Atmospheric Pressure Plasma-Treated Polyurethane Foam as Reusable Absorbent for Removal of Oils and Organic Solvents from Water

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

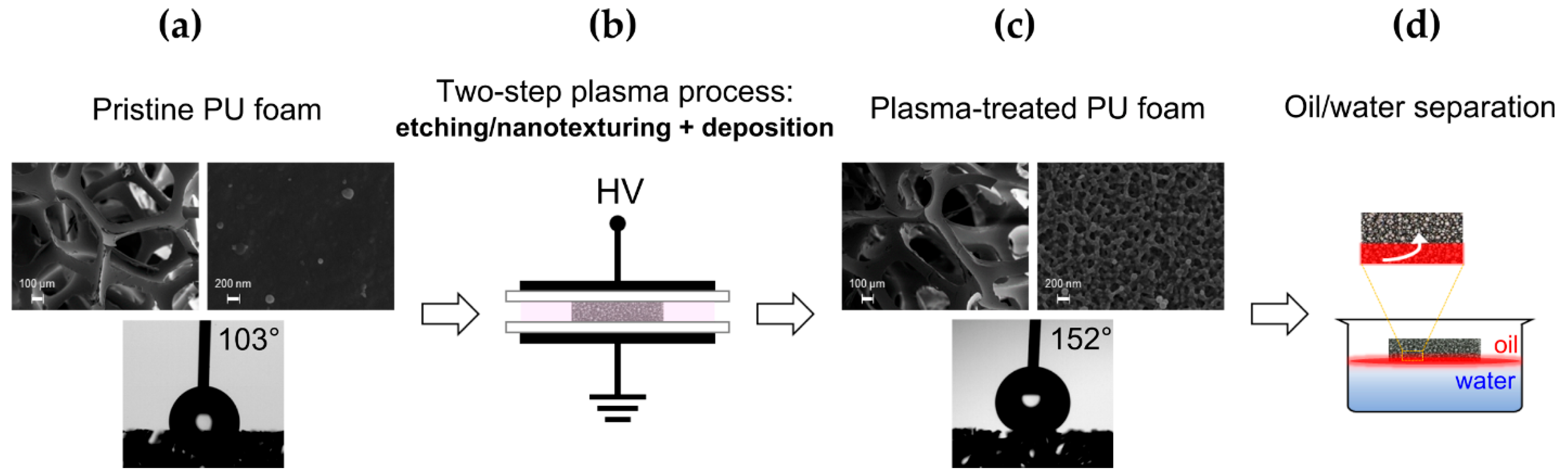

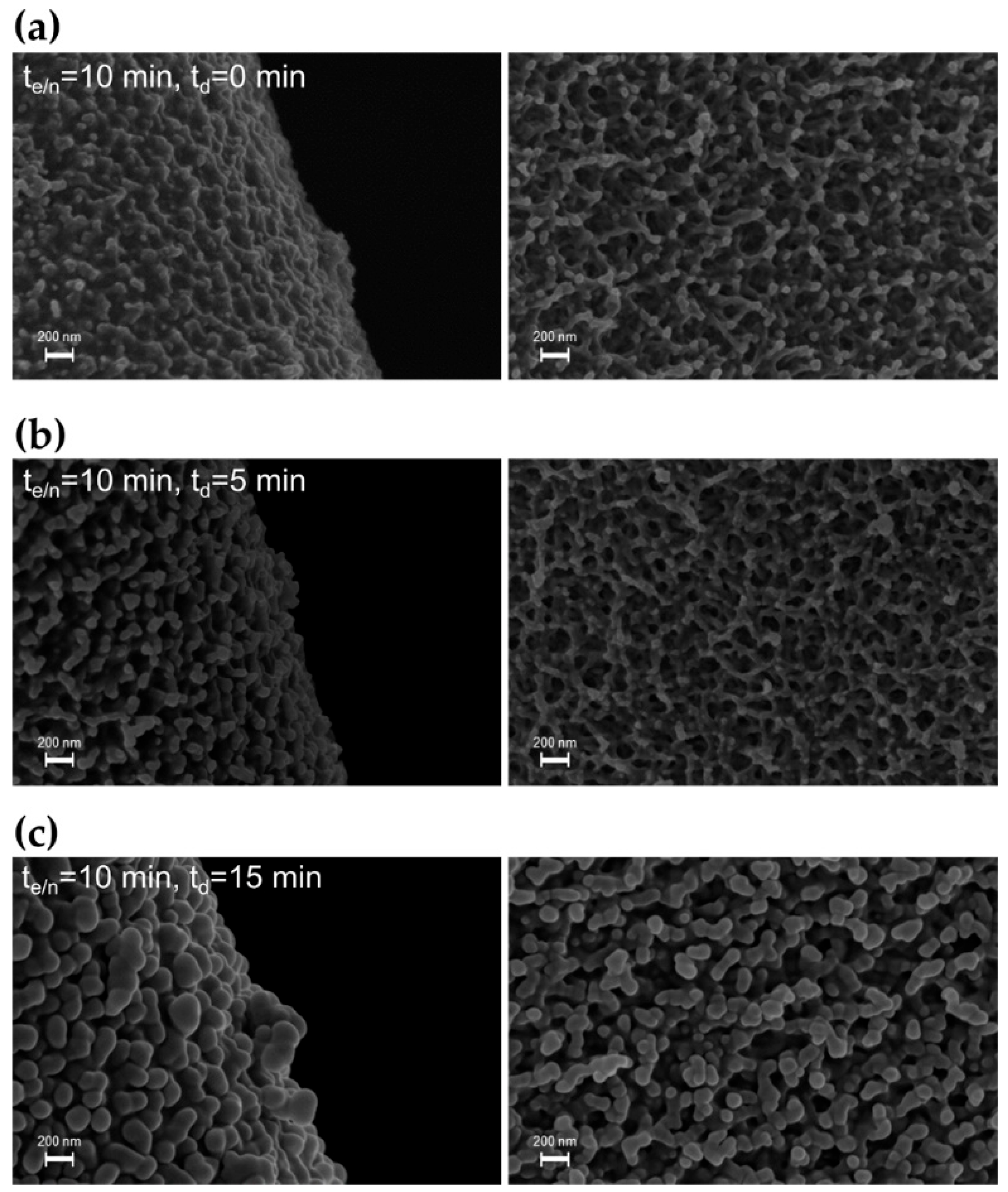

2.2. Atmospheric Pressure Plasma Processes

- Step 1—etching/nanotexturing, in which the plasma was fed with a He/O2 mixture at He flow rate of 6 standard liters per minute (slm) and O2 concentration of 0.5% (hereafter referred to as He/0.5% O2 mixture).

- Step 2—thin-film deposition, involving the use of a DBD fed with a He/C2H4 mixture at He flow rate and C2H4 concentration of 6 slm and 0.5%, respectively (hereafter referred to as He/0.5% C2H4 mixture).

