Effect of Cold Rolling on Microstructural and Mechanical Properties of a Dual-Phase Steel for Automotive Field

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Samples Preparation

2.2. Electron Backscatter Diffraction and Kernel Average Matrix Measurements

- consider neighbors up to order n, e.g., n = 1, 2, 3, …;

- consider only neighbors belonging to the same grain;

- consider only neighbors with a misorientation angle smaller than a threshold angle.

2.3. Tensile Tests

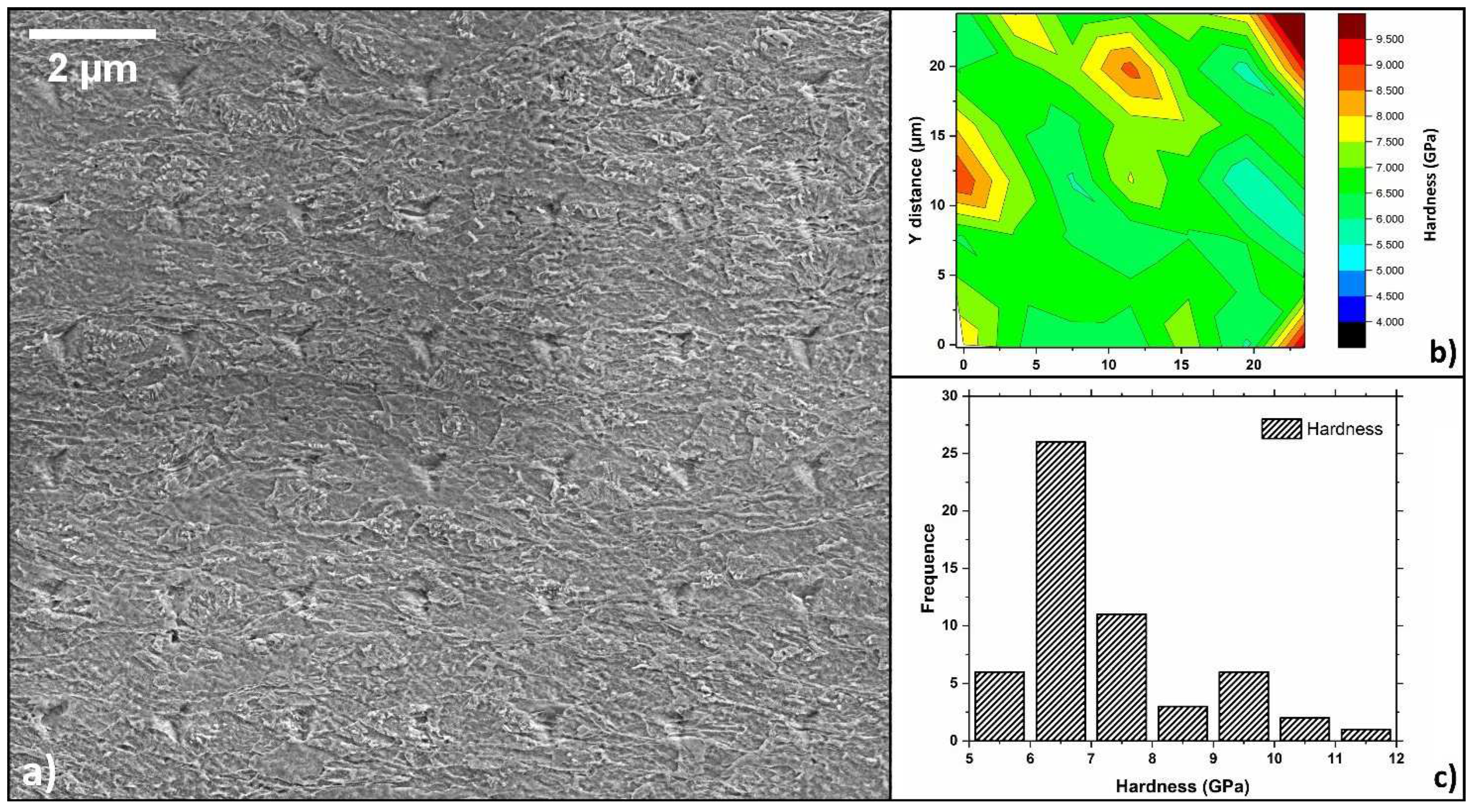

