Effect of Silicon Source (Fly Ash, Silica Dust, Gangue) on the Preparation of Porous Mullite Ceramics from Aluminum Dross

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Experimental Procedure

2.3. Analytical and Characterization Methods

3. Results and Discussion

3.1. Effects of Silicon Source on Phase Compositions

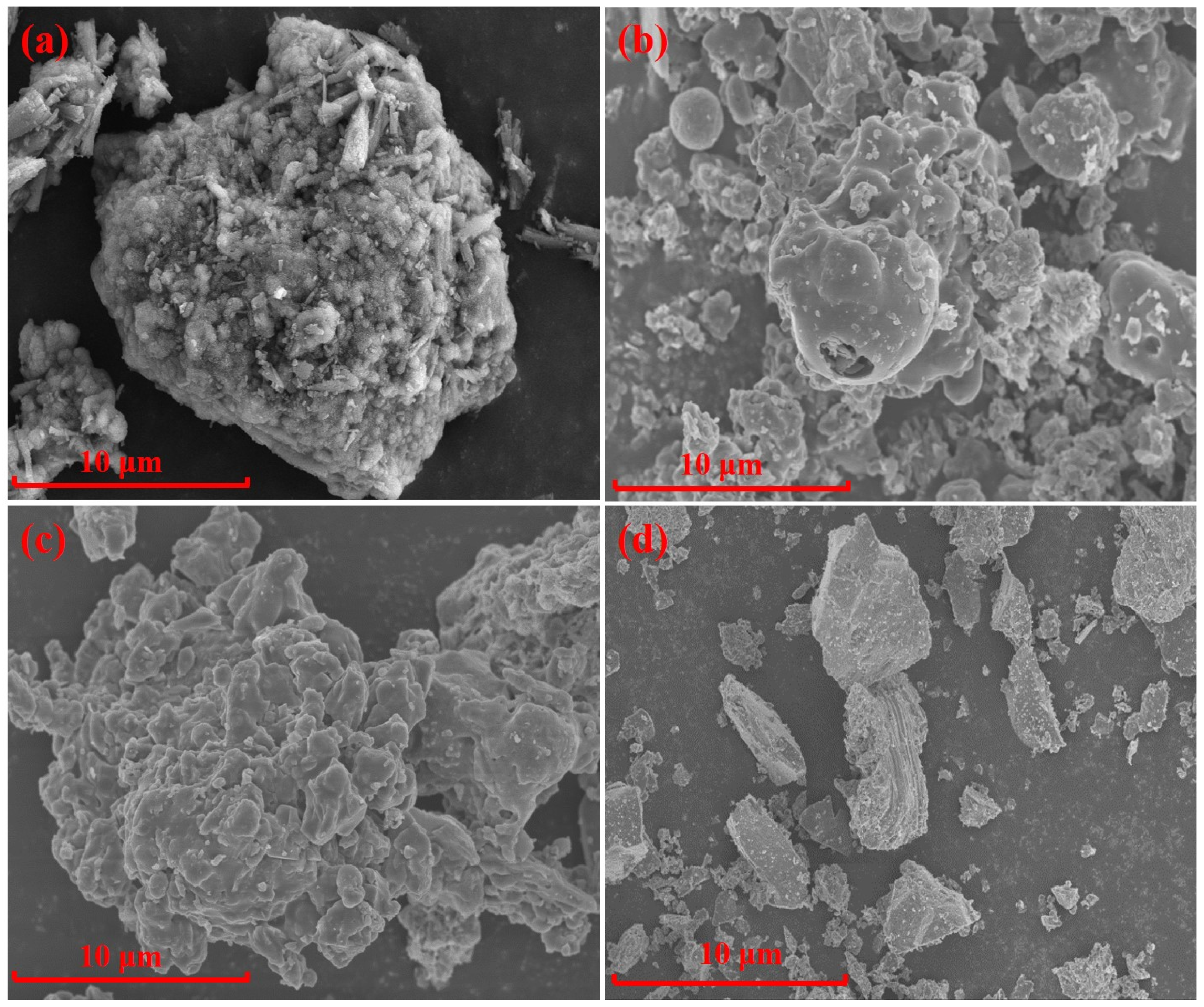

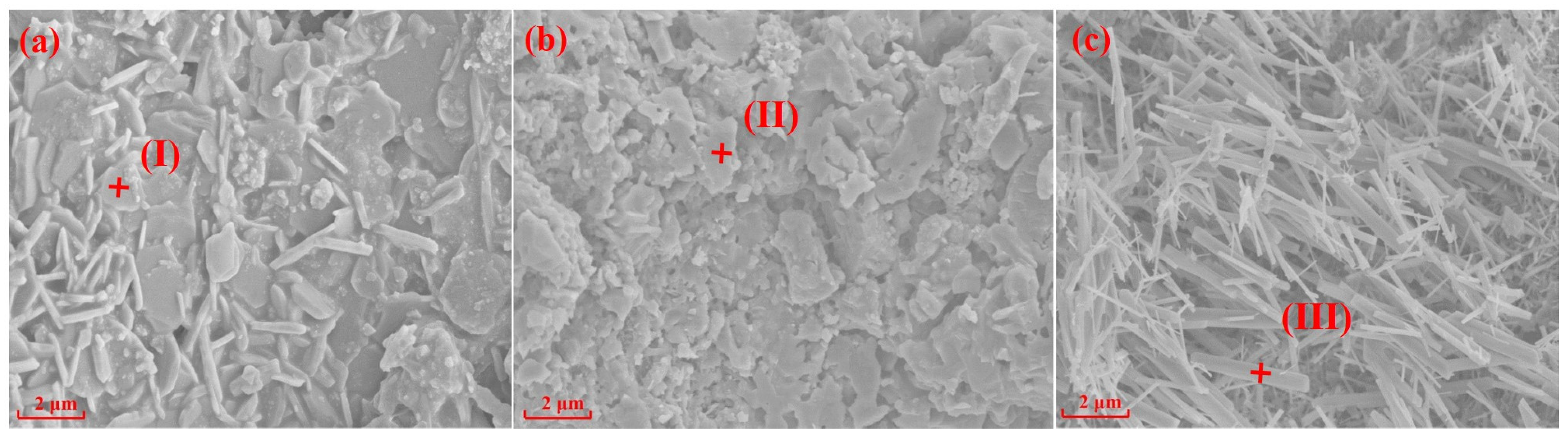

