Detecting the Deformation Behavior of Bimodal Ti-6Al-4V Using a Digital Image Correlation Technique

Abstract

1. Introduction

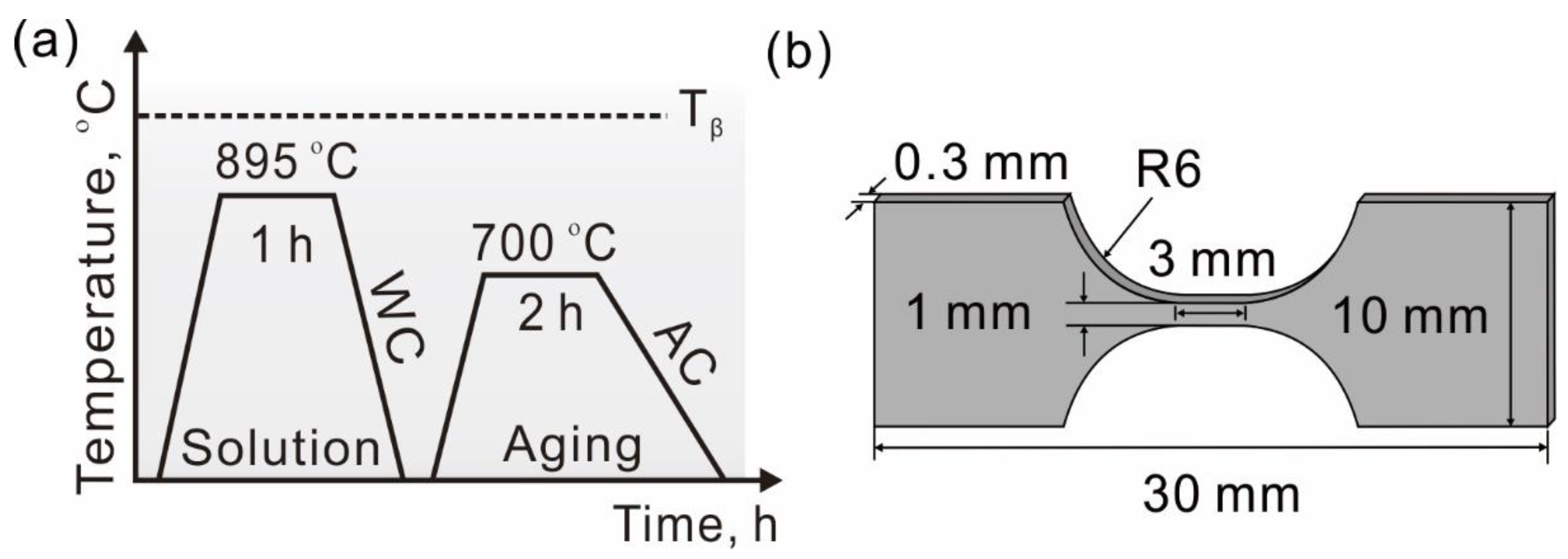

2. Materials and Methods

