Effect of Temperature and Material Flow Gradients on Mechanical Performances of Friction Stir Welded AA6082-T6 Joints

Abstract

:1. Introduction

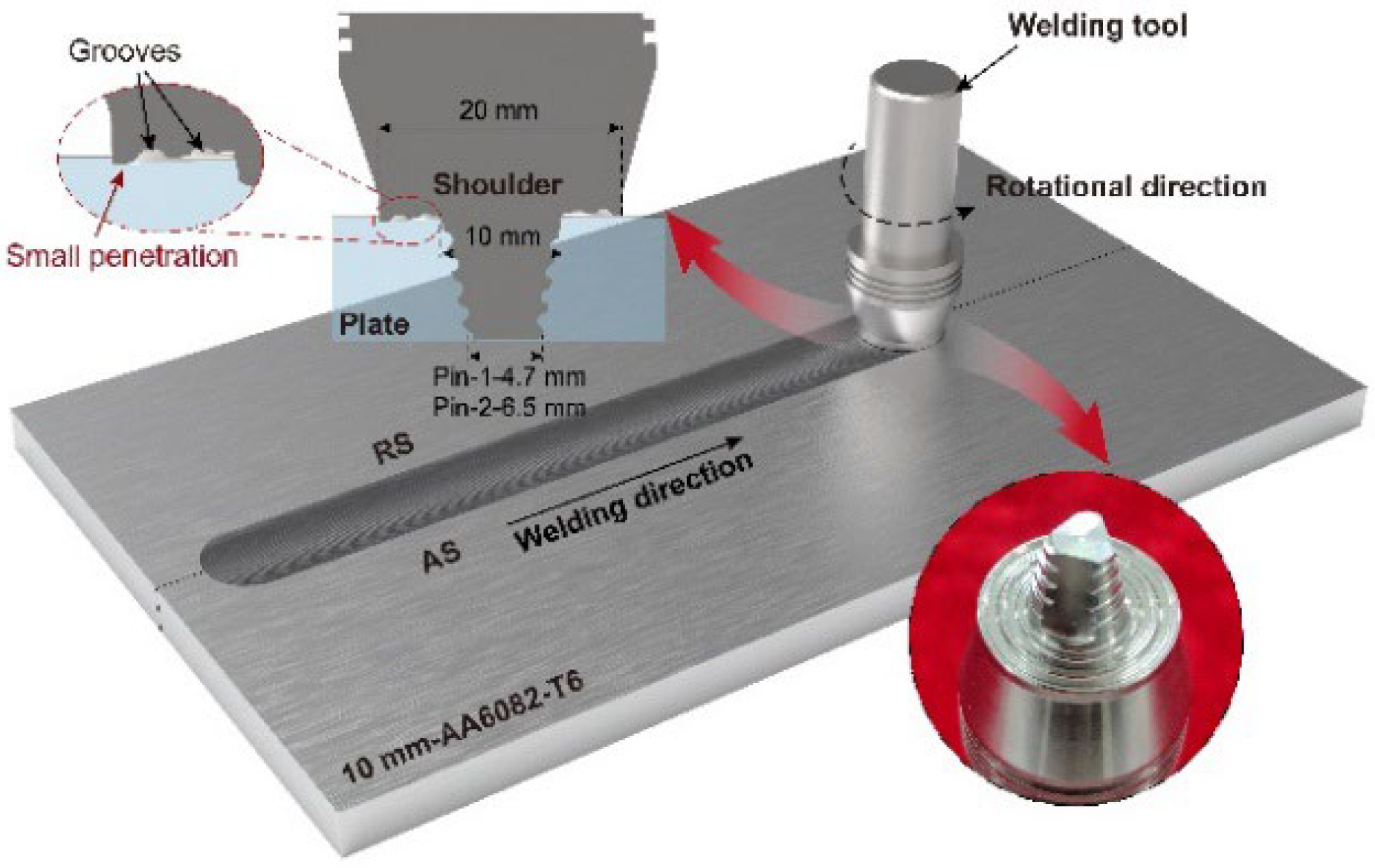

2. Materials and Methods