2.4. Nano Hardness Tests

3. Results

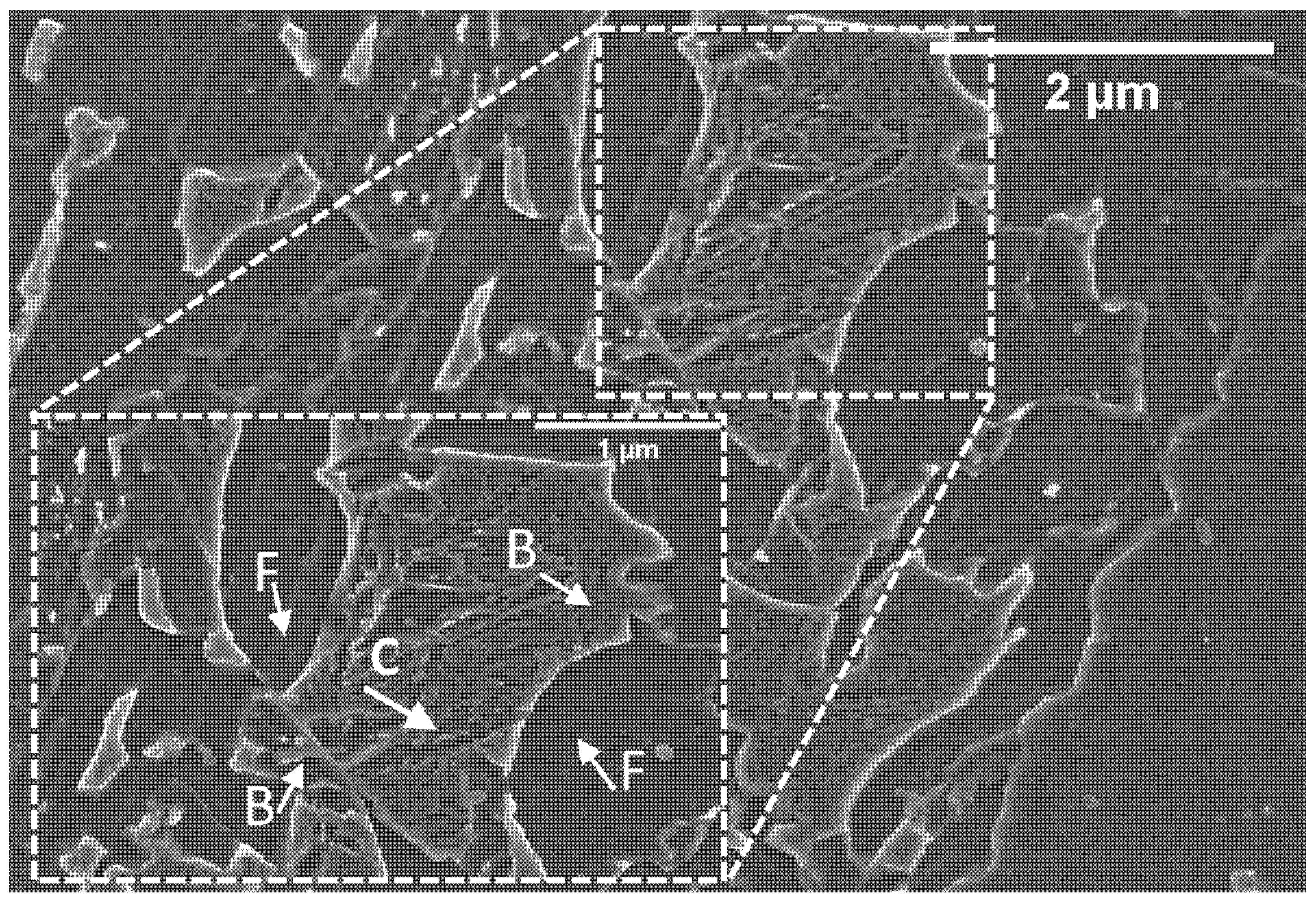

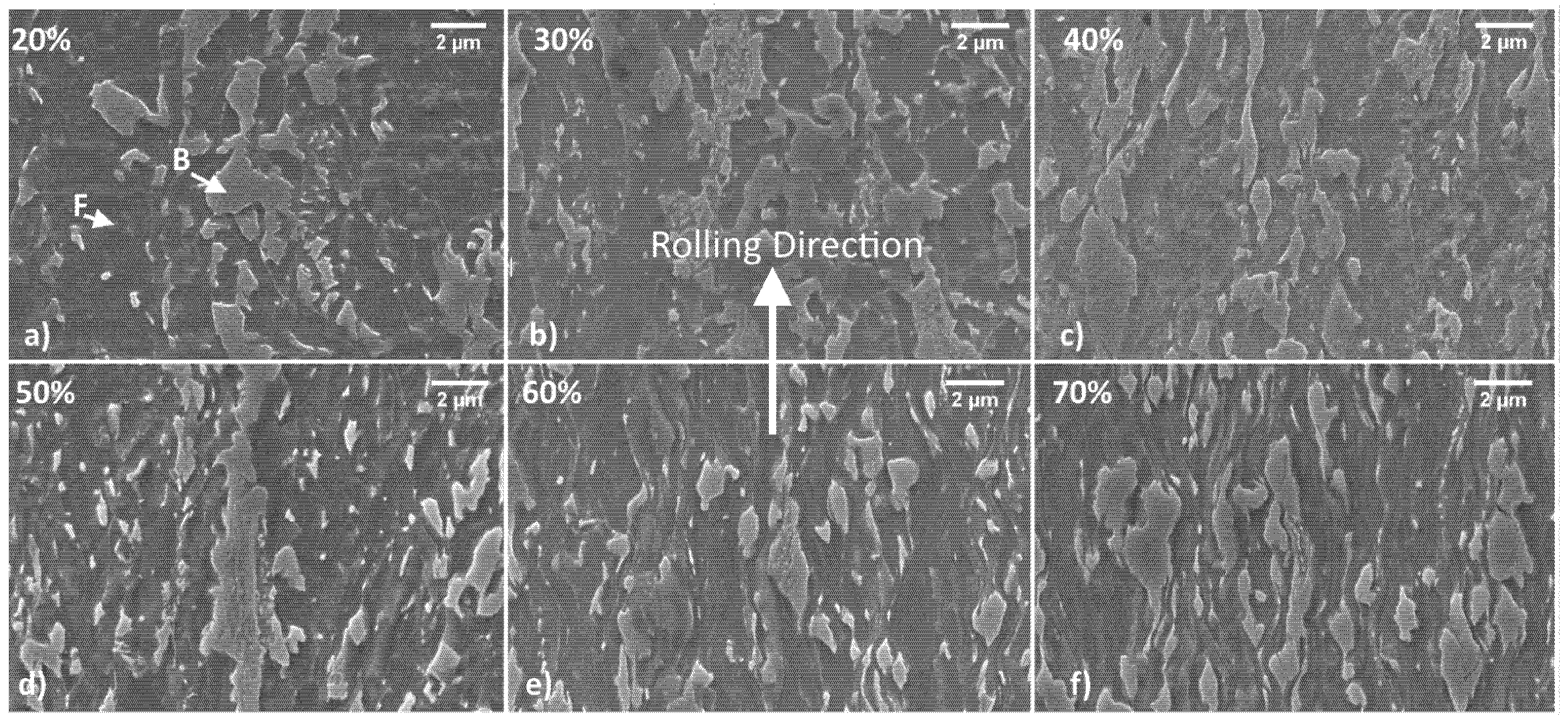

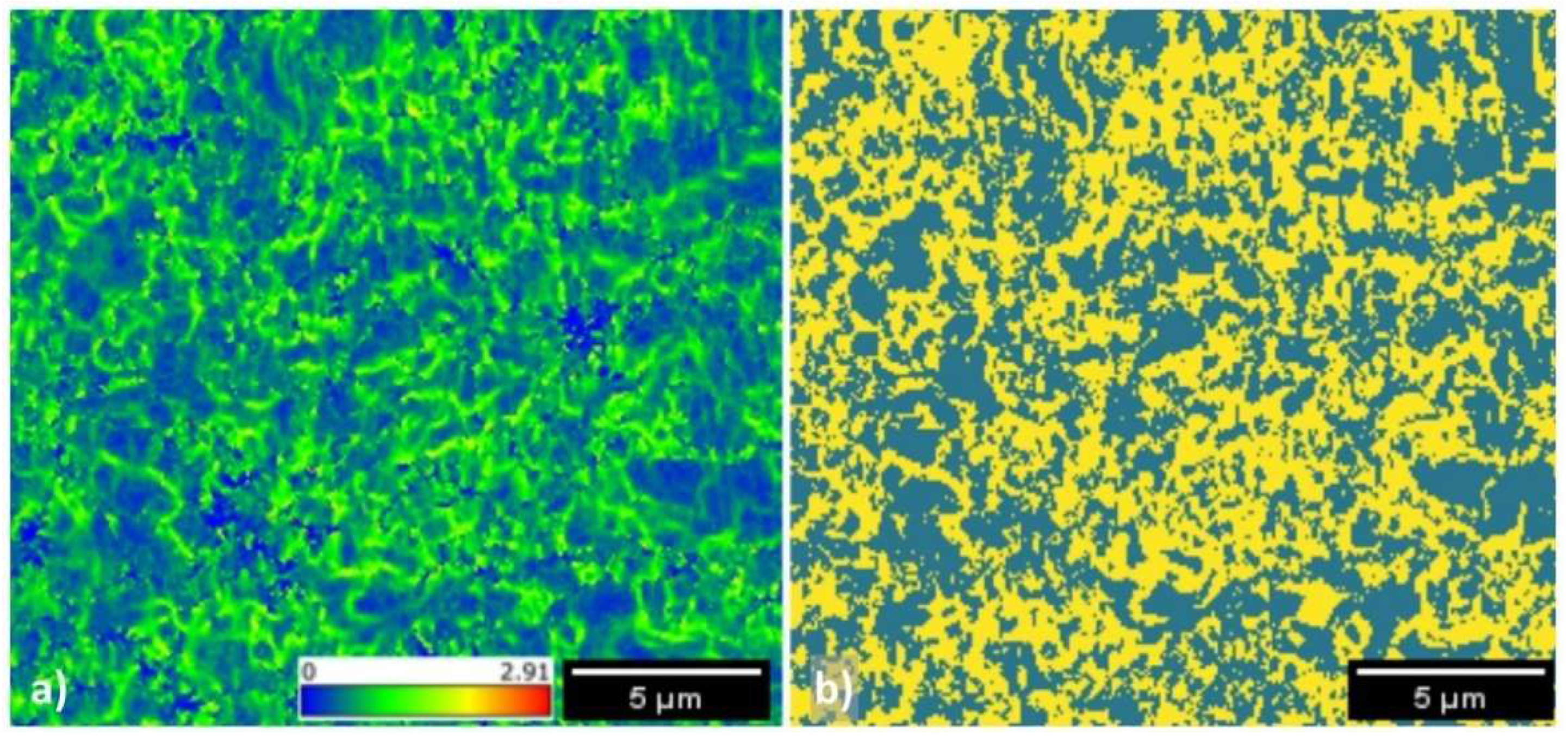

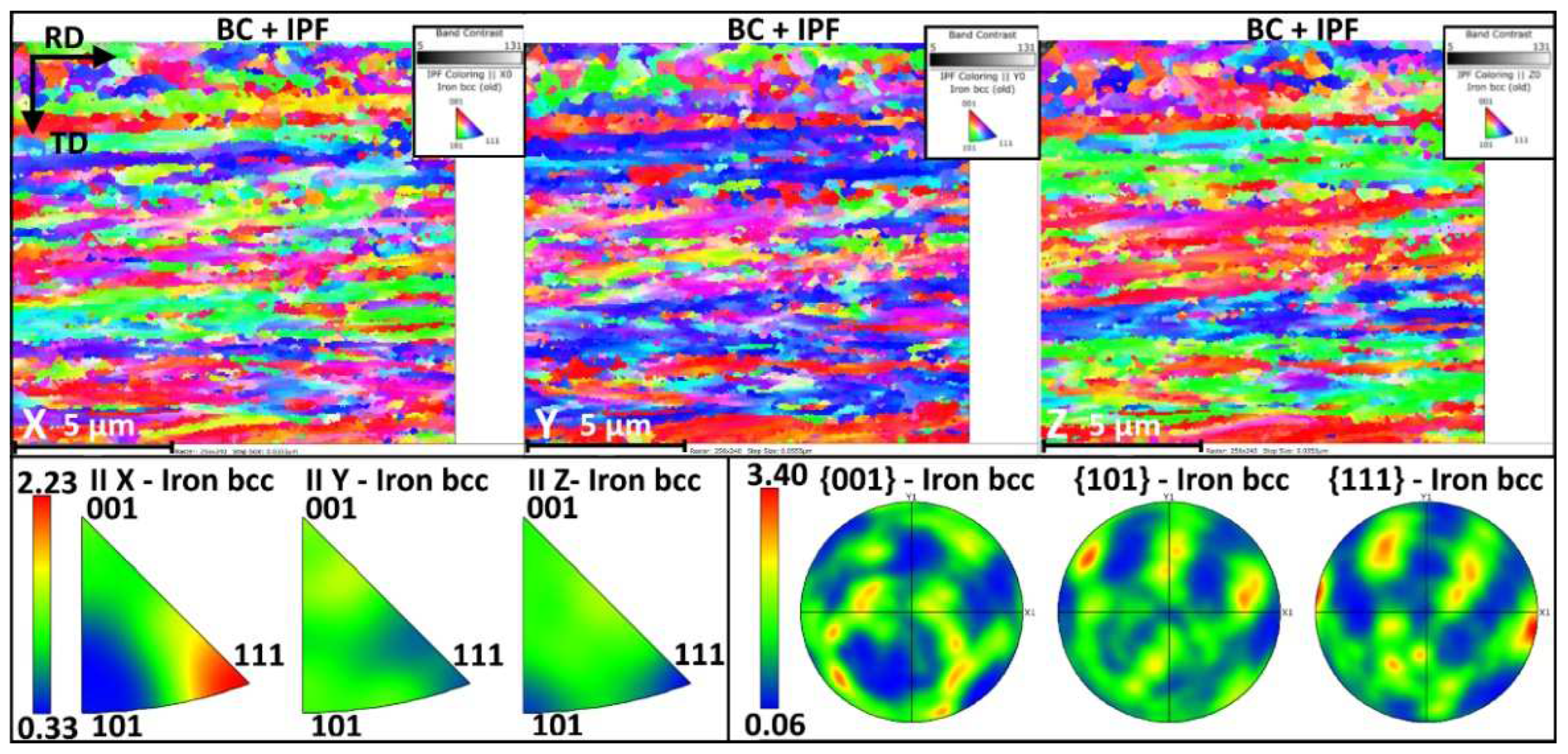

