Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite

Abstract

1. Introduction

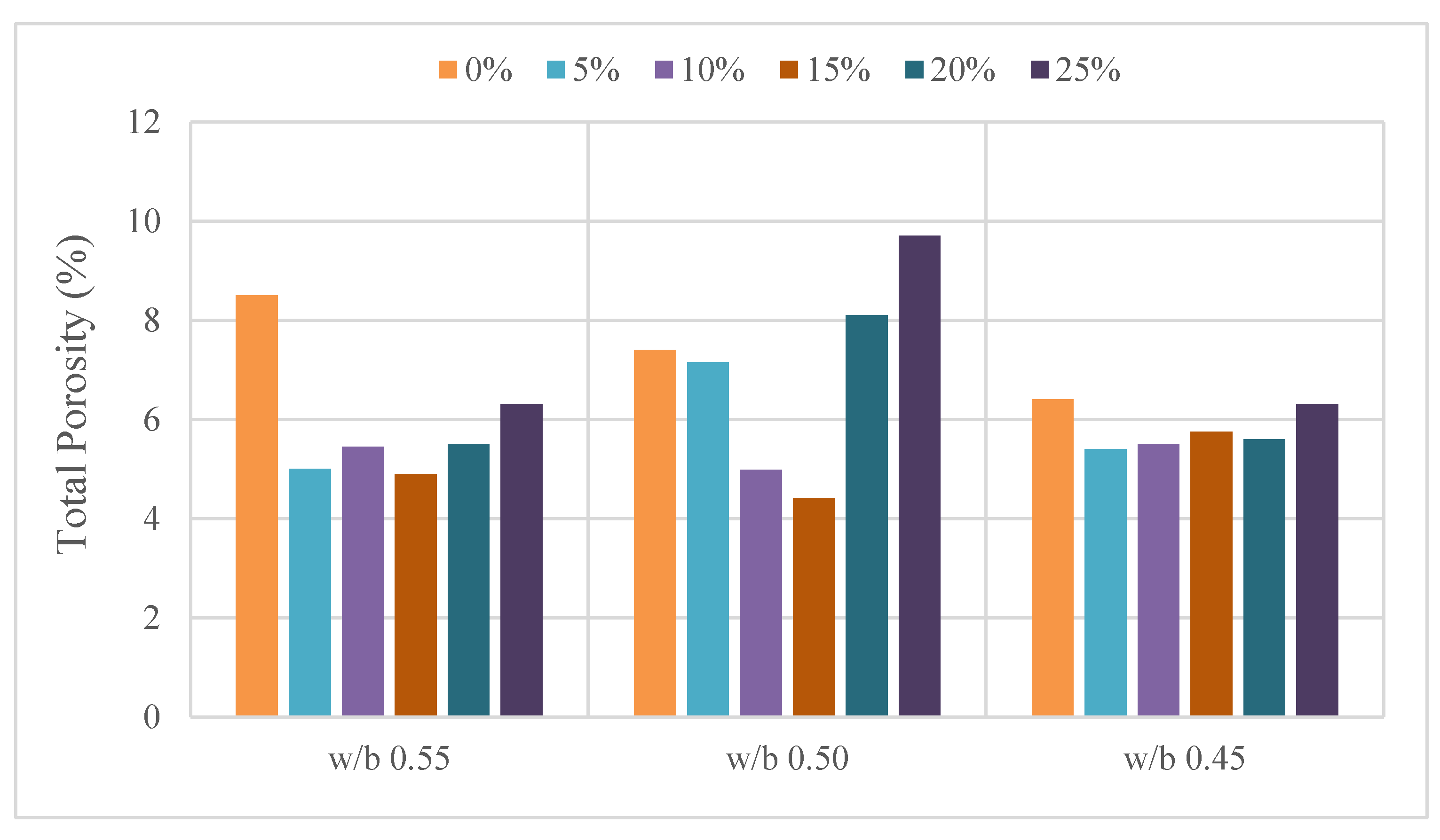

2. Cement Paste and Mortar

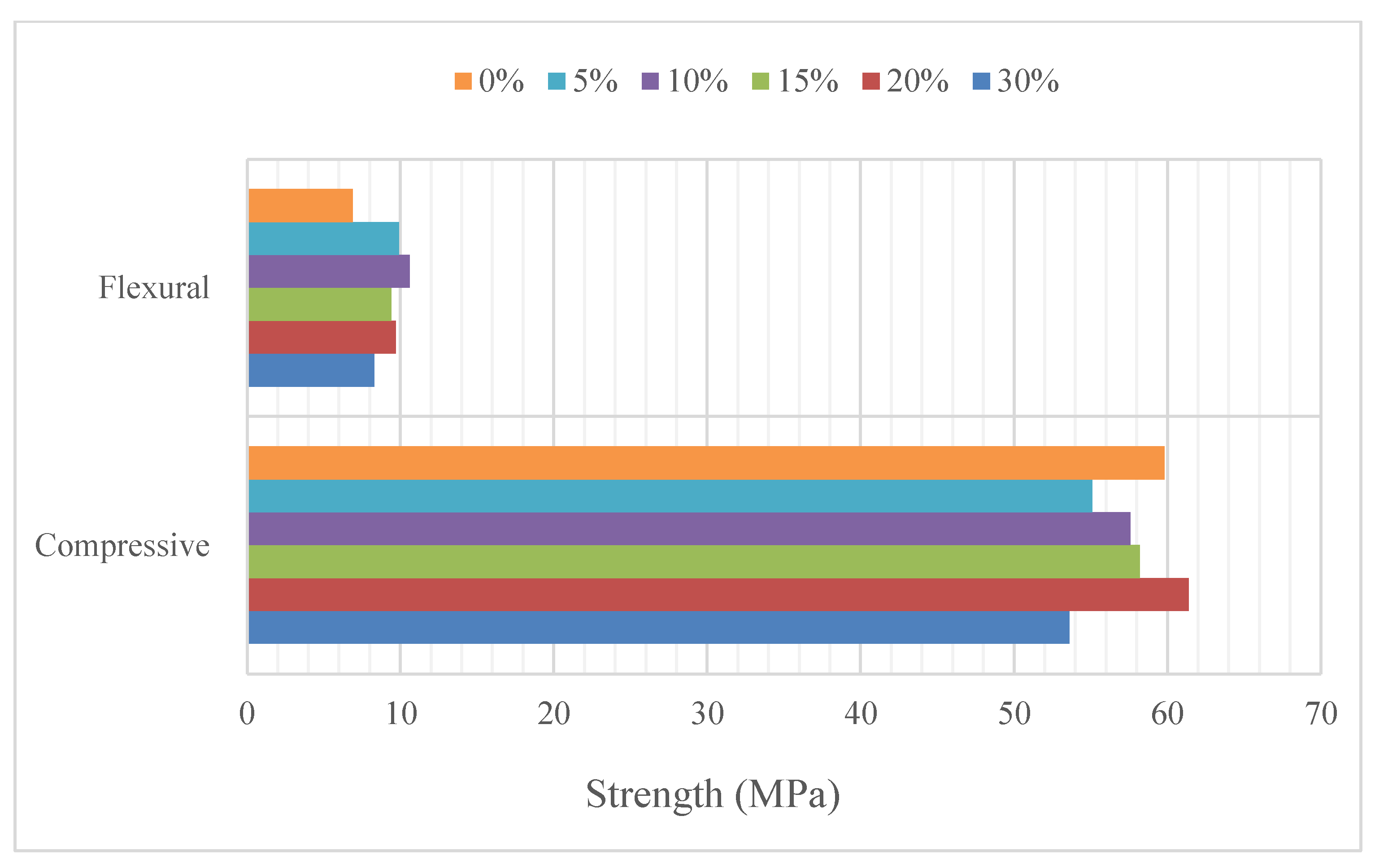

3. Conventional Concrete

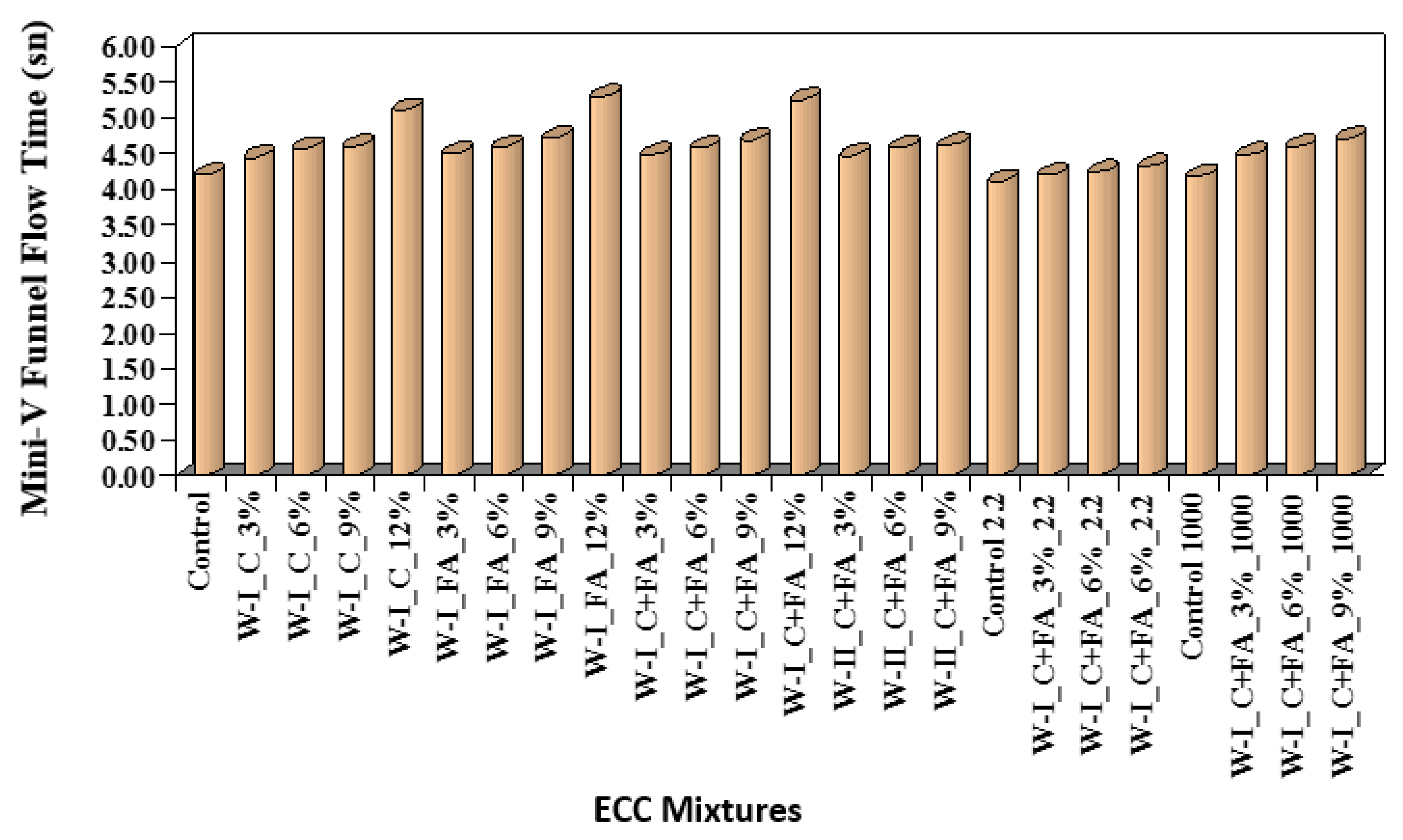

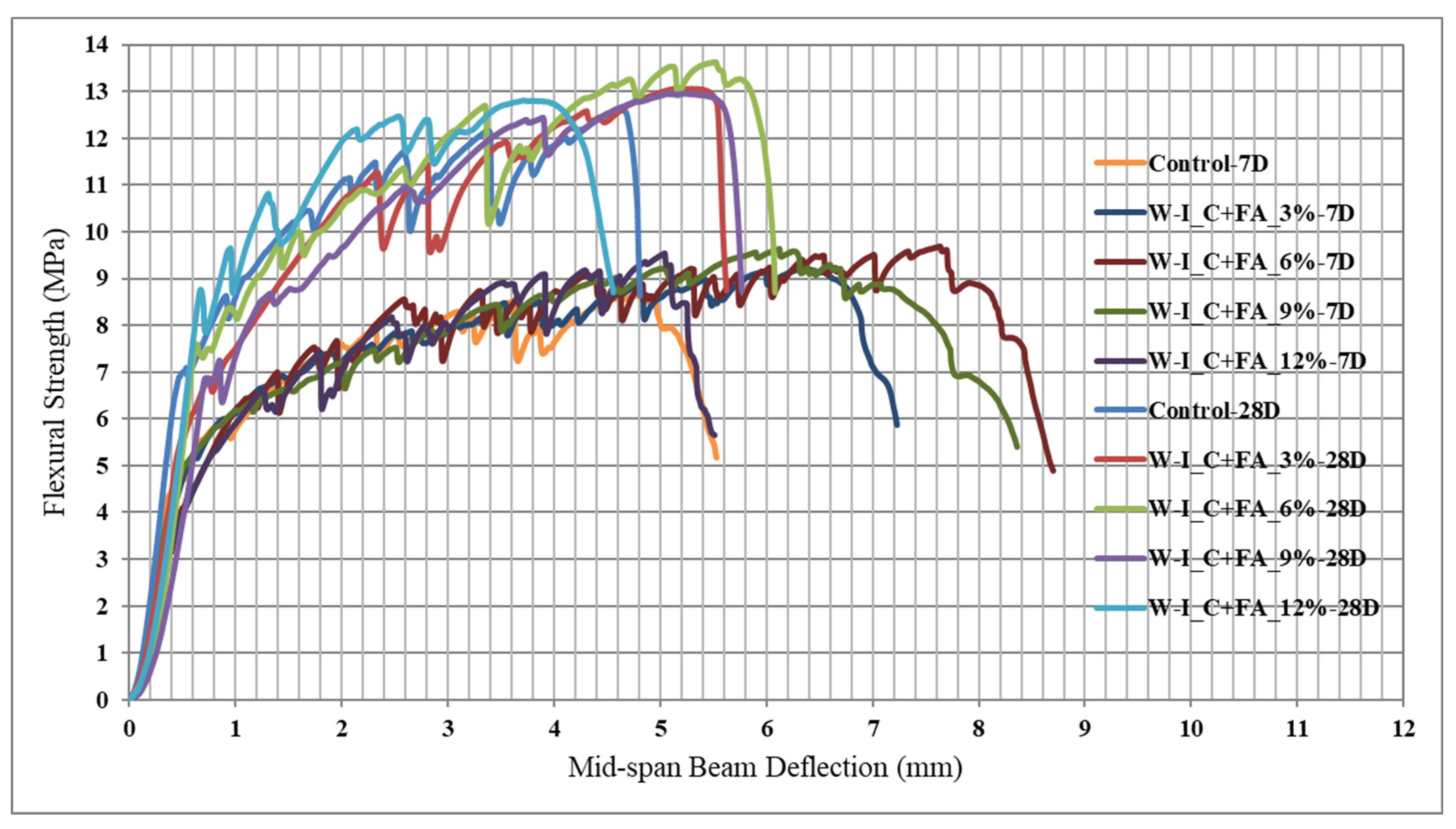

4. Engineered Cementitious Composite (ECC)

5. Geopolymer Concrete

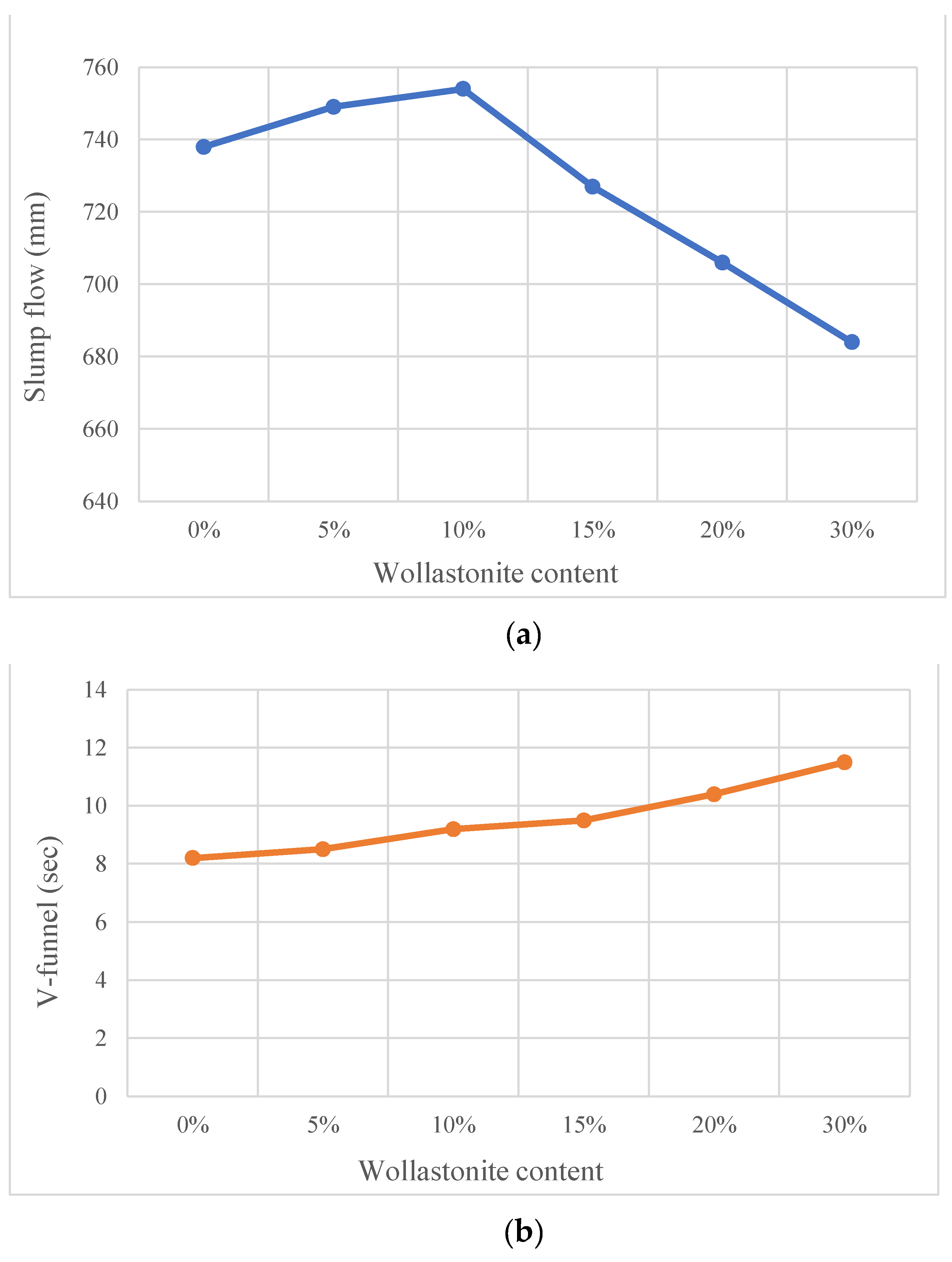

6. Self-Compacting Concrete

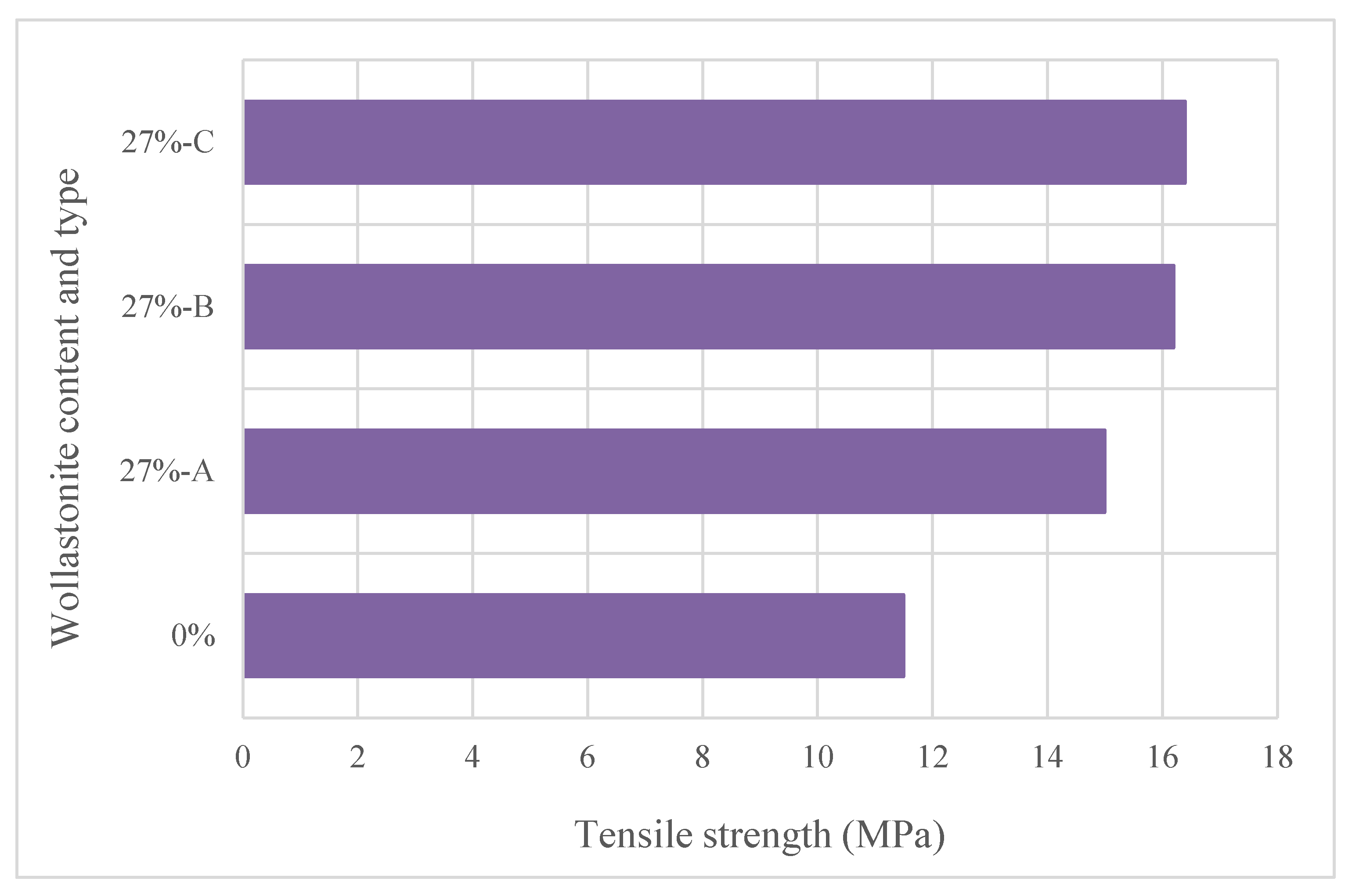

7. Ultra-High-Performance Concrete

