Effect of Geometrical Parameters of Microscale Particles on Particle-Stimulated Nucleation and Recrystallization Texture of Al-Si-Mg-Cu-Based Alloy Sheets

Abstract

1. Introduction

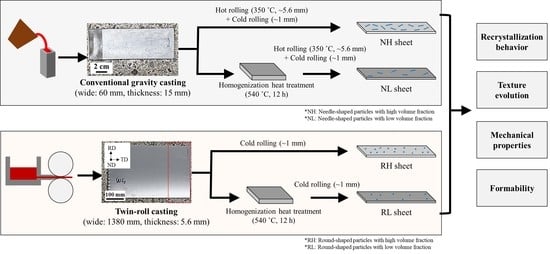

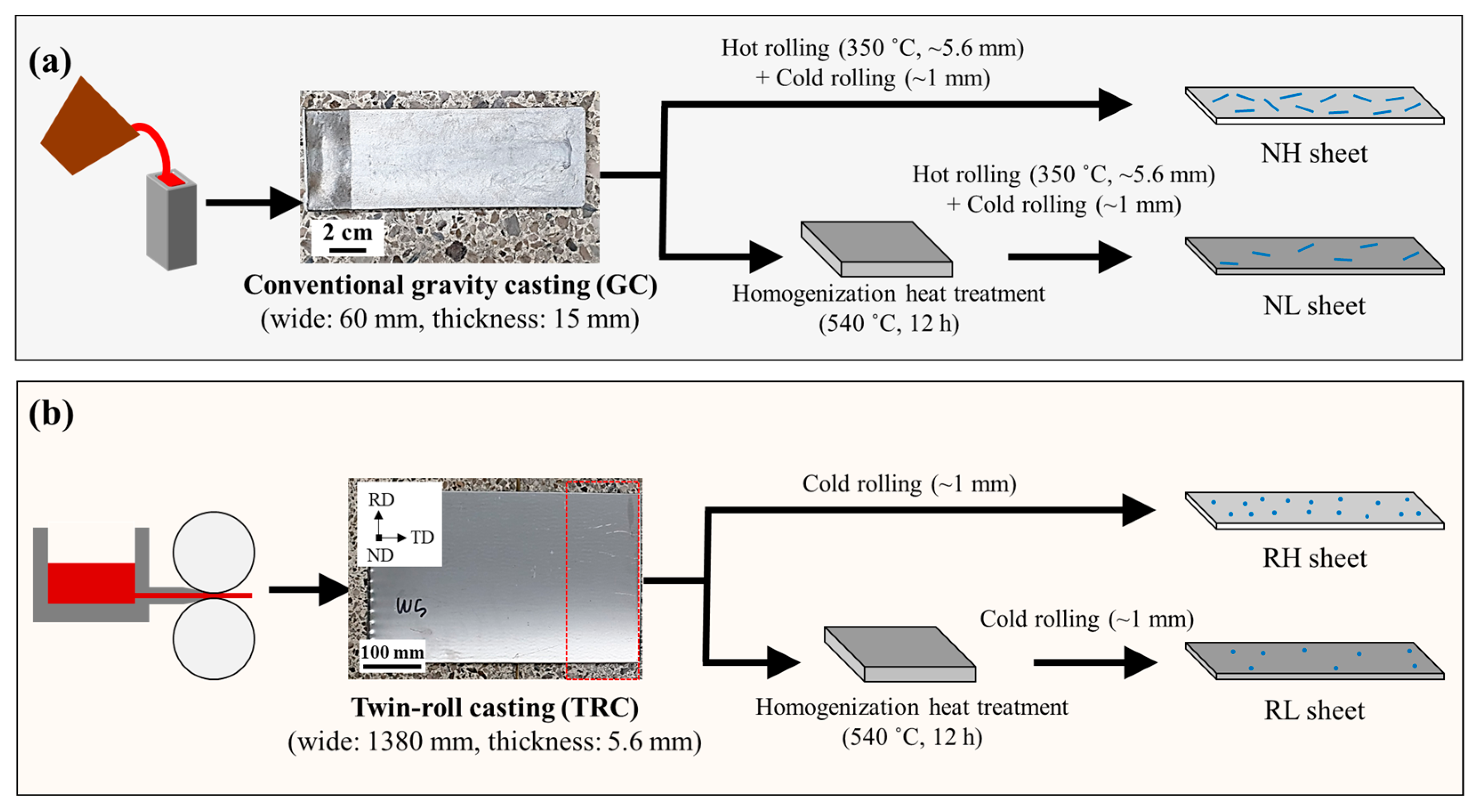

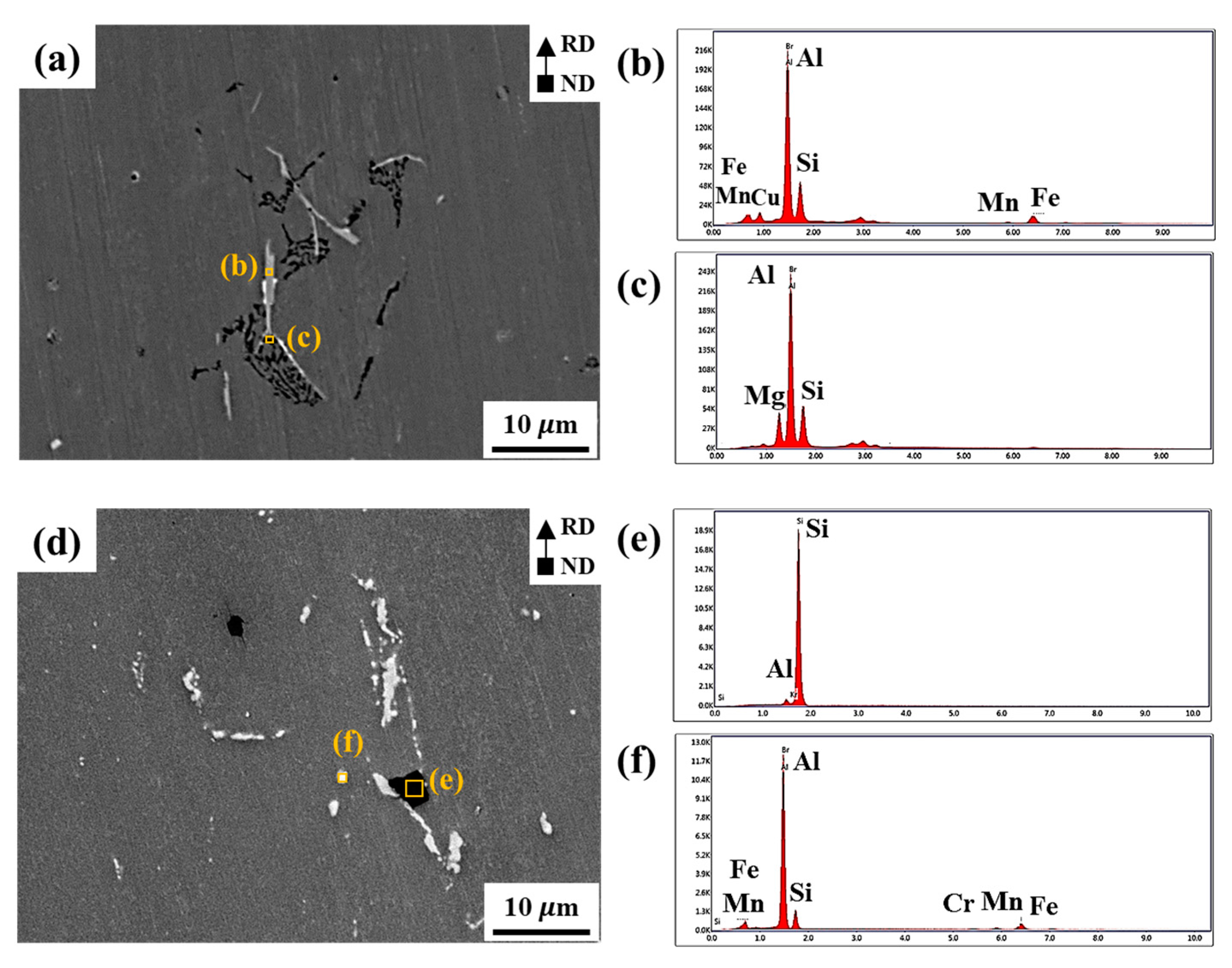

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, L.; Guo, M.; Dong, X.; Zhuang, L. Design, Evolution, Formation and Effect Mechanism of Coupling Distributed Soft and Hard Micro-Regions in Al–Zn–Mg–Cu–Fe Alloys with High Formability. Mater. Sci. Eng. A 2022, 855, 143951. [Google Scholar] [CrossRef]

- Yuan, L.; Guo, M.; Habraken, A.M.; Duchene, L.; Zhuang, L. Extremely Improved Formability of Al–Zn–Mg–Cu Alloys Via Micro-Domain Heterogeneous Structure. Mater. Sci. Eng. A 2022, 837, 142737. [Google Scholar] [CrossRef]

- Mahabunphachai, S.; Koç, M. Investigations on Forming of Aluminum 5052 and 6061 Sheet Alloys at Warm Temperatures. Mater. Des. 2010, 31, 2422–2434. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, the Netherlands, 2012. [Google Scholar]

