Strength Characteristics of Electrospun Coconut Fibre Reinforced Polylactic Acid: Experimental and Representative Volume Element (RVE) Prediction

Abstract

1. Introduction

2. Experimental and Representative Volume Element (RVE) Methodology

2.1. Materials

2.2. Processing the Coconut Fibre

2.3. PLA-Coconut Solution

2.4. Electro Spinning of the CCP Reinforced Poly Lactide Nanocomposite Fibres

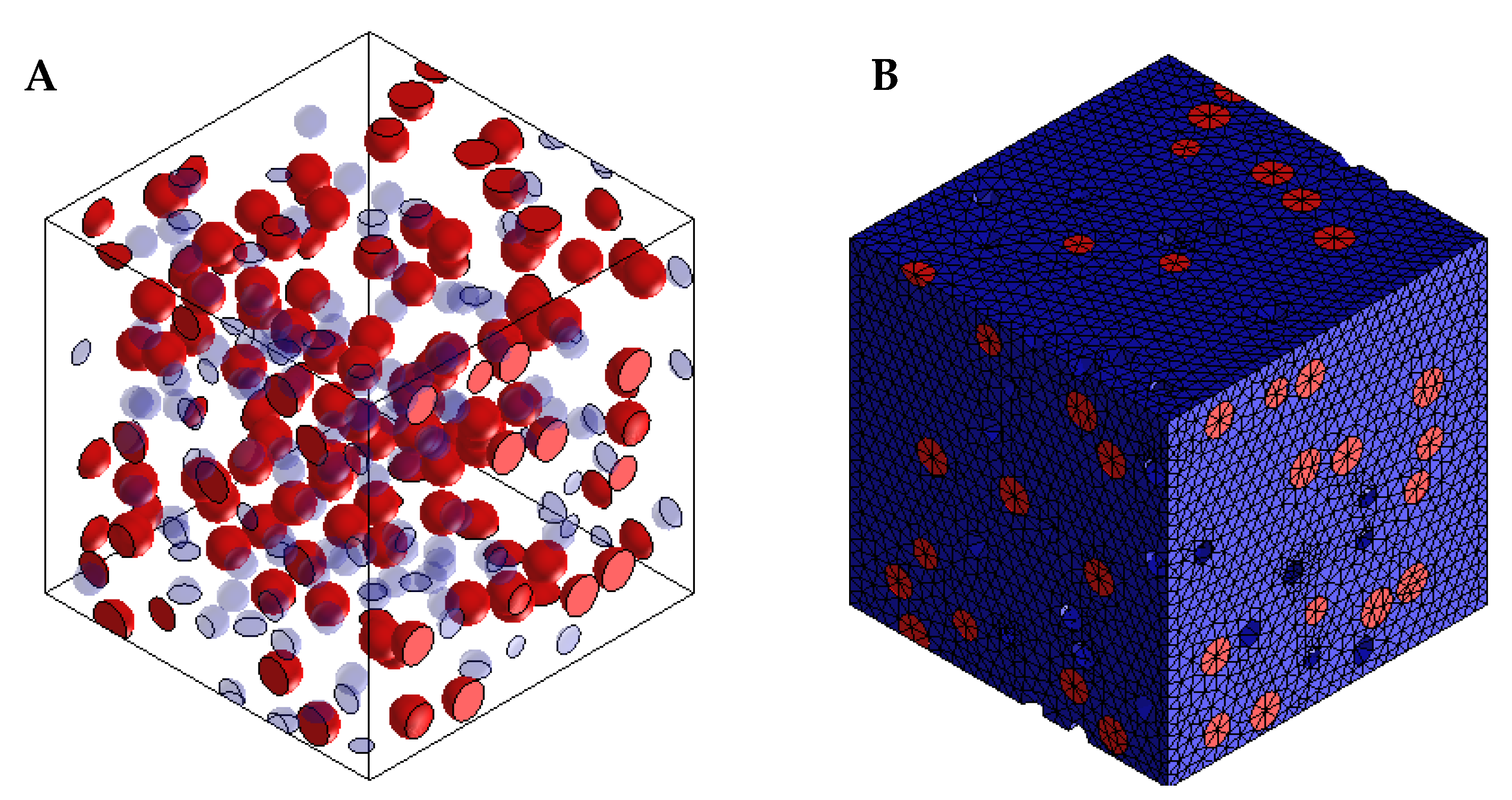

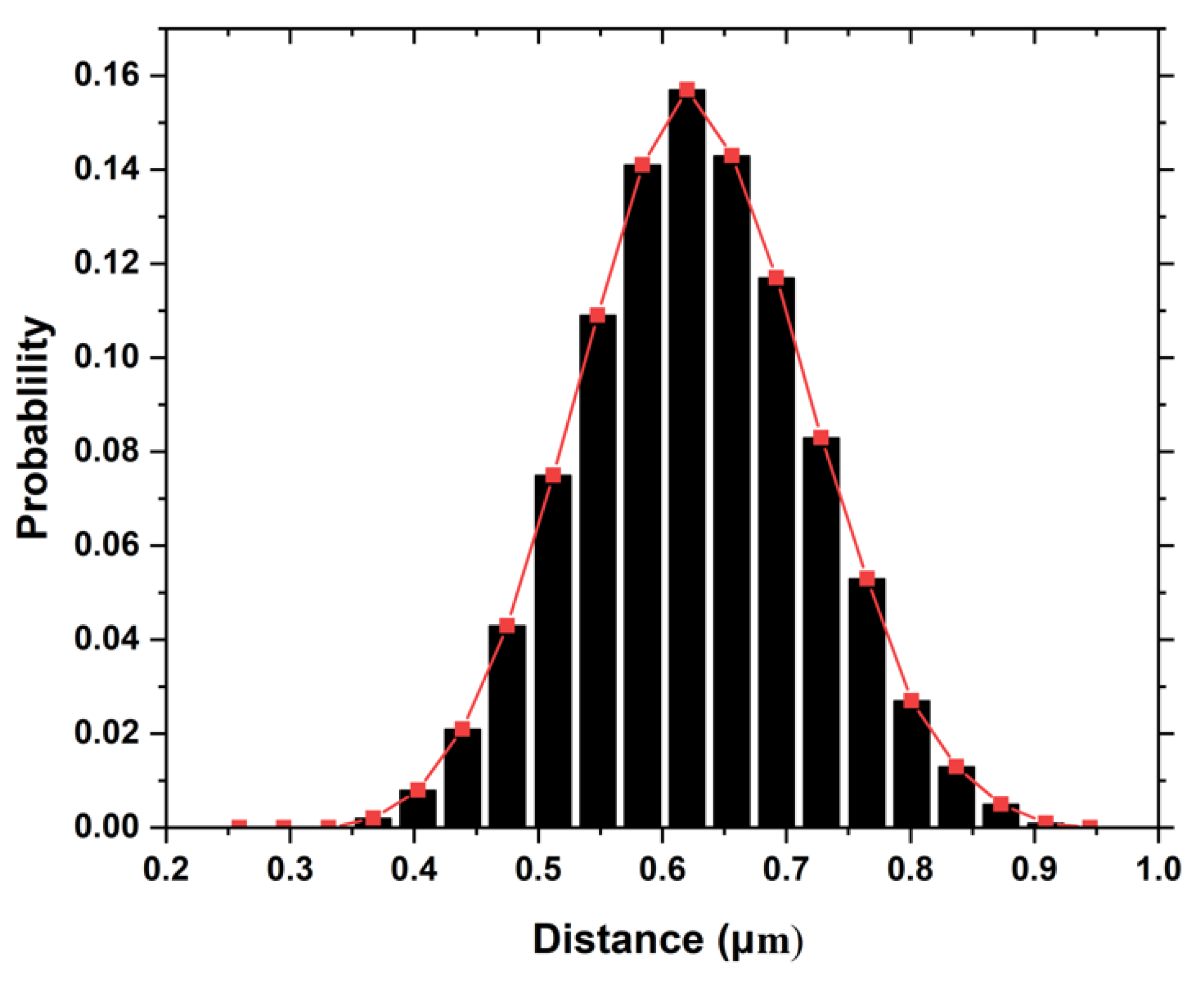

