1. Introduction

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer, classified among thermoplastics [

1,

2]. It has many excellent characteristics such as high-temperature stability, chemical resistance, and low coefficient of friction [

3,

4]. Hence, it is widely used in semiconductor manufacturing equipment, especially as critical preparation material for the key sealing parts of immersion lithography. PTFE is typically manufactured with processes such as sintering or high-velocity compaction [

5]. However, PTFE parts produced by molding techniques often do not meet the required dimensional tolerances and assembly requirements. In order to improve accuracy, machining such as drilling is used to further process these materials [

6,

7]. Due to the low intermolecular forces, PTFE suffers from poor creep resistance as well as low stiffness and yield stress [

8]. The machining performance of PTFE is significantly affected by cutting parameters. With improper cutting parameters, it is difficult to accurately process PTFE, resulting in burr, edge overcutting, inner surface damage, and other problems [

9].

In recent years, the relationship between machining performance and cutting parameters of polymers and polymer composites has been extensively studied, among which thrust [

9], torque [

10], and surface roughness [

11] are often paid more attention as indicators to evaluate machining properties. Rubio et al. compared the influence of cutting parameters on the machining performance of engineering plastics such as ultra-high molecular weight polyethylene (UHMWPE), polyformaldehyde (POM), and polytetrafluoroethylene (PTFE) [

12]. They found that the surface roughness of PTFE is minimum at a lower spindle speed and feed rate and the minimum thrust values of the three materials are obtained at a high level of spindle speed and a low level of feed speed. Cui et al. studied the effect of cutting parameters on cutting force and surface quality during orthogonal cutting pure PTFE [

13]. The results showed that cutting speed had the most obvious effect on cutting force while the cutting speed had the most significant effect on surface roughness. Gan et al. introduced cooling technology during milling of PTFE [

14]. They found that cryogenic cooling could make PTFE show little viscous behavior. This leads to the increase of the cutting force. Ramesh et al. focused on the effect of drilling parameters on thrust force in the drilling of sisal-glass fiber reinforced polymer composite laminates [

15]. The quadratic response models are developed by using response surface methodology (RSM) to predict the influence of cutting parameters on thrust force. The results showed that the thrust force is significantly influenced by feed rate, followed by spindle speed. The influence of drilling parameters on the thrust force and torque during traditional drilling of glass fiber reinforced composites was studied by Mohan et al. The effect of spindle speed has more significance concerning thrust by Taguchi analysis and analysis of variance (ANOVA) experiment [

16]. Susac Florin et al. investigated the effect of machining parameters on the hole quality in the drilling of polyethylene, polyamide, and polyacetale [

17]. The results indicated that the surface roughness increases with increasing spindle speed. The ideal surface roughness can be obtained by drilling at a lower spindle speed and a higher feed rate. Yasar, Nafiz et al. pointed out that the surface roughness value of carbon fiber reinforced polymer composites increases with the increase of the feed rate in drilling [

18]. The feed rate is determined to be the most significant factor affecting the surface roughness by the analysis of variance.