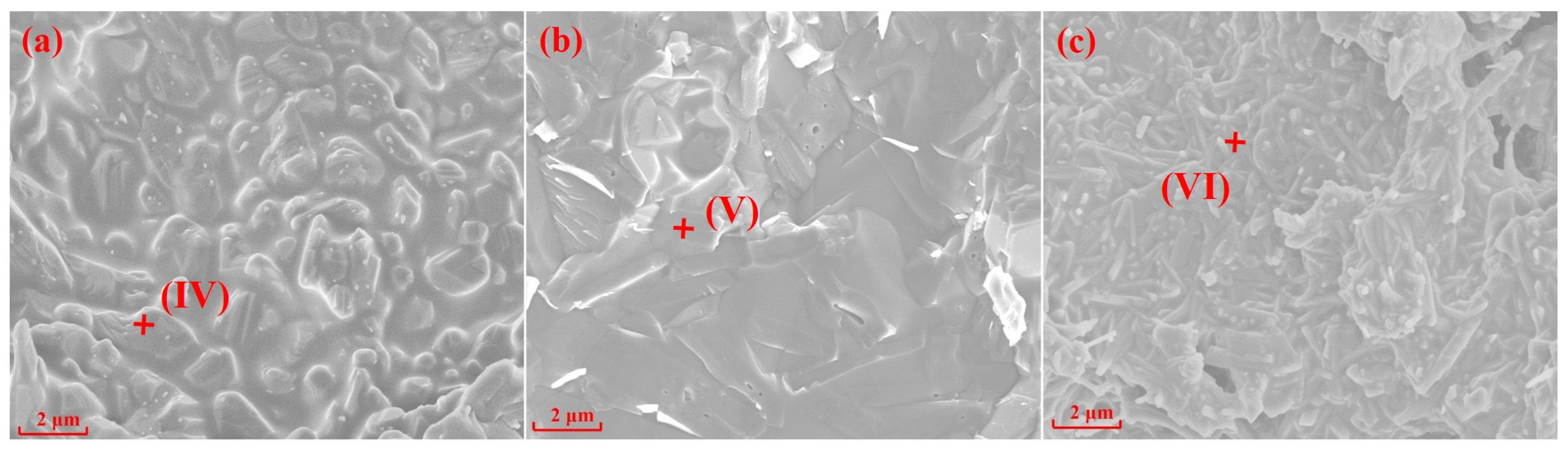

3.2. Effects of Silicon Source on Morphologies

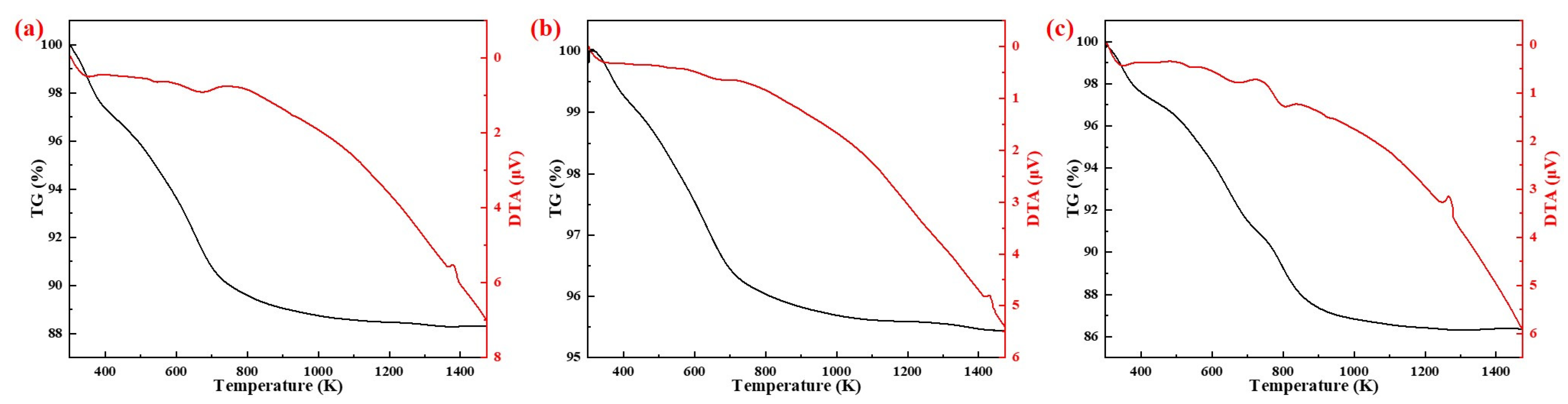

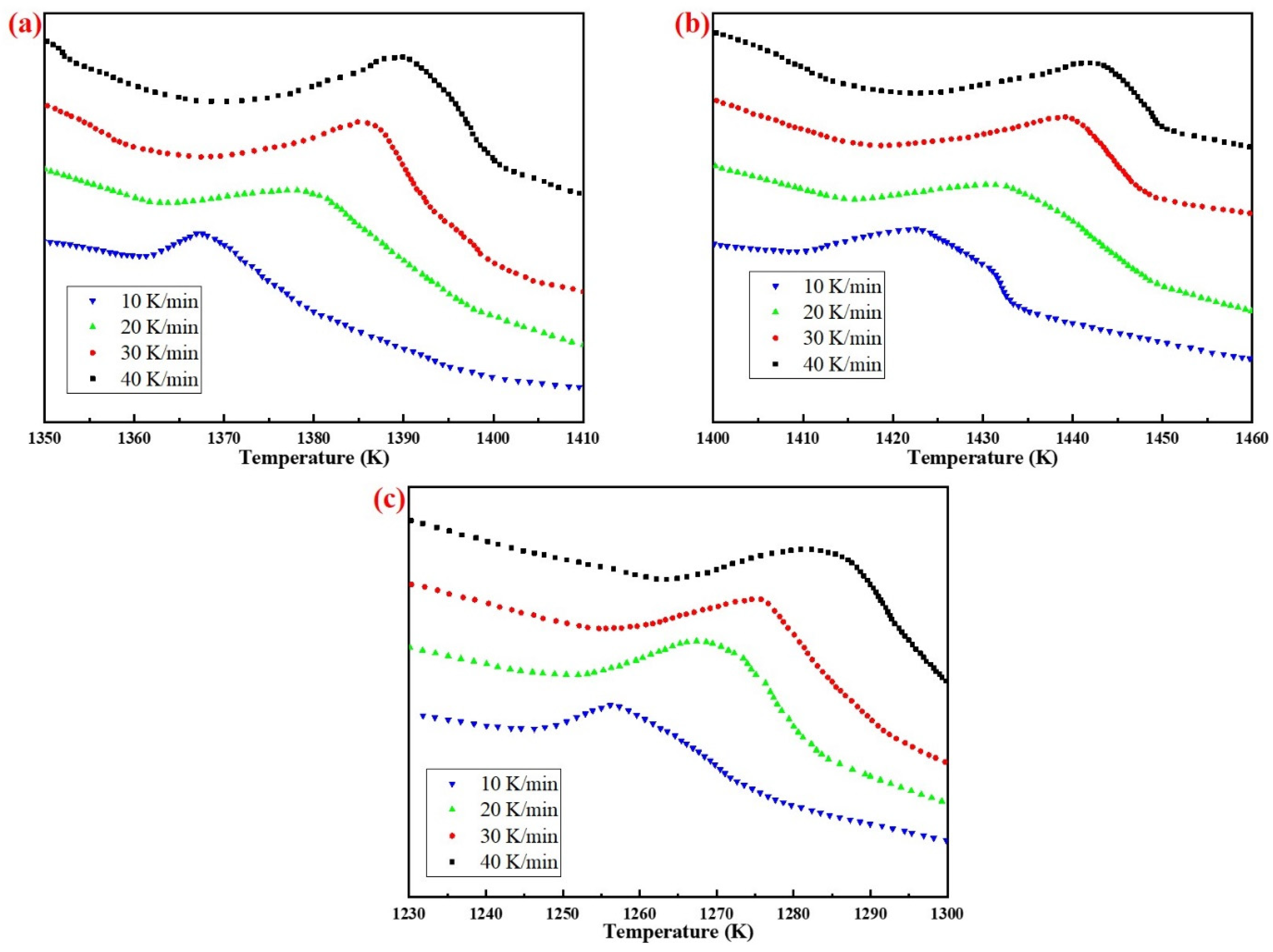

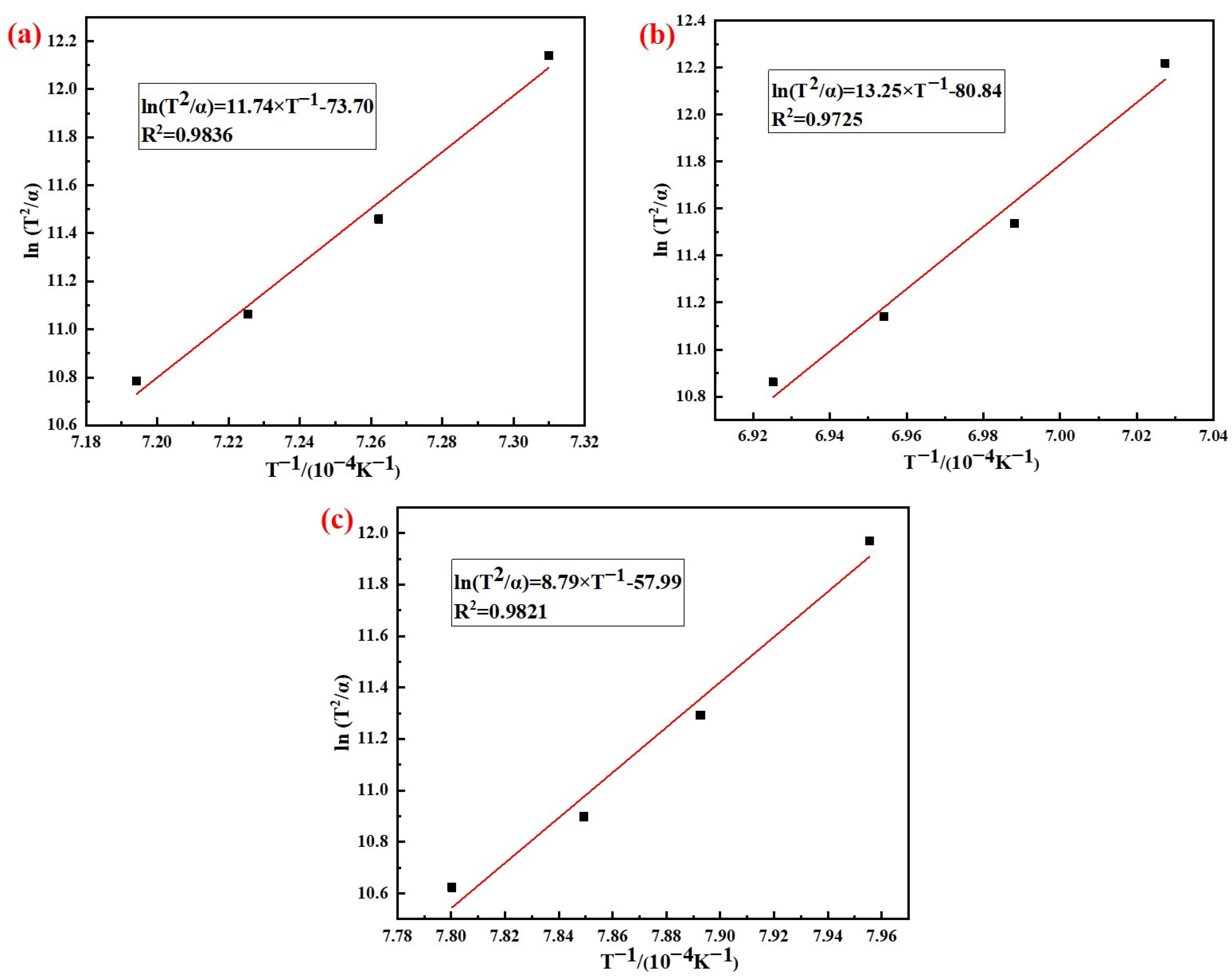