- Huo, W.T.; Shi, J.T.; Hou, L.G.; Zhang, J.S. An Improved Thermo-Mechanical Treatment of High-Strength Al–Zn–Mg–Cu Alloy for Effective Grain Refinement and Ductility Modification. J. Mater. Process. Technol. 2017, 239, 303–314. [Google Scholar] [CrossRef]

- Wu, Y.; Liao, H.; Liu, Y.; Zhou, K. Dynamic Precipitation of Mg2Si Induced by Temperature and Strain During Hot Extrusion and Its Impact on Microstructure and Mechanical Properties of near Eutectic Al–Si–Mg–V Alloy. Mater. Sci. Eng. A 2014, 614, 162–170. [Google Scholar] [CrossRef]

- Dumont, D.; Deschamps, A.; Brechet, Y. On the Relationship between Microstructure, Strength and Toughness in Aa7050 Aluminum Alloy. Mater. Sci. Eng. A 2003, 356, 326–336. [Google Scholar] [CrossRef]

- Zhang, G.W.; Nagaumi, H.; Han, Y.; Xu, Y.; Parish, C.M.; Zhai, T.G. Effects of Mn and Cr Additions on the Recrystallization Behavior of Al-Mg-Si-Cu Alloys. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2017. [Google Scholar]

- She, H.; Shu, D.; Dong, A.; Wang, J.; Sun, B.; Lai, H. Relationship of Particle Stimulated Nucleation, Recrystallization and Mechanical Properties Responding to Fe and Si Contents in Hot-Extruded 7055 Aluminum Alloys. J. Mater. Sci. Technol. 2019, 35, 2570–2581. [Google Scholar] [CrossRef]

- Schäfer, C.; Song, J.; Gottstein, G. Modeling of Texture Evolution in the Deformation Zone of Second-Phase Particles. Acta Mater. 2009, 57, 1026–1034. [Google Scholar] [CrossRef]

- Kim, J.; Shin, S.; Lee, S. Correlation between Microstructural Evolution and Corrosion Resistance of Hypoeutectic Al–Si–Mg Alloy: Influence of Corrosion Product Layer. Mater. Charact. 2022, 193, 112276. [Google Scholar] [CrossRef]

- Kumar, L.; Jang, J.C.; Yu, H.; Shin, K.S. Effects of Cr and Ti Addition on Mechanical Properties and Thermal Conductivity of Al–7Si–3Mg Die-Casting Alloys. Met. Mater. Int. 2022, 1–11. [Google Scholar] [CrossRef]

- Ling, H.; Shi, H.; Du, X.; Zan, J.; Liu, J. Effect of Chromium Content on Microstructure and Properties of Casting Al-7Si-0.35 Mg-0.02 Sr Alloy. Mater. Und Werkst. 2022, 53, 1229–1241. [Google Scholar] [CrossRef]

