A Method of Managing Waste Oak Flour as a Biocomponent for Obtaining Composites Based on Modified Soybean Oil

Abstract

1. Introduction

2. Materials and Methods

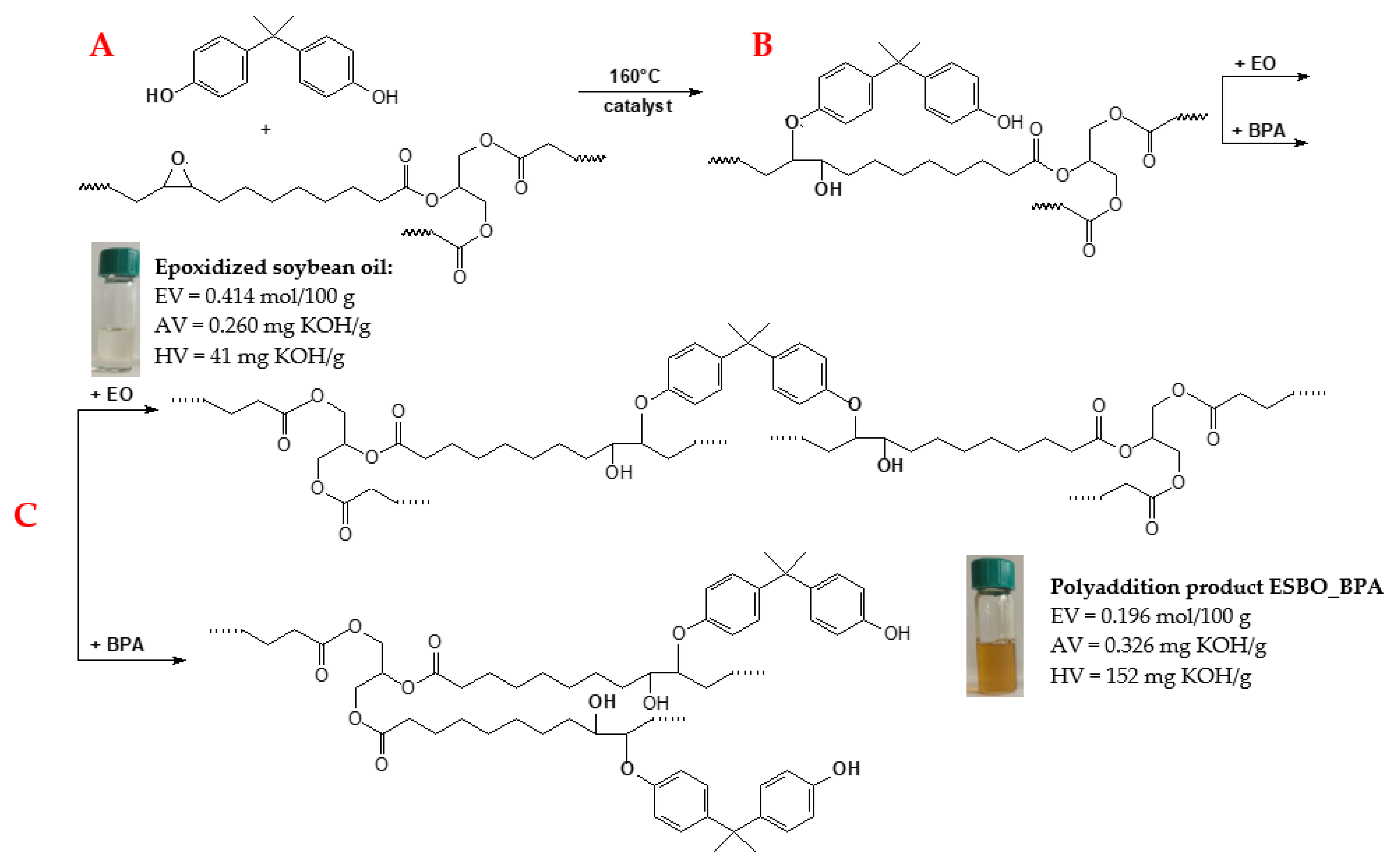

2.1. Epoxy Fusion

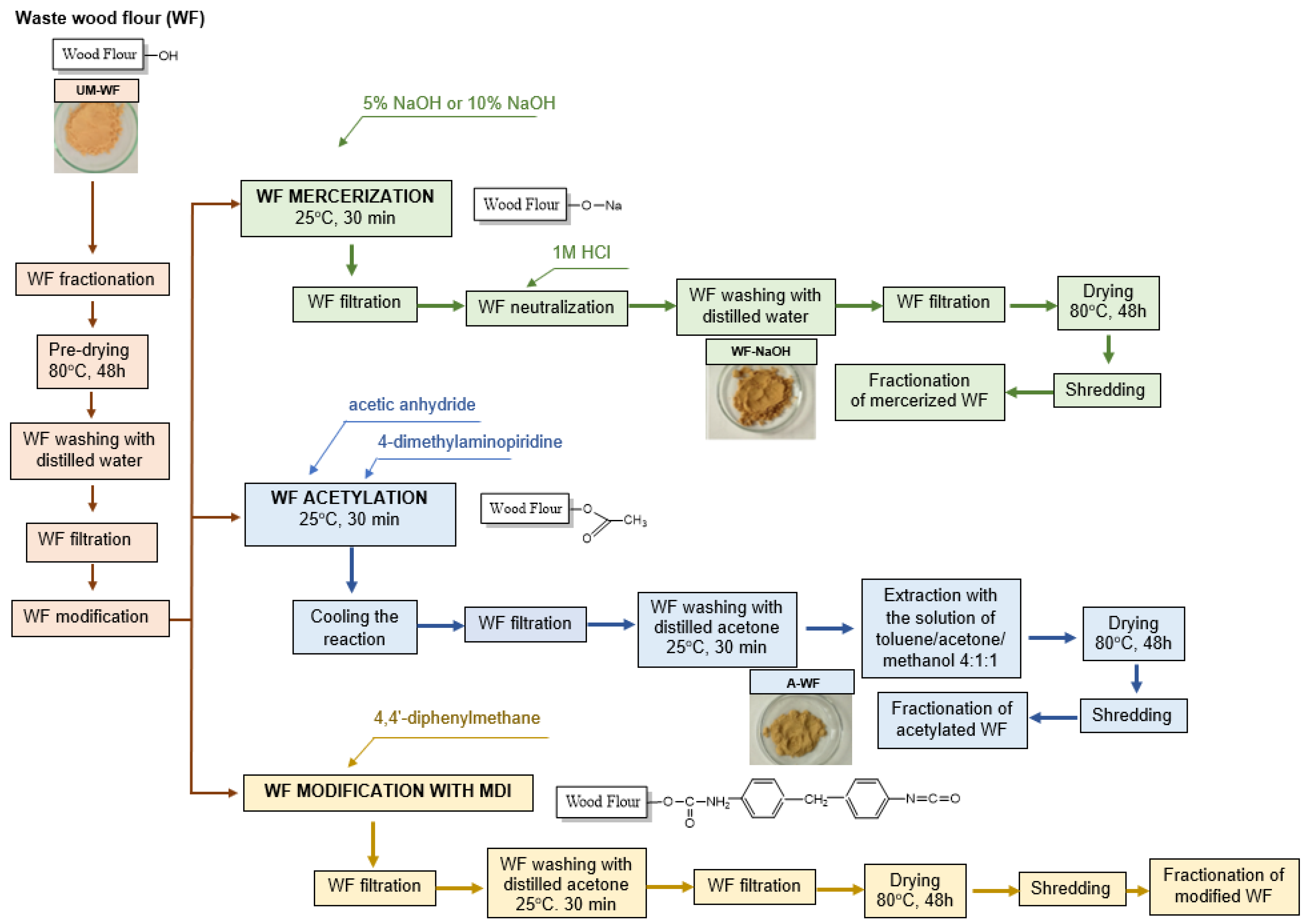

