Theoretical Analysis and Experimental Verification of the Stress and Strain of Axially Compressed Steel-Reinforced Concrete Columns under Long-Term Loads

Abstract

1. Introduction

2. Theoretical Derivation

2.1. Basic Assumptions

- Concrete is a homogeneous and isotropic material, and has good working performance with steel bars without relative slip;

- The plane section of the section is assumed to hold;

- The steel bar is always elastic, regardless of creep and stress relaxation effects;

- The assumption of the linear creep of concrete and the principle of superposition of strains are valid.

2.2. Calculation of Short-Term Stress and Strain

2.3. Calculation of Long-Term Stress and Strain

- Obtain according to Equation (12);

- Calculate an iteration according to Formula (13) to obtain ,,…, successively;

- According to the results of step 1 and step 2, the cumulative increment of stress of concrete under long-term load can be obtained.

- From Equation (8), the cumulative increment of stress of the steel bar under long-term loading can be described as follows:

- According to Equation (10), the cumulative increment of strain produced by SRC in the process of shrinkage and creep is:

3. Implementation of Programming

3.1. Prediction Model of Concrete Shrinkage and Creep

3.2. Programming Flowchart

3.3. Example Verification

4. Experimental Validation

4.1. Experimental Setup

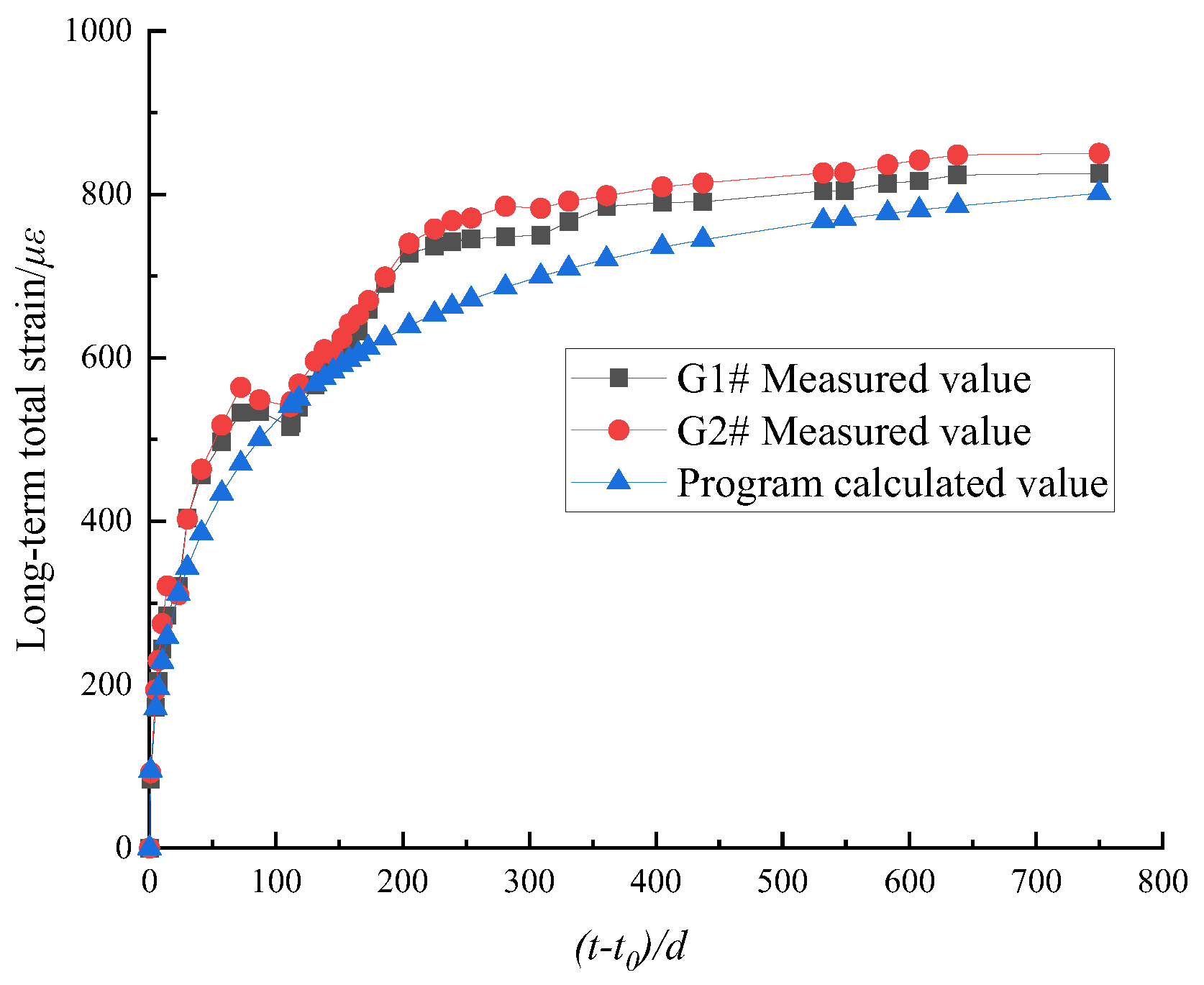

4.2. Comparison of Test Results and Program Calculation Results

5. Results and Discussion

5.1. Long-Term Stress

5.2. Long-Term Stress and Strain

6. Conclusions

- The theoretical calculations agreed with the results of classic examples by the study verification. Therefore, the derived formula for the stress and strain of the SRC axial compression column under long-term loading and the calculation program were more accurate.

- An experimental study of the long-term deformation performance of concrete columns under a constant temperature and humidity environment was performed to validate the proposed theoretical formulae. The long-term strain of plain concrete and SRC shows the same trend with load holding time. The growth rate was high in the first 270 days and strongly decreases after 270 days, the total strain gradually becomes stable. The strain of the plain concrete column was significantly larger than that of the SRC column. When the load holding time was 750 days, the maximum difference in total strain between the plain concrete column and the SRC column reached 26.60%, which was large. Therefore, the steel bar constrains the shrinkage and creep of the concrete column.