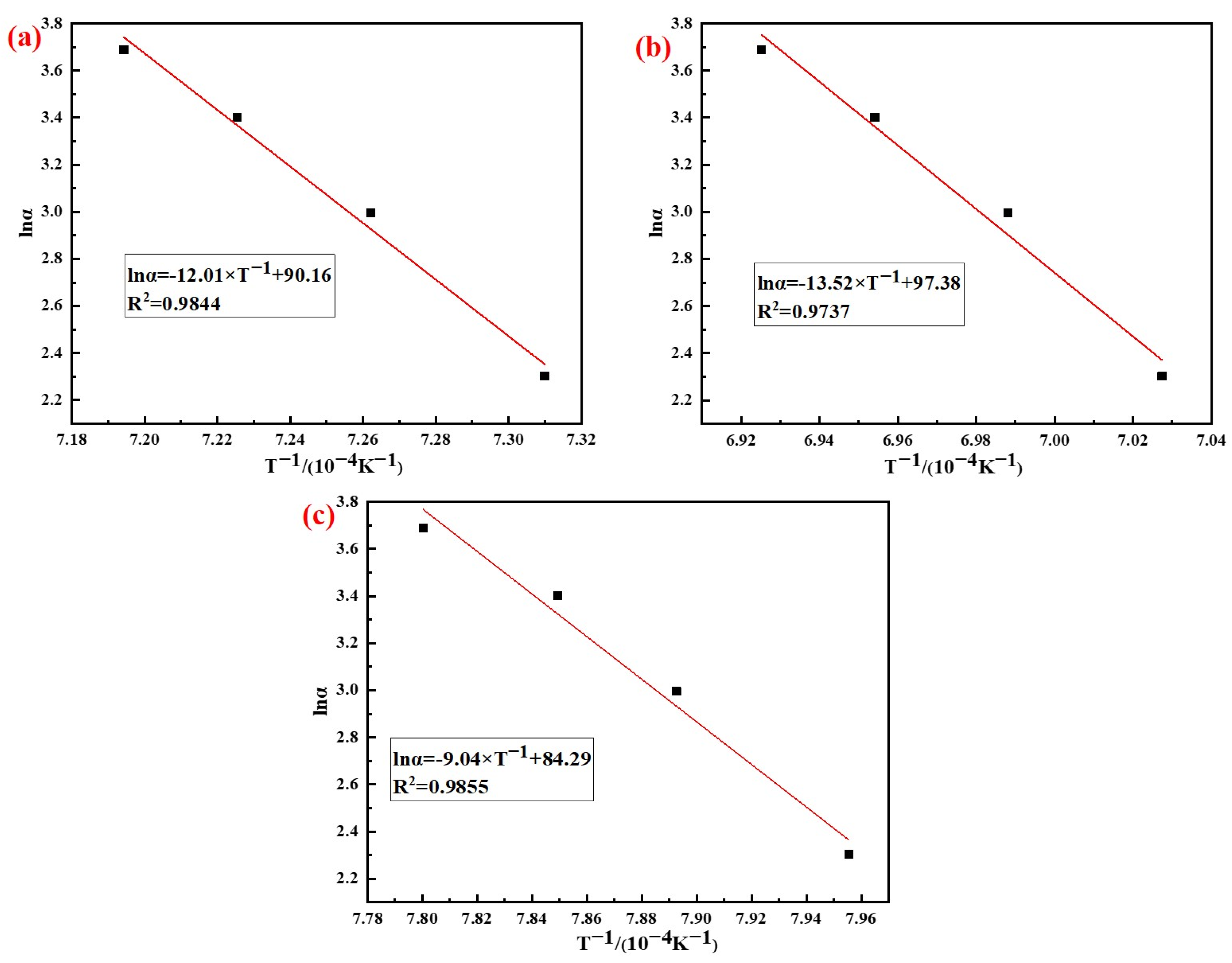

3.3. Effects of Silicon Source on Phase Transition Kinetics

3.4. Effects of Silicon Sources on Physical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tsakiridis, P.E.; Oustadakis, P.; Agatzini-Leonardou, S. Aluminium recovery during black dross hydrothermal treatment. J. Environ. Chem. Eng. 2013, 1, 23–32. [Google Scholar] [CrossRef]

