Effect of Metal-Cored Filler Wire on Surface Morphology and Micro-Hardness of Regulated Metal Deposition Welded ASTM A387-Gr.11-Cl.2 Steel Plates

Abstract

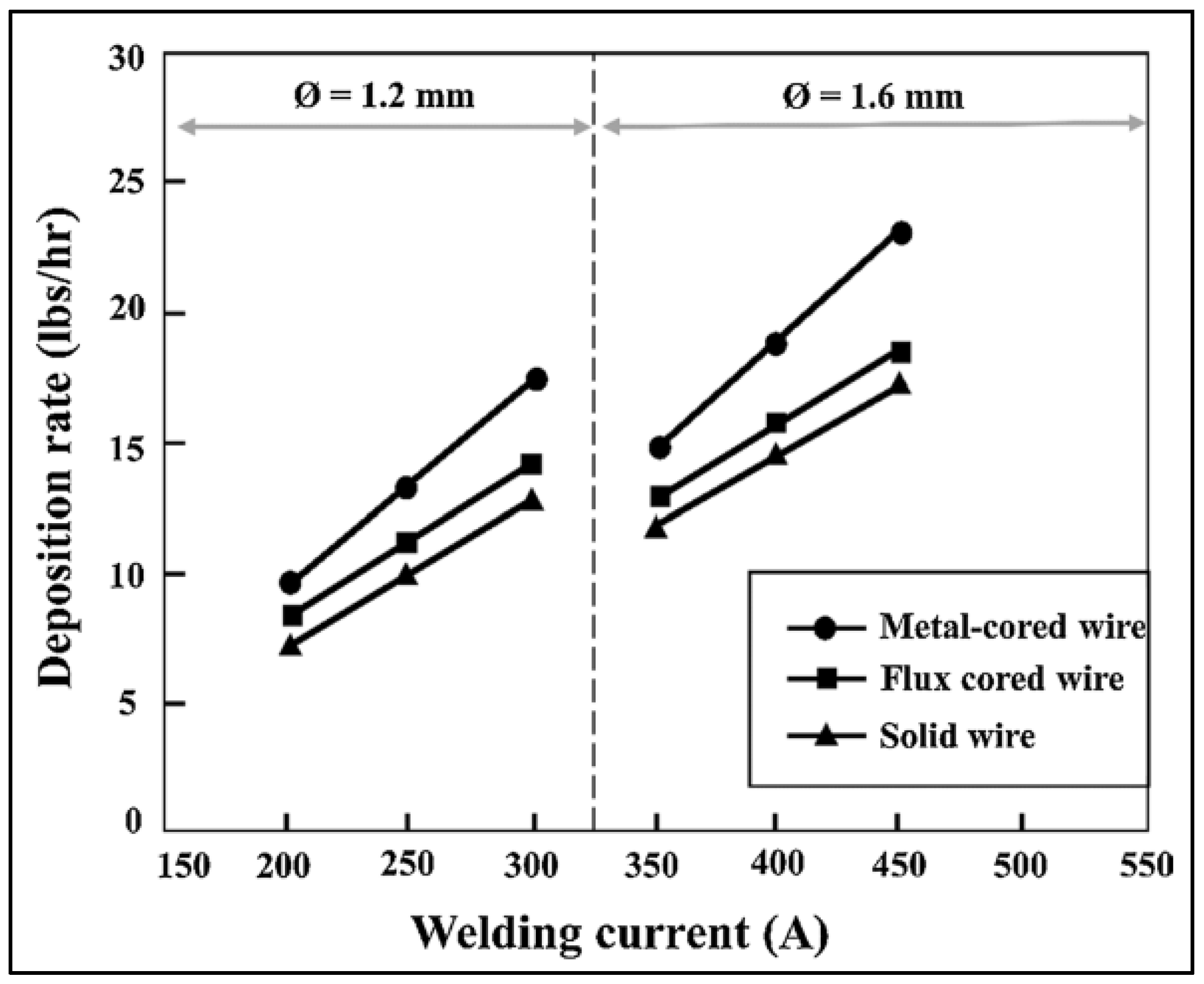

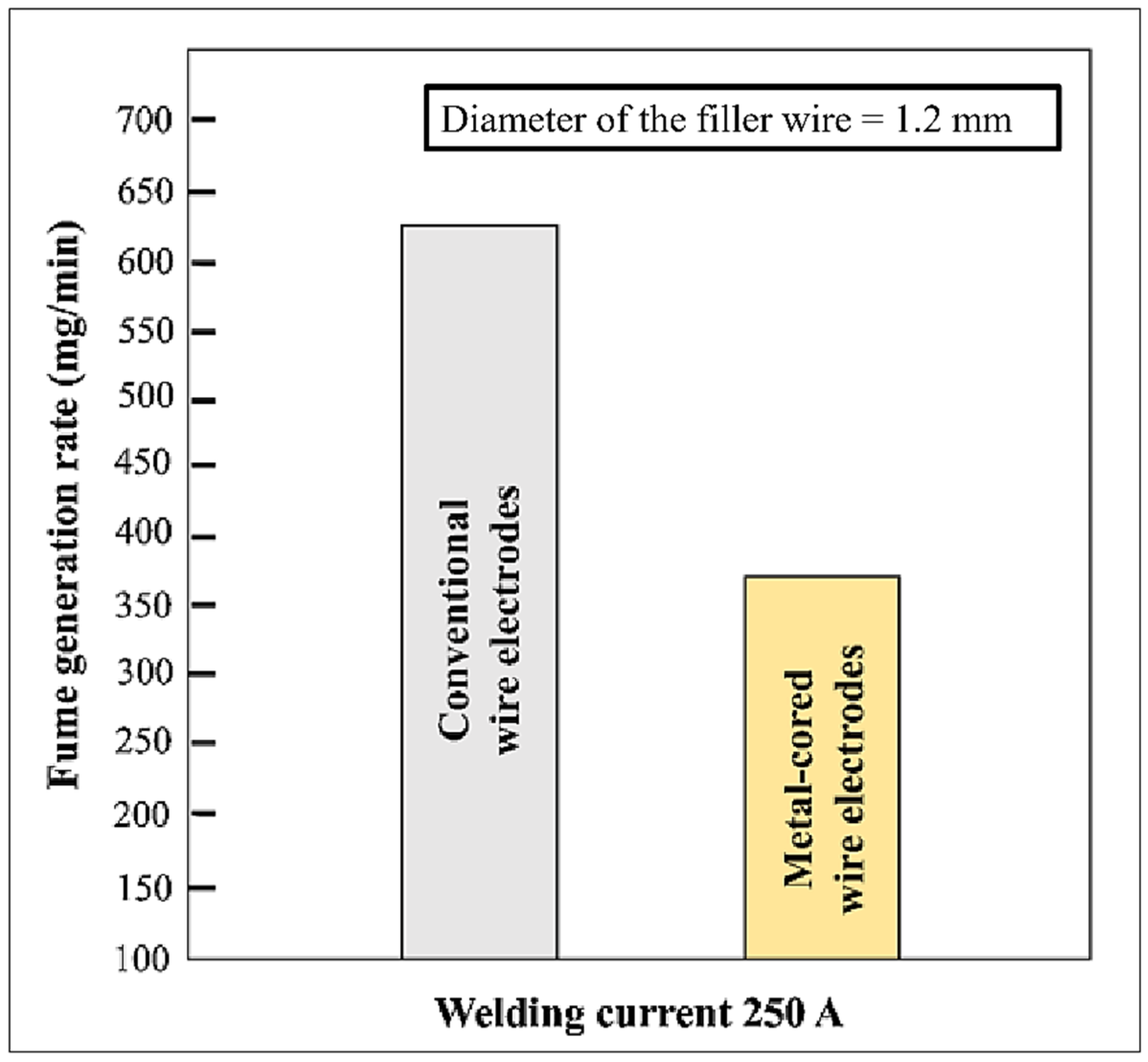

1. Introduction

2. Materials and Methods

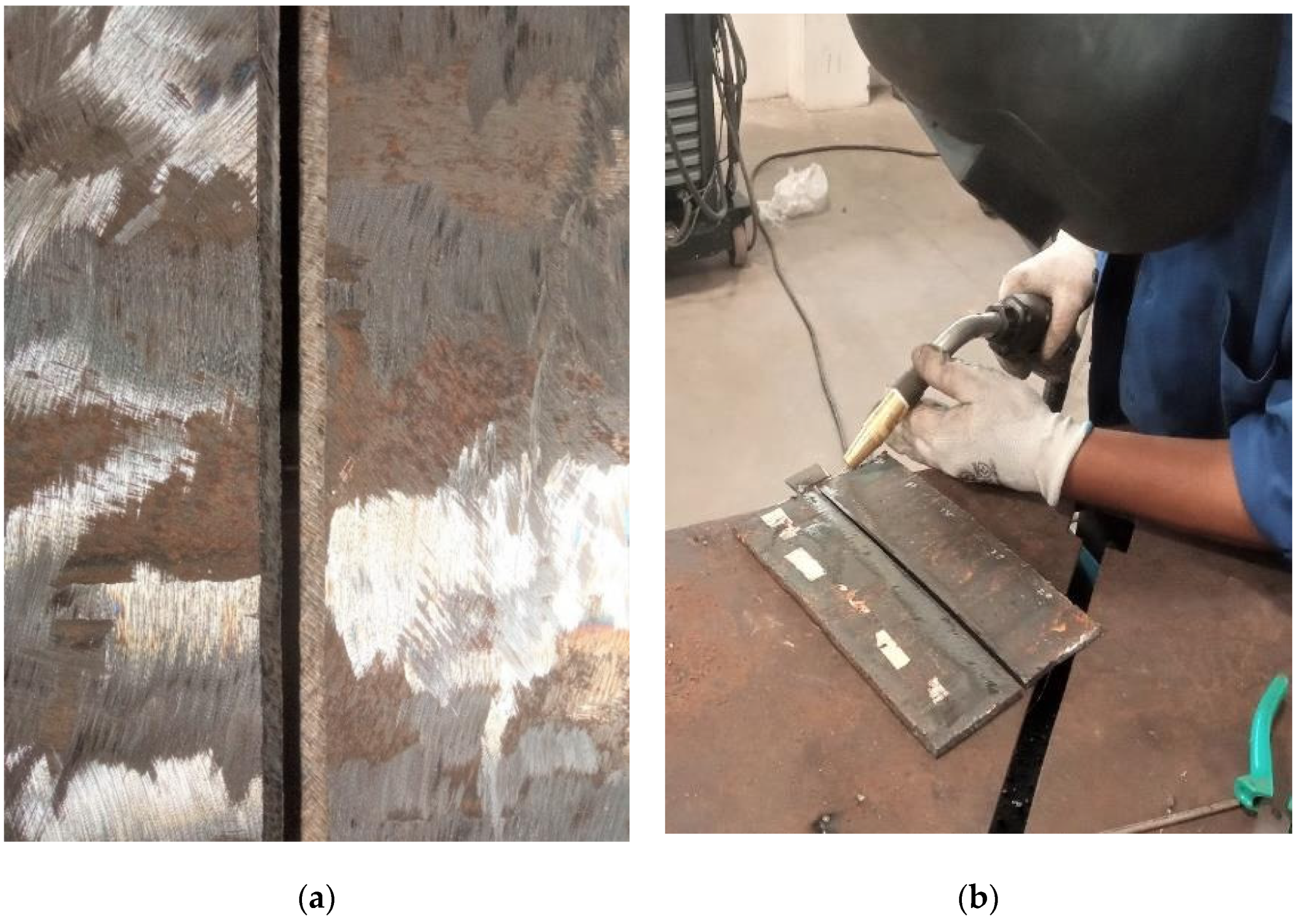

2.1. Experimentation

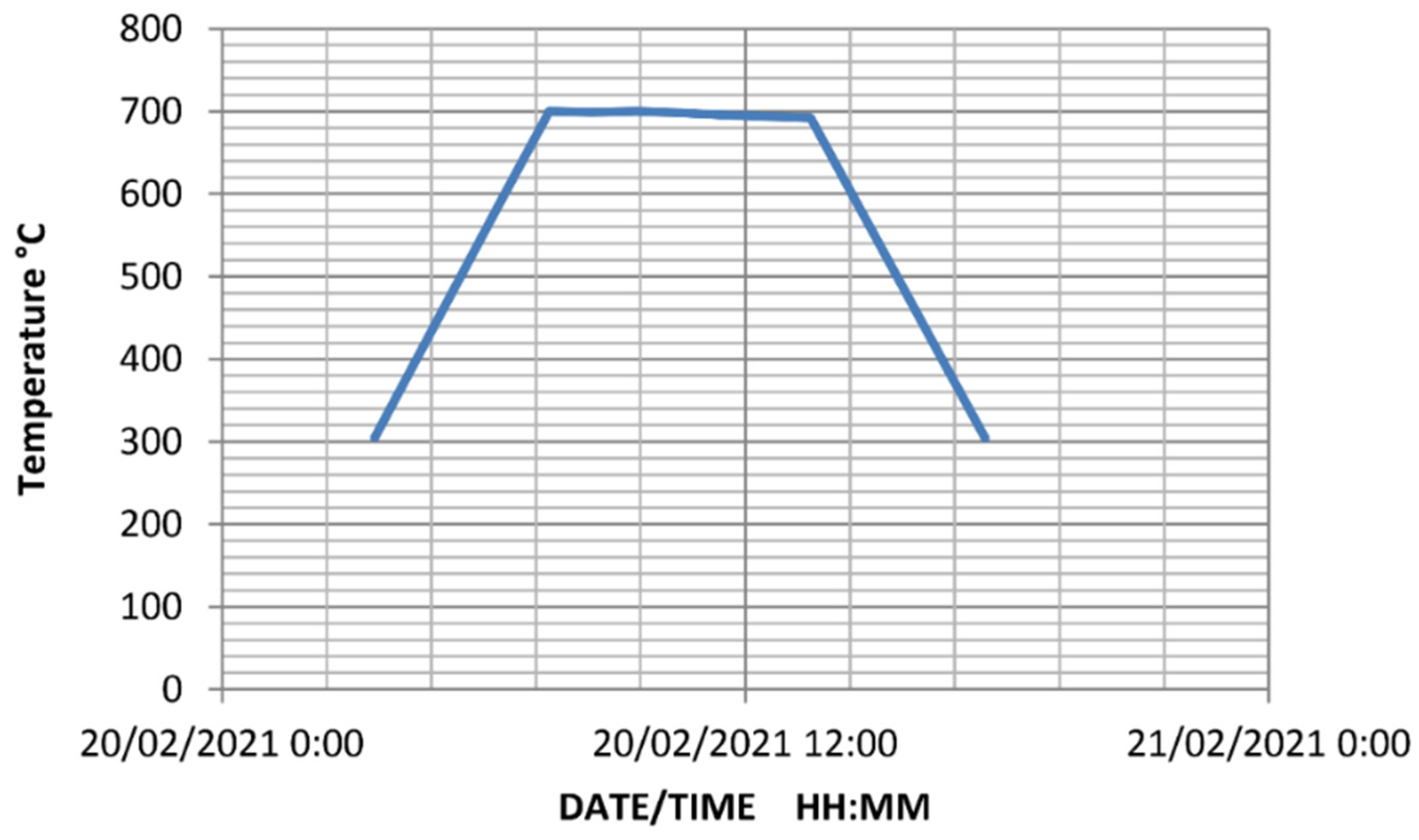

2.2. Post-Weld Heat Treatment

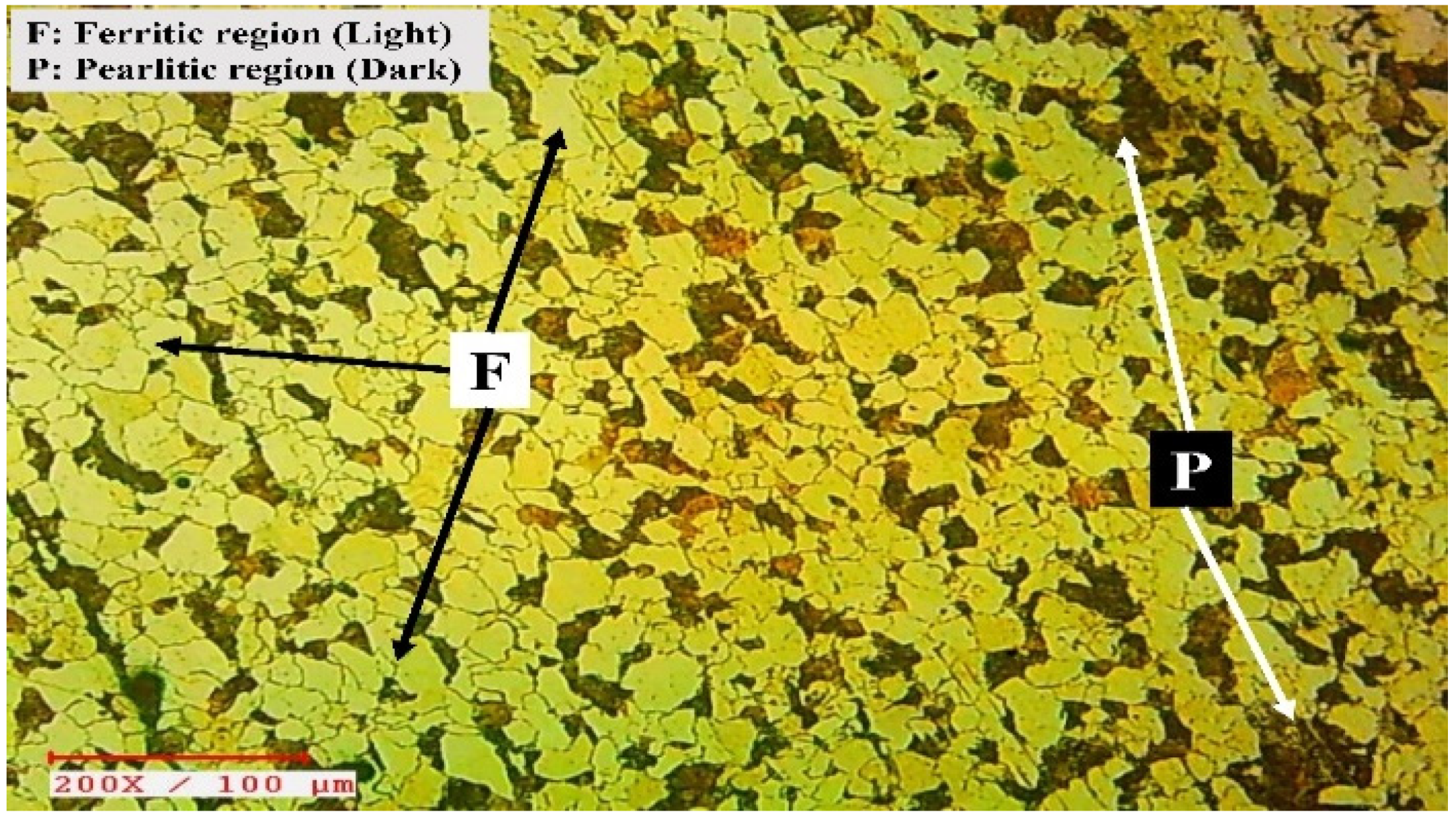

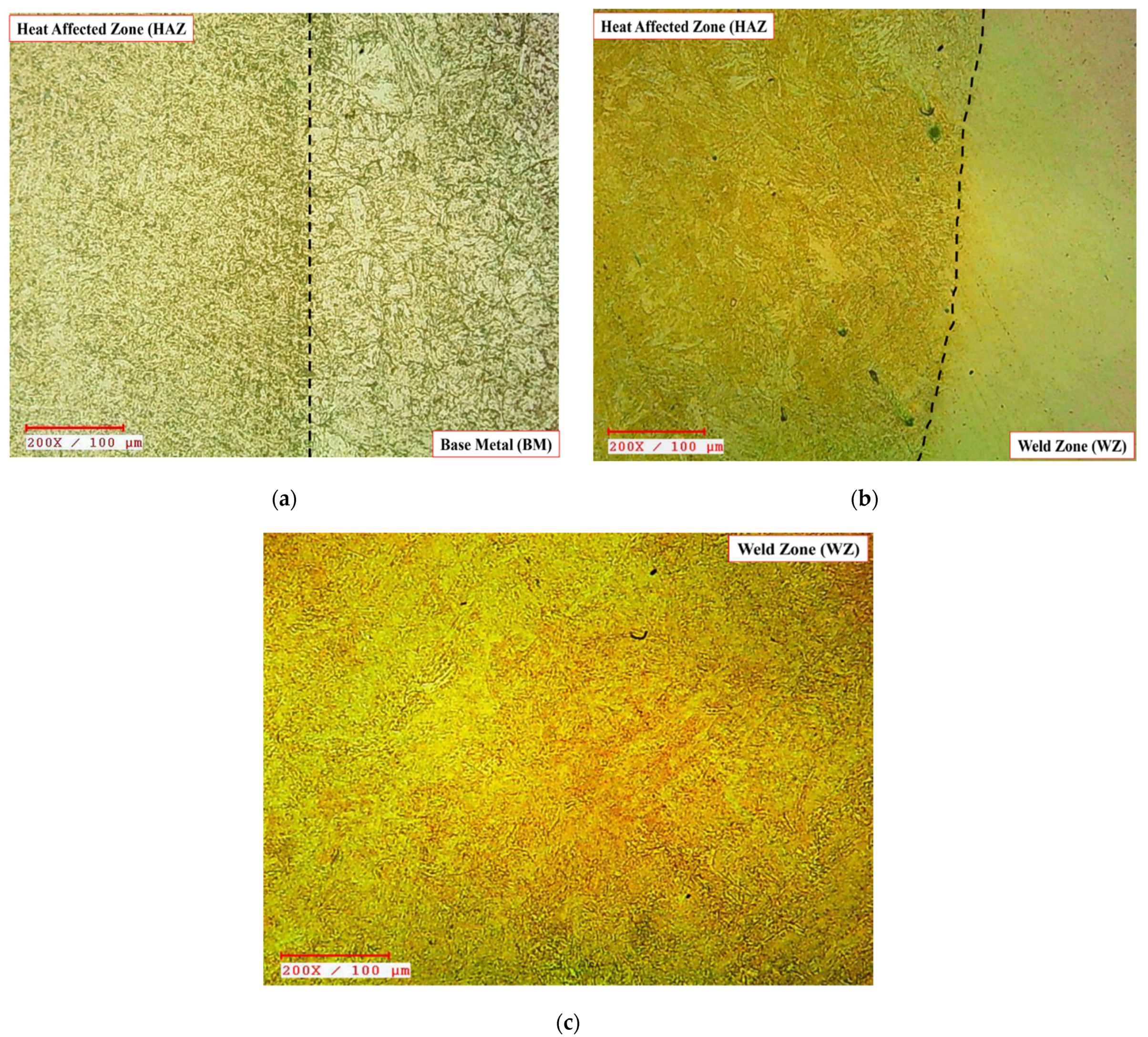

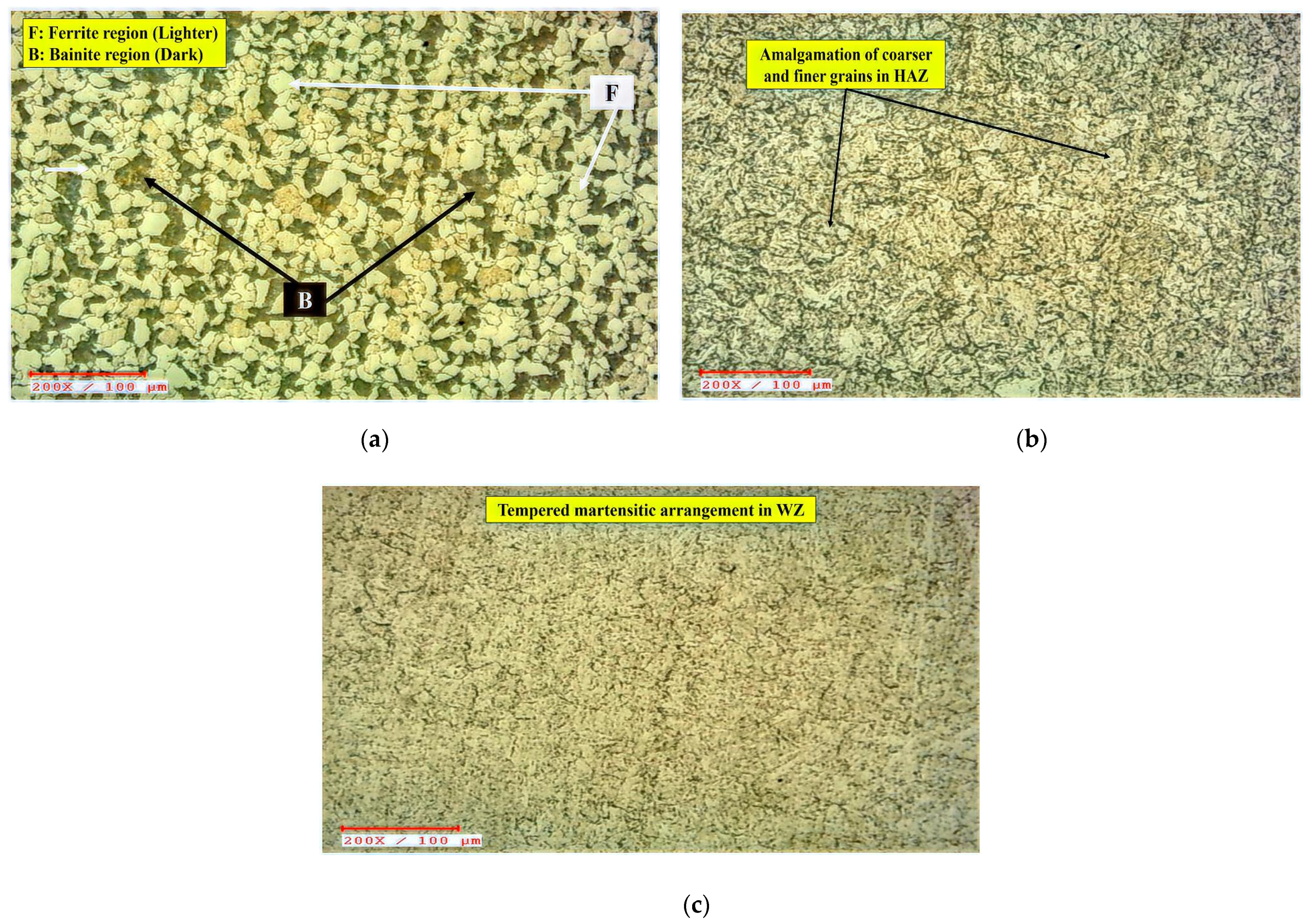

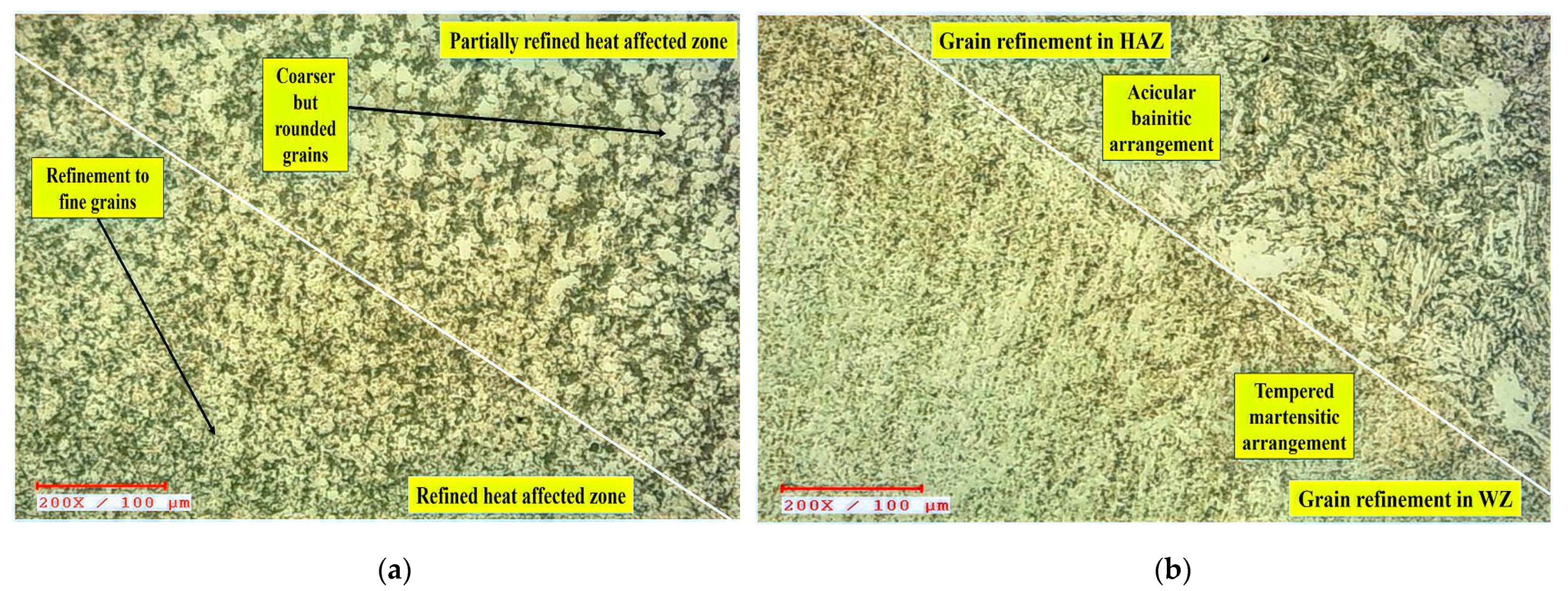

2.3. Microstructure Examination

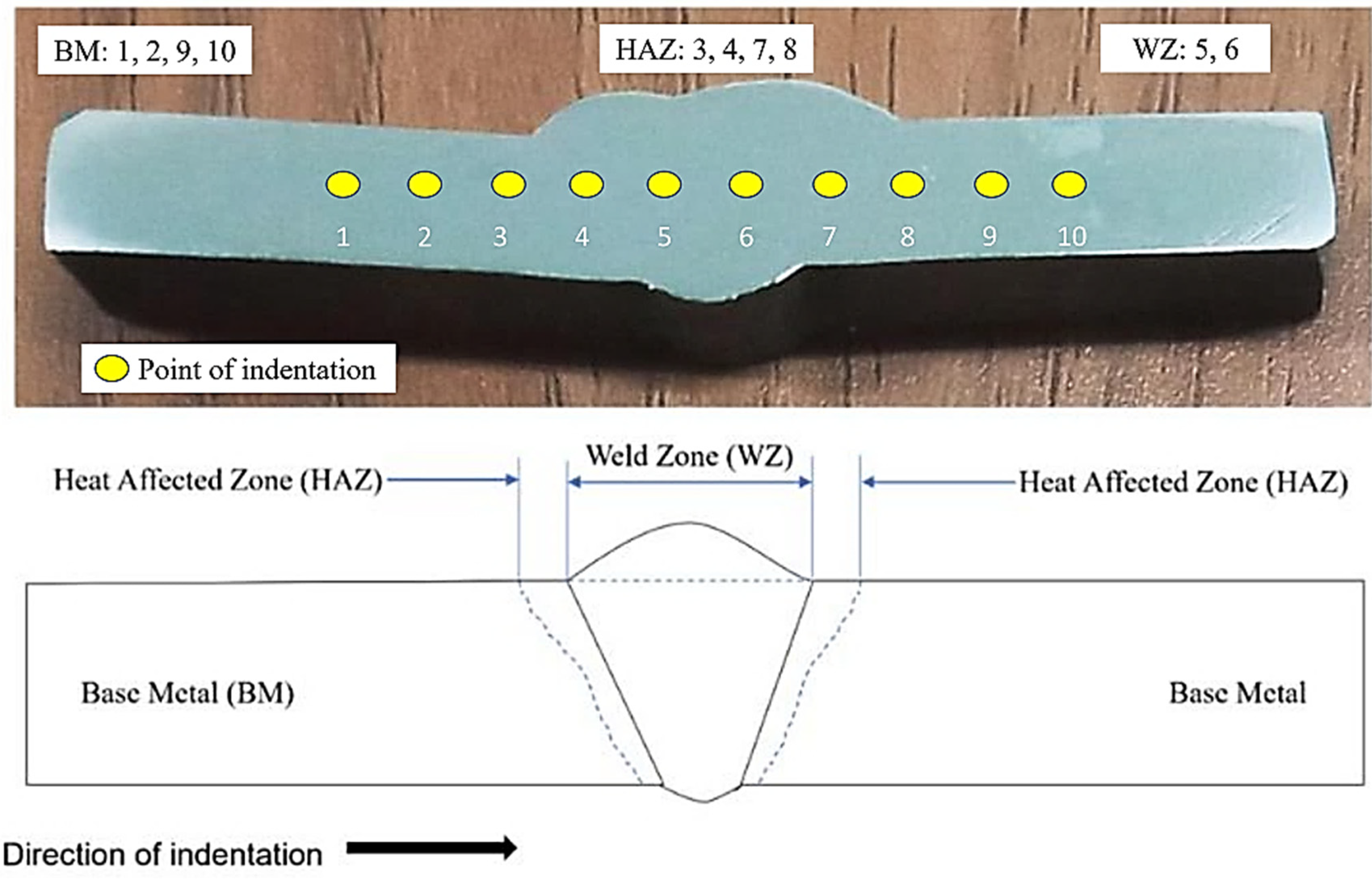

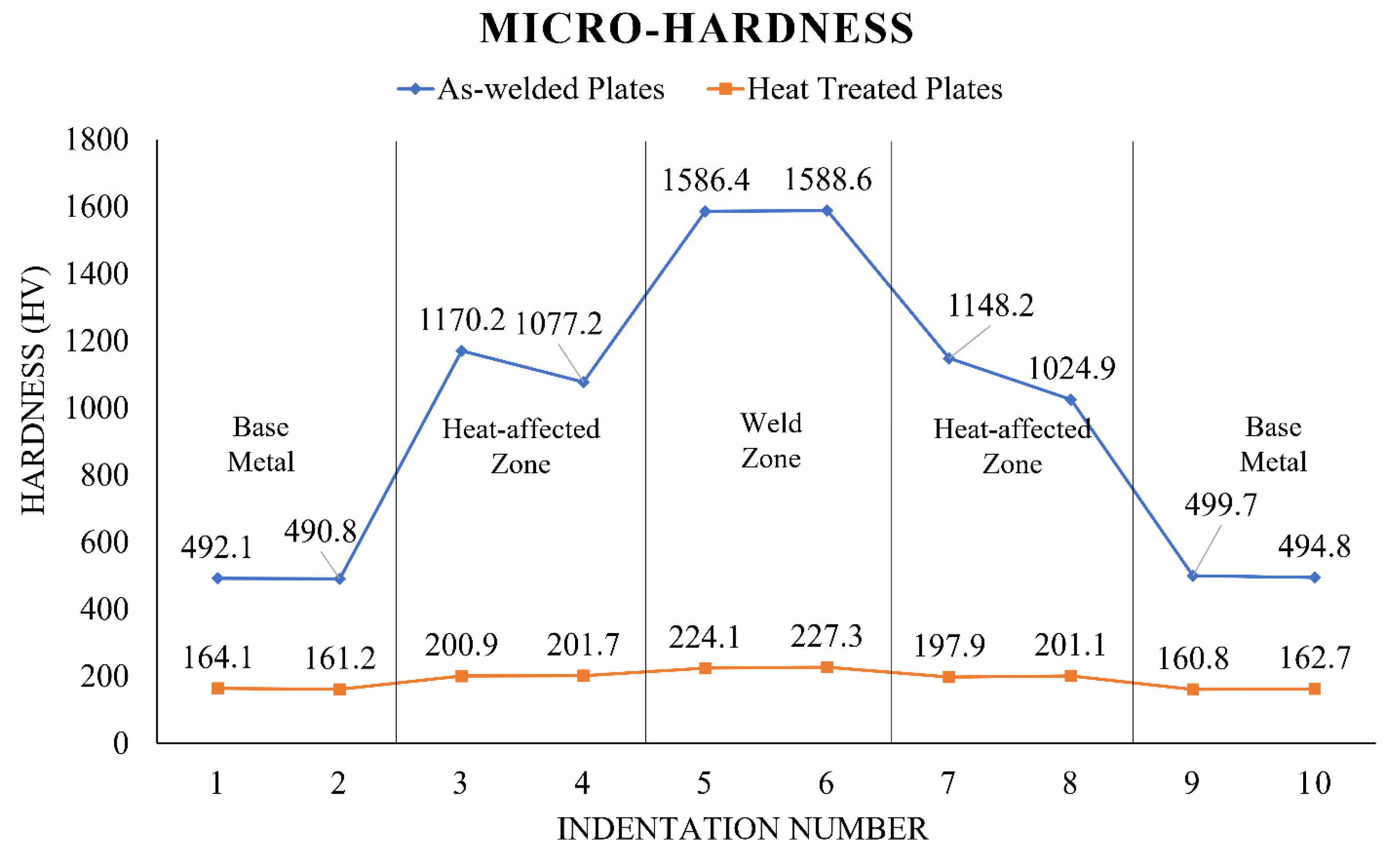

2.4. Microhardness Test

3. Results and Discussion

3.1. Surface Morphology