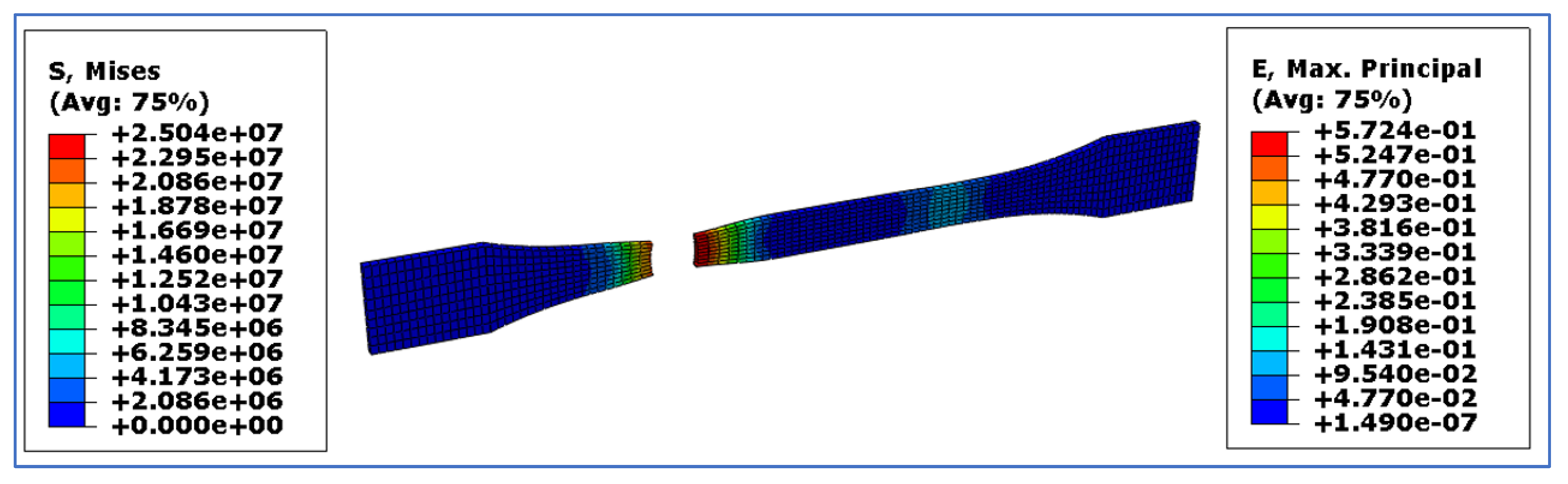

2.5. Representative Volume Element Methodology

2.6. Mechanical Test

2.7. Morphological Examination

2.8. Water Absorption (Apparent Porosity)

3. Results and Discussion