3. Results and Discussion

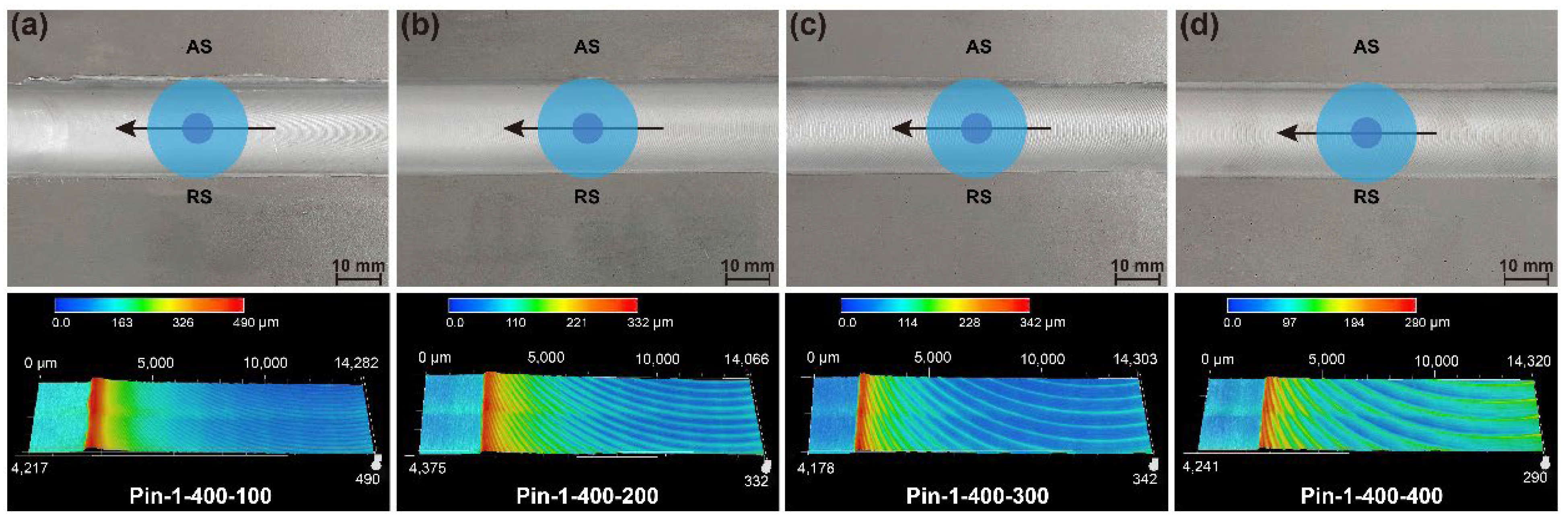

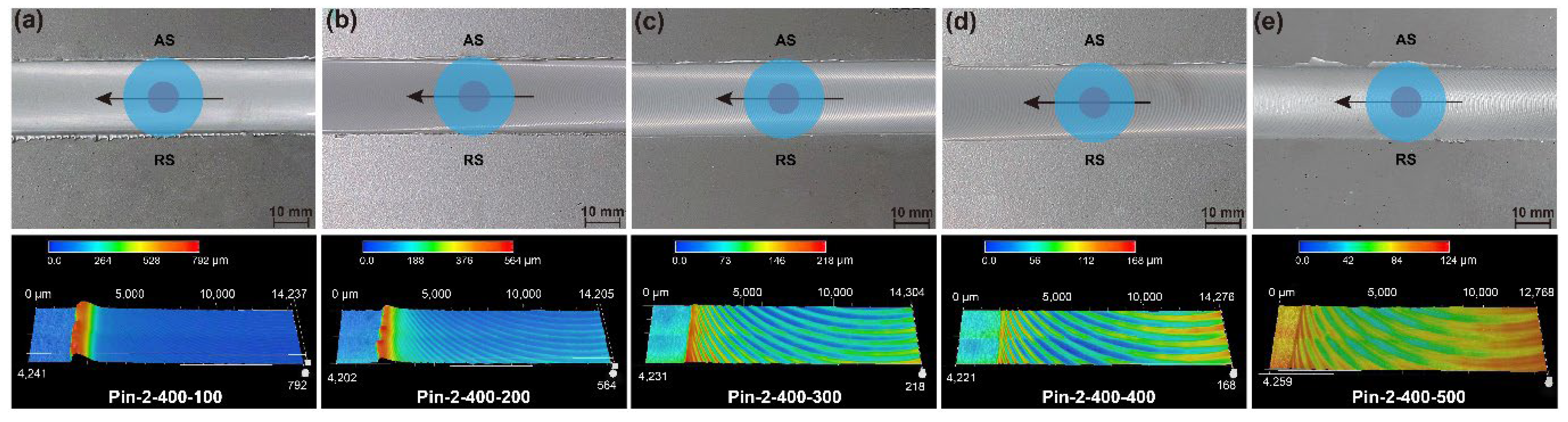