3.2. Microhardness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Sah, I.; Kim, E.-S. High-Temperature Tensile Behavior of Diffusion-Welded Hastelloy X. J. Mech. Sci. Technol. 2022, 36, 3419–3428. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Par, M.A. Twenty-year uninterrupted endeavor of friction stir processing by focusing on copper and its alloys. J. Alloy Compd. 2019, 781, 1074–1090. [Google Scholar] [CrossRef]

- Bandhu, D.; Kumar, R.; Nishant, A.; Thakur, A. Characterization of Friction Stir Welding for AA 2014-6061 and Influence of Aging on Their Mechanical Behavior. In Proceedings of the 5th National Conference on Topical Transcend in Mechanical Technology SJBIT Bangalore (TTMT-17), Bangalore, India, June 2017; pp. 98–102. [Google Scholar]

- Bai, Y.; Nardi, D.C.; Zhou, X.; Picón, R.A.; Flórez-López, J. A New Comprehensive Model of Damage for Flexural Subassemblies Prone to Fatigue. Comput. Struct. 2021, 256, 106639. [Google Scholar] [CrossRef]

- Mousavi, A.A.; Zhang, C.; Masri, S.F.; Gholipour, G. Structural Damage Detection Method Based on the Complete Ensemble Empirical Mode Decomposition with Adaptive Noise: A Model Steel Truss Bridge Case Study. Struct. Health Monit. 2021, 21, 887–912. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Pospisil, S.; Wu, T. Experimental Investigation on Rehabilitation of Corroded RC Columns with BSP and HPFL under Combined Loadings. J. Struct. Eng. 2020, 146, 04020157. [Google Scholar] [CrossRef]

- Cuhel, J.; Packard, K. RMD® Short-Circuit Metal Transfer, Pulsed MIG Processes with Metal-Cored Wires Improve Pipe Fabrication for Swartfager Welding, Inc.; Miller Electric Mfg. LLC: Appleton, WI, USA, 2009; pp. 1–8. [Google Scholar]

