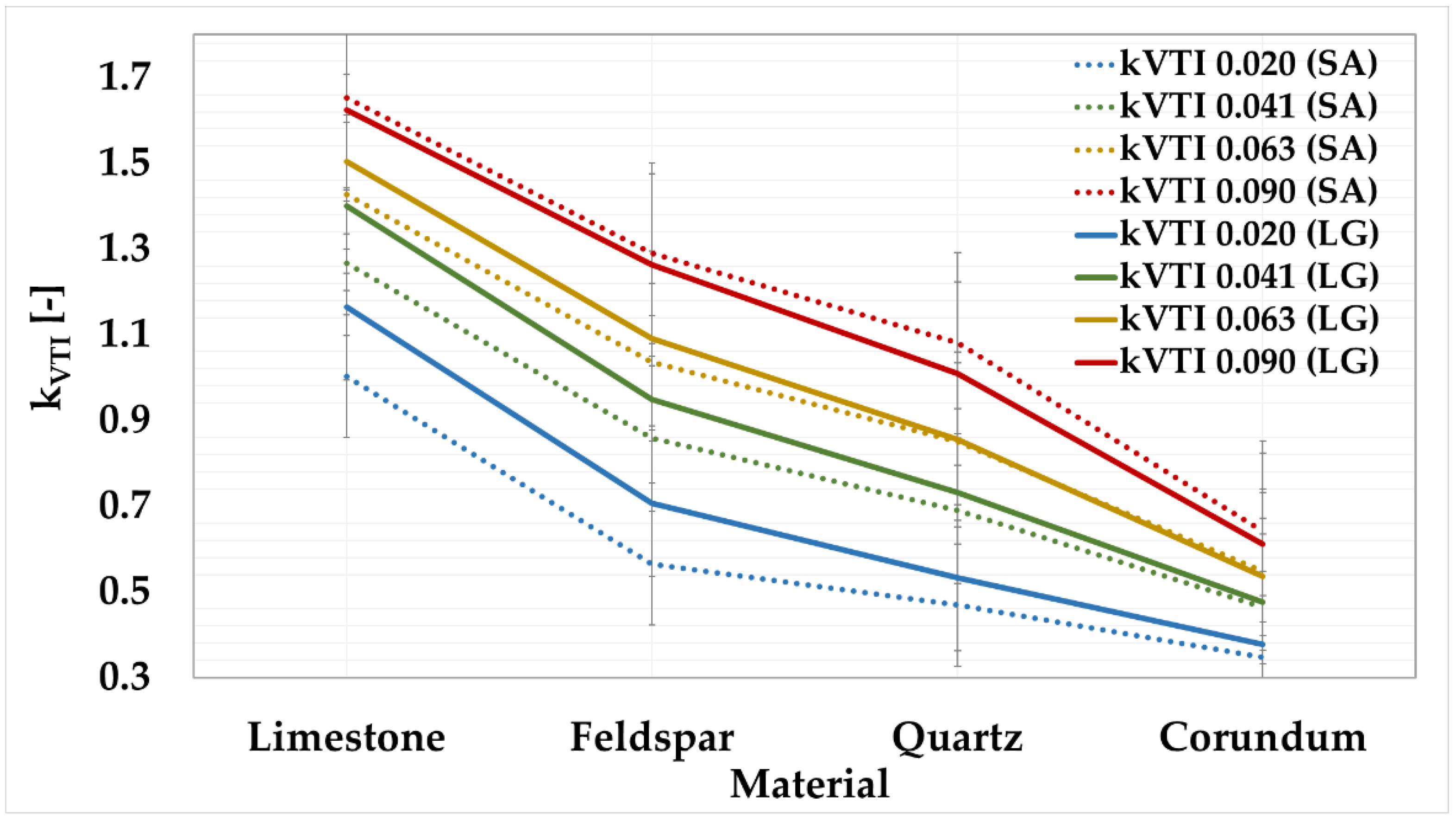

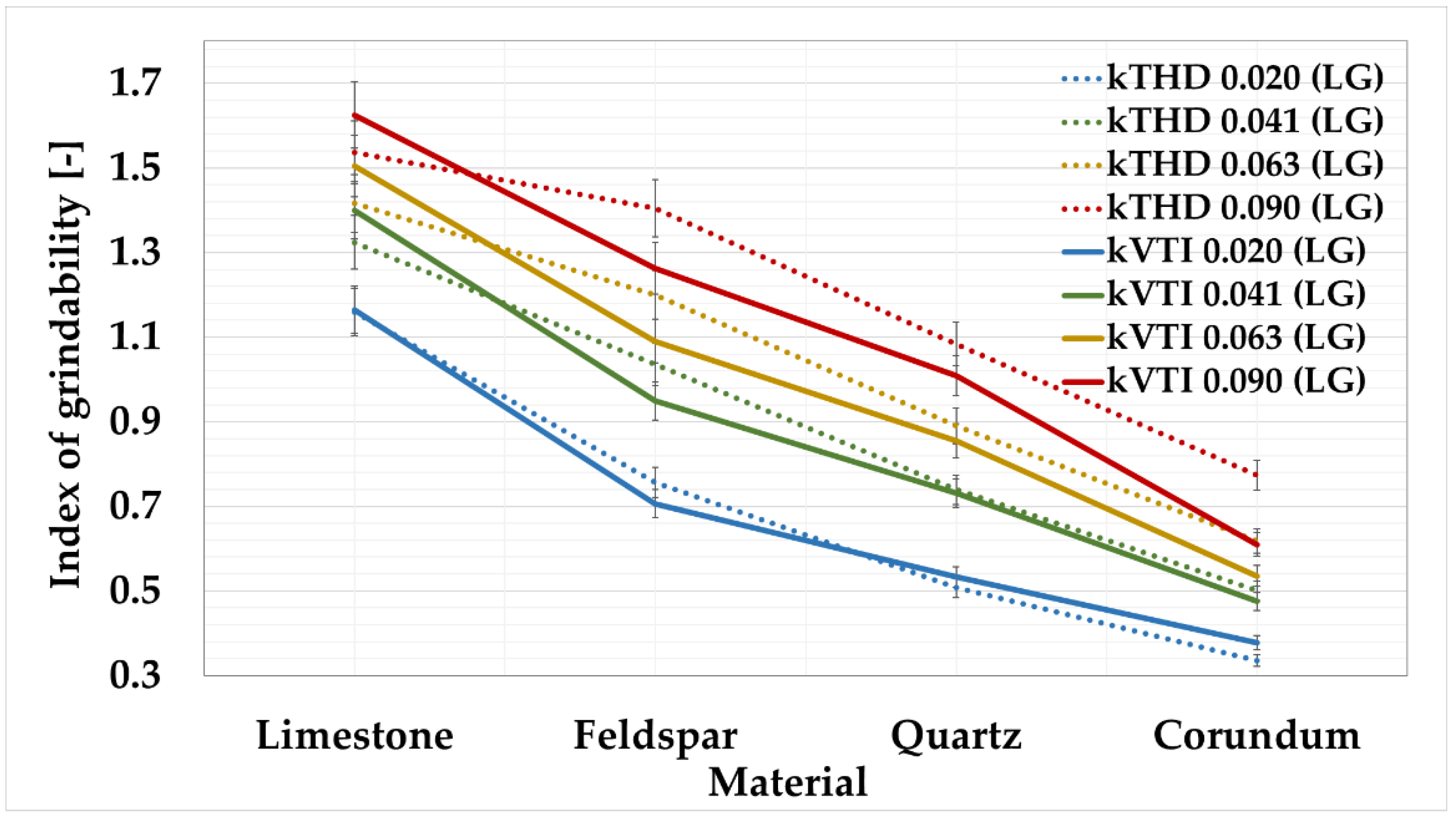

The grindability index values from the sieve analysis were compared with the grindability index values from laser granulometry, as shown in

Figure 4.

The above graph shows that, for a given sieve, the lines of the average values of the grindability indexes determined by sieve analysis and laser granulometry are almost identical. For the 0.041 mm, 0.063 mm, and 0.090 mm sieves, this dependence is evident.

Table 12 shows the calculated absolute deviations between the grindability indexes from sieve analysis and laser granulometry.

For these sieves, the overall absolute deviations were determined to be the lowest. For the 0.041 mm sieve, the deviation was 7%; for the 0.063 mm sieve, the deviation was 4%; and for the 0.090 mm sieve, the deviation was 5%. For the 0.020 mm sieve, the deviation was set at 18%. When evaluating the deviations relative to the materials, the following values were calculated: feldspar showed the highest variation of 12%; the lowest value was obtained for corundum at 5%; the overall deviation of the kVTI (LG) measurement from the kVTI (SA) was determined to be 8%. This value is satisfactory; thus, it can be concluded that laser granulometry can fully replace the time consuming and inaccurate sieve analysis.