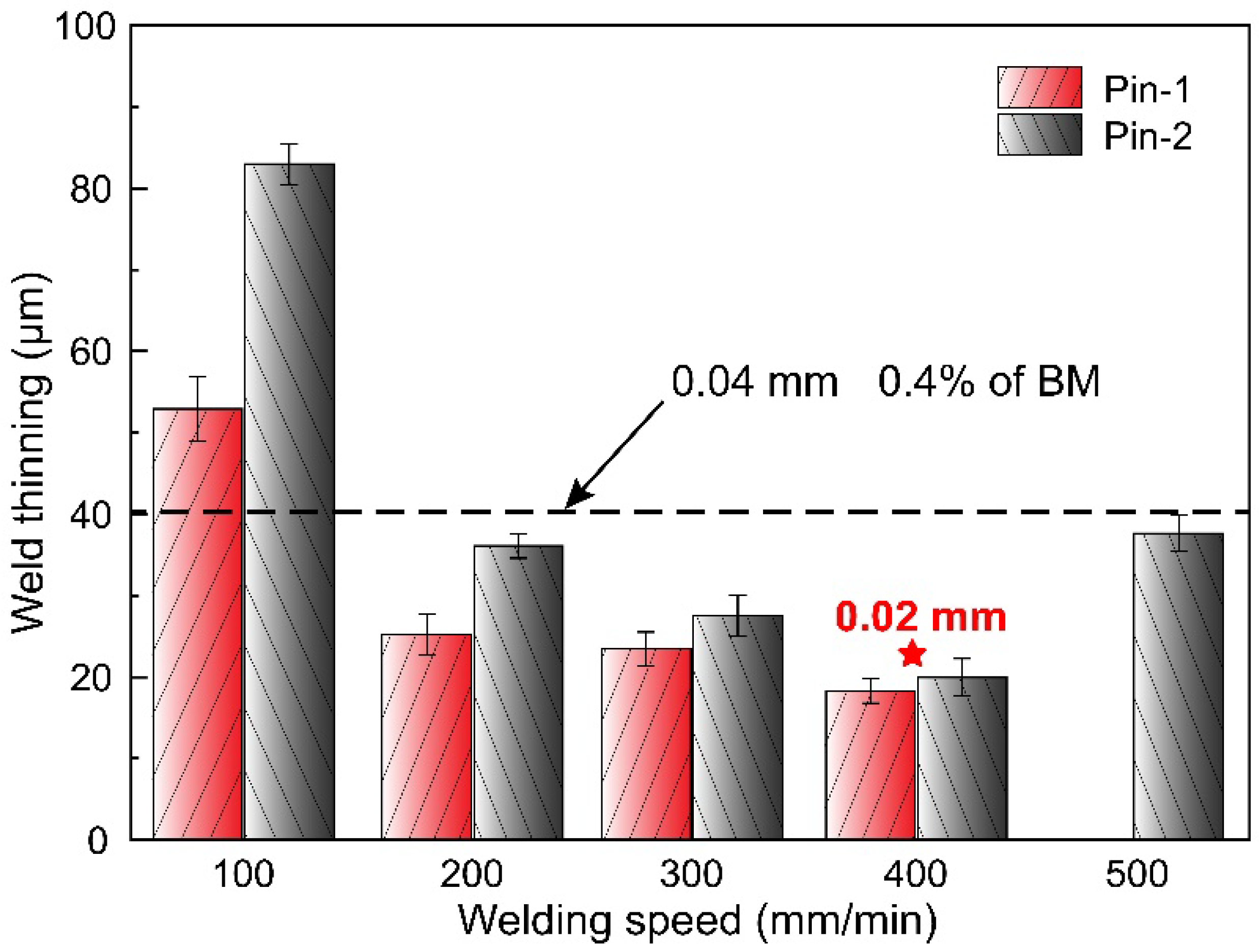

3.1. Surface Integrity

3.2. Thermal Analysis