- Shinzato, M.C.; Hypolito, R. Solid waste from aluminum recycling process: Characterization and reuse of its economically valuable constituents. Waste Manag. 2005, 25, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Hwang, J.Y.; Huang, X.; Xu, Z. Recovery of Metals from Aluminum Dross and Saltcake. J. Miner. Mater. Charact. 2006, 5, 47–62. [Google Scholar] [CrossRef]

- Meshram, A.; Singh, K.K. Recovery of valuable products from hazardous aluminum dross: A review. Res. Conserv. Recycl. 2018, 130, 95–108. [Google Scholar] [CrossRef]

- Nguyen, T.T.N.; Song, S.J.; Lee, M.S. Development of a hydrometallurgical process for the recovery of pure alumina from black dross and synthesis of magnesium spinel. J. Mater. Res. Technol. 2020, 9, 2568–2577. [Google Scholar] [CrossRef]

- Lv, H.; Zhao, H.; Zuo, Z. A thermodynamic and kinetic study of catalyzed hydrolysis of aluminum nitride in secondary aluminum dross. J. Mater. Res. Technol. 2020, 9, 9735–9745. [Google Scholar] [CrossRef]

- Li, Y.; Qin, Z.; Li, C. Hazardous characteristics and transformation mechanism in hydrometallurgical disposing strategy of secondary aluminum dross. J. Environ. Chem. Eng. 2021, 9, 2213–2223. [Google Scholar] [CrossRef]

- Mahinroosta, M.; Allahverdi, A. Hazardous aluminum dross characterization and recycling strategies: A critical review. J. Environ. Manag. 2018, 223, 452–468. [Google Scholar] [CrossRef]

- Su, N.; Li, Z.S.; Ding, Y.D. Waste to Wealth Strategy: Preparation and Properties of Lightweight Al2O3-SiO2-Rich Castables Using Aluminum Dross Waste. Materials 2021, 14, 13. [Google Scholar] [CrossRef]

- Yang, H.L.; Li, Z.S.; Ding, Y.D. Hydrolysis Behavior and Kinetics of AlN in Aluminum Dross during the Hydrometallurgical Process. Materials 2022, 15, 5499. [Google Scholar] [CrossRef]

- Nath, S.; Biswas, K.; Basu, B. Phase stability and microstructure development in hydroxyapatite–mullite system. Scr. Mater. 2008, 58, 1054–1057. [Google Scholar] [CrossRef]

- Schneider, H.; Schreuer, J.; Hildmann, B. Structure and properties of mullite—A review. J. Eur. Ceram. Soc. 2008, 28, 329–344. [Google Scholar] [CrossRef]

- Dong, Y.; Hampshire, S.; Zhou, J. Sintering and characterization of flyash-based mullite with MgO addition. J. Eur. Ceram. Soc. 2011, 31, 687–695. [Google Scholar] [CrossRef]

- Kong, L.B.; Chen, Y.Z.; Zhang, T.S. Effect of alkaline-earth oxides on phase formation and morphology development of mullite ceramics. Ceram. Int. 2004, 30, 1319–1323. [Google Scholar] [CrossRef]

- Medvedovski, E. Alumina–mullite ceramics for structural applications. Ceram. Int. 2006, 32, 369–375. [Google Scholar] [CrossRef]

- Meng, B.; Peng, J. Effects of in situ synthesized mullite whiskers on flexural strength and fracture toughness of corundum-mullite refractory materials. Ceram. Int. 2013, 39, 1525–1531. [Google Scholar] [CrossRef]

- Shin, C.; Oh, S.H.; Choi, J.H. Synthesis of porous ceramic with well-developed mullite whiskers in system of Al2O3-Kaolin-MoO3. J. Mater. Res. Technol. 2021, 15, 1457–1466. [Google Scholar] [CrossRef]

