Discrete Element Modelling of Cold Crushing Tests Considering Various Interface Property Distributions in Ordinary Refractory Ceramics

Abstract

1. Introduction

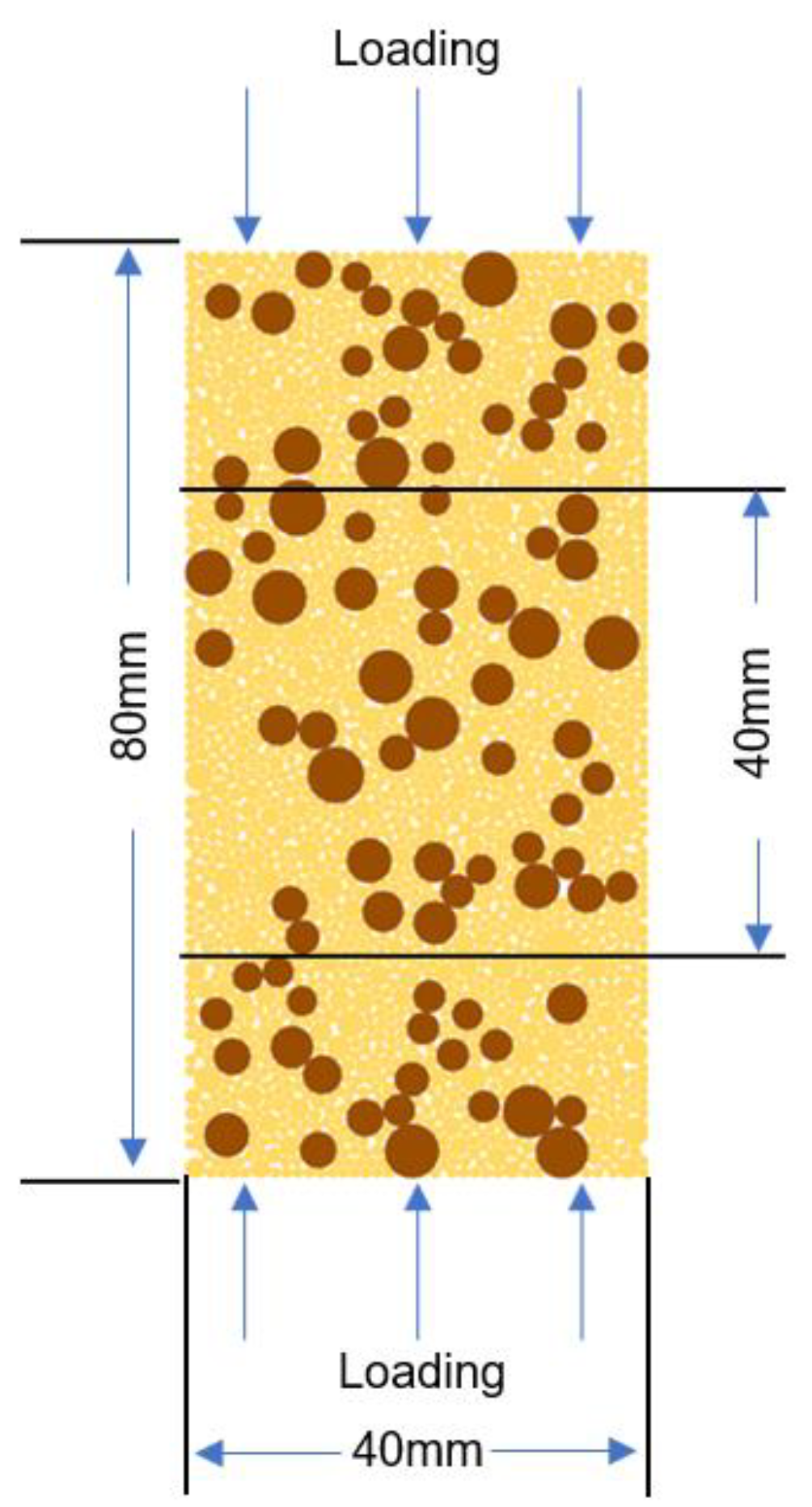