- Dinbandhu, V.P.; Vora, J.J.; Abhishek, K. Advances in Gas Metal Arc Welding Process: Modifications in Short-Circuiting Transfer Mode. In Advanced Welding and Deforming; Elsevier: Amsterdam, The Netherlands, 2021; pp. 67–104. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Wang, Q.; Attarilar, S. A comprehensive review of magnesium-based alloys and composites processed by cyclic extrusion compression and the related techniques. Prog. Mater. Sci. 2022, 131, 101016. [Google Scholar] [CrossRef]

- Huang, H.; Huang, M.; Zhang, W.; Yang, S. Experimental Study of Predamaged Columns Strengthened by hpfl and bsp Under Combined Load Cases. Struct. Infrastruct. Eng. 2020, 17, 1210–1227. [Google Scholar] [CrossRef]

- Keen Ovens. Flux-Cored Wire versus Solid Wire. Available online: https://www.keenovens.com/articles/flux-core-solid-wire.html (accessed on 23 March 2022).

- Wei, J.; Xie, Z.; Zhang, W.; Luo, X.; Yang, Y.; Chen, B. Experimental Study on Circular Steel Tube-Confined Reinforced UHPC Columns Under Axial Loading. Eng. Struc. 2021, 230, 111599. [Google Scholar] [CrossRef]