2.1. Material and Specimen

2.2. Tensile Testing and Characterization Method

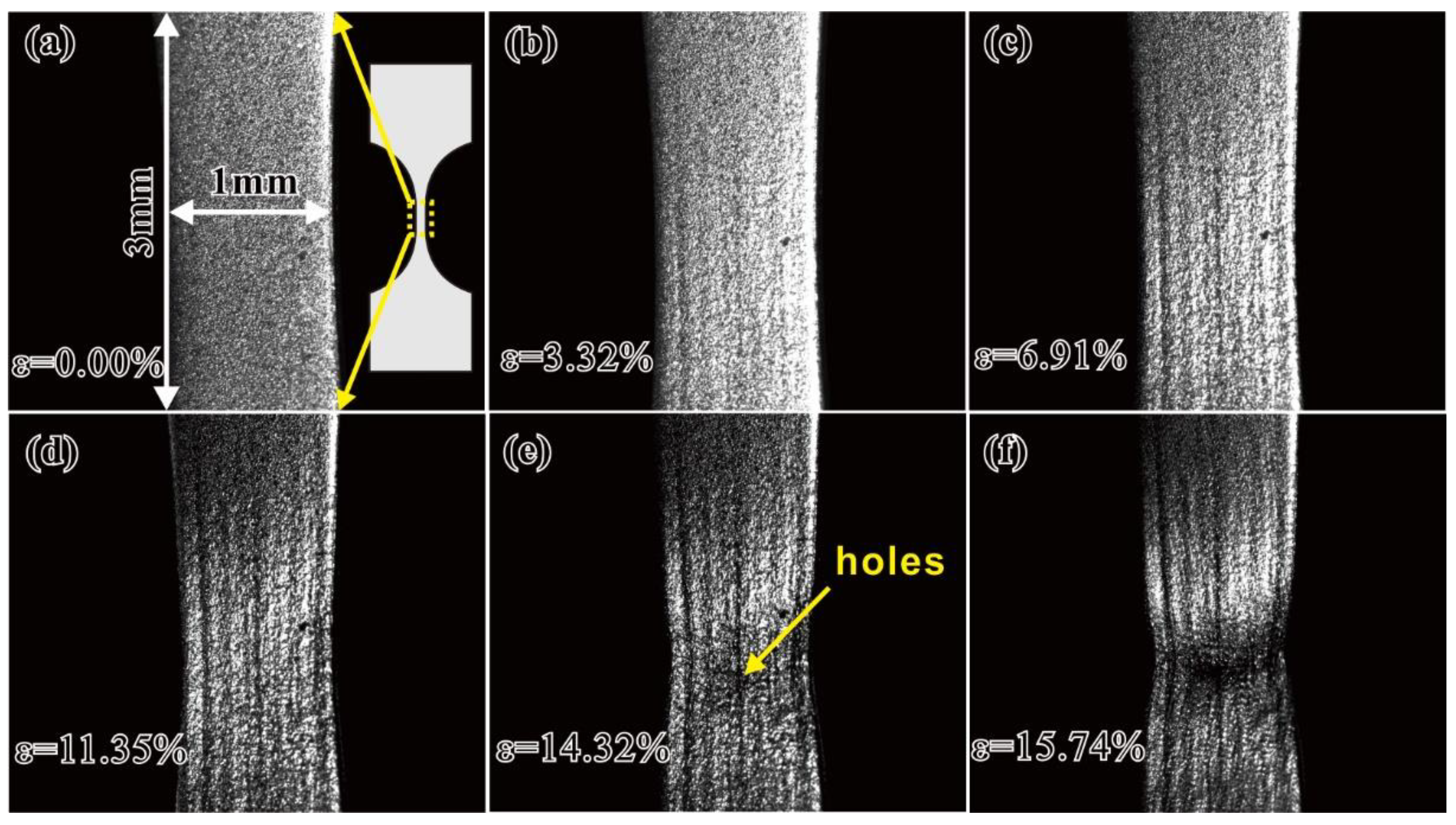

2.3. Quasi-In Situ Tensile Testing Method

3. Results

