Optimized Alkali-Activated Slag-Based Concrete Reinforced with Recycled Tire Steel Fiber

Abstract

1. Introduction

2. Research Significance

3. Materials and Methods

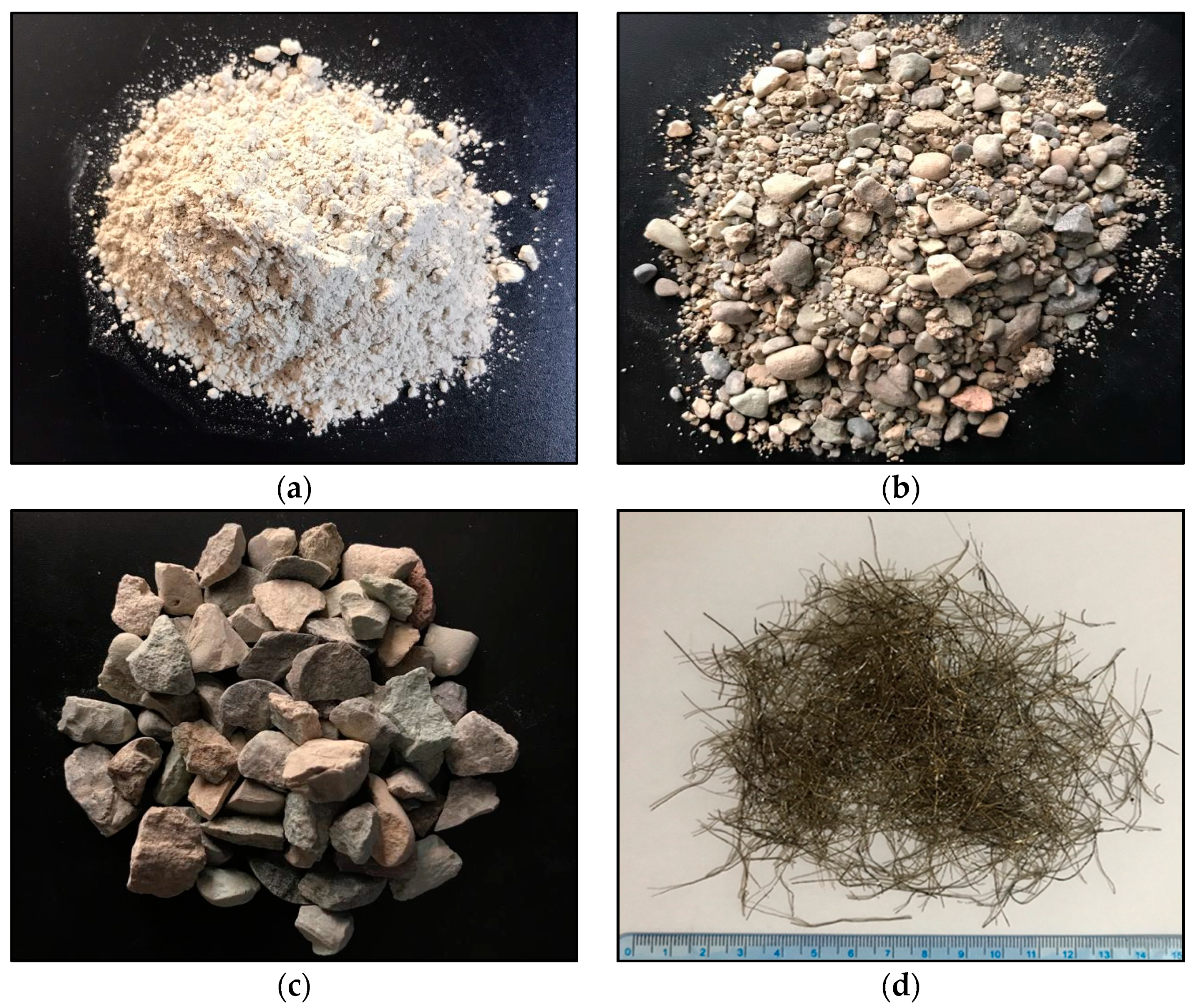

3.1. Materials

3.1.1. Slag

3.1.2. Activators

3.1.3. Aggregates

3.1.4. Superplasticizer

3.1.5. Fiber

3.2. Mixing, Casting, and Curing

3.3. Testing Methods

3.3.1. Optimization of AASC

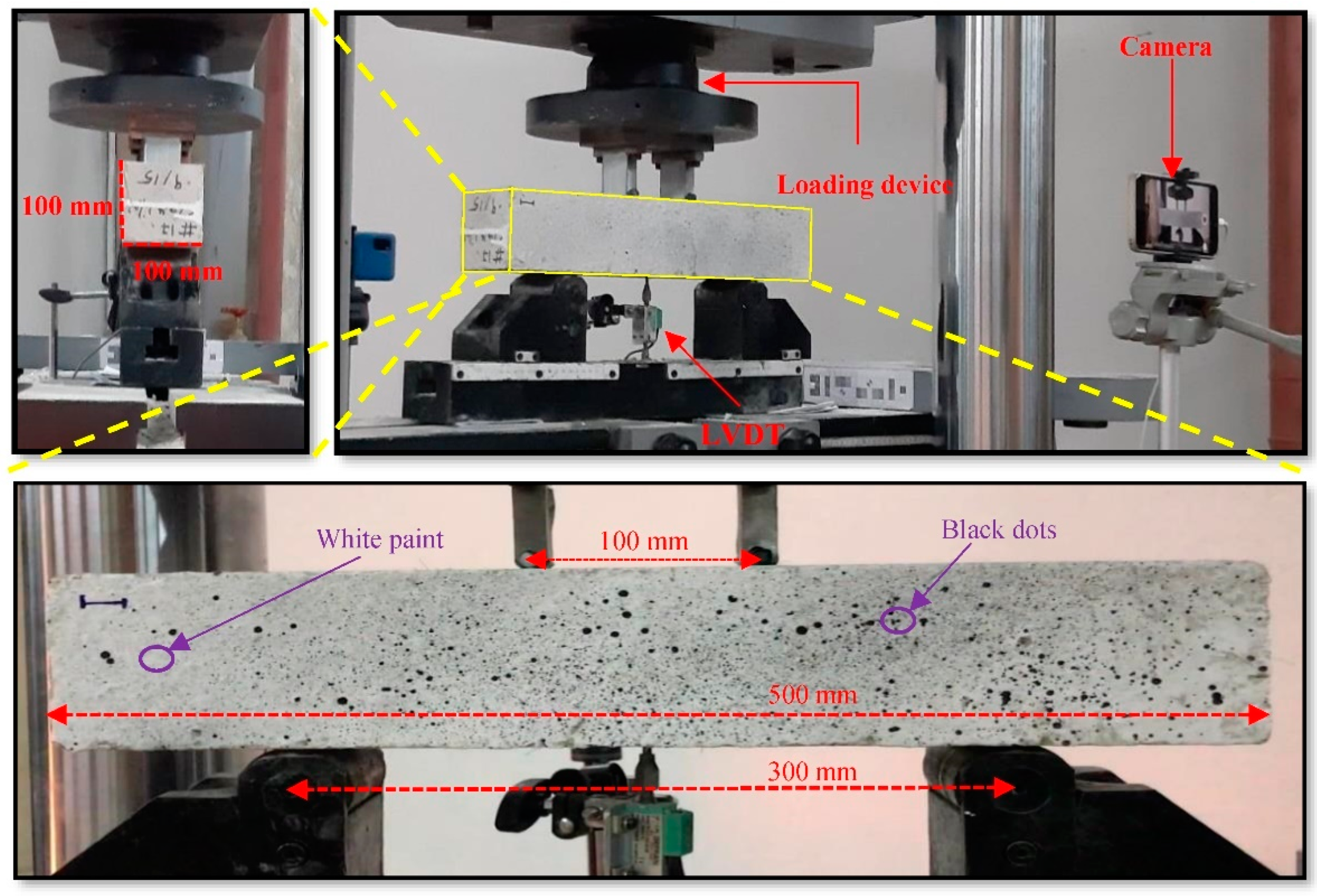

3.3.2. Physical and Mechanical Properties of FR-AASC

3.4. Optimization Method

3.4.1. Determination of Parameters and Responses

3.4.2. Selection of Taguchi Orthogonal Array

3.4.3. Signal-to-Noise Ratio

3.4.4. Grey Relational Analysis

- Grey relational generating;

- Grey relational coefficient;

- Grey relational grade;

- Optimal levels of factors;