2.2. Wood Waste Preparation

2.3. Synthesis of Composites

2.4. The Mechanical Properties

2.5. Spectroscopic Measurements

2.6. Morphological Analysis

3. Results

3.1. Synthesis of the Biocomposites Based on Modified Soybean Oil Filled with Waste Oak Flour

3.1.1. Synthesis of the Polymeric Matrix

3.1.2. Preparation of the Biofiller

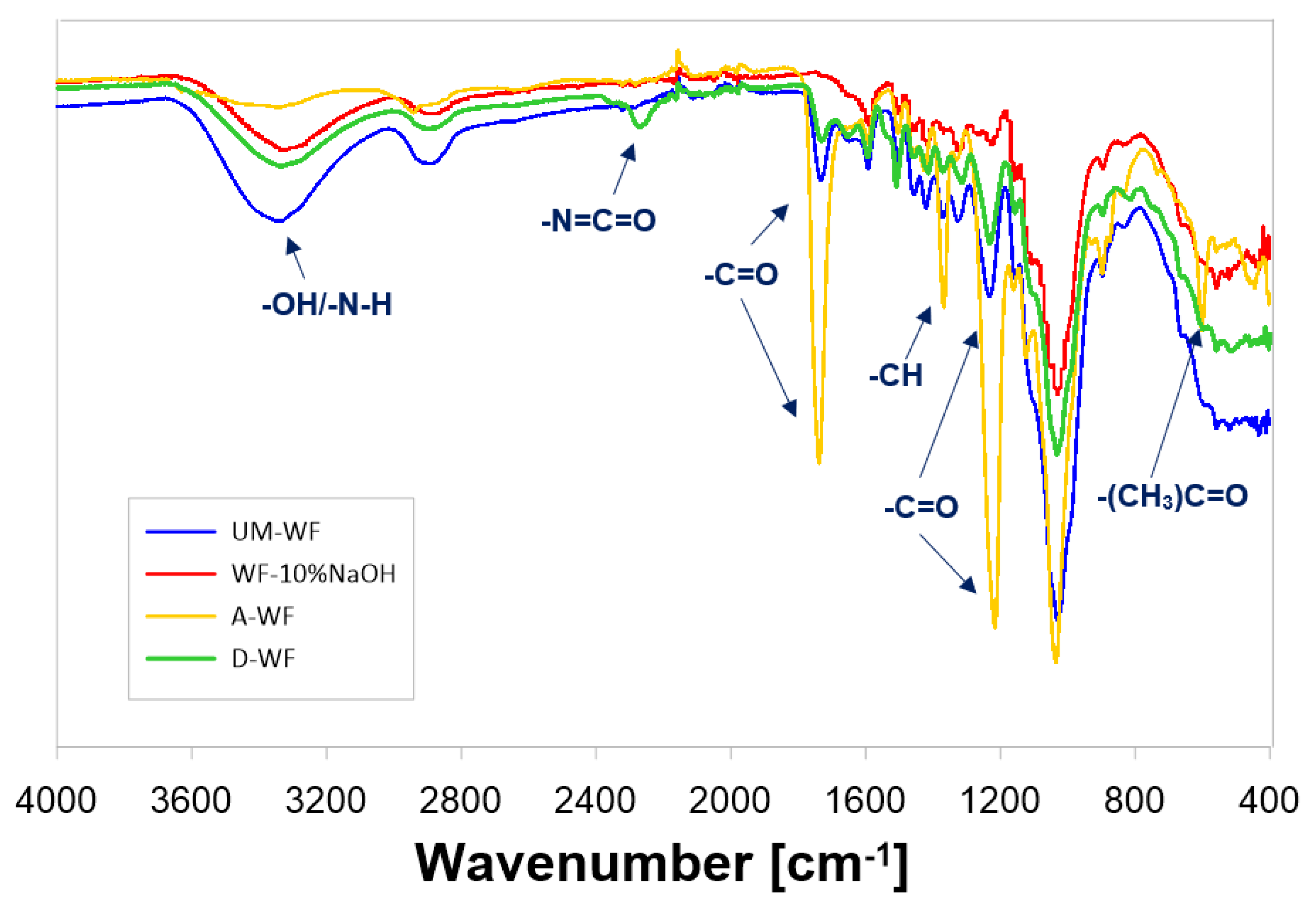

Results of the FTIR Analysis of the Wood Filler

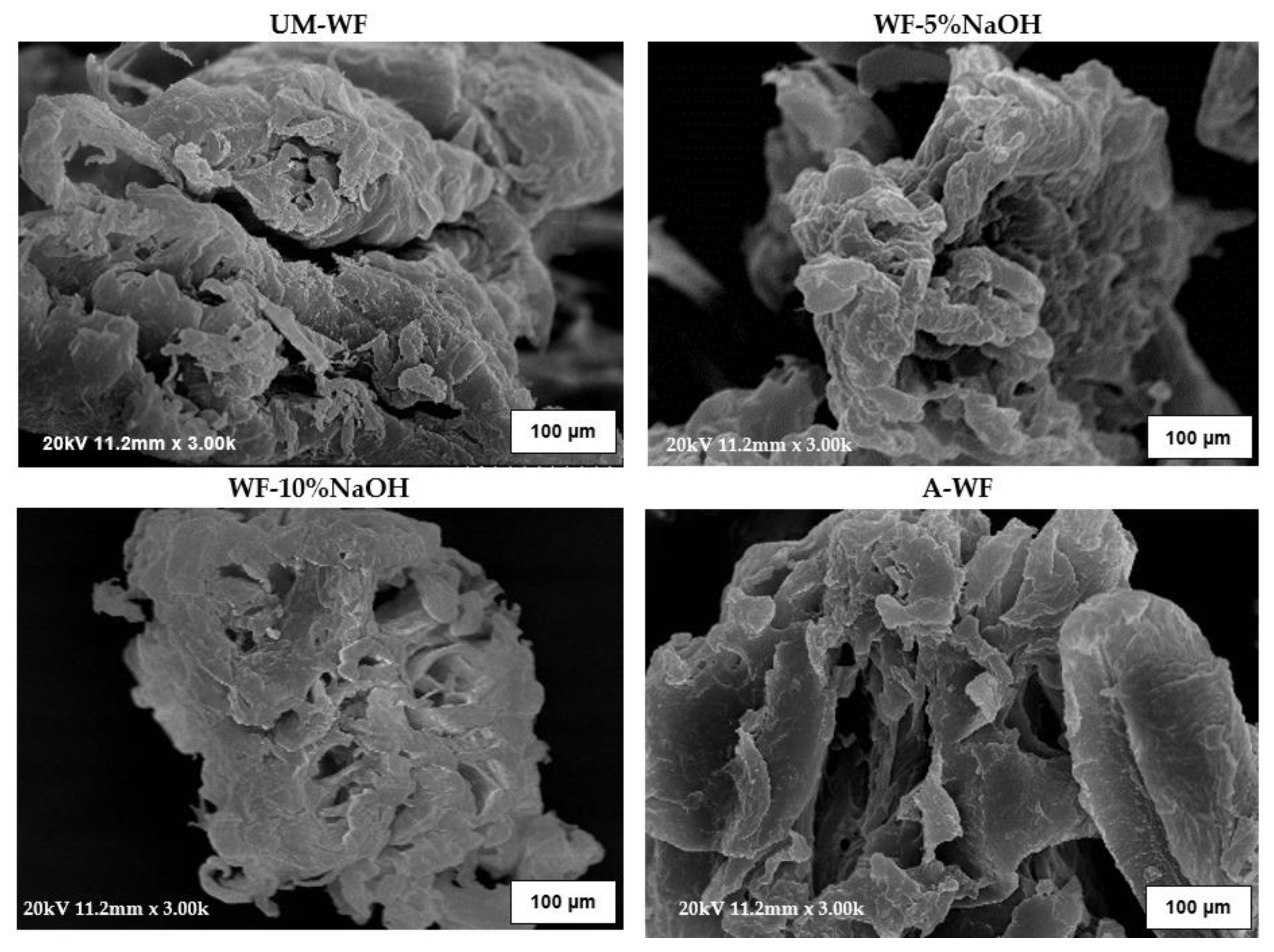

Results of the Morphological Analysis of the Wood Flour