- Lv, B.; Wang, S.; Xu, T.; Guo, F. Effects of Minor Nd and Er Additions on the Precipitation Evolution and Dynamic Recrystallization Behavior of Mg–6.0Zn–0.5Mn Alloy. J. Magnes. Alloy 2021, 9, 840–852. [Google Scholar] [CrossRef]

- Prajapati, P.; Badheka, V.J.; Mehta, K.P. Hybridization of Filler Wire in Multi-Pass Gas Metal Arc Welding of SA516 Gr70 Carbon Steel. Mater. Manuf. Process. 2018, 33, 315–322. [Google Scholar] [CrossRef]

- Hao, R.; Lu, Z.; Ding, H.; Chen, L. A Nonlinear Vibration Isolator Supported on a Flexible Plate: Analysis and Experiment. Nonlinear Dyn. 2022, 108, 941–958. [Google Scholar] [CrossRef]

- D’Arcy, A. How Metal-Cored Wires Reduce Hidden Welding Costs. Available online: https://www.welding.com.au/resources-articles/view/how-metal-cored-wires-reduce-hidden-welding-costs (accessed on 23 March 2022).

- WIA. Is Metal Cored Wire the Right Choice. Available online: https://www.welding.com.au/news/view/is-metal-cored-wire-the-right-choice (accessed on 23 March 2022).

- Djavanroodi, F.; Ebrahimi, M.; Nayfeh, J. Tribological and mechanical investigation of multi-directional forged nickel. Sci. Rep. 2019, 9, 241. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yang, X.; Yi, D.; Liu, B.; Zhu, J.; Li, J.; Gao, C.; Wang, L. Effects of Nbc Content on Microstructural Evolution and Mechanical Properties of Laser Cladded Fe50mn30co10cr10-Xnbc Composite Coatings. Intermetallics 2021, 138, 107309. [Google Scholar] [CrossRef]

- Welding Engineers. Metal Cored Wires vs. Solid Wire. Available online: https://weldingengineers.co.nz/news/welding-assistance/metal-cored-wires-vs-solid-wire (accessed on 23 March 2022).