- The calculated results of the program are consistent with the trends of the measured strains with the load holding time. The strain growth rate was high in the first 270 days and strongly decreases after 270 days, the total strain gradually becomes stable. When the load holding time was 750 days, the errors between the calculated strains of the program and the measured strains of the G1# and G2# columns were only 2.96% and 5.78%, respectively. The program based on the theory of long-term stress and strain calculation can thus accurately predict the long-term stress and strain of the SRC axial compression column.

- The long-term stresses of columns G1# and G2# were analyzed by the calculation program. The long-term stresses of the concrete and steel bars show the same trends as the load-holding time. The stress growth rate was high in the first 270 days and strongly decreases after 270 days, the total stress gradually becomes stable. When the load holding time was 750 days, the difference in stress between the concrete and steel bar was large, which indicates that the steel bar has a strong influence on the long-term stress of the concrete column, and the steel bar constrains the stress of the concrete column, causing stress redistribution in the section. The long-term strain and stress increment of columns G1# and G2# were predicted by the calculation program. In the first 3 years, the stress and strain of the concrete and steel bars developed rapidly and then gradually slowed down.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bazant, Z.P.; LI, G.H. Unbiased statistical comparison of creep and shrinkage prediction models. ACI Mater. J. 2008, 105, 610–621. [Google Scholar]

- Bal, L.; Buyle-Bodin, F. Artificial neural network for predicting creep of concrete. Neural Comput. Appl. 2014, 25, 1359–1367. [Google Scholar] [CrossRef]

- Drexel, M.; Theiner, Y.; Hofstetter, G. Tests on shrinkage and creep behavior of concrete taking into account the moisture content. Bauingenieur 2018, 93, 95–102. [Google Scholar] [CrossRef]

- Liang, S.; Wei, Y. Methodology of obtaining intrinsic creep property of concrete by flexural deflection test. Cem. Concr. Compos. 2019, 97, 288–299. [Google Scholar] [CrossRef]

- Barr, B.; Hoseinian, S.B.; Beygi, M.A. Shrinkage of concrete stored in natural environments. Cem. Concr. Compos. 2003, 25, 19–29. [Google Scholar] [CrossRef]

- Islam, M. Investigation of tensile creep for Ultra-High-Performance Fiber Reinforced Concrete (UHPFRC) for the long-term. Constr. Build. Mater. 2021, 305, 124752. [Google Scholar] [CrossRef]

- Tang, H.Y.; Wang, R.J.; Peng, C.M. Simulation of uncertainties in shrinkage and creep effects in concrete. Emerg. Mater. Res. 2017, 6, 210–213. [Google Scholar] [CrossRef]

