Characterization of Wear Properties of Pure Nickel Modified by Ni-Cr Composite and CaF2 Solid Lubricant Addition

Abstract

1. Introduction

2. Experimental Methods

2.1. Powder Metallurgy

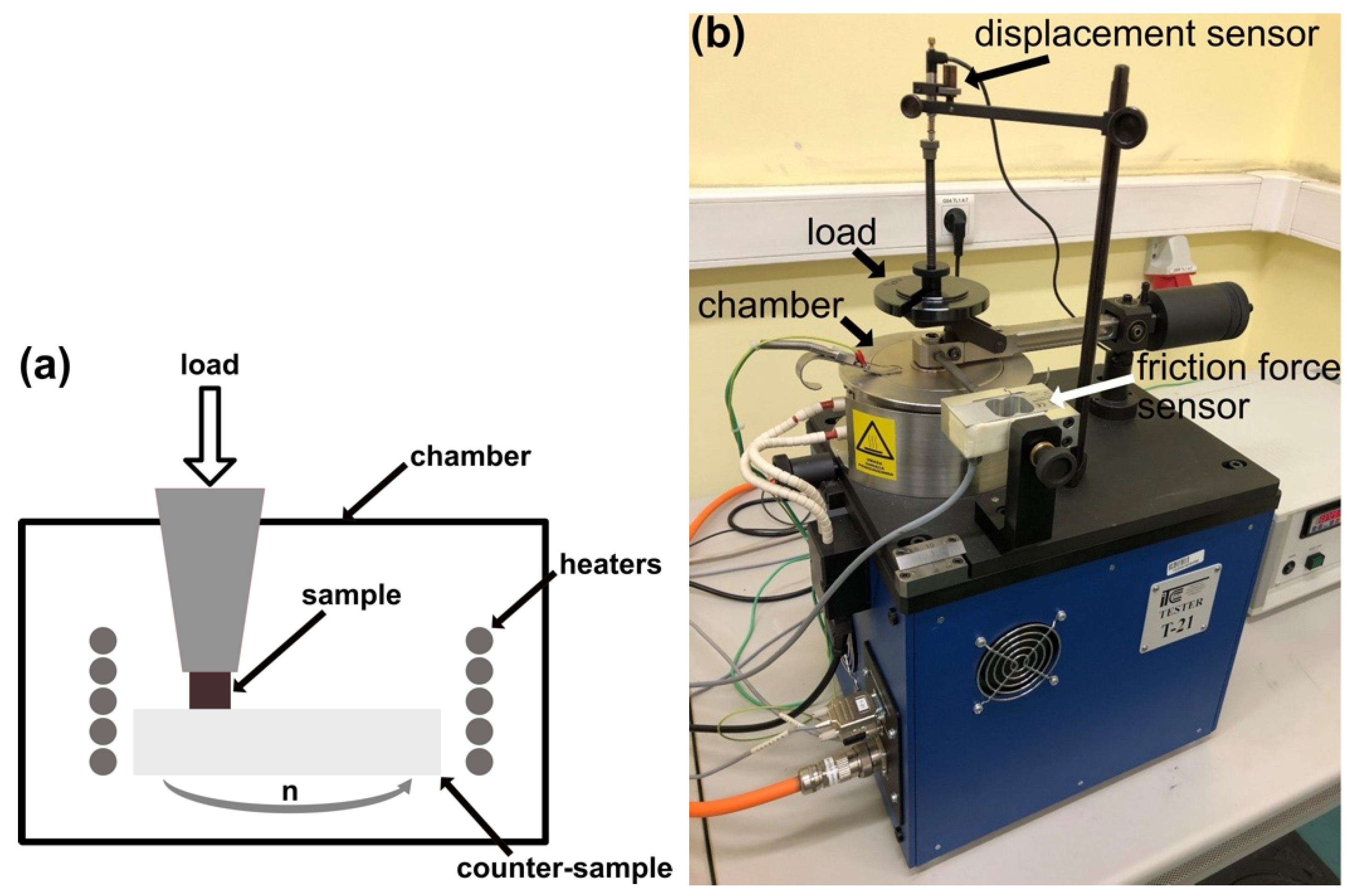

2.2. Wear Tests

2.3. Surface Analysis

