Rapid Microstructure Homogenization of a Laser Melting Deposition Additive Manufactured Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloy by Electropulsing

Abstract

1. Introduction

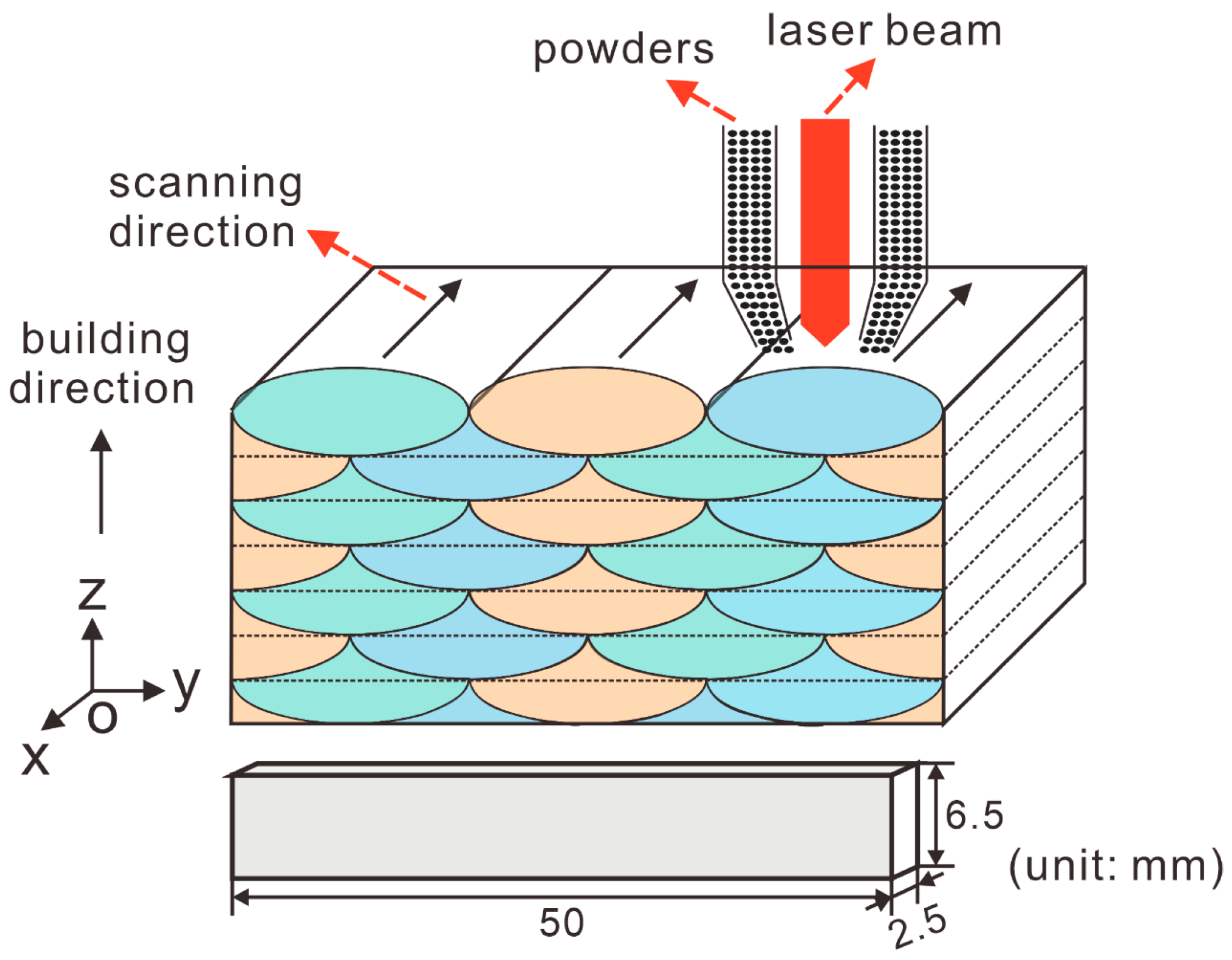

2. Experimental

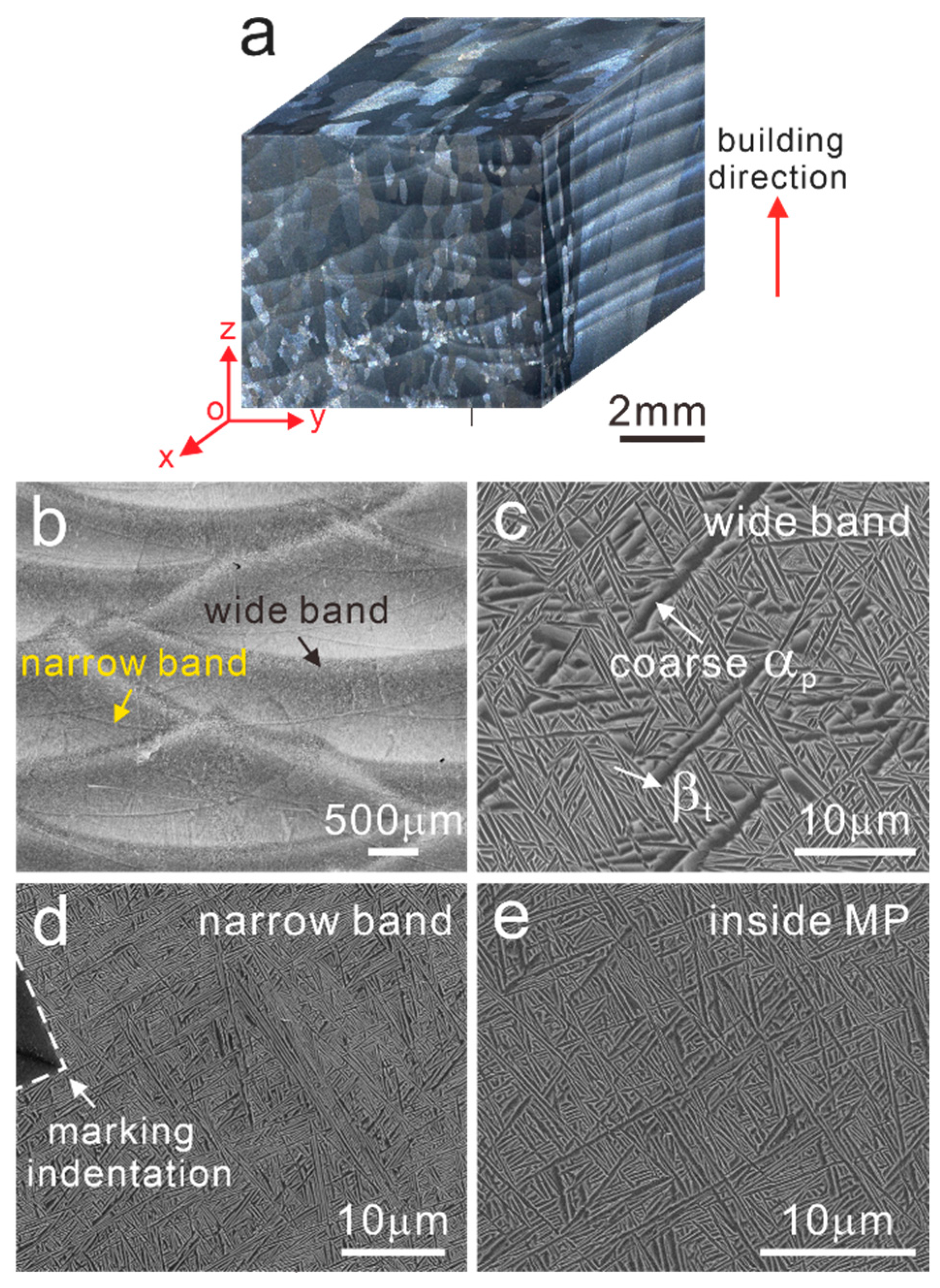