3.1.3. The Preparation of Biocomposites

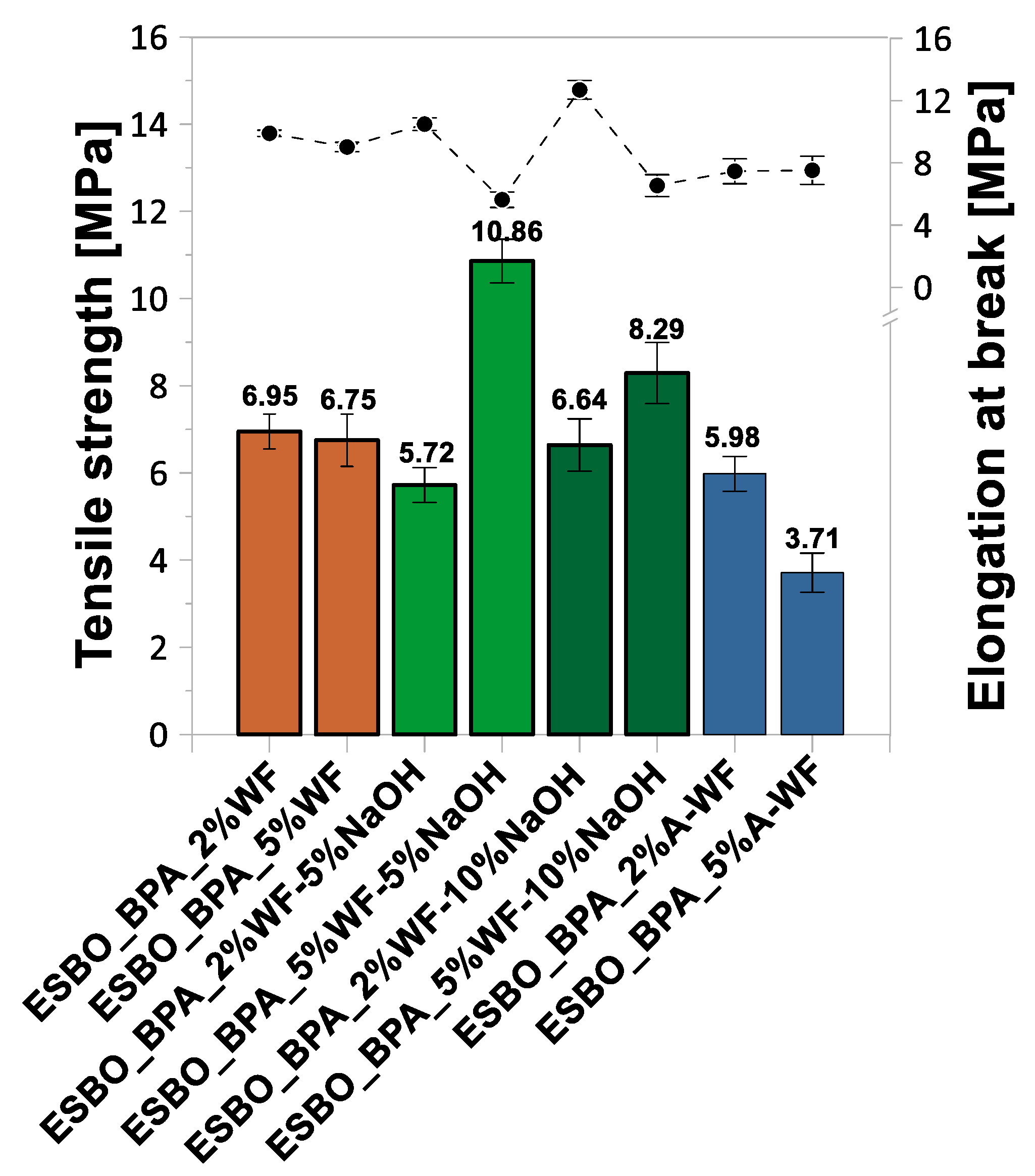

3.2. Mechanical Properties of ESBO_BPA/Wood Flour Composites

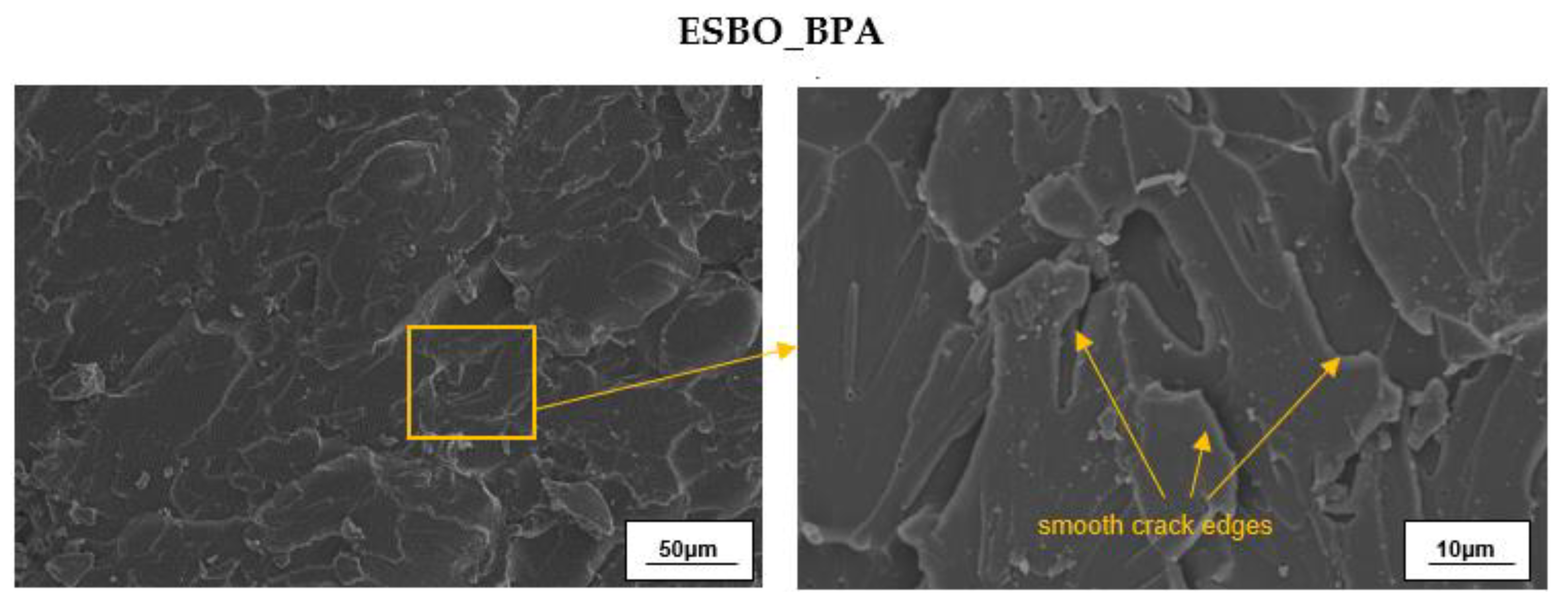

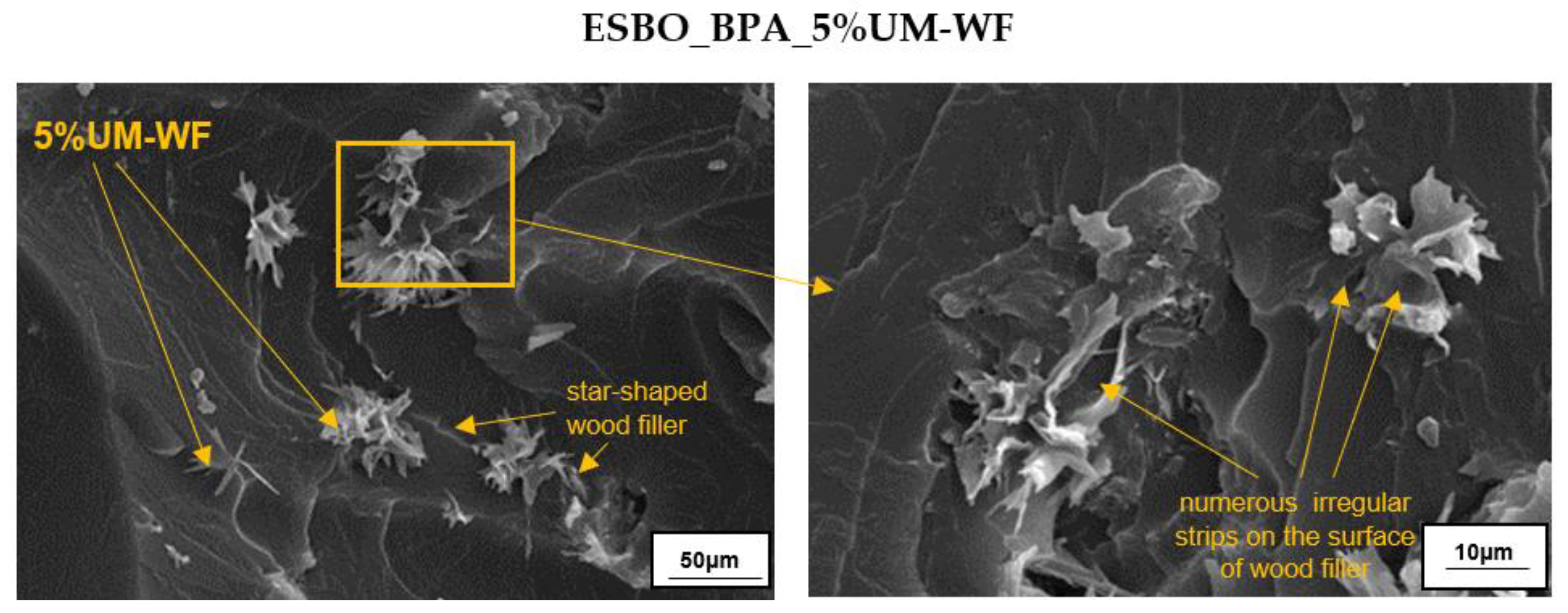

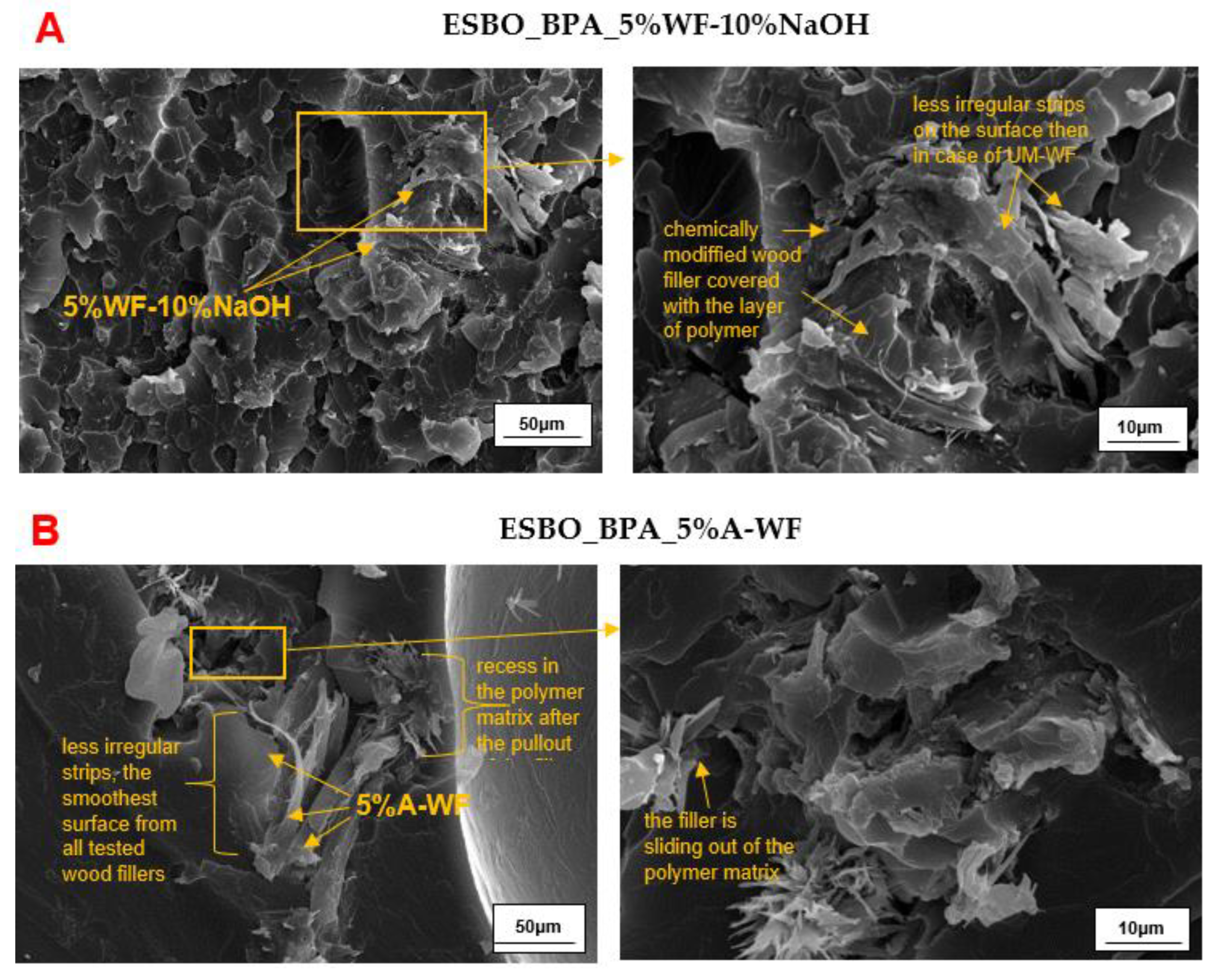

3.3. Results of SEM Analysis of ESBO_BPA/Wood Flour Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sousa, A.F.; Silvestre, A.J. Plastics from renewable sources as green and sustainable alternatives. Curr. Opin. Green Sustain. Chem. 2022, 33, 100557. [Google Scholar] [CrossRef]