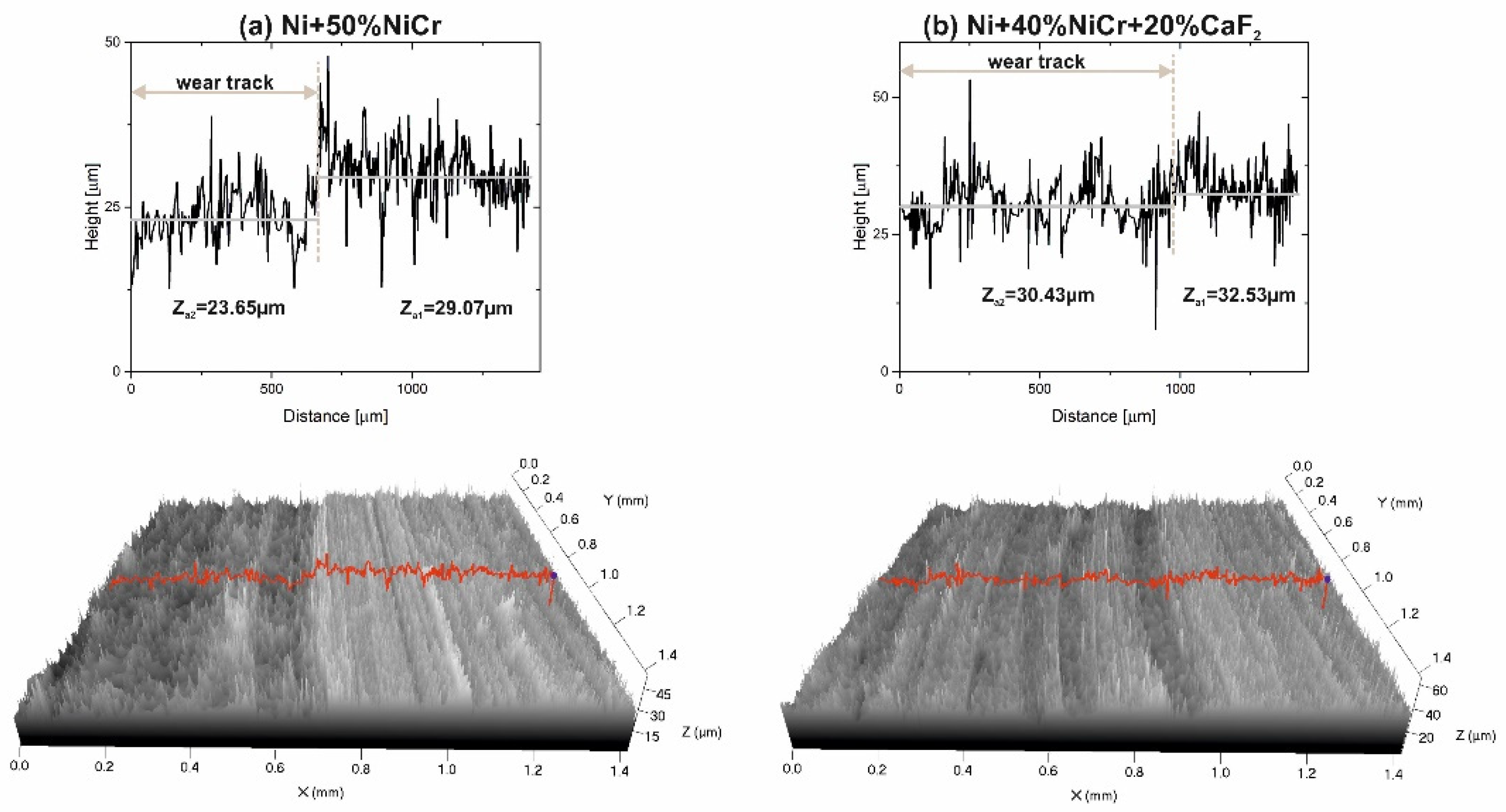

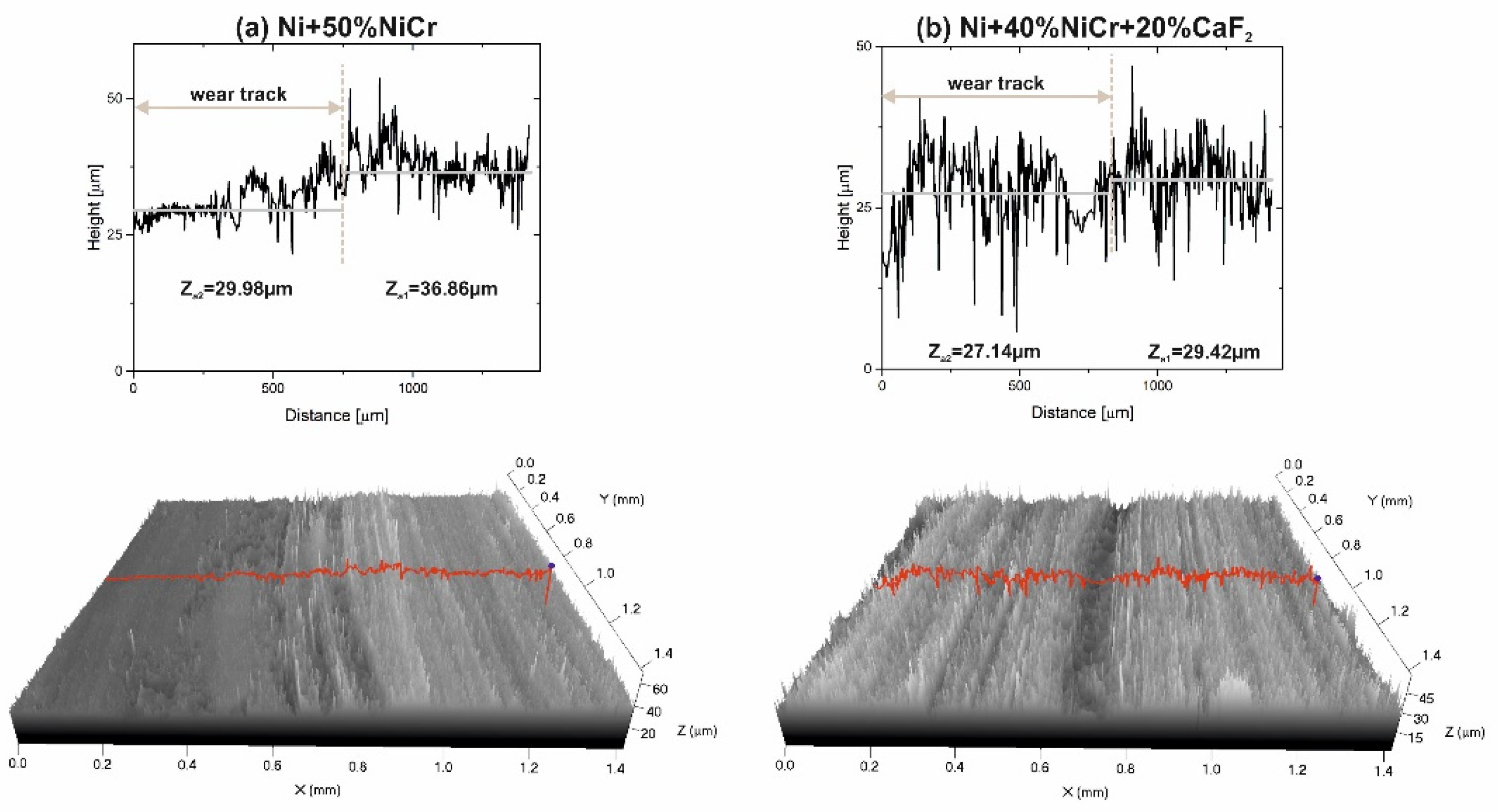

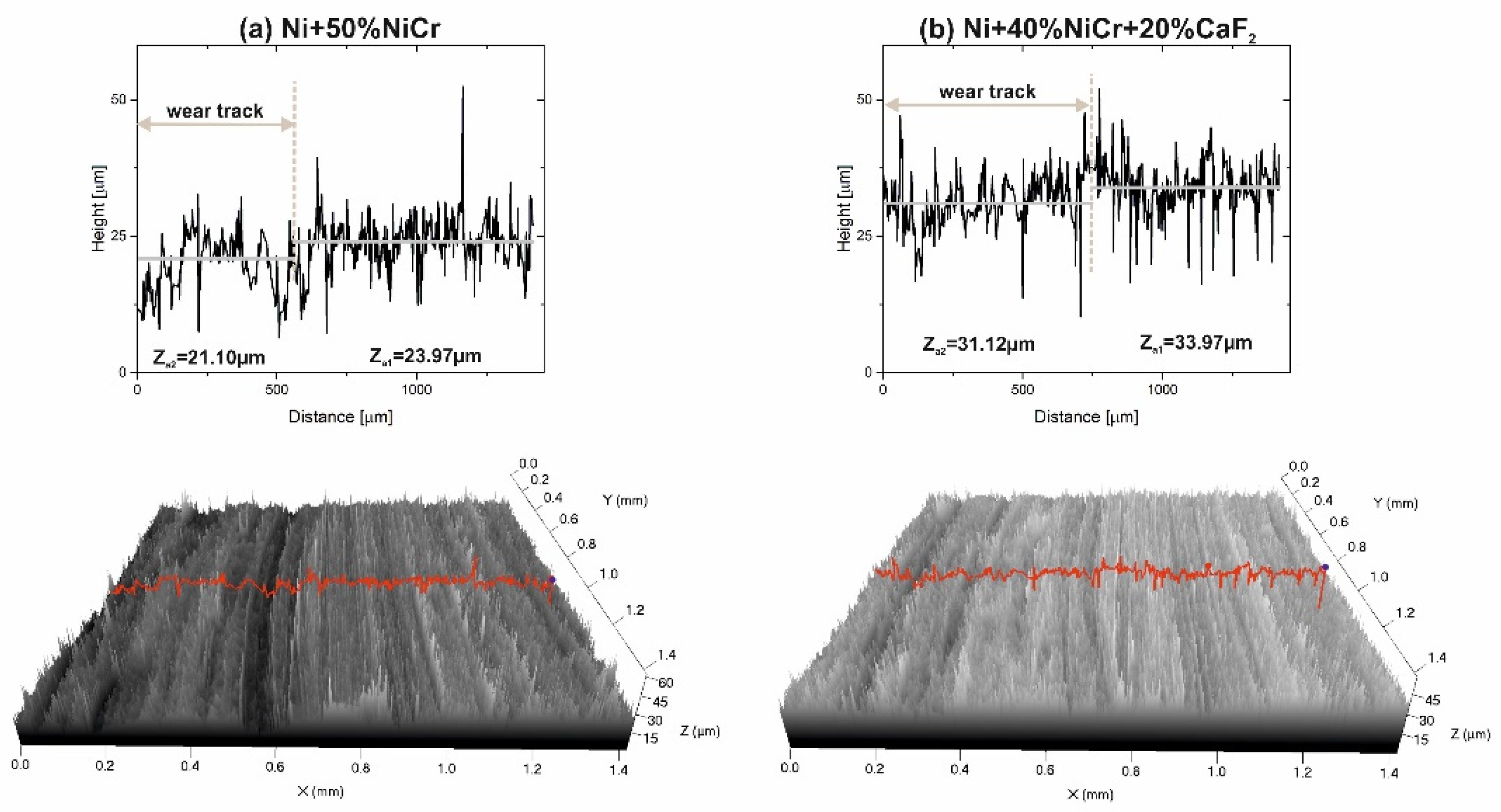

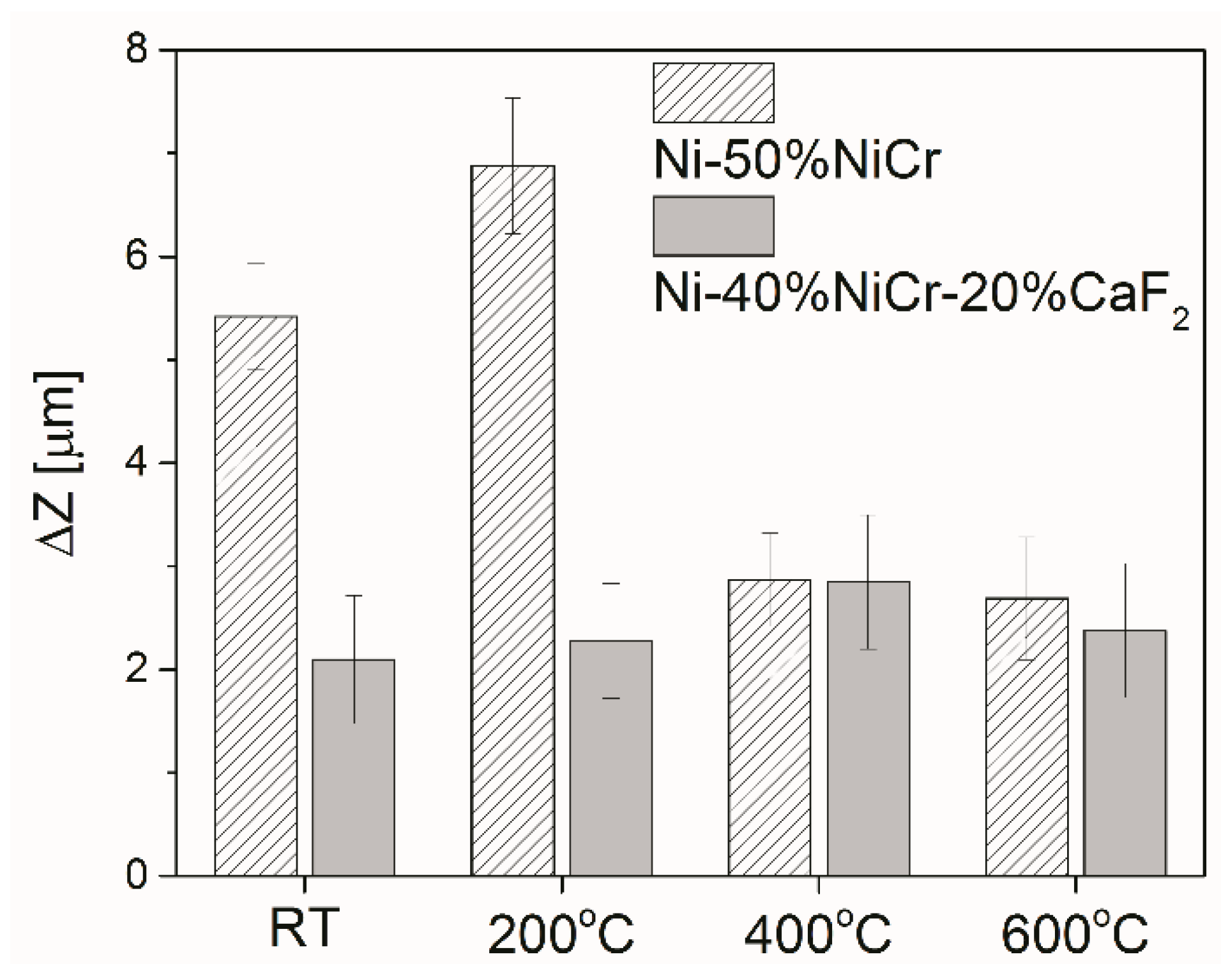

2.4. Confocal Microscopy

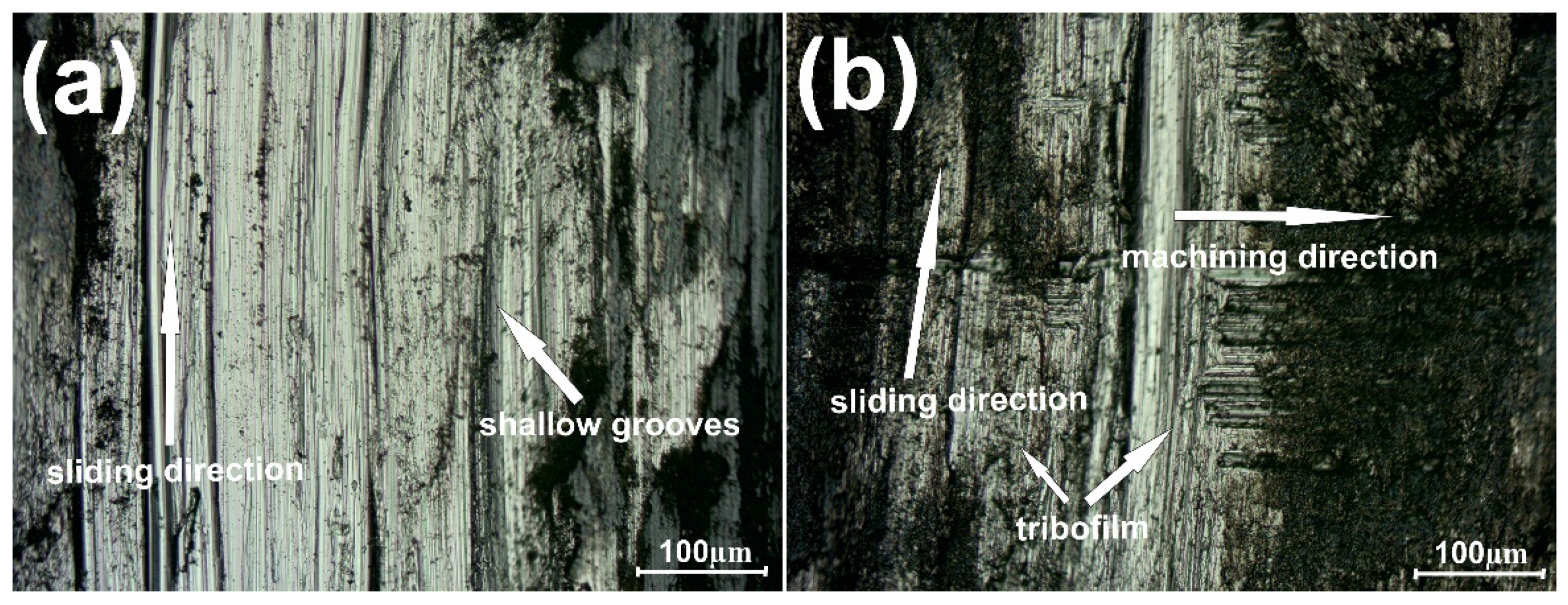

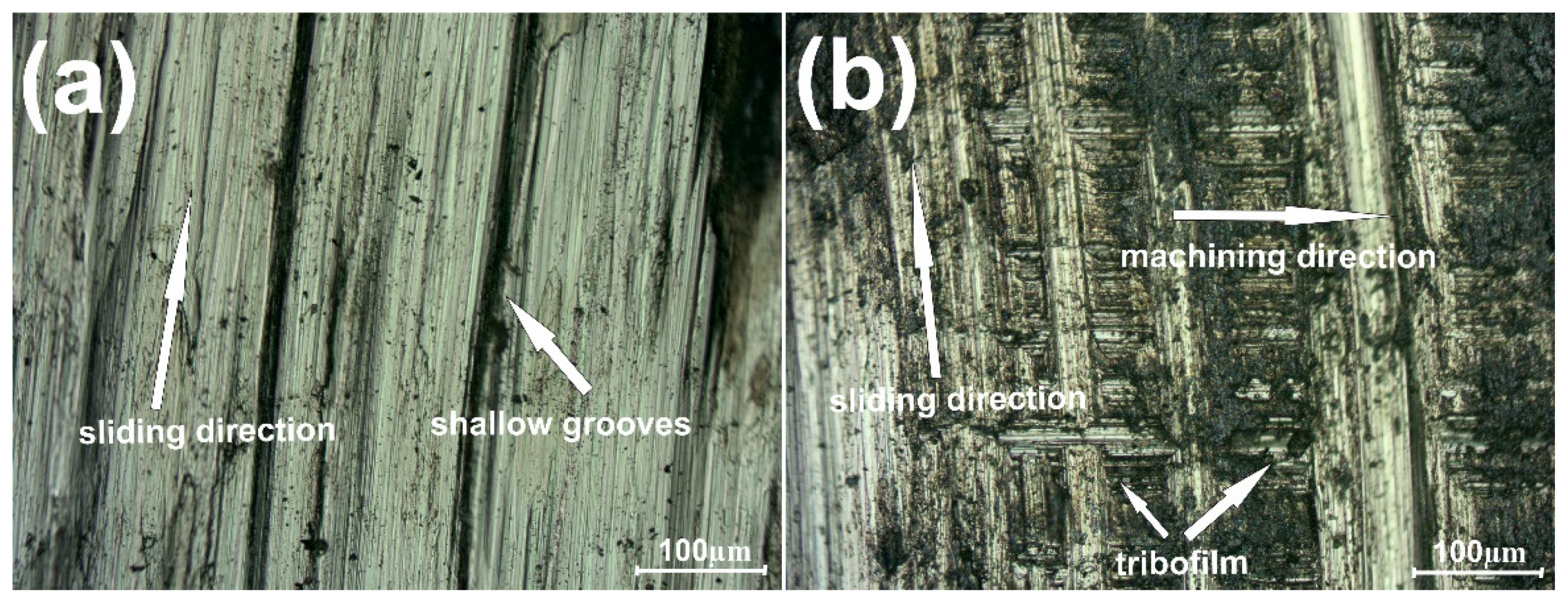