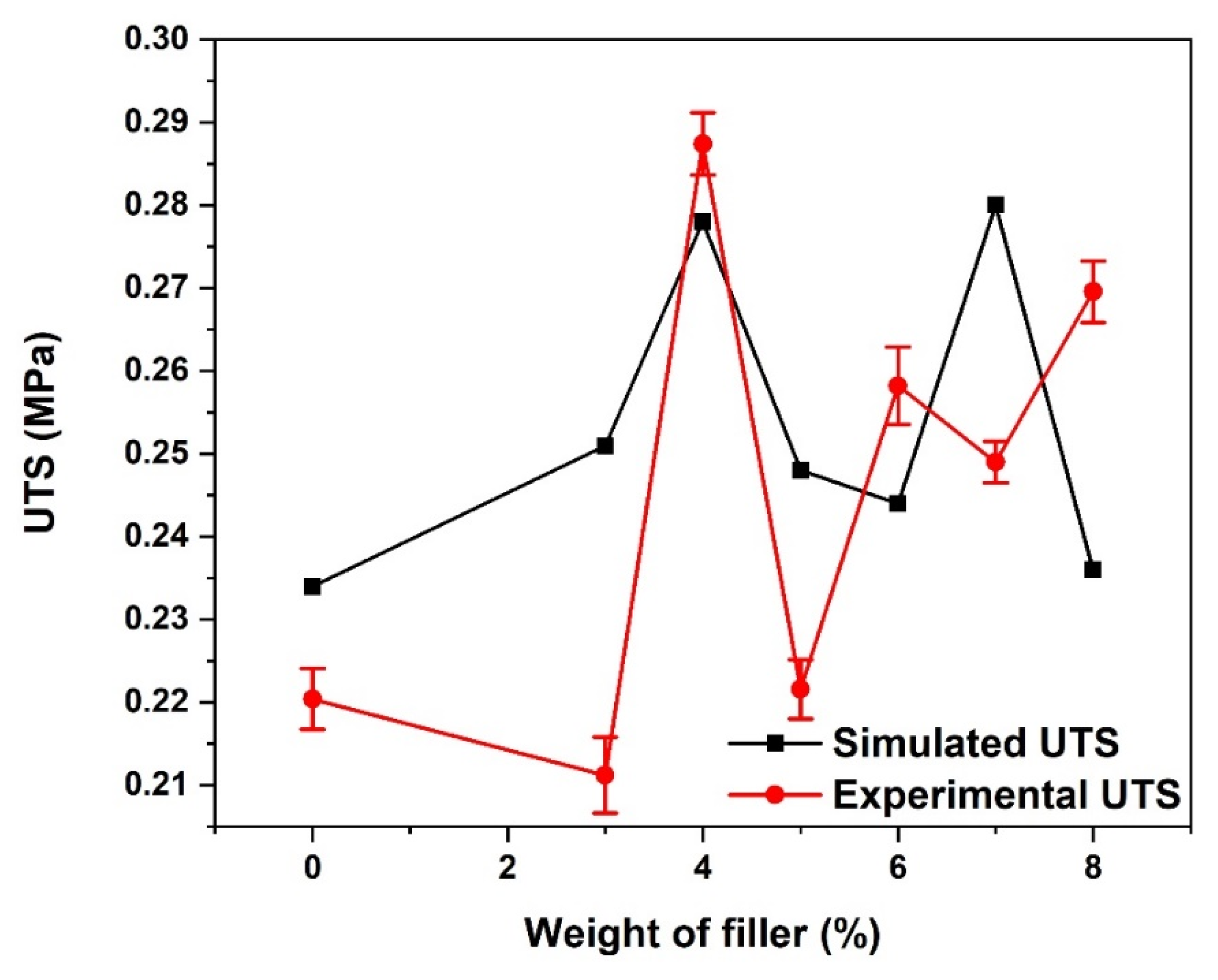

3.1. Ultimate Tensile Strength

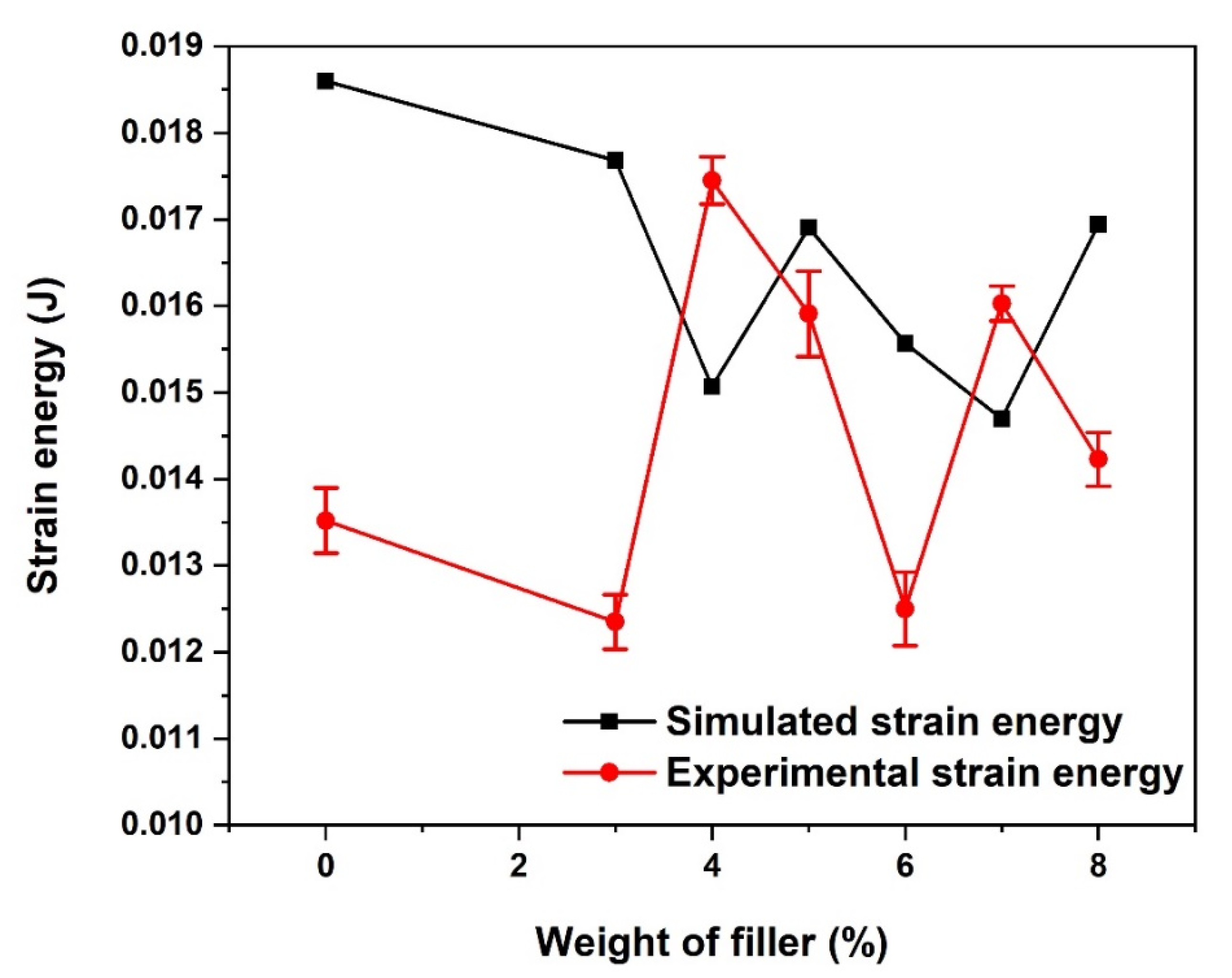

3.2. Tensile Energy-at-Break

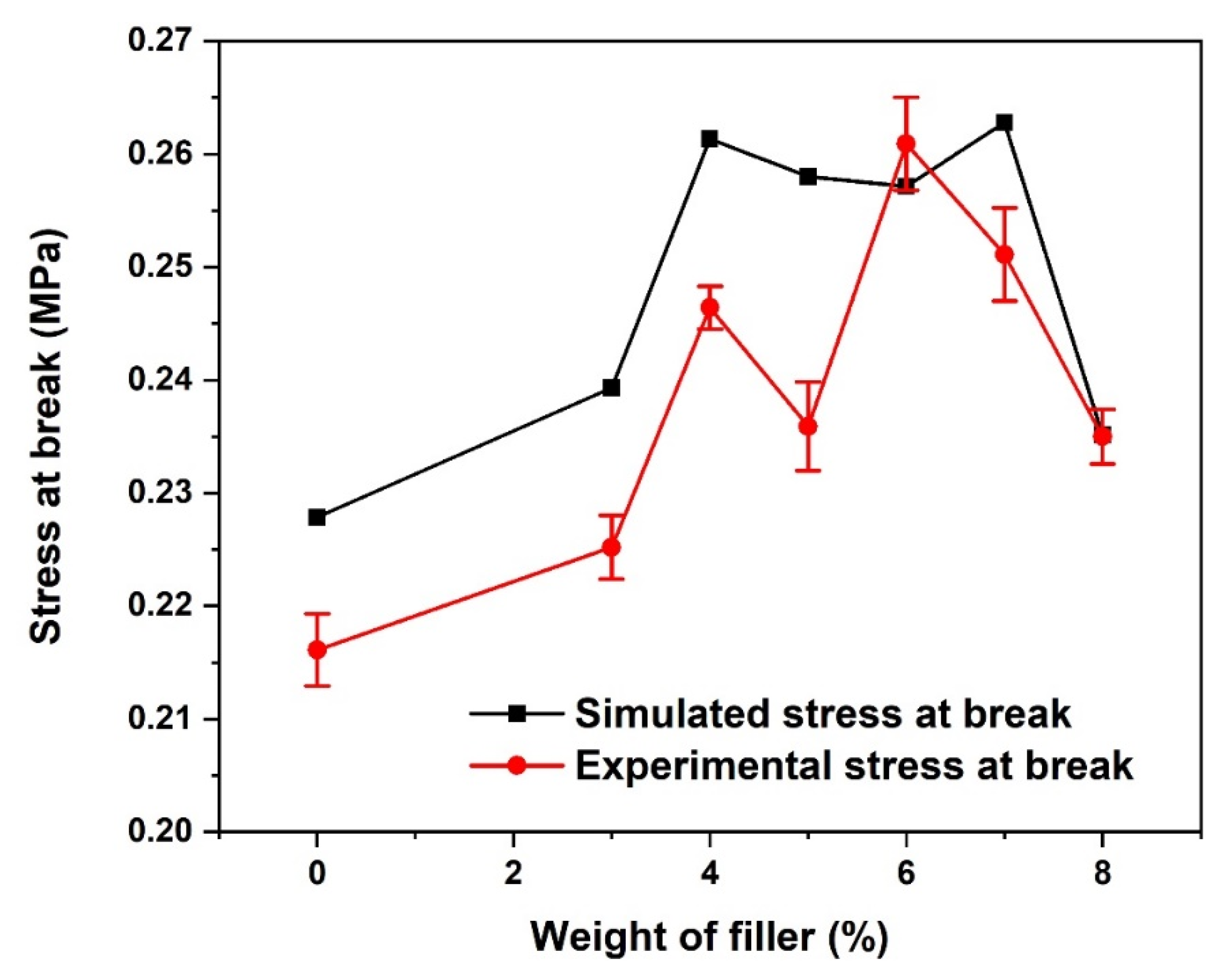

3.3. Stress-at-Break

3.4. Young Modulus

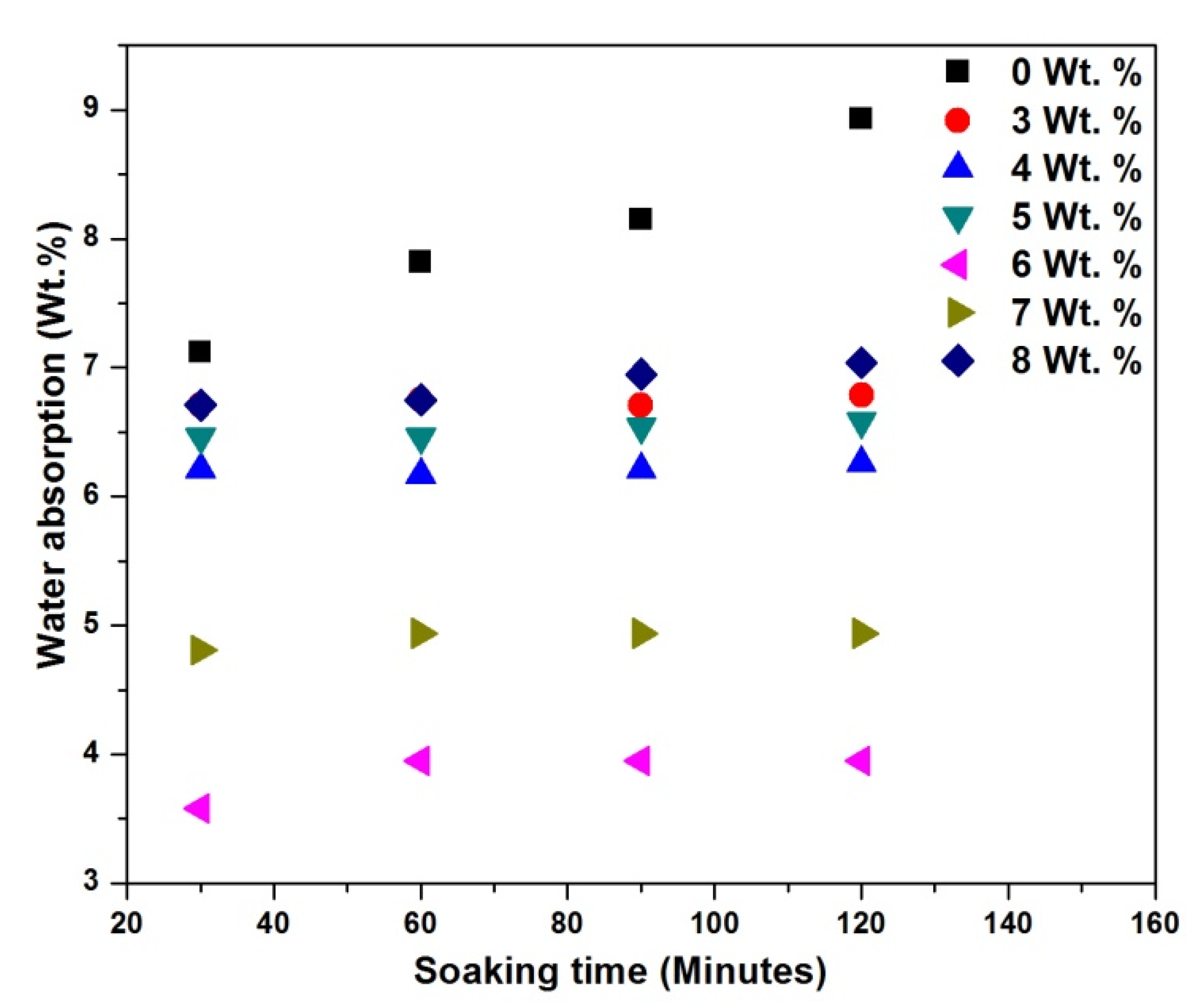