3.4.5. Analysis of Variance

3.4.6. Verification Experiments

4. Results and Discussion

4.1. Optimization of AASC

4.2. Physical and Mechanical Properties of FR-AASC

4.2.1. Workability

4.2.2. Demolded Density and Water Absorption

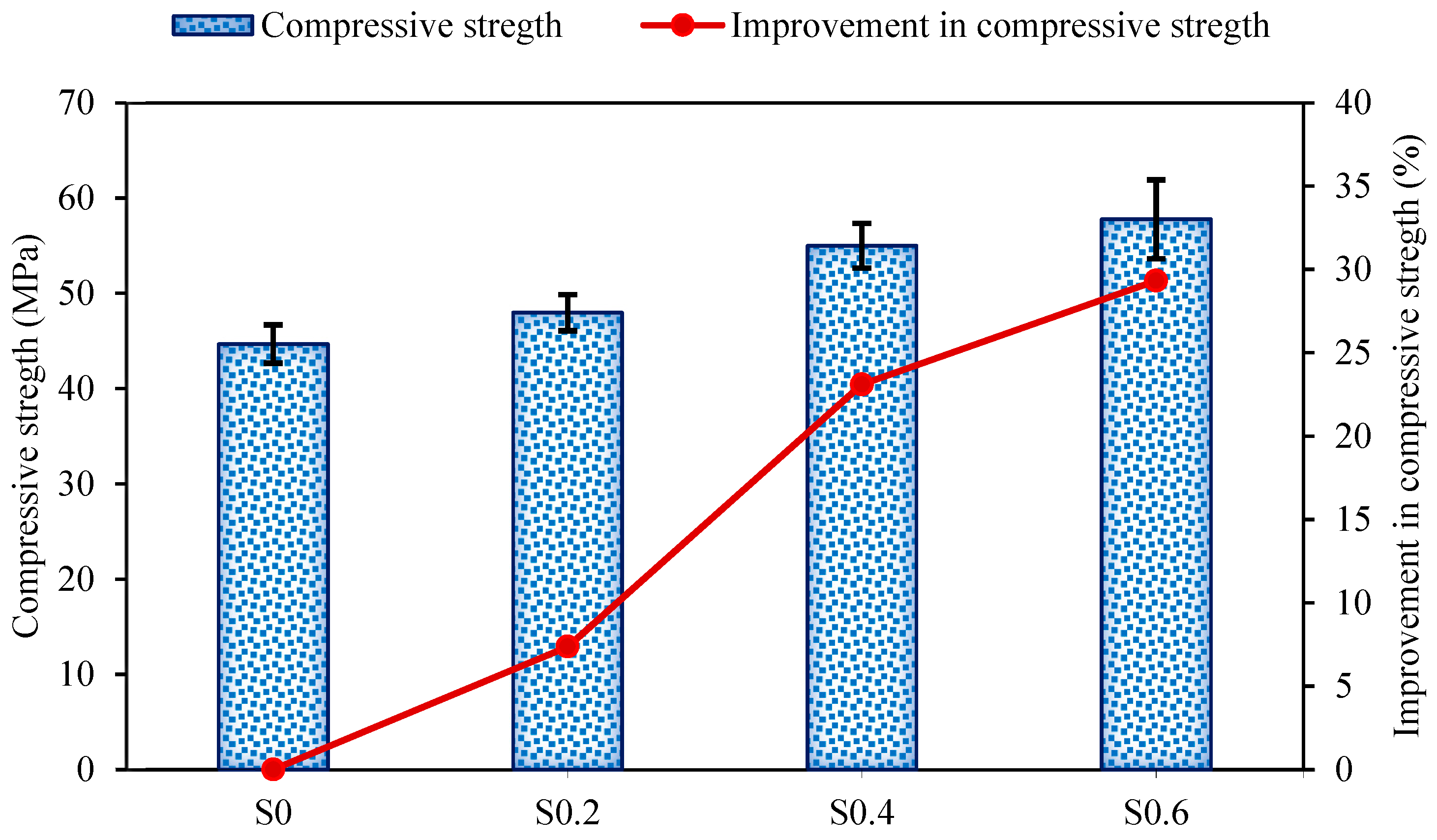

4.2.3. Compressive Strength

4.2.4. Flexural Performance of FR-AASC

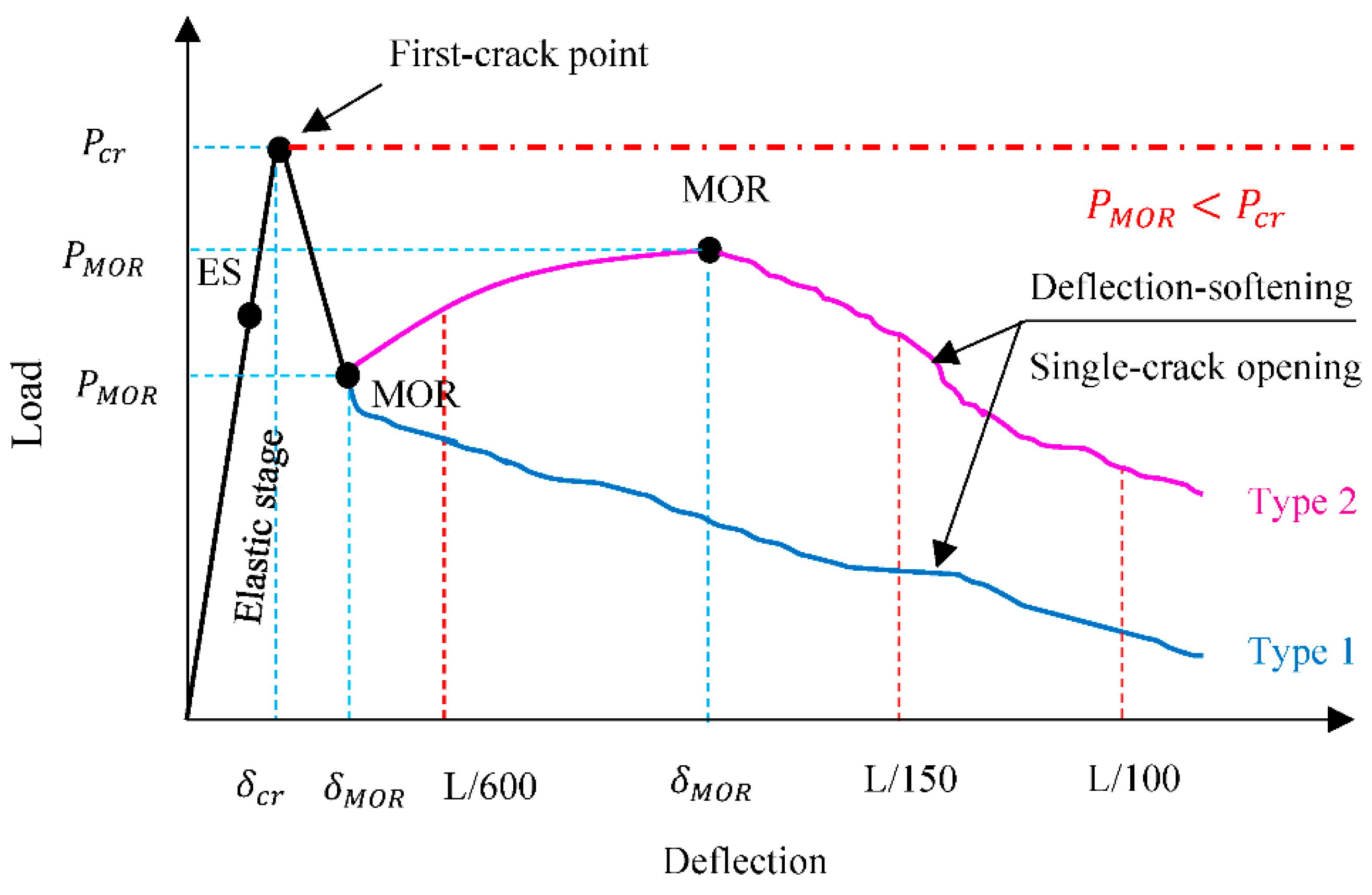

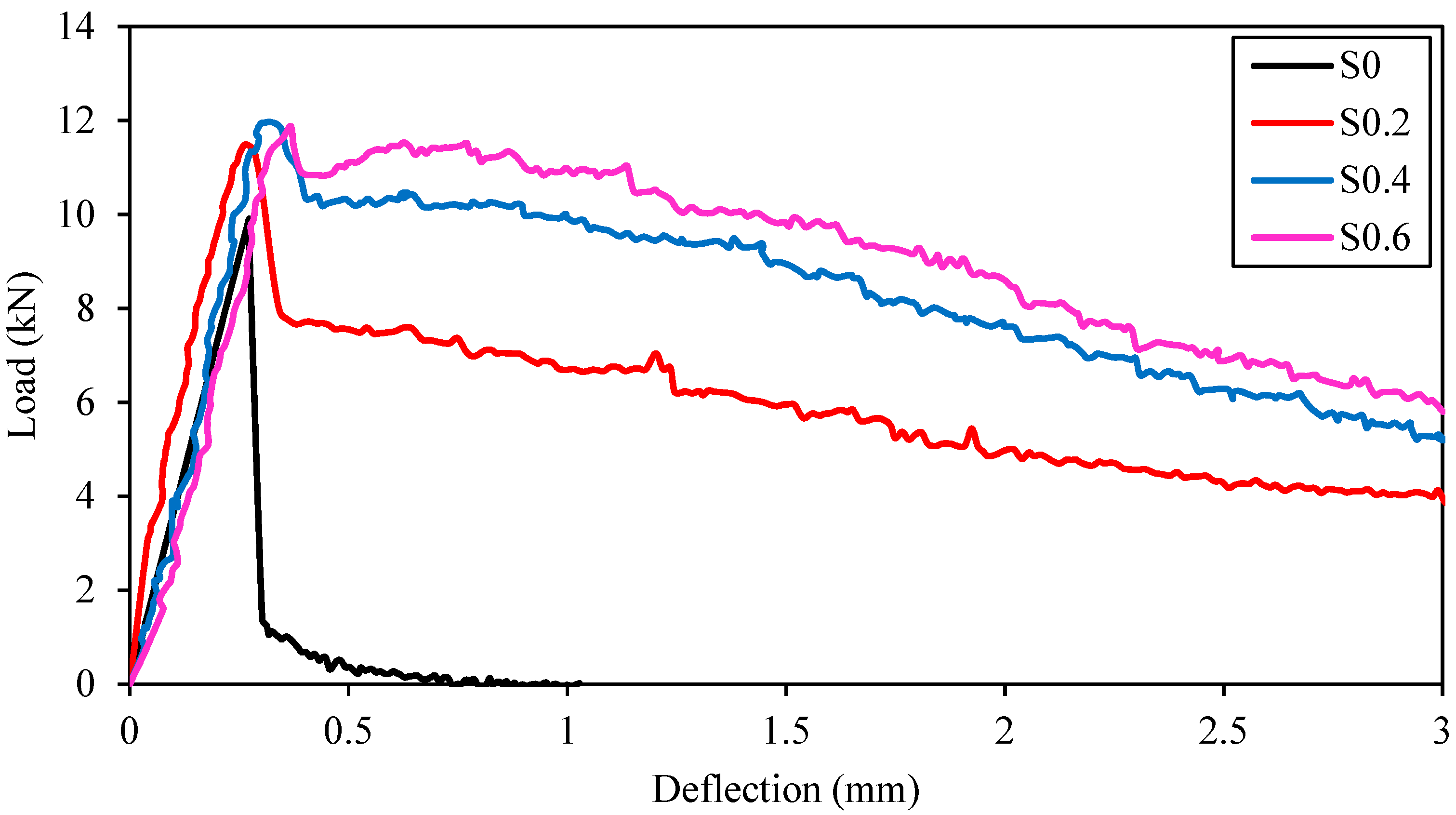

Load-Deflection Behavior

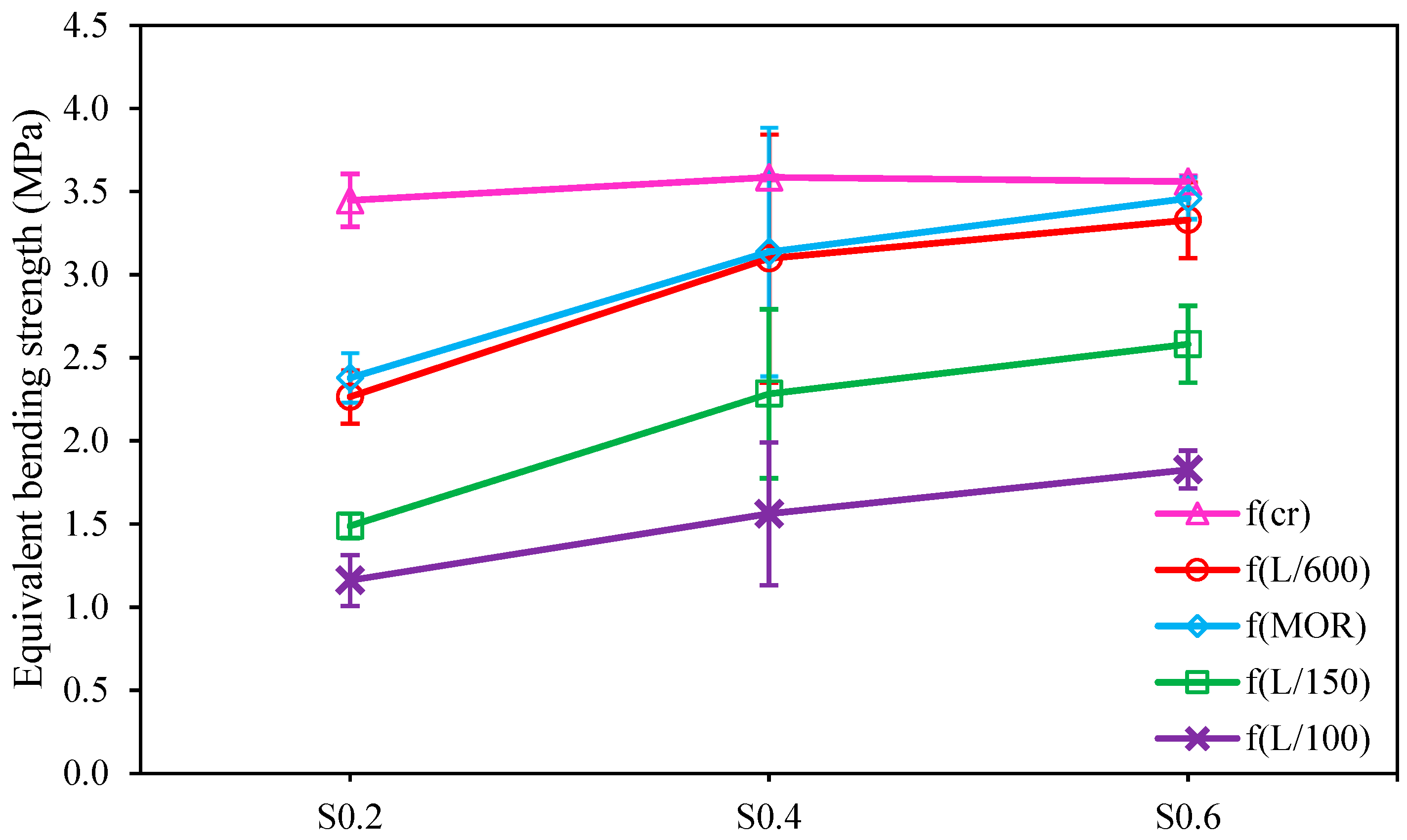

Equivalent Bending Strength (Load Carrying Capacity)