2.3. Material Characterization

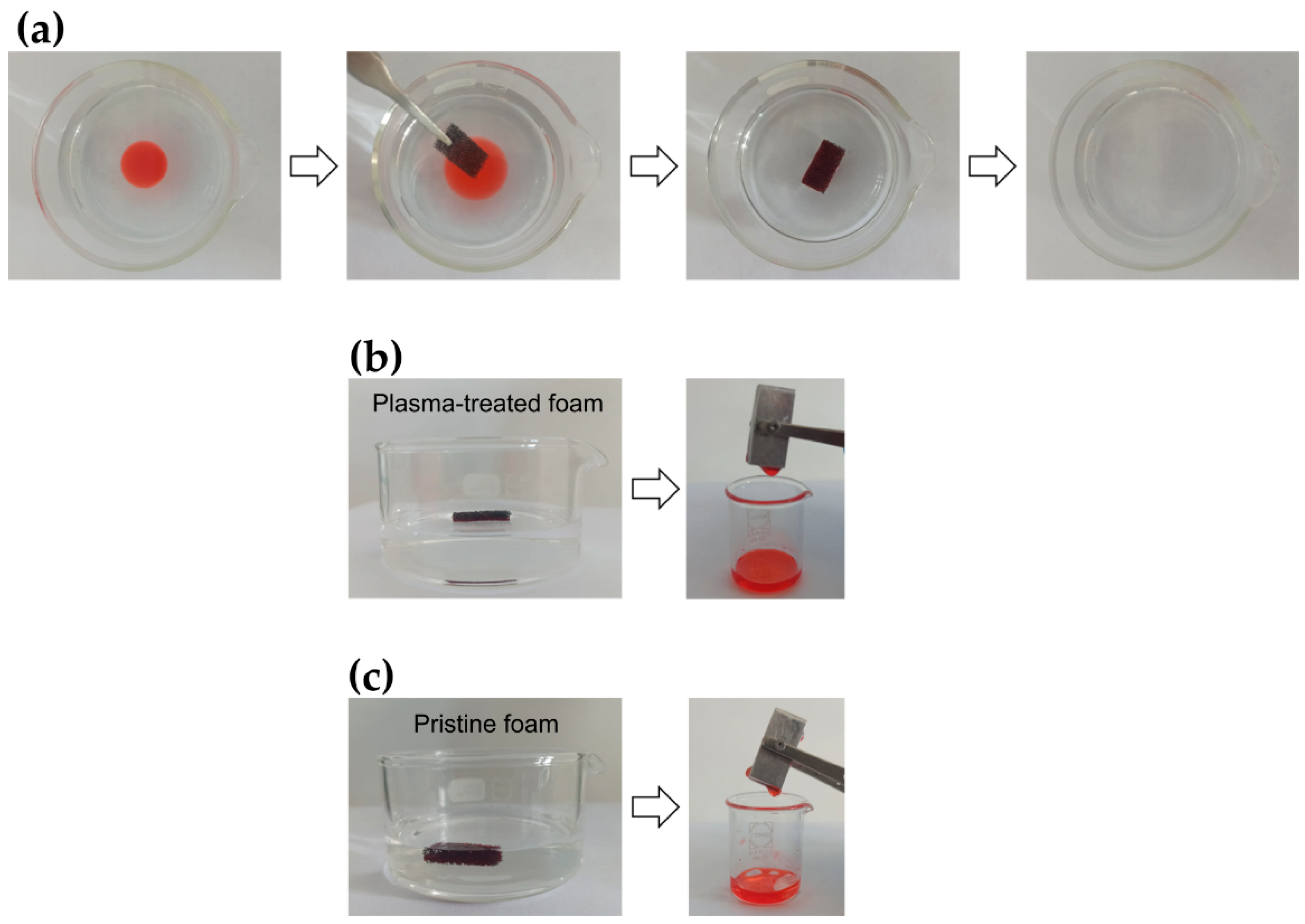

2.4. Absorption and Oil–Water Separation Experiments

3. Results

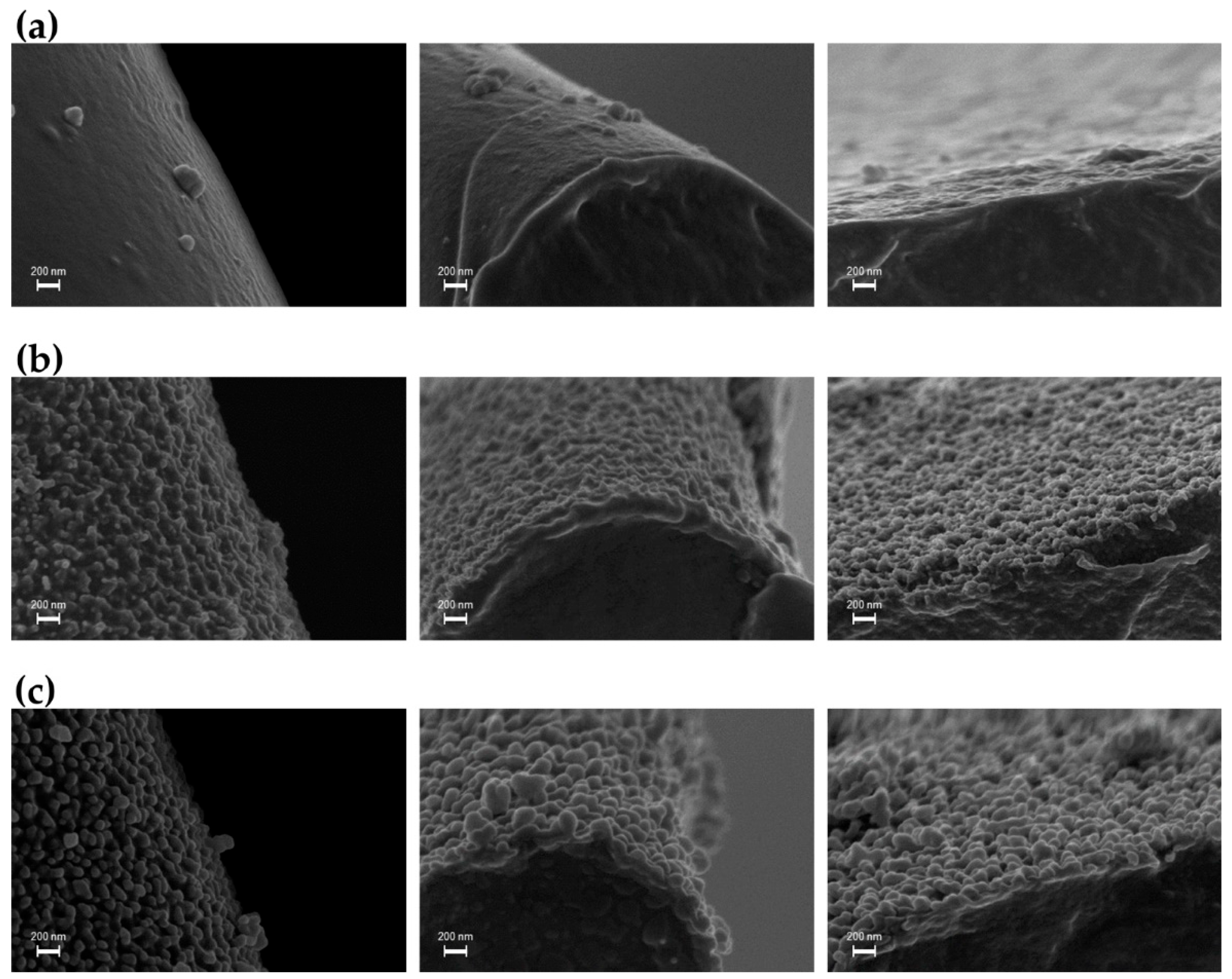

3.1. Plasma Process and Material Characterization

3.2. Oil–Water Separation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, H.-J.; Choi, W.S. 2D and 3D bulk materials for environmental remediation: Air filtration and oil/water separation. Materials 2020, 13, 5714. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Vaya, D.; Prasad, G.; Surolia, P.K. Photocatalytic process for oily wastewater treatment: A review. Int. J. Environ. Sci. Techn. 2022. [Google Scholar] [CrossRef]

- Abdulkareem, A.; Popelka, A.; Sobolčiak, P.; Tanvir, A.; Ouederni, M.; AlMaadeed, M.A.; Kasak, P.; Adham, S.; Krupa, I. The separation of emulsified water/oil mixtures through adsorption on plasma-treated polyethylene powder. Materials 2021, 14, 1086. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Huang, J.; Li, S.; Ge, M.; Teng, L.; Chen, Z.; Lai, Y. Advanced materials with special wettability toward intelligent oily wastewater remediation. ACS Appl. Mater. Interfaces 2021, 13, 67–87. [Google Scholar] [CrossRef] [PubMed]

- Ge, J.; Zhao, H.-Y.; Zhu, H.-W.; Huang, J.; Shu, L.-A.; Yu, S.-H. Advanced sorbents for oil-spill cleanup: Recent advances and future perspectives. Adv. Mater. 2016, 28, 10459–10490. [Google Scholar] [CrossRef] [PubMed]