3.3. THD Method

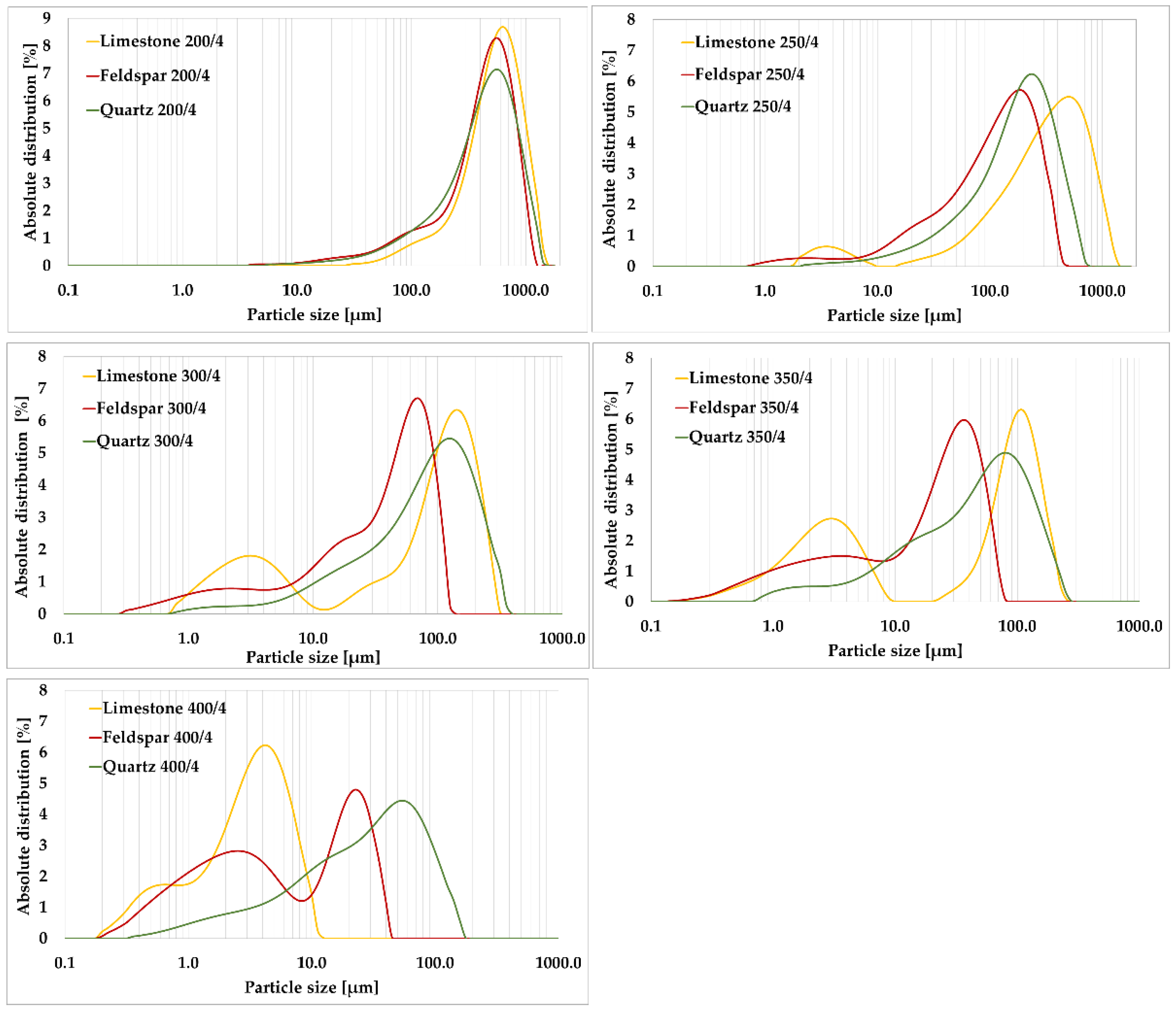

As a first step in the development of the new method, a set of measurements was constructed in which different milling speeds were combined, namely, 200, 250, 300, 350, and 400 rpm. The milling time was set at 4 min. Only limestone, feldspar, and quartz were milled at the above combinations of milling modes, see

Figure 5.