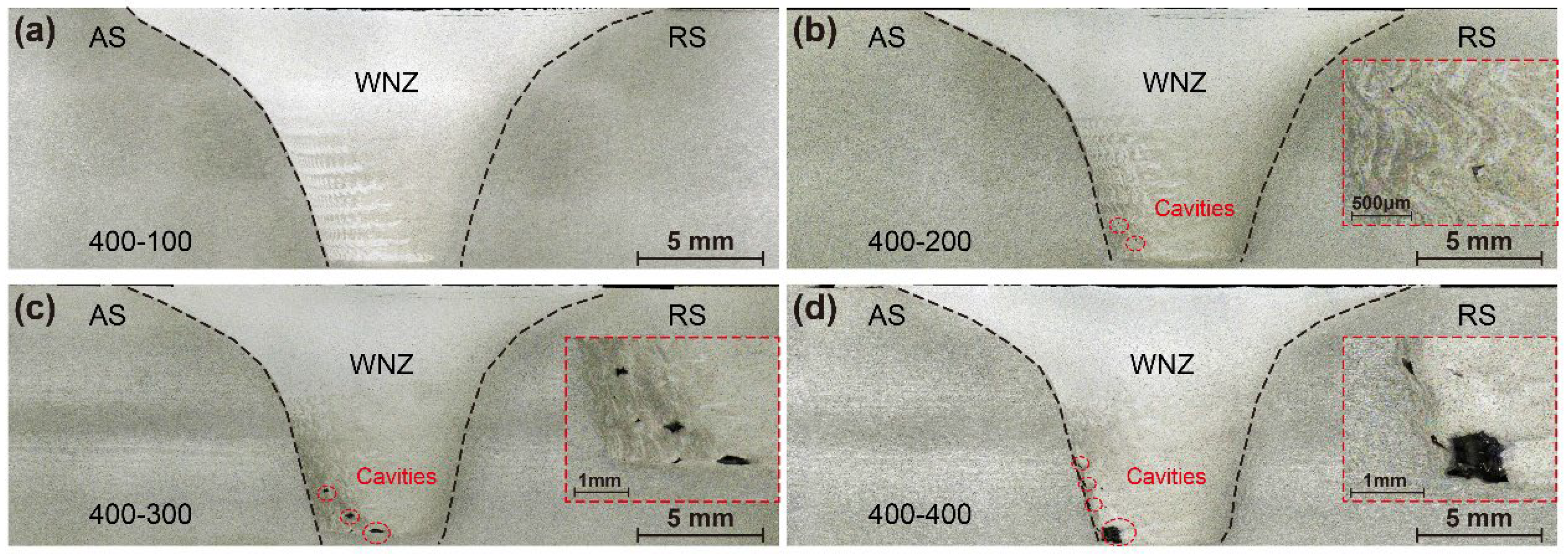

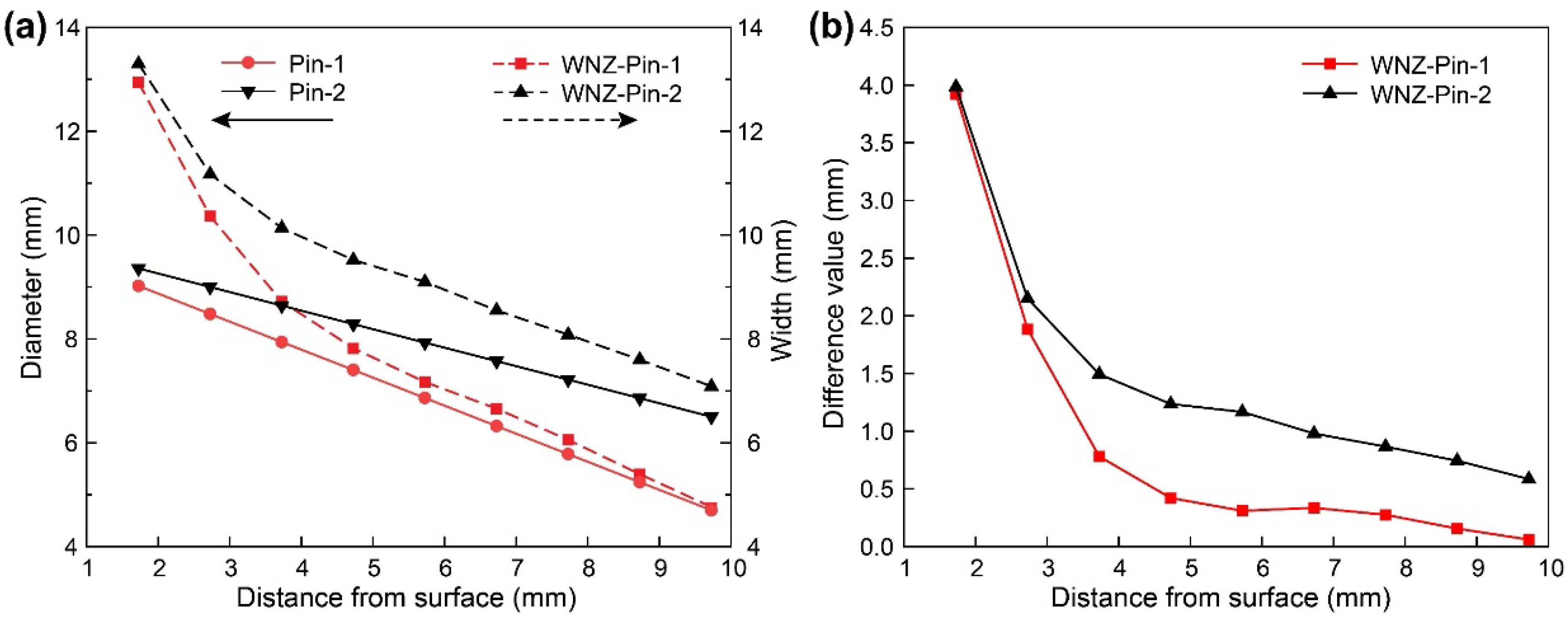

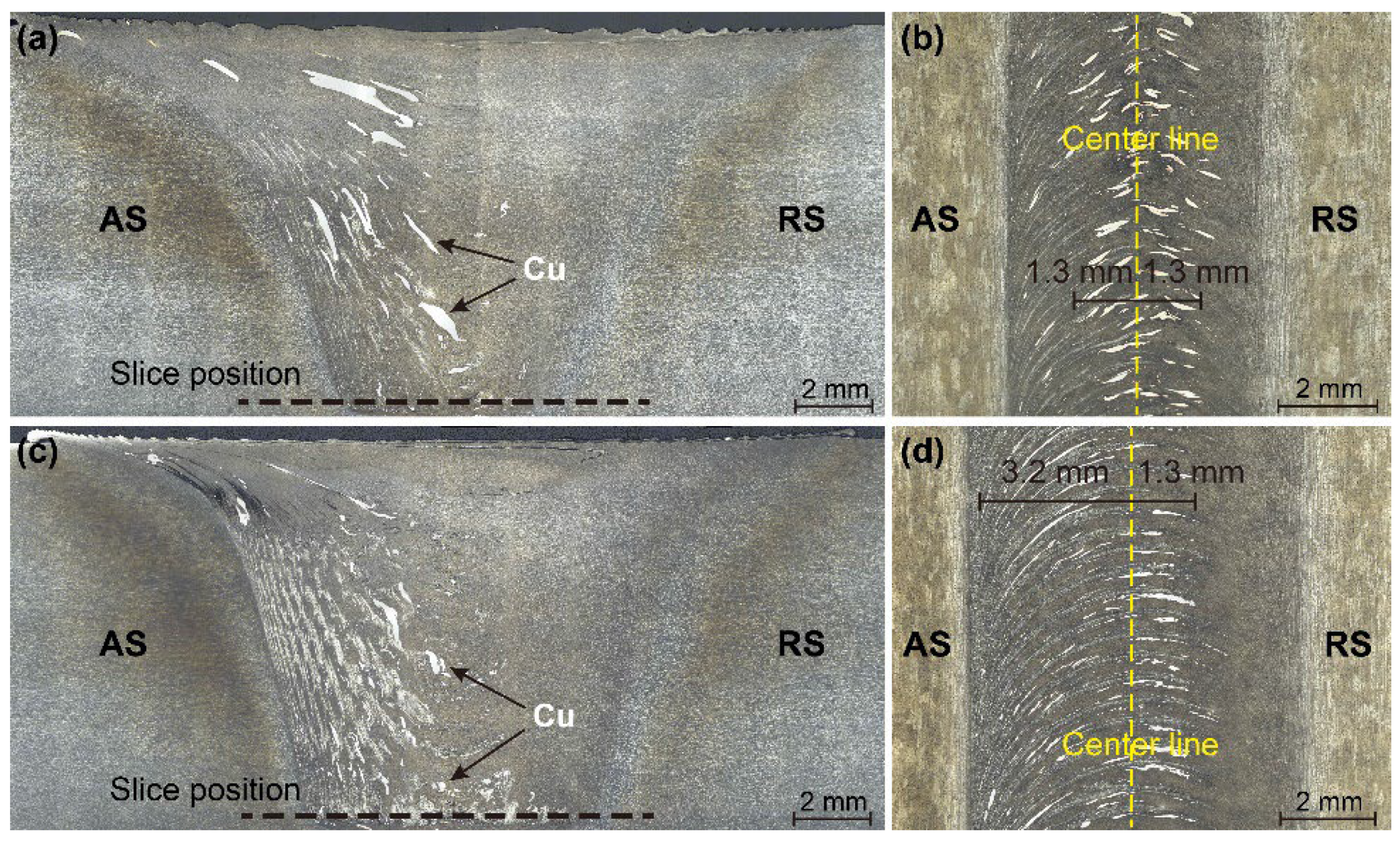