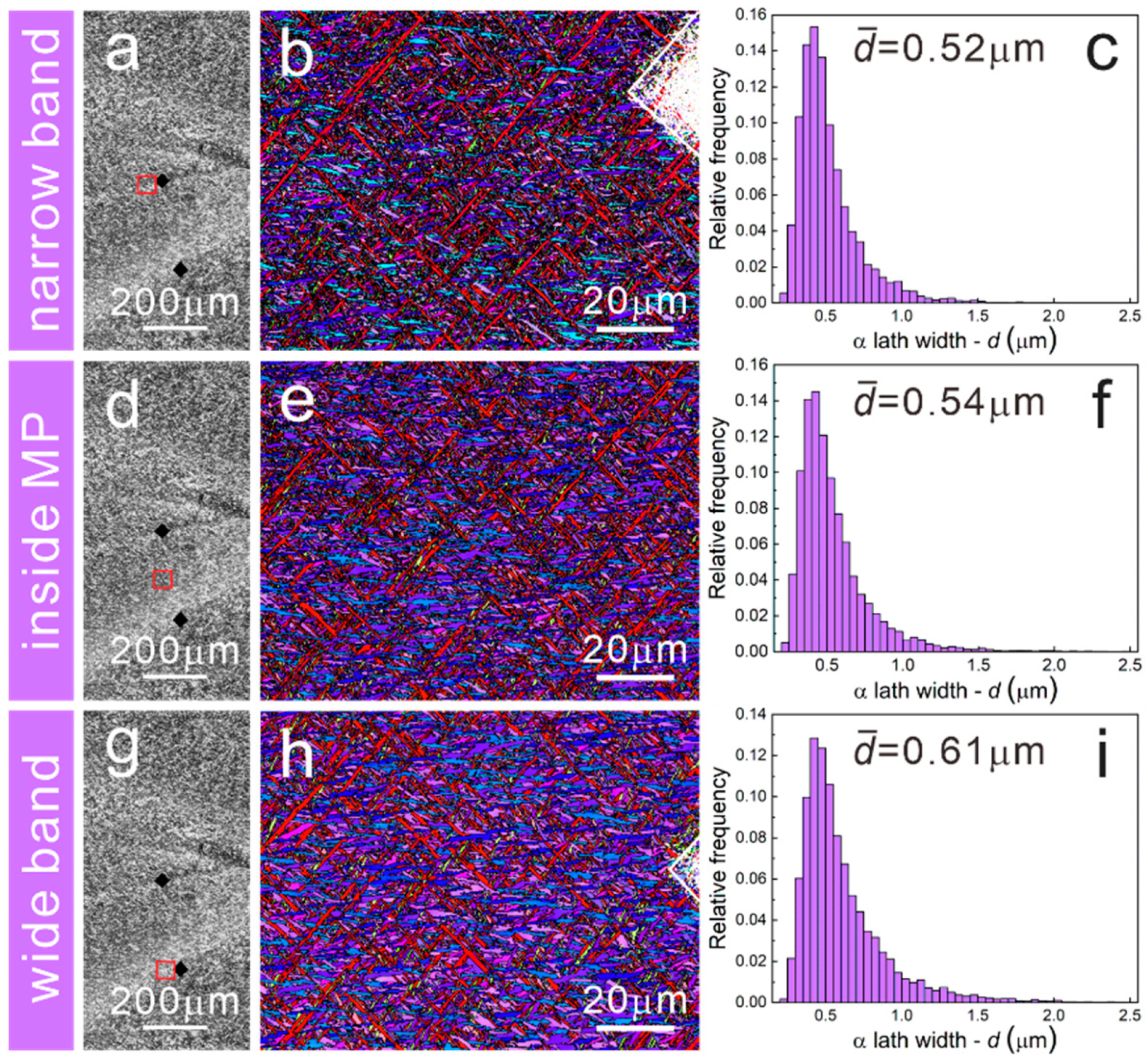

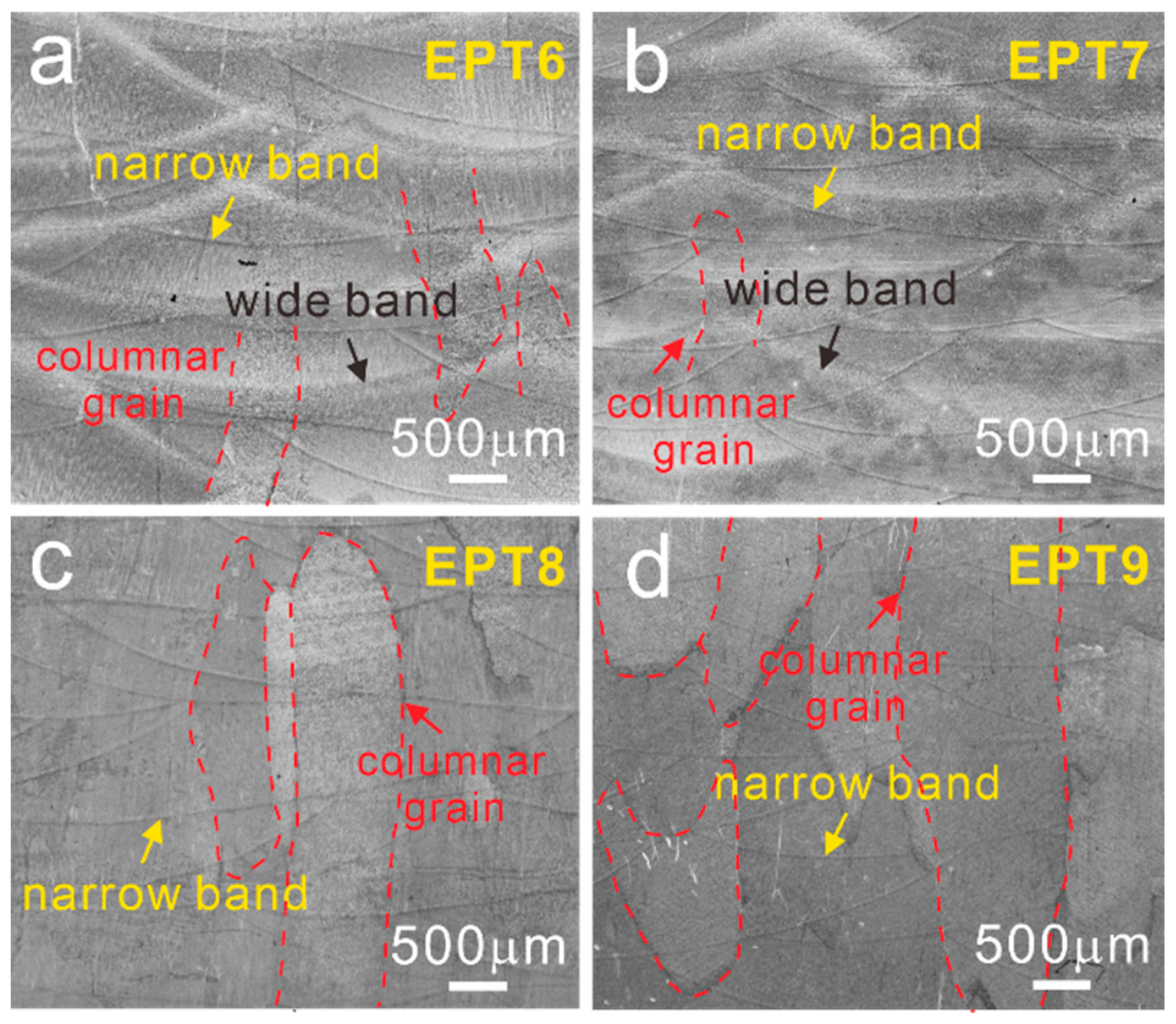

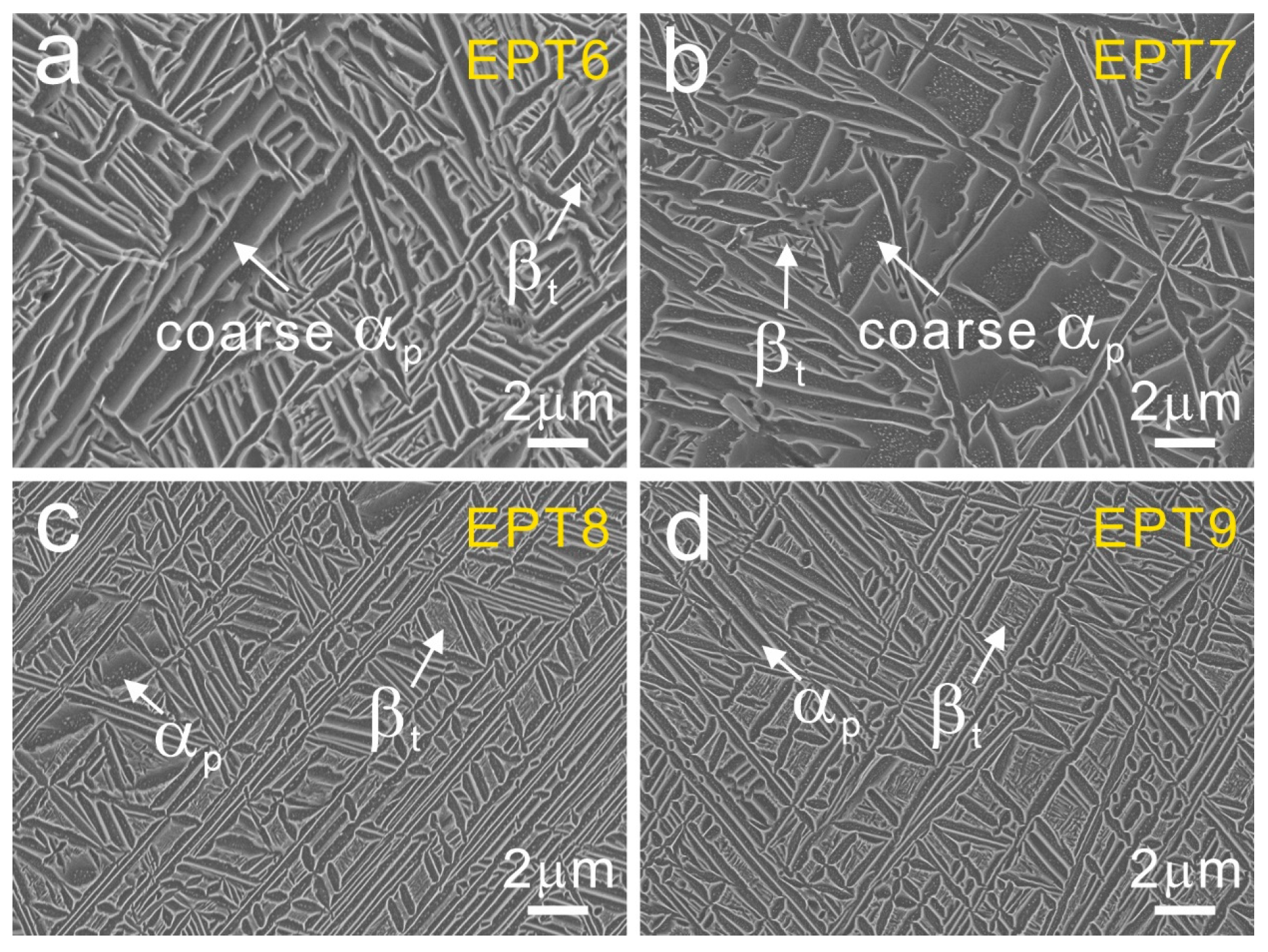