- Yue, X.; Li, Z.; Zhang, T.; Yang, D.; Qiu, F. Design and fabrication of superwetting fiber-based membranes for oil/water separation applications. Chem. Eng. J. 2019, 364, 292–309. [Google Scholar] [CrossRef]

- Lee, Y.S.; Lim, Y.T.; Choi, W.S. One-step synthesis of environmentally friendly superhydrophilic and superhydrophobic sponges for oil/water separation. Materials 2019, 12, 1182. [Google Scholar] [CrossRef]

- Udayakumar, K.V.; Gore, P.M.; Kandasubramanianb, B. Foamed materials for oil-water separation. J. Adv. Chem. Eng. 2021, 5, 100076. [Google Scholar] [CrossRef]

- Satria, M.; Saleh, T.A. Facile approach of eco-friendly superhydrophilic/underwater superoleophobic zinc-functionalized polyurethane foams for continuous oil-water separation. J. Mol. Liq. 2022, 367, 120341. [Google Scholar] [CrossRef]

- Sam, E.K.; Liu, J.; Lv, X. Surface engineering materials of superhydrophobic sponges for oil/water separation: A review. Ind. Eng. Chem. Res. 2021, 60, 2353–2364. [Google Scholar] [CrossRef]

- Barroso-Solares, S.; Pinto, J.; Fragouli, D.; Athanassiou, A. Facile oil removal from water-in-oil stable emulsions using PU foams. Materials 2018, 11, 2382. [Google Scholar] [CrossRef] [PubMed]

- Hailan, S.M.; Ponnamma, D.; Krupa, I. The separation of oil/water mixtures by modified melamine and polyurethane foams: A review. Polymers 2021, 13, 4142. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Fan, Z.; Liu, Q.; Tong, Q.; Wang, B. Fabrication of PDMS@Fe3O4/MS composite materials and its application for oil-water separation. Materials 2022, 15, 115. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Tai, N.-H. Carbon materials as oil sorbents: A review on the synthesis and performance. J. Mater. Chem. A 2016, 4, 1550. [Google Scholar] [CrossRef]

- Ju, G.; Zhou, L.; Jiao, C.; Shen, J.; Luan, Y.; Zhao, X. One-step fabrication of a functionally integrated device based on polydimethylsiloxane-coated SiO2 NPs for efficient and continuous oil absorption. Materials 2021, 14, 5998. [Google Scholar] [CrossRef] [PubMed]

- Peng, M.; Zhi, Y.; Li, H.; He, K.; Zeng, G.; Chen, A.; Huang, Z.; Huang, T.; Yuan, L.; Chen, G. Synthesis and application of modified commercial sponges for oil-water separation. Chem. Eng. J. 2019, 373, 213–226. [Google Scholar] [CrossRef]

- Pantone, V.; Annese, C.; Fusco, C.; Fini, P.; Nacci, A.; Russo, A.; D’Accolti, L. One-pot conversion of epoxidized soybean oil (ESO) into soy-based polyurethanes by MoCl2O2 Catalysis. Molecules 2017, 22, 333. [Google Scholar] [CrossRef]

- Guo, G.; Liu, L.; Dang, Z.; Fang, W. Recent progress of polyurethane-based materials for oil/water separation. Nano 2017, 4, 1730001. [Google Scholar] [CrossRef]

- Ranganathan, P.; Chen, C.-W.; Chou, Y.-L.; Rwei, S.-P.; Ramaraj, S.K. Biomass chemical upcycling of waste rPET for the fabrication of formamide-free TPEE microcellular foams via scCO2 foaming. J. CO2 Util. 2022, 65, 102199. [Google Scholar] [CrossRef]

- Chang, C.-J.; Venkatesan, M.; Cho, C.-J.; Chung, P.-Y.; Chandrasekar, J.; Lee, C.-H.; Wang, H.-T.; Wong, C.-M.; Kuo, C.-C. Thermoplastic starch with poly(butylene adipate-co-terephthalate) blends foamed by supercritical carbon dioxide. Polymers 2022, 14, 1952. [Google Scholar] [CrossRef]

- Zhu, Q.; Pan, Q.; Liu, F. Facile removal and collection of oils from water surfaces through superhydrophobic and superoleophilic sponges. J. Phys. Chem. C 2011, 115, 17464–17470. [Google Scholar] [CrossRef]

- Calcagnile, P.; Fragouli, D.; Bayer, I.S.; Anyfantis, G.C.; Martiradonna, L.; Cozzoli, P.D.; Cingolani, R.; Athanassiou, A. Magnetically driven floating foams for the removal of oil contaminants from water. ACS Nano 2012, 6, 5413–5419. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Wang, J.; Zhang, S.; Ma, X.; Qiu, Z.; Peng, X.; Ying, J.; Wang, Y.; Wu, G. One-step modification of PU sponges for selective absorption of oil–water mixtures. N. J. Chem. 2017, 41, 90. [Google Scholar] [CrossRef]

- Pantone, V.; Laurenza, A.G.; Annese, C.; Comparelli, R.; Fracassi, F.; Fini, P.; Nacci, A.; Russo, A.; Fusco, C.; D’Accolti, L. Preparation and characterization of soybean oil-based polyurethanes for digital doming applications. Materials 2017, 10, 848. [Google Scholar] [CrossRef]