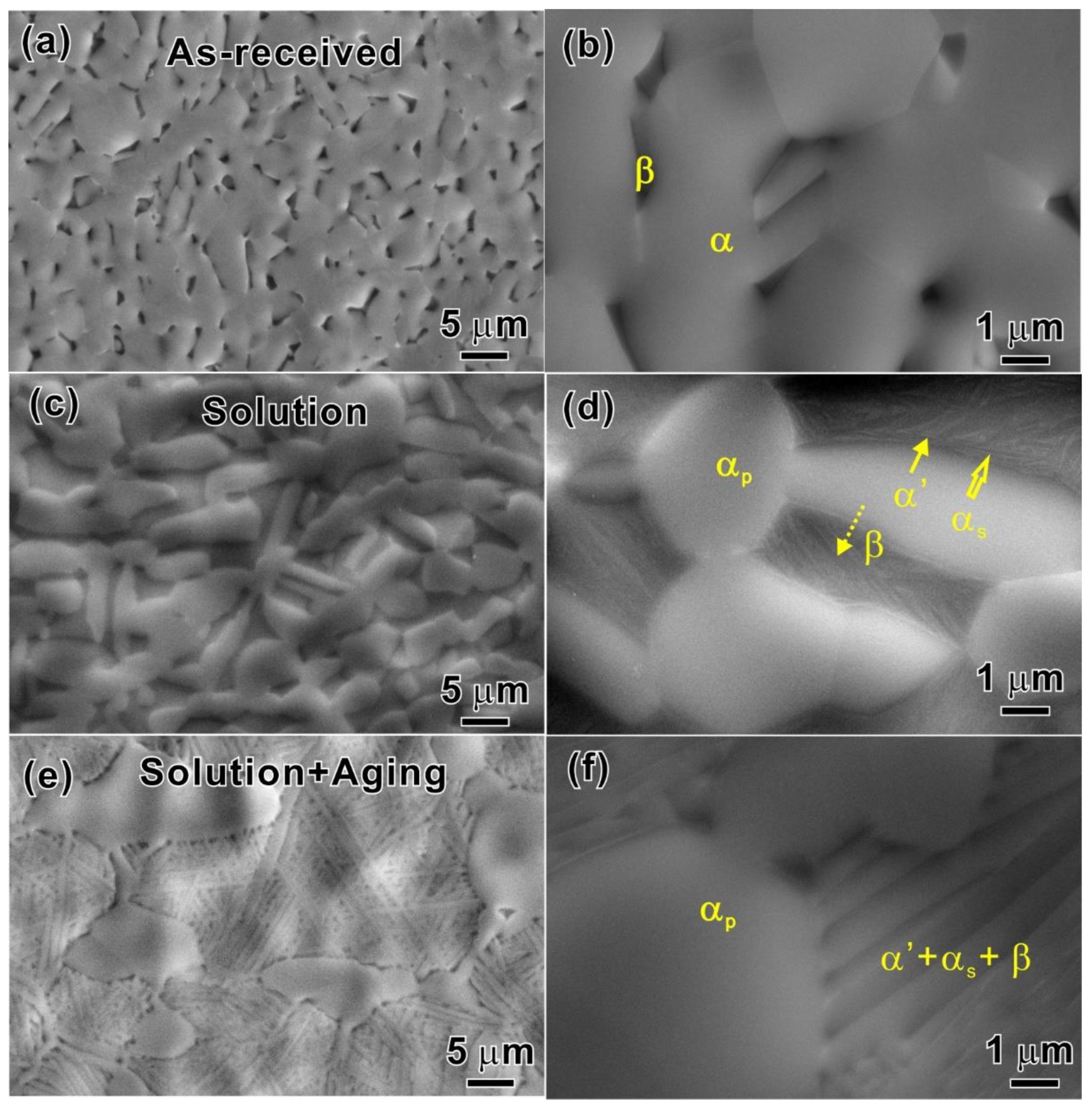

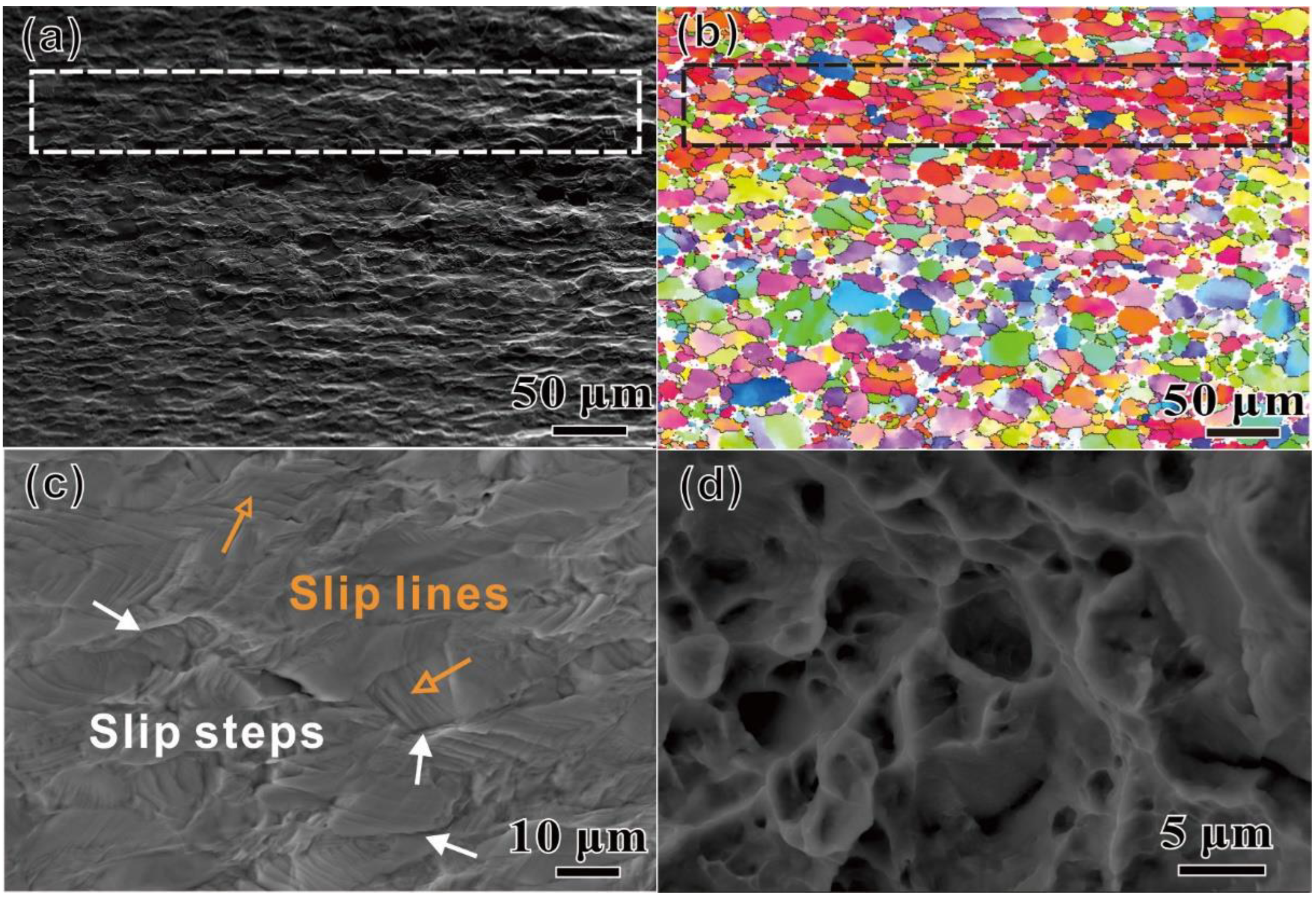

3.1. Heat Treatment

3.2. Deformation Process

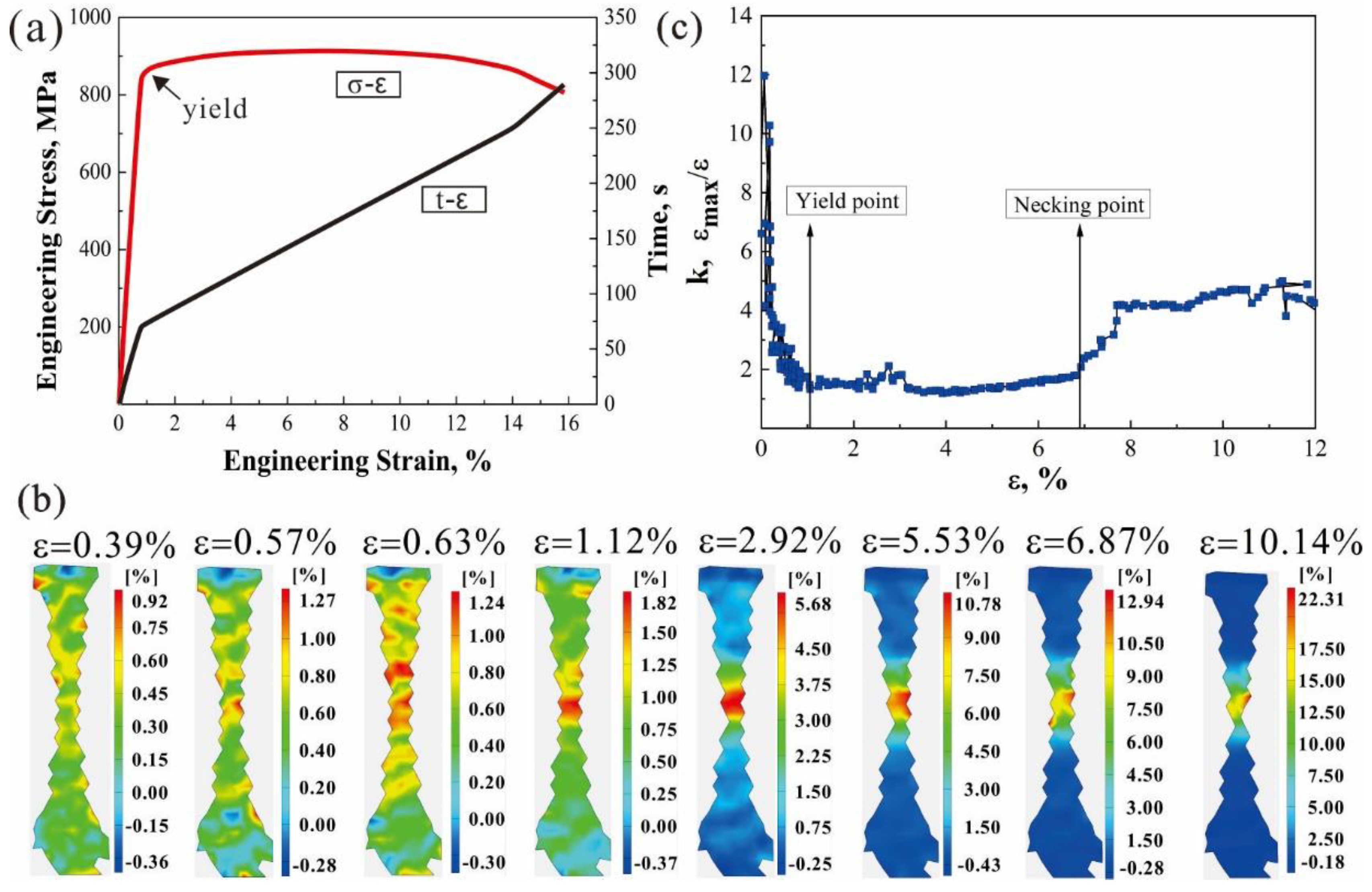

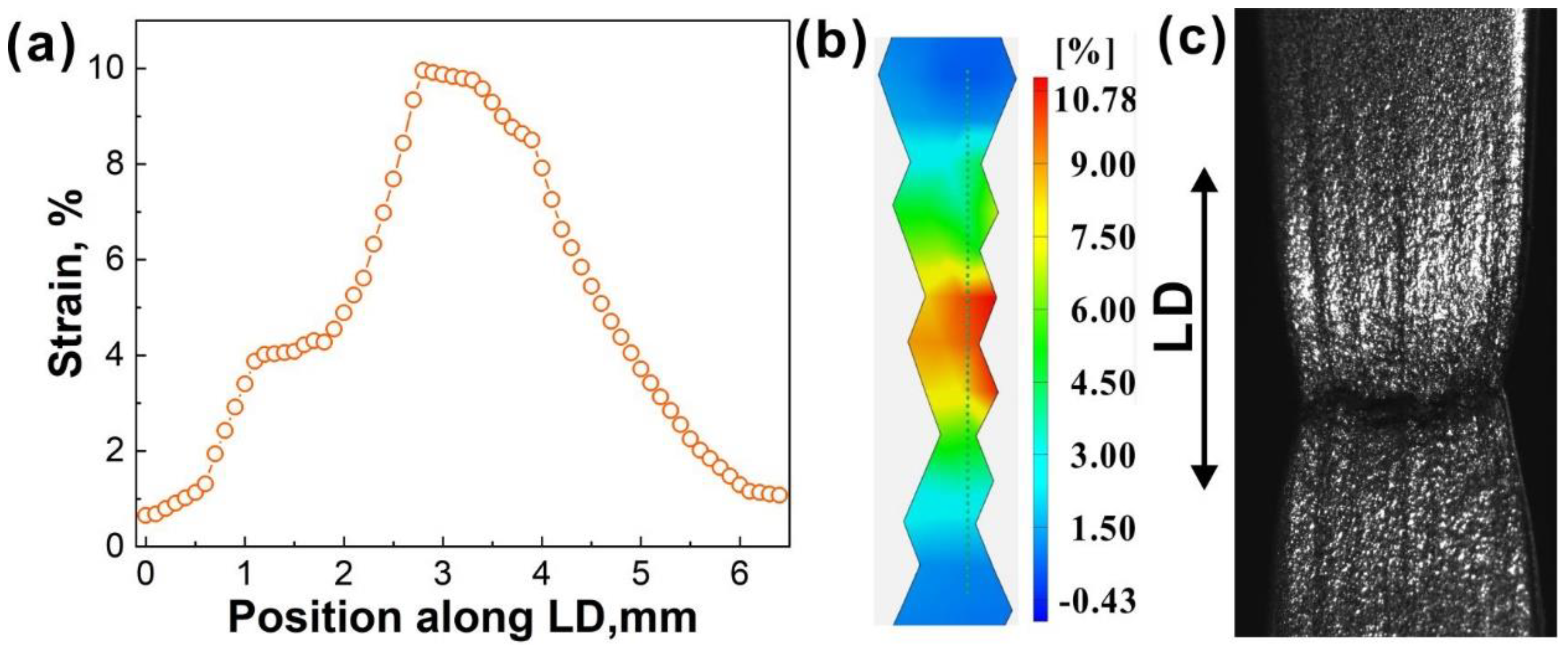