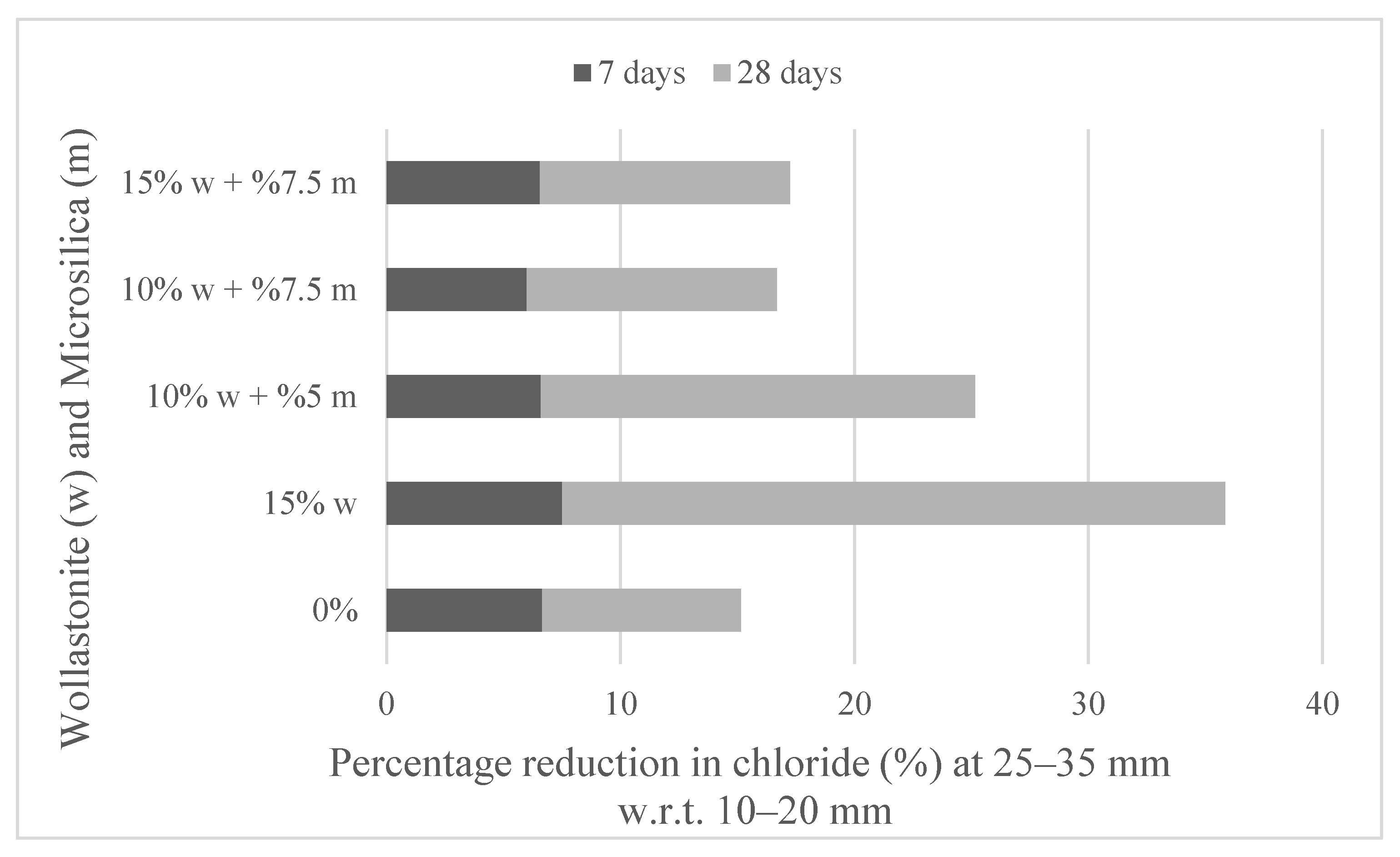

8. Pavement Concrete

9. Conclusions

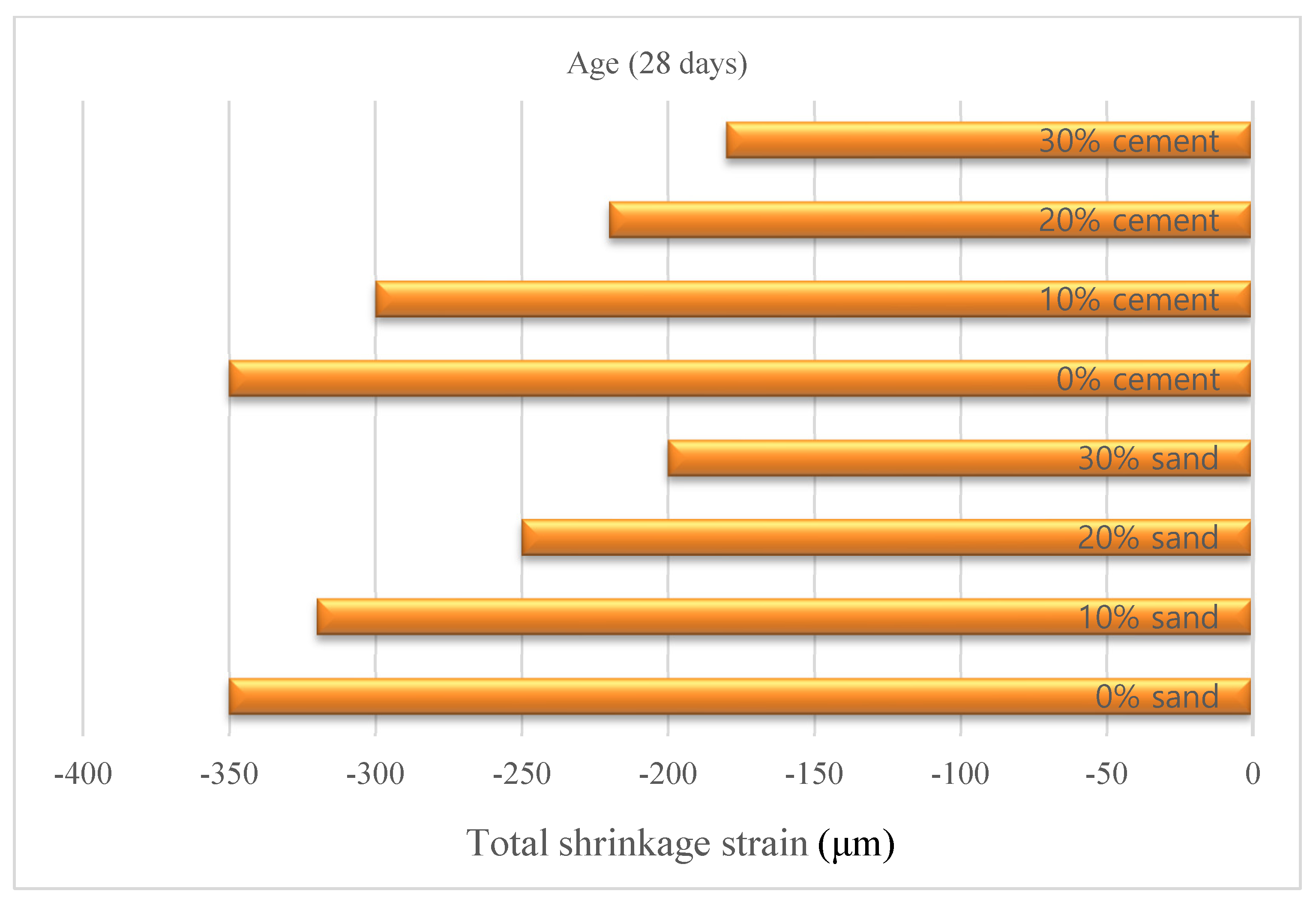

- In the use of cement paste and mortar of wollastonite, rates of 3–10% usage instead of cement demonstrated a positive effect, while this rate increased up to 30% in sand. Wollastonite and different material combinations also provided applicable results. The use of synthetic wollastonite instead of cement by up to 10% for improving the performance characteristics of mortar is crucial for sustainability.