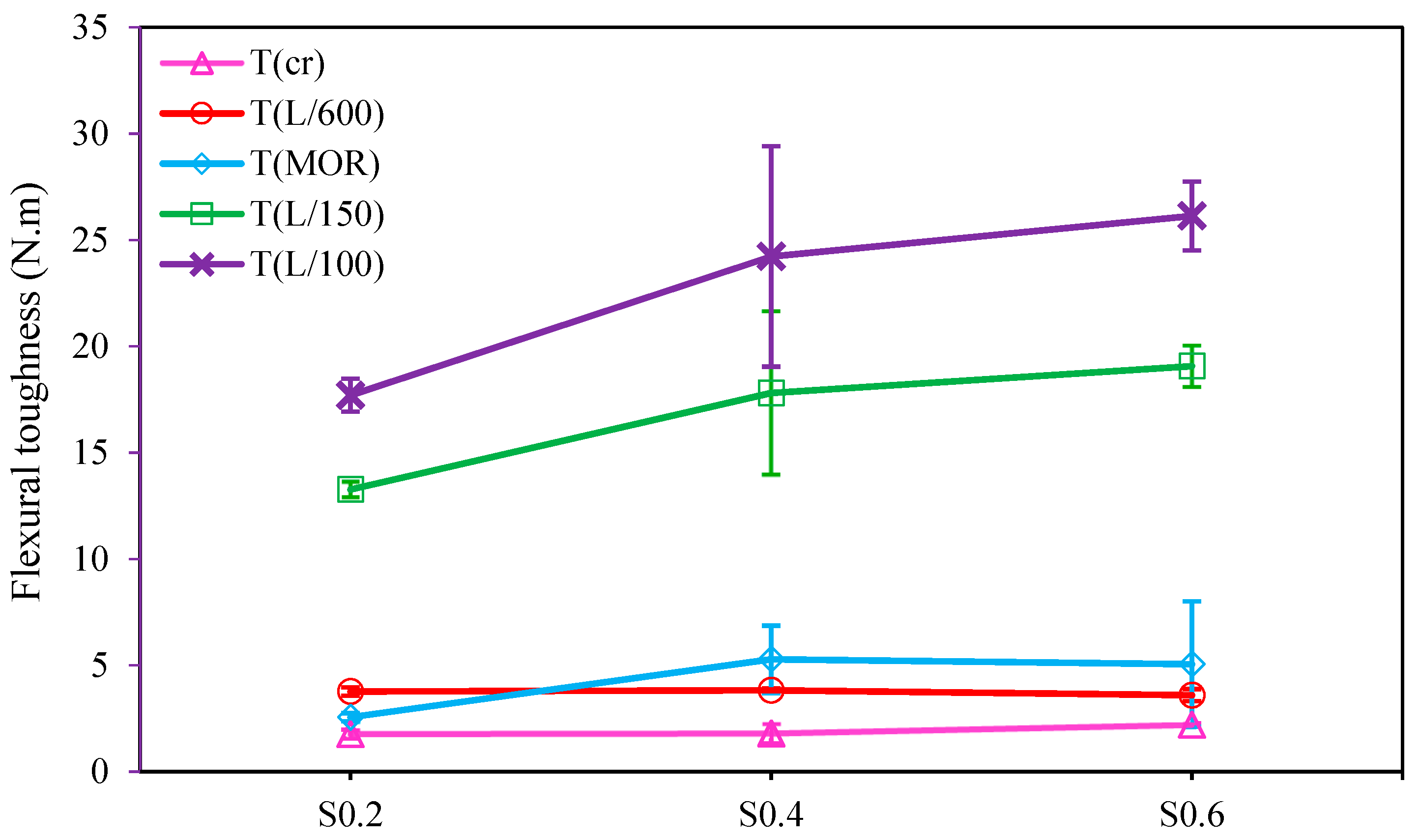

Flexural Toughness

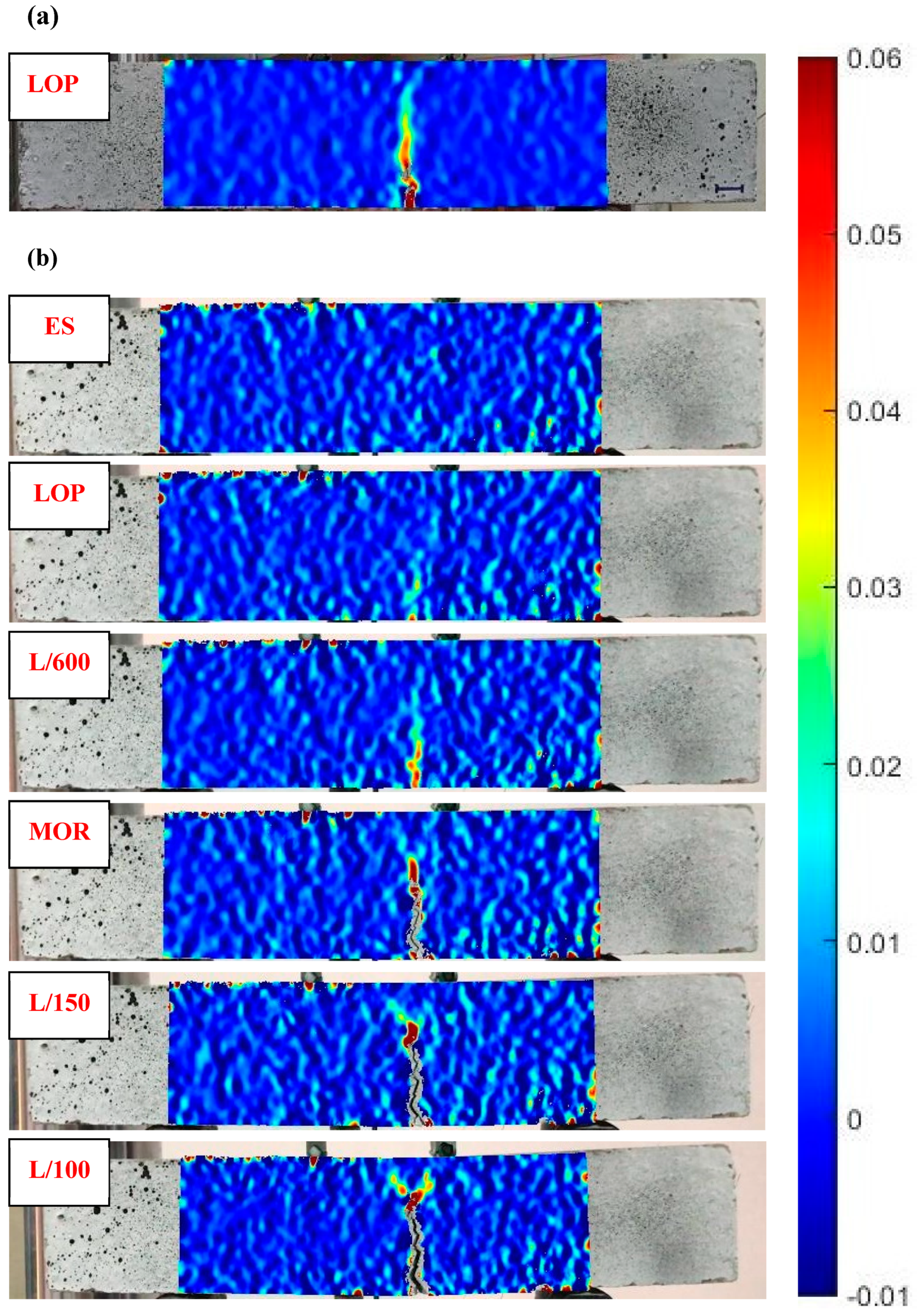

Analysis of Crack Propagation Utilizing the DIC Technique

5. Conclusions

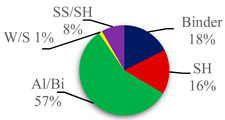

- Based on the results of grey relation analysis, the optimal AASC mixture in terms of multi-response is obtained from the A3B3C4D3E1 combination with a binder content of 400 kg/m3, SH molarity of 14 M, Al/Bi ratio of 0.55, W/S ratio of 0.40, and SS/SH ratio of 1.75. The Al/Bi ratio and workability have the strongest correlation to responses and parameters, respectively.

- The results of the ANOVA of the GRG showed that the Al/Bi ratio has the greatest influence (57%) on multiple responses of AASC, followed by the binder content (18%), the molarity of SH (16%), the SS/SH ratio (8%), and the W/S ratio (1%).

- Based on the confirmation tests results, the overall performance characteristics of AASC are improved, and the highest GRG among all AASC mixes is attained, indicating that the combination of optimal parameters proposed by Taguchi-Grey relational analysis performs well in terms of multiple characteristics of AASC.

- Considering the physical properties, the inclusion of RTSF in the AASC mixtures causes a reduction of 54% in workability, a slight rise of 1.2% in demolded density, and a slight reduction of 7.5% in water absorption when the RTSF volume fraction increases from 0% to 0.6%.

- The compressive strength of AASC improves by nearly 30% with the inclusion of a 0.6% volume fraction of RTSF (S0.6) and reaches 57.8 MPa. The vertical columnar cracking pattern in unreinforced cylindrical specimens (used for compressive strength tests) changes to distributed small vertical cracks and diagonal cracking patterns as the RTSF dosage in the mixture increases.