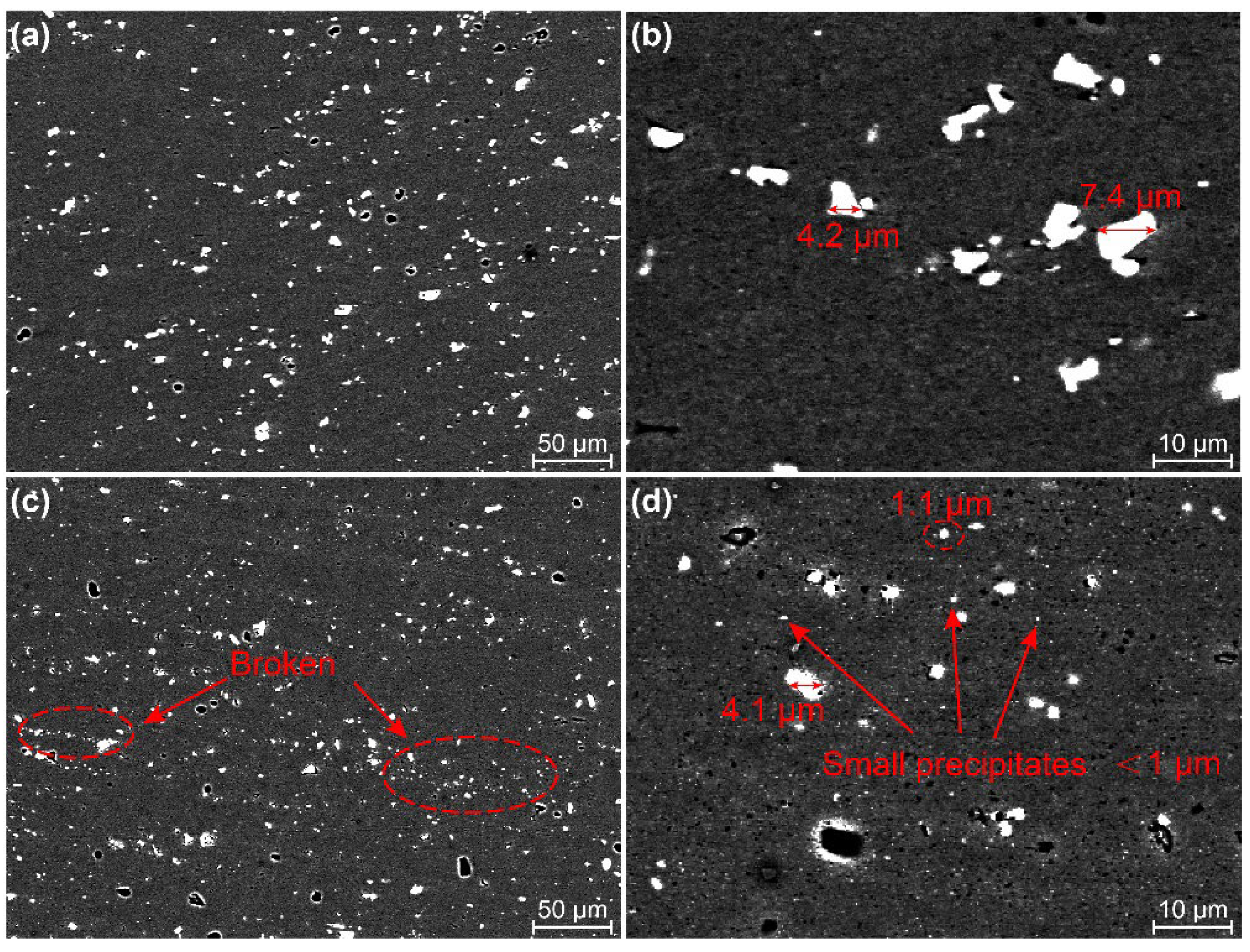

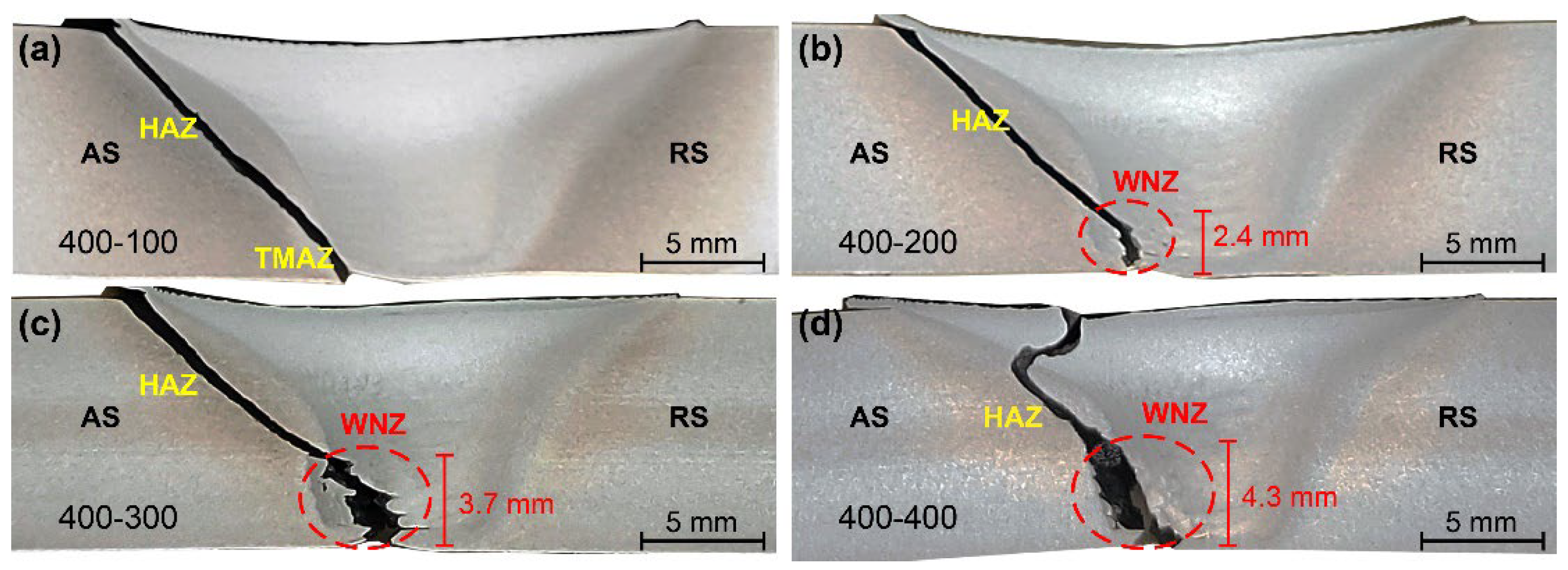