2. DE Model Configurations

3. Results and Discussion

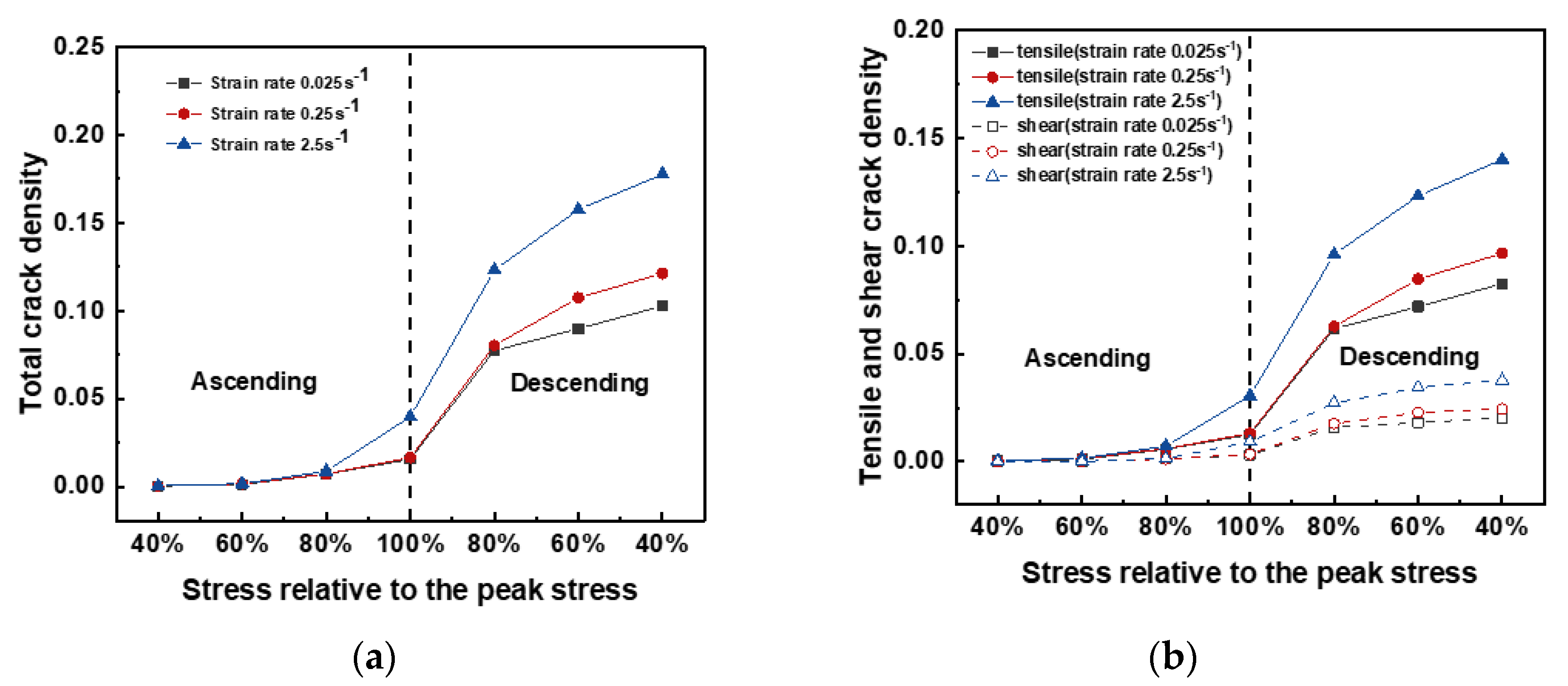

3.1. Optimized Loading Strain Rate

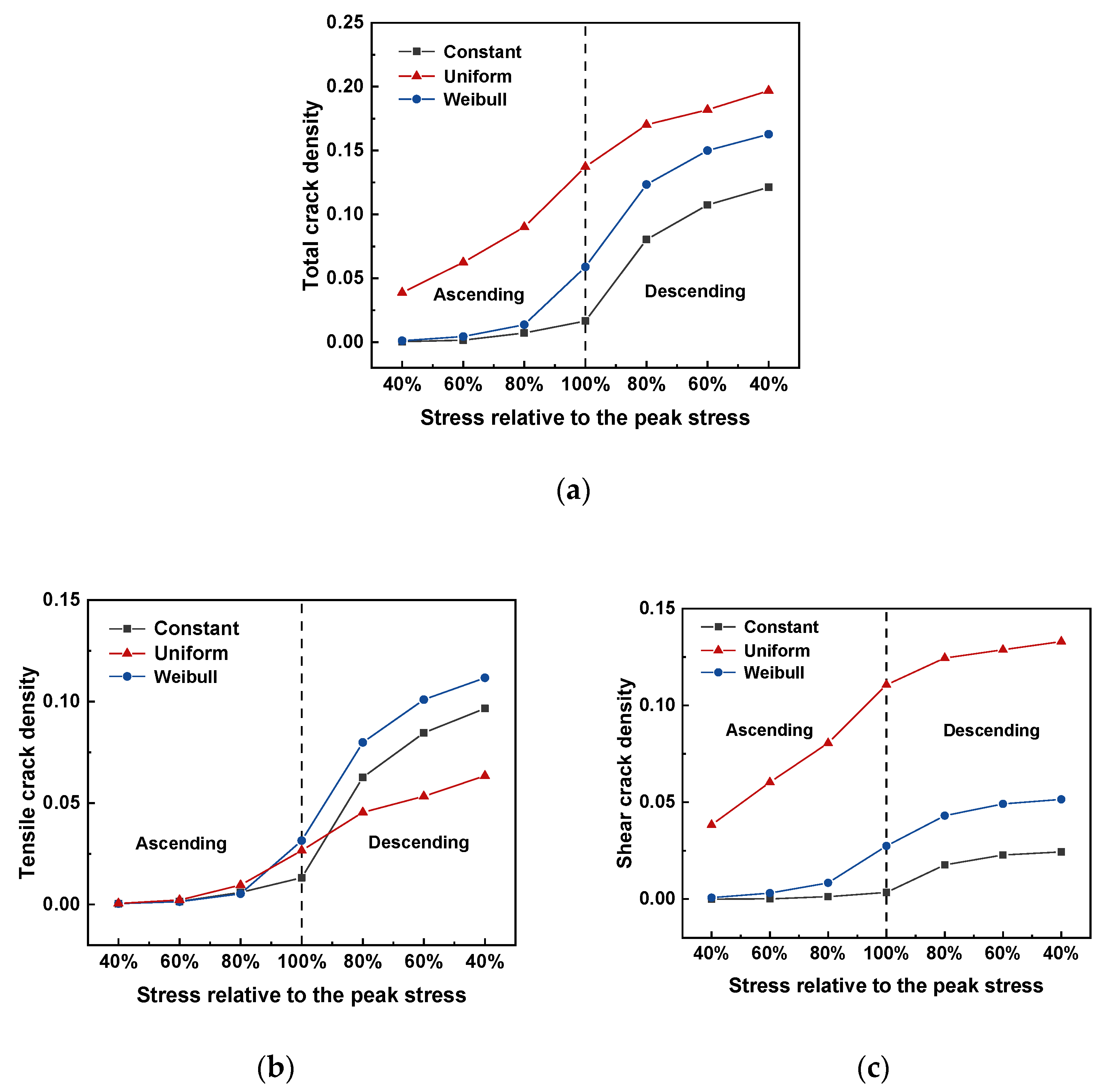

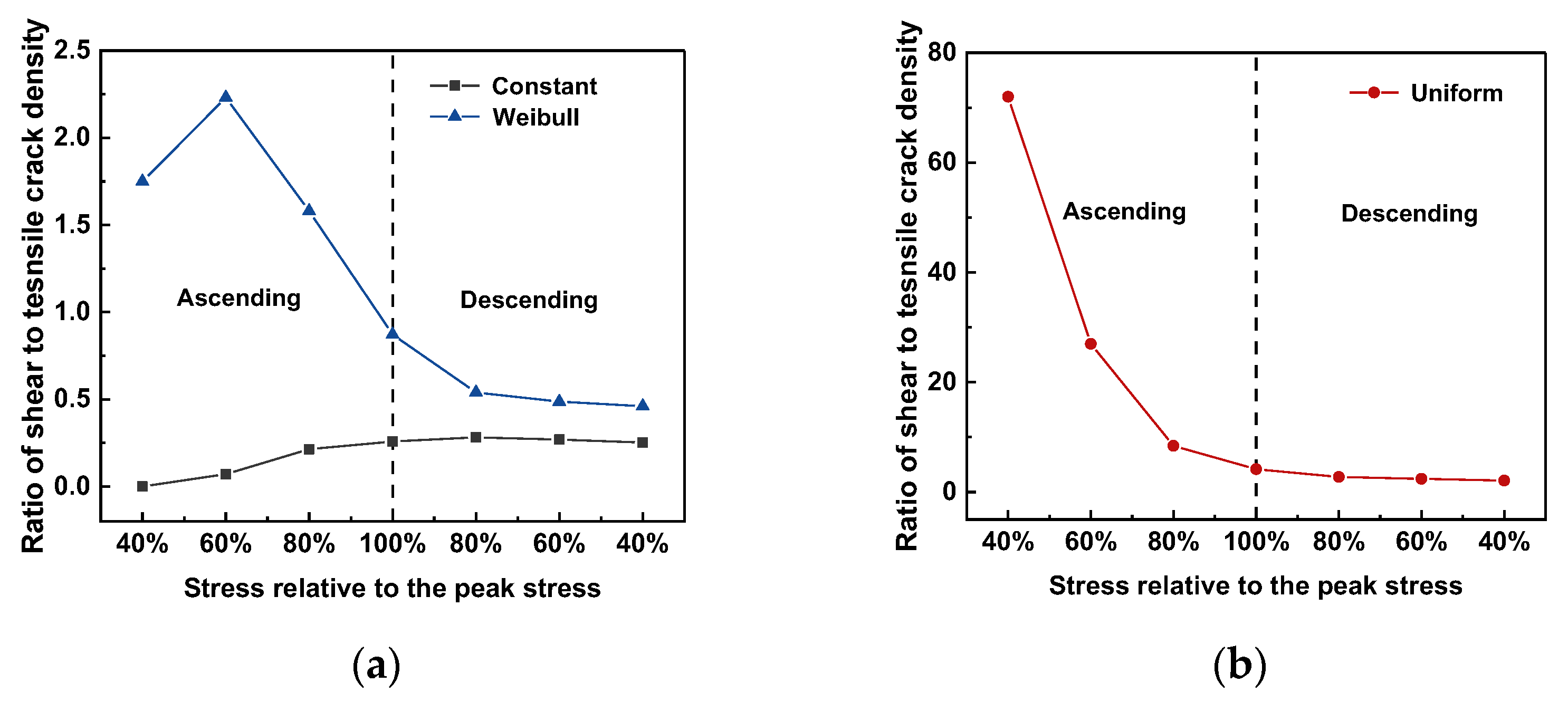