- In the range of 10–15%, use of wollastonite instead of cement enhanced the mechanical and durability properties of conventional concrete. The positive effect of using a combination of fly ash and wollastonite up to 60% was also available in the studies.

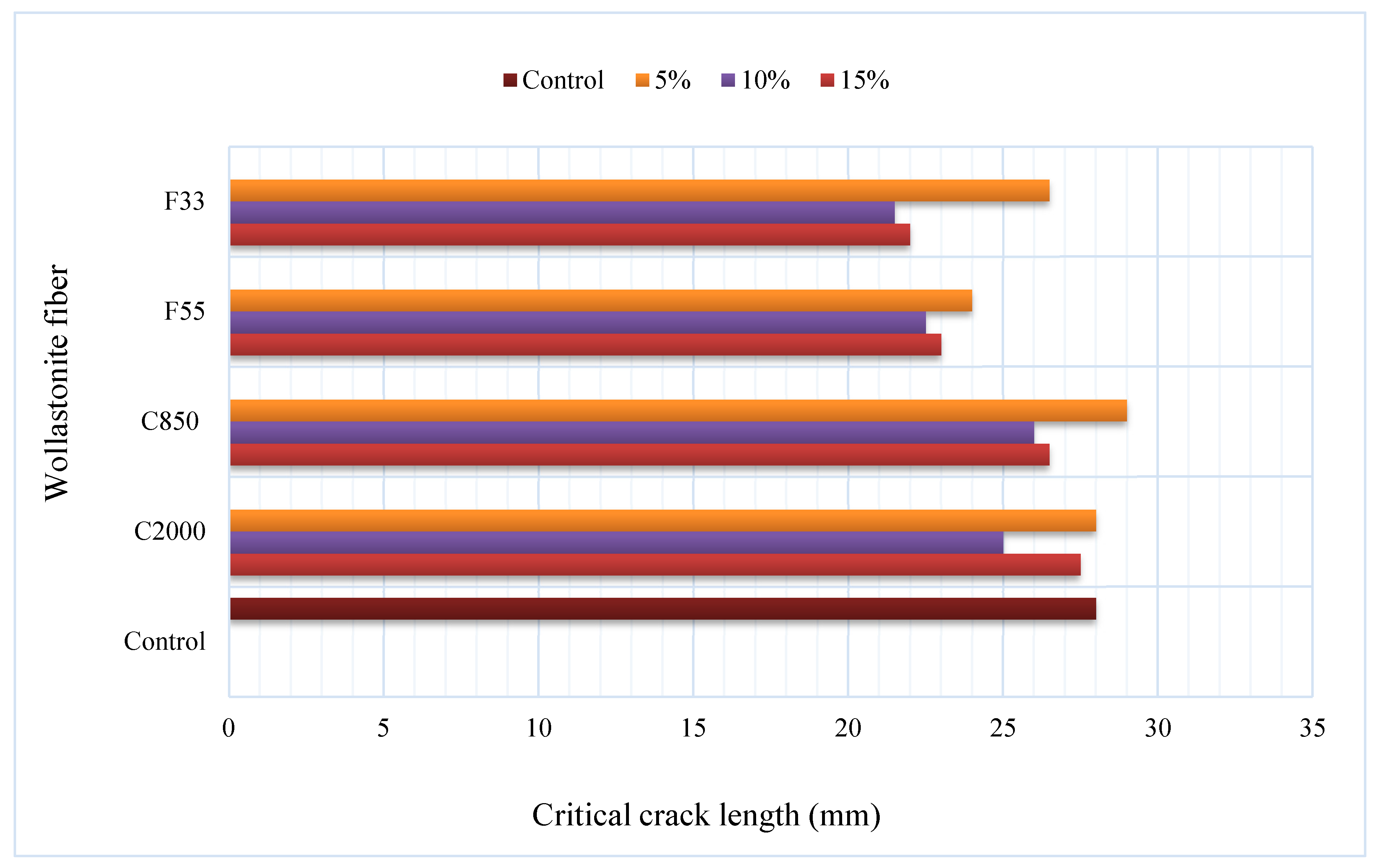

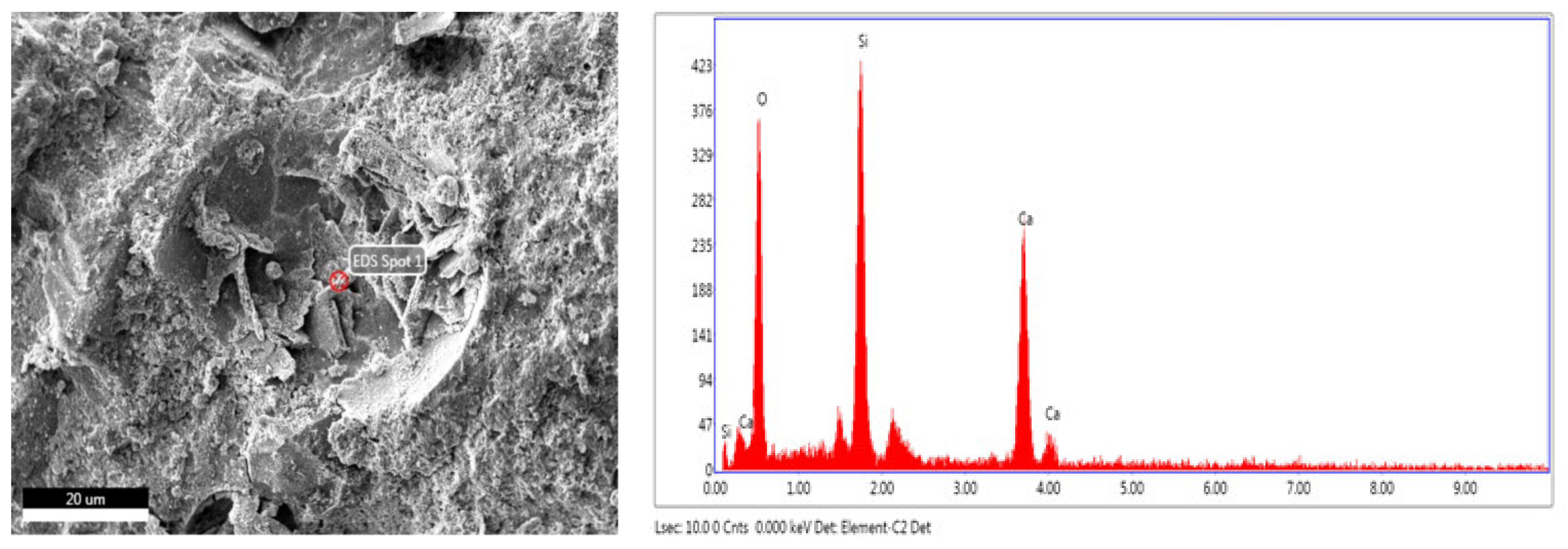

- Superior performance characteristics of engineered cementitious composite (ECC) are further enhanced with wollastonite, and 6% wollastonite substitution was stated as the optimum ratio. In addition, synthetic wollastonite with high aspect ratios of 44:1 and 33:1 was tested. The synthetic wollastonite with an aspect ratio of 44:1 showed better performance than 33:1. The effect of high aspect ratio was observed on ECC.

- Wollastonite was used instead of a precursor and sand in geopolymer concrete. The low mechanical property disadvantage of geopolymer was partially eliminated with the utilization of wollastonite. Strength increases were achieved with the use of 10–20% instead of sand.