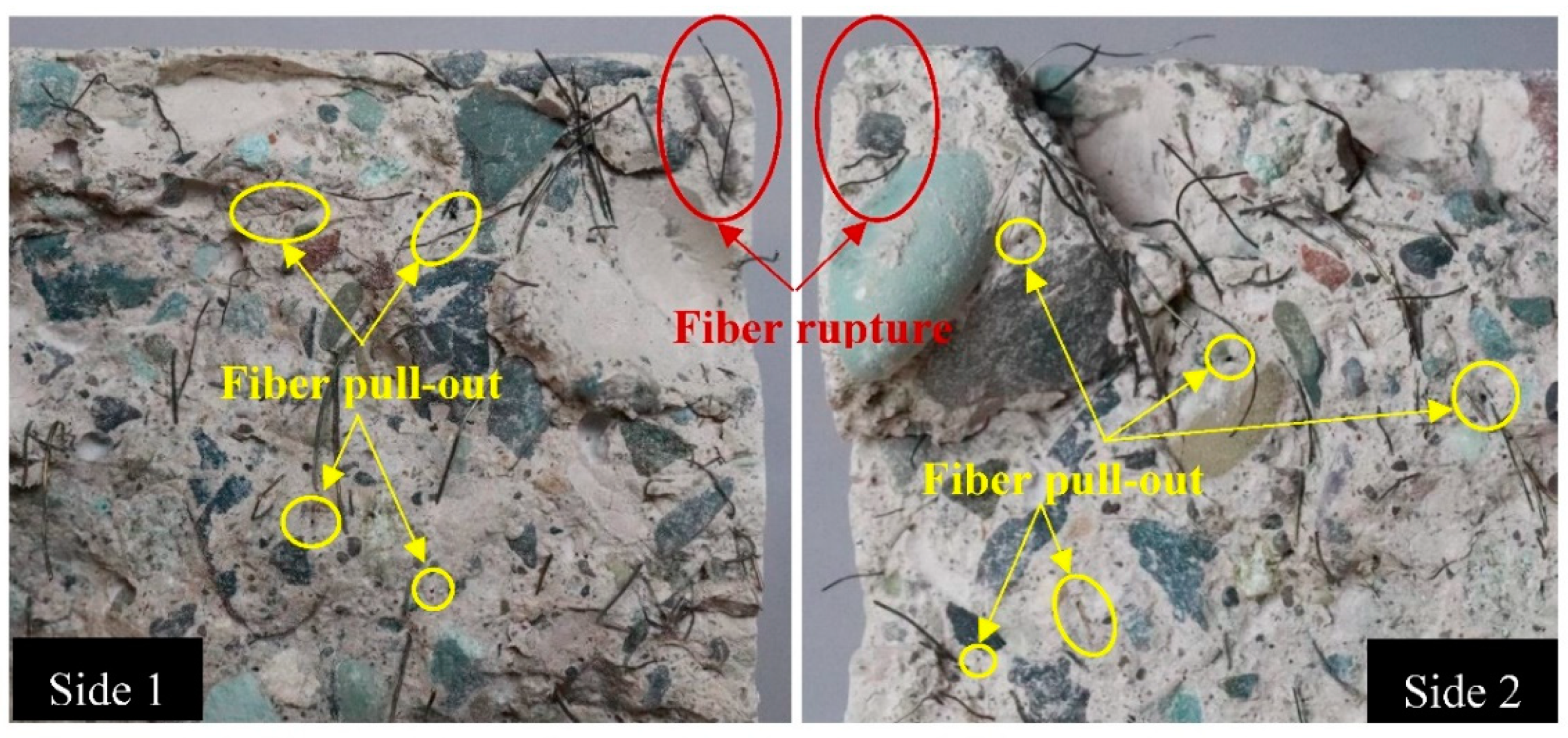

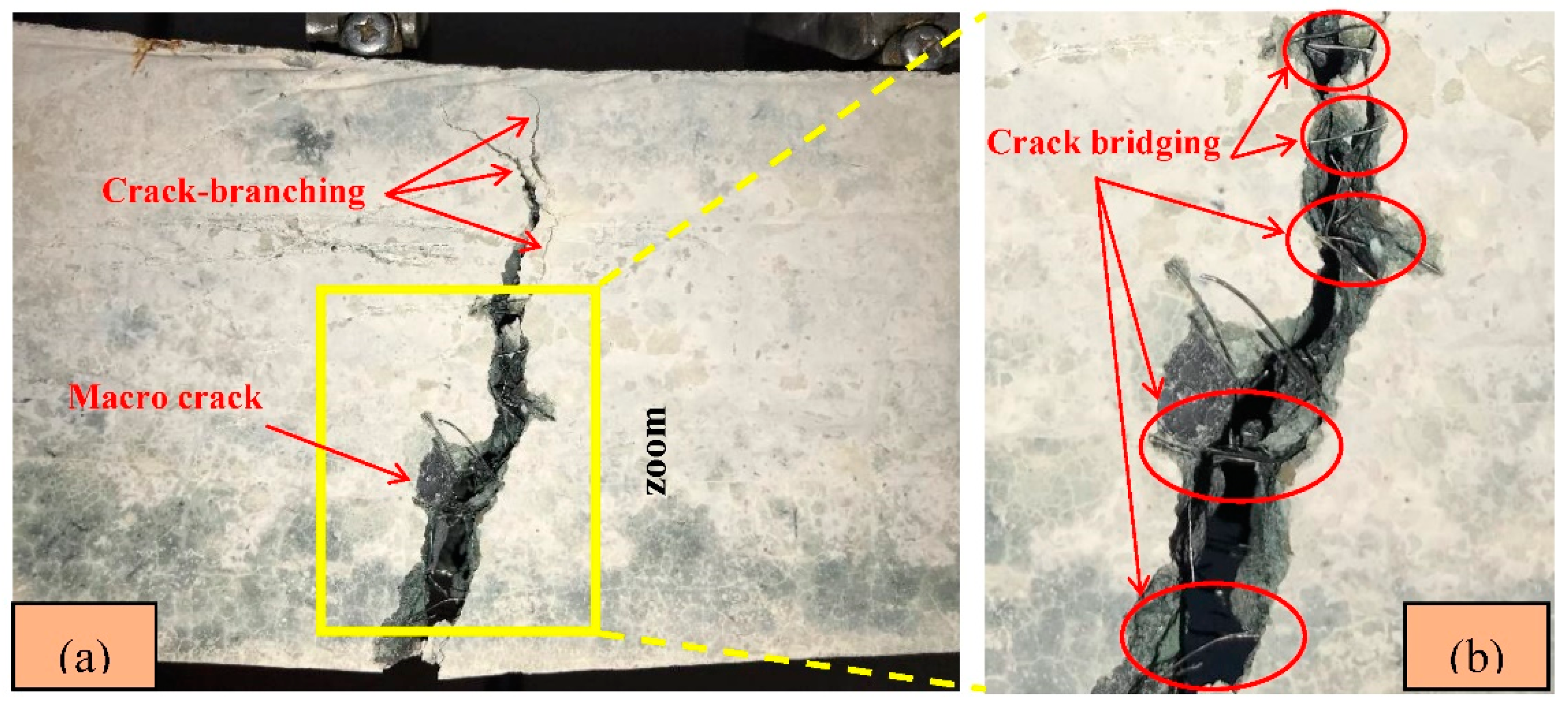

- Regarding flexural behavior, RTSF incorporation in the AASC mixture transforms the brittle mode of failure to ductile. A slight deflection-hardening stage in the load-deflection curve of bending specimens emerges when the RTSF content increases. A growth of 19.3% in first-crack strength (fcr) is recognized by increasing the RTSF content, while it seems to have no significant influence on first-crack deflection (cr). Accordingly, the post-cracking performance of fiber-reinforced AASC (FR-AASC) in terms of strength enhances via the fiber-bridging mechanism. S0.6 attained the highest Modulus of Rupture (fMOR) of 3.46 MPa, about 10.3% and 45.4% higher than that of S0.4 and S0.2 with 0.4% and 0.2% volume fractions of RTSF, respectively.

- The outstanding contribution of fiber bridging to the flexural toughness becomes evident at high deflection values. In this regard, the more the fiber content, the higher the flexural toughness. For example, S0.6 attained the highest toughness of 26.12 N. m at a mid-span deflection of 3 mm (TL/100), whereas S0.2 had the lowest TL/100 (17.70 N. m).

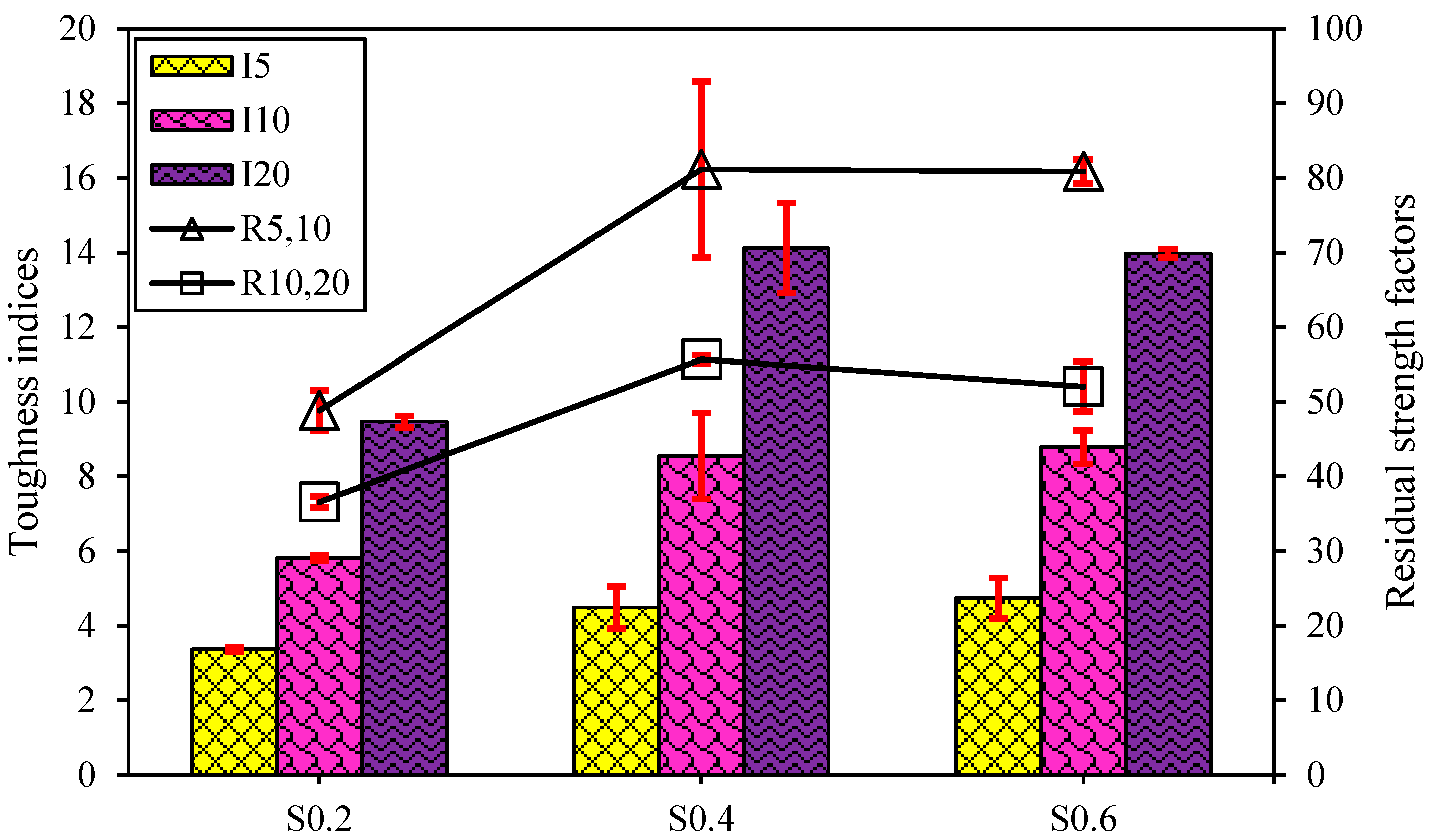

- Due to the balling of fibers with a 0.6% volume fraction in the AASC mixture, the inconsistent properties of RTSF and fiber rupture, toughness indices, and residual strength factors level off in 0.4% RTSF volume fraction after growth is observed due to increasing the fiber content from 0.2% to 0.4%.

- With the help of the DIC technique in tracing the crack evolution, it is observed that increasing the RTSF content postpones crack development by bridging action. Additionally, a single crack is transformed into a twisty branched crack due to the shorter distance between the fibers of the high-volume fraction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, X.; Yu, Q.L.; Yu, R.; Brouwers, H.J.H. Evaluation of hybrid steel fiber reinforcement in high performance geopolymer composites. Mater. Struct. 2017, 50, 1033. [Google Scholar] [CrossRef]

- Jithendra, C.; Elavenil, S. Influences of Parameters on Slump Flow and Compressive Strength Properties of Aluminosilicate Based Flowable Geopolymer Concrete Using Taguchi Method. Silicon 2020, 12, 595–602. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Salem, H.A. Effect of water addition, plasticizer and alkaline solution constitution on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 121, 694–703. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Puertas, F.; Palacios, M.; Manzano, H.; Dolado, J.S.; Rico, A.; Rodríguez, J. A model for the C-A-S-H gel formed in alkali-activated slag cements. J. Eur. Ceram. Soc. 2011, 31, 2043–2056. [Google Scholar] [CrossRef]