3.1. Assessment of Microstructural Properties of DP Steel with Different Strain Hardening Levels

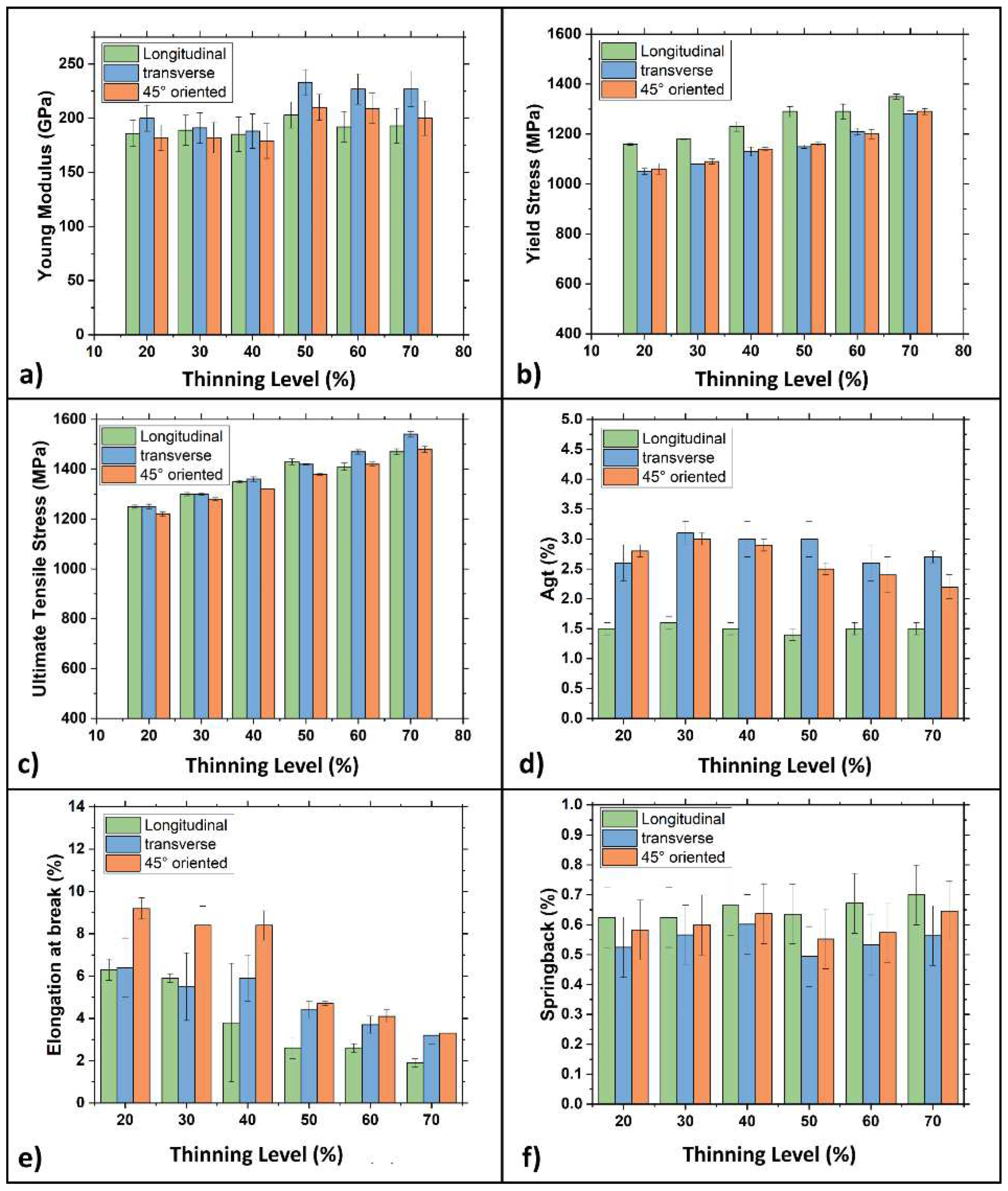

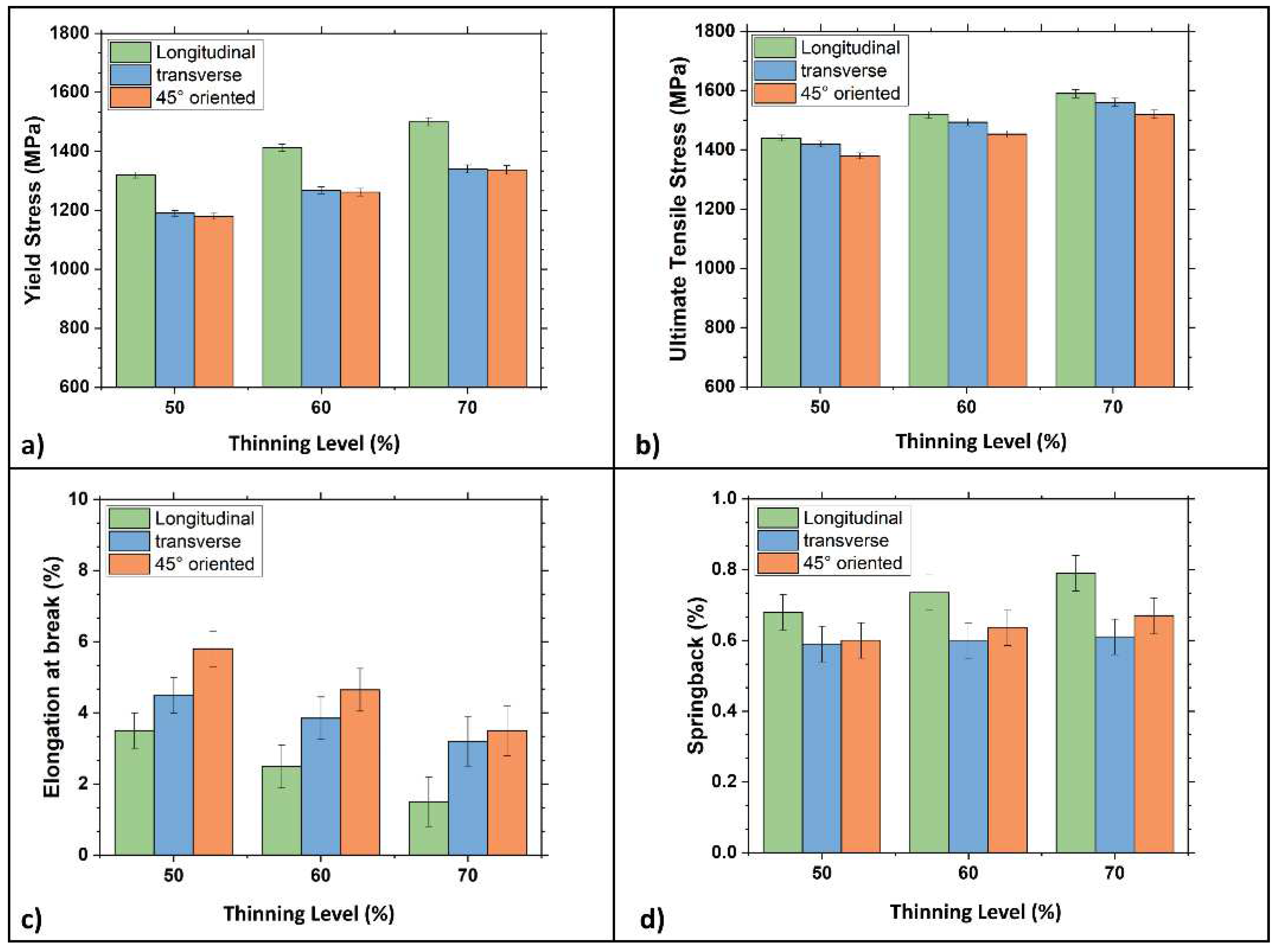

3.2. Analysis of Tensile Properties

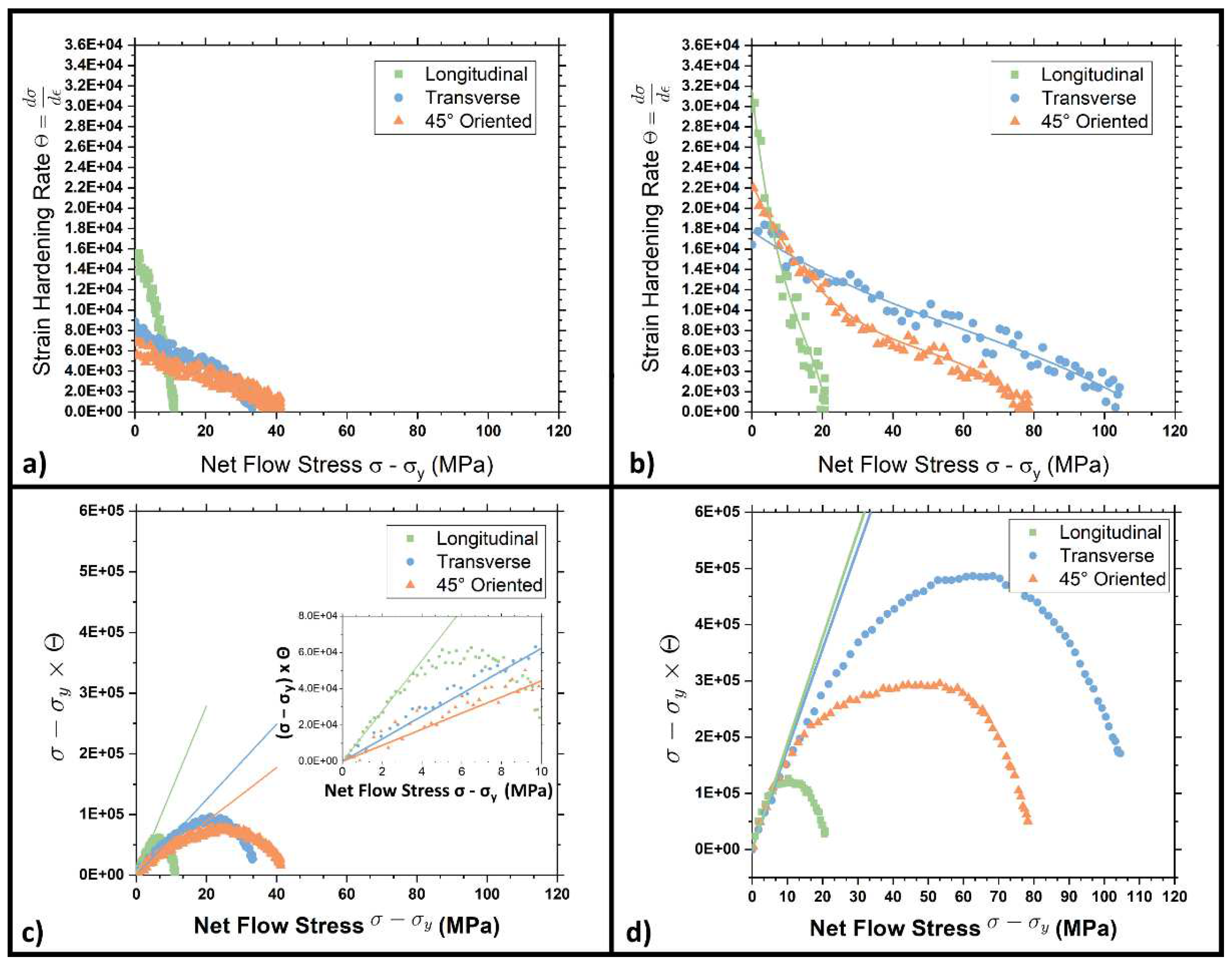

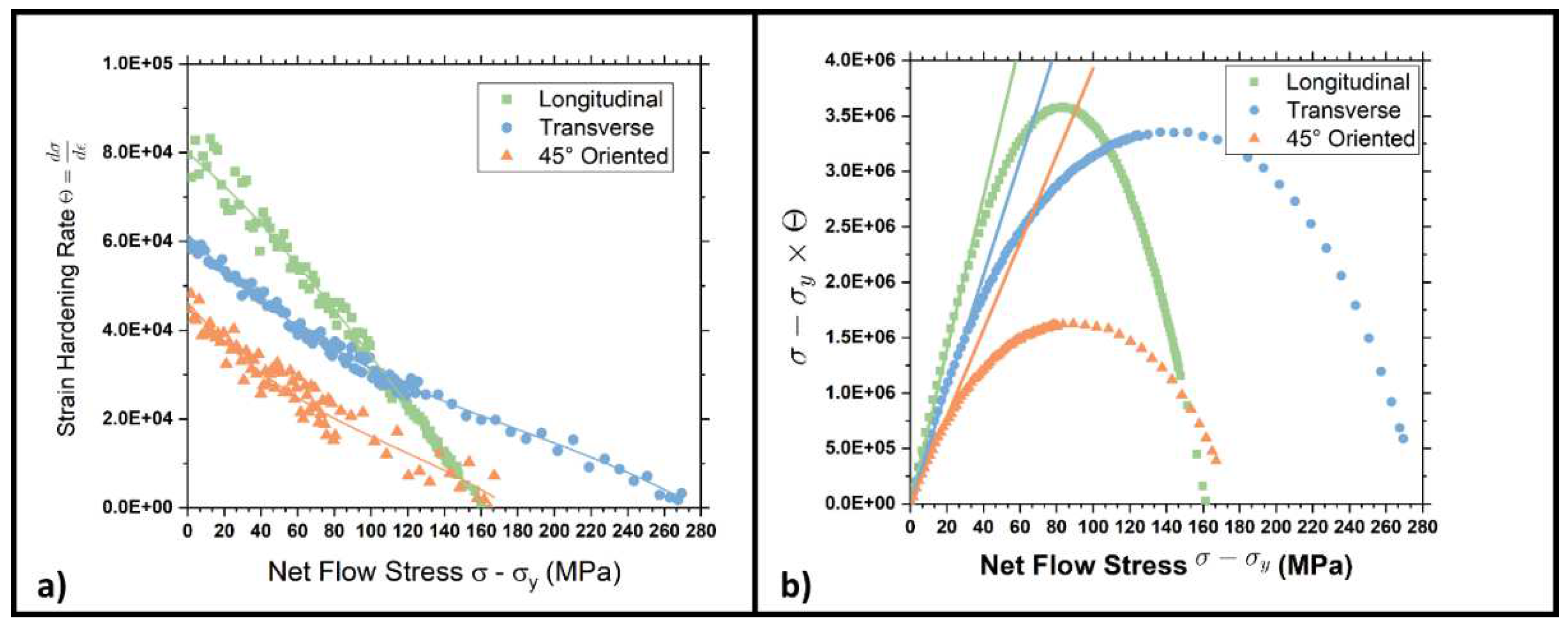