- Kim, H.Y.; Park, T.Y.; Han, S.W.; Lee, H.M. Effects of Mn on the Crystal Structure of A-Al (Mn, Fe) Si Particles in A356 Alloys. J. Cryst. Growth 2006, 291, 207–211. [Google Scholar] [CrossRef]

- Wang, M.; Guo, Y.; Wang, H.; Zhao, S. Characterization of Refining the Morphology of Al–Fe–Si in A380 Aluminum Alloy Due to Ca Addition. Processes 2022, 10, 672. [Google Scholar] [CrossRef]

- Alvarez-Antolin, F.; Asensio-Lozano, J.; Cofiño-Villar, A.; Gonzalez-Pociño, A. Analysis of Different Solution Treatments in the Transformation of Β-Alfesi Particles into A-(Femn) Si and Their Influence on Different Ageing Treatments in Al–Mg–Si Alloys. Metals 2020, 10, 620. [Google Scholar] [CrossRef]

- Kumar, S.; Grant, P.; O’Reilly, K.A.Q. Evolution of Fe Bearing Intermetallics During Dc Casting and Homogenization of an Al-Mg-Si Al Alloy. Metall. Mater. Trans. A 2016, 47, 3000–3014. [Google Scholar] [CrossRef]

- Kuijpers, N.C.W.; Vermolen, F.J.; Vuik, K.; van der Zwaag, S. A Model of the Β-Alfesi to A-Al (Femn) Si Transformation in Al-Mg-Si Alloys. Mater. Trans. 2003, 44, 1448–1456. [Google Scholar] [CrossRef]

- Wang, M.; Xu, W.; Han, Q. Effect of Heat Treatment on Controlling the Morphology of Alfesi Phase in A380 Alloy. Int. J. Met. 2016, 10, 516–523. [Google Scholar] [CrossRef]

- Kuijpers, N.C.W.; Vermolen, F.J.; Vuik, C.; Koenis, P.T.G.; Nilsen, K.E.; van der Zwaag, S. The Dependence of the Β-Alfesi to A-Al (Femn) Si Transformation Kinetics in Al–Mg–Si Alloys on the Alloying Elements. Mater. Sci. Eng. A 2005, 394, 9–19. [Google Scholar] [CrossRef]

- Chen, X.-M.; Dong, Q.-P.; Liu, Z.-G.; Wang, X.-N.; Zhang, Q.-Y.; Hu, Z.-R.; Nagaumi, H. Fe-Bearing Intermetallics Transformation and Its Influence on the Corrosion Resistance of Al–Mg–Si Alloy Weld Joints. J. Mater. Res. Technol. 2020, 9, 16116–16125. [Google Scholar] [CrossRef]

- Verma, A.; Kumar, S.; Grant, P.; O’Reilly, K. Influence of Cooling Rate on the Fe Intermetallic Formation in an Aa6063 Al Alloy. J. Alloy. Compd. 2013, 555, 274–282. [Google Scholar] [CrossRef]

- Belmares-Perales, S.; Castro-Román, M.; Herrera-Trejo, M.; Ramírez-Vidaurri, L.E. Effect of Cooling Rate and Fe/Mn Weight Ratio on Volume Fractions of A-Alfesi and Β-Alfesi Phases in Al−7.3 Si−3.5 Cu Alloy. Met. Mater. Int. 2008, 14, 307–314. [Google Scholar] [CrossRef]

- Mahmoud, M.G.; Mosleh, A.O.; Pozdniakov, A.V.; Khalifa, W.; Mohamed, M.S. Characterization of the Solidification Behavior, Microstructure and Mechanical Properties of Aluminum Alloy 6063 with Samarium Addition. J. Alloy. Compd. 2022, 929, 167234. [Google Scholar] [CrossRef]

- Ammar, H.R.; Samuel, A.M.; Doty, H.W.; Samuel, F.H. Premium Strength and Optimum Quality in Al-Si-Mg/Al-Si-Mg-Cu Cast Alloys Using Two Different Types of Molds. Int. J. Met. 2022, 16, 1347–1362. [Google Scholar] [CrossRef]