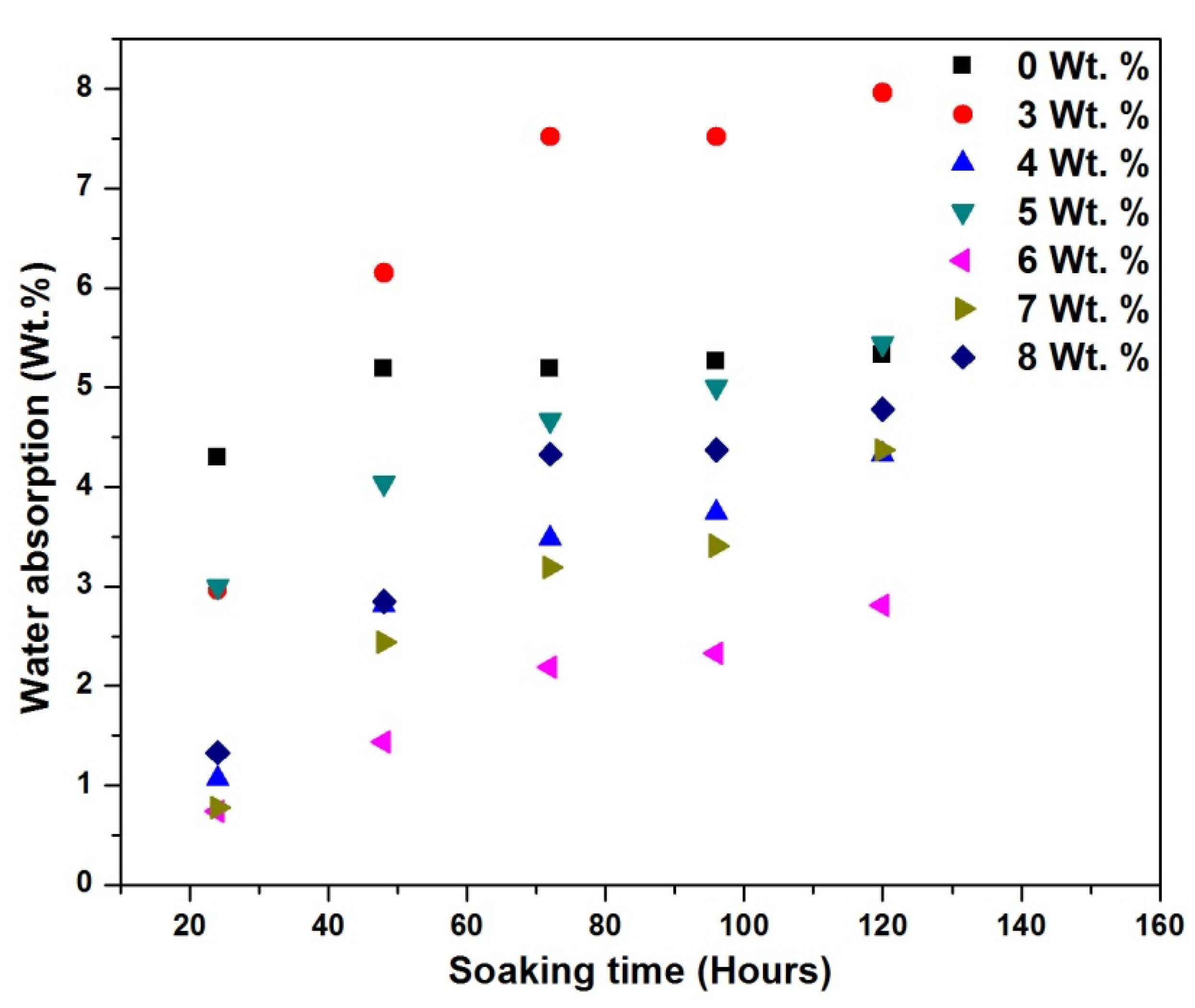

3.5. Water Absorption

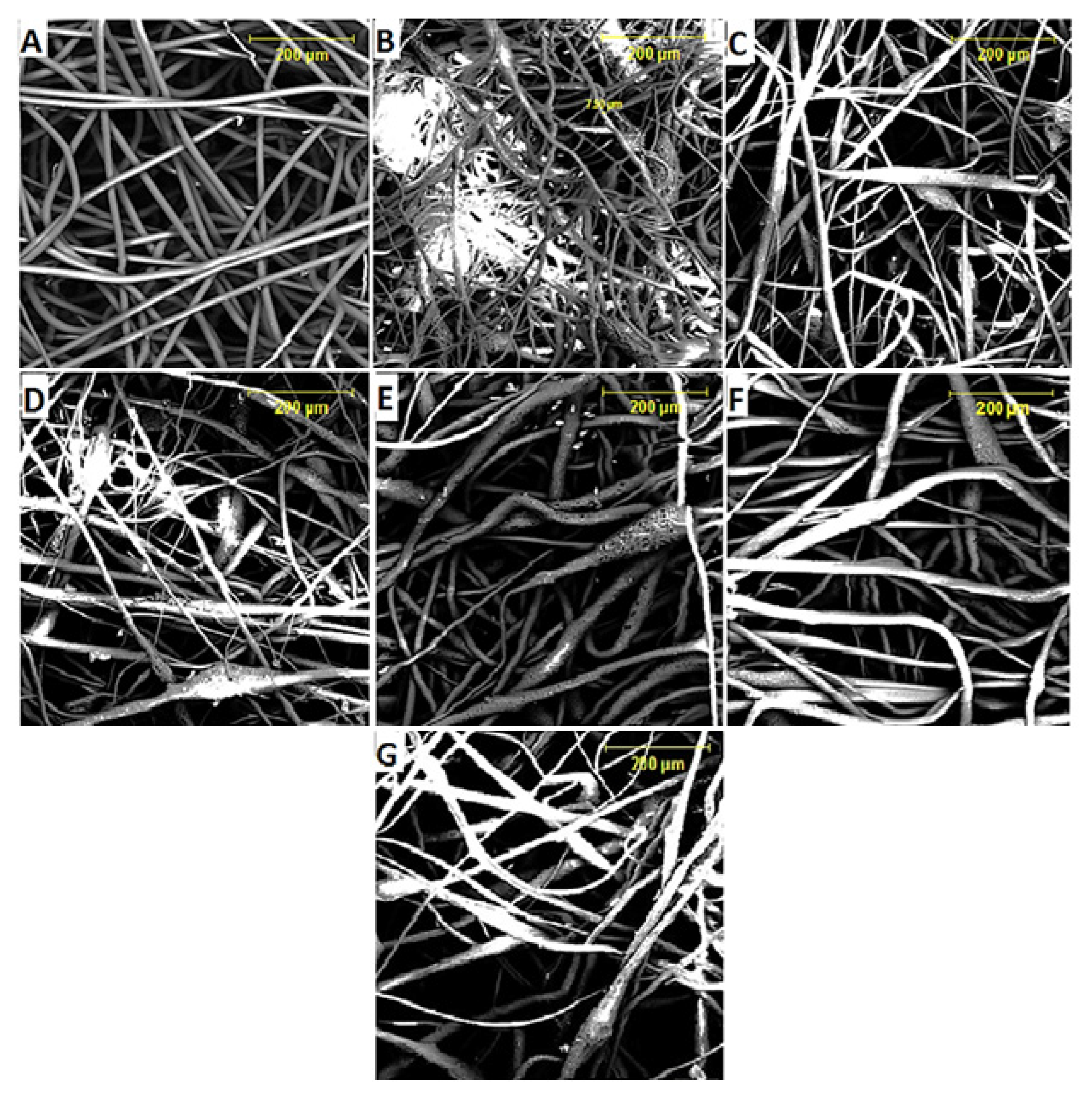

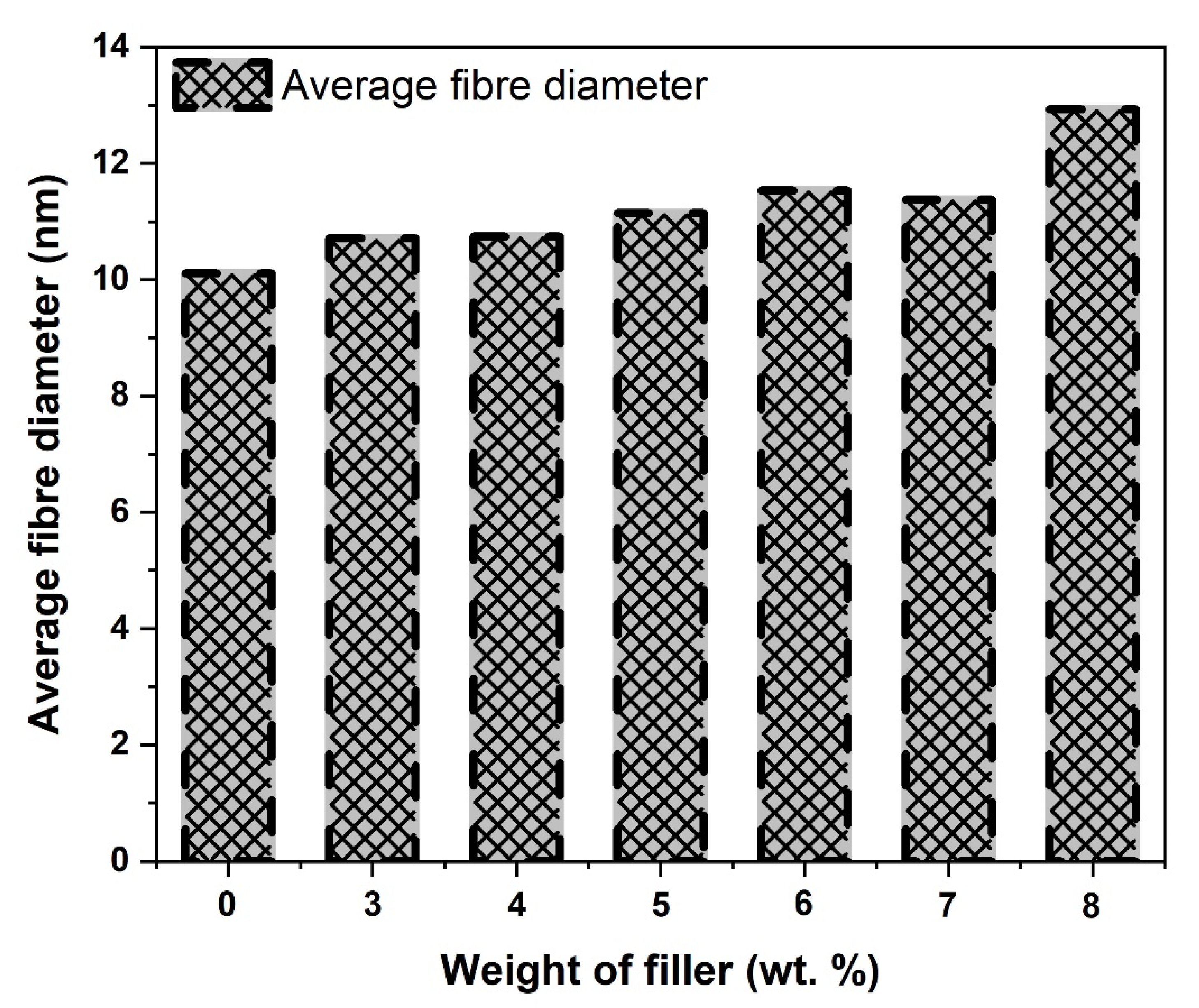

3.6. Morphological Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, N.; Dai, Q.; Wang, Z.; Luo, X.; Xue, Y.; Yu, F. Toughening of electrospun poly (L-lactic acid) nanofiber scaffolds with unidirectionally aligned halloysite nanotubes. J. Mater. Sci. 2015, 50, 1435–1445. [Google Scholar] [CrossRef]