- Rangan, B.V. Geopolymer concrete for environmental protection. Indian Concr. J. 2014, 88, 41–59. Available online: http://hdl.handle.net/20.500.11937/29749 (accessed on 1 April 2014).

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Salem, H.A.; Elmoaty, A.; Elmoaty, M.A.; Salem, H.A.; Elmoaty, A.E.M.A.; Salem, H.A. Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 123, 581–593. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Zhang, H.; Parkinson, S. Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J. Build. Eng. 2019, 23, 301–313. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Goodier, C.I.; Austin, S.A. Factors affecting the slump and strength development of geopolymer concrete. Constr. Build. Mater. 2020, 261, 119945. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Aravinthan, T. Bond behaviour of composite sandwich panel and epoxy polymer matrix: Taguchi design of experiments and theoretical predictions. Constr. Build. Mater. 2017, 145, 76–87. [Google Scholar] [CrossRef]

- Chou, C.S.; Yang, R.Y.; Chen, J.H.; Chou, S.W. The optimum conditions for preparing the lead-free piezoelectric ceramic of Bi0.5Na0.5TiO3 using the Taguchi method. Powder Technol. 2010, 199, 264–271. [Google Scholar] [CrossRef]

- Olivia, M.; Nikraz, H. Properties of fly ash geopolymer concrete designed by Taguchi method. Mater. Des. 2012, 36, 191–198. [Google Scholar] [CrossRef]

- Agboola, O.O.; Ikubanni, P.P.; Adeleke, A.A.; Adediran, A.A.; Adesina, O.S.; Aliyu, S.J.; Olabamiji, T.S. Optimization of heat treatment parameters of medium carbon steel quenched in different media using Taguchi method and grey relational analysis. Heliyon 2020, 6, e04444. [Google Scholar] [CrossRef]

- Chiang, J.S.; Wu, P.L.; Chiang, S.D.; Chang, T.J.; Chang, S.T.; Wen, K.L. Introduction to Grey System Theory. J. Grey Syst. 1998, 1, 1–24. [Google Scholar]

- Fung, C.P. Manufacturing process optimization for wear property of fiber-reinforced polybutylene terephthalate composites with grey relational analysis. Wear 2003, 254, 298–306. [Google Scholar] [CrossRef]

- Chang, C.Y.; Huang, R.; Lee, P.C.; Weng, T.L. Application of a weighted Grey-Taguchi method for optimizing recycled aggregate concrete mixtures. Cem. Concr. Compos. 2011, 33, 1038–1049. [Google Scholar] [CrossRef]