3.3. Evolution of Local Strain under Tensile Loading

4. Discussion

4.1. Evolution of Deformation Calculated from DIC Data during Tensile Test

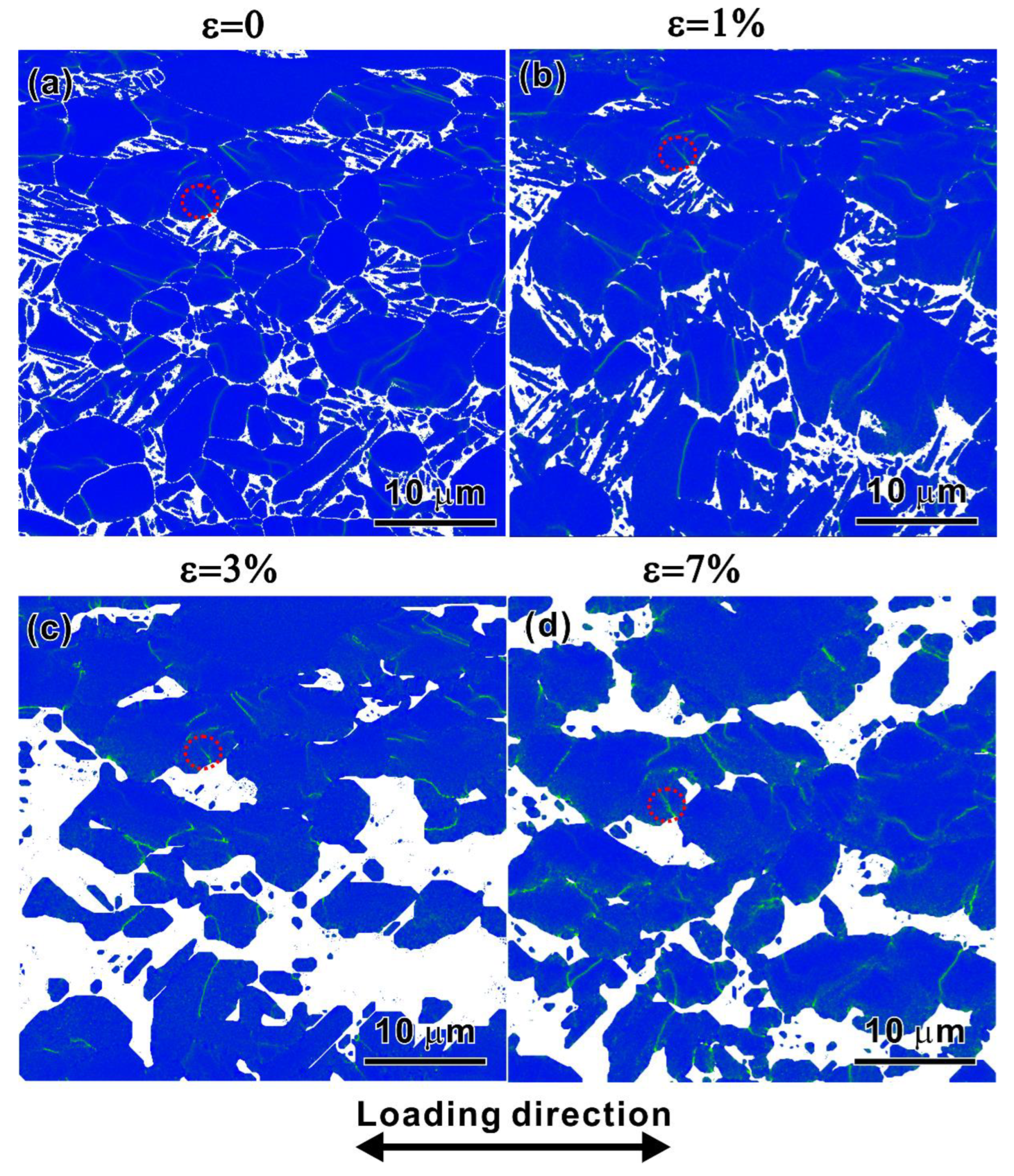