- Tawakkal, I.S.; Cran, M.J.; Miltz, J.; Bigger, S.W. A review of poly (lactic acid)-based materials for antimicrobial packaging. J. Food Sci. 2014, 79, R1477–R1490. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, J.B.; Guerrini, L.M.; Conejo, L.D.S.; Rezende, M.C.; Botelho, E.C. Viscoelastic evaluation of epoxy nanocomposite based on carbon nanofiber obtained from electrospinning processing. Polym. Bull. 2019, 76, 6063–6076. [Google Scholar] [CrossRef]

- Cruz, K.F.N.; Botelho, E.C.; Cristovan, F.H.; Guerrini, L.M. Electrospinning TPU/poly o-phenetidine (POEA) fibers: Influence of POEA on fiber morphology. Polym. Bull. 2017, 74, 2905–2919. [Google Scholar] [CrossRef]

- Gorain, B.; Choudhury, H.; Pandey, M.; Kesharwani, P.; Abeer, M.M.; Tekade, R.K.; Hussain, Z. Carbon nanotube scaffolds as emerging nanoplatform for myocardial tissue regeneration: A review of recent developments and therapeutic implications. Biomed. Pharmacother. 2018, 104, 496–508. [Google Scholar] [CrossRef]

- Hu, X.; Su, T.; Li, P.; Wang, Z. Blending modification of PBS/PLA and its enzymatic degradation. Polym. Bull. 2018, 75, 533–546. [Google Scholar] [CrossRef]

- Adesina, O.T.; Sadiku, E.R.; Jamiru, T.; Ogunbiyi, O.F.; Adesina, O.S. Thermal properties of spark plasma-sintered polylactide/graphene composites. Mater. Chem. Phys. 2020, 242, 122545. [Google Scholar] [CrossRef]

- Adesina, O.T.; Sadiku, E.R.; Jamiru, T.; Adesina, O.S.; Ogunbiyi, O.F.; Obadele, B.A.; Salifu, S. Polylactic acid/graphene nanocomposite consolidated by SPS technique. J. Mater. Res. Technol. 2020, 9, 11801–11812. [Google Scholar] [CrossRef]

- Xing, Q.; Zhang, X.; Dong, X.; Liu, G.; Wang, D. Low-molecular weight aliphatic amides as nucleating agents for poly (L-lactic acid): Conformation variation induced crystallization enhancement. Polymer 2012, 53, 2306–2314. [Google Scholar] [CrossRef]

- Sun, J.; Shen, J.; Chen, S.; Cooper, M.; Fu, H.; Wu, D.; Yang, Z. Nanofiller reinforced biodegradable PLA/PHA composites: Current status and future trends. Polymers 2018, 10, 505. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Yang, H.; Deri, F.; Ko, Y. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 5. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.M.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials–An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Asim, M. Recent advances in nanoclay/natural fibers hybrid composites. In Nanoclay Reinforced Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–28. [Google Scholar]

- Saba, N.; Tahir, P.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E. Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: A review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Bijarimi, M.; Ahmad, S.; Alam, A.M. Toughening effect of liquid natural rubber on the morphology and thermo-mechanical properties of the poly (lactic acid) ternary blend. Polym. Bull. 2017, 74, 3301–3317. [Google Scholar] [CrossRef]

- Essabir, H.; Boujmal, R.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R.; Qaiss, A.E.K. Mechanical and thermal properties of hybrid composites: Oil-palm fiber/clay reinforced high density polyethylene. Mech. Mater. 2016, 98, 36–43. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B. Influence of date palm fibre and graphite filler on mechanical and wear characteristics of epoxy composites. Mater. Des. 2014, 59, 264–273. [Google Scholar] [CrossRef]

- Ma, S.; Zhuang, X.; Wang, X. 3D micromechanical simulation of the mechanical behavior of an in-situ Al3Ti/A356 composite. Compos. Part B Eng. 2019, 176, 107115. [Google Scholar] [CrossRef]

- Qing, H. 2D micromechanical analysis of SiC/Al metal matrix composites under tensile, shear and combined tensile/shear loads. Mater. Des. 2013, 51, 438–447. [Google Scholar] [CrossRef]

- El Moumen, A.; Kanit, T.; Imad, A. Numerical evaluation of the representative volume element for random composites. Eur. J. Mech.-A/Solids 2021, 86, 104181. [Google Scholar] [CrossRef]

- Ramazani, A.; Mukherjee, K.; Quade, H.; Prahl, U.; Bleck, W. Correlation between 2D and 3D flow curve modelling of DP steels using a microstructure-based RVE approach. Mater. Sci. Eng. A 2013, 560, 129–139. [Google Scholar] [CrossRef]

- Liu, H.; Zeng, D.; Li, Y.; Jiang, L. Development of RVE-embedded solid elements model for predicting effective elastic constants of discontinuous fiber reinforced composites. Mech. Mater. 2016, 93, 109–123. [Google Scholar] [CrossRef]

- e-Xstream Engineering. V. Digimat User’ s Manual; MSC: Geneva, Switzerland, 2017. [Google Scholar]

- Luo, Y. Microstructure-Free Finite Element Modeling for Elasticity Characterization and Design of Fine-Particulate Composites. J. Compos. Sci. 2022, 6, 35. [Google Scholar] [CrossRef]

- Wang, W.; Dai, Y.; Zhang, C.; Gao, X.; Zhao, M. Micromechanical modeling of fiber-reinforced composites with statistically equivalent random fiber distribution. Materials 2016, 9, 624. [Google Scholar] [CrossRef] [PubMed]