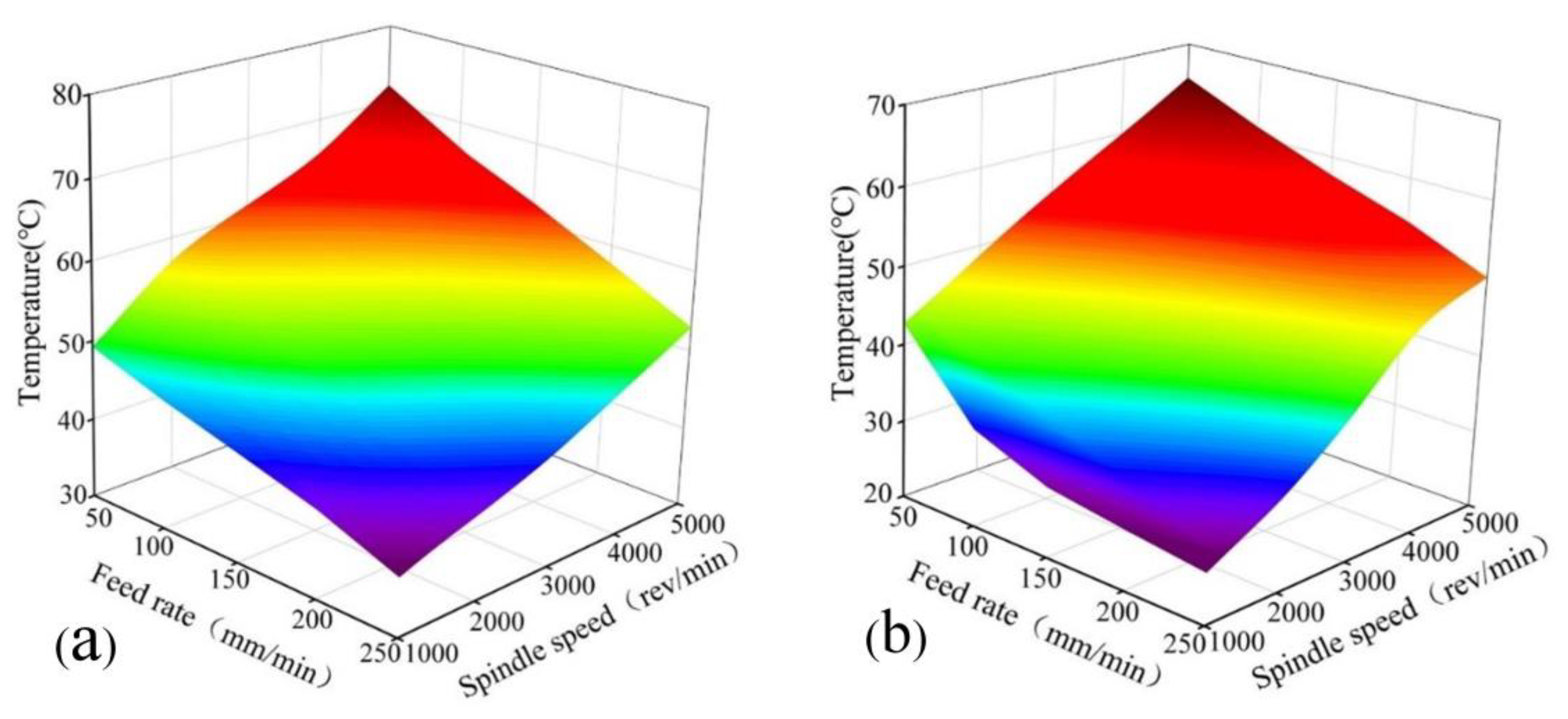

In addition, due to the low thermal conductivity of PTFE, the high temperatures generated during the drilling process can soften the material, resulting in machining defects. So, the temperature is also an important evaluation index of machining performance. At present, the relationship between cutting parameters and temperature of PTFE and other thermoplastic materials has been reported. Alper Uysal et al. investigated the effect of drilling angle, cutting speed, and feed on the cutting temperature of drills in drilling of pure polypropylene, using a two-wire infrared thermometer [

19]. The results indicated that the cutting temperature decreased with increasing feed during drilling polymer material. Under the condition of constant cutting speed, more heat is transferred from the drill to the polymer material. Chang et al. explored the influence of cutting parameters on the temperature of polyetheretherketone (PEEK); an infrared thermography was used to record the temperature variation within the drilling area [

20]. Experimental results showed that the temperature is inverse to the feed rate. Khashaba et al. explored the effect of spindle speed and feed rate on temperature in drilling GFRP composites [

21]. Two temperature measurement methods are used, one is to use a thermal infrared camera, and the other is to use a K-type thermocouple, which is placed in a cooling hole inside the drill bit. The results showed that compared with the feed rate, the spindle speed has a more significant influence on the temperature than the feed.

