A Comprehensive Study on High-Temperature Oxidation Behavior of Ceramic Molds for Hot Embossing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

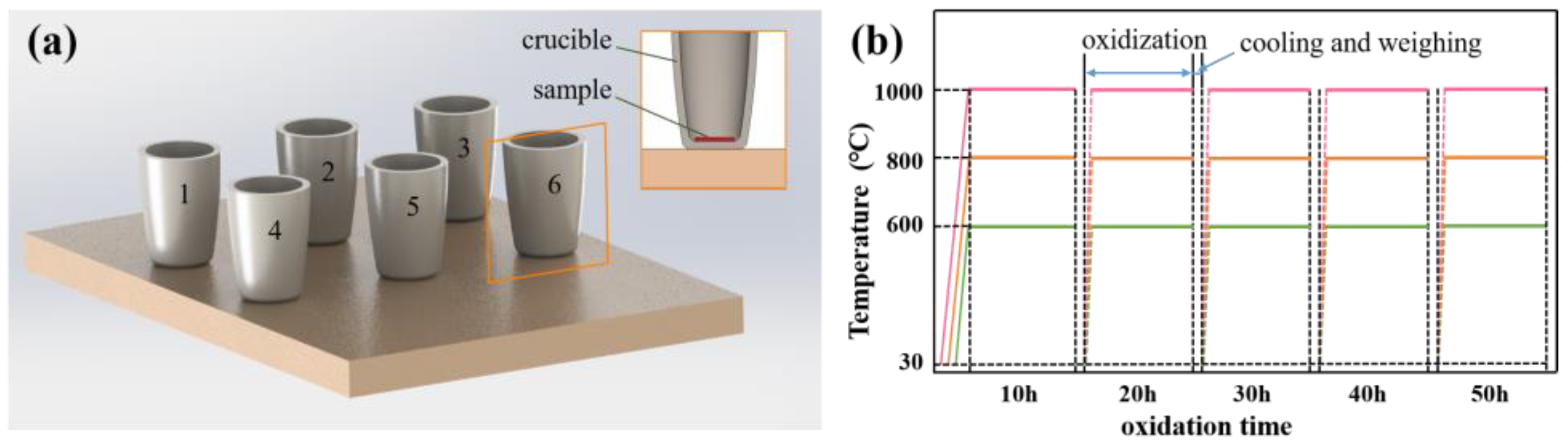

2.2. The Oxidation Experiments

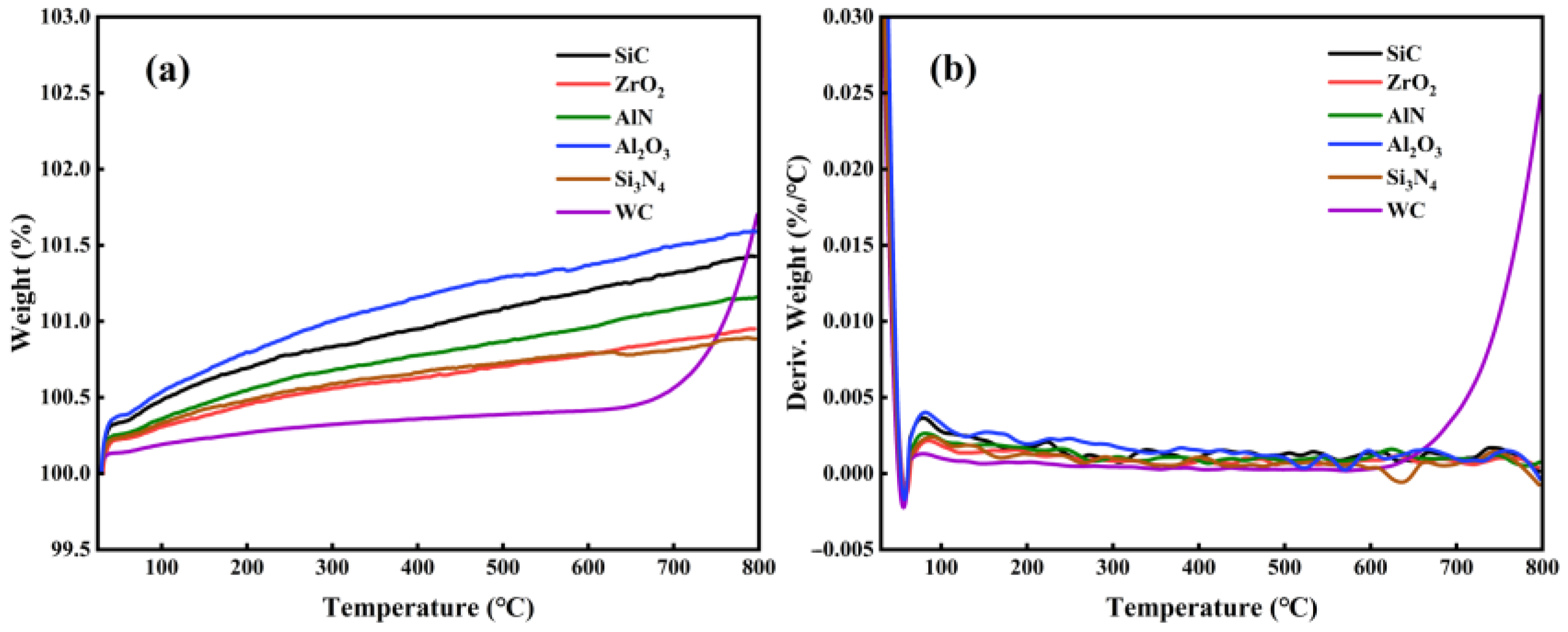

2.3. Thermogravimetric Analysis

2.4. Structural Analysis and Characterization of Oxidation Diffusion

2.5. Measurement of Surface Roughness