3. Results and Discussion

4. Conclusions

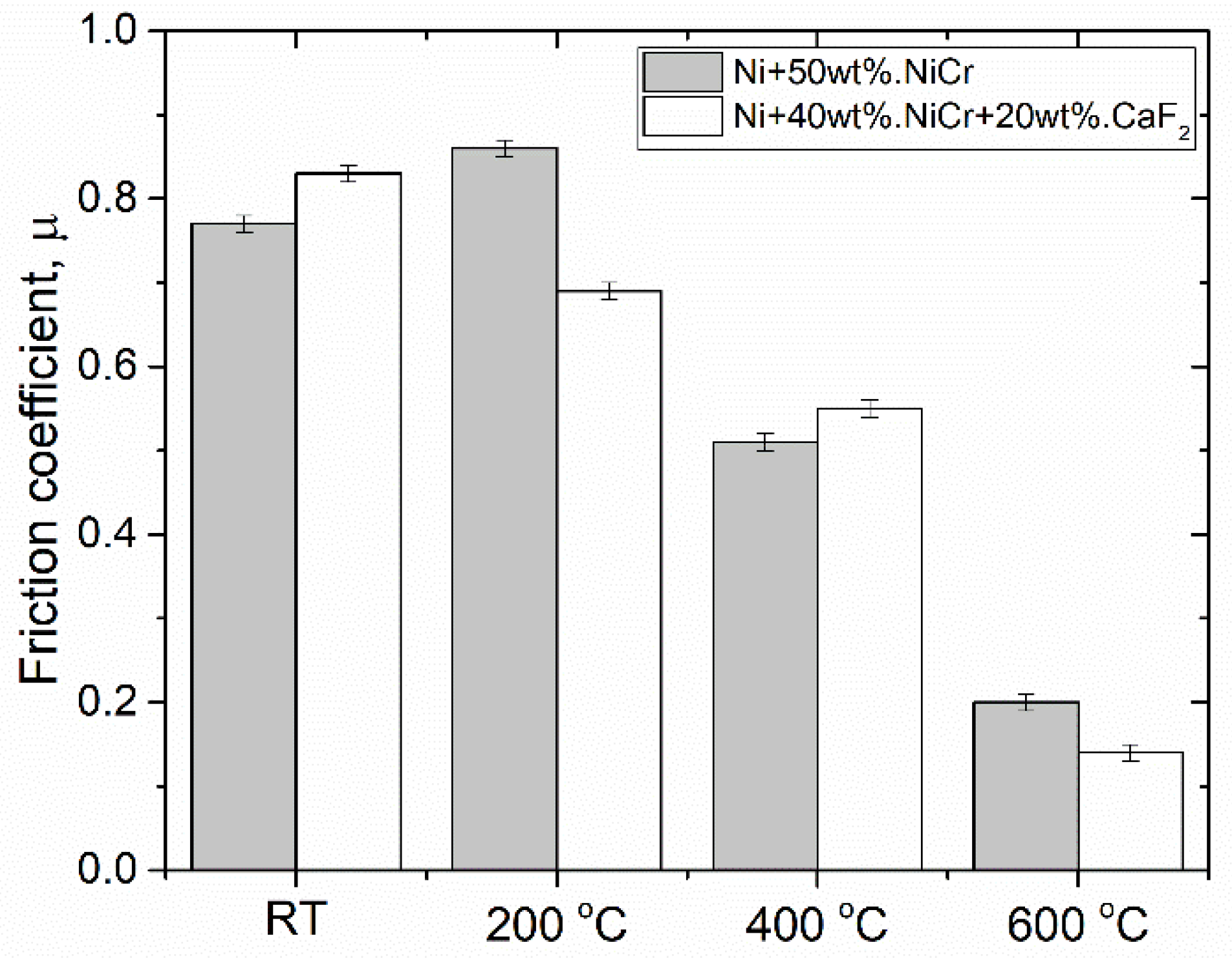

- At room temperature, the friction coefficient of the self-lubricating composite was higher than that of the composite without the addition of solid lubricant.