From the laser granulometry plot, the curves achieve a steady increase in the content of crushed particles. There is no over-milling of any material. For the 250 rpm milling of limestone, a higher number of ultrafine fractions in the region of 0.001 to 0.010 mm were already produced. Furthermore, the content of ultrafine particles below 0.010 mm was determined to be almost twice as high in limestone as in feldspar. For limestone and feldspar, the content of particles below 0.020 mm was 6.12% and 8.98%, respectively. The difference was in the representation of individual particle sizes below 0.020 mm. For quartz, the value was determined to be 3.76%. Feldspar showed the highest value of 8.94% for grain size 0.063 to 0.090 mm. The lowest value was determined for limestone at 3.09%. It was verified that the milling time was selected optimally as there was no mineral over-milling and agglomerate formation.

At a milling speed of 300 rpm, at first glance, the graph shows a uniform grain size reduction in feldspar and quartz. For limestone, greater amounts of ultrafine fractions in the region of 0.001 to 0.010 mm were already formed. Furthermore, the content of ultrafine particles below 0.010 mm was almost twice as high in limestone as in feldspar. For limestone and feldspar, the content of particles below 0.020 mm was 27.10% and 28.85%, respectively. These values were almost identical. The difference was in the representation of individual particle sizes below 0.020 mm. For quartz, the value was determined to be 12.99%. At 13.28%, feldspar showed the highest value of grain size content of 0.063 to 0.090 mm. The lowest value was determined for limestone at 5.32%, where there was already a large refinement of particles.

At 350 rpm, the graph showed the formation of agglomerates in limestone, which is undesirable (an area outside the validity of Rittinger’s hypothesis). In feldspar and quartz, agglomerates do not form. Furthermore, the content of ultrafine particles below 0.020 mm was found to be almost twice as high in limestone and feldspar. This value was 42.08% for limestone and 43.66% for feldspar. For quartz, this value was determined to be 23.60%. Quartz had the highest value of grain size at 0.063 to 0.090 mm, at 13.85%. The lowest value was determined for feldspar at 6.99%. Furthermore, it was evident from the graph that the curves could not be correctly compared with each other as they were very heterogeneous. A single quartz showed a uniform increase in the content of crushed particles. For both limestone and feldspar, the reworking to form ultrafine fractions was already evident. Almost the same trend was then observed at a higher grinding speed of 400 rpm.

To determine the optimum milling mode, 250 rpm was selected and the suitability of this was verified on corundum. A set of five measurements was taken for each calibration material, averaged, and plotted on a graph, see

Figure 6.

Subsequently, the over-sieve share percentages were determined, see

Table 13, from which the grindability indexes k

THD were determined.

The

Figure 6 shows that the individual materials were milled uniformly without the formation of agglomerates, i.e., within the validity of Rittinger’s hypothesis.

For corundum, the highest average value of over-sieve shares was observed at 0.090 mm, with a value of 80.44%. The lowest observed mean value of over-sieve shares fraction was observed for limestone, with the value being only 52.71%. The average value of over-sieve shares was found to be 57.27% for feldspar and 68.97% for quartz. When comparing the shares, it was evident that the values of the over-sieve shares for the pure minerals corresponded to the values of relative hardness. It was evaluated that the average values of over-sieve shares for 0.020 mm, 0.041 mm, and 0.063 sieves showed the same trend as for the 0.090 mm sieve. The highest over-sieve values are for corundum and the lowest are for limestone.

From the graph, the following average values of the grindability indexes were found, see

Table 14. The highest values were again achieved by corundum with an average value of k

THD 0.090 = 0.72, which was close to the limiting region for medium-to-non-easily grindable materials in the VTI method. Limestone had the lowest average grindability index value of k

THD 0.090 = 1.49, which was close to the limit for easily grindable materials in the VTI method. For feldspar, an average value of k

THD 0.090 = 1.35 was found, while for quartz, an average value of k

THD 0.090 = 1.03 was calculated.

Another objective in the development of the new method was to look for a possible dependence between the values obtained by the VTI method and the values obtained by the developed THD method. The trend lines for the grindability indexes for the different materials, which were determined by laser granulometry for both methods, were monitored. The values of the basic calibration minerals were used for comparison.

Table 15 shows the absolute values of the measurement deviations. The k

THD (LG) indexes show a higher precision of measurement than the k

VTI (LG) indexes.