- Sahraoui, T.; Belhouchet, H.; Heraiz, M. The effects of mechanical activation on the sintering of mullite produced from kaolin and aluminum powder. Ceram. Int. 2016, 42, 12185–12193. [Google Scholar] [CrossRef]

- Rashad, M.; Balasubramanian, M. Characteristics of porous mullite developed from clay and AlF3·3H2O. J. Eur. Ceram. Soc. 2018, 38, 3673–3680. [Google Scholar] [CrossRef]

- Kim, B.M.; Cho, Y.K.; Yoon, S.Y. Mullite whiskers derived from kaolin. Ceram. Int. 2009, 35, 579–583. [Google Scholar] [CrossRef]

- Foo, C.T.; Salleh, M.A.M.; Ying, K.K. Mineralogy and thermal expansion study of mullite-based ceramics synthesized from coal fly ash and aluminum dross industrial wastes. Ceram. Int. 2019, 45, 7488–7494. [Google Scholar] [CrossRef]

- Zawrah, M.F.; Wassel, A.R.; Youness, R.A. Recycling of aluminum dross and silica fume wastes for production of mullite-containing ceramics: Powder preparation, sinterability and properties. Ceram. Int. 2022, 48, 31661–31676. [Google Scholar] [CrossRef]

- Valášková, M.; Blahůšková, V.; Vlček, J. Effects of kaolin additives in fly ash on sintering and properties of mullite ceramics. Minerals 2021, 11, 887. [Google Scholar] [CrossRef]

- Lian, W.; Liu, Y.; Wang, W.J. Preparation of environmentally friendly low-cost mullite porous Ceramics and the effect of waste glass powder on structure and mechanical properties. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 577–585. [Google Scholar] [CrossRef]

- Ibarra, C.M.N.; Almanza, R.J.M.; Cortés, H.D.A. Development of mullite/zirconia composites from a mixture of aluminum dross and zircon. Ceram. Int. 2009, 35, 921–924. [Google Scholar] [CrossRef]

- Ma, B.Y.; Su, C.; Ren, X.M. Preparation and properties of porous mullite ceramics with high-closed porosity and high strength from fly ash via reaction synthesis process. J. Alloys Compd. 2019, 803, 981–991. [Google Scholar] [CrossRef]

- Xia, B.; Wang, Z.; Gou, L. Porous mullite ceramics with enhanced compressive strength from fly ash-based ceramic microspheres: Facile synthesis, structure, and performance. Ceram. Int. 2021, 48, 10472–10479. [Google Scholar] [CrossRef]

- Chen, Y.F.; Chang, Y.H.; Wang, M.C. Effects of Al2O3 addition on the phases, flow characteristics and morphology of the porous kaolin ceramics. Mater. Sci. Eng. A 2004, 373, 221–228. [Google Scholar] [CrossRef]

- Li, J.H.; Ma, H.W.; Huang, W.H. Effect of V2O5 on the properties of mullite ceramics synthesized from high-aluminum fly ash and bauxite. J. Hazard. Mater. 2009, 166, 1535–1539. [Google Scholar] [CrossRef]

- Guo, A.; Liu, J.; Xu, R. Preparation of mullite from desilication fly ash. Fuel 2010, 89, 3630–3636. [Google Scholar] [CrossRef]

- Alves, H.P.A.; Silva, J.B.; Campos, L.F.A. Preparation of mullite based ceramics from clay–kaolin waste mixtures. Ceram. Int. 2016, 42, 19086–19090. [Google Scholar] [CrossRef]

- Chargui, F.; Hamidouche, M.; Belhouchet, H. Mullite fabrication from natural kaolin and aluminium slag. Bol. Soc. Esp. Cerám. Vidr. 2018, 57, 169–177. [Google Scholar] [CrossRef]

- Chen, Y.F.; Wang, M.C.; Hon, M.H. Phase transformation and growth of mullite in kaolin ceramics. J. Eur. Ceram. Soc. 2004, 24, 2389–2397. [Google Scholar] [CrossRef]

- Chen, C.Y.; Lan, G.S.; Tuan, W.H. Microstructural evolution of mullite during the sintering of kaolin powder compacts. Ceram. Int. 2000, 26, 715–720. [Google Scholar] [CrossRef]

- Li, S.; Du, H.; Guo, A. Preparation of self-reinforcement of porous mullite ceramics through in situ synthesis of mullite whisker in flyash body. Ceram. Int. 2012, 38, 1027–1032. [Google Scholar] [CrossRef]