- Silva, A.B.; Costa, M.F.; Duarte, A.C. Biotechnology advances for dealing with environmental pollution by micro (nano) plastics: Lessons on theory and practices. Curr. Opin. Environ. Sci. Health 2018, 1, 30–35. [Google Scholar] [CrossRef]

- Yadav, V.; Sherly, M.A.; Ranjan, P.; Tinoco, R.O.; Boldrin, A.; Damgaard, A.; Laurent, A. Framework for quantifying environmental losses of plastics from landfills. Resour. Conserv. Recycl. 2020, 161, 104914. [Google Scholar] [CrossRef]

- Rai, P.K.; Lee, J.; Brown, R.J.; Kim, K.H. Micro-and nano-plastic pollution: Behavior, microbial ecology, and remediation technologies. J. Clean. Prod. 2021, 291, 125240. [Google Scholar] [CrossRef]

- Allouzi, M.M.A.; Tang, D.Y.Y.; Chew, K.W.; Rinklebe, J.; Bolan, N.; Allouzi, S.M.A.; Show, P.L. Micro (nano) plastic pollution: The ecological influence on soil-plant system and human health. Sci. Total Environ. 2021, 788, 147815. [Google Scholar] [CrossRef]

- Zhuo, C.; Levendis, Y.A. Upcycling waste plastics into carbon nanomaterials: A review. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Degli Esposti, M.; Morselli, D.; Fava, F.; Bertin, L.; Cavani, F.; Viaggi, D.; Fabbri, P. The role of biotechnology in the transition from plastics to bioplastics: An opportunity to reconnect global growth with sustainability. FEBS Open Bio 2021, 11, 967–983. [Google Scholar] [CrossRef]

- Chang, B.P.; Thakur, S.; Mohanty, A.K.; Misra, M. Novel sustainable biobased flame retardant from functionalized vegetable oil for enhanced flame retardancy of engineering plastic. Sci. Rep. 2019, 9, 1–14. [Google Scholar] [CrossRef]

- Mustapha, R.; Rahmat, A.R.; Abdul Majid, R.; Mustapha, S.N.H. Vegetable oil-based epoxy resins and their composites with bio-based hardener: A short review. Polym.-Plast. Technol. Mater. 2019, 58, 1311–1326. [Google Scholar] [CrossRef]

- Bertolino, V.; Cavallaro, G.; Milioto, S.; Lazzara, G. Polysaccharides/Halloysite nanotubes for smart bionanocomposite materials. Carbohydr. Polym. 2020, 245, 116502. [Google Scholar] [CrossRef]

- Nechita, P. Review on polysaccharides used in coatings for food packaging papers. Coatings 2020, 10, 566. [Google Scholar] [CrossRef]

- Ojogbo, E.; Ogunsona, E.O.; Mekonnen, T.H. Chemical and physical modifications of starch for renewable polymeric materials. Mater. Today Sustain. 2020, 7, 100028. [Google Scholar] [CrossRef]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Teaca, C.A.; Tanasa, F.; Zanoaga, M. Multi-component polymer systems comprising wood as bio-based component and thermoplastic polymer matrices–an overview. BioResources 2018, 13, 4728–4769. [Google Scholar] [CrossRef]

- Safin, R.R.; Talipova, G.A.; Galyavetdinov, N.R.; Nazipova, F.V.; Salimgaraeva, R.V. The study of the destructive properties of wood-filled composites for the production of biodegradable packaging materials. Int. Multidiscip. Sci. GeoConference SGEM 2019, 19, 541–546. [Google Scholar] [CrossRef]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable polymers and plastics: Performance beyond the green. New Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef]

- Mann, G.S.; Singh, L.P.; Kumar, P.; Singh, S. Green composites: A review of processing technologies and recent applications. J. Thermoplast. Compos. Mater. 2020, 33, 1145–1171. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Dhakal, H.N. Green-composites: Ecofriendly and sustainability. Appl. Sci. Eng. Prog. 2020, 13, 183–184. [Google Scholar] [CrossRef]

- Kumar, S.; Krishnan, S.; Mohanty, S.; Nayak, S.K. Synthesis and characterization of petroleum and biobased epoxy resins: A review. Polym. Int. 2018, 67, 815–839. [Google Scholar] [CrossRef]

- Chen, C.; He, Y.; Xiao, G.; Zhong, F.; Xie, P.; Li, H.; He, L. Co-modification of epoxy based polyhedral oligomeric silsesquioxanes and polyaniline on graphene for enhancing corrosion resistance of waterborne epoxy coating. Colloids Surf. A Physicochem. Eng. Asp. 2021, 614, 126190. [Google Scholar] [CrossRef]

- Capricho, J.C.; Fox, B.; Hameed, N. Multifunctionality in epoxy resins. Polym. Rev. 2020, 60, 1–41. [Google Scholar] [CrossRef]

- Sarfraz, M.S.; Hong, H.; Kim, S.S. Recent developments in the manufacturing technologies of composite components and their cost-effectiveness in the automotive industry: A review study. Compos. Struct. 2021, 266, 113864. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- Özmen, F.K.; Üreyen, M.E.; Koparal, A.S. Cleaner production of flame-retardant-glass reinforced epoxy resin composite for aviation and reducing smoke toxicity. J. Clean. Prod. 2020, 276, 124065. [Google Scholar] [CrossRef]

- Chatterjee, B.; Bhowmik, S. Evolution of material selection in commercial aviation industry—A review. Sustain. Eng. Prod. Manuf. Technol. 2019, 199–219. [Google Scholar] [CrossRef]

- Ramon, E.; Sguazzo, C.; Moreira, P.M. A review of recent research on bio-based epoxy systems for engineering applications and potentialities in the aviation sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef]