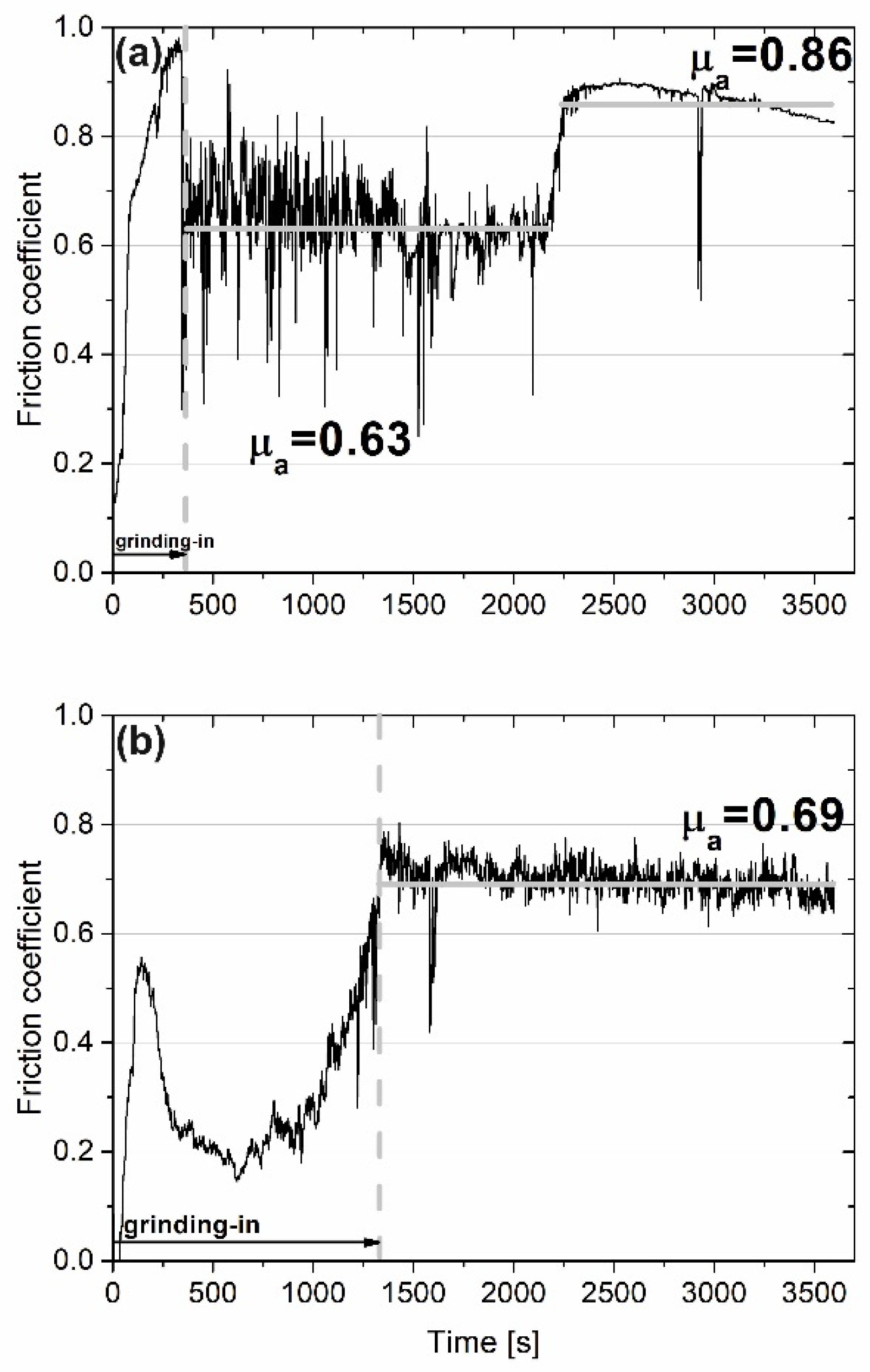

- At 200 °C, initially, the µa value for the Ni–NiCr composite was lower than the value for the self-lubricating composite (0.63 vs. 0.69), but after some time, adhesive wear became the main wear mechanism and µa increased to 0.86.