3.3. Macro and Microstructures

3.4. Mechanical Properties

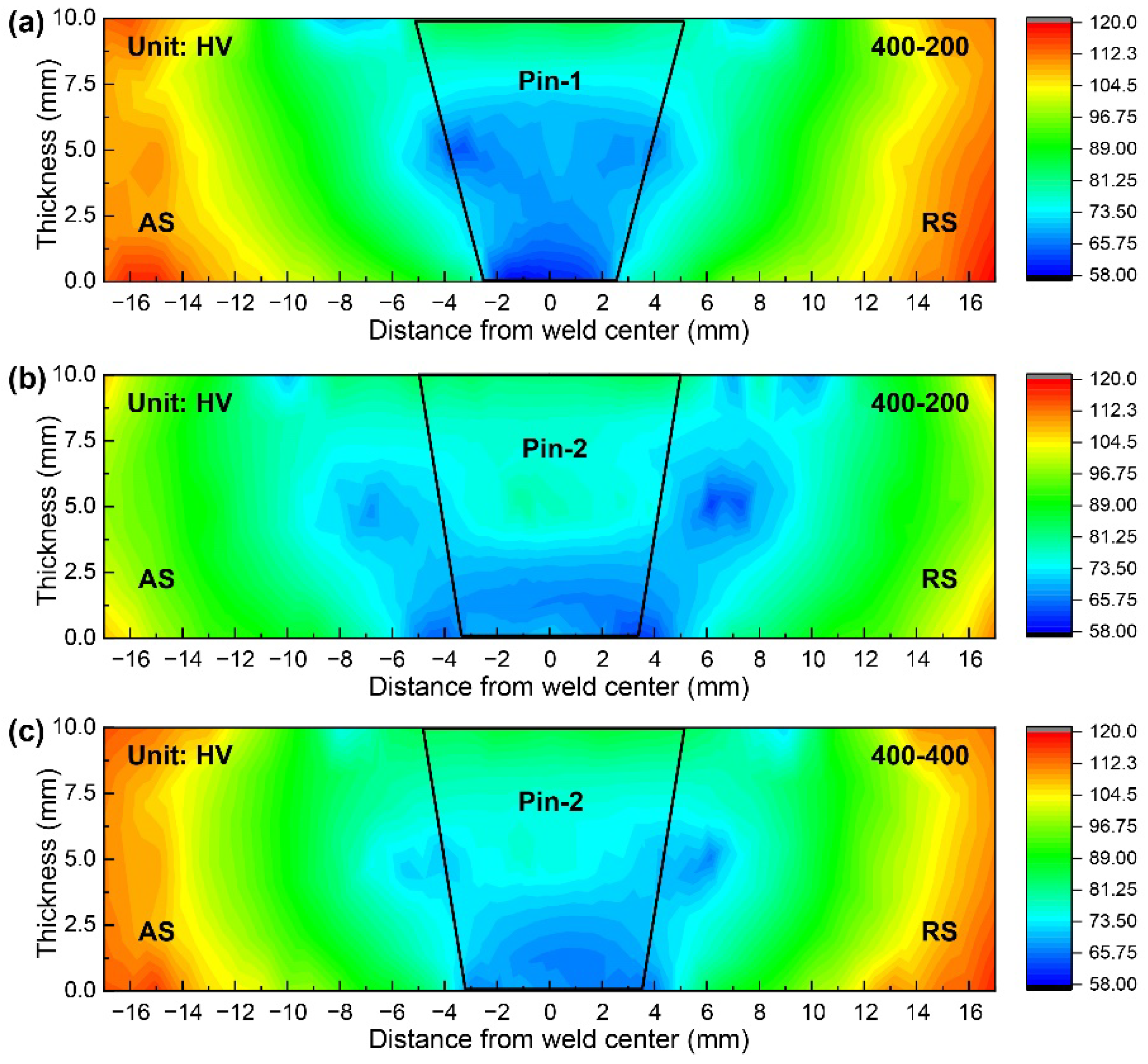