- Armenise, V.; Fanelli, F.; Milella, A.; D’Accolti, L.; Uricchio, A.; Fracassi, F. Atmospheric pressure plasma treatment of polyurethane foams with He–O2 fed dielectric barrier discharges. Surf. Interfaces 2020, 20, 100600. [Google Scholar] [CrossRef]

- Wu, L.; Li, L.; Li, B.; Zhang, J.; Wang, A. Magnetic, durable, and superhydrophobic polyurethane@Fe3O4@SiO2@fluoropolymer sponges for selective oil absorption and oil/water separation. ACS Appl. Mater. Interfaces 2015, 7, 4936–4946. [Google Scholar] [CrossRef]

- Wang, G.; Zeng, Z.; Wu, X.; Ren, T.; Han, J.; Xue, Q. Three-dimensional structured sponge with high oil wettability for the clean-up of oil contaminations and separation of oil–water mixtures. Polym. Chem. 2014, 5, 5942–5948. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Liu, K.; Jiang, L. Bioinspired multifunctional foam with self-cleaning and oil/water separation. Adv. Funct. Mater. 2013, 23, 2881–2886. [Google Scholar] [CrossRef]

- Lin, B.; Chen, J.; Li, Z.-T.; He, F.-A.; Li, D.-H. Superhydrophobic modification of polyurethane sponge for the oil-water separation. Surf. Coat. Technol. 2019, 359, 216–226. [Google Scholar] [CrossRef]

- Qiang, F.; Hu, L.-L.; Gong, L.-X.; Zhao, L.; Li, S.-N.; Tang, L.-C. Facile synthesis of super-hydrophobic, electrically conductive and mechanically flexible functionalized graphene nanoribbon/polyurethane sponge for efficient oil/water separation at static and dynamic states. Chem. Eng. J. 2018, 334, 2154–2166. [Google Scholar] [CrossRef]

- Guo, H.; Wang, X.; Li, X.; Zhang, X.; Liu, X.; Dai, Y.; Wang, R.; Guo, X.; Jia, X. Sprayable and rapidly bondable phenolic-metal coating for versatile oil/water separation. Front. Mater. Sci. 2019, 13, 193–202. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, H.; Xiong, S.; Chen, R.; Wang, Y. Extremely efficient and recyclable absorbents for oily pollutants enabled by ultrathin-layered functionalization. ACS Appl. Mater. Interfaces 2014, 6, 18816–18823. [Google Scholar] [CrossRef] [PubMed]

- Massines, F.; Sarra-Burnet, C.; Fanelli, F.; Naudé, N.; Gherardi, N. Atmospheric pressure low temperature direct plasma technology: Status and challenges for thin film deposition. Plasma Proc. Polym. 2012, 9, 1041–1073. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Gogolides, E. Hydrophobic and superhydrophobic surfaces fabricated using atmospheric pressure cold plasma technology: A review. Adv. Colloid Interface Sci. 2018, 254, 1–21. [Google Scholar] [CrossRef]

- Mariotti, D.; Belmonte, T.; Benedickt, J.; Velusamy, T.; Jain, G.; Svrcek, V. Low-temperature atmospheric pressure plasma processes for “green” third generation photovoltaics. Plasma Polym. Proc. 2016, 13, 70–90. [Google Scholar] [CrossRef]

- Fanelli, F.; Fracassi, F. Thin film deposition on open-cell foams by atmospheric pressure dielectric barrier discharges. Plasma Proc. Polym. 2016, 13, 470–479. [Google Scholar] [CrossRef]

- Fanelli, F.; Bosso, P.; Mastrangelo, A.M.; Fracassi, F. Thin film deposition at atmospheric pressure using dielectric barrier discharges: Advances on three-dimensional porous substrates and functional coatings. Jpn. J. Appl. Phys. 2016, 55, 07LA01. [Google Scholar] [CrossRef]

- Uricchio, A.; Nadal, E.; Plujat, B.; Plantard, G.; Massines, F.; Fanelli, F. Low-temperature atmospheric pressure plasma deposition of TiO2-based nanocomposite coatings on open-cell polymer foams for photocatalytic water treatment. Appl. Surf. Sci. 2021, 561, 150014. [Google Scholar] [CrossRef]

- Gao, M.; Wang, Y.; Zhang, Y.; Li, Y.; Tang, Y.; Huang, Y. Deposition of thin films on glass fiber fabrics by atmospheric pressure plasma jet. Surf. Coat. Technol. 2020, 404, 126498. [Google Scholar] [CrossRef]

- Michlíček, M.; Manakhov, A.; Dvořáková, E.; Zajíčková, L. Homogeneity and penetration depth of atmospheric pressure plasma polymerization onto electrospun nanofibrous mats. Appl. Surf. Sci. 2019, 471, 835–841. [Google Scholar] [CrossRef]

- Meunier, L.-F.; Profili, J.; Babaei, S.; Asadollahi, S.; Sarkissian, A.; Dorris, A.; Beck, S.; Naudé, N.; Stafford, L. Modification of microfibrillated cellulosic foams in a dielectric barrier discharge at atmospheric pressure. Plasma Proc. Polym. 2021, 18, e2000158. [Google Scholar] [CrossRef]