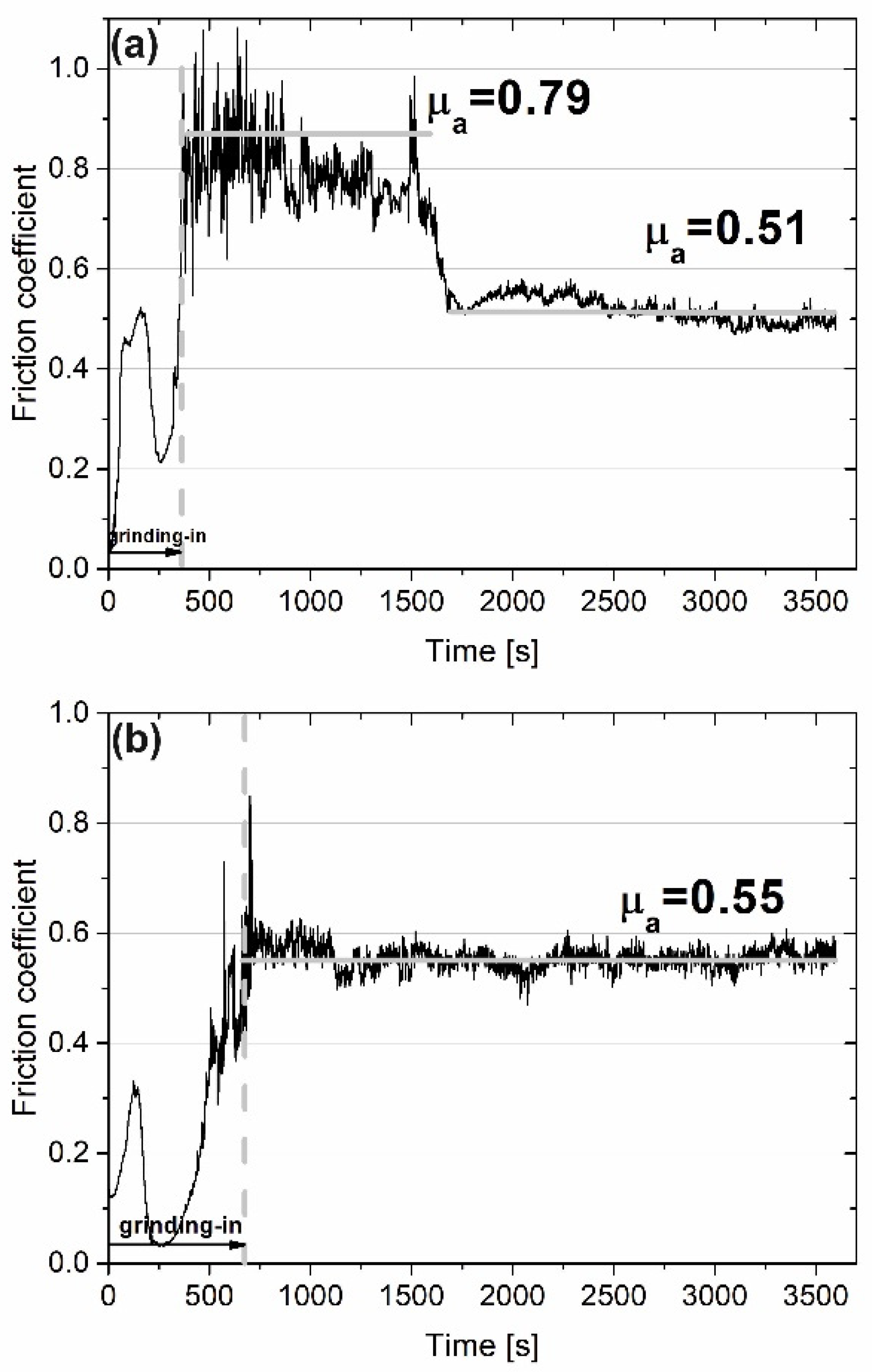

- At 400 °C, the µa value for the composite without the addition of CaF2,was equal to 0.79, and after 1500 s this value dropped to 0.51, whereas the average friction coefficient for the self-lubricating composite was equal to 0.55.

- At 600 °C, the average friction coefficient was lower for the self-lubricating composite in relation to the Ni–NiCr composite (0.14 vs. 0.20).

- Grinding-in times were lower for the sample without the addition of solid-lubricant at room temperature, 200 °C, and 400 °C. However, at 600 °C, the grinding-in time for the self-lubricating composite was approximately two times lower than for the Ni–NiCr composite (720 s vs. 1350 s).