2.6. Test of Mechanical Properties

3. Results and Discussion

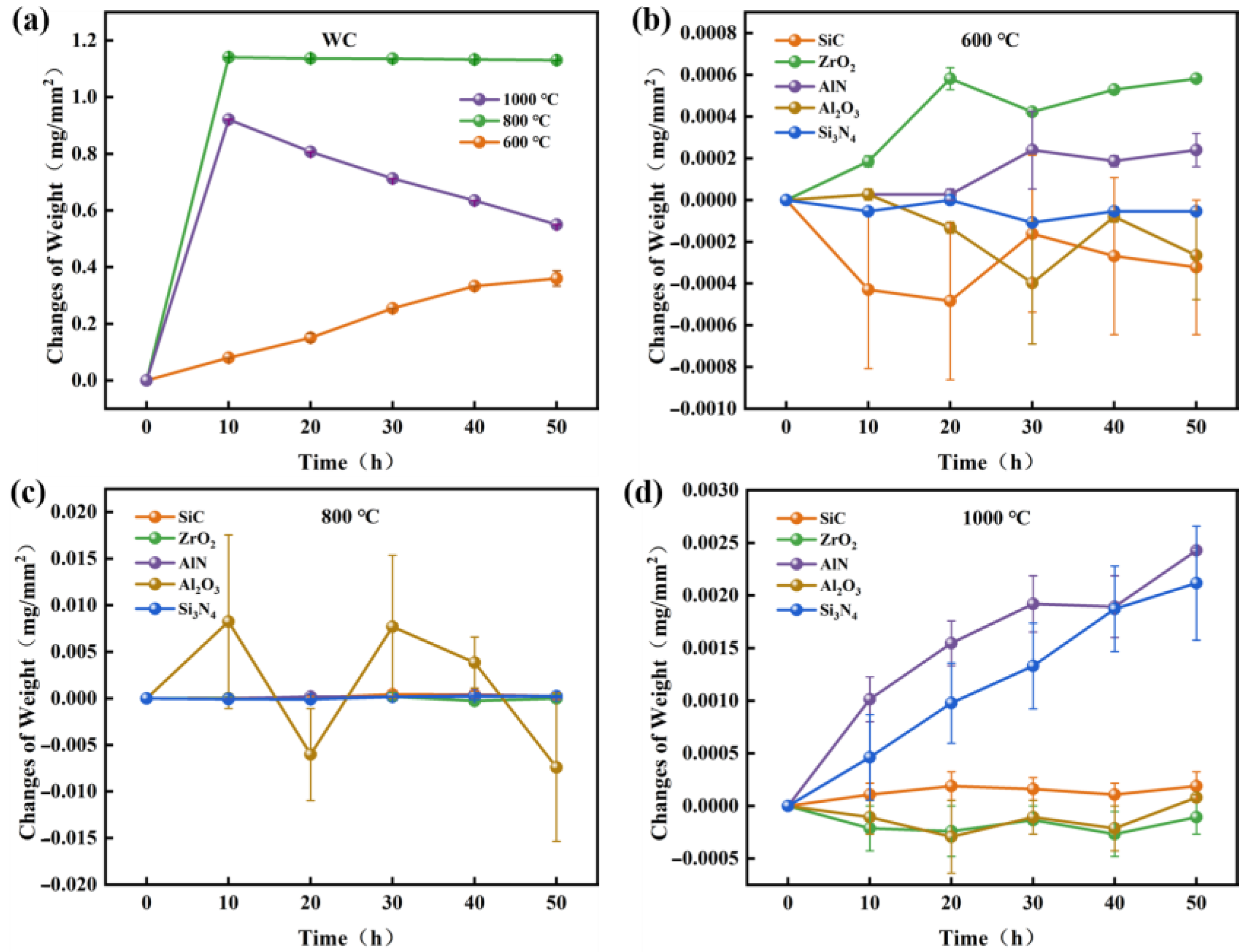

3.1. Weight Changes

3.2. Structural Analysis

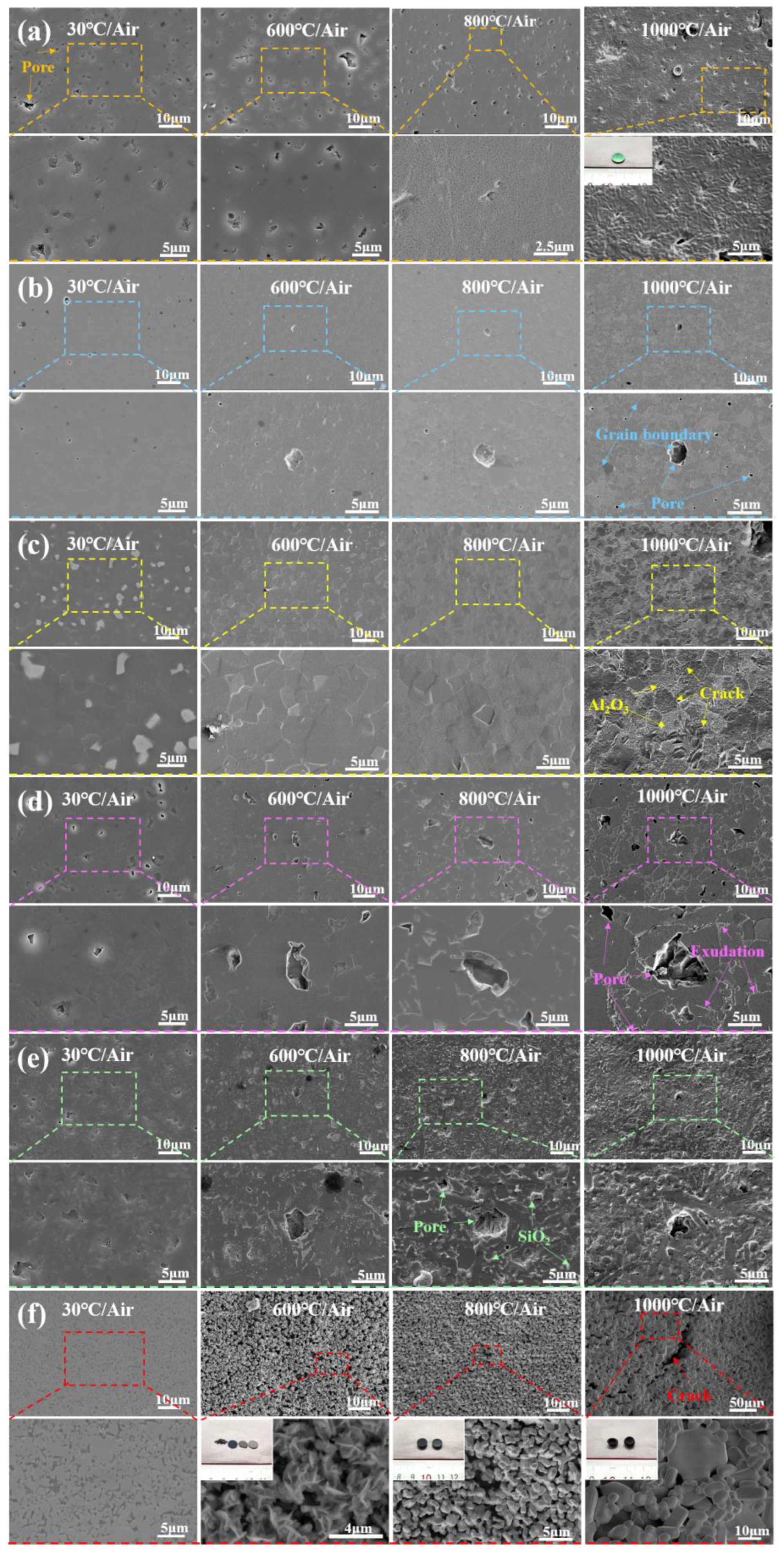

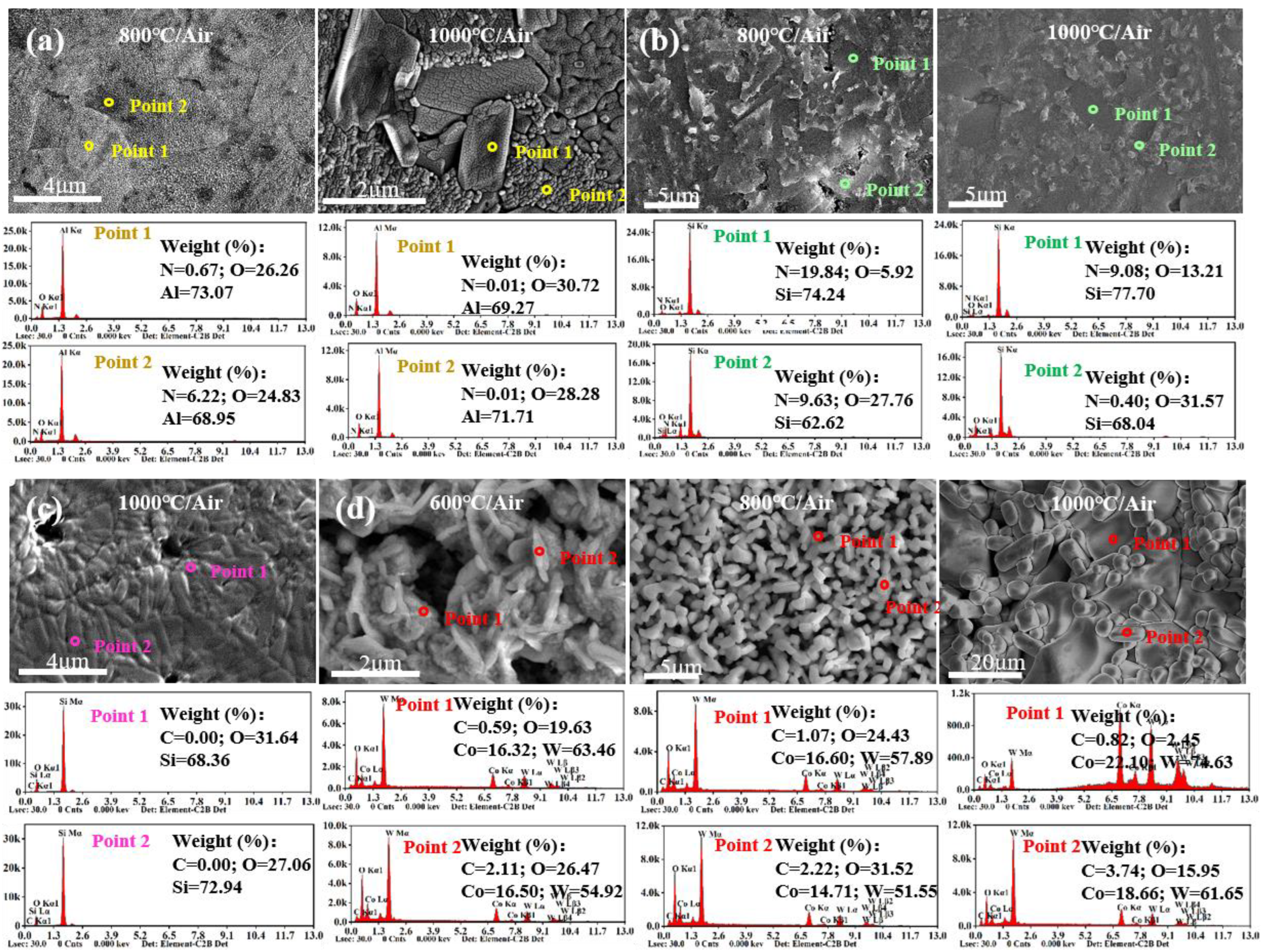

3.3. Surface Morphology

3.4. Oxygen Diffusion Mechanism

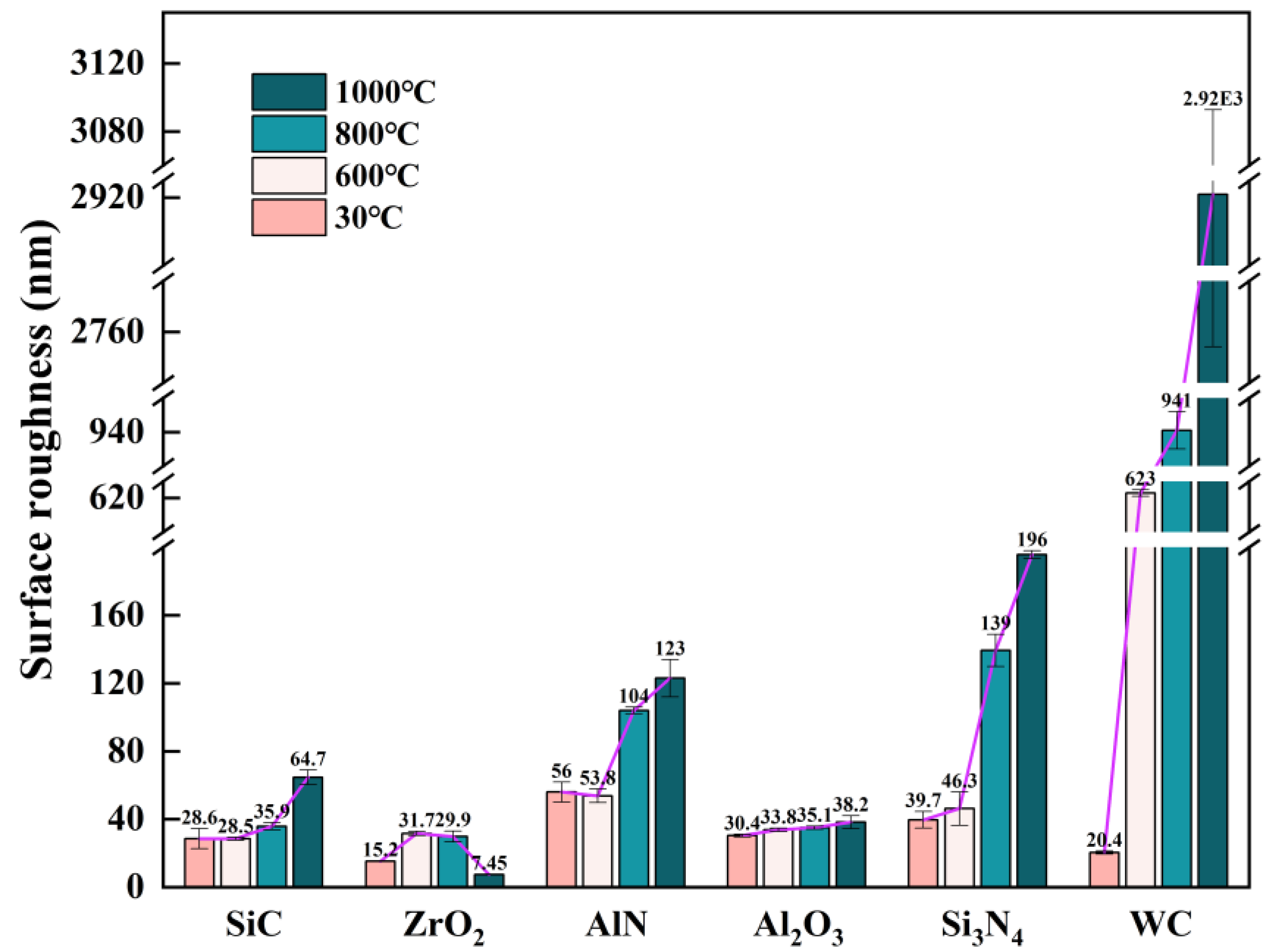

3.5. Surface Roughness

3.6. Mechanical Properties

4. Conclusions