3.2. Influence of Interface Properties

3.2.1. Stress–Strain Curves

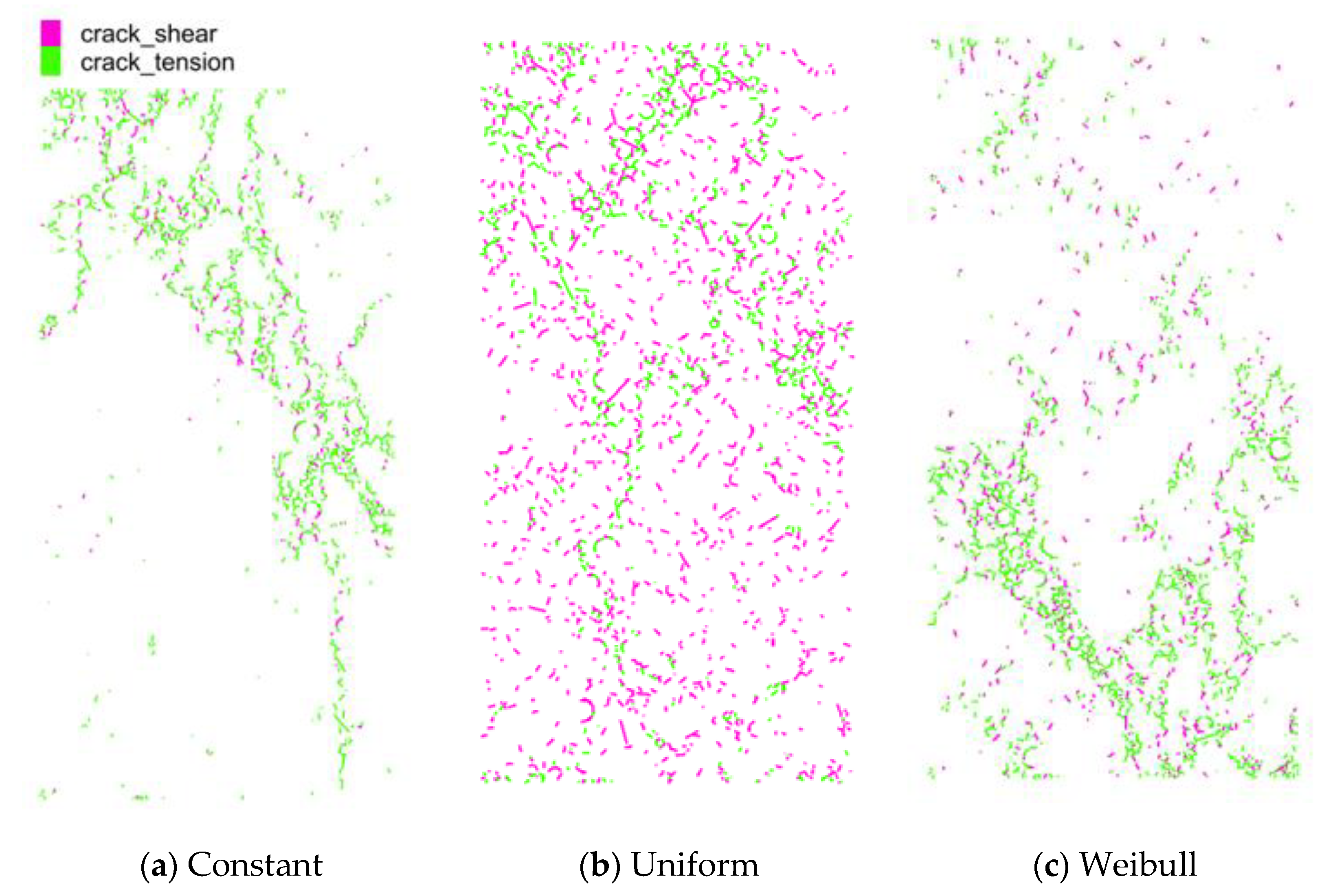

3.2.2. Crack Events

3.2.3. Energy Dissipation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heindl, R.A.; Mong, L.E. Young’s Modulus of Elasticity, Strength, and Extensibility of Refractories in Tension. J. Res. Natl. Bur. Stand. 1936, 17, 463–682. [Google Scholar] [CrossRef]