- Aili, A.; Vandamme, M.; Torrenti, J.M.; Masson, B. Is long-term autogenous shrinkage a creep phenomenon induced by capillary effects due to self-desiccation? Cem. Concr. Res. 2018, 108, 186–200. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Qiao, Q.Y.; Cao, W.L. Study on axial compressive behavior of circular steel tube confined rubberized concrete stub columns. Structures 2022, 41, 887–907. [Google Scholar]

- Jia, Z.-L.; Wang, W.-D.; Shi, Y.-L.; Xian, W. Performance of steel-reinforced concrete-filled square steel tubular members under sustained axial compression loading. Eng. Struct. 2022, 264, 114464. [Google Scholar] [CrossRef]

- Gamnitzer, P.; Brugger, A.; Drexel, M.; Hofstetter, G. Modelling of Coupled Shrinkage and Creep in Multiphase Formulations for Hardening Concrete. Materials 2019, 12, 1745. [Google Scholar] [CrossRef] [PubMed]

- Hedegaard, B. Creep and Shrinkage Modeling of Concrete Using Solidification Theory. J. Mater. Civ. Eng. 2020, 32, 04020179. [Google Scholar] [CrossRef]

- Park, H.S.; Hong, T.; Lee, D.-E.; Oh, B.K.; Glisic, B. Long-term structural response prediction models for concrete structures using weather data, fiber-optic sensing and convolutional neural network. Expert Syst. Appl. 2022, 201, 117152. [Google Scholar] [CrossRef]

- Cao, G.H.; Han, C.C.; Peng, P.; Zhang, W.; Tang, H. Creep Test and Analysis of Concrete Columns under Corrosion and Load Coupling. ACI Struct. J. 2019, 116, 121–130. [Google Scholar] [CrossRef]

- Hamed, E.; Lai, C. Geometrically and materially nonlinear creep behaviour of reinforced concrete columns. Structures 2016, 5, 1–12. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, L.; Li, Y.H.; Dong, Y. Prediction of dry shrinkage deformation for partially enclosed steel reinforced concrete columns. J. Build. Eng. 2021, 44, 102675. [Google Scholar] [CrossRef]

- Shariff, M.N.; Saravanan, U.; Menon, D. Time-Dependent Strains in Axially Loaded Reinforced Concrete Columns. J. Eng. Mech. 2020, 146, 04020076. [Google Scholar] [CrossRef]

- An, G.-H.; Cha, S.-L.; Kim, J.-K. Modification of the long-term deformation models for steel reinforced concrete columns. Constr. Build. Mater. 2018, 189, 245–252. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Dai, T.Z.; Lei, Y.; Wu, J.Q.; Wang, Y. Experimental study on the time-dependent behavior of short steel-reinforced concrete columns under sustained axial loading. Eng. Mech. 2015, 32, 74–79. [Google Scholar]

- Zhang, K.; Cao, G.H.; Hu, J.X. Experimental study on influence of reinforcement on long-term shrinkage strain of concrete. J. Highw. Transp. Res. Dev. 2014, 31, 78–81+147. [Google Scholar]

- Zheng, W.; Tang, C.; Liu, Y. Creep behavior of reinforced concrete column in consideration of sectional stress redistribution. J. Build. Struct. 2016, 37, 264–272. [Google Scholar]

- Zhou, L.; Chen, Y.C. Shrinkage and Creep; China Railway Press: Beijing, China, 1994. [Google Scholar]

- Tadros, M.K.; Ghali, A.; Dilger, W.H. Effect of non-prestressed steel on prestress loss and deflection. PCI J. 1977, 22, 50–63. [Google Scholar] [CrossRef]

- Fu, X.Y.; Gao, H. Analysis on shrinkage and creep for reinforced concrete column. J. Build. Struct. 2009, 30, 191–194+199. [Google Scholar]

- Ferretti, D.; Bazant, Z.P. Stability of ancient masonry towers: Stress redistribution due to drying, carbonation and creep. Cem. Concr. Res. 2006, 36, 1389–1398. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.L. Interface stress redistribution in FRP-strengthened reinforced concrete beams using a three-parameter viscoelastic foundation model. Compos. Part B Eng. 2012, 43, 3009–3019. [Google Scholar] [CrossRef]

- Katsuhiko, K.; Toshiyuki, S.; Haruo, N. Development of T-headed bars and examples of construction. Concr. J. 2004, 42, 21–29. [Google Scholar]