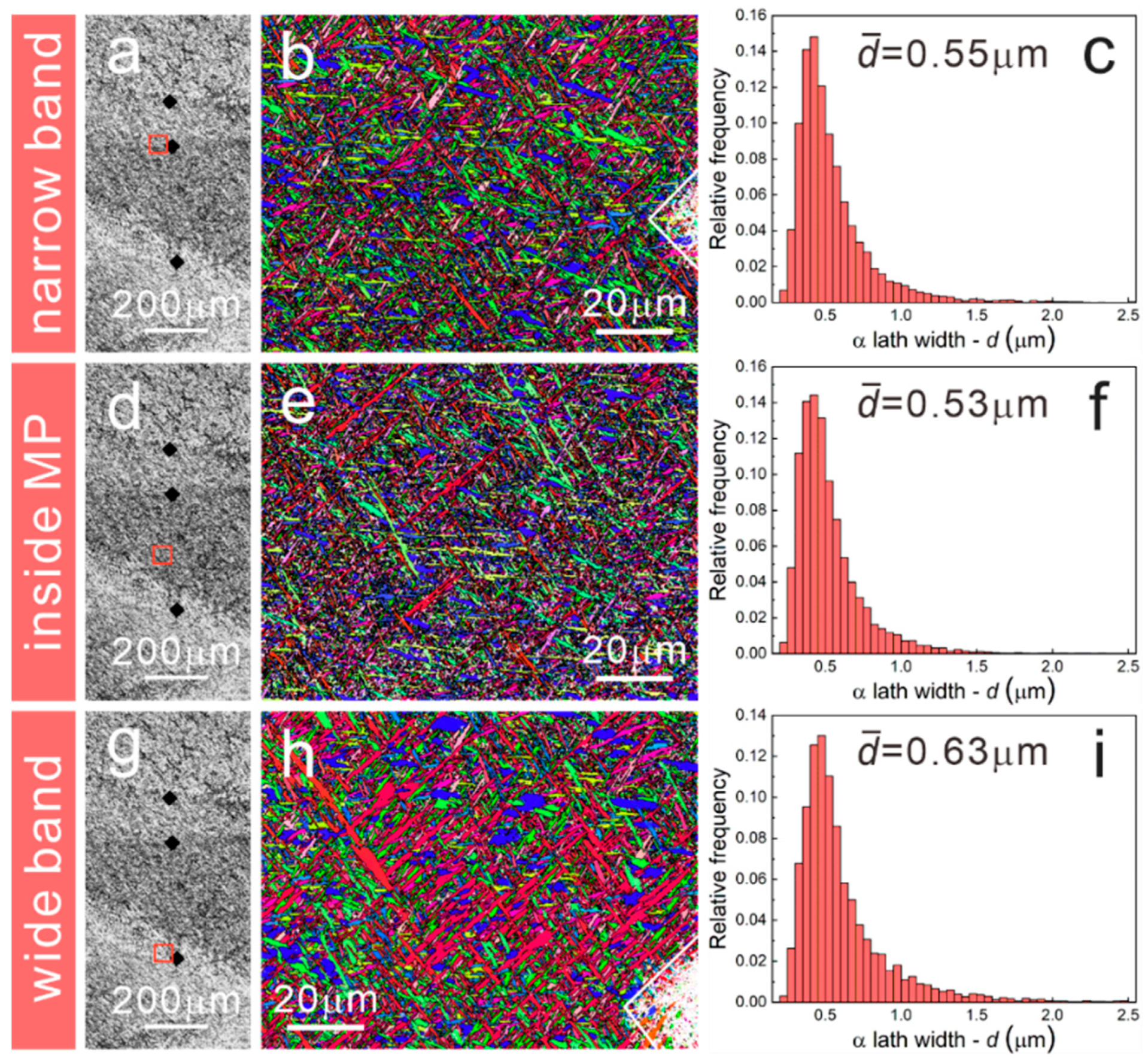

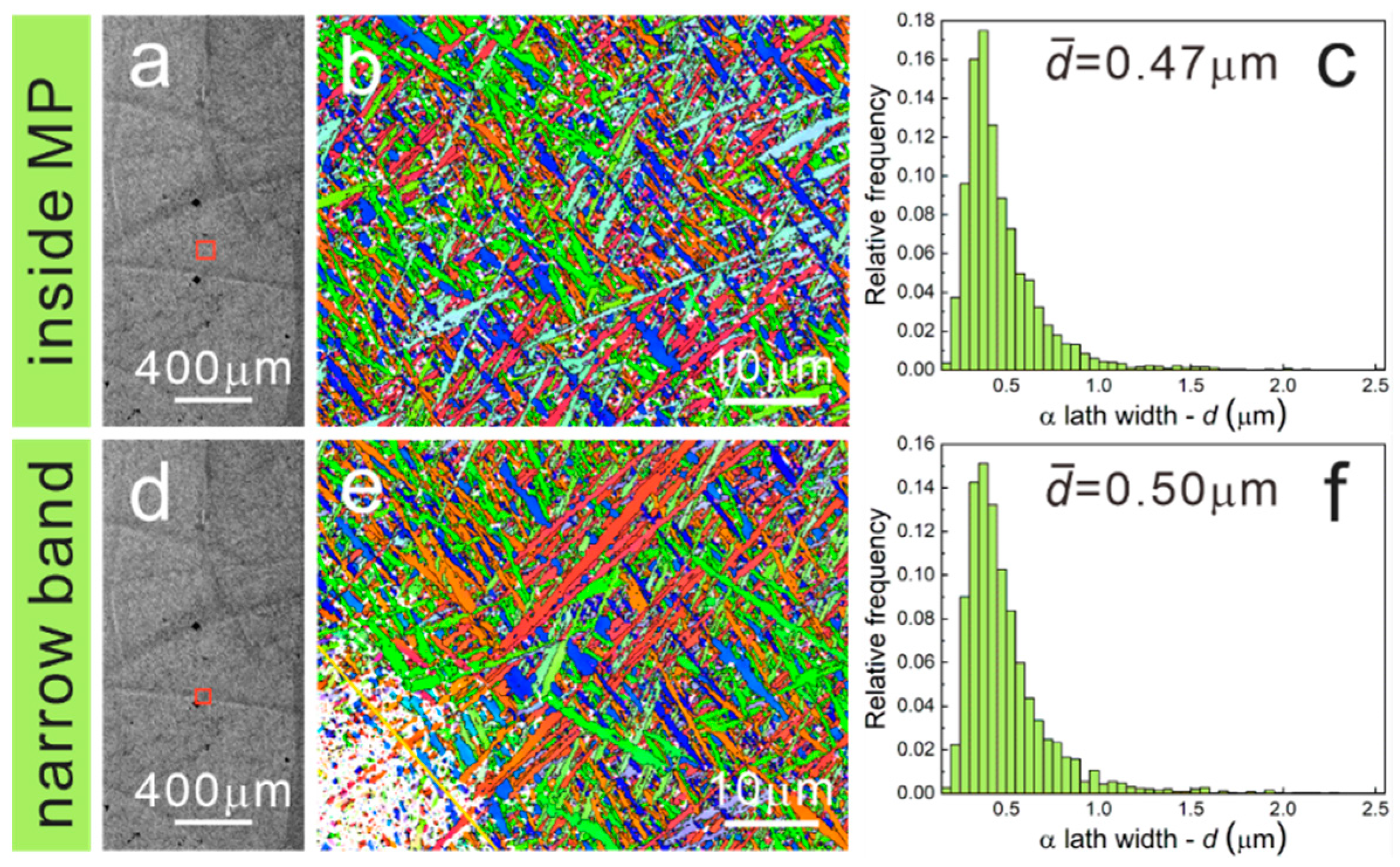

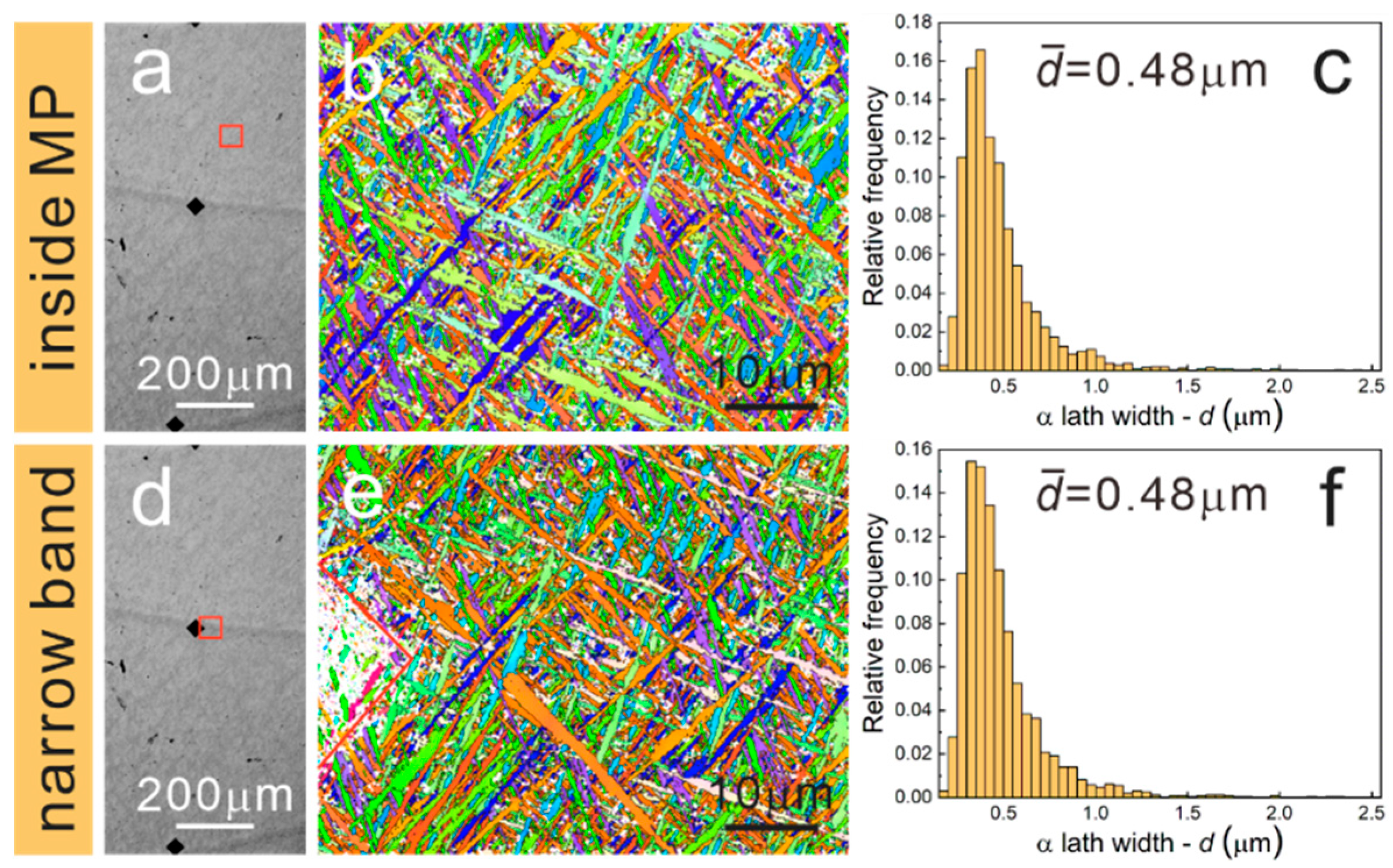

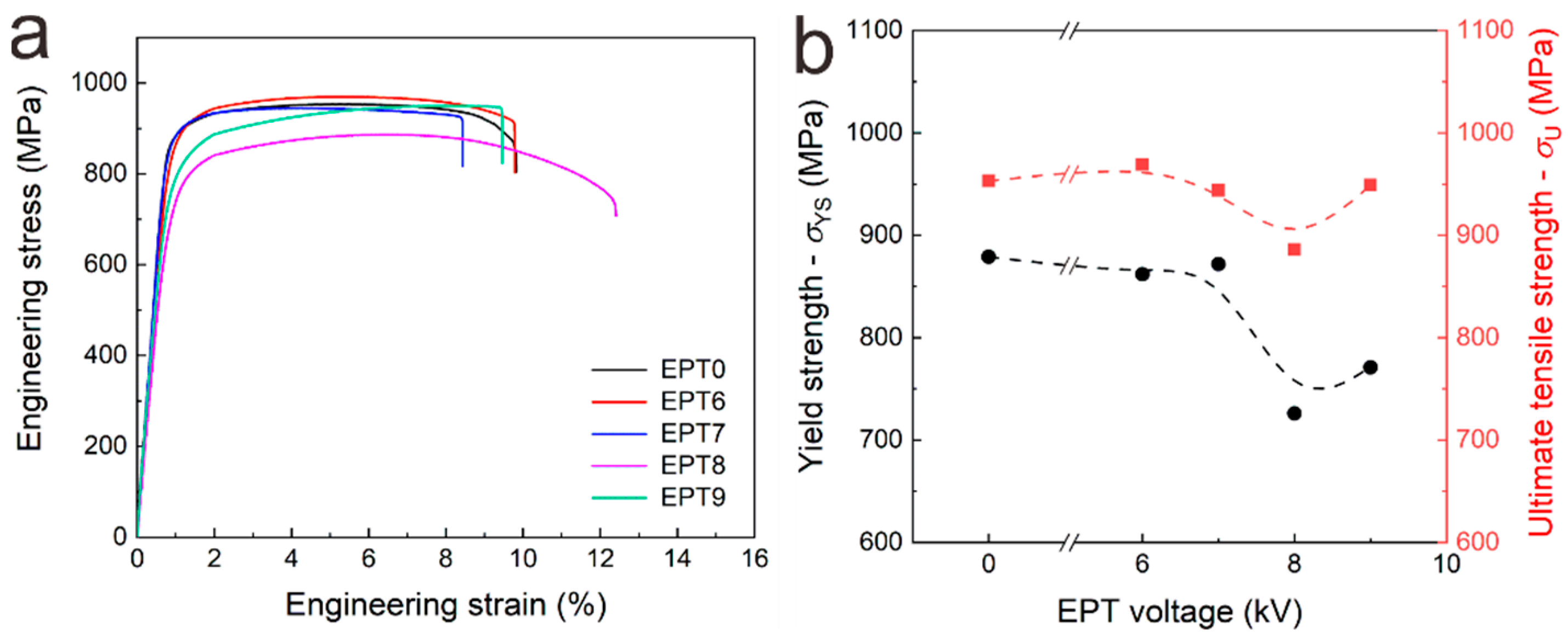

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, C.; Hu, B.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Peters, M.; Kumpfert, J.; Ward, C.H.; Leyens, C. Titanium Alloys for Aerospace Applications. Adv. Eng. Mater. 2003, 5, 419–427. [Google Scholar] [CrossRef]