- Nourbakhsh, A.A.; Lotfian, N.; Asgarian, P. Development of Nitride-Bonded SiC Refractories by MgO and Nanocomposite (MgO/SiC) Additives. Refract. Worldforum. 2017, 9, 106–112. [Google Scholar]

- Stuppfler, A.; Dahlem, E. Investigation of the Parameters Influencing the Refractoriness Under Load (RuL) Testing Results for Refractory Materials. Refract. Worldforum. 2015, 7, 87–93. [Google Scholar]

- Dahlem, E.; Clasen, S.; Dannert, C. Investigation of the Factors Influencing the Bulk Density and Open Porosity Testing Results for Refractory Materials. Refract. Worldforum. 2015, 7, 95–104. [Google Scholar]

- Czechowski, J.; Gerle, A.; Podworny, J.; Dahlem, E. Investigation of the Testing Parameters Influencing the Cold Crushing Strength Testing Results of Refractory Materials. Refract. Worldforum. 2015, 7, 105–112. [Google Scholar]

- Samadi, S.; Jin, S.; Gruber, D.; Harmuth, H.; Schachner, S. Statistical study of compressive creep parameters of an alumina spinel refractory. Ceram. Int. 2020, 46, 14662–14668. [Google Scholar] [CrossRef]

- Dai, Y.; Li, Y.; Jin, S.; Harmuth, H.; Wen, Y.; Xu, X. Mechanical and fracture investigation of magnesia refractories with acoustic emission-based method. J. Eur. Ceram. Soc. 2020, 40, 181–191. [Google Scholar] [CrossRef]

- Xu, Y.; Kafui, K.D.; Thornton, C.; Lian, G. Effects of material properties on granular flow in a silo using DEM simulation. Part. Sci. Technol. 2002, 20, 109–124. [Google Scholar] [CrossRef]

- Liu, X.; Hu, Z.; Wu, W.; Zhan, J.; Herz, F.; Specht, E. DEM study on the surface mixing and whole mixing of granular materials in rotary drums. Powder Technol. 2017, 315, 438–444. [Google Scholar] [CrossRef]

- Nguyen, N.H.T.; Bui, H.H.; Nguyen, G.D.; Kodikara, J. A cohesive damage-plasticity model for DEM and its application for numerical investigation of soft rock fracture properties. Int. J. Plasticity 2017, 98, 175–196. [Google Scholar] [CrossRef]

- Vo, T.D.; Pouya, A.; Hemmati, S.; Tang, A.M. Numerical modelling of desiccation cracking of clayey soil using a cohesive fracture method. Comput. Geotech. 2017, 85, 15–27. [Google Scholar] [CrossRef]

- Wang, J.; Yan, H. On the role of particle breakage in the shear failure behavior of granular soils by DEM. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 832–854. [Google Scholar] [CrossRef]

- André, D.; Levraut, B.; Tessier-Doyen, N.; Huger, M. A discrete element thermo-mechanical modelling of diffuse damage induced by thermal expansion mismatch of two-phase materials. Comput. Methods Appl. Mech. Eng. 2017, 318, 898–916. [Google Scholar] [CrossRef]

- Tran, V.T.; Donzé, F.V.; Marin, P. A discrete element model of concrete under high triaxial loading. Cem. Concr. Compos. 2011, 33, 936–948. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Cundall, P.A. Formulation of a three-dimensional distinct element model—Part I. A scheme to detect and represent contacts in a system composed of many polyhedral blocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 25, 107–116. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Wang, P.; Yin, Z.Y.; Zhou, W.H.; Chen, W.B. Micro-mechanical analysis of soil–structure interface behavior under constant normal stiffness condition with DEM. Acta Geotech. 2022, 17, 2711–2733. [Google Scholar] [CrossRef]

- Suchorzewski, J.; Nitka, M. Size effect at aggregate level in microCT scans and DEM simulation–Splitting tensile test of concrete. Eng. Fract. Mech. 2022, 264, 108357. [Google Scholar] [CrossRef]