- Alipooramirabad, H.; Paradowska, A.; Ghomashchi, R.; Reid, M. Investigating the Effects of Welding Process on Residual Stresses, Microstructure and Mechanical Properties in HSLA Steel Welds. J. Manuf. Process. 2017, 28, 70–81. [Google Scholar] [CrossRef]

- Zhang, X.; Mi, G.; Wang, C. Microstructure and Performance of Hybrid Laser-Arc Welded High-Strength Low Alloy Steel and Austenitic Stainless Steel Dissimilar Joint. Opt. Laser Technol. 2020, 122, 105878. [Google Scholar] [CrossRef]

- Nielsen, I.; Grznár, P.; Stanisz, D.; Machniewicz, T.; Parzych, S.; Je, G.; Dvorkin, L.; Hebda, M. Microstructure and Mechanical Properties of Joints Depending on the Process Used. Materials 2022, 15, 5171. [Google Scholar] [CrossRef]

- Xi, B.; Liu, B.; Li, S.; Wang, D.; Zhang, Y.; Szakálos, P.; Ejenstam, J.; Wallenius, J.; He, G.; Zhang, W. Influence of TIG and Laser Welding Processes of Fe-10Cr-4Al-RE Alloy Cracks Overlayed on 316L Steel Plate. Materials 2022, 15, 3541. [Google Scholar] [CrossRef]

- Sepe, R.; Wiebesiek, J.; Sonsino, C.M. Numerical and Experimental Validation of Residual Stresses of Laser-Welded Joints and Their Influence on the Fatigue Behaviour. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1126–1141. [Google Scholar] [CrossRef]

- Sim, B.M.; Tang, S.H.; Alrifaey, M.; Jong, E.N.T. Analyzing the Effects of Heat Treatment on SMAW Duplex Stainless Steel Weld Overlays. Materials 2022, 15, 1833. [Google Scholar] [CrossRef]

- Sepe, R.; Giannella, V.; Greco, A.; De Luca, A. FEM Simulation and Experimental Tests on the SMAW Welding of a Dissimilar T-Joint. Metals 2021, 11, 1016. [Google Scholar] [CrossRef]

- Chen, L.; Nie, P.; Qu, Z.; Ojo, O.A.; Xia, L.; Li, Z.; Huang, J. Influence of Heat Input on the Changes in the Microstructure and Fracture Behavior of Laser Welded 800 MPa Grade High-Strength Low-Alloy Steel. J. Manuf. Process. 2020, 50, 132–141. [Google Scholar] [CrossRef]

- Sepe, R.; Greco, A.; De Luca, A.; Caputo, F.; Berto, F. Influence of Thermo-Mechanical Material Properties on the Structural Response of a Welded Butt-Joint by FEM Simulation and Experimental Tests. Forces Mech. 2021, 4, 100018. [Google Scholar] [CrossRef]

- Dinbandhu, V.P.; Vora, J.J.; Das, S.; Abhishek, K. Experimental Studies of Regulated Metal Deposition (RMDTM) on ASTM A387 Steel: Study of Parametric Influence and Welding Performance Optimization. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 78. [Google Scholar] [CrossRef]

- Fan, X.; Wei, G.; Lin, X.; Wang, X.; Si, Z.; Zhang, X.; Shao, O.; Mangin, S.; Fullerton, E.; Jiang, L.; et al. Reversible Switching of Interlayer Exchange Coupling through Atomically Thin VO2 via Electronic State Modulation. Matter 2020, 2, 1582–1593. [Google Scholar] [CrossRef]

- Bandhu, D.; Abhishek, K. Assessment of Weld Bead Geometry in Modified Shortcircuiting Gas Metal Arc Welding Process for Low Alloy Steel. Mater. Manuf. Process. 2021, 36, 1384–1402. [Google Scholar] [CrossRef]

- API 934-C; Materials and Fabrication of 1.25Cr-0.25Mo Steel Heavy Wall Pressure Vessels for Highpressure Hydrogen Service Operating at or Below 825 Degrees F (441 Degrees C). American Petroleum Institute: Washington, DC, USA, 2008.

- Zhong, Y.; Xie, J.; Chen, Y.; Yin, L.; He, P.; Lu, W. Microstructure and mechanical properties of micro laser welding NiTiNb/Ti6Al4V dissimilar alloys lap joints with nickel interlayer. Mater. Lett. 2022, 306, 130896. [Google Scholar] [CrossRef]

- Chaudhuri, S.; Ghosh, R.N. Some Aspects of Mechanisms and Modelling of Creep Behaviour of 2.25Cr-1Mo Steel. ISIJ Int. 1998, 38, 881–887. [Google Scholar] [CrossRef]

- Huang, C.C.; Chuang, T.H. Effects of Post-Weld Heat Treatments on the Residual Stress and Mechanical Properties of Laser Beam Welded SAE 4130 Steel Plates. Mater. Manuf. Process. 1997, 12, 779–797. [Google Scholar] [CrossRef]

- Bandhu, D.; Vora, J.J.; Das, S.; Thakur, A.; Kumari, S.; Abhishek, K.; Sastry, M.N. Experimental Study on Application of Gas Metal Arc Welding Based Regulated Metal Deposition Technique for Low Alloy Steel. Mater. Manuf. Process. 2022, 1–19. [Google Scholar] [CrossRef]

- Gojić, M.; Mioč, B.; Kosec, L. The Effect of Post-Weld Heat Treatment on Properties of Low-Alloyed CrMoNb Steel after Submerged Welding. Kov. Mater. 2006, 44, 119–126. [Google Scholar]

- Fujibayashi, S.; Endo, T. Creep Behavior at the Intercritical HAZ of a 1.25Cr-0.5Mo Steel. ISIJ Int. 2002, 42, 1309–1317. [Google Scholar] [CrossRef]

- Mahajan, S.; Chhibber, R. Investigations on Dissimilar Welding of P91/SS304L Using Nickel-Based Electrodes. Mater. Manuf. Process. 2020, 35, 1010–1023. [Google Scholar] [CrossRef]

- Rajesh, S.; Badheka, V. Influence of Heat Input/Multiple Passes and Post Weld Heat Treatment on Strength/Electrochemical Characteristics of Friction Stir Weld Joint. Mater. Manuf. Process. 2018, 33, 156–164. [Google Scholar] [CrossRef]

- Pandya, D.; Badgujar, A.; Ghetiya, N. A Novel Perception toward Welding of Stainless Steel by Activated TIG Welding: A Review. Mater. Manuf. Process. 2020, 36, 877–903. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of Welding Thermal Treatment on the Microstructure and Mechanical Properties of Nickel-Based Superalloy Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Prasad, K.; Dwivedi, D.K. Microstructure and Tensile Properties of Submerged Arc Welded 1.25Cr-0.5Mo Steel Joints. Mater. Manuf. Process. 2008, 23, 463–468. [Google Scholar] [CrossRef]