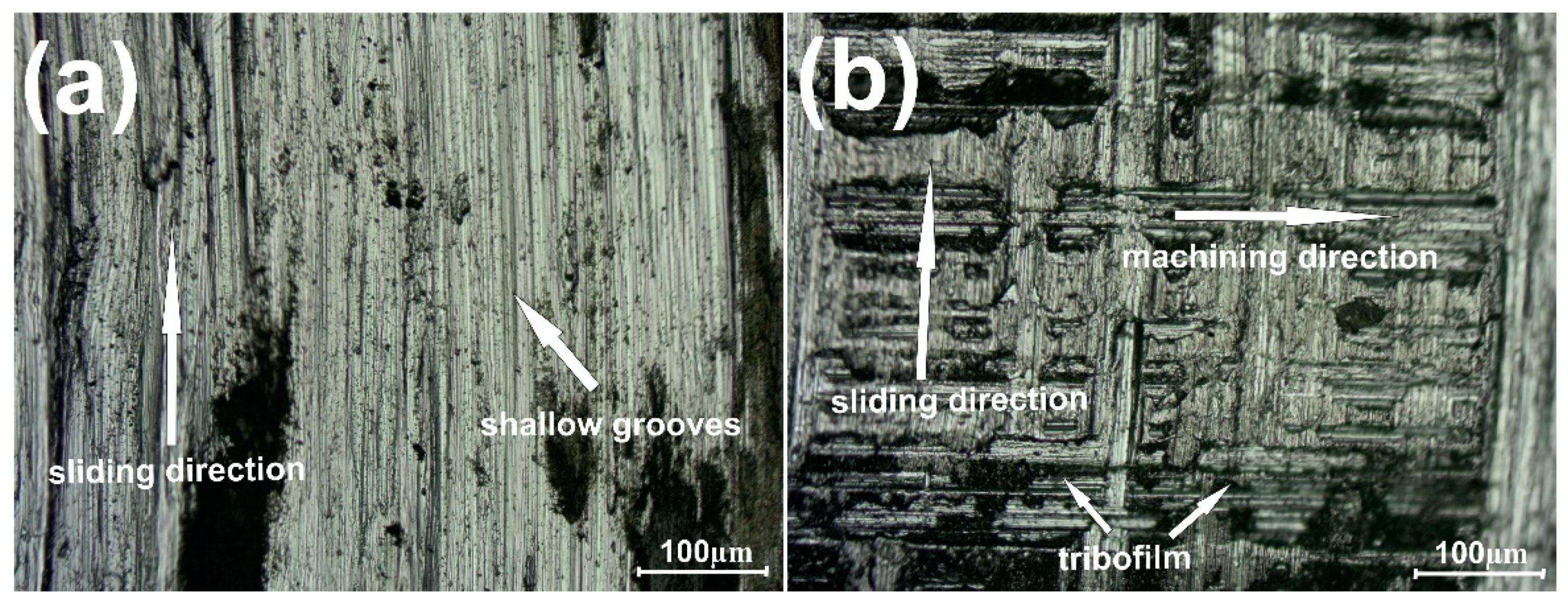

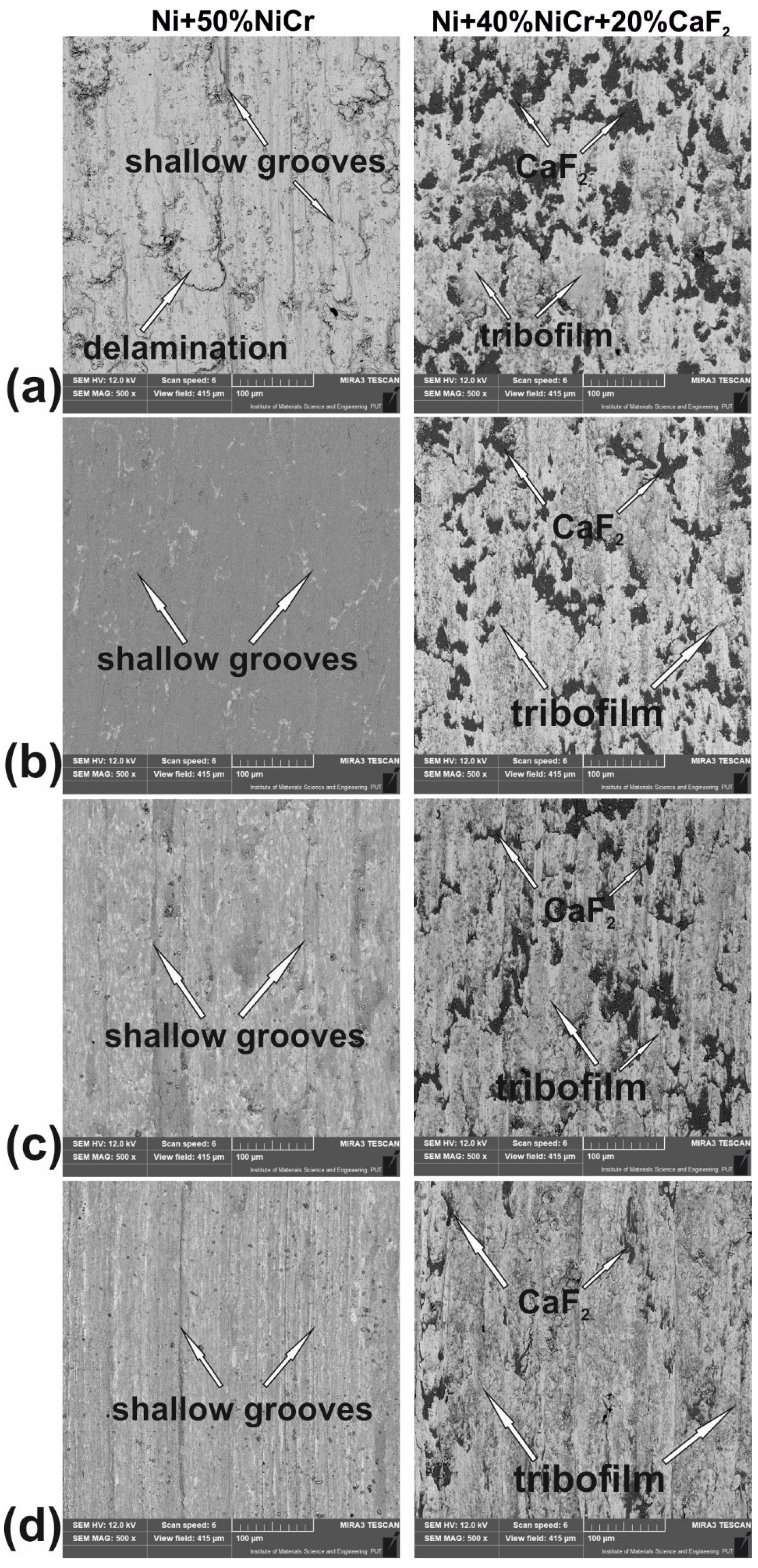

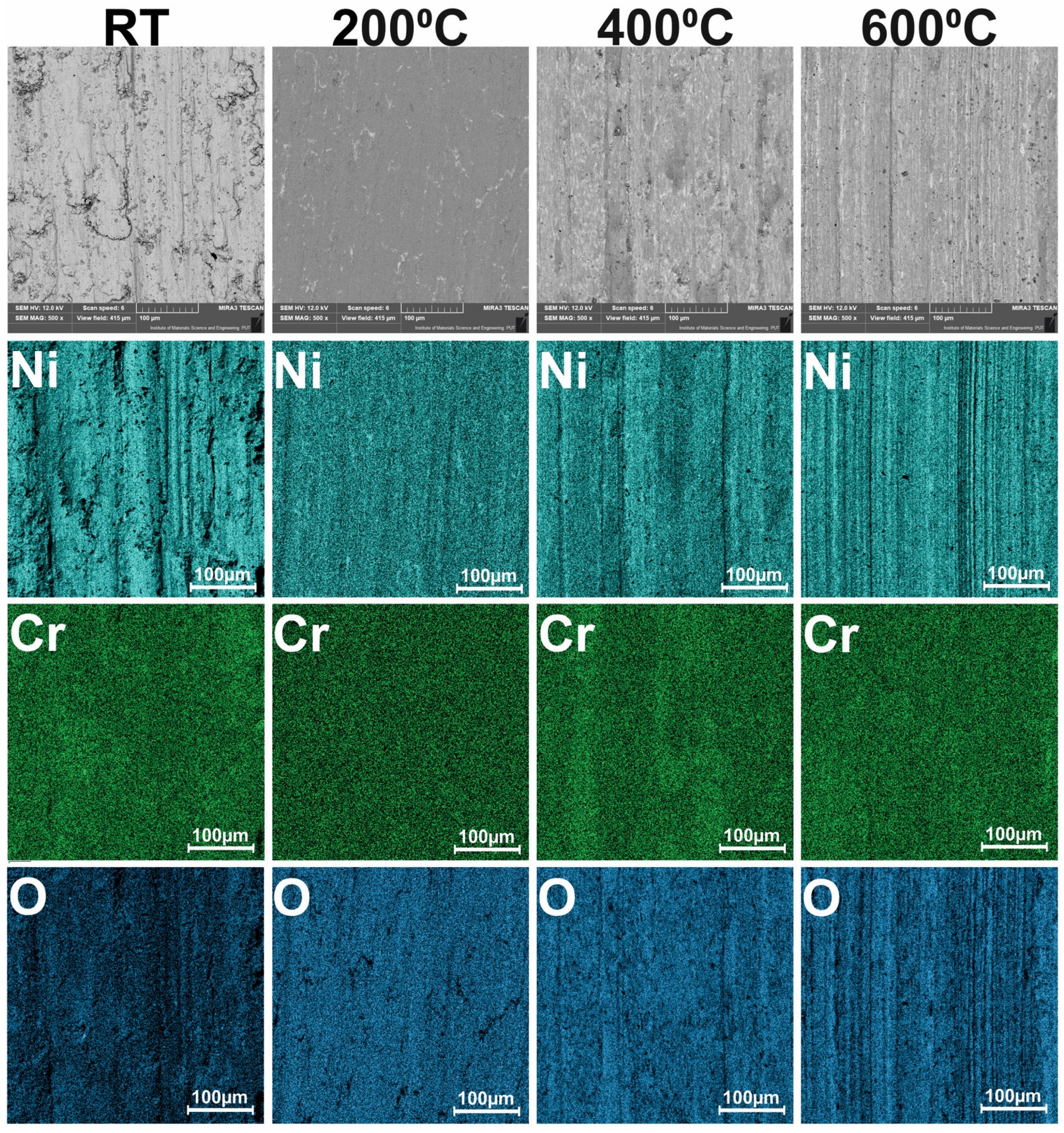

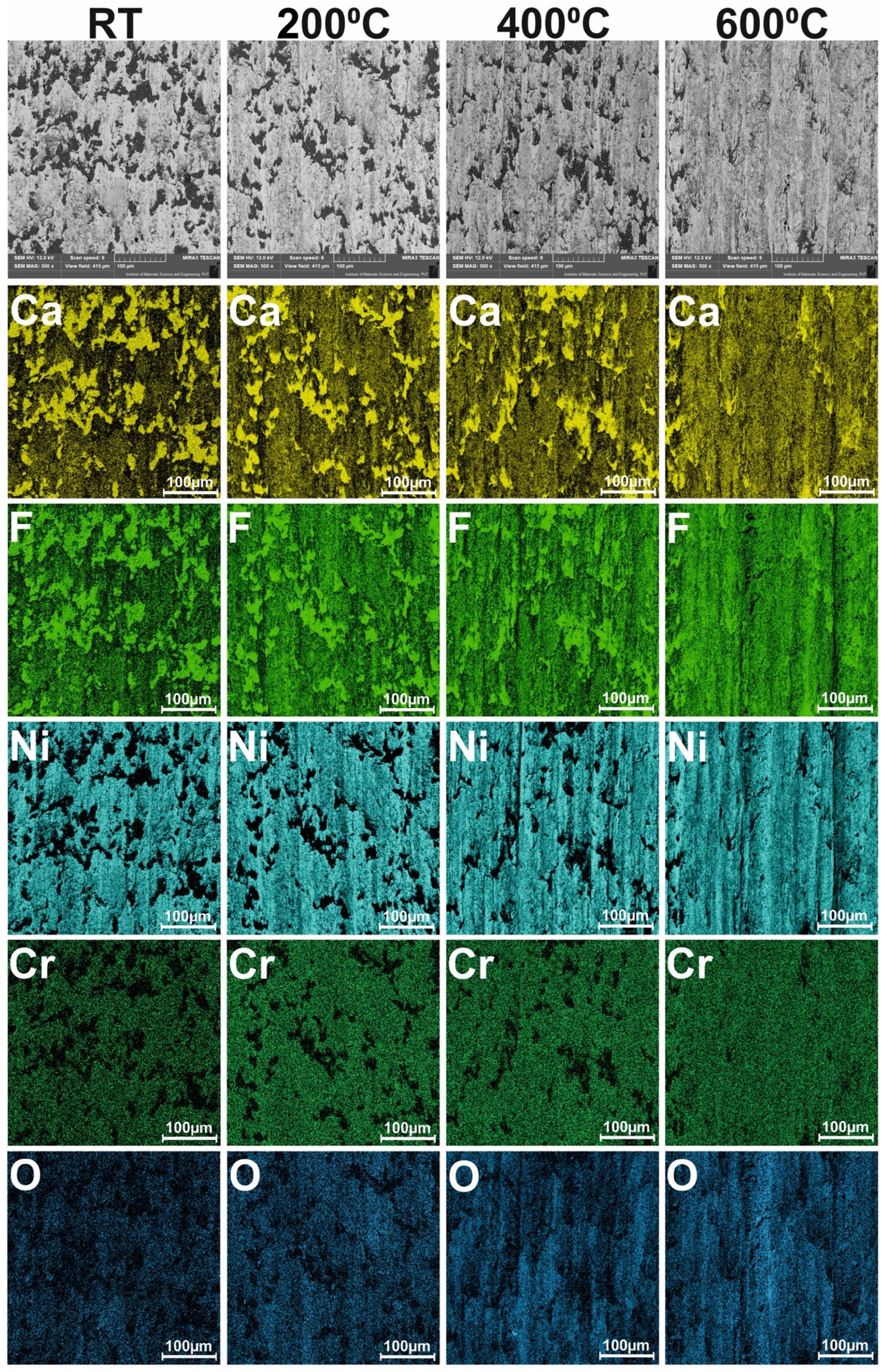

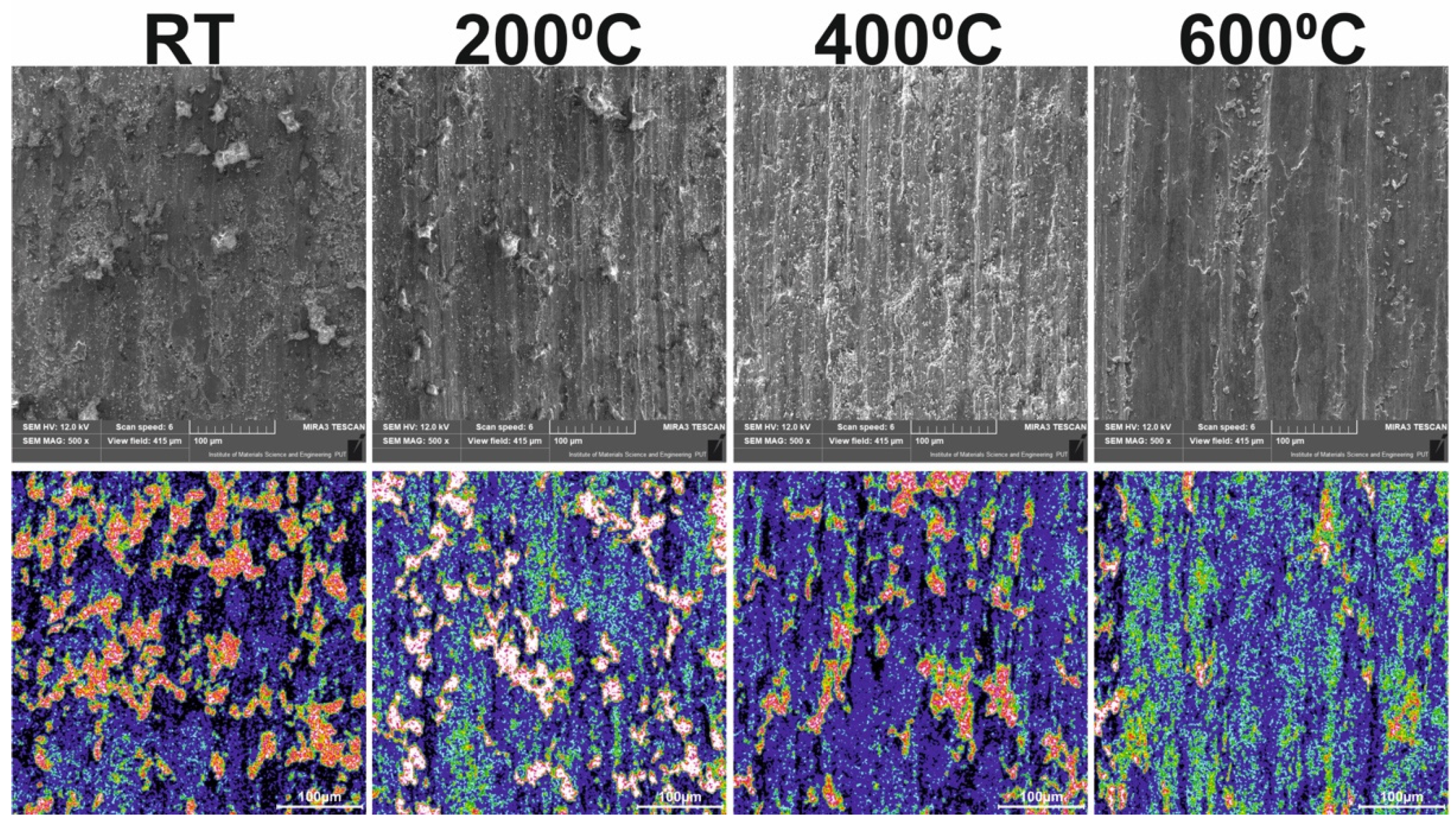

- A surface analysis of the samples proved that the self-lubricating composite was coated by the thin tribofilm layer. EDS analysis showed that tribofilm consisted of calcium and fluorine and was characterized by diversified thickness.

- The EDS analysis confirmed that tribofilm was well smeared on the sample surface at higher temperatures (400 °C and 600 °C) and the tribofilm protected samples against oxidation.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Özbek, I.; Akbulut, H.; Zeytin, S.; Bindal, C.; Ucisik, A.H. The Characterization of Borided 99.5% Purity Nickel. Surf. Coat. Technol. 2000, 126, 166–170. [Google Scholar] [CrossRef]

- Mu, D.; Shen, B.-I.; Yang, C.; Zhao, X. Microstructure Analysis of Boronized Pure Nickel Using Boronizing Powders with SiC as Diluent. Vacuum 2009, 83, 1481–1484. [Google Scholar] [CrossRef]

- Anthymidis, K.G.; Zinoviadis, P.; Roussos, D.; Tsipas, D.N. Boriding of Nickel in a Fluidized Bed Reactor. Mater. Res. Bull. 2002, 37, 515–522. [Google Scholar] [CrossRef]

- Lou, D.C.; Solberg, J.K.; Akselsen, O.M.; Dahl, N. Microstructure and Property Investigation of Paste Boronized Pure Nickel and Nimonic 90 Superalloy. Mater. Chem. Phys. 2009, 115, 239–244. [Google Scholar] [CrossRef]

- Piasecki, A.; Kotkowiak, M.; Makuch, N.; Kulka, M. Wear Behavior of Self-Lubricating Boride Layers Produced on Inconel 600-Alloy by Laser Alloying. Wear 2019, 426–427, 919–933. [Google Scholar] [CrossRef]

- Kulka, M.; Dziarski, P.; Makuch, N.; Piasecki, A.; Miklaszewski, A. Applied Surface Science Microstructure and Properties of Laser-Borided Inconel 600-Alloy. Appl. Surf. Sci. 2013, 284, 757–771. [Google Scholar] [CrossRef]

- Knosalla, C.; Lau, M.; Schmies, L.; Lippmann, W.; Hurtado, A. Investigation on the Corrosion Behavior of Nickel-Base Alloys in Molten Chlorides for Sensible Heat Energy Applications. Adv. Eng. Mater. 2020, 22, 2000099. [Google Scholar] [CrossRef]