- Prusty, J.K.; Pradhan, B. Multi-response optimization using Taguchi-Grey relational analysis for composition of fly ash-ground granulated blast furnace slag based geopolymer concrete. Constr. Build. Mater. 2020, 241, 118049. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Mehrali, M.; Alengaram, U.J.; Jumaat, M.Z. High tensile strength fly ash based geopolymer composite using copper coated micro steel fiber. Constr. Build. Mater. 2016, 112, 629–638. [Google Scholar] [CrossRef]

- Wang, Y.; Aslani, F.; Valizadeh, A. An investigation into the mechanical behaviour of fibre-reinforced geopolymer concrete incorporating NiTi shape memory alloy, steel and polypropylene fibres. Constr. Build. Mater. 2020, 259, 119765. [Google Scholar] [CrossRef]

- Koenig, A.; Wuestemann, A.; Gatti, F.; Rossi, L.; Fuchs, F.; Fessel, D.; Dathe, F.; Dehn, F.; Minelli, F. Flexural behaviour of steel and macro-PP fibre reinforced concretes based on alkali-activated binders. Constr. Build. Mater. 2019, 211, 583–593. [Google Scholar] [CrossRef]

- Kim, S.; Jang, S.; Kang, D.; Ahn, K.; Yun, H. Mechanical Properties and Eco-Efficiency of Steel Fiber Reinforced Alkali-Activated Slag Concrete. Materials 2015, 8, 7309–7321. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Zhang, N.; Yan, C.; Li, L.; Khan, M. Assessment of fiber factor for the fracture toughness of polyethylene fiber reinforced geopolymer. Constr. Build. Mater. 2022, 319, 126130. [Google Scholar] [CrossRef]

- Cao, M.; Khan, M. Effectiveness of multiscale hybrid fiber reinforced cementitious composites under single degree of freedom hydraulic shaking table. Struct. Concr. 2021, 22, 535–549. [Google Scholar] [CrossRef]

- Li, L.; Sun, H.X.; Zhang, Y.; Yu, B. Surface cracking and fractal characteristics of bending fractured polypropylene fiber-reinforced geopolymer mortar. Fractal Fract. 2021, 5, 142. [Google Scholar] [CrossRef]

- Pu, S.; Zhu, Z.; Huo, W. Evaluation of engineering properties and environmental effect of recycled gypsum stabilized soil in geotechnical engineering: A comprehensive review. Resour. Conserv. Recycl. 2021, 174, 105780. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Scrap tire steel fiber as a substitute for commercial steel fiber in cement mortar: Engineering properties and cost-bene fit analyses. Resour. Conserv. Recycl. 2018, 134, 248–256. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef] [PubMed]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299. [Google Scholar] [CrossRef]

- Zamanzadeh, Z.; Lourenço, L.; Barros, J. Recycled Steel Fibre Reinforced Concrete failing in bending and in shear. Constr. Build. Mater. 2015, 85, 195–207. [Google Scholar] [CrossRef]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Mucsi, G.; Szenczi, Á.; Nagy, S. Fiber reinforced geopolymer from synergetic utilization of fly ash and waste tire. J. Clean Prod. 2018, 178, 429–440. [Google Scholar] [CrossRef]

- Zhong, H.; Poon, E.W.; Chen, K.; Zhang, M. Engineering properties of crumb rubber alkali-activated mortar reinforced with recycled steel fibres. J. Clean Prod. 2019, 238, 117950. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Law, D.W.; Adam, A.A.; Molyneaux, T.K.; Patnaikuni, I. Durability assessment of alkali activated slag (AAS) concrete. Mater. Struct. 2012, 45, 1425–1437. [Google Scholar] [CrossRef]

- Chang, J.J. A study on the setting characteristics of sodium silicate-activated slag pastes. Cem. Concr. Res. 2003, 33, 1005–1011. [Google Scholar] [CrossRef]

- ASTM C128-15; Standard Test Method for Relative Gravity (Specific Gravity) and Absorption of Fine Aggregate. ASTM International, Annual Book of ASTM Standards. ASTM Standard: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/Standards/C128 (accessed on 1 January 2015).

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM Standard: West Conshohocken, PA, USA, 2015; pp. 1–5. Available online: https://www.astm.org/Standards/C127 (accessed on 1 January 2015).

- Wongpa, J.; Kiattikomol, K.; Jaturapitakkul, C.; Chindaprasirt, P. Compressive strength, modulus of elasticity, and water permeability of inorganic polymer concrete. Mater. Des. 2010, 31, 4748–4754. [Google Scholar] [CrossRef]

- Eskandarinia, M.; Esmailzade, M.; Aslani, F. Splitting tensile strength of recycled tire steel fiber-reinforced alkali-activated slag concrete designed by Taguchi method. Struct. Concr. 2022, 41, 2. [Google Scholar] [CrossRef]

- Afshar, A.; Jahandari, S.; Rasekh, H.; Shariati, M.; Afshar, A.; Shokrgozar, A. Corrosion resistance evaluation of rebars with various primers and coatings in concrete modified with different additives. Constr. Build. Mater. 2020, 262, 120034. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Jahandari, S.; Mohammadi, M.; Rahmani, A.; Abolhasani, M.; Miraki, H.; Mohammadifar, L.; Kazemi, M.; Saberian, M.; Rashidi, M. Mechanical properties of recycled aggregate concretes containing silica fume and steel fibres. Materials 2021, 14, 7065. [Google Scholar] [CrossRef] [PubMed]

- Jahandari, S.; Tao, Z.; Saberian, M.; Shariati, M.; Li, J.; Abolhasani, M.; Kazemi, M.; Rahmani, A.; Rashidi, M. Geotechnical properties of lime-geogrid improved clayey subgrade under various moisture conditions. Road Mater. Pavement Des. 2021, 23, 2057–2075. [Google Scholar] [CrossRef]

- Sadeghian, F.; Jahandari, S.; Haddad, A.; Rasekh, H.; Li, J. Effects of variations of voltage and pH value on the shear strength of soil and durability of different electrodes and piles during electrokinetic phenomenon. Rock Mech. Geotech. Eng. 2021, 14, 625–636. [Google Scholar] [CrossRef]

- Miraki, H.; Shariatmadari, N.; Ghadir, P.; Jahandari, S.; Tao, Z.; Siddique, R. Clayey soil stabilization using alkali-activated volcanic ash and slag. J. Rock Mech. Geotech. Eng. 2022, 14, 576–591. [Google Scholar] [CrossRef]

- Jahandari, S.; Saberian, M.; Tao, Z.; Mojtahedi, S.F.; Li, J.; Ghasemi, M.; Rezvani, S.S.; Li, W. Effects of saturation degrees, freezing-thawing, and curing on geotechnical properties of lime and lime-cement concretes. Cold Reg. Sci. Technol. 2019, 160, 242–251. [Google Scholar] [CrossRef]

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM Standard: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/Standards/C143 (accessed on 1 June 2020).

- ASTM C191-19; Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM Standard: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/Standards/C191 (accessed on 1 August 2019).

- BS 1881-116; Testing Concrete—Compressive Strength of Concrete Cubes. British Standard Institution: London, UK, 1983.

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM Standard: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/Standards/C138.htm (accessed on 15 March 2017).

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM Standard: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/Standards/C642.htm (accessed on 1 February 2013).

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM Standard: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/Standards/C39.htm (accessed on 1 March 2021).

- ASTM C1609/C1609M-19a; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM Standard: West Conshohocken, PA, USA, 2020. Available online: https://www.astm.org/Standards/C1609 (accessed on 15 December 2019).

- Kim, D.; Naaman, A.E.; El-tawil, S. Comparative flexural behavior of four fiber reinforced cementitious composites. Cem. Concr. Compos. 2008, 30, 917–928. [Google Scholar] [CrossRef]

- ASTM C1018-97; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM Standard: West Conshohocken, PA, USA, 1997; Volume 4, p. 7.

- Shi, F.; Pham, T.M.; Hao, H.; Hao, Y. Post-cracking behaviour of basalt and macro polypropylene hybrid fibre reinforced concrete with different compressive strengths. Constr. Build. Mater. 2020, 262, 120108. [Google Scholar] [CrossRef]

- Roy, R.K. A Primer on the Taguchi Method Second Edition. 2010. Available online: www.sme.org/store (accessed on 17 August 2021).

- Mehat, N.M.; Kamaruddin, S.; Othman, A.R. Hybrid Integration of Taguchi Parametric Design, Grey Relational Analysis, and Principal Component Analysis Optimization for Plastic Gear Production. Chin. J. Eng. 2014, 2014, 351206. [Google Scholar] [CrossRef]

- Hasçalik, A.; Çaydaş, U. Optimization of turning parameters for surface roughness and tool life based on the Taguchi method. Int. J. Adv. Manuf. Technol. 2008, 38, 896–903. [Google Scholar] [CrossRef]

- Song, C.; Wang, H.; Sun, Z.; Wei, Z.; Yu, H.; Chen, H.; Wang, Y. Optimization of process parameters using the Grey-Taguchi method and experimental validation in TRIP-assisted steel. Mater. Sci. Eng. A 2020, 777, 139084. [Google Scholar] [CrossRef]

- Equbal, I.; Kumar, R.; Shamim, M.; Ohdar, R. A Grey-based Taguchi Method to Optimize Hot Forging Process. Procedia Mater. Sci. 2014, 6, 1495–1504. [Google Scholar] [CrossRef][Green Version]

- Arıcı, E.; Keleştemur, O. Optimization of mortars containing steel scale using Taguchi based grey relational analysis method. Constr. Build. Mater. 2019, 214, 232–241. [Google Scholar] [CrossRef]

- Thapa, S.; Engelken, R. Optimization of pelleting parameters for producing composite pellets using agricultural and agro-processing wastes by Taguchi-Grey relational analysis. Carbon Resour. Convers. 2020, 3, 104–111. [Google Scholar] [CrossRef]

- Canbolat, A.S.; Bademlioglu, A.H.; Arslanoglu, N.; Kaynakli, O. Performance optimization of absorption refrigeration systems using Taguchi, ANOVA and Grey Relational Analysis methods. J. Clean Prod. 2019, 229, 874–885. [Google Scholar] [CrossRef]