- Kamikawa, N.; Huang, X.; Tsuji, N.; Hansen, N. Strengthening Mechanisms in Nanostructured High-Purity Aluminium Deformed to High Strain and Annealed. Acta Mater. 2009, 57, 4198–4208. [Google Scholar] [CrossRef]

- Liu, W.; Man, C.-S.; Raabe, D.; Morris, J. Effect of Hot and Cold Deformation on the Recrystallization Texture of Continuous Cast Aa 5052 Aluminum Alloy. Scr. Mater. 2005, 53, 1273–1277. [Google Scholar] [CrossRef]

- Wen, Z.; Liu, Y.Y.; Jia, Z.H.; Zhao, P.Z.; Zhang, Z.Q.; Liu, Q. Study of Texture in 6016 Aluminum Alloy During Processing. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2017. [Google Scholar]

- Kim, H.-K.; Kim, H.-W.; Cho, J.-H.; Lee, J.-C. High-Formability Al Alloy Sheet Produced by Asymmetric Rolling of Strip-Cast Sheet. Mater. Sci. Eng. A 2013, 574, 31–36. [Google Scholar] [CrossRef]

- Sidor, J.; Miroux, A.; Petrov, R.; Kestens, L. Microstructural and Crystallographic Aspects of Conventional and Asymmetric Rolling Processes. Acta Mater. 2008, 56, 2495–2507. [Google Scholar] [CrossRef]

- Wakeel, A.; Huang, T.L.; Wu, G.L.; Mishin, O.V.; Huang, X. Development of a Strong Goss Texture During Annealing of a Heavily Rolled Al—0.3% Cu Alloy. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015. [Google Scholar]

- Engler, O.; Hirsch, J.; Lücke, K. Texture Development in Al-1.8 Wt% Cu Depending on the Precipitation State—II. Recrystallization Textures. Acta Metall. Mater. 1995, 43, 121–138. [Google Scholar]

- Pérez-Prado, M.T.; González-Doncel, G.; Ruano, O.A.; McNelley, T.R. Texture Analysis of the Transition from Slip to Grain Boundary Sliding in a Discontinuously Recrystallized Superplastic Aluminum Alloy. Acta Mater. 2001, 49, 2259–2268. [Google Scholar] [CrossRef]

- Doherty, R.; Hughes, D.; Humphreys, F.; Jonas, J.; Jensen, D.; Kassner, M.; King, W.; McNelley, T.; McQueen, H.; Rollett, A. Current Issues in Recrystallization: A Review. Mater. Sci. Eng. A 1997, 238, 219–274. [Google Scholar] [CrossRef]

- Engler, O.; Hirsch, J. Texture Control by Thermomechanical Processing of Aa6xxx Al–Mg–Si Sheet Alloys for Automotive Applications—A Review. Mater. Sci. Eng. A 2002, 336, 249–262. [Google Scholar] [CrossRef]

- Li, S.; Engler, O.; Van Houtte, P. Plastic Anisotropy and Texture Evolution During Tensile Testing of Extruded Aluminium Profiles. Model. Simul. Mater. Sci. Eng. 2005, 13, 783. [Google Scholar] [CrossRef]

- Gao, G.-J.; Chen, H.E.; Yong, L.I.; Li, J.-D.; Wang, Z.-D.; Misra, R.D.K. Influence of Different Solution Methods on Microstructure, Precipitation Behavior and Mechanical Properties of Al–Mg–Si Alloy. Trans. Nonferrous Met. Soc. China 2018, 28, 839–847. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Ryazantseva, M.A.; Portnoy, V.K. Effect of Eutectic Particles on the Grain Size Control and the Superplasticity of Aluminium Alloys. Mater. Sci. Eng. A 2011, 528, 7306–7309. [Google Scholar] [CrossRef]

- Bhattacharya, V.; Chattopadhyay, K. Microstructure and Wear Behaviour of Aluminium Alloys Containing Embedded Nanoscaled Lead Dispersoids. Acta Mater. 2004, 52, 2293–2304. [Google Scholar] [CrossRef]