3.4.1. Microhardness

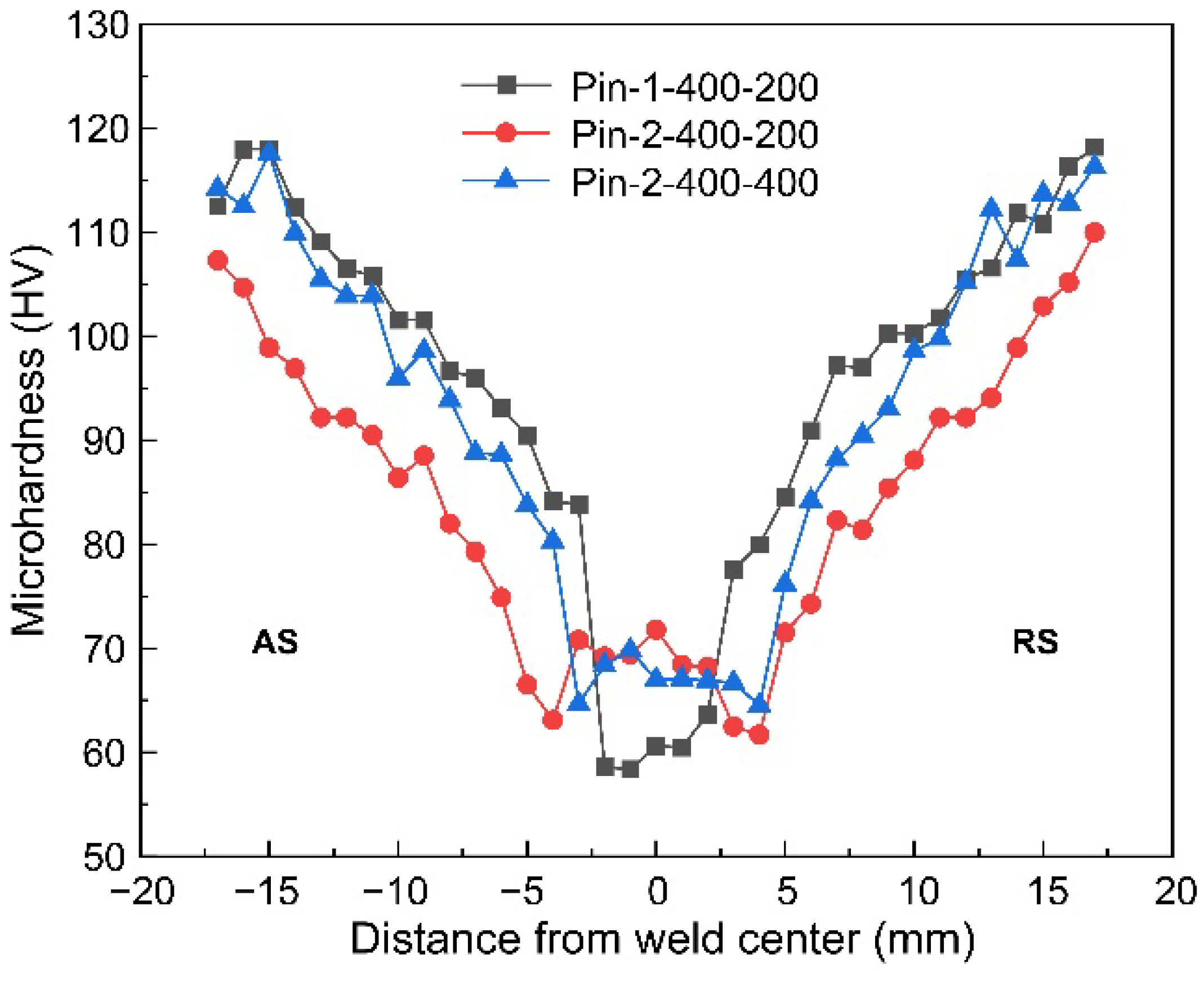

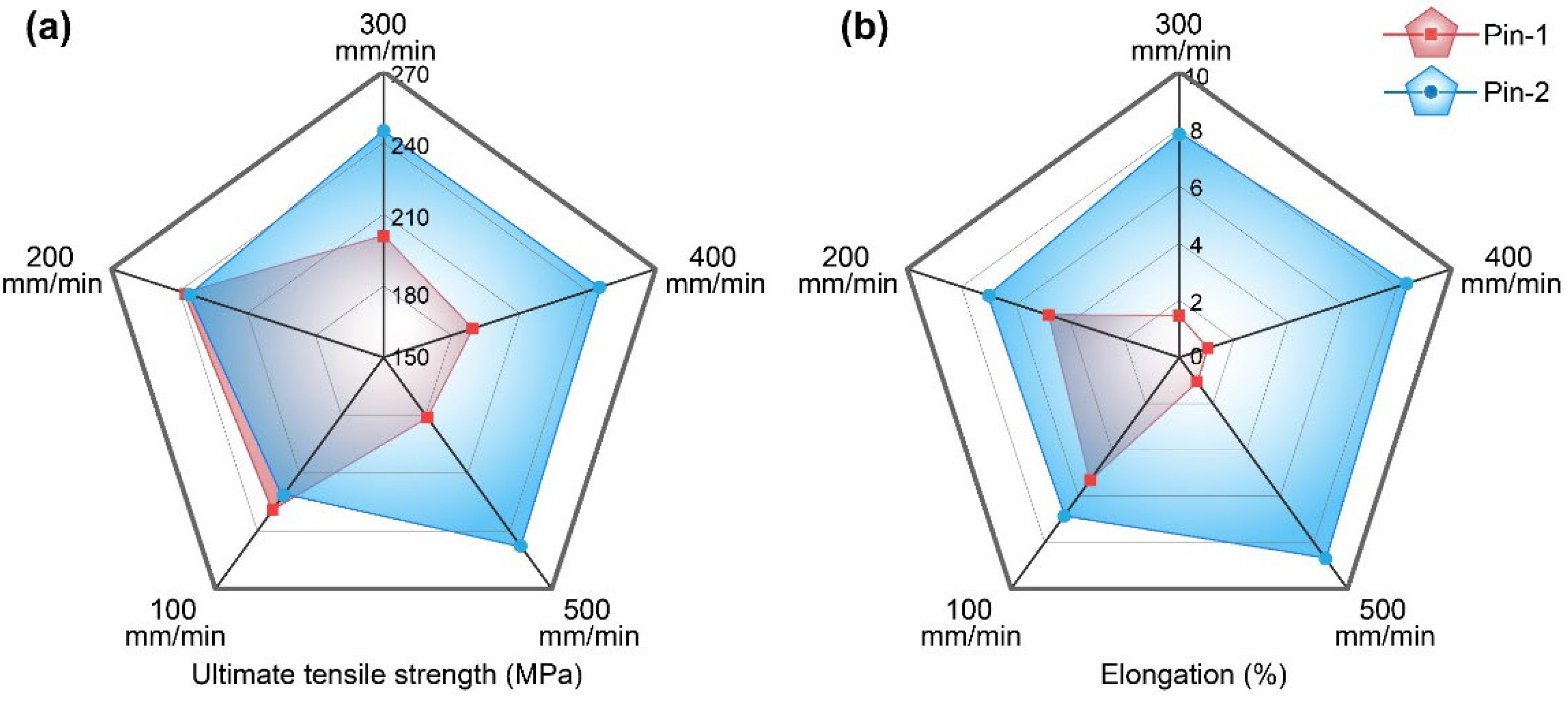