- Iskhakov, I.; Ribakov, Y. Ultimate limit state of pre-stressed reinforced concrete elements. Mater. Des. 2015, 75, 9–16. [Google Scholar] [CrossRef]

- Khatri, A.P.; Hinge, G.A. Comparative study of confining reinforcement used for the rectangular concrete short column. Mater. Today Proc. 2022, 49, 1844–1851. [Google Scholar] [CrossRef]

- Ananthi, G.B.G.; Sivakumar, N. A study on self-curing self-compacting concrete filled steel columns subjected to axial compression. Mater. Today Proc. 2022, 65, 1335–1342. [Google Scholar] [CrossRef]

- Yin, F.; Wang, R.W.; Cao, W.L.; Zhao, Y.; Song, Y. Experimental and analytical research on steel reinforced high-strength concrete columns with different steel sections. Structures 2021, 34, 4350–4363. [Google Scholar] [CrossRef]

- Taghipoor, H.; Sadeghian, A. Experimental investigation of single and hybrid-fiber reinforced concrete under drop weight test. Structures 2022, 43, 1073–1083. [Google Scholar] [CrossRef]

- Su, M.; Gong, S.; Liu, Y.; Peng, H. Flexural behavior of RC beams strengthened with fully or partially prestressed near-surface mounted FRP strips: An experimental investigation. Eng. Struct. 2022, 262, 114345. [Google Scholar] [CrossRef]

- Su, M.; Zhong, Q.; Peng, H.; Li, S. Selected machine learning approaches for predicting the interfacial bond strength between FRPs and concrete. Constr. Build. Mater. 2021, 270, 121456. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Baweja, S. Creep and shrinkage prediction model for analysis and design of concrete structures-model B3. Mater. Struct. 1995, 28, 57–365. [Google Scholar]

- ACI Committee 209. Prediction of Creep, Shrinkage and Temperature Effects in Concrete Structures; America Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Han, W.W.; Lv, Y.G. Experimental research on prediction model of concrete shrinkage and creep. J. Cent. South Univ. (Sci. Technol.) 2016, 47, 3515–3522. [Google Scholar]

- JTG 3362-2018; Code for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. China Communications Highway Planning and Design Institute Co., Ltd.: Beijing, China, 2018.

| Calculated Age | ||||

|---|---|---|---|---|

| Concrete Stress/MPa | Steel Bar Stress/MPa | Concrete Stress/MPa | Steel Bar Stress/MPa | |

| Reference [22] | 7.86 | 55.02 | 6.13 | 229.10 |

| Procedure | 7.86 | 55.02 | 6.11 | 237.21 |

| 3 Years | 4 Years | 5 Years | 10 Years | 15 Years | 20 Years | |

|---|---|---|---|---|---|---|

| concrete or steel bar Strain/με | 831 | 851 | 863 | 889 | 899 | 904 |

| concrete stress/MPa | −1.99 | −2.04 | −2.07 | −2.13 | −2.16 | −2.17 |

| Steel bar stress/MPa | 174.54 | 178.63 | 181.23 | 186.79 | 188.76 | 189.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, W.; Wang, C.; Lv, Y.; Su, M.; Liu, Y.; Peng, H. Theoretical Analysis and Experimental Verification of the Stress and Strain of Axially Compressed Steel-Reinforced Concrete Columns under Long-Term Loads. Materials 2022, 15, 7630. https://doi.org/10.3390/ma15217630

Han W, Wang C, Lv Y, Su M, Liu Y, Peng H. Theoretical Analysis and Experimental Verification of the Stress and Strain of Axially Compressed Steel-Reinforced Concrete Columns under Long-Term Loads. Materials. 2022; 15(21):7630. https://doi.org/10.3390/ma15217630

Chicago/Turabian StyleHan, Weiwei, Cui Wang, Yigang Lv, Miao Su, Yuting Liu, and Hui Peng. 2022. "Theoretical Analysis and Experimental Verification of the Stress and Strain of Axially Compressed Steel-Reinforced Concrete Columns under Long-Term Loads" Materials 15, no. 21: 7630. https://doi.org/10.3390/ma15217630

APA StyleHan, W., Wang, C., Lv, Y., Su, M., Liu, Y., & Peng, H. (2022). Theoretical Analysis and Experimental Verification of the Stress and Strain of Axially Compressed Steel-Reinforced Concrete Columns under Long-Term Loads. Materials, 15(21), 7630. https://doi.org/10.3390/ma15217630