- Taiwo, A.E.; Madzimbamuto, T.N.; Ojumu, T.V. Optimization of process variables for acetoin production in a bioreactor using Taguchi orthogonal array design. Heliyon 2020, 6, e05103. [Google Scholar] [CrossRef]

- Hussain, M.Z.; Khan, S.; Sarmah, P. Optimization of powder metallurgy processing parameters of Al2O3/Cu composite through Taguchi method with Grey relational analysis. J. King Saud Univ.-Eng. Sci. 2020, 32, 274–286. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Shi, C.; Zhu, D.; Li, N.; Deng, Y. Development of ultra-high performance geopolymer concrete (UHPGC): Influence of steel fiber on mechanical properties. Cem. Concr. Compos. 2020, 112, 103670. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Rashad, A.M. Effect of steel fibers on geopolymer properties—The best synopsis for civil engineer. Constr. Build. Mater. 2020, 246, 118534. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Dai, J.-G.G. Tensile behavior and microstructure of hybrid fiber ambient cured one-part engineered geopolymer composites. Constr. Build. Mater. 2018, 184, 419–431. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Metselaar, H.S.C.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Ganesan, N.; Abraham, R.; Raj, S.D. Durability characteristics of steel fibre reinforced geopolymer concrete. Constr. Build. Mater. 2015, 93, 471–476. [Google Scholar] [CrossRef]

- Moradikhou, A.B.; Esparham, A.; Avanaki, M.J. Physical & mechanical properties of fiber reinforced metakaolin-based geopolymer concrete. Constr. Build. Mater. 2020, 251, 118965. [Google Scholar] [CrossRef]

- Abdullah, M.M.A.B.; Faris, M.A.; Tahir, M.F.M.; Kadir, A.A.; Sandu, A.V.; Isa, N.A.A.M.; Corbu, O. Performance and Characterization of Geopolymer Concrete Reinforced with Short Steel Fiber. IOP Conf. Series: Mater. Sci. Eng. 2017, 209, 12038. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Rossi, P.; Acker, P.; Malier, Y. Effect of steel fibres at two different stages: The material and the structure. Mater. Struct. 1987, 20, 436–439. [Google Scholar] [CrossRef]

- Turk, K.; Bassurucu, M.; Enes, R. Workability, strength and flexural toughness properties of hybrid steel fiber reinforced SCC with high-volume fiber. Constr. Build. Mater. 2021, 266, 120944. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Experimental study on engineering properties of concrete reinforced with hybrid recycled tyre steel and polypropylene fibres. J. Clean. Prod. 2020, 259, 120914. [Google Scholar] [CrossRef]

- Grzymski, F.; Musiał, M.; Trapko, T. Mechanical properties of fibre reinforced concrete with recycled fibres. Constr. Build. Mater. 2019, 198, 323–331. [Google Scholar] [CrossRef]

- Frazão, C.; Díaz, B.; Barros, J.; Bogas, A.; Toptan, F. An Experimental Study on the Corrosion Susceptibility of Recycled Steel Fiber Reinforced Concrete. Cem. Concr. Compos. 2018, 96, 138–153. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. Experimental investigation on the flexural behavior of hybrid steel-PVA fiber reinforced concrete containing fly ash and slag powder. Constr. Build. Mater. 2019, 228, 116706. [Google Scholar] [CrossRef]

- Niu, Y.; Huang, H.; Zhang, J.; Jin, W.; Wei, J.; Yu, Q. Development of the strain field along the crack in ultra-high-performance fi ber-reinforced concrete (UHPFRC) under bending by digital image correlation technique. Cem. Concr. Res. 2019, 125, 105821. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

| Content | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | Mn2O3 | TiO2 | LOI | Kb | HM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Results | 36.50(%) | 11.00(%) | 0.70(%) | 38.50(%) | 9.20(%) | 0.30(%) | 0.60(%) | 0.55(%) | 1.50(%) | 1.50(%) | 0.50(%) | 1.00(-) | 1.61(-) |

| Parameters | Designation | Level-1 | Level-2 | Level-3 | Level-4 |

|---|---|---|---|---|---|

| Binder content (kg/m3) | A | 350 | 375 | 400 | 425 |

| SH (M) | B | 10 | 12 | 14 | 16 |

| Al/Bi ratio | C | 0.4 | 0.45 | 0.5 | 0.55 |

| W/S ratio | D | 0.35 | 0.375 | 0.4 | 0.425 |

| SS/SH ratio | E | 1.75 | 2 | 2.25 | 2.5 |

| Trial Mix | Mix ID | Factors and Values | Concrete Mixture Quantity (kg/m3) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Binder Content (kg/m3) | Molarity of SH (M) | Al/Bi Ratio | W/S Ratio | SS/SH Ratio | Slag | SS | SH | Al | EW | SP | CA | FA | ||

| TM1 | A1B1C1D1E1 | 350 | 10 | 0.40 | 0.35 | 1.75 | 350 | 89.1 | 50.9 | 140.0 | 52.1 | 3.5 | 943.5 | 932.5 |

| TM2 | A1B2C2D2E2 | 350 | 12 | 0.45 | 0.38 | 2.00 | 350 | 105.0 | 52.5 | 157.5 | 57.5 | 3.5 | 923.5 | 912.7 |

| TM3 | A1B3C3D3E3 | 350 | 14 | 0.50 | 0.40 | 2.25 | 350 | 121.2 | 53.8 | 175.0 | 63.8 | 3.5 | 902.5 | 891.9 |

| TM4 | A1B4C4D4E4 | 350 | 16 | 0.55 | 0.43 | 2.50 | 350 | 137.5 | 55.0 | 192.5 | 70.7 | 3.5 | 880.4 | 870.1 |

| TM5 | A2B1C2D3E4 | 375 | 10 | 0.45 | 0.40 | 2.50 | 375 | 120.5 | 48.2 | 168.8 | 69.9 | 3.8 | 886.8 | 876.4 |

| TM6 | A2B2C1D4E3 | 375 | 12 | 0.40 | 0.43 | 2.25 | 375 | 103.8 | 46.2 | 150.0 | 92.2 | 3.8 | 875.2 | 865.0 |

| TM7 | A2B3C4D1E2 | 375 | 14 | 0.55 | 0.35 | 2.00 | 375 | 137.5 | 68.8 | 206.3 | 37.3 | 3.8 | 898.3 | 887.8 |

| TM8 | A2B4C3D2E1 | 375 | 16 | 0.50 | 0.38 | 1.75 | 375 | 119.3 | 68.2 | 187.5 | 61.9 | 3.8 | 883.9 | 873.6 |

| TM9 | A3B1C3D4E1 | 400 | 10 | 0.50 | 0.43 | 2.00 | 400 | 133.3 | 66.7 | 200.0 | 75.7 | 4.0 | 839.5 | 829.7 |

| TM10 | A3B2C4D3E1 | 400 | 12 | 0.55 | 0.40 | 1.75 | 400 | 140.0 | 80.0 | 220.0 | 58.7 | 4.0 | 844.9 | 835.0 |

| TM11 | A3B3C1D2E4 | 400 | 14 | 0.40 | 0.38 | 2.50 | 400 | 114.3 | 45.7 | 160.0 | 78.6 | 4.0 | 875.2 | 865.0 |

| TM12 | A3B4C2D1E3 | 400 | 16 | 0.45 | 0.35 | 2.25 | 400 | 124.6 | 55.4 | 180.0 | 61.7 | 4.0 | 880.8 | 870.5 |

| TM13 | A4B1C4D2E3 | 425 | 10 | 0.55 | 0.38 | 2.25 | 425 | 161.8 | 71.9 | 233.8 | 45.6 | 4.3 | 838.8 | 829.0 |

| TM14 | A4B2C3D1E4 | 425 | 12 | 0.50 | 0.35 | 2.50 | 425 | 151.8 | 60.7 | 212.5 | 47.7 | 4.3 | 857.5 | 847.4 |

| TM15 | A4B3C2D4E1 | 425 | 14 | 0.45 | 0.43 | 1.75 | 425 | 121.7 | 69.5 | 191.3 | 99.4 | 4.3 | 809.2 | 799.7 |

| TM16 | A4B4C1D3E2 | 425 | 16 | 0.40 | 0.40 | 2.00 | 425 | 113.3 | 56.7 | 170.0 | 99.9 | 4.3 | 829.0 | 819.3 |

| Trial Mix | Mix ID (Combination) | Experimental Results | Signal-to-Noise (S/N) Ratio | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Slump (mm) | ST (min) | CS (MPa) | Slump | ST | CS | ||||||