- Galeev, R.R.; Nizamov, R.K.; Abdrakhmanova, L.A. Filling of epoxy polymers with chemically precipitated chalk from chemical water treatment sludge. In International Conference Industrial and Civil Construction; Springer: Cham, Switzerland, 2021; pp. 93–97. [Google Scholar] [CrossRef]

- Miturska, I.; Rudawska, A.; Müller, M.; Valášek, P. The influence of modification with natural fillers on the mechanical properties of epoxy adhesive compositions after storage time. Materials 2020, 13, 291. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, T.C.; Zhang, Y.X.; Rao, J.; Yuan, S. A route for large-scale preparation of multifunctional superhydrophobic coating with electrochemically-modified kaolin for efficient corrosion protection of magnesium alloys. J. Magnes. Alloy. 2021, in press. [CrossRef]

- Luo, H.; Ding, J.; Huang, Z.; Yang, T. Investigation of properties of nano-silica modified epoxy resin films and composites using RFI technology. Compos. Part B: Eng. 2018, 155, 288–298. [Google Scholar] [CrossRef]

- Bifulco, A.; Parida, D.; Salmeia, K.A.; Nazir, R.; Lehner, S.; Stämpfli, R.; Gaan, S. Fire and mechanical properties of DGEBA-based epoxy resin cured with a cycloaliphatic hardener: Combined action of silica, melamine and DOPO-derivative. Mater. Des. 2020, 193, 108862. [Google Scholar] [CrossRef]

- Cai, Y.; Meng, F.; Liu, L.; Liu, R.; Cui, Y.; Zheng, H.; Wang, F. The effect of the modification of mica by high-temperature mechanochemistry on the anticorrosion performance of epoxy coatings. Polymers 2021, 13, 378. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.D.; Li, Y.P.; Wang, H.W.; Li, J.L.; Fu, A.Q.; Chen, G.; Cheng, F. Corrosion Resistance Mechanism of Mica–Graphene/Epoxy Composite Coating in CO2-Cl− System. Materials 2022, 15, 1194. [Google Scholar] [CrossRef]

- Baghdadi, Y.N.; Youssef, L.; Bouhadir, K.; Harb, M.; Mustapha, S.; Patra, D.; Tehrani-Bagha, A.R. The effects of modified zinc oxide nanoparticles on the mechanical/thermal properties of epoxy resin. J. Appl. Polym. Sci. 2020, 137, 49330. [Google Scholar] [CrossRef]

- Jin, F.L.; Park, S.J. Thermal properties of epoxy resin/filler hybrid composites. Polym. Degrad. Stab. 2012, 97, 2148–2153. [Google Scholar] [CrossRef]

- Saravanakumar, K.; Arumugam, V.; Souhith, R.; Santulli, C. Influence of milled glass fiber fillers on mode i & mode II interlaminar fracture toughness of epoxy resin for fabrication of glass/epoxy composites. Fibers 2020, 8, 36. [Google Scholar] [CrossRef]

- Zhu, M.; Li, J.; Chen, J.; Song, H.; Zhang, H. Improving thermal conductivity of epoxy resin by filling boron nitride nanomaterials: A molecular dynamics investigation. Comput. Mater. Sci. 2019, 164, 108–115. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, X.; Cao, J.; Chen, R.; Aziz, T.; Fan, H.; Bittencourt, C. Behavior of epoxy resin filled with nano-SiO2 treated with a Eugenol epoxy silane. J. Appl. Polym. Sci. 2021, 138, 50138. [Google Scholar] [CrossRef]

- Datsyuk, V.; Trotsenko, S.; Trakakis, G.; Boden, A.; Vyzas-Asimakopoulos, K.; Parthenios, J.; Papagelis, K. Thermal properties enhancement of epoxy resins by incorporating polybenzimidazole nanofibers filled with graphene and carbon nanotubes as reinforcing material. Polym. Test. 2020, 82, 106317. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, K.; Bhowmik, S. Mechanical characterization and quantification of tensile, fracture and viscoelastic characteristics of wood filler reinforced epoxy composite. Wood Sci. Technol. 2018, 52, 677–699. [Google Scholar] [CrossRef]

- Jain, N.K.; Gupta, M.K. Hybrid teak/Sal wood flour reinforced composites: Mechanical, thermal and water absorption properties. Mater. Res. Express 2018, 5, 125306. [Google Scholar] [CrossRef]

- Dinesh, S.; Kumaran, P.; Mohanamurugan, S.; Vijay, R.; Singaravelu, D.L.; Vinod, A.; Sanjay, M.R.; Suchart Siengchin, B.K.S. Influence of wood dust fillers on the mechanical, thermal, water absorption and biodegradation characteristics of jute fiber epoxy composites. J. Polym. Res. 2020, 27, 1–13. [Google Scholar] [CrossRef]

- Sarikaya, E.; Çallioğlu, H.; Demirel, H. Production of epoxy composites reinforced by different natural fibers and their mechanical properties. Compos. Part B Eng. 2019, 167, 461–466. [Google Scholar] [CrossRef]

- Hanan, F.; Jawaid, M.; Tahir, P.M. Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J. Nat. Fibers 2018, 17, 155–167. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Synthesis of high-molecular weight biobased epoxy resins: Determination of the course of the process by MALDI-TOF mass spectrometry. ACS Sustain. Chem. Eng. 2018, 6, 6084–6093. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Novel bio-based epoxy-polyurethane materials from modified vegetable oils-synthesis and characterization. Express Polym. Lett. 2017, 11, 308–319. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M. Chemical modification of hemp, sisal, jute and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Weyenberg, I.; Truong, T.C.; Vangrimde, B.; Verpoest, I. Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Compos. Part A. 2006, 37, 1368–1376. [Google Scholar] [CrossRef]

- Wertz, J.L.; Bedue, O.; Mercier, J.P. Cellulose Science and Technology, 1st ed.; Taylor and Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar]

- Olaru, N.; Olaru, L.; Vasile, C.; Ander, P. Surface modified cellulose obtained by acetylation without solvents of bleached and unbleached kraft pulps. Polimery 2018, 56, 834–840. [Google Scholar] [CrossRef]