- Kotkowiak, M.; Piasecki, A.; Kotkowiak, M.; Kulka, M. Heat-Resisting Aluminized Coatings Modified by Chromium Addition Produced on Nickel-Based Alloys. Trans. Indian Inst. Met. 2018, 71, 2919–2931. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Shi, C.C.; Liu, Z.G.; Wang, Y.M.; Wang, Y.J. Fabrication and High-Temperature Tribological Properties of Self-Lubricating NiCr-BaMoO4 Composites. Wear 2015, 330–331, 272–279. [Google Scholar] [CrossRef]

- Huang, X.-y.; Wang, J.h.; Zhang, H.q.; Ren, J.; Zan, Q.f.; Gong, Q.m.; Wu, B. WC-Ni-Cr-Based Self-Lubricating Composites Fabricated by Pulsed Electric Current Sintering with Addition of WS2 Solid Lubricant. Int. J. Refract. Met. Hard Mater. 2017, 66, 158–162. [Google Scholar] [CrossRef]

- Li, Y.F.; Yin, H.; Li, X.L.; Mao, C.C. Friction and Wear Properties of Spark Plasma Sintering NiCr–SrSO4 Composites at Elevated Temperatures in Sliding Against Alumina Ball. Tribol. Lett. 2016, 64, 29. [Google Scholar] [CrossRef]

- Fattahi, Z.; Sajjadi, S.A.; Babakhani, A.; Saba, F. Ni–Cr Matrix Composites Reinforced with Nano- and Micron-Sized Surface-Modified Zirconia: Synthesis, Microstructure and Mechanical Properties. J. Alloys Compd. 2020, 817, 152755. [Google Scholar] [CrossRef]

- Torgerson, T.B.; Mantri, S.A.; Banerjee, R.; Scharf, T.W. Room and Elevated Temperature Sliding Wear Behavior and Mechanisms of Additively Manufactured Novel Precipitation Strengthened Metallic Composites. Wear 2019, 426–427, 942–951. [Google Scholar] [CrossRef]

- Harachai, K.; Kothanam, N.; Qin, J.; Boonyongmaneerat, Y.; Jaroenapibal, P. Hardness and Tribological Properties of Co-Electrodeposited Ni-W-B/B Coatings. Surf. Coat. Technol. 2020, 402, 126313. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, T.; Chen, L.; Chen, Y.; Guan, C.; Sun, J. Microstructure and Wear Resistance Behavior of Ti–C–B4C-Reinforced Composite Coating. Ceram. Int. 2020, 46, 25136–25148. [Google Scholar] [CrossRef]

- Han, T.; Xiao, M.; Zhang, J.; Feng, X.; Shen, Y. Laser Cladding Composite Coating on Mild Steel Using Ni–Cr–Ti–B4C Powder. Surf. Eng. 2020, 36, 1278–1284. [Google Scholar] [CrossRef]

- Yang, J.F.; Jiang, Y.; Hardell, J.; Prakash, B.; Fang, Q.F. Influence of Service Temperature on Tribological Characteristics of Self-Lubricant Coatings: A Review. Front. Mater. Sci. 2013, 7, 28–39. [Google Scholar] [CrossRef]

- Sarkar, M.; Mandal, N. Solid Lubricant Materials for High Temperature Application: A Review. Mater. Today Proc. 2022, 66, 3762–3768. [Google Scholar] [CrossRef]