- Meunier, L.-F.; Profili, J.; Babaei, S.; Asadollahi, S.; Sarkissian, A.; Dorris, A.; Beck, S.; Naudé, N.; Stafford, L. Characterization of non-thermal dielectric barrier discharges at atmospheric pressure in presence of microfibrillated cellulosic foams. Plasma Sources Sci. Technol. 2021, 30, 095019. [Google Scholar] [CrossRef]

- Cámara-Torres, M.; Sinha, R.; Scopece, P.; Neubert, T.; Lachmann, K.; Patelli, A.; Mota, C.; Moroni, L. Tuning cell behavior on 3D scaffolds fabricated by atmospheric plasma-assisted additive manufacturing. ACS Appl. Mater. Interfaces 2021, 13, 3631–3644. [Google Scholar] [CrossRef]

- Akhavan, B.; Jarvis, K.; Majewski, P. Hydrophobic plasma polymer coated silica particles for petroleum hydrocarbon removal. ACS Appl. Mater. Interfaces 2013, 5, 8563–8571. [Google Scholar] [CrossRef]

- Chen, F.; Song, J.; Liu, Z.; Liu, J.; Zheng, H.; Huang, S.; Sun, J.; Xu, W.; Liu, X. Atmospheric pressure plasma functionalized polymer mesh: An environmentally friendly and efficient tool for oil/water separation. ACS Sustain. Chem. Eng. 2016, 4, 6828–6837. [Google Scholar] [CrossRef]

- You, Y.S.; Kang, S.; Mauchauffé, R.; Moon, S.Y. Rapid and selective surface functionalization of the membrane for high efficiency oil-water separation via an atmospheric pressure plasma process. Sci. Rep. 2017, 7, 15345. [Google Scholar] [CrossRef] [PubMed]

- Sadeghi, I.; Aroujalian, A.; Raisi, A.; Dabir, B.; Fathizadeh, M. Surface modification of polyethersulfone ultrafiltration membranes by corona air plasma for separation of oil/water emulsions. J. Membr. Sci. 2013, 430, 24–36. [Google Scholar] [CrossRef]

- Cortese, B.; Caschera, D.; Federici, F.; Ingo, G.M.; Gigli, G. Superhydrophobic fabrics for oil–water separation through a diamond like carbon (DLC) coating. J. Mater. Chem. A 2014, 2, 6781. [Google Scholar] [CrossRef]

- Liu, Y.-Q.; Zhang, Y.-L.; Fu, X.-Y.; Sun, H.-B. Bioinspired underwater superoleophobic membrane based on a graphene oxide coated wire mesh for efficient oil/water separation. ACS Appl. Mater. Interfaces 2015, 7, 20930–20936. [Google Scholar] [CrossRef]

- Zhang, M.; Pang, J.; Bao, W.; Zhang, W.; Gao, H.; Wang, C.; Shi, J.; Li, J. Antimicrobial cotton textiles with robust superhydrophobicity via plasma for oily water separation. Appl. Surf. Sci. 2017, 419, 16–23. [Google Scholar] [CrossRef]

- Ma, C.; Nikiforov, A.; Gromov, M.; Ostrikov, K.; Geyter, N.D.; Morent, R. Plasma-aerosol-assisted surface engineering for scalable oil/water membrane separation, Appl. Surf. Sci. 2022, 606, 154807. [Google Scholar] [CrossRef]

- Guo, J.; Wang, J.; Gao, Y.; Wang, J.; Chang, W.; Liao, S.; Qian, Z.; Liu, Y. pH-responsive sponges fabricated by Ag−S ligands possess smart double-transformed superhydrophilic−superhydrophobic−superhydrophilic wettability for oil−water separation. ACS Sustain. Chem. Eng. 2017, 5, 10772–10782. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Y.; Chen, P.; Du, W.; Feng, X.; Liu, B.-F. Paraffin oil based soft-template approach to fabricate reusable porous PDMS sponge for effective oil/water separation. Langmuir 2019, 35, 11123–11131. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Gogolides, E. Transition between stable hydrophilization and fast etching/hydrophilization of poly(methyl)methacrylate polymer using a novel atmospheric pressure dielectric barrier discharge source. J. Vac. Sci. Technol. A 2017, 35, 041303. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Gogolides, E. Atmospheric plasma etching of polymers: A palette of applications in cleaning/ashing, pattern formation, nanotexturing and superhydrophobic surface fabrication. Microelectr. Eng. 2018, 194, 109–115. [Google Scholar] [CrossRef]

- Tsougeni, K.; Vourdas, N.; Tserepi, A.; Gogolides, E. Mechanisms of oxygen plasma nanotexturing of organic polymer surfaces: From stable super hydrophilic to super hydrophobic surfaces. Langmuir 2009, 25, 11748–11759. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Smyrnakis, A.; Constantoudis, V.; Tsoutsou, D.; Dimoulas, A.; Gogolides, E. Atmospheric pressure plasma directed assembly during photoresist removal: A new route to micro and nano pattern formation. Micro Nano Eng. 2019, 3, 15–21. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Patsidis, A.C.; Smyrnakis, A.; Psarras, G.C.; Gogolides, E. Atmospheric plasma nanotexturing of organic−inorganic nanocomposite coatings for multifunctional surface fabrication. ACS Appl. Nano Mater. 2019, 2, 2969–2978. [Google Scholar] [CrossRef]

- Bosso, P.; Fanelli, F.; Fracassi, F. Deposition of water-stable coatings containing carboxylic acid groups by atmospheric pressure cold plasma jet. Plasma Proc. Polym. 2016, 13, 217–226. [Google Scholar] [CrossRef]