- Positive performance properties were obtained from self-compacting concrete produced with wollastonite, both alone and in combination with different materials, up to 30% replacement.

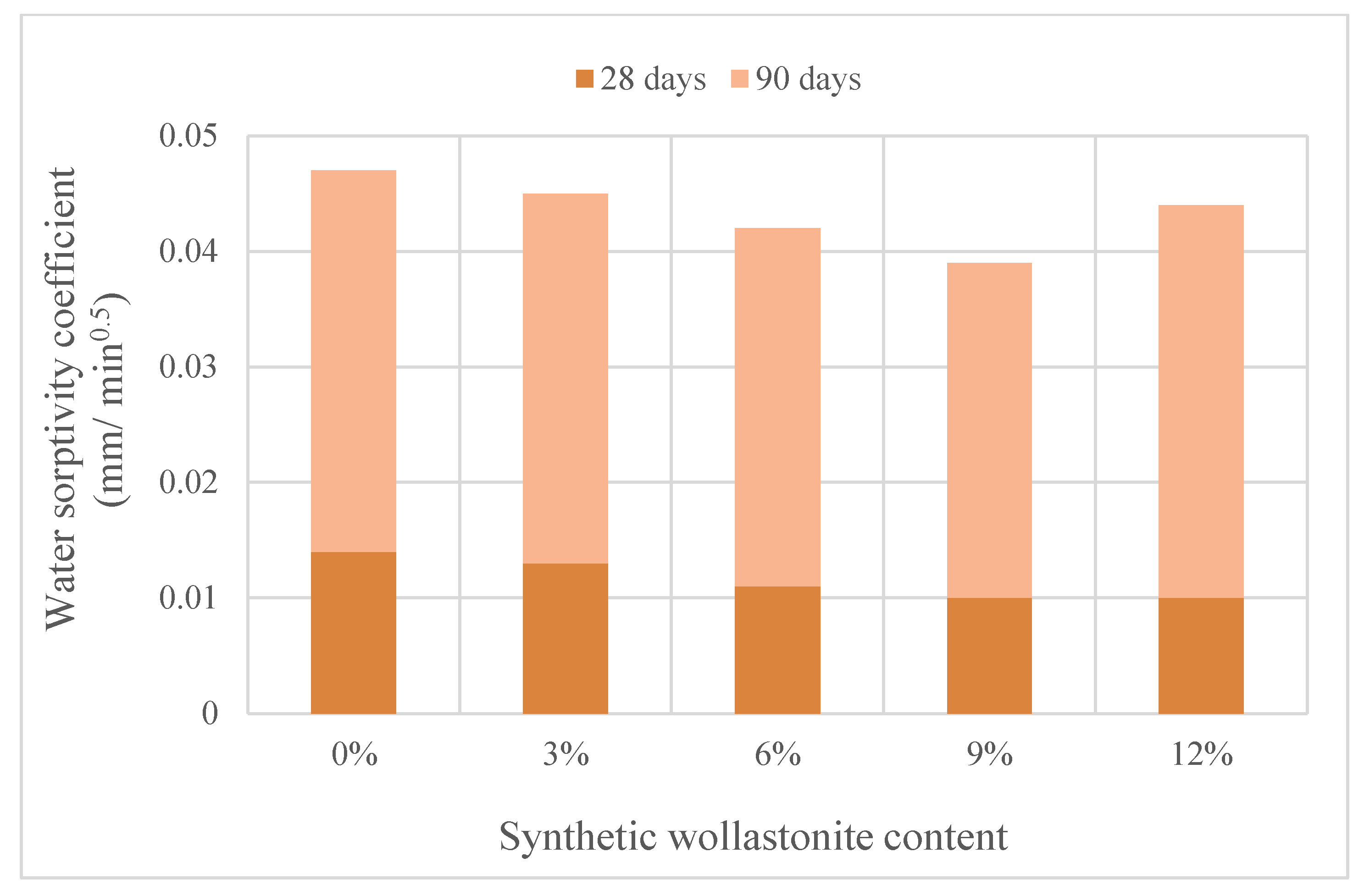

- In ultra-high-performance concrete, the usage of wollastonite 27% instead of sand and up to 12% instead of cement increased the performance properties. Wollastonite can also increase sustainability without losing its performance properties.

- Only wollastonite and different material combinations were tested in pavements. Positive effects were observed in the use of up to 15% wollastonite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Erdoğan, T.Y. Beton; ODTÜ Geliştirme Vakfı Yayıncılık ve İletişim: Ankara, Turkey, 2007. [Google Scholar]

- Bhasya, V.; Bharatkumar, B.H. Mechanical and Durability Properties of Concrete Produced with Treated Recycled Concrete Aggregate. ACI Mater. J. 2018, 115, 209–217. [Google Scholar] [CrossRef]

- Jalil, A.; Khitab, A.; Ishtiaq, H.; Bukhari, S.H.; Arshad, M.T.; Anwar, W. Evaluation of Steel Industrial Slag as Partial Replacement of Cement in Concrete. Civ. Eng. J. 2019, 5, 181–190. [Google Scholar] [CrossRef]

- Arif, R.; Khitab, A.; Kırgız, M.S.; Khan, R.B.N.; Tayyab, S.; Khan, R.A.; Anwar, W.; Arshad, M.T. Experimental Analysis on Partial Replacement of Cement with Brick Powder in Concrete. Case Stud. Constr. Mater. 2021, 15, e00749. [Google Scholar] [CrossRef]

- Kumar Mehta, P.; M Monteiro, P.J. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw Hill: New York, NY, USA, 2017. [Google Scholar]

- Kannan, D.M.; Aboubakr, S.H.; EL-Dieb, A.S.; Reda Taha, M.M. High Performance Concrete Incorporating Ceramic Waste Powder as Large Partial Replacement of Portland Cement. Constr. Build. Mater. 2017, 144, 35–41. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Güneş, M. The Effects of Synthetic Wollastonite Developed with Calcite and Quartz on High Performance Mortars. Struct. Concr. 2021, 22, E257–E272. [Google Scholar] [CrossRef]

- Chen, W.; Liu, W.; Geng, Y.; Ohnishi, S.; Sun, L.; Han, W.; Tian, X.; Zhong, S. Life Cycle Based Emergy Analysis on China’s Cement Production. J. Clean. Prod. 2016, 131, 272–279. [Google Scholar] [CrossRef]

- Huang, H.; Guo, R.; Wang, T.; Hu, X.; Garcia, S.; Fang, M.; Luo, Z.; Maroto-Valer, M.M. Carbonation Curing for Wollastonite-Portland Cementitious Materials: CO2 Sequestration Potential and Feasibility Assessment. J. Clean. Prod. 2019, 211, 830–841. [Google Scholar] [CrossRef]

- Humphreys, K.; Mahasenan, M. Towards a Sustainable Cement Industry: Climate Change; Substudy 8; World Business Council for Sustainable Development (WBCSD): Geneva, Switzerland, 2002. [Google Scholar]

- Mikulčić, H.; Klemeš, J.J.; Vujanović, M.; Urbaniec, K.; Duić, N. Reducing Greenhouse Gasses Emissions by Fostering the Deployment of Alternative Raw Materials and Energy Sources in the Cleaner Cement Manufacturing Process. J. Clean. Prod. 2016, 136, 119–132. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Carbon Footprint Assessment of Residential Buildings, a Review and a Case Study in Turkey. J. Clean. Prod. 2022, 340, 130691. [Google Scholar] [CrossRef]