- Azeh, Y.; Olatunji, G.A.; Mohammed, C.; Mamza, P.A. Acetylation of wood flour from four wood species grown in Nigeria using vinegar and acetic anhydride. Int. J. Carbohydr. Chem. 2013, 2013, 141034. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Enayati, A.A.; Rials, T.G. Effects of hemicellulose extraction on properties of wood flour and wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 686–694. [Google Scholar] [CrossRef]

- Yu, W.; Li, M.; Lei, W.; Pu, Y.; Sun, K.; Ma, Y. Effects of Wood Flour (WF) Pretreatment and the Addition of a Toughening Agent on the Properties of FDM 3D-Printed WF/Poly (lactic acid) Biocomposites. Molecules 2022, 27, 2985. [Google Scholar] [CrossRef]

- Casado, U.; Marcovich, N.E.; Aranguren, M.I.; Mosiewicki, M.A. High-Strength Composites Based on Tung Oil Polyurethane and Wood Flour: Effect of the Filler Concentration on the Mechanical Properties. Polym. Eng. Sci. 2009, 49, 713–721. [Google Scholar] [CrossRef]

- Quirino, R.L.; Woodford, J.; Larock, R.C. Soybean and linseed oil-based composites reinforced with wood flour and wood fibers. J. Appl. Polym. Sci. 2012, 124, 1520–1528. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Ogunesan, E.A.; Vunain, E.; Lafia-Araga, R.A.; Doyoyo, M.; Meijboom, R. Mechanism of fiber/matrix bond and properties of wood polymer composites produced from alkaline-treated Daniella oliveri wood flour. Polym. Compos. 2016, 37, 2657–2672. [Google Scholar] [CrossRef]

- Gu, H. Tensile behaviours of the coir fibre and related composites after NaOH treatment. Mater. Des. 2009, 30, 3931–3934. [Google Scholar] [CrossRef]

- Czub, P. Characterization of an Epoxy Resin Modified with Natural Oil-Based Reactive Diluents. Macromol. Symp. 2006, 245, 533–538. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural fillers as potential modifying agents for epoxy composition: A review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef]

- Gargol, M.; Klepka, T.; Klapiszewski, Ł.; Podkościelna, B. Synthesis and thermo-mechanical study of epoxy resin-based composites with waste fibers of hemp as an eco-friendly filler. Polymers 2021, 13, 503. [Google Scholar] [CrossRef]

| Frequency (cm−1) | Associated Band | ||||||

|---|---|---|---|---|---|---|---|

| UM-WF | WF-5%NaOH | WF-10%NaOH | A-WF | D-WF | |||

| 3607–3080 | 3560–3080 | 3600–3035 | - | 3642–2999 | vb | -OH | v valencene |

| 2980–2822 | 2965–2785 | 2996–2785 | 2938 | 2992–2812 | w | -CH3 | v valencene |

| - | - | - | - | 2271 | s, asym | -N=C=O | v valencene |

| 1728.89 | - | - | 1735 | 1725 | s | -C=O | v valencene |

| 1595.81 | 1587.13 | 1590.02 | 1593 | - | vb | -C=C- | skeletal ring |

| - | - | - | - | 1365 | s-m, sym | -CH | δ deformation |

| 1297–1188 | - | - | 1286–1180 | 1278–1194 | w | -C-O | v valencene |

| 1178–860 | 1172-883 | 1172-930 | 1140–942 | 1167–915 | sym | -C-O | v valencene |

| - | - | - | 600 | - | s | -COCO | δ deformation |

| Mechanical Properties | Tested Epoxy–Polyurethane Compositions Based on ESBO_BPA | |||||||

|---|---|---|---|---|---|---|---|---|

| Unmodified Wood Flour | Modified Wood Flour | |||||||

| 5% NaOH | 10% NaOH | Acetylation | ||||||

| 2%WF | 5%WF | 2%WF | 5%WF | 2%WF | 5%WF | 2%WF | 5%WF | |

| Modulus of elasticity (MPa) | 129.13 ± 17.31 | 133.12 ± 18.40 | 117.07 ± 11.01 | 236.92 ± 30.15 | 144.85 ± 11.29 | 215.30 ± 29.64 | 132.33 ± 9.98 | 80.24 ± 4.86 |

| Elasticity flexural modulus (MPa) | 163.33 ± 31.21 | 115.20 ± 9.83 | 106.75 ± 9.71 | 229.20 ± 19.63 | 121.25 ± 24.60 | 124.00 ± 16.09 | 64.00 ± 24.00 | 81.67 ± 16.65 |

| Shore Hardness (Sh°A) | 90.2 ± 4.2 | 88.5 ± 2.7 | 92.4 ± 2.6 | 92.6 ± 3.1 | 90.9 ± 4.1 | 91.1 ± 2.1 | 87.5 ± 2.5 | 90.4 ± 2.9 |

| Impact toughness (kJ/m2) | 4.64 ± 0.57 | 7.00 ± 1.89 | 3.24 ± 0.22 | 4.52 ± 0.25 | 6.99 ± 0.89 | 3.90 ± 0.85 | 4.88 ± 1.82 | 4.24 ± 0.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sienkiewicz, A.; Czub, P. A Method of Managing Waste Oak Flour as a Biocomponent for Obtaining Composites Based on Modified Soybean Oil. Materials 2022, 15, 7737. https://doi.org/10.3390/ma15217737

Sienkiewicz A, Czub P. A Method of Managing Waste Oak Flour as a Biocomponent for Obtaining Composites Based on Modified Soybean Oil. Materials. 2022; 15(21):7737. https://doi.org/10.3390/ma15217737

Chicago/Turabian StyleSienkiewicz, Anna, and Piotr Czub. 2022. "A Method of Managing Waste Oak Flour as a Biocomponent for Obtaining Composites Based on Modified Soybean Oil" Materials 15, no. 21: 7737. https://doi.org/10.3390/ma15217737

APA StyleSienkiewicz, A., & Czub, P. (2022). A Method of Managing Waste Oak Flour as a Biocomponent for Obtaining Composites Based on Modified Soybean Oil. Materials, 15(21), 7737. https://doi.org/10.3390/ma15217737