- Gong, P.; Wang, D.; Zhang, C.; Wang, Y.; Jamili-Shirvan, Z.; Yao, K.; Wang, X. Corrosion Behavior of TiZrHfBeCu(Ni) High-Entropy Bulk Metallic Glasses in 3.5 wt. % NaCl. Mater. Degrad. 2022, 6, 77. [Google Scholar] [CrossRef]

- Prasad, K.; Dwivedi, D.K. Some Investigations on Microstructure and Mechanical Properties of Submerged Arc Welded HSLA Steel Joints. Int. J. Adv. Manuf. Technol. 2008, 36, 475–483. [Google Scholar] [CrossRef]

- Cetine, H.; Ayvaz, M. Microstructure and Mechanical Properties of Aa 5083 and Aa 6061 Welds Joined with Aisi5 and Aisi12wires. In Materialpruefung/Materials Testing; Carl Hanser Verlag: Munich, Germany, 2014; Volume 56, pp. 884–890. [Google Scholar] [CrossRef]

- Hung, C.H.; Chen, W.T.; Sehhat, M.H.; Leu, M.C. The Effect of Laser Welding Modes on Mechanical Properties and Microstructure of 304L Stainless Steel Parts Fabricated by Laser-Foil-Printing Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2021, 112, 867–877. [Google Scholar] [CrossRef]

- Tathgir, S.; Bhattacharya, A. Activated-TIG Welding of Different Steels: Influence of Various Flux and Shielding Gas. Mater. Manuf. Process. 2016, 31, 335–342. [Google Scholar] [CrossRef]

- Ahmed, S.R.; Agarwal, L.A.; Daniel, B.S.S. Effect of Different Post Weld Heat Treatments on the Mechanical Properties of Cr-Mo Boiler Steel Welded with SMAW Process. Mater. Today Proc. 2015, 2, 1059–1066. [Google Scholar] [CrossRef]

- Yoo, I.; Lee, J.M.; Lim, H.S.; Suh, J.Y.; Lee, J.; Hwang, B. Comparative Study of Hydrogen Embrittlement of Three Heat-Resistant Cr-Mo Steels Subjected to Electrochemical and Gaseous Hydrogen Charging. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 2118–2125. [Google Scholar] [CrossRef]

- Juliermes, C.; Vitor, L.; Ayrton, S.; Luís, P.; Renata, B.; José, F. Microstructural and Mechanical Characterization of Steel 2, 25Cr-1Mo Treated by Quenching Process. Int. J. Metall. Met. Phys. 2019, 4, 40. [Google Scholar] [CrossRef]

- Jorge, L.D.J.; Cândido, V.S.; Da Silva, A.C.R.; Garcia Filho, F.D.C.; Pereira, A.C.; Da Luz, F.S.; Monteiro, S.N. Mechanical Properties and Microstructure of SMAW Welded and Thermically Treated HSLA-80 Steel. J. Mater. Res. Technol. 2018, 7, 598–605. [Google Scholar] [CrossRef]

- Ţălu, S. Micro and Nanoscale Characterization of Three Dimensional Surfaces. Basics and Applications; Ţălu, S., Ed.; Napoca Star Publishing House: Cluj-Napoca, Romania, 2015. [Google Scholar]

- Ramesh, S. Designing Weldments, 1st ed.; Singh, R., Ed.; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar] [CrossRef]

- Vora, J.J.; Badheka, V.J. Improved Penetration with the Use of Oxide Fluxes in Activated TIG Welding of Low Activation Ferritic/Martensitic Steel. Trans. Indian Inst. Met. 2016, 69, 1755–1764. [Google Scholar] [CrossRef]

- Vora, J.J.; Badheka, V.J. Experimental Investigation on Microstructure and Mechanical Properties of Activated TIG Welded Reduced Activation Ferritic/Martensitic Steel Joints. J. Manuf. Process. 2017, 25, 85–93. [Google Scholar] [CrossRef]

- Chuvas, T.C.; Garcia, P.S.P.; Pardal, J.M.; Fonseca, M.D.P.C. Influence of Heat Treatment in Residual Stresses Generated in P91 Steel-Pipe Weld. Mater. Res. 2015, 18, 614–621. [Google Scholar] [CrossRef][Green Version]

- Kirana, R.; Mythili, R.; Raju, S.; Saroja, S.; Jayakumar, T.; Rajendrakumar, E. Influence of W and Ta Content on Microstructural Characteristics in Heat Treated 9Cr-Reduced Activation Ferritic/Martensitic Steels. Mater. Charact. 2013, 84, 196–204. [Google Scholar] [CrossRef]

| Cr | Mo | Mn | S | C | Si | P | |

|---|---|---|---|---|---|---|---|

| MEGAFIL 237 M | 2.3% | 1.1% | 1.0% | 0.015% | 0.07% | 0.3% | 0.015% |

| ASTM A387-Gr.11-Cl.2 | 1.00–1.50% | 0.45–0.65% | 0.40–0.65% | 0.035% | 0.05–0.17% | 0.50–0.80% | 0.035% |

| Elements | MCFW | MCFW Diameter | Shielding Gas | Welding Position and Progression |

|---|---|---|---|---|

| Values | MEGAFIL 237 M | 1.2 mm | 90% Ar + 10% CO2 | 3G (Vertical) Downhill |

| Elements | GFR | Voltage | Current | Wire stick-out |

| Values | 21 L/min | 13 V | 100 A | 3–5 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandhu, D.; Djavanroodi, F.; Shaikshavali, G.; Vora, J.J.; Abhishek, K.; Thakur, A.; Kumari, S.; Saxena, K.K.; Ebrahimi, M.; Attarilar, S. Effect of Metal-Cored Filler Wire on Surface Morphology and Micro-Hardness of Regulated Metal Deposition Welded ASTM A387-Gr.11-Cl.2 Steel Plates. Materials 2022, 15, 6661. https://doi.org/10.3390/ma15196661

Bandhu D, Djavanroodi F, Shaikshavali G, Vora JJ, Abhishek K, Thakur A, Kumari S, Saxena KK, Ebrahimi M, Attarilar S. Effect of Metal-Cored Filler Wire on Surface Morphology and Micro-Hardness of Regulated Metal Deposition Welded ASTM A387-Gr.11-Cl.2 Steel Plates. Materials. 2022; 15(19):6661. https://doi.org/10.3390/ma15196661

Chicago/Turabian StyleBandhu, Din, Faramarz Djavanroodi, G. Shaikshavali, Jay J. Vora, Kumar Abhishek, Ashish Thakur, Soni Kumari, Kuldeep K. Saxena, Mahmoud Ebrahimi, and Shokouh Attarilar. 2022. "Effect of Metal-Cored Filler Wire on Surface Morphology and Micro-Hardness of Regulated Metal Deposition Welded ASTM A387-Gr.11-Cl.2 Steel Plates" Materials 15, no. 19: 6661. https://doi.org/10.3390/ma15196661

APA StyleBandhu, D., Djavanroodi, F., Shaikshavali, G., Vora, J. J., Abhishek, K., Thakur, A., Kumari, S., Saxena, K. K., Ebrahimi, M., & Attarilar, S. (2022). Effect of Metal-Cored Filler Wire on Surface Morphology and Micro-Hardness of Regulated Metal Deposition Welded ASTM A387-Gr.11-Cl.2 Steel Plates. Materials, 15(19), 6661. https://doi.org/10.3390/ma15196661