- Fanelli, F.; Fracassi, F.; Lapenna, A.; Angarano, V.; Palazzo, G.; Mallardi, A. Atmospheric pressure cold plasma: A friendly environment for dry enzymes. Adv. Mater. Interfaces 2018, 24, 1801373. [Google Scholar] [CrossRef]

- Choi, B.G.; Park, H.S. Superhydrophobic graphene/nafion nanohybrid films with hierarchical roughness. J. Phys. Chem. C 2012, 116, 3207–3211. [Google Scholar] [CrossRef]

- Bashandeh, K.; Marchert, A.; Takayuki, U.; Polycarpou, A.A.; Meyer, J.; Lan, P. The effect of surface texturing on thin film reversible adhesive bond strength. Int. J. Adhes. Adhes. 2021, 107, 102829. [Google Scholar] [CrossRef]

| Sample | C at % | O at % | N at % | Si at % |

|---|---|---|---|---|

| Pristine foam | 74.5 ± 4.0 | 20.0 ± 1.0 | 4.5 ± 0.2 | 1.00 ± 0.10 |

| Plasma-treated foam/Step 1 | 64 ± 3 | 28.0 ± 1.5 | 7.0 ± 0.3 | 1.00 ± 0.10 |

| Plasma-treated foam/Step 1+2 | 98.0 ± 1.0 | 2.0 ± 1.0 | -- | -- |

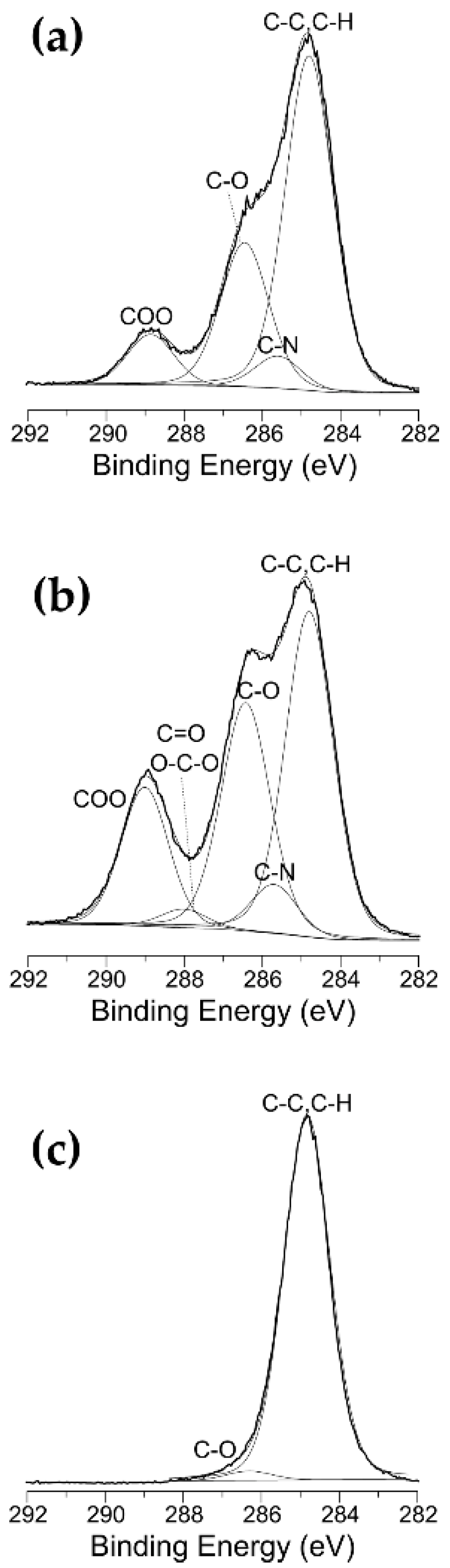

| Sample | C-C, C-H Peak Area % | C-N Peak Area % | C-O Peak Area % | C=O, O-C-O Peak Area % | COO Peak Area % |

|---|---|---|---|---|---|

| Pristine foam | 60 ± 4 | 5.5 ± 0.5 | 26 ± 2 | -- | 8.5 ± 0.5 |

| Plasma-treated foam/Step 1 | 43 ± 3 | 6.5 ± 0.5 | 31 ± 2 | 2.0 ± 0.2 | 17.5 ± 1.0 |