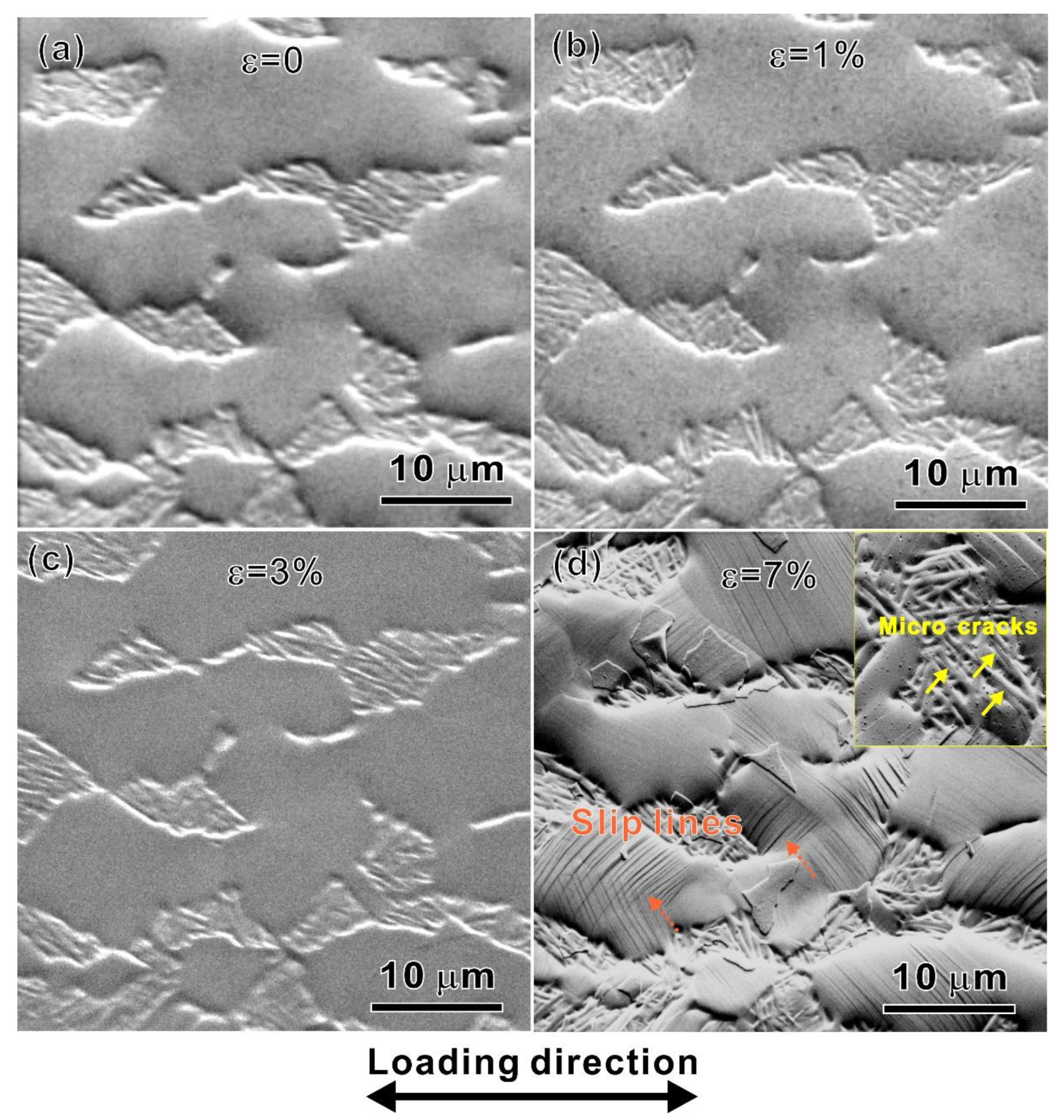

4.2. Evolution of Deformation Observed Directly by Quasi-In Situ Experiment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Ding, R.; Gong, J.; Wilkinson, A.J.; Jones, I.P. A study of dislocation transmission through a grain boundary in hcp Ti-6Al using micro-cantilevers. Acta Mater. 2016, 103, 416–423. [Google Scholar] [CrossRef]