- Brown, N.J.; Chen, J.F.; Ooi, J.Y. A bond model for DEM simulation of cementitious materials and deformable structures. Granul. Matter 2014, 16, 299–311. [Google Scholar] [CrossRef]

- Kruggel-Emden, H.; Wirtz, S.; Scherer, V. A study on tangential force laws applicable to the discrete element method (DEM) for materials with viscoelastic or plastic behavior. Chem. Eng. Sci. 2008, 63, 1523–1541. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, L.; Ma, G.; Chang, X.; Lai, Z.; Xu, K. DEM analysis of the size effects on the behavior of crushable granular materials. Granul. Matter 2016, 18, 1–11. [Google Scholar] [CrossRef]

- Du, W.; Jin, S.; Emam, S.; Gruber, D.; Harmuth, H. Discrete element modelling of ordinary refractory ceramics under cold crushing testing: Influence of minimum element size. Ceram. Int. 2022, 48, 17934–17941. [Google Scholar] [CrossRef]

- Asadi, F.; André, D.; Emam, S.; Doumalin, P.; Huger, M. Numerical modelling of the quasi-brittle behaviour of refractory ceramics by considering microcracks effect. J. Eur. Ceram. Soc. 2022, 42, 1149–1161. [Google Scholar] [CrossRef]

- Caulk, R. Stochastic Augmentation of the Discrete Element Method for the Investigation of Tensile Rupture in Heterogeneous Rock, Yade Technical Archive. 2018. Available online: https://zenodo.org/record/1744939#.Y14l7-RByUk (accessed on 23 October 2022).

- Nitka, M.; Tejchman, J. Modelling of concrete behaviour in uniaxial compression and tension with DEM. Granul. Matter 2015, 17, 145–164. [Google Scholar] [CrossRef]

- Wang, P.; Gao, N.; Ji, K.; Stewart, L.; Arson, C. DEM analysis on the role of aggregates on concrete strength. Comput. Geotech. 2020, 119, 103290. [Google Scholar] [CrossRef]

- Asadi, F.; André, D.; Emam, S.; Doumalin, P.; Huger, M. Numerical Modelling of the Quasi-Brittle Behavior Of Materials by Considering Microcracks Effect. In Proceedings of the Applied Numerical Modeling in Geomechanics, Vienna, Austria, 18–20 February 2020. [Google Scholar]

- Jin, S.; Harmuth, H.; Gruber, D. Compressive creep testing of refractories at elevated loads—Device, material law and evaluation techniques. J. Eur. Ceram. Soc. 2014, 34, 4037–4042. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions: Applied to Ceramic Manufacturing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Potyondy, D.O.; Cundall, P.A. A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Harmuth, H. Stability of crack propagation associated with fracture energy determined by wedge splitting specimen. Theor. Appl. Fract. Mech. 1995, 23, 103–108. [Google Scholar] [CrossRef]

- Jin, S.; Gruber, D.; Harmuth, H. Determination of Young’s modulus, fracture energy and tensile strength of refractories by inverse estimation of a wedge splitting procedure. Eng. Fract. Mech. 2014, 116, 228–236. [Google Scholar] [CrossRef]

- O’Sullivan, C.; Bray, J.D. Selecting a suitable time step for discrete element simulations that use the central difference time integration scheme. Eng. Comput. 2004, 21, 278–303. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Fischer, I.; Pichler, B.; Lach, E.; Terner, C.; Barraud, E.; Britz, F. Compressive strength of cement paste as a function of loading rate: Experiments and engineering mechanics analysis. Cem. Concr. Res. 2014, 58, 186–200. [Google Scholar] [CrossRef]

- Bischoff, P.H.; Perry, S.H. Compressive behaviour of concrete at high strain rates. Mater. Struct. 1991, 24, 425–450. [Google Scholar] [CrossRef]

- Abrams, D.A. Effect of rate of application of load on the compressive strength of concrete. Proc. ASTM 1917, 17, 364–377. [Google Scholar]

- Jones, P.G. The effect of testing speed on strength and elastic properties of concrete. Proc. ASTM 1936, 36, 380–391. [Google Scholar]

- Evans, R.H. Effect of rate of loading on the mechanical properties of some materials. J. Inst. Civ. Eng. 1942, 18, 296–306. [Google Scholar] [CrossRef]

- Katsuta, T. On the elastic and plastic properties of concrete in compression tests with high deformation velocity, part 1. Trans. Inst. Jap. Arch. 1943, 29, 268–274. [Google Scholar]

- Thaulow, S. Rate of loading for compressive strength tests. Betong 1953, 38, 11–15. [Google Scholar]

- Watstein, D. Effect of straining rate on the compressive strength and elastic properties of concrete. J. Proc. 1953, 49, 729–744. [Google Scholar]