- WC has the most significant weight change at high temperatures. At 1000 °C, the weights of AlN and Si3N4 start to significantly increase, while the weight changes of SiC, ZrO2 and Al2O3 ceramics are still imperceptible.

- Si3N4 and WC ceramics are oxidized at 600 °C, while SiC and AlN ceramics start to oxidize at 800 °C. ZrO2 ceramic shows phase transform into m-ZrO2 at 600 °C, and Al2O3 ceramic generates precipitate at 1000 °C.

- At modest temperatures, oxygen tends to diffuse into the matrix of ceramics. As the temperature rises, oxides are generated on surfaces of nitride and carbide ceramic substrate due to the increase of surface energy and the presence of oxygen molecules.

- The surface roughness of Al2O3 ceramics hardly changes within 1000 °C. The surface roughness of SiC remains stable below 800 °C, but doubles at 1000 °C. The surface roughness of AlN and Si3N4 ceramics are relatively stable below 600 °C, but exceed 100 nm when the oxidation temperature is above 800 °C.

- The surface roughness of ZrO2 ceramic rises sharply to 31.72 nm at 600 °C, due to the precipitation of m-ZrO2 on the surface of ZrO2 ceramic. However, the surface roughness decreases slightly to 29.9 nm at 800 °C, and eventually drops to 7.45 nm at 1000 °C, which is resulted from the transition of m-ZrO2 to t-ZrO2.

- SiC ceramics have the highest hardness and remain stable at elevated temperatures. As the temperature increases, oxidized Si3N4 ceramics have lower hardness, while oxidized AlN ceramics have the opposite trend. The hardness of Al2O3 continues to drop from 600 °C to 800 °C, but rises slightly at 1000 °C.