- Huo, W.; Hou, L.; Lang, Y.; Cui, H.; Zhuang, L.; Zhang, J. Improved Thermo-Mechanical Processing for Effective Grain Refinement of High-Strength Aa 7050 Al Alloy. Mater. Sci. Eng. A 2015, 626, 86–93. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Guo, W.; Zhang, Y. Effects of Thermomechanical Treatment on Grain Refinement, Second-Phase Particle Dissolution, and Mechanical Properties of 2219 Al Alloy. J. Mater. Process. Technol. 2020, 278, 116506. [Google Scholar] [CrossRef]

- Humphreys, J.; Bate, P. Gradient Plasticity and Deformation Structures around Inclusions. Scr. Mater. 2003, 48, 173–178. [Google Scholar] [CrossRef]

- Engler, O.; Kong, X.W.; Lücke, K. Influence of Precipitates on the Microstructure and Texture During the Rolling of Al-Cu and Al-Mn Single Crystals with Rolling Texture Orientations. Philos. Mag. A 2001, 81, 543–570. [Google Scholar] [CrossRef]

- Engler, O.; Yang, P.; Kong, X. On the Formation of Recrystallization Textures in Binary Al-1.3% Mn Investigated by Means of Local Texture Analysis. Acta Mater. 1996, 44, 3349–3369. [Google Scholar] [CrossRef]