- Hao, Y.L.; Li, S.J.; Yang, R. Biomedical titanium alloys and their additive manufacturing. Rare Met. 2016, 35, 661–671. [Google Scholar] [CrossRef]

- Zhang, L.C.; Liu, Y. Additive manufacturing of titanium alloys for biomedical applications. In Additive Manufacturing of Emerging Materials; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Wang, H.M.; Zhang, S.Q.; Wang, X.M. Progress and challenges of laser direct manufacturing of large titanium structural components. Chin. J. Lasers 2009, 36, 3204–3209. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive manufacturing of structural materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Meng, L.X.; Yang, H.J.; Ben, D.D.; Ji, H.B.; Lian, D.L.; Ren, D.C.; Li, Y.; Bai, T.S.; Cai, Y.S.; Chen, J.; et al. Effects of defects and microstructures on tensile properties of selective laser melted Ti6Al4V alloys fabricated in the optimal process zone. Mater. Sci. Eng. A 2022, 830, 142294. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The Additive Manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Ren, H.S.; Tian, X.J.; Liu, D.; Liu, J.; Wang, H.-M. Microstructural evolution and mechanical properties of laser melting deposited Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 1856–1864. [Google Scholar] [CrossRef]

- Xi, M.Z.; Lv, C.; Wu, Z.H.; Shang, J.Y.; Zhou, W.; Dong, R.M.; Gao, S.Y. Microstructures and mechanical properties of TC11 titanium alloy formed by laser rapid forming and its combination with consecutive point-mode forging. Acta Metall. Sin. 2017, 53, 1065–1074. [Google Scholar]

- Shao, Z.; Pang, J.C.; Zhang, Z.J.; Liu, H.Q.; Zhang, Z.Q.; Li, S.X.; Zhang, Z.F. Tensile deformation behaviors of Ti-6.5Al-3.5Mo-1.5Zr-0.25Si alloy with different percentages of primary α phase. Mater. Sci. Eng. A 2022, 842, 143097. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Liu, D.; Tian, X.J.; Tang, H.B.; Wang, H.M. Characterization of microstructure and mechanical properties of laser melting deposited Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater. Des. (1980–2015) 2014, 56, 445–453. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Zeng, W.D.; Yu, H.Q. An investigation of a new near-beta forging process for titanium alloys and its application in aviation components. Mater. Sci. Eng. A 2005, 393, 204–212. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Zheng, P.Q.; Li, A.B.; Cui, X.P. Hot tensile characterization of Ti–6.5Al–3.5Mo–1.5Zr–0.3Si alloy with an equiaxed microstructure. Mater. Des. 2009, 30, 838–841. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Tian, X.J.; Li, J.; Wang, H.M. Microstructure evolution and layer bands of laser melting deposition Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. J. Alloys Compd. 2014, 616, 468–474. [Google Scholar] [CrossRef]

- Zhu, Y.Y.; Tian, X.J.; Li, J.; Wang, H.M. The anisotropy of laser melting deposition additive manufacturing Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater. Des. 2015, 67, 538–542. [Google Scholar] [CrossRef]

- Ma, Y.R.; Yang, H.J.; Tian, Y.Z.; Pang, J.C.; Zhang, Z.F. Hardening and softening mechanisms in a nano-lamellar austenitic steel induced by electropulsing treatment. Mater. Sci. Eng. A 2018, 13, 146–150. [Google Scholar] [CrossRef]

- Chen, K.; Zhan, L.H.; Yu, W.F. Rapidly modifying microstructure and mechanical properties of AA7150 Al alloy processed with electropulsing treatment. J. Mater. Sci. Technol. 2021, 95, 172–179. [Google Scholar] [CrossRef]

- Ben, D.D.; Yang, H.J.; Ma, Y.R.; Shao, X.H.; Pang, J.C.; Zhang, Z.F. Rapid hardening of AISI 4340 steel induced by electropulsing treatment. Mater. Sci. Eng. A 2018, 725, 28–32. [Google Scholar] [CrossRef]

- Conrad, H. Effects of electric current on solid state phase transformations in metals. Mater. Sci. Eng. A 2000, 287, 227–237. [Google Scholar] [CrossRef]

- Qin, S.Y.; Ba, X.; Zhang, X.F. Accelerated cluster dissolution using electropulsing for ultrafast performance regeneration. Scr. Mater. 2020, 178, 24–28. [Google Scholar] [CrossRef]

- Xu, X.F.; Zhao, Y.G.; Ma, B.D.; Zhang, M. Electropulsing induced evolution of grain-boundary precipitates without loss of strength in the 7075 Al alloy. Mater. Charact. 2015, 105, 90–94. [Google Scholar] [CrossRef]

- Zhang, X.F.; Lu, W.J.; Qin, R.S. Removal of MnS inclusions in molten steel using electropulsing. Scr. Mater. 2013, 69, 453–456. [Google Scholar] [CrossRef]

- Ben, D.D.; Yang, H.J.; Ma, Y.R.; Wang, Q.; Tian, Y.Z.; Zhang, P.; Duan, Q.Q.; Zhang, Z.F. Declined Fatigue Crack Propagation Rate of a High-Strength Steel by Electropulsing Treatment. Adv. Eng. Mater. 2019, 21, 1801345. [Google Scholar] [CrossRef]

- Yang, C.L.; Yang, H.J.; Zhang, Z.J.; Zhang, Z.F. Recovery of tensile properties of twinning-induced plasticity steel via electropulsing induced void healing. Scr. Mater. 2018, 147, 88–92. [Google Scholar] [CrossRef]

- Hosoi, A.; Nagahama, T.; Ju, Y. Fatigue crack healing by a controlled high density electric current field. Mater. Sci. Eng. A 2012, 533, 38–42. [Google Scholar] [CrossRef]