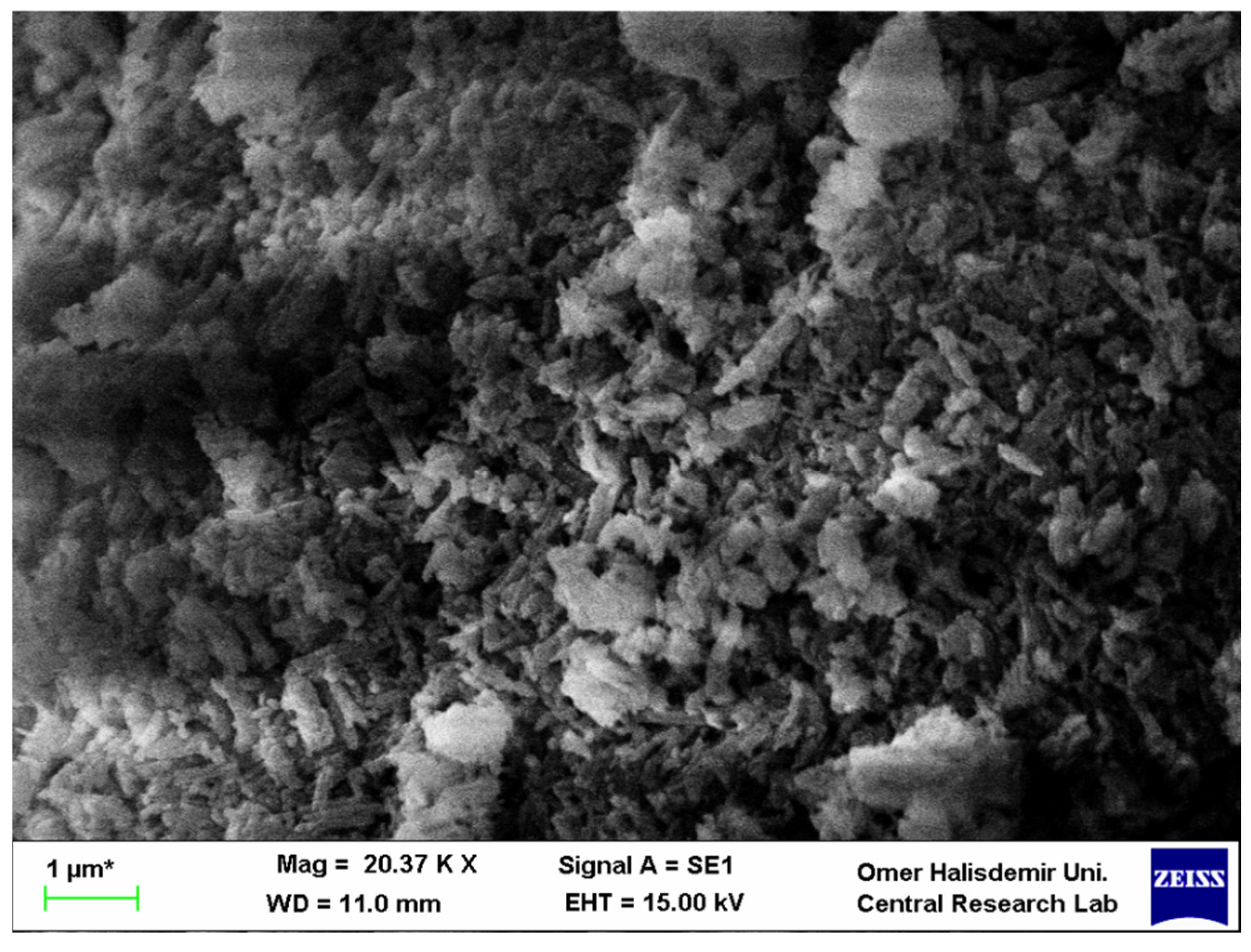

- Yücel, H.E.; Özcan, S. Strength Characteristics and Microstructural Properties of Cement Mortars Incorporating Synthetic Wollastonite Produced with a New Technique. Constr. Build. Mater. 2019, 223, 165–176. [Google Scholar] [CrossRef]

- Nair, N.A.; Sairam, V. Research Initiatives on the Influence of Wollastonite in Cement-Based Construction Material—A Review. J. Clean. Prod. 2021, 283, 124665. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, C.; Zhou, S.; Luo, C. The Self-Gelation Properties of Calcined Wollastonite Powder. Constr. Build. Mater. 2021, 290, 123061. [Google Scholar] [CrossRef]

- Maxim, L.D.; McConnell, E.E. A Review of the Toxicology and Epidemiology of Wollastonite. Inhal. Toxicol. 2008, 17, 451–466. [Google Scholar] [CrossRef]

- Saxena, S.K.; Kumar, M.; Chundawat, D.S.; Singh, N.B. Utilization of Wollastonite in Cement Manufacturing. Mater. Today Proc. 2020, 29, 733–737. [Google Scholar] [CrossRef]

- Ahmad, F.; Ullah, S.; Oñate, E.; Al-Sehemi, A.G.; Yeoh, G.H. An Investigation on Thermal Performance of Wollastonite and Bentonite Reinforced Intumescent Fire-Retardant Coating for Steel Structures. Constr. Build. Mater. 2019, 228, 116734. [Google Scholar] [CrossRef]

- Paul, F.K. Mineral Descriptions-Wollastonite, Optical Mineralogy, 4th ed.; McGraw Hill: New York, NY, USA, 1977. [Google Scholar]

- Ransinchung RN, G.D.; Kumar, B. Investigations on Pastes and Mortars of Ordinary Portland Cement Admixed with Wollastonite and Microsilica. J. Mater. Civ. Eng. 2010, 22, 305–313. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of Natural Wollastonite Microfibers on Early-Age Behavior of UHPC. J. Mater. Civ. Eng. 2012, 24, 816–824. [Google Scholar] [CrossRef]

- Harabi, A.; Chehlatt, S. Preparation Process of a Highly Resistant Wollastonite Bioceramics Using Local Raw Materials: Effect of B2O3 Additions on Sintering and Mechanical Properties. J. Therm. Anal. Calorim. 2013, 111, 203–211. [Google Scholar] [CrossRef]

- Obeid, M.; Mont, M.; Schneider, J.; Rodrigues, A.; Obeid, M.M. Crystallization of Synthetic Wollastonite Prepared from Local Raw Materials. Int. J. Mater. Chem. 2014, 4, 79–87. [Google Scholar] [CrossRef]

- Shamsudin, R.; ’Atiqah Abdul Azam, F.; Abdul Hamid, M.A.; Ismail, H. Bioactivity and Cell Compatibility of β-Wollastonite Derived from Rice Husk Ash and Limestone. Materials 2017, 10, 1188. [Google Scholar] [CrossRef]

- He, Z.; Shen, A.; Lyu, Z.; Li, Y.; Wu, H.; Wang, W. Effect of Wollastonite Microfibers as Cement Replacement on the Properties of Cementitious Composites: A Review. Constr. Build. Mater. 2020, 261, 119920. [Google Scholar] [CrossRef]

- Low, N.M.P.; Beaudoin, J.J. Flexural Strength and Microstructure of Cement Binders Reinforced with Wollastonite Micro-Fibres. Cem. Concr. Res. 1993, 23, 905–916. [Google Scholar] [CrossRef]

- Ransinchung, G.D.; Kumar, B.; Kumar, V. Assessment of Water Absorption and Chloride Ion Penetration of Pavement Quality Concrete Admixed with Wollastonite and Microsilica. Constr. Build. Mater. 2009, 23, 1168–1177. [Google Scholar] [CrossRef]

- Dey, V.; Kachala, R.; Bonakdar, A.; Mobasher, B. Mechanical Properties of Micro and Sub-Micron Wollastonite Fibers in Cementitious Composites. Constr. Build. Mater. 2015, 82, 351–359. [Google Scholar] [CrossRef]

- Kalkan, Ş.O.; Yavaş, A.; Güler, S.; Torman Kayalar, M.; Sütçü, M.; Gündüz, L. An Experimental Approach to a Cementitious Lightweight Composite Mortar Using Synthetic Wollastonite. Constr. Build. Mater. 2022, 341, 127911. [Google Scholar] [CrossRef]

- Vichaphund, S.; Kitiwan, M.; Atong, D.; Thavorniti, P. Microwave Synthesis of Wollastonite Powder from Eggshells. J. Eur. Ceram. Soc. 2011, 31, 2435–2440. [Google Scholar] [CrossRef]

- Emrullahoǧlu, S.B.; Emrullahoǧlu, C.B.; Emrullahoǧlu, Ö.F. Syntetic Wollastonite Production from Raw and Tailing Materials. Key Eng. Mater. 2004, 264–268, 2485–2488. [Google Scholar] [CrossRef]

- Kalla, P.; Rana, A.; Chad, Y.B.; Misra, A.; Csetenyi, L. Durability Studies on Concrete Containing Wollastonite. J. Clean. Prod. 2015, 87, 726–734. [Google Scholar] [CrossRef]

- Yücel, H.E.; Öz, H.Ö.; Güneş, M.; Kaya, Y. Rheological Properties, Strength Characteristics and Flexural Performances of Engineered Cementitious Composites Incorporating Synthetic Wollastonite Microfibers with Two Different High Aspect Ratios. Constr. Build. Mater. 2021, 306, 124921. [Google Scholar] [CrossRef]