| Initial | Final | 7-day | 28-day | Initial | Final | 7-day | 28-day | ||||

| TM1 | A1B1C1D1E1 | 45 | 30 | 54 | 35.48 | 43.59 | 33.06 | 29.54 | 34.65 | 31.00 | 32.79 |

| TM2 | A1B2C2D2E2 | 80 | 34 | 59 | 44.10 | 48.10 | 38.06 | 30.63 | 35.42 | 32.89 | 33.64 |

| TM3 | A1B3C3D3E3 | 120 | 48 | 83 | 42.06 | 47.56 | 41.58 | 33.62 | 38.38 | 32.48 | 33.54 |

| TM4 | A1B4C4D4E4 | 150 | 50 | 79 | 42.29 | 52.49 | 43.52 | 33.98 | 37.95 | 32.52 | 34.40 |

| TM5 | A2B1C2D3E4 | 180 | 33 | 55 | 36.78 | 45.65 | 45.11 | 30.37 | 34.81 | 31.31 | 33.19 |

| TM6 | A2B2C1D4E3 | 190 | 35 | 63 | 36.48 | 44.96 | 45.58 | 30.88 | 35.99 | 31.24 | 33.06 |

| TM7 | A2B3C4D1E2 | 55 | 52 | 90 | 47.41 | 59.44 | 34.81 | 34.32 | 39.08 | 33.52 | 35.48 |

| TM8 | A2B4C3D2E1 | 90 | 50 | 85 | 46.26 | 54.64 | 39.08 | 33.98 | 38.59 | 33.30 | 34.75 |

| TM9 | A3B1C3D4E1 | 240 | 49 | 84 | 36.63 | 50.62 | 47.60 | 33.80 | 38.49 | 31.28 | 34.09 |

| TM10 | A3B2C4D3E1 | 200 | 54 | 88 | 44.89 | 58.00 | 46.02 | 34.65 | 38.89 | 33.04 | 35.27 |

| TM11 | A3B3C1D2E4 | 130 | 34 | 60 | 41.64 | 55.82 | 42.28 | 30.63 | 35.56 | 32.39 | 34.94 |

| TM12 | A3B4C2D1E3 | 65 | 37 | 63 | 46.19 | 61.53 | 36.26 | 31.36 | 35.99 | 33.29 | 35.78 |

| TM13 | A4B1C4D2E3 | 225 | 41 | 72 | 38.63 | 52.38 | 47.04 | 32.26 | 37.15 | 31.74 | 34.38 |

| TM14 | A4B2C3D1E4 | 115 | 38 | 64 | 44.78 | 56.81 | 41.21 | 31.60 | 36.12 | 33.02 | 35.09 |

| TM15 | A4B3C2D4E1 | 260 | 40 | 68 | 41.29 | 53.54 | 48.30 | 32.04 | 36.65 | 32.32 | 34.57 |

| TM16 | A4B4C1D3E2 | 210 | 33 | 57 | 41.37 | 54.20 | 46.44 | 30.37 | 35.12 | 32.33 | 34.68 |

| Mix No | Normalized S/N Ratio | Deviation Sequences | Grey Relational Coefficient (GRC) | GRG | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Slump | ST | CS | Slump | ST | CS | Slump | ST | CS | Value | Rank | |||||||

| Initial | Final | 7-Day | 28-Day | Initial | Final | 7-Day | 28-Day | Initial | Final | 7-Day | 28-Day | ||||||

| TM1 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 0.33 | 16 |

| TM2 | 0.33 | 0.21 | 0.17 | 0.75 | 0.29 | 0.67 | 0.79 | 0.83 | 0.25 | 0.71 | 0.43 | 0.39 | 0.38 | 0.67 | 0.41 | 0.45 | 13 |

| TM3 | 0.56 | 0.80 | 0.84 | 0.59 | 0.25 | 0.44 | 0.20 | 0.16 | 0.41 | 0.75 | 0.53 | 0.71 | 0.76 | 0.55 | 0.40 | 0.59 | 8 |

| TM4 | 0.69 | 0.87 | 0.74 | 0.61 | 0.54 | 0.31 | 0.13 | 0.26 | 0.39 | 0.46 | 0.61 | 0.79 | 0.66 | 0.56 | 0.52 | 0.63 | 5 |

| TM5 | 0.79 | 0.16 | 0.04 | 0.12 | 0.13 | 0.21 | 0.84 | 0.96 | 0.88 | 0.87 | 0.70 | 0.37 | 0.34 | 0.36 | 0.37 | 0.43 | 15 |

| TM6 | 0.82 | 0.26 | 0.30 | 0.10 | 0.09 | 0.18 | 0.74 | 0.70 | 0.90 | 0.91 | 0.74 | 0.40 | 0.42 | 0.36 | 0.35 | 0.45 | 14 |

| TM7 | 0.11 | 0.94 | 1.00 | 1.00 | 0.90 | 0.89 | 0.06 | 0.00 | 0.00 | 0.10 | 0.36 | 0.89 | 1.00 | 1.00 | 0.83 | 0.82 | 2 |

| TM8 | 0.40 | 0.87 | 0.89 | 0.92 | 0.66 | 0.60 | 0.13 | 0.11 | 0.08 | 0.34 | 0.45 | 0.79 | 0.82 | 0.86 | 0.59 | 0.70 | 3 |

| TM9 | 0.95 | 0.83 | 0.86 | 0.11 | 0.43 | 0.05 | 0.17 | 0.14 | 0.89 | 0.57 | 0.92 | 0.75 | 0.79 | 0.36 | 0.47 | 0.66 | 4 |

| TM10 | 0.85 | 1.00 | 0.96 | 0.81 | 0.83 | 0.15 | 0.00 | 0.04 | 0.19 | 0.17 | 0.77 | 1.00 | 0.92 | 0.73 | 0.74 | 0.83 | 1 |

| TM11 | 0.60 | 0.21 | 0.21 | 0.55 | 0.72 | 0.40 | 0.79 | 0.79 | 0.45 | 0.28 | 0.56 | 0.39 | 0.39 | 0.53 | 0.64 | 0.50 | 12 |

| TM12 | 0.21 | 0.36 | 0.30 | 0.91 | 1.00 | 0.79 | 0.64 | 0.70 | 0.09 | 0.00 | 0.39 | 0.44 | 0.42 | 0.85 | 1.00 | 0.62 | 6 |

| TM13 | 0.92 | 0.53 | 0.56 | 0.29 | 0.53 | 0.08 | 0.47 | 0.44 | 0.71 | 0.47 | 0.86 | 0.52 | 0.53 | 0.41 | 0.52 | 0.57 | 9 |

| TM14 | 0.53 | 0.40 | 0.33 | 0.80 | 0.77 | 0.47 | 0.60 | 0.67 | 0.20 | 0.23 | 0.52 | 0.46 | 0.43 | 0.72 | 0.68 | 0.56 | 10 |

| TM15 | 1.00 | 0.49 | 0.45 | 0.52 | 0.60 | 0.00 | 0.51 | 0.55 | 0.48 | 0.40 | 1.00 | 0.49 | 0.48 | 0.51 | 0.55 | 0.61 | 7 |

| TM16 | 0.88 | 0.16 | 0.11 | 0.53 | 0.63 | 0.12 | 0.84 | 0.89 | 0.47 | 0.37 | 0.80 | 0.37 | 0.36 | 0.52 | 0.58 | 0.53 | 11 |

| Mean GRC | 0.62 | 0.57 | 0.56 | 0.58 | 0.56 | ||||||||||||

| Parameters | Mean Grey Relational Grade | Effect | ||||

|---|---|---|---|---|---|---|

| Level-1 | Level-2 | Level-3 | Level-4 | Delta | Rank | |

| A: Binder content | 0.50 | 0.60 | 0.65 | 0.57 | 0.15 | 2 |

| B: SH | 0.50 | 0.58 | 0.63 | 0.62 | 0.13 | 3 |

| C: Al/Bi ratio | 0.45 | 0.53 | 0.63 | 0.71 | 0.26 | 1 |

| D: W/S ratio | 0.58 | 0.56 | 0.60 | 0.59 | 0.04 | 5 |

| E: SS/SH ratio | 0.62 | 0.61 | 0.56 | 0.53 | 0.09 | 4 |

| Factor | DOF | SOS | MS | Contribution (%) |

|---|---|---|---|---|

| A: Binder content | 3 | 0.0474 | 0.01581 |  |

| B: SH | 3 | 0.0431 | 0.01436 | |

| C: Al/Bi | 3 | 0.1535 | 0.05118 | |

| D: W/S | 3 | 0.0034 | 0.00112 | |

| E: SS/SH | 3 | 0.0224 | 0.00745 | |

| Error | - | - | - | |

| Total | 15 | 0.2698 |

| AASC Outputs | Initial Condition | Optimum Parameters Condition | |

|---|---|---|---|

| Prediction | Experiment | ||

| A3B2C4D3E1 | A3B3C4D3E1 | A3B3C4D3E1 | |

| Slump (mm) | 200 | 195 | |

| Initial ST (min) | 54 | 56 | |

| Final ST (min) | 88 | 95 | |

| 7-day CS (N/mm2) | 44.89 | 45.67 | |

| 28-day CS (N/mm2) | 58 | 59.4 | |

| Grey relational grade | 0.83 | 0.885 | 0.876 |

| Mix No. | Mixture ID | RTSF Volume Fraction (%) | Binder Content (kg/m3) | Molarity of SH (M) | Al/Bi Ratio | W/S Ratio | SS/SH Ratio | Slump (mm) |

|---|---|---|---|---|---|---|---|---|

| TM17 | S0 | 0 | 400 | 14 | 0.55 | 0.4 | 1.75 | 195 |

| TM18 | S0.2 | 0.2 | 400 | 14 | 0.55 | 0.4 | 1.75 | 180 |

| TM19 | S0.4 | 0.4 | 400 | 14 | 0.55 | 0.4 | 1.75 | 140 |

| TM20 | S0.6 | 0.6 | 400 | 14 | 0.55 | 0.4 | 1.75 | 90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eskandarinia, M.; Esmailzade, M.; Hojatkashani, A.; Rahmani, A.; Jahandari, S. Optimized Alkali-Activated Slag-Based Concrete Reinforced with Recycled Tire Steel Fiber. Materials 2022, 15, 6623. https://doi.org/10.3390/ma15196623

Eskandarinia M, Esmailzade M, Hojatkashani A, Rahmani A, Jahandari S. Optimized Alkali-Activated Slag-Based Concrete Reinforced with Recycled Tire Steel Fiber. Materials. 2022; 15(19):6623. https://doi.org/10.3390/ma15196623

Chicago/Turabian StyleEskandarinia, Milad, Mina Esmailzade, Ata Hojatkashani, Aida Rahmani, and Soheil Jahandari. 2022. "Optimized Alkali-Activated Slag-Based Concrete Reinforced with Recycled Tire Steel Fiber" Materials 15, no. 19: 6623. https://doi.org/10.3390/ma15196623

APA StyleEskandarinia, M., Esmailzade, M., Hojatkashani, A., Rahmani, A., & Jahandari, S. (2022). Optimized Alkali-Activated Slag-Based Concrete Reinforced with Recycled Tire Steel Fiber. Materials, 15(19), 6623. https://doi.org/10.3390/ma15196623