| Plasma-treated foam/Step 1+2 | 98.0 ± 1.0 | -- | 2.0 ± 1.0 | -- | -- |

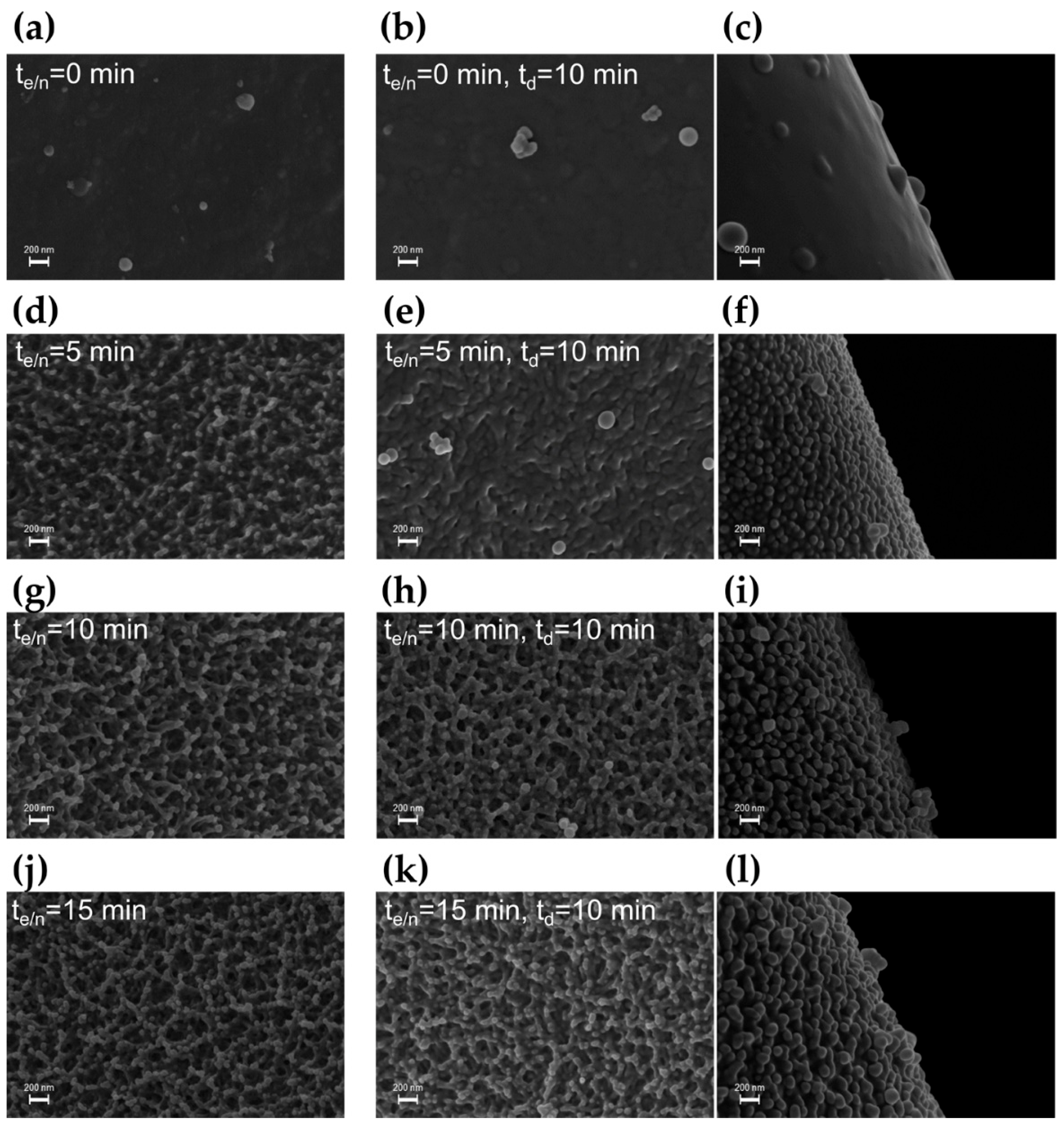

| Sample | Step 1 Duration, te/n (min) | Step 2 Duration, td (min) | WCA (°) | ROA (°) |

|---|---|---|---|---|

| Pristine foam | - | - | 103 ± 6 | pinned |

| Plasma-treated foam | 0 | 10 | 130 ± 5 | pinned |

| 5 | 10 | 140 ± 3 | 47 ± 5 | |

| 10 | 10 | 152 ± 4 | 13 ± 2 | |

| 15 | 10 | 148 ± 3 | 32 ± 5 | |

| Plasma-treated foam | 10 | 0 | absorption | - |

| 10 | 5 | 145 ± 3 | 45 ± 4 | |

| 10 | 10 | 152 ± 4 | 13 ± 2 | |

| 10 | 15 | 141 ± 3 | 35 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uricchio, A.; Lasalandra, T.; Tamborra, E.R.G.; Caputo, G.; Mota, R.P.; Fanelli, F. Atmospheric Pressure Plasma-Treated Polyurethane Foam as Reusable Absorbent for Removal of Oils and Organic Solvents from Water. Materials 2022, 15, 7948. https://doi.org/10.3390/ma15227948

Uricchio A, Lasalandra T, Tamborra ERG, Caputo G, Mota RP, Fanelli F. Atmospheric Pressure Plasma-Treated Polyurethane Foam as Reusable Absorbent for Removal of Oils and Organic Solvents from Water. Materials. 2022; 15(22):7948. https://doi.org/10.3390/ma15227948

Chicago/Turabian StyleUricchio, Antonella, Teresa Lasalandra, Eliana R. G. Tamborra, Gianvito Caputo, Rogério P. Mota, and Fiorenza Fanelli. 2022. "Atmospheric Pressure Plasma-Treated Polyurethane Foam as Reusable Absorbent for Removal of Oils and Organic Solvents from Water" Materials 15, no. 22: 7948. https://doi.org/10.3390/ma15227948

APA StyleUricchio, A., Lasalandra, T., Tamborra, E. R. G., Caputo, G., Mota, R. P., & Fanelli, F. (2022). Atmospheric Pressure Plasma-Treated Polyurethane Foam as Reusable Absorbent for Removal of Oils and Organic Solvents from Water. Materials, 15(22), 7948. https://doi.org/10.3390/ma15227948