3.3. Strain-Hardening Curves

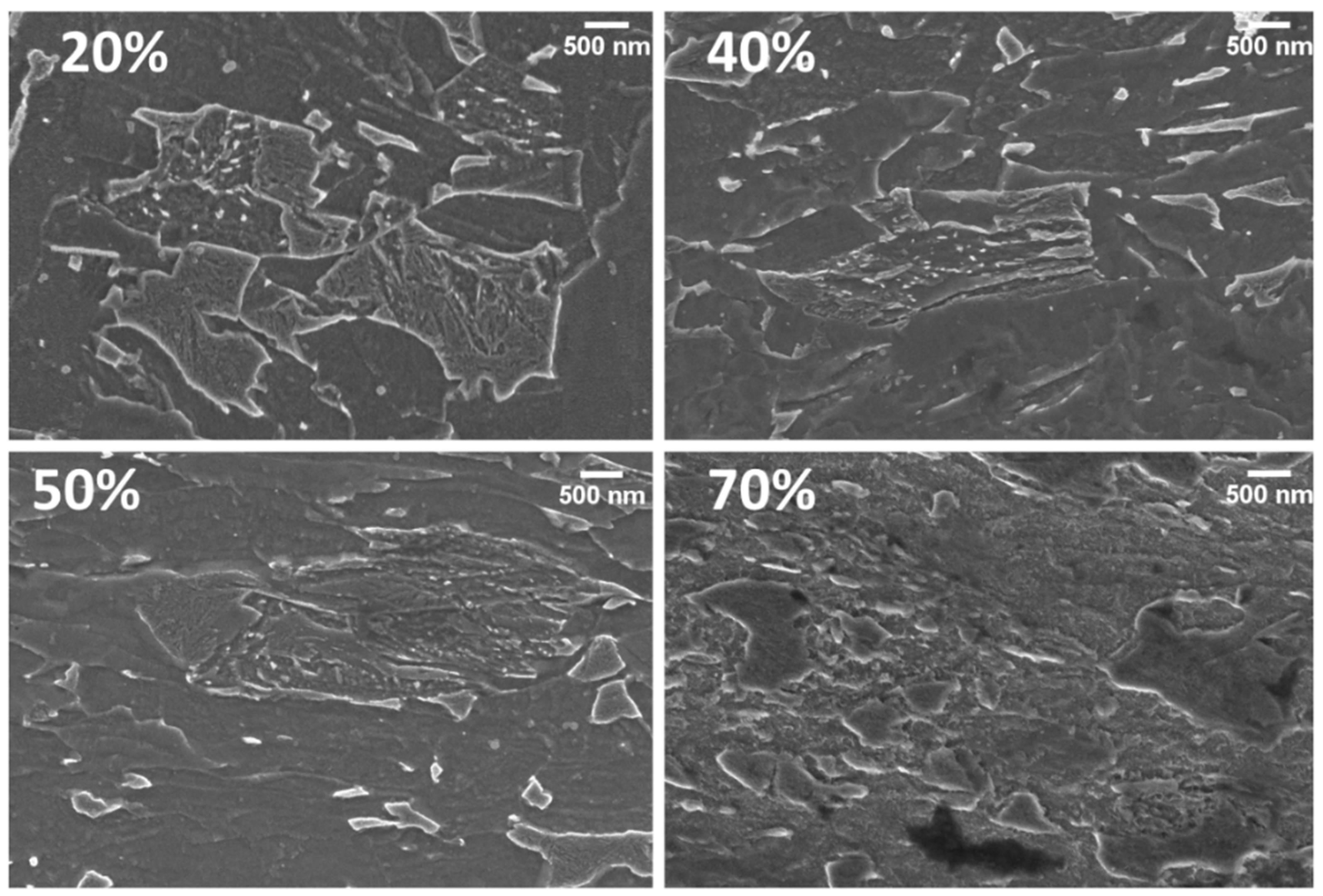

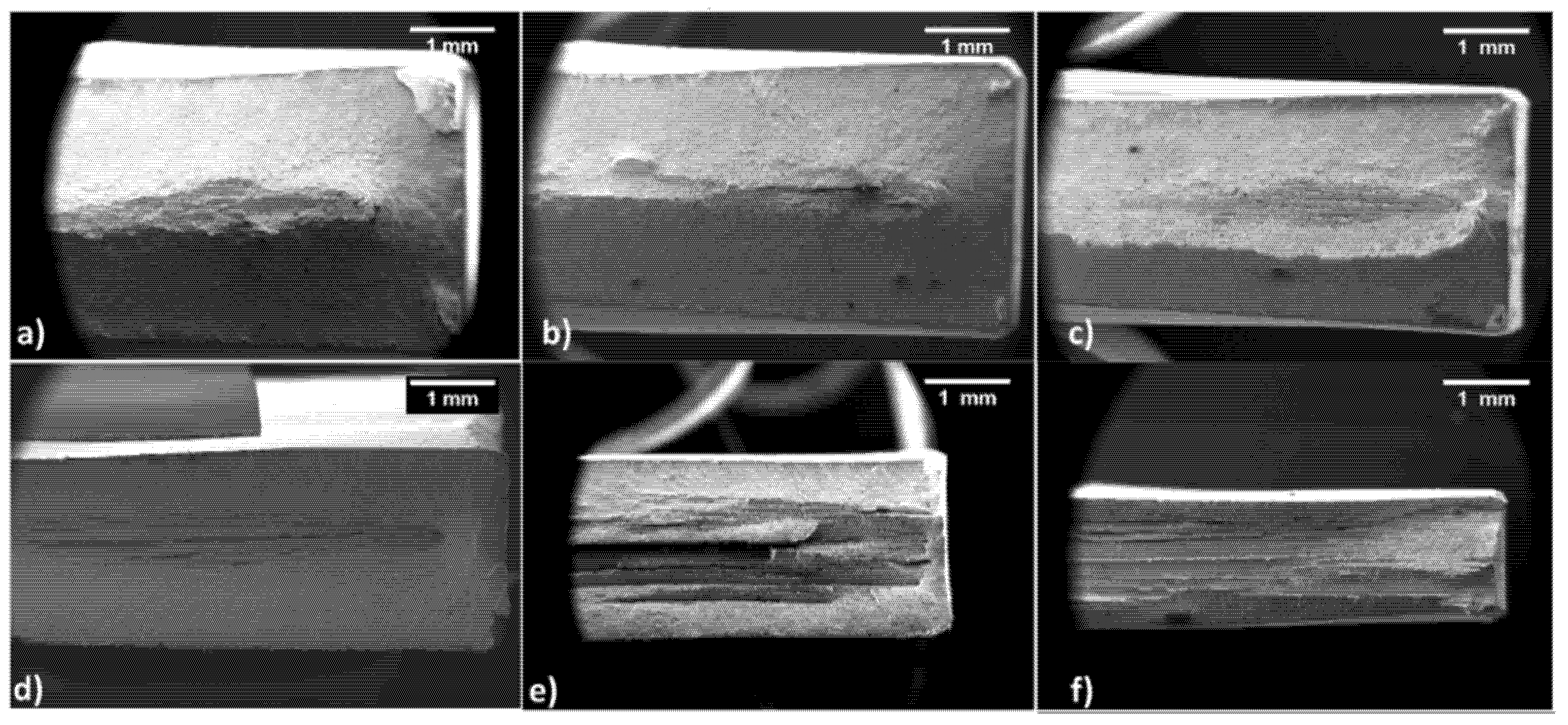

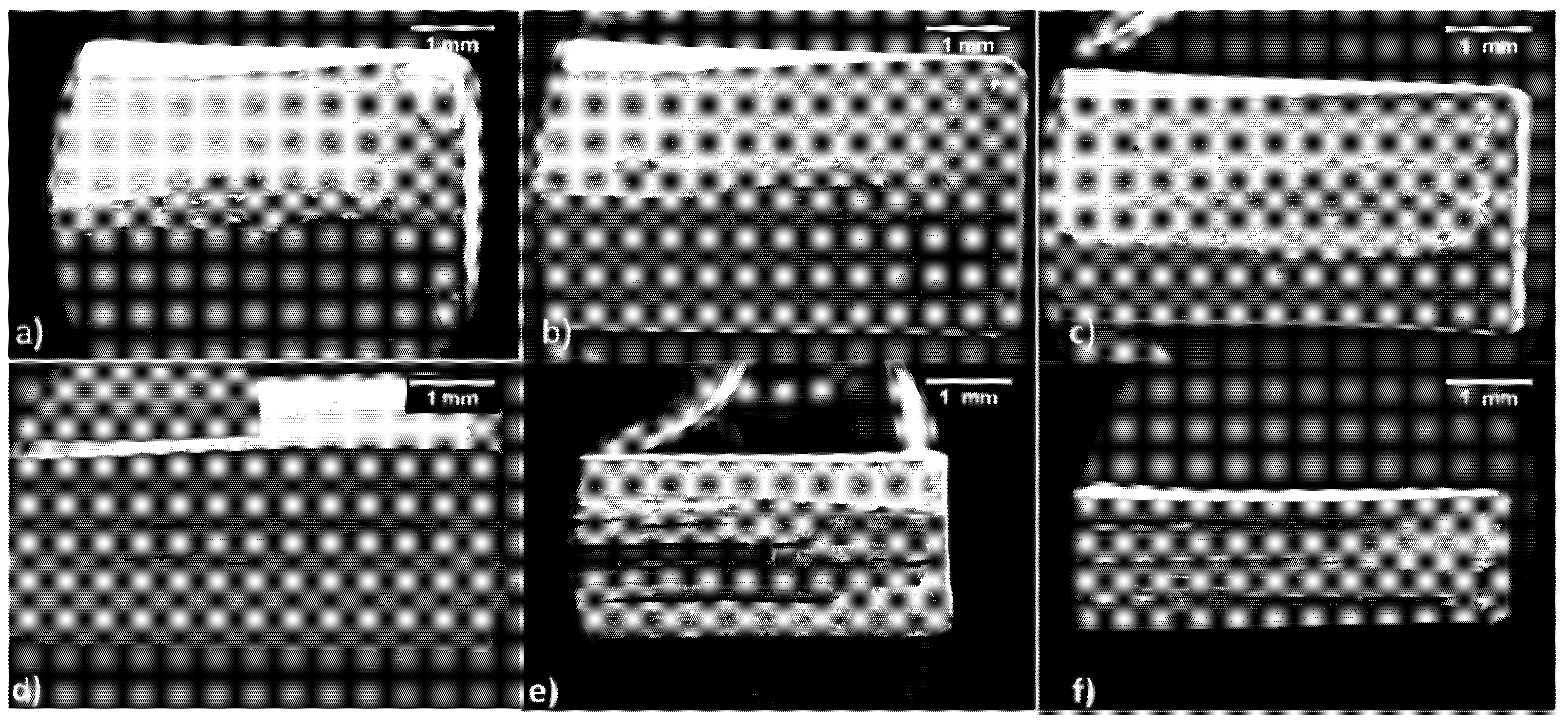

3.4. Analysis of Fracture Surfaces

4. Discussion

4.1. Bainitic Island Size Reduction and Anisotropy Modifications

4.2. Use of Kocks–Mecking Model to Evaluate the Strain Hardening Rate

5. Conclusions

- Increasing the strain hardening level enhances material properties, i.e., UTS and yield stress increase, while ductility is lowered.