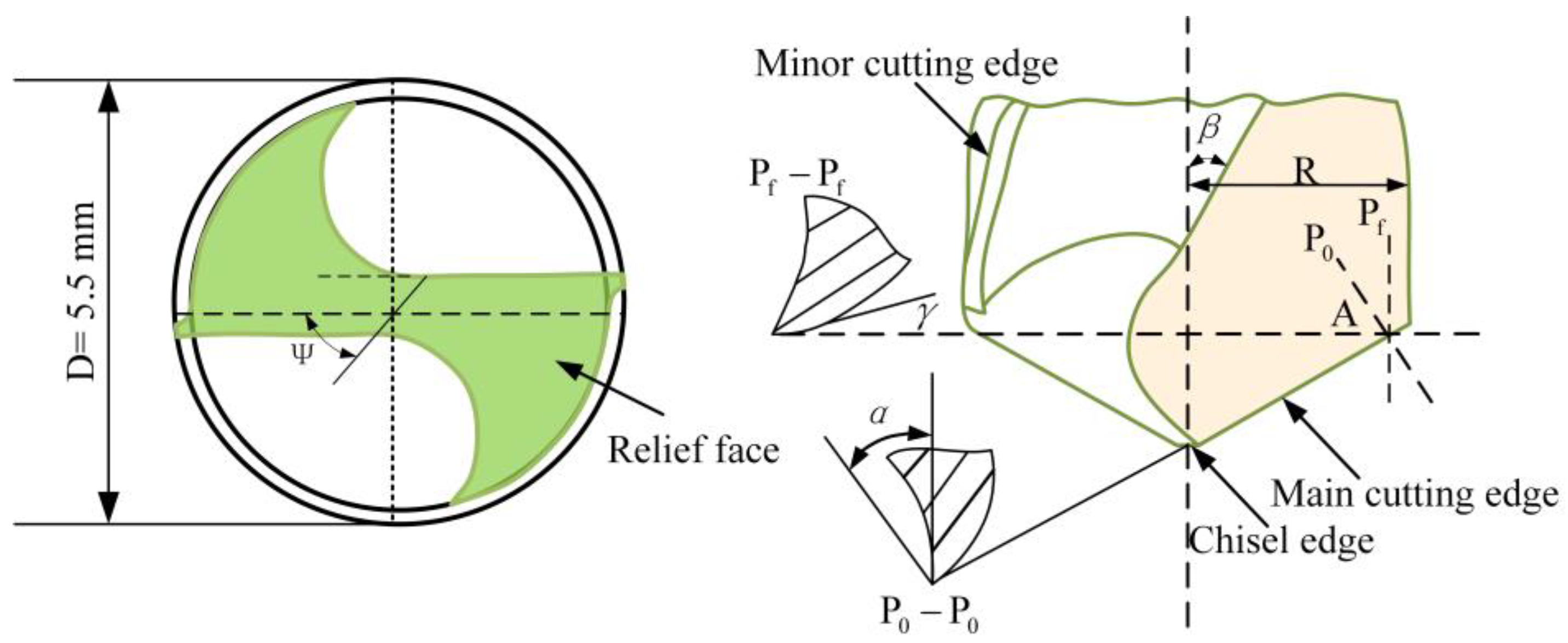

So far, some studies on the cutting performance of polymers and polymer matrix composites have been reported, but the effects of cutting process parameters on machining properties such as thrust, torque, surface roughness, and cutting temperature have not been considered comprehensively. Although polytetrafluoroethylene (PTFE) is widely used, few studies have focused on the drilling of PTFE materials. Therefore, thrust, torque, workpiece temperature, and surface roughness are used as indicators to characterize the machining performance in this paper. Small hole dry drilling experiments were conducted on PTFE. The effect of cutting parameters such as spindle speed and feed rate on the machining performance of PTFE was systematically investigated.