The graph and table show that the deviations are not very large. The total deviations in absolute value have been determined. For the 0.041 mm sieve, the deviation was only 5%; for the 0.020 mm sieve, the deviation was 6%; for the 0.063 mm sieve, the deviation was 9%, with the largest deviation recorded for the 0.090 mm sieve at 11%. When evaluating the deviations relative to the materials, the following values were calculated. The lowest deviations were obtained for limestone and quartz, namely, 4%. The highest value was obtained for feldspar, at 14%. The overall deviation of the kVTI (LG) measurement from kTHD (LG) was determined to be 8%. This value is satisfactory; thus, it can be concluded that the laser granulometries correspond with each other.

It will be possible to maintain the limits of the grindability grades for the 0.090 mm sieve, which are processed for the VTI method. For other sieves, the following recalculation must be made, as shown in

Table 16. These limits have been adjusted according to

Table 14 and

Figure 7 to be consistent with the classification of minerals from the original VTI method.

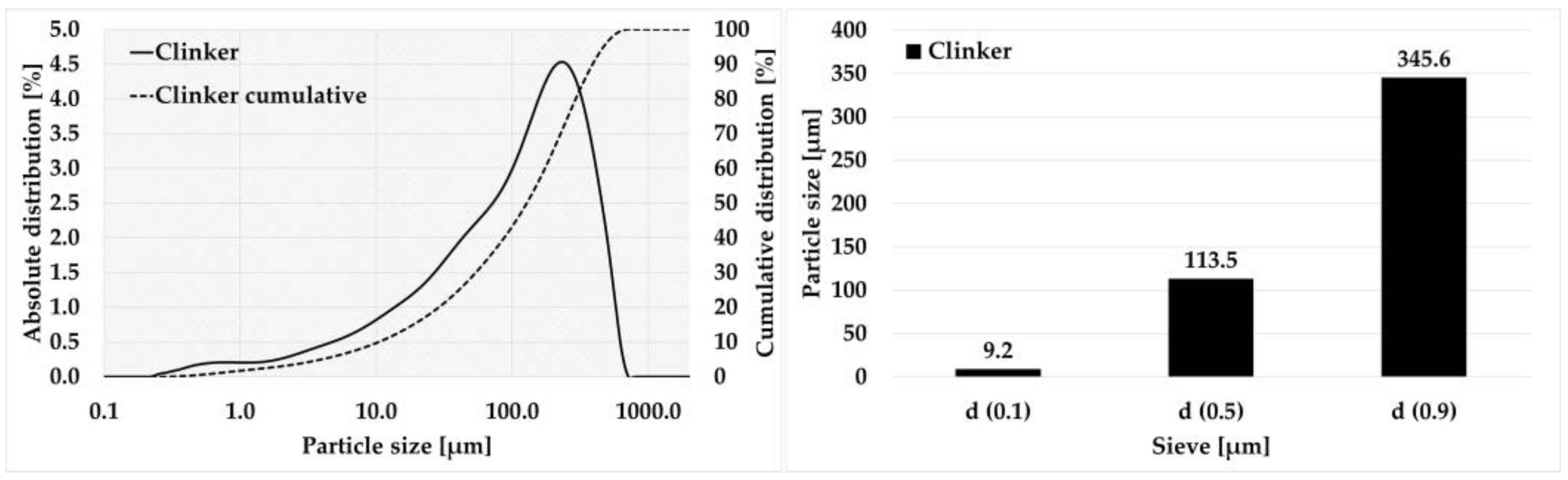

The performance of the newly developed THD method was also verified on Portland clinker. The results of the laser analysis are shown in the

Figure 8.

For clinker, the average value of the over-sieve share on the 0.090 mm grid was found to be 60.49%, see

Table 17. The assumption that the value would be between the values for feldspar and quartz was confirmed. Most likely, this phenomenon was caused by finer milling of clinker, when the grains of the minerals themselves, which are compact, could already be milled. The average value of the grindability index was determined to be k

THD 0.090 = 1.26. Here again, the assumption was that the value would be between that of feldspar and quartz, which was again confirmed.

The deviation between the grindability index calculated from the VTI method and the THD method was only 3%, see

Table 18.

Based on the new classification, as shown in

Table 16, clinker is classified into the group of moderately grindable materials as in the case of the VTI method. It can be concluded that the given grinding conditions for the THD method also work for clinker milling.