- Briffod, F.; Bleuset, A.; Shiraiwa, T.; Enoki, M. Effect of crystallographic orientation and geometrical compatibility on fatigue crack initiation and propagation in rolled Ti-6Al-4V alloy. Acta Mater. 2019, 177, 56–67. [Google Scholar] [CrossRef]

- Bieler, T.R.; Eisenlohr, P.; Roters, F.; Kumar, D.; Mason, D.E.; Crimp, M.A.; Raabe, D. The role of heterogeneous deformation on damage nucleation at grain boundaries in single phase metals. Int. J. Plast. 2009, 25, 1655–1683. [Google Scholar] [CrossRef]

- Luster, J.; Morris, M.A. Compatibility of deformation in two-phase Ti-Al alloys: Dependence on microstructure and orientation relationships. Metall. Mater. Trans. A 1995, 26, 1745–1756. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 062001. [Google Scholar] [CrossRef]

- del Rey Castillo, E.; Allen, T.; Henry, R.; Griffith, M.; Ingham, J. Digital image correlation (DIC) for measurement of strains and displacements in coarse, low volume-fraction FRP composites used in civil infrastructure. Compos. Struct. 2019, 212, 43–57. [Google Scholar] [CrossRef]

- Tekieli, M.; De Santis, S.; de Felice, G.; Kwiecień, A.; Roscini, F. Application of Digital Image Correlation to composite reinforcements testing. Compos. Struct. 2017, 160, 670–688. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Jin, Z.Q.; Zhao, T.J.; Chen, Y.F.; Chen, F.X. Strain Field of Reinforced Concrete under Accelerated Corrosion by Digital Image Correlation Technique. J. Adv. Concr. Technol. 2017, 15, 290–299. [Google Scholar] [CrossRef]

- Dong Sheng, Z.; Dwayne, D.A. Applications of digital image correlation to biological tissues. J. Biomed. Opt. 2004, 9, 691–699. [Google Scholar]

- Jiang, J.; Zhang, T.; Dunne, F.P.E.; Ben Britton, T. Deformation compatibility in a single crystalline Ni superalloy. Proc. R. Soc. AMath. Phys. Eng. Sci. 2016, 472, 20150690. [Google Scholar] [CrossRef]

- Xia, D.; Huang, G.; Liu, S.; Tang, A.; Gavras, S.; Huang, Y.; Hort, N.; Jiang, B.; Pan, F. Microscopic deformation compatibility during biaxial tension in AZ31 Mg alloy rolled sheet at room temperature. Mater. Sci. Eng. A 2019, 756, 1–10. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, C.; Li, Y.; Guo, F.; He, Q.; Wang, M.; Wu, X.; Scattergood, R.O.; Zhu, Y. Dense dispersed shear bands in gradient-structured Ni. Int. J. Plast. 2020, 124, 186–198. [Google Scholar] [CrossRef]

- Wang, Y.F.; Huang, C.X.; He, Q.; Guo, F.J.; Wang, M.S.; Song, L.Y.; Zhu, Y.T. Heterostructure induced dispersive shear bands in heterostructured Cu. Scr. Mater. 2019, 170, 76–80. [Google Scholar] [CrossRef]

- Li, X.; Xu, D.; Yang, R. Crystal Plasticity Finite Element Method Investigation of the High Temperature Deformation Consistency in Dual-Phase Titanium Alloy. Acta Metall. Sin. 2019, 55, 928–938. [Google Scholar]

- Ye, P.; Yao, J.; Wang, B.; Liu, H.; Deng, L.; Wang, C.; Chen, J.; Li, Q. A comparative study between {11-22} twinning and {10-12} twinning variant selection mechanisms during uniaxial compression in pure titanium. Mater. Charact. 2020, 162, 110188. [Google Scholar] [CrossRef]

- Bornert, M.; Bremand, F.; Doumalin, P.; Dupre, J.C.; Fazzini, M.; Grediac, M.; Hild, F.; Mistou, S.; Molimard, J.; Orteu, J.J.; et al. Assessment of Digital Image Correlation Measurement Errors: Methodology and Results. Exp. Mech. 2009, 49, 353–370. [Google Scholar] [CrossRef]

- Luo, Y.; Guo, W.; Wang, B.; Wei, R. Revealing Microstructural Evolution and Deformation Mechanism of Pure Titanium through a Quasi In Situ Compression Method at High Strain Rate. Crystals 2022, 12, 677. [Google Scholar] [CrossRef]

- Lunt, D.; da Fonseca, J.Q.; Rugg, D.; Preuss, M. Microscopic strain localisation in Ti-6Al-4V during uniaxial tensile loading. Mater. Sci. Eng. A 2017, 680, 444–453. [Google Scholar] [CrossRef]