- Xie, L.C.; Liu, C.; Song, Y.L.; Guo, H.J.; Wang, Z.Q.; Hua, L.; Wang, L.Q.; Zhang, L.-C. Evaluation of microstructure variation of TC11 alloy after electroshocking treatment. J. Mater. Res. Technol. 2020, 9, 2455–2466. [Google Scholar] [CrossRef]

- Noell, P.J.; Rodelas, J.M.; Ghanbari, Z.N.; Laursen, C.M. Microstructural modification of additively manufactured metals by electropulsing. Addit. Manuf. 2020, 33, 101128. [Google Scholar] [CrossRef]

- Waryoba, D.; Islam, Z.; Reutzel, T.; Haque, A. Electro-strengthening of the additively manufactured Ti−6Al−4V alloy. Mater. Sci. Eng. A 2020, 798, 140062. [Google Scholar] [CrossRef]

- Gao, J.B.; Ben, D.D.; Yang, H.J.; Meng, L.X.; Ji, H.B.; Lian, D.L.; Chen, J.; Yi, J.L.; Wang, L.; Li, P.; et al. Effects of electropulsing on the microstructure and microhardness of a selective laser melted Ti6Al4V alloy. J. Alloys Compd. 2021, 875, 160044. [Google Scholar] [CrossRef]

- Zhan, X.H.; Meng, Y.; Zhou, J.J.; Qi, C.Q.; Zhang, C.L.; Gu, D.D. Quantitative research on microstructure and thermal physical mechanism in laser melting deposition for Invar alloy. J. Manuf. Process 2018, 31, 221–231. [Google Scholar] [CrossRef]

- Ben, D.D.; Ma, Y.R.; Yang, H.J.; Meng, L.X.; Shao, X.H.; Liu, H.Q.; Wang, S.G.; Duan, Q.Q.; Zhang, Z.F. Heterogeneous microstructure and voids dependence of tensile deformation in a selective laser melted AlSi10Mg alloy. Mater. Sci. Eng. A 2020, 798, 140109. [Google Scholar] [CrossRef]

- Zhang, W.; Sui, M.L.; Hu, K.Y.; Li, D.X.; Guo, X.N.; He, G.H.; Zhou, B.L. Formation of nanophases in a Cu–Zn alloy under high current density electropulsing. J. Mater. Res. 2000, 15, 2065–2068. [Google Scholar] [CrossRef]

- Zhou, Y.Z.; Zhang, W.; Wang, B.Q.; He, G.H.; Guo, J.D. Grain refinement and formation of ultrafine-grained microstructure in a low-carbon steel under electropulsing. J. Mater. Res. 2002, 17, 2105–2111. [Google Scholar] [CrossRef]

- Ao, D.W.; Chu, X.R.; Yang, Y.; Lin, S.X.; Gao, J. Effect of electropulsing treatment on microstructure and mechanical behavior of Ti-6Al-4V alloy sheet under argon gas protection. Vacuum 2018, 148, 230–238. [Google Scholar] [CrossRef]

- Tamirisakandala, S.; Bhat, R.B.; Miracle, D.B.; Boddapati, S.; Bordia, R.; Vanover, R.; Vasudevan, V.K. Effect of boron on the beta transus of Ti−6Al−4V alloy. Scr. Mater. 2005, 53, 217–222. [Google Scholar] [CrossRef]

- Huang, S.S.; Zhang, J.H.; Ma, Y.J.; Zhang, S.L.; Youssef, S.S.; Qi, M.; Wang, H.; Qiu, J.K.; Xu, D.S.; Lei, J.F.; et al. Influence of thermal treatment on element partitioning in α+β titanium alloy. J. Alloys Compd. 2019, 791, 575–585. [Google Scholar] [CrossRef]

- Zhu, Y.H.; To, S.; Lee, W.B.; Liu, X.M.; Jiang, Y.B.; Tang, G.Y. Effects of dynamic electropulsing on microstructure and elongation of a Zn–Al alloy. Mater. Sci. Eng. A 2009, 501, 125–132. [Google Scholar] [CrossRef]

- Zhu, R.F.; Jiang, Y.B.; Guan, L.; Li, H.L.; Tang, G.Y. Difference in recrystallization between electropulsing-treated and furnace-treated NiTi alloy. J. Alloys Compd. 2016, 658, 548–554. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben, D.; Yang, H.; Gao, J.; Yang, B.; Dong, Y.; Liu, X.; Wang, X.; Duan, Q.; Zhang, P.; Zhang, Z. Rapid Microstructure Homogenization of a Laser Melting Deposition Additive Manufactured Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloy by Electropulsing. Materials 2022, 15, 7103. https://doi.org/10.3390/ma15207103

Ben D, Yang H, Gao J, Yang B, Dong Y, Liu X, Wang X, Duan Q, Zhang P, Zhang Z. Rapid Microstructure Homogenization of a Laser Melting Deposition Additive Manufactured Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloy by Electropulsing. Materials. 2022; 15(20):7103. https://doi.org/10.3390/ma15207103

Chicago/Turabian StyleBen, Dandan, Huajie Yang, Jiabao Gao, Bingyu Yang, Yu’ang Dong, Xiangyu Liu, Xuegang Wang, Qiqiang Duan, Peng Zhang, and Zhefeng Zhang. 2022. "Rapid Microstructure Homogenization of a Laser Melting Deposition Additive Manufactured Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloy by Electropulsing" Materials 15, no. 20: 7103. https://doi.org/10.3390/ma15207103

APA StyleBen, D., Yang, H., Gao, J., Yang, B., Dong, Y., Liu, X., Wang, X., Duan, Q., Zhang, P., & Zhang, Z. (2022). Rapid Microstructure Homogenization of a Laser Melting Deposition Additive Manufactured Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Alloy by Electropulsing. Materials, 15(20), 7103. https://doi.org/10.3390/ma15207103