Author Contributions

Funding

Conflicts of Interest

References

- Deshmukh, S.S.; Goswami, A. Recent developments in hot embossing—A review. Mater. Manuf. Process. 2020, 36, 501–543. [Google Scholar] [CrossRef]

- Heckele, M.; Schomburg, W.K. Review on micro molding of thermoplastic polymers. J. Micromech. Microeng. 2004, 14, R1–R14. [Google Scholar] [CrossRef]

- Pan, C.T.; Wu, T.T.; Chen, M.F.; Chang, Y.C.; Lee, C.J.; Huang, J.C. Hot embossing of micro-lens array on bulk metallic glass. Sens. Actuators A Phys. 2008, 141, 422–431. [Google Scholar] [CrossRef]

- Fu, G.; Tor, S.B.; Loh, N.H.; Hardt, D.E. Micro-hot-embossing of 316L stainless steel micro-structures. Appl. Phys. A 2009, 97, 925–931. [Google Scholar] [CrossRef]

- Kurka, M.; Palka, K.; Jancalek, J.; Slang, S.; Vlcek, M. Structuring of solution processed and thermally evaporated As33S67 thin films by soft stamp hot embossing method. J. Non-Cryst. Solids 2021, 559, 120674. [Google Scholar] [CrossRef]

- Kuchler, M.; Otto, T.; Gessner, T. Hot embossing for MEMS using silicon tools. Int. J. Comput. Eng. Sci. 2003, 4, 609–612. [Google Scholar] [CrossRef]

- Chien, R.-D. Hot embossing of microfluidic platform. Int. Commun. Heat Mass Transf. 2006, 33, 645–653. [Google Scholar] [CrossRef]

- Kim, Y.K.; Ju, J.H.; Kim, S.M. Replication of a glass microlens array using a vitreous carbon mold. Opt. Express 2018, 26, 14936–14944. [Google Scholar] [CrossRef] [PubMed]

- Marvila, M.T.; Azevedo, A.R.G.; Alexandre, J.; Zanelato, E.B.; Azeredo, N.G.; Simonassi, N.T.; Monteiro, S.N. Correlation between the properties of structural clay blocks obtained by destructive tests and Ultrasonic Pulse Tests. J. Build. Eng. 2019, 26, 100869. [Google Scholar] [CrossRef]

- Balegh, B.; Sellaf, H.; Hadjmostefa, A. Effect of ceramic waste on mechanical and geotechnical properties of tuff treated by cement. Case Stud. Constr. Mater. 2020, 13, e00368. [Google Scholar] [CrossRef]

- Medved, D.; Balko, J.; Sedlák, R.; Kovalčíková, A.; Shepa, I.; Naughton-Duszová, A.; Bączek, E.; Podsiadło, M.; Dusza, J. Wear resistance of ZrB2 based ceramic composites. Int. J. Refract. Met. Hard Mater. 2019, 81, 214–224. [Google Scholar] [CrossRef]

- Aborkin, A.V.; Elkin, A.I.; Reshetniak, V.V.; Ob’edkov, A.M.; Sytschev, A.E.; Leontiev, V.G.; Titov, D.D.; Alymov, M.I. Thermal expansion of aluminum matrix composites reinforced by carbon nanotubes with in-situ and ex-situ designed interfaces ceramics layers. J. Alloys Compd. 2021, 872, 159593. [Google Scholar] [CrossRef]

- Zegardło, B. Heat-resistant concretes containing waste carbon fibers from the sailing industry and recycled ceramic aggregates. Case Stud. Constr. Mater. 2022, 16, e01084. [Google Scholar] [CrossRef]

- Li, Z.; Jin, G.; Fang, F.; Gong, H.; Jia, H. Ultrasonically Assisted Single Point Diamond Turning of Optical Mold of Tungsten Carbide. Micromachines 2018, 9, 77. [Google Scholar] [CrossRef]

- Suzuki, N.; Haritani, M.; Yang, J.; Hino, R.; Shamoto, E. Elliptical Vibration Cutting of Tungsten Alloy Molds for Optical Glass Parts. CIRP Ann. 2007, 56, 127–130. [Google Scholar] [CrossRef]