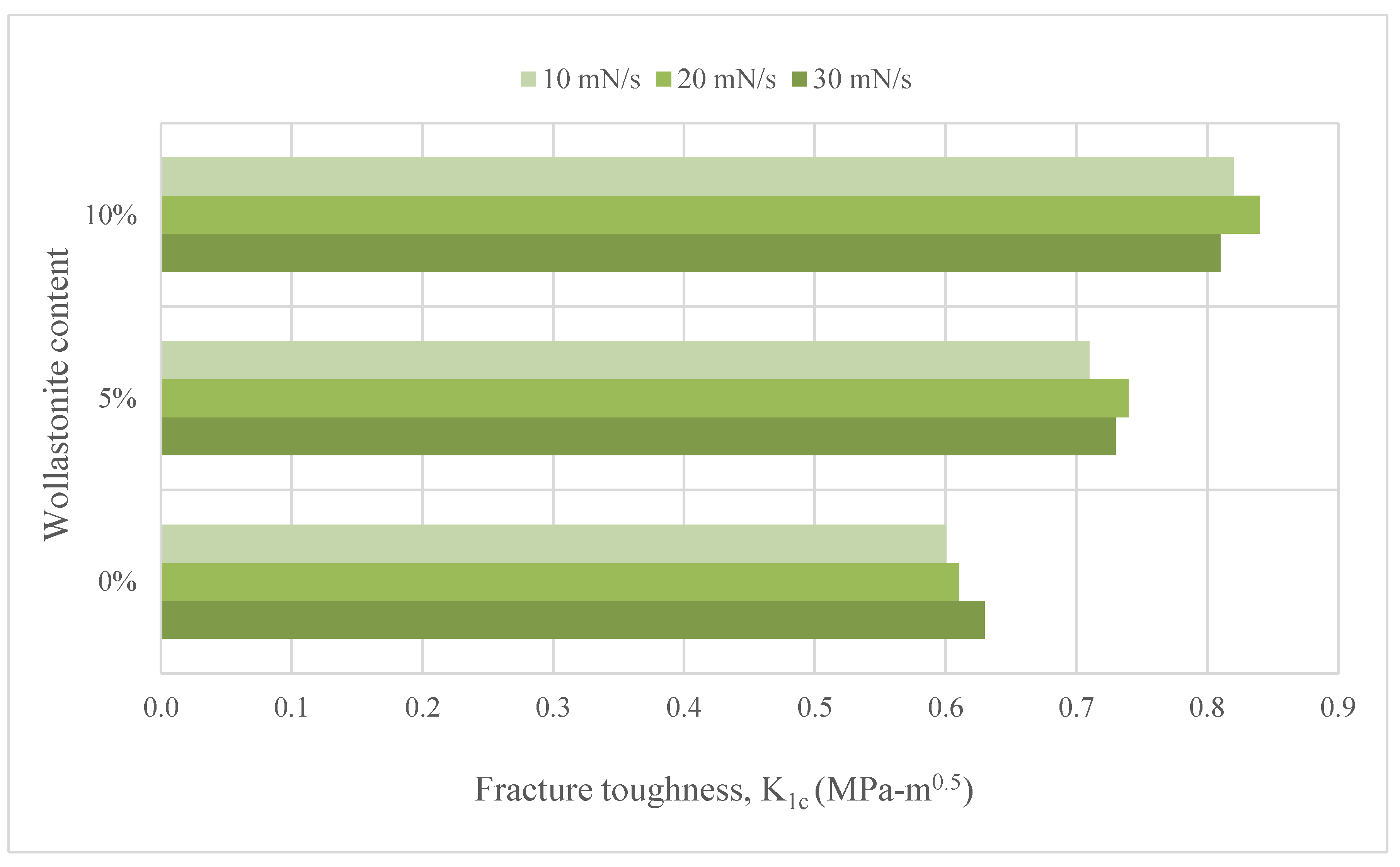

- Doner, S.; Lyngdoh, G.A.; Nayak, S.; Das, S. Fracture Response of Wollastonite Fiber-Reinforced Cementitious Composites: Evaluation Using Micro-Indentation and Finite Element Simulation. Ceram. Int. 2022, 48, 15493–15503. [Google Scholar] [CrossRef]

- Öz, H.Ö.; Yücel, H.E.; Güneş, M.; Malkoç, B. The Effects on High Performance Mortars of Natural Wollastonite. NOHU J. Eng. Sci. 2020, 9, 966–974. [Google Scholar] [CrossRef]

- Khan, R.I.; Ashraf, W. Effects of Ground Wollastonite on Cement Hydration Kinetics and Strength Development. Constr. Build. Mater. 2019, 218, 150–161. [Google Scholar] [CrossRef]

- Abdel Wahab, M.; Abdel Latif, I.; Kohail, M.; Almasry, A. The Use of Wollastonite to Enhance the Mechanical Properties of Mortar Mixes. Constr. Build. Mater. 2017, 152, 304–309. [Google Scholar] [CrossRef]

- Leemann, A.; Winnefeld, F.; Münch, B.; Läng, F. Carbonated Wollastonite—An Effective Supplementary Cementitious Material? J. Microsc. 2022, 286, 120–125. [Google Scholar] [CrossRef] [PubMed]

- Mathur, R.; Misra, A.K.; Goel, P.; Mathur, R.; Misra, A.K.; Goel, P. Influence of Wollastonite on Mechanical Properties of Concrete. J. Sci. Ind. Res. 2007, 66, 1029–1034. [Google Scholar]

- Kh, K. Research of Light-Weight Concrete Properties on Base Wollastonite Addition. Middle Eur. Sci. Bull. 2021, 8. [Google Scholar] [CrossRef]

- Aziza, K.; Kh, K.; Aziza, K. Durability Characteristics of Concrete Admixed with Wollastonite Mineral. Eur. J. Life Saf. Stab. 2021, 5, 9–13. [Google Scholar]

- Kuldasheva, A.; Saidmuratov, B.; Kuldashev, H. The Use of Wollastonite Fiber to Enhance the Mechanical Properties of Cement Compositions. Int. J. Progress. Sci. Technol. 2020, 22, 37–45. [Google Scholar]

- Kalla, P.; Misra, A.; Gupta, R.C.; Csetenyi, L.; Gahlot, V.; Arora, A. Mechanical and Durability Studies on Concrete Containing Wollastonite-Fly Ash Combination. Constr. Build. Mater. 2013, 40, 1142–1150. [Google Scholar] [CrossRef]

- Kumar Mandrawalia, A.; Gaur, A. Compressive and Sorptivity Characteristic of Concrete Modified with Wollastonite Fibre and Waste Granite Fines. Mater. Today Proc. 2021, 42, 1012–1016. [Google Scholar] [CrossRef]

- Atiş, C.D.; Görür, E.B.; Karahan, O.; Bilim, C.; Ilkentapar, S.; Luga, E. Very High Strength (120 MPa) Class F Fly Ash Geopolymer Mortar Activated at Different NaOH Amount, Heat Curing Temperature and Heat Curing Duration. Constr. Build. Mater. 2015, 96, 673–678. [Google Scholar] [CrossRef]

- Choi, Y.C.; Park, B. Effects of High-Temperature Exposure on Fractal Dimension of Fly-Ash-Based Geopolymer Composites. J. Mater. Res. Technol. 2020, 9, 7655–7668. [Google Scholar] [CrossRef]

- Hemalatha, P.; Ramujee, K. Influence of Nano Material (TiO2) on Self Compacting Geo Polymer Concrete Containing Flyash, GGBS and Wollastonite. Mater. Today Proc. 2021, 43, 2438–2442. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J. Properties of One-Part Geopolymer Incorporating Wollastonite as Partial Replacement of Geopolymer Precursor or Sand. Mater. Lett. 2020, 263, 127236. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Ghaffar, S.H.; Pan, J.; Dai, J.G. Properties of Additively Manufactured Geopolymer Incorporating Mineral Wollastonite Microfibers. Constr. Build. Mater. 2022, 331, 127282. [Google Scholar] [CrossRef]

- Ren, D.; Yan, C.; Duan, P.; Zhang, Z.; Li, L.; Yan, Z. Durability Performances of Wollastonite, Tremolite and Basalt Fiber-Reinforced Metakaolin Geopolymer Composites under Sulfate and Chloride Attack. Constr. Build. Mater. 2017, 134, 56–66. [Google Scholar] [CrossRef]

- Guo, L.; Wu, Y.; Xu, F.; Song, X.; Ye, J.; Duan, P.; Zhang, Z. Sulfate Resistance of Hybrid Fiber Reinforced Metakaolin Geopolymer Composites. Compos. Part B Eng. 2020, 183, 107689. [Google Scholar] [CrossRef]

- Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Influence of the Wollastonite and Glass Fibers on Geopolymer Composites Workability and Mechanical Properties. Constr. Build. Mater. 2020, 257, 119511. [Google Scholar] [CrossRef]

- Vishnu, N.; Kolli, R.; Ravella, D.P. Studies on Self-Compacting Geopolymer Concrete Containing Flyash, GGBS, Wollastonite and Graphene Oxide. Mater. Today Proc. 2021, 43, 2422–2427. [Google Scholar] [CrossRef]

- Jindal, A.; Ransinchung, R.N.G.D.; Kumar, P. Behavioral Study of Self-Compacting Concrete with Wollastonite Microfiber as Part Replacement of Sand for Pavement Quality Concrete (PQC). Int. J. Transp. Sci. Technol. 2020, 9, 170–181. [Google Scholar] [CrossRef]

- Gouse Mohiuddin, M.D.; Malagavelli, V.; kumar Balguri, P. Influence of Wollastonite-GGBS on Properties of Ternary Blended Self Compacting Concrete. Mater. Today Proc. 2022, 62, 3027–3032. [Google Scholar] [CrossRef]

- Sharma, S.K. Properties of SCC Containing Pozzolans, Wollastonite Micro Fiber, and Recycled Aggregates. Heliyon 2019, 5, e02081. [Google Scholar] [CrossRef]

- Kwon, S.; Nishiwaki, T.; Choi, H.; Mihashi, H. Effect of Wollastonite Microfiber on Ultra-High-Performance Fiber-Reinforced Cement-Based Composites Based on Application of Multi-Scale Fiber-Reinforcement System. J. Adv. Concr. Technol. 2015, 13, 332–344. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effects of Shrinkage Reducing Admixture and Wollastonite Microfiber on Early-Age Behavior of Ultra-High Performance Concrete. Cem. Concr. Compos. 2014, 46, 81–89. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Shoaei, P.; Bahrami, N. Recycled Ceramic Waste High Strength Concrete Containing Wollastonite Particles and Micro-Silica: A Comprehensive Experimental Study. Constr. Build. Mater. 2019, 201, 11–32. [Google Scholar] [CrossRef]

- Ransinchung, G.D.; Kumar, P.N. Laboratory Study on Use of Wollastonite Micro-Fibers for Abrasion Resistance of Pavement Quality Concrete. In Proceedings of the International Conference on Engineering and Information Technology “ICEIT2012”, Toronto, ON, Canada, 17–18 September 2012. [Google Scholar]