- Hatano, T.; Tsutsumi, H. Dynamical compressive deformation and failure of concrete under earthquake load. Trans. Jpn. Soc. Civ. Eng. 1960, 67, 19–26. [Google Scholar] [CrossRef]

- Ban, S. Behaviour of plain concrete under dynamic loading with straining rate comparable to earthquake loading. In Proceedings of the 2’nd World Conference on Earthquake Engineering, Tokyo, Japan, 11–18 July 1960. [Google Scholar]

- Takeda, J.I.; Tachikawa, H. Deformation and fracture of concrete subjected to dynamic load. In Proceedings of the Conference on Mechanical Behavior of Materials, Kyoto, Japan, 1 January 1972. [Google Scholar]

- Lundeen, R.L. Dynamic and Static Tests of Plain Concrete Specimens, Report 1; Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1963; Available online: https://apps.dtic.mil/sti/citations/AD0752803 (accessed on 23 October 2022).

- Horibe, T.; Kobayashi, R. On mechanical behavior of rock under various loading rates. J. Soc. Mater. Sci. 1965, 14, 498–506. [Google Scholar] [CrossRef]

- Cowell, W.L. Dynamic Properties of Plain Portland Cement Concrete; Naval Civil Engineering Lab Port: Hueneme, CA, USA, 1966; Available online: https://apps.dtic.mil/sti/citations/AD0635055 (accessed on 23 October 2022).

- Atchley, B.L.; Furr, H.L. Strength and energy absorption capabilities of plain concrete under dynamic and static loadings. J. Proc. 1967, 64, 745–756. [Google Scholar]

- Hughes, B.P.; Gregory, R. Concrete subjected to high rates of loading in compression. Mag. Concr. Res. 1972, 24, 25–36. [Google Scholar] [CrossRef]

- Millstein, L.; Sabnis, G.M. Concrete strength under impact loading. In Proceedings of the Concrete Structures under Impact and Impulsive Loading, Berlin, Germany, 2–4 June 1982; Available online: https://inis.iaea.org/search/search.aspx?orig_q=RN:14720296 (accessed on 23 October 2022).

- Bertero, V.V.; Rea, D.; Mahin, S.; Atalay, M.B. Rate of loading effects on uncracked and repaired reinforced concrete members. In Proceedings of the Fifth World Conference on Earthquake Engineering, Rome, Italy, 25–29 June 1973; Volume 1, pp. 1461–1470. [Google Scholar]

- Wesche, K.; Krause, K. The effect of loading rate on compressive strength and modulus of elasticity of concrete. Materialpruefung 1972, 14, 212–218. [Google Scholar]

- Sparks, P.R.; Menzies, J.B. The effect of rate of loading upon the static and fatigue strengths of plain concrete in compression. Mag. Concr. Res. 1973, 25, 73–80. [Google Scholar] [CrossRef]

- Bresler, B.; Bertero, V.V. Influence of high strain rate and cyclic loading of unconfined and confined concrete in compression. In Proceedings of the 2nd Canadian Conference on Earthquake Engineering, Hamilton, ON, USA, 5–6 June 1975; pp. 1–13. [Google Scholar]

- Hjorth, O. A Contribution to the Problem of Strength and Bond Relationships for Steel and Concrete at High Loading Rates, Doctoral dissertation, Braunschweig Universitaet of Technology, Braunschweig, Germany, 1976.

- Kvirikadze, O.P. Determination of the ultimate strength and modulus of deformation of concrete at different rates of loading. In Proceedings of the International Symposium, Testing In-Situ of Concrete Structures, Budapest, Hungry, 5–9 September 1977. [Google Scholar]

- Popp, C. Untersuchungen Über Das Verhalten Von Beton Bei Schlagartiger Beanspruchung; Ernst in Komm: Berlin, Germany; München, Germany; Düsseldorf, Germany, 1977. [Google Scholar]

- Hughes, B.P.; Watson, A.J. Compressive strength and ultimate strain of concrete under impact loading. Mag. Concr. Res. 1978, 30, 189–199. [Google Scholar] [CrossRef]

- Fagerlund, G.; Larsson, B. Betongs slaghållfasthet: Impact strength of concrete. Cem. -Och Betonginst 1979, 79, 434. [Google Scholar]

- Paulmann, K.; Steinert, J. Concrete under very short-term loading. Betong 1982, 32, 225–228. [Google Scholar]

- Rostasy, F.S.; Scheuermann, J.; Sprenger, K.H. Mechanical behaviour of some construction materials subjected to rapid loading and low temperature. Betonw. + Fert. -Tech. 1984, 50, 393–401. [Google Scholar]

- Rostasy, F.S.; Hartwich, K. Compressive strength and deformation of steel fibre reinforced concrete under high rate of strain. Int. J. Cem. Compos. Lightweight Concr. 1985, 7, 21–28. [Google Scholar] [CrossRef]

- Dilger, W.H.; Koch, R.; Kowalczyk, R. Ductility of plain and confined concrete under different strain rates. J. Proc. 1984, 81, 73–81. [Google Scholar]

- Malvern, L.E.; Ross, C.A. Dynamic Response of Concrete and Concrete Structures; Florida University Gainesville, Department of Engineering Sciences: Gainesville, FL, USA, 1986; Available online: https://apps.dtic.mil/sti/citations/ADA173082 (accessed on 23 October 2022).