- Dong, Y.; Diwu, J.; Feng, X. Phase evolution and sintering characteristics of porous mullite ceramics produced from the flyash-Al(OH)3 coating powders. J. Alloys Compd. 2008, 460, 651–657. [Google Scholar] [CrossRef]

- Yuan, W.; Kuang, J.; Huang, Z. Effect of aluminum source on the kinetics and mechanism of mullite preparation from kaolinite. Chem. Phys. Lett. 2022, 787, 139242. [Google Scholar] [CrossRef]

- Chen, Y. Kinetics of secondary mullite formation in kaolin-Al2O3 ceramics. Scr. Mater. 2004, 51, 231–235. [Google Scholar] [CrossRef]

- Ondro, T.; Al-Shantir, O.; Csáki, Š. Kinetic analysis of sinter-crystallization of mullite and cristobalite from kaolinite. Thermochim. Acta 2019, 678, 178312. [Google Scholar] [CrossRef]

- Kuang, J.; Li, L.; Liu, P. Effect of Er2O3 and Pr6O11 on non-isothermal kinetics of mullite formation from kaolinite. J. Rare Earths 2017, 35, 831–836. [Google Scholar] [CrossRef]

| Al2O3 | SiO2 | MgO | CaO | Fe2O3 | TiO2 | K2O | Else | |

|---|---|---|---|---|---|---|---|---|

| AD | 87.80 | 1.74 | 8.44 | 0.55 | 0.39 | 0.41 | 0.12 | 0.55 |

| Fly ash | 12.81 | 71.18 | 0.62 | 7.71 | 4.73 | 0.59 | 0.88 | 1.48 |

| Silica dust | 1.83 | 93.26 | 0.31 | 1.11 | 1.89 | 0.24 | 0.57 | 0.79 |

| Gangue | 35.03 | 59.08 | 0.44 | 0.77 | 1.31 | 2.27 | 0.65 | 0.45 |

| AD | Fly Ash | Silica Dust | Gangue | |

|---|---|---|---|---|

| 1 | 6.7 | 3.3 | ||

| 2 | 7.8 | 2.2 | ||

| 3 | 6.8 | 3.2 |

| Point | Elements and Content/wt% | |||

|---|---|---|---|---|

| Si | Al | O | Mg | |

| I | 7.0 | 38.2 | 53.5 | 1.3 |

| II | 20.6 | 28.3 | 51.1 | — |

| III | 12.9 | 30.3 | 56.8 | — |

| IV | 14.2 | 26.4 | 53.3 | 6.1 |

| V | 8.5 | 34.7 | 56.8 | — |

| VI | 11.3 | 43.0 | 41.7 | 4.0 |

| Silicon Source | Activation Energy/kJ·mol−1 | Average/kJ·mol−1 | |

|---|---|---|---|

| Kissinger | Ozawa | ||

| Fly ash | 970 | 998 | 984 |

| Silica dust | 1102 | 1124 | 1113 |

| Gangue | 731 | 751 | 741 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.-L.; Li, Z.-S.; Ding, Y.-D.; Ge, Q.-Q.; Shi, Y.-J.; Jiang, L. Effect of Silicon Source (Fly Ash, Silica Dust, Gangue) on the Preparation of Porous Mullite Ceramics from Aluminum Dross. Materials 2022, 15, 7212. https://doi.org/10.3390/ma15207212

Yang H-L, Li Z-S, Ding Y-D, Ge Q-Q, Shi Y-J, Jiang L. Effect of Silicon Source (Fly Ash, Silica Dust, Gangue) on the Preparation of Porous Mullite Ceramics from Aluminum Dross. Materials. 2022; 15(20):7212. https://doi.org/10.3390/ma15207212

Chicago/Turabian StyleYang, Hong-Liang, Zi-Shen Li, You-Dong Ding, Qi-Qi Ge, Yu-Juan Shi, and Lan Jiang. 2022. "Effect of Silicon Source (Fly Ash, Silica Dust, Gangue) on the Preparation of Porous Mullite Ceramics from Aluminum Dross" Materials 15, no. 20: 7212. https://doi.org/10.3390/ma15207212

APA StyleYang, H.-L., Li, Z.-S., Ding, Y.-D., Ge, Q.-Q., Shi, Y.-J., & Jiang, L. (2022). Effect of Silicon Source (Fly Ash, Silica Dust, Gangue) on the Preparation of Porous Mullite Ceramics from Aluminum Dross. Materials, 15(20), 7212. https://doi.org/10.3390/ma15207212