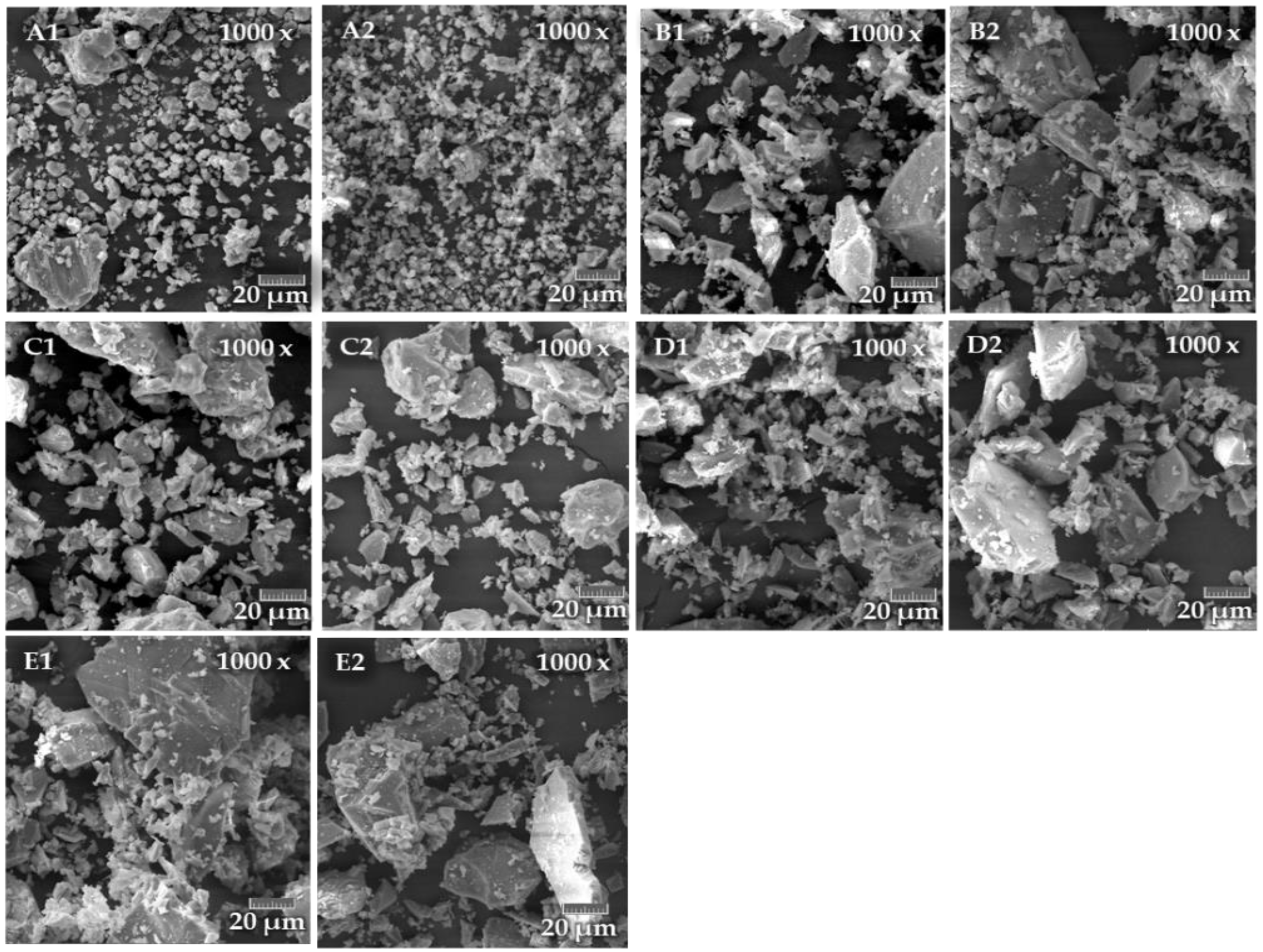

As additional information, particle morphology was performed by SEM. Microscopic images of the individual materials ground by both methods are shown in the following figures at 1000× magnification.

Electron microscope images, see

Figure 9, show a larger volume represented by smaller particles in the newly developed THD method. In the traditional VTI method, coarser particles are represented. This is most evident in limestone.

Furthermore, the grains of corundum and quartz are pointed, which indicates their hardness and brittleness. In clinker, the rounded edges of the grains are noticeable compared to quartz or corundum. In feldspar, the grains are pointed. They have an elongated shape due to feldspar’s preferential cleavage. In limestone, the grains are rounded because it is a soft mineral.