- Mohamad, W.F.; Khan, A.A.; Ahmad, F.; Yassin, A. Phase Analysis and Microstructure Study of Sintered Ni-Cr Composites Containing MoS2, Ag and CaF2 Additives as Solid Lubricants. J. Mech. Eng. Sci. 2020, 14, 6548–6556. [Google Scholar] [CrossRef]

- Ding, C.H.; Liu, C.H.; Yang, Z.M.; Wang, Y.P.; Sun, Z.B.; Yu, L. Effect of Size Refinement and Distribution of Lubricants on Friction Coefficient of High Temperature Self-Lubricating Composites. Compos. Sci. Technol. 2010, 70, 1000–1005. [Google Scholar] [CrossRef]

- Ye, F.; Lou, Z.; Wang, Y.; Liu, W. Wear Mechanism of Ag as Solid Lubricant for Wide Range Temperature Application in Micro-Beam Plasma Cladded Ni60 Coatings. Tribol. Int. 2022, 167, 107402. [Google Scholar] [CrossRef]

- Xing, Y.; Deng, J.; Li, S.; Yue, H.; Meng, R.; Gao, P. Cutting Performance and Wear Characteristics of Al2O3/TiC Ceramic Cutting Tools with WS2/Zr Soft-Coatings and Nano-Textures in Dry Cutting. Wear 2014, 318, 12–26. [Google Scholar] [CrossRef]

- Rapoport, L.; Moshkovich, A.; Perfilyev, V.; Lapsker, I.; Halperin, G.; Itovich, Y.; Etsion, I. Friction and Wear of MoS2 Films on Laser Textured Steel Surfaces. Surf. Coat. Technol. 2008, 202, 3332–3340. [Google Scholar] [CrossRef]

- Ren, S.; Shang, K.; Cui, M.; Wang, L.; Pu, J.; Yi, P. Structural Design of MoS2-Based Coatings toward High Humidity and Wide Temperature. J. Mater. Sci. 2019, 54, 11889–11902. [Google Scholar] [CrossRef]

- He, J.; Sun, J. Synergistic Lubrication Effect of Al2O3 and MoS2 Nanoparticles Confined between Iron Surfaces: A Molecular Dynamics Study. J. Mater. Sci. 2021, 56, 9227–9241. [Google Scholar] [CrossRef]

- Krauß, S.; Seynstahl, A.; Tremmel, S.; Meyer, B.; Bitzek, E.; Göken, M.; Yokosawa, T.; Zubiri, B.A.; Spiecker, E.; Merle, B. Structural Reorientation and Compaction of Porous MoS2 Coatings during Wear Testing. Wear 2022, 500–501, 204339. [Google Scholar] [CrossRef]

- Tan, B.; Stephens, L.S. Evaluation of Viscoelastic Characteristics of PTFE-Based Materials. Tribol. Int. 2019, 140, 105870. [Google Scholar] [CrossRef]

- Jianxin, D.; Tongkun, C.; Zeliang, D.; Jianhua, L.; Junlong, S.; Jinlong, Z. Tribological Behaviors of Hot-Pressed Al2O3/TiC Ceramic Composites with the Additions of CaF2 Solid Lubricants. J. Eur. Ceram. Soc. 2006, 26, 1317–1323. [Google Scholar] [CrossRef]

- Deng, J.; Liu, L.; Yang, X.; Liu, J.; Sun, J.; Zhao, J. Self-Lubrication of Al2O3/TiC/CaF2 Ceramic Composites in Sliding Wear Tests and in Machining Processes. Mater. Des. 2007, 28, 757–764. [Google Scholar] [CrossRef]

- Murakami, T.; Ouyang, J.H.; Sasaki, S.; Umeda, K.; Yoneyama, Y. High-Temperature Tribological Properties of Al2O3, Ni-20 Mass% Cr and NiAl Spark-Plasma-Sintered Composites Containing BaF 2-CaF2 Phase. Wear 2005, 259, 626–633. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Sasaki, S.; Umeda, K. The Friction and Wear Characteristics of Plasma-Sprayed ZrO2-Cr2O3-CaF2 from Room Temperature to 800 °C. J. Mater. Sci. 2001, 36, 547–555. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, Q.; Zhai, W. Tribological Properties of TiAl Matrix Self-Lubricating Composites Incorporated with Tungsten Disulfide and Zinc Oxide. RSC Adv. 2015, 5, 45044–45052. [Google Scholar] [CrossRef]

- Birleanu, C.; Pustan, M.; Cioaza, M.; Molea, A.; Popa, F.; Contiu, G. Effect of TiO2 Nanoparticles on the Tribological Properties of Lubricating Oil: An Experimental Investigation. Sci. Rep. 2022, 12, 5201. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, J.H.; Li, Y.F.; Wang, Y.M.; Zhou, Y.; Murakami, T.; Sasaki, S. Microstructure and Tribological Properties of ZrO2(Y2O3) Matrix Composites Doped with Different Solid Lubricants from Room Temperature to 800 °C. Wear 2009, 267, 1353–1360. [Google Scholar] [CrossRef]

- Zhang, W.; Du, L.; Lan, H.; Huang, C.; Zhang, W. Wear Behavior of a NiCr/AgVO3 Self-Lubricating Composite. Acta Metall. Sin. (Engl. Lett.) 2013, 26, 435–440. [Google Scholar] [CrossRef]

- Zhang, P.; Zhao, G.; Wang, W.; Wang, B.; Shi, P.; Qi, G.; Yi, G. Study on the Mechanical and Tribological Properties and the Mechanisms of Cr-Free Ni-Based Self-Lubricating Composites at a Wide Temperature Range. Metals 2020, 10, 268. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Sasaki, S.; Murakami, T.; Umeda, K. Tribological Properties of Spark-Plasma-Sintered ZrO2(Y2O3)-CaF2-Ag Composites at Elevated Temperatures. Wear 2005, 258, 1444–1454. [Google Scholar] [CrossRef]

- Kotkowiak, M.; Piasecki, A.; Kulka, M. The Influence of Solid Lubricant on Tribological Properties of Sintered Ni–20%CaF2 Composite Material. Ceram. Int. 2019, 45, 17103–17113. [Google Scholar] [CrossRef]

- Zhen, J.; Cheng, J.; Zhu, S.; Hao, J.; Qiao, Z.; Yang, J.; Liu, W. High-Temperature Tribological Behavior of a Nickel Alloy Matrix Solid-Lubricating Composite under Vacuum. Tribol. Int. 2017, 110, 52–56. [Google Scholar] [CrossRef]

- Cheng, J.; Zhen, J.; Zhu, S.; Yang, J.; Ma, J.; Li, W.; Liu, W. Friction and Wear Behavior of Ni-Based Solid-Lubricating Composites at High Temperature in a Vacuum Environment. Mater. Des. 2017, 122, 405–413. [Google Scholar] [CrossRef]

- Ding, C.H.; Li, P.L.; Ran, G.; Tian, Y.W.; Zhou, J.N. Tribological Property of Self-Lubricating PM304 Composite. Wear 2007, 262, 575–581. [Google Scholar] [CrossRef]

- Zhen, J.; Cheng, J.; Li, M.; Zhu, S.; Long, Z.; Yang, B.; Yang, J. Lubricating Behavior of Adaptive Nickel Alloy Matrix Composites with Multiple Solid Lubricants from 25 °C to 700 °C. Tribol. Int. 2017, 109, 174–181. [Google Scholar] [CrossRef]

| RT | 200 °C | 400 °C | 600 °C | |

|---|---|---|---|---|

| µa | ||||

| Ni + 50 wt.% NiCr | 0.77 ± 0.01 | 0.86 ± 0.01 | 0.51 ± 0.01 | 0.20 ± 0.01 |

| Ni + 40 wt.% NiCr + 20 wt.% CaF2 | 0.83 ± 0.01 | 0.69 ± 0.01 | 0.55 ± 0.01 | 0.14 ± 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotkowiak, M.; Piasecki, A. Characterization of Wear Properties of Pure Nickel Modified by Ni-Cr Composite and CaF2 Solid Lubricant Addition. Materials 2022, 15, 7511. https://doi.org/10.3390/ma15217511

Kotkowiak M, Piasecki A. Characterization of Wear Properties of Pure Nickel Modified by Ni-Cr Composite and CaF2 Solid Lubricant Addition. Materials. 2022; 15(21):7511. https://doi.org/10.3390/ma15217511

Chicago/Turabian StyleKotkowiak, Mateusz, and Adam Piasecki. 2022. "Characterization of Wear Properties of Pure Nickel Modified by Ni-Cr Composite and CaF2 Solid Lubricant Addition" Materials 15, no. 21: 7511. https://doi.org/10.3390/ma15217511

APA StyleKotkowiak, M., & Piasecki, A. (2022). Characterization of Wear Properties of Pure Nickel Modified by Ni-Cr Composite and CaF2 Solid Lubricant Addition. Materials, 15(21), 7511. https://doi.org/10.3390/ma15217511