| Samples | Si | Mg | Cu | Fe | Mn | Cr | Al |

|---|---|---|---|---|---|---|---|

| NH | 1.51 | 0.40 | 0.30 | 0.18 | 0.10 | 0.05 | Bal. |

| NL | |||||||

| RH | 1.53 | 0.41 | 0.29 | 0.16 | 0.09 | 0.06 | |

| RL |

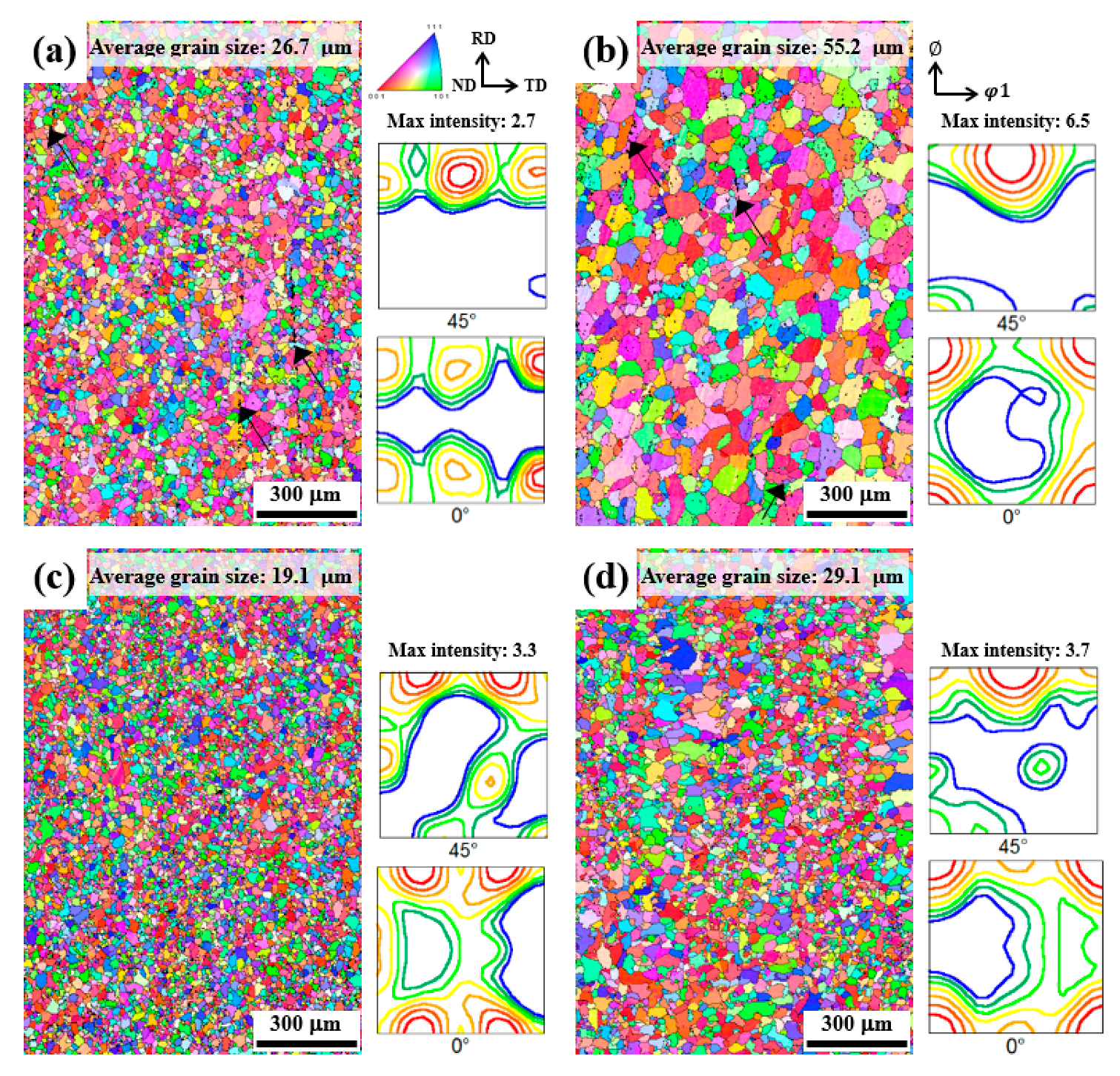

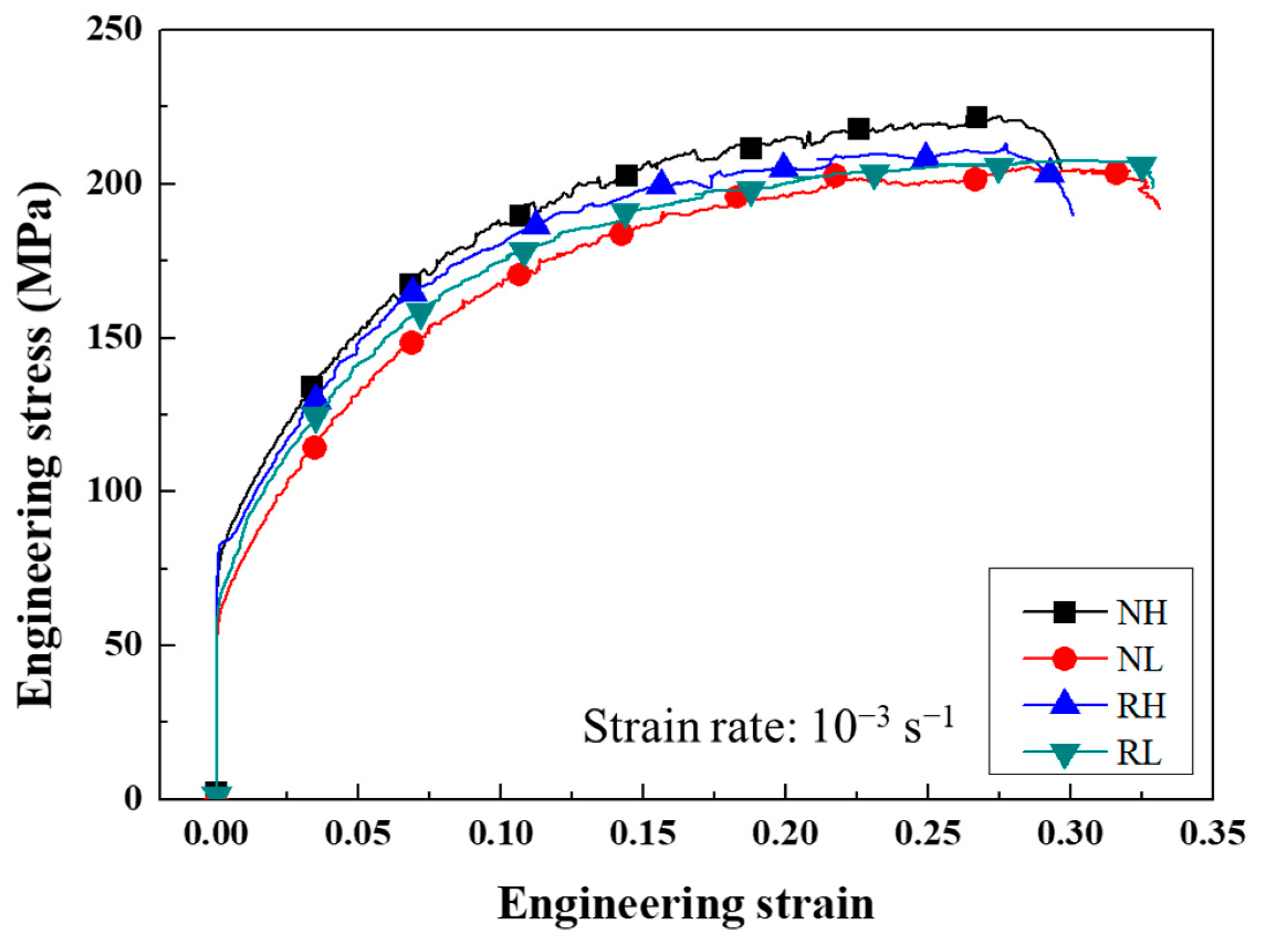

| Samples | Tensile Direction (°) | Grain Size (μm) | YS (MPa) | UTS (MPa) | EL (%) | r | ||

|---|---|---|---|---|---|---|---|---|

| NH | 0 | 26.7 | 78.8 | 219.9 | 29.9 | 0.63 | 0.66 | −0.006 |

| 45 | 75.8 | 226.5 | 30.1 | 0.66 | ||||

| 90 | 78.4 | 224.6 | 29.2 | 0.68 | ||||

| NL | 0 | 55.2 | 61.8 | 210.9 | 32.0 | 0.61 | 0.58 | −0.07 |

| 45 | 66.4 | 211.4 | 28.9 | 0.55 | ||||

| 90 | 66.3 | 216.6 | 29.6 | 0.63 | ||||

| RH | 0 | 19.1 | 80.4 | 210.7 | 32.2 | 0.58 | 0.69 | −0.22 |

| 45 | 80.8 | 207.9 | 32.5 | 0.80 | ||||

| 90 | 81.1 | 211.4 | 29.6 | 0.58 | ||||

| RL | 0 | 29.1 | 73.7 | 210.8 | 31.9 | 0.91 | 0.66 | 0.29 |

| 45 | 74.2 | 211.3 | 31.9 | 0.51 | ||||