- Hao, Y.; Hao, H.; Li, Z. Numerical analysis of lateral inertial confinement effects on impact test of concrete compressive material properties. Int. J. Prot. Struct. 2010, 1, 145–167. [Google Scholar] [CrossRef]

- Cruz, F.D.; Emam, S.; Prochnow, M.; Roux, J.N.; Chevoir, F. Rheophysics of dense granular materials: Discrete simulation of plane shear flows. Phys. Rev. E 2005, 72, 021309. [Google Scholar] [CrossRef]

- Das, S.K.; Das, A. Influence of quasi-static loading rates on crushable granular materials: A DEM analysis. Powder Technol. 2019, 344, 393–403. [Google Scholar] [CrossRef]

- Midi, G.D.R. On dense granular flows. Eur. Phys. J. E 2004, 14, 341–365. [Google Scholar] [CrossRef]

- Rognon, P.G.; Roux, J.N.; Naaïm, M.; Chevoir, F. Dense flows of bidisperse assemblies of disks down an inclined plane. Phys. Fluids 2007, 19, 058101. [Google Scholar] [CrossRef]

- Shire, T.; Hanley, K.J.; Stratford, K. DEM simulations of polydisperse media: Efficient contact detection applied to investigate the quasi-static limit. Comput. Part. Mech. 2021, 8, 653–663. [Google Scholar] [CrossRef]

- Modenese, C.; Utili, S.; Houlsby, G.T. A Numerical Investigation of Quasi-Static Conditions for Granular Media. In Discrete Element Modelling Particulate Media; Royal Society of Chemistry: London, UK, 2012; pp. 187–195. [Google Scholar]

| Interface | Properties | Values | |

|---|---|---|---|

| Contacts between particles | Bonded and unbonded | Effective modulus (GPa) | 104 |

| Normal to shear stiffness ratio | 1.27 | ||

| Unbonded | Friction coefficient | 0.493 | |

| Bonded | Friction angle (°) | 40 | |

| Cohesion (MPa) | 40 | ||

| Tensile strength (MPa) | 53 | ||

| Properties | Values | |

|---|---|---|

| Contacts between pistons and particles | Effective modulus (GPa) | 4.8 |

| Normal to shear stiffness ratio | 1.27 | |

| Friction coefficient | 0.09 |

| Loading Strain Rate (s−1) | Cold Crushing Strength (MPa) | Relative Cold Crushing Strength | Fracture Energy (N/m) | Relative Fracture Energy |

|---|---|---|---|---|

| 2.5 | 54.91 | 1.06 | 2200.25 | 2.00 |

| 0.25 | 52.17 | 1.01 | 1246.50 | 1.14 |

| 0.025 | 51.65 | 1.00 | 1098.00 | 1.00 |

| Interface Properties Distribution | Dissipated Energy (Walls) (N/m) | |

|---|---|---|

| Loading Walls | Gauge Elements | |

| Constant | 1246.50 | 1449.75 |

| Uniform | 646.50 | 593.00 |

| Weibull | 1264.50 | 1148.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, W.; Jin, S. Discrete Element Modelling of Cold Crushing Tests Considering Various Interface Property Distributions in Ordinary Refractory Ceramics. Materials 2022, 15, 7650. https://doi.org/10.3390/ma15217650

Du W, Jin S. Discrete Element Modelling of Cold Crushing Tests Considering Various Interface Property Distributions in Ordinary Refractory Ceramics. Materials. 2022; 15(21):7650. https://doi.org/10.3390/ma15217650

Chicago/Turabian StyleDu, Weiliang, and Shengli Jin. 2022. "Discrete Element Modelling of Cold Crushing Tests Considering Various Interface Property Distributions in Ordinary Refractory Ceramics" Materials 15, no. 21: 7650. https://doi.org/10.3390/ma15217650

APA StyleDu, W., & Jin, S. (2022). Discrete Element Modelling of Cold Crushing Tests Considering Various Interface Property Distributions in Ordinary Refractory Ceramics. Materials, 15(21), 7650. https://doi.org/10.3390/ma15217650