- The strain hardening curves for the DP steel were obtained, and demonstrate the DP mechanical properties to be affected by the w/t ratio of the tested dog bone samples. This was particularly evident for yield and ultimate tensile stress, while it was less relevant for elongation at break.

- Fracture surfaces are characterized by delamination of the samples’ innermost part, which is even more evident as the strain hardening level increases. The trend is particularly apparent for longitudinal samples, while transversal ones show a less noticeable trend.

- The 50% thickness reduction is considered the forming limit of the material on the base of fractured surfaces analysis and ductility reduction.

- The cold rolling process causes a progressive microstructural reorganization, reducing the material inhomogeneity, as demonstrated by the levels of planar anisotropy, which becomes zero for a 50% strain hardening level. When a higher level of strain hardening is applied, the microstructure once again shows larger bainitic islands and a net increase in anisotropy. This condition was also evidenced using the Θ(σ − σy) vs. (σ − σy) plots derived from the Kocks–Mecking model. At 50% strain hardening, and independent to the sample test direction, the linear part of the DP steel curves all have practically the same slope indicating that the bainitic island reinforces the material in an isotropic manner.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, Z.; Guan, Z.; Lian, J. Effects of microstructural variables on the deformation behaviour of dual-phase steel. Mater. Sci. Eng. A 1995, 190, 55–64. [Google Scholar] [CrossRef]

- Saeidi, N.; Karimi, M.; Toroghinejad, M. Development of a new dual phase steel with laminated microstructural morphology. Mater. Chem. Phys. 2017, 192, 1–7. [Google Scholar] [CrossRef]

- Zhang, Z.-Y.; Cao, J.-C.; Zhong, Z.-H.; Zhou, X.-L.; Chen, W.; Yang, Y.-H. Tensile deformation behavior of high strength anti-seismic steel with multi-phase microstructure. J. Iron Steel Res. Int. 2017, 24, 111–120. [Google Scholar] [CrossRef]

- Tang, C.-J.; Liu, S.-L.; Shang, C.-J. Micromechanical behavior and failure mechanism of F/B multi-phase high performance steel. J. Iron Steel Res. Int. 2016, 23, 489–494. [Google Scholar] [CrossRef]

- Varshney, A.; Sangal, S.; Kundu, S.; Mondal, K. Super strong and highly ductile low alloy multiphase steels consisting of bainite, ferrite and retained austenite. Mater. Des. 2016, 95, 75–88. [Google Scholar] [CrossRef]

- Saeidi, N.; Ekrami, A. Comparison of mechanical properties of martensite/ferrite and bainite/ferrite dual phase 4340 steels. Mater. Sci. Eng. A 2009, 523, 125–129. [Google Scholar] [CrossRef]

- Bakhtiari, R.; Ekrami, A. The effect of bainite morphology on the mechanical properties of a high bainite dual phase (HBDP) steel. Mater. Sci. Eng. A 2009, 525, 159–165. [Google Scholar] [CrossRef]

- Guo, H.; Gao, G.; Gui, X.; Misra, R.; Bai, B. Structure-property relation in a quenched-partitioned low alloy steel involving bainite transformation. Mater. Sci. Eng. A 2016, 667, 224–231. [Google Scholar] [CrossRef]

- Gui, X.; Gao, G.; Guo, H.; Zhao, F.; Tan, Z.; Bai, B. Effect of bainitic transformation during BQ&P process on the mechanical properties in an ultrahigh strength Mn-Si-Cr-C steel. Mater. Sci. Eng. A 2017, 684, 598–605. [Google Scholar] [CrossRef]

- Min, J.; Lin, J.; Min, Y.; Li, F. On the ferrite and bainite transformation in isothermally deformed 22MnB5 steels. Mater. Sci. Eng. A 2012, 550, 375–387. [Google Scholar] [CrossRef]

- Abdollah-Zadeh, A.; Salemi, A.; Assadi, H. Mechanical behavior of CrMo steel with tempered martensite and ferrite–bainite–martensite microstructure. Mater. Sci. Eng. A 2008, 483–484, 325–328. [Google Scholar] [CrossRef]

- Murari, F.D.; da Costa e Silva, A.L.V.; de Avillez, R.R. Cold-rolled multiphase boron steels: Microstructure and mechanical properties. J. Mater. Res. Technol. 2015, 4, 191–196. [Google Scholar] [CrossRef][Green Version]

- Hug, E.; Martinez, M.; Chottin, J. Temperature and stress state influence on void evolution in a high-strength dual-phase steel. Mater. Sci. Eng. A 2015, 626, 286–295. [Google Scholar] [CrossRef]

- Han, S.-H.; Choi, S.-H.; Choi, J.-K.; Seong, H.-G.; Kim, I.-B. Effect of hot-rolling processing on texture and r-value of annealed dual-phase steels. Mater. Sci. Eng. A 2010, 527, 1686–1694. [Google Scholar] [CrossRef]

- Kalashami, A.G.; Kermanpur, A.; Ghassemali, E.; Najafizadeh, A.; Mazaheri, Y. The effect of Nb on texture evolutions of the ultrafine-grained dual-phase steels fabricated by cold rolling and intercritical annealing. J. Alloys Compd. 2017, 694, 1026–1035. [Google Scholar] [CrossRef]

- Goto, S.; Kami, C.; Kawamura, S. Effect of alloying elements and hot-rolling conditions on microstructure of bainitic-ferrite/martensite dual phase steel with high toughness. Mater. Sci. Eng. A 2015, 648, 436–442. [Google Scholar] [CrossRef]

- Wang, K.; Tan, Z.; Gao, G.; Gao, B.; Gui, X.; Misra, R.; Bai, B. Microstructure-property relationship in bainitic steel: The effect of austempering. Mater. Sci. Eng. A 2016, 675, 120–127. [Google Scholar] [CrossRef]

- Hashemi, S.G.; Eghbali, B. Evolution of high strength and ductile ultrafine grained dual phase superferrite low carbon V-Nb-Mo steel. Mater. Sci. Eng. A 2017, 705, 32–41. [Google Scholar] [CrossRef]

- Kang, Y.-L.; Han, Q.-H.; Zhao, X.-M.; Cai, M.-H. Influence of nanoparticle reinforcements on the strengthening mechanisms of an ultrafine-grained dual phase steel containing titanium. Mater. Des. 2013, 44, 331–339. [Google Scholar] [CrossRef]

- Akbarpour, M.R.; Ekrami, A. Effect of ferrite volume fraction on work hardening behavior of high bainite dual phase (DP) steels. Mater. Sci. Eng. A 2008, 477, 306–310. [Google Scholar] [CrossRef]

- Golling, S.; Östlund, R.; Oldenburg, M. A study on homogenization methods for steels with varying content of ferrite, bainite and martensite. J. Mater. Process. Technol. 2016, 228, 88–97. [Google Scholar] [CrossRef]