| 90 | 70.5 | 205.1 | 29.8 | 0.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, J.; Lee, S.; Kyeong, J.; Shin, S.; Kang, H. Effect of Geometrical Parameters of Microscale Particles on Particle-Stimulated Nucleation and Recrystallization Texture of Al-Si-Mg-Cu-Based Alloy Sheets. Materials 2022, 15, 7924. https://doi.org/10.3390/ma15227924

Jeon J, Lee S, Kyeong J, Shin S, Kang H. Effect of Geometrical Parameters of Microscale Particles on Particle-Stimulated Nucleation and Recrystallization Texture of Al-Si-Mg-Cu-Based Alloy Sheets. Materials. 2022; 15(22):7924. https://doi.org/10.3390/ma15227924

Chicago/Turabian StyleJeon, Jonggyu, Sangjun Lee, Joonseok Kyeong, Seeun Shin, and Heon Kang. 2022. "Effect of Geometrical Parameters of Microscale Particles on Particle-Stimulated Nucleation and Recrystallization Texture of Al-Si-Mg-Cu-Based Alloy Sheets" Materials 15, no. 22: 7924. https://doi.org/10.3390/ma15227924

APA StyleJeon, J., Lee, S., Kyeong, J., Shin, S., & Kang, H. (2022). Effect of Geometrical Parameters of Microscale Particles on Particle-Stimulated Nucleation and Recrystallization Texture of Al-Si-Mg-Cu-Based Alloy Sheets. Materials, 15(22), 7924. https://doi.org/10.3390/ma15227924