- Liu, C.; Jin, L.; Dong, J.; Wang, F. The use of the fracture initiation parameter F1 to predict microcrack nucleation at grain boundaries in Mg-2%Gd alloy. Mater. Des. 2016, 111, 369–374. [Google Scholar] [CrossRef]

- Young, W.C.; Budynas, R.G.; Sadegh, A.M. Roark’s Formulas for Stress and Strain, 8th ed.; McGraw-Hill: New York, NY, USA, 1989. [Google Scholar]

- Noda, N.A.; Shen, Y.; Takaki, R.; Akagi, D.; Ikeda, T.; Sano, Y.; Takase, Y. Relationship between strain rate concentration factor and stress concentration factor. Theor. Appl. Fract. Mech. 2017, 90, 218–227. [Google Scholar] [CrossRef]

- Yang, Z. Stress and strain concentration factors for tension bars of circular cross-section with semicircular groove. Eng. Fract. Mech. 2009, 76, 1683–1690. [Google Scholar] [CrossRef]

- Le Biavant, K.; Pommier, S.; Prioul, C. Local texture and fatigue crack initiation in a Ti-6AI-4V titanium alloy. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 527–545. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, K.V.; Lim, S.; Wu, X.; Davies, C.H.J. Effect of the presence of macrozones on short crack propagation in forged two-phase titanium alloys. Int. J. Fatigue 2017, 104, 1–11. [Google Scholar] [CrossRef]

- Qiu, X.; Huang, Y.; Nix, W.D.; Hwang, K.C.; Gao, H. Effect of intrinsic lattice resistance in strain gradient plasticity. Acta Mater. 2001, 49, 3949–3958. [Google Scholar] [CrossRef]

- Arsenlis, A.; Parks, D.M. Crystallographic aspects of geometrically-necessary and statistically-stored dislocation density. Acta Mater. 1999, 47, 1597–1611. [Google Scholar] [CrossRef]

- Ali, M.A.; Amin, W.; Shchyglo, O.; Steinbach, I. 45-degree rafting in Ni-based superalloys: A combined phase-field and strain gradient crystal plasticity study. Int. J. Plast. 2020, 128, 102659. [Google Scholar] [CrossRef]

- Bantounas, I.; Dye, D.; Lindley, T.C. The effect of grain orientation on fracture morphology during high-cycle fatigue of Ti-6Al-4V. Acta Mater. 2009, 57, 3584–3595. [Google Scholar] [CrossRef]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2021, 9, 1–31. [Google Scholar] [CrossRef]

- Guo, Y.; Britton, T.B.; Wilkinson, A.J. Slip band-grain boundary interactions in commercial-purity titanium. Acta Mater. 2014, 76, 1–12. [Google Scholar] [CrossRef]

- Hémery, S.; Tromas, C.; Villechaise, P. Slip-stimulated grain boundary sliding in Ti-6Al-4 V at room temperature. Materialia 2019, 5, 100189. [Google Scholar] [CrossRef]

- Zhao, H.Z.; You, Z.S.; Tao, N.R.; Lu, L. Anisotropic strengthening of nanotwin bundles in heterogeneous nanostructured Cu: Effect of deformation compatibility. Acta Mater. 2021, 210, 116830. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Jiang, J.; Britton, T.B.; Wilkinson, A.J. Evolution of dislocation density distributions in copper during tensile deformation. Acta Materialia 2013, 61, 7227–7239. [Google Scholar] [CrossRef]

- Gao, H.; Huang, Y.; Nix, W.D.; Hutchinson, J.W. Mechanism-based strain gradient plasticity— I. Theory. J. Mech. Phys. Solids 1999, 47, 1239–1263. [Google Scholar] [CrossRef]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.-Y.; Zhang, B.; Song, Z.-M.; Luo, X.-M.; Zhang, G.-P. Detecting the Deformation Behavior of Bimodal Ti-6Al-4V Using a Digital Image Correlation Technique. Materials 2022, 15, 7504. https://doi.org/10.3390/ma15217504

Li M-Y, Zhang B, Song Z-M, Luo X-M, Zhang G-P. Detecting the Deformation Behavior of Bimodal Ti-6Al-4V Using a Digital Image Correlation Technique. Materials. 2022; 15(21):7504. https://doi.org/10.3390/ma15217504

Chicago/Turabian StyleLi, Mei-Yue, Bin Zhang, Zhu-Man Song, Xue-Mei Luo, and Guang-Ping Zhang. 2022. "Detecting the Deformation Behavior of Bimodal Ti-6Al-4V Using a Digital Image Correlation Technique" Materials 15, no. 21: 7504. https://doi.org/10.3390/ma15217504

APA StyleLi, M.-Y., Zhang, B., Song, Z.-M., Luo, X.-M., & Zhang, G.-P. (2022). Detecting the Deformation Behavior of Bimodal Ti-6Al-4V Using a Digital Image Correlation Technique. Materials, 15(21), 7504. https://doi.org/10.3390/ma15217504