- Zhao, Z.-P.; Qiao, G.-Y.; Tang, L.; Zhu, H.-W.; Liao, B.; Xiao, F.-R. Fatigue properties of X80 pipeline steels with ferrite/bainite dual-phase microstructure. Mater. Sci. Eng. A 2016, 657, 96–103. [Google Scholar] [CrossRef]

- Ormsuptave, N.; Uthaisangsuk, V. Modeling of bake-hardening effect for fine grain bainite-aided dual phase steel. Mater. Des. 2017, 118, 314–329. [Google Scholar] [CrossRef]

- Ishikawa, N.; Yasuda, K.; Sueyoshi, H.; Endo, S.; Ikeda, H.; Morikawa, T.; Higashida, K. Microscopic deformation and strain hardening analysis of ferrite–bainite dual-phase steels using micro-grid method. Acta Mater. 2015, 97, 257–268. [Google Scholar] [CrossRef]

- Saeidi, N.; Ekrami, A. Impact properties of tempered bainite–ferrite dual phase steels. Mater. Sci. Eng. A 2010, 527, 5575–5581. [Google Scholar] [CrossRef]

- Bassini, E.; Sivo, A.; Ugues, D. Assessment of the Hardening Behavior and Tensile Properties of a Cold-Rolled Bainitic–Ferritic Steel. Materials 2021, 14, 6662. [Google Scholar] [CrossRef] [PubMed]

- Ashrafi, H.; Shamanian, M.; Emadi, R.; Saeidi, N. A novel and simple technique for development of dual phase steels with excellent ductility. Mater. Sci. Eng. A 2017, 680, 197–202. [Google Scholar] [CrossRef]

- Magnabosco, R.; Matheisen, A.S.; Lima, C.G. Anisotropy Indexes Determination In HSLA Steels. In Proceedings of the XV Congresso Brasileiro de Engenharia Mecanica, Aguas de Lindoia, SP, Brazil, 22–26 November 1999; pp. 1–8. [Google Scholar]

- Kocks, U.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Nasser, A.; Yadav, A.; Pathak, P.; Altan, T. Determination of the flow stress of five AHSS sheet materials (DP 600, DP 780, DP 780-CR, DP 780-HY and TRIP 780) using the uniaxial tensile and the biaxial Viscous Pressure Bulge (VPB) tests. J. Mater. Process. Technol. 2009, 210, 429–436. [Google Scholar] [CrossRef]

- Kang, J.-Y.; Lee, H.-C.; Han, S.H. Effect of Al and Mo on the textures and microstructures of dual phase steels. Mater. Sci. Eng. A 2011, 530, 183–190. [Google Scholar] [CrossRef]

- Shen, X.; Tang, S.; Wu, Y.; Yang, X.; Chen, J.; Liu, Z.; Misra, R.; Wang, G. Evolution of microstructure and crystallographic texture of microalloyed steel during warm rolling in dual phase region and their influence on mechanical properties. Mater. Sci. Eng. A 2017, 685, 194–204. [Google Scholar] [CrossRef]

- Kimura, Y.; Inoue, T.; Yin, F.; Tsuzaki, K. Inverse Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel. Science 2008, 320, 1057–1060. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-S.; Yuan, G.; Kang, J.; Cao, G.; Li, C.-G.; Misra, R.; Wang, G. Microstructural evolution and mechanical properties of dual phase steel produced by strip casting. Mater. Sci. Eng. A 2017, 703, 486–495. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Bainite in Steels Transformation, Microstructure and Properties, 2nd ed.; IOM Communications Ltd.: Cambridge, UK, 2001. [Google Scholar]

- Furuhara, T. Carbide-Containing Bainite in Steels; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; pp. 417–435. [Google Scholar] [CrossRef]

- Zaefferer, S.; Romano, P.; Friedel, F. EBSD as a tool to identify and quantify bainite and ferrite in low-alloyed Al-TRIP steels. J. Microsc. 2008, 230, 499–508. [Google Scholar] [CrossRef]

- Yuan, W.; Zhang, Z.; Su, Y.; Qiao, L.; Chu, W. Influence of specimen thickness with rectangular cross-section on the tensile properties of structural steels. Mater. Sci. Eng. A 2012, 532, 601–605. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Akram, M.; Palkowski, H.; Soliman, M. High-Strength Low-Cost Nano-Bainitic Steel. J. Mater. Eng. Perform. 2020, 29, 2418–2427. [Google Scholar] [CrossRef]

- Ariza, M.; Ortiz, M.; Ariza, P. Discrete dislocations in graphene. J. Mech. Phys. Solids 2010, 58, 710–734. [Google Scholar] [CrossRef]

- Lynch, S.; Wanhill, R.; Byrnes, R.; Bray, G. Fracture Toughness and Fracture Modes of Aerospace Aluminum–Lithium Alloys; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; pp. 415–455. [Google Scholar] [CrossRef]

- Jiang, C.; Ma, H.; Chen, Y.; Wang, N.; Zhao, Q.; Wu, G.; Zhu, L.; Luo, J.; Zhao, Y. Crack propagation behavior of dual-phase steel at low temperature. Int. J. Fatigue 2021, 155, 106633. [Google Scholar] [CrossRef]

- Varanasi, R.S.; Koyama, M.; Shibayama, Y.; Akiyama, E. Mixed type brittle fracture in 1.5 GPa dual-phase steel via {100} ferrite cleavage cracking. Mater. Sci. Eng. A 2022, 857, 144021. [Google Scholar] [CrossRef]

- Tsuchida, N.; Tomota, Y.; Moriya, H.; Umezawa, O.; Nagai, K. Application of the Kocks–Mecking model to tensile deformation of an austenitic 25Cr–19Ni steel. Acta Mater. 2001, 49, 3029–3038. [Google Scholar] [CrossRef]

- Wu, H.-Y.; Yan, J.-C.; Tsai, H.-H.; Chiu, C.-H.; Zhou, G.-Z.; Lin, C.-F. Tensile flow and strain-hardening behaviors of dual-phase Mg–Li–Zn alloy thin sheets. Mater. Sci. Eng. A 2010, 527, 7197–7203. [Google Scholar] [CrossRef]

| C | Si | Mn | Al | Cr | V | Mo |

|---|---|---|---|---|---|---|

| 0.09 | 0.15 | 1.45 | 0.02 | 1.25 | 0.12 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bassini, E.; Marchese, G.; Sivo, A.; Martelli, P.A.; Gullino, A.; Ugues, D. Effect of Cold Rolling on Microstructural and Mechanical Properties of a Dual-Phase Steel for Automotive Field. Materials 2022, 15, 7482. https://doi.org/10.3390/ma15217482

Bassini E, Marchese G, Sivo A, Martelli PA, Gullino A, Ugues D. Effect of Cold Rolling on Microstructural and Mechanical Properties of a Dual-Phase Steel for Automotive Field. Materials. 2022; 15(21):7482. https://doi.org/10.3390/ma15217482

Chicago/Turabian StyleBassini, Emilio, Giulio Marchese, Antonio Sivo, Pietro Antonio Martelli, Alessio Gullino, and Daniele Ugues. 2022. "Effect of Cold Rolling on Microstructural and Mechanical Properties of a Dual-Phase Steel for Automotive Field" Materials 15, no. 21: 7482. https://doi.org/10.3390/ma15217482

APA StyleBassini, E., Marchese, G., Sivo, A., Martelli, P. A., Gullino, A., & Ugues, D. (2022). Effect of Cold Rolling on Microstructural and Mechanical Properties of a Dual-Phase Steel for Automotive Field. Materials, 15(21), 7482. https://doi.org/10.3390/ma15217482