- Melro, A.R.; Camanho, P.P.; Pinho, S.T. Generation of random distribution of fibres in long-fibre reinforced composites. Compos. Sci. Technol. 2008, 68, 2092–2102. [Google Scholar] [CrossRef]

- Romanov, V.; Lomov, S.V.; Swolfs, Y.; Orlova, S.; Gorbatikh, L.; Verpoest, I. Statistical analysis of real and simulated fibre arrangements in unidirectional composites. Compos. Sci. Technol. 2013, 87, 126–134. [Google Scholar] [CrossRef]

- Drygaś, P.; Gluzman, S.; Mityushev, V.; Nawalaniec, W. Applied Analysis of Composite Media: Analytical and Computational Results for Materials Scientists and Engineers; Woodhead Publishing: Sawston, UK, 2019. [Google Scholar]

- Gbenebor, O.; Atoba, R.; Akpan, E.; Aworinde, A.; Adeosun, S.; Olaleye, S. Study on polylactide-coconut fibre for biomedical applications. In Proceedings of the TMS Annual Meeting & Exhibition, Phoenix, AZ, USA, 11–15 March 2018; pp. 263–273. [Google Scholar]

- Systemes, S.D. ABAQUS 6.13 User’s manual. Dassault Syst. Provid. RI 2013, 305, 306. [Google Scholar]

- Xia, X.; Liu, W.; Zhou, L.; Hua, Z.; Liu, H.; He, S. Modification of flax fiber surface and its compatibilization in polylactic acid/flax composites. Iran. Polym. J. 2016, 25, 25–35. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface-treatments on the properties of laminated biocomposites from poly (lactic acid)(PLA) and kenaf fibers. Compos. Sci. Technol. 2008, 68, 424–432. [Google Scholar] [CrossRef]

- Onyeagoro, G. Effect of fibre acetylation on some mechanical properties of cellulose acetate butyrate (cab)/yellow poplar wood fibre composites. Int. J. Acad. Res. 2012, 4, 64–70. [Google Scholar]

- Wu, C.-S.; Wu, D.-Y.; Wang, S.-S.; Chan, L.-P.; Liang, C.-H. Modulation of polylactic acid nanofiber containing corn stalk waste via electrospinning: Fabrication, characterization, and cytocompatibility. Int. J. Polym. Mater. Polym. Biomater. 2021, 70, 1236–1247. [Google Scholar] [CrossRef]

- Reneker, D.H.; Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 7, 216. [Google Scholar] [CrossRef]

- Mosadeghzad, Z.; Ahmad, I.; Daik, R.; Ramli, A.; Jalaludin, Z. Preparation and properties of acacia sawdust/UPR composite based on recycled PET. Malays. Polym. J. 2009, 4, 30–41. [Google Scholar]

- Kenyó, C.; Kajtár, D.A.; Renner, K.; Kröhnke, C.; Pukánszky, B. Functional packaging materials: Factors affecting the capacity and rate of water adsorption in desiccant composites. J. Polym. Res. 2013, 20, 294. [Google Scholar] [CrossRef]

- Zong, X.; Kim, K.; Fang, D.; Ran, S.; Hsiao, B.S.; Chu, B. Structure and process relationship of electrospun bioabsorbable nanofiber membranes. Polymer 2002, 43, 4403–4412. [Google Scholar] [CrossRef]

- Salifu, A.; Nury, B.; Lekakou, C. Electrospinning of nanocomposite fibrillar tubular and flat scaffolds with controlled fiber orientation. Ann. Biomed. Eng. 2011, 39, 2510. [Google Scholar] [CrossRef]

- Jacobs, V.; Anandjiwala, R.D.; Maaza, M. The influence of electrospinning parameters on the structural morphology and diameter of electrospun nanofibers. J. Appl. Polym. Sci. 2010, 115, 3130–3136. [Google Scholar] [CrossRef]

- Li, D.; Frey, M.W.; Baeumner, A.J. Electrospun polylactic acid nanofiber membranes as substrates for biosensor assemblies. J. Membr. Sci. 2006, 279, 354–363. [Google Scholar] [CrossRef]

| Constituent | Lignin | Moisture | Pentosans | Ash | Cellulose | Solvent Extractives | Uronic Anhydrides |

|---|---|---|---|---|---|---|---|

| wt.% | 29.4 | 8.0 | 27.7 | 0.6 | 26.8 | 4.2 | 3.5 |

| Material | Density (kg/m3) | Modulus of Elasticity (GPa) | Poisson’s Ratio |

|---|---|---|---|

| PLA | 1.250 | 3.420 | 0.3 |

| Coconut Fibre | 1.200 | 4.600 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogunbiyi, O.; Gbenebor, O.; Salifu, S.; Olaleye, S.; Jamiru, T.; Sadiku, R.; Adeosun, S. Strength Characteristics of Electrospun Coconut Fibre Reinforced Polylactic Acid: Experimental and Representative Volume Element (RVE) Prediction. Materials 2022, 15, 6676. https://doi.org/10.3390/ma15196676

Ogunbiyi O, Gbenebor O, Salifu S, Olaleye S, Jamiru T, Sadiku R, Adeosun S. Strength Characteristics of Electrospun Coconut Fibre Reinforced Polylactic Acid: Experimental and Representative Volume Element (RVE) Prediction. Materials. 2022; 15(19):6676. https://doi.org/10.3390/ma15196676

Chicago/Turabian StyleOgunbiyi, Olugbenga, Oluwashina Gbenebor, Smith Salifu, Samuel Olaleye, Tamba Jamiru, Rotimi Sadiku, and Samson Adeosun. 2022. "Strength Characteristics of Electrospun Coconut Fibre Reinforced Polylactic Acid: Experimental and Representative Volume Element (RVE) Prediction" Materials 15, no. 19: 6676. https://doi.org/10.3390/ma15196676

APA StyleOgunbiyi, O., Gbenebor, O., Salifu, S., Olaleye, S., Jamiru, T., Sadiku, R., & Adeosun, S. (2022). Strength Characteristics of Electrospun Coconut Fibre Reinforced Polylactic Acid: Experimental and Representative Volume Element (RVE) Prediction. Materials, 15(19), 6676. https://doi.org/10.3390/ma15196676