- Sun, S.; Li, K.; Chu, W.; Gong, F. Tungsten carbide molds for precision glass molding process: Mechanism of high-temperature degradation. Int. J. Refract. Met. Hard Mater. 2022, 105, 105841. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Huang, Z.; Yan, K.; Shen, X.; Xing, J.; Gao, Y.; Jian, Y.; Yang, H.; Li, B. A Review on Binderless Tungsten Carbide: Development and Application. Nanomicro Lett. 2019, 12, 13. [Google Scholar] [CrossRef] [PubMed]

- Narushima, T.; Goto, T.; Hirai, T.; Iguchi, T. High-temperature oxidation of silicon carbide and silicon nitride. Mater. Trans. JIM 1997, 38, 821–835. [Google Scholar] [CrossRef]

- Chen, M.W.; Qiu, H.P.; Jiao, J.; Wang, Y.; Xie, W.J. High Temperature Oxidation Behavior of Silicon Carbide Ceramic. Key Eng. Mater. 2016, 680, 89–92. [Google Scholar] [CrossRef]

- Hannink, R.; Kelly, P.; Muddle, B. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Dutta, I.; Mitra, S.; Rabenberg, L. Oxidation of Sintered Aluminum Nitride at Near-Ambient Temperatures. J. Am. Ceram. Soc. 1992, 75, 3149–3153. [Google Scholar] [CrossRef]

- Ye, B.; Wen, T.; Chu, Y. High-temperature oxidation behavior of (Hf0.2Zr0.2Ta0.2Nb0.2Ti0.2)C high-entropy ceramics in air. J. Am. Ceram. Soc. 2019, 103, 500–507. [Google Scholar] [CrossRef]

- Kane, K.A.; Pint, B.A.; Mitchell, D.; Haynes, J.A. Oxidation of ultrahigh temperature ceramics: Kinetics, mechanisms, and applications. J. Eur. Ceram. Soc. 2021, 41, 6130–6150. [Google Scholar] [CrossRef]

- Miller-Oana, M.; Corral, E.L. High-Temperature Isothermal Oxidation of Ultra-High Temperature Ceramics Using Thermal Gravimetric Analysis. J. Am. Ceram. Soc. 2016, 99, 619–626. [Google Scholar] [CrossRef]

- Wiame, H.; Centeno, M.A.; Picard, S.; Bastians, P.; Grange, P. Thermal oxidation under oxygen of zirconium nitride studied by XPS, DRIFTS, TG-MS. J. Eur. Ceram. Soc. 1998, 18, 1293–1299. [Google Scholar] [CrossRef]

- Karlsdottir, S.N.; Halloran, J.W. Rapid oxidation characterization of ultra-high temperature ceramics. J. Am. Ceram. Soc. 2007, 90, 3233–3238. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, S.; Li, W.; Yu, Y.; Jiang, J. Understanding the oxidation behavior of Ta–Hf–C ternary ceramics at high temperature. Corros. Sci. 2020, 164, 108348. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Gong, F.; Yang, G. A Comprehensive Study on High-Temperature Oxidation Behavior of Ceramic Molds for Hot Embossing. Materials 2022, 15, 8045. https://doi.org/10.3390/ma15228045

Zhu Y, Gong F, Yang G. A Comprehensive Study on High-Temperature Oxidation Behavior of Ceramic Molds for Hot Embossing. Materials. 2022; 15(22):8045. https://doi.org/10.3390/ma15228045

Chicago/Turabian StyleZhu, Youcheng, Feng Gong, and Gao Yang. 2022. "A Comprehensive Study on High-Temperature Oxidation Behavior of Ceramic Molds for Hot Embossing" Materials 15, no. 22: 8045. https://doi.org/10.3390/ma15228045

APA StyleZhu, Y., Gong, F., & Yang, G. (2022). A Comprehensive Study on High-Temperature Oxidation Behavior of Ceramic Molds for Hot Embossing. Materials, 15(22), 8045. https://doi.org/10.3390/ma15228045