- Kumar, R. Wollastonite Mineral Fibre in Manufacturing of an Economical Pavement Concrete. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

| Chemical Analysis (%) | Wollastonite |

|---|---|

| CaO | 44.55 |

| SiO2 | 50.78 |

| Al2O3 | 0.83 |

| Fe2O3 | 0.17 |

| MgO | 0.47 |

| SO3 | 0.04 |

| K2O | 0.001 |

| Na2O | 0.363 |

| TiO2 | 0.49 |

| Mix | W/b Ratio | OPC | * WF | CA | FA | * WGF | Water | * SPDosage % |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.35 | 425 | 0 | 1298 | 628 | 0 | 148.75 | 1.25 |

| 2 | 0.35 | 382.5 | 42.5 | 1298 | 565.2 | 62.8 | 148.75 | 1.3 |

| 3 | 0.35 | 382.5 | 42.5 | 1298 | 502.4 | 125.6 | 148.75 | 1.5 |

| 4 | 0.35 | 382.5 | 42.5 | 1298 | 439.6 | 188.4 | 148.75 | 1.65 |

| 5 | 0.35 | 382.5 | 42.5 | 1298 | 376.8 | 251.2 | 148.75 | 1.9 |

| 6 | 0.35 | 382.5 | 42.5 | 1298 | 314 | 314 | 148.75 | 2.1 |

| Study in Literature | Wollastonite Replacement | Effect of Wollastonite |

|---|---|---|

| [34] | 5–10% instead of cement | Increment about 34% fracture toughness |

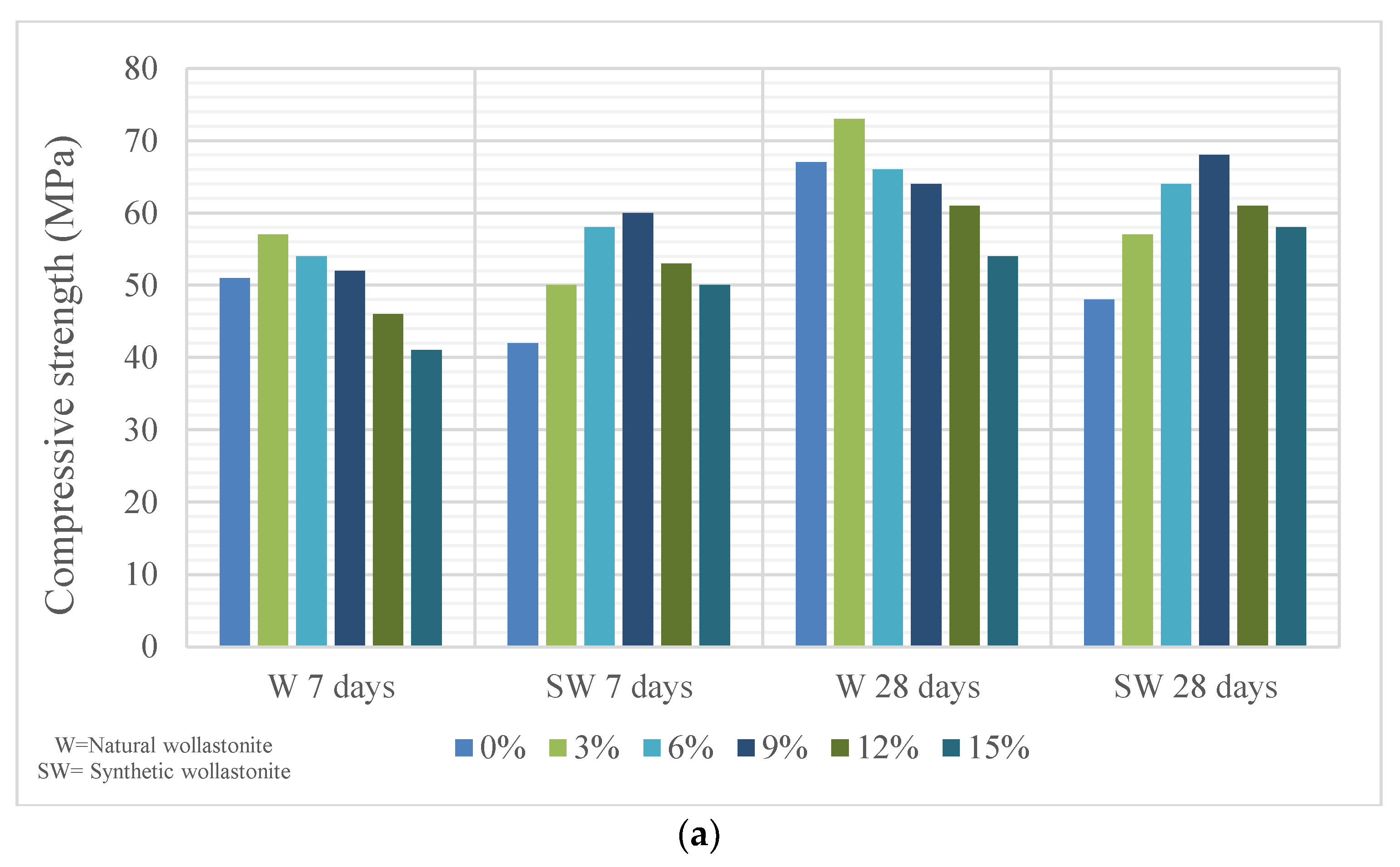

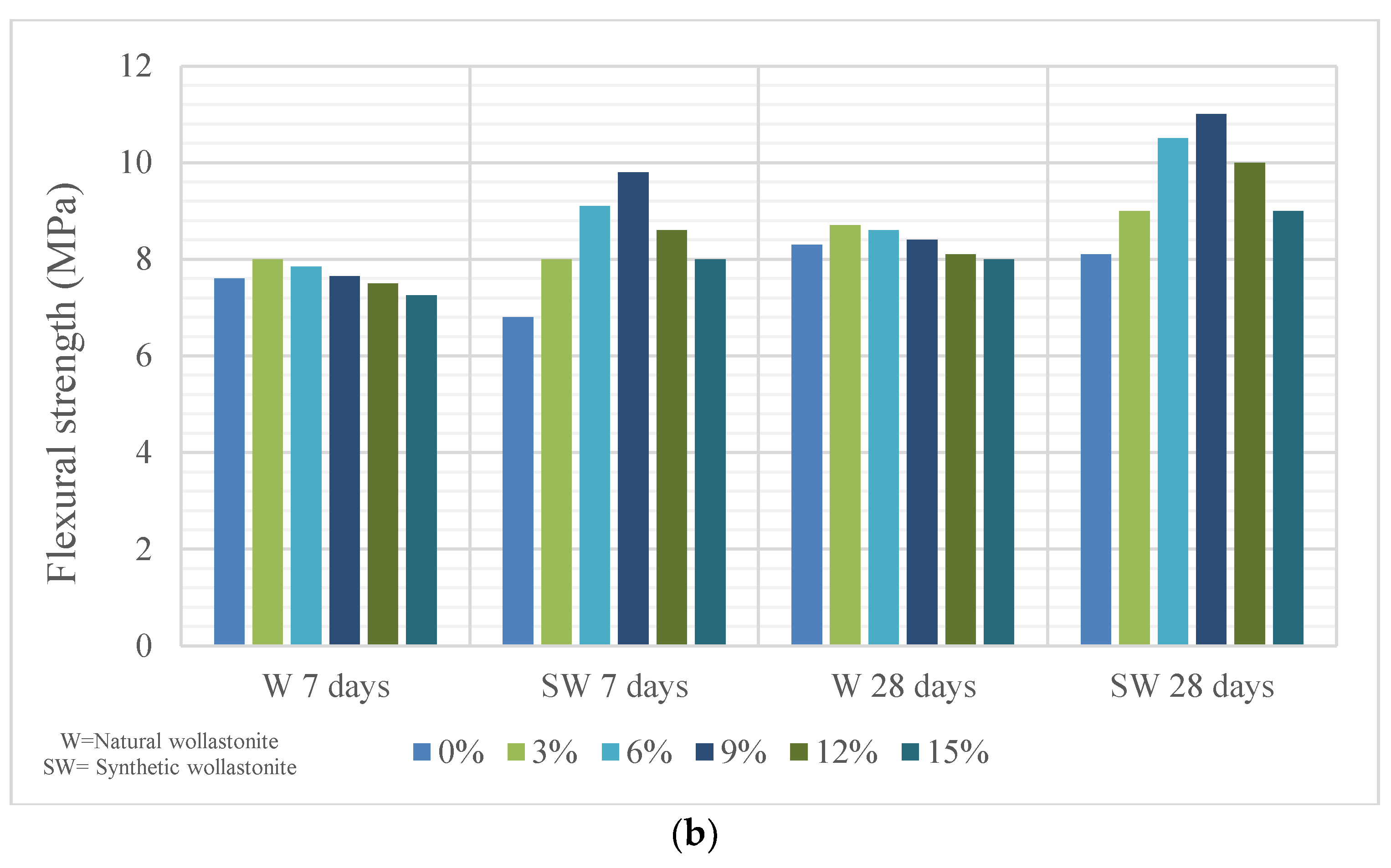

| [35] | 0–15% instead of cement | Increment about 12% compressive and increment about 6% flexural strength |

| [36] | 0–50% instead of cement | Decrease in workability and increment in cement hydration |

| [28] | 5–15% instead of cement | Increment in crack growth resistance and ductility |

| [37] | 10–30% instead of cement and sand | Increment in initial setting time and decrease about 47% drying shrinkage |

| [7] | 0–12% instead of cement (synthetic wollastonite) | Increment about 8% compressive and increment about 11% flexural strength; decrease about 15% water sorptivity coefficient, about 4% rapid chloride permeability and about 25% gas permeability |

| [32] | 0–25% instead of cement | Decrease in porosity, water permeability, chloride diffusion and carbonation depth |

| [43] | 0–25% instead of cement | Increment in resistance against corrosion |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dutkiewicz, M.; Yücel, H.E.; Yıldızhan, F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials 2022, 15, 6904. https://doi.org/10.3390/ma15196904

Dutkiewicz M, Yücel HE, Yıldızhan F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials. 2022; 15(19):6904. https://doi.org/10.3390/ma15196904

Chicago/Turabian StyleDutkiewicz, Maciej, Hasan Erhan Yücel, and Fatih Yıldızhan. 2022. "Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite" Materials 15, no. 19: 6904. https://doi.org/10.3390/ma15196904

APA StyleDutkiewicz, M., Yücel, H. E., & Yıldızhan, F. (2022). Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials, 15(19), 6904. https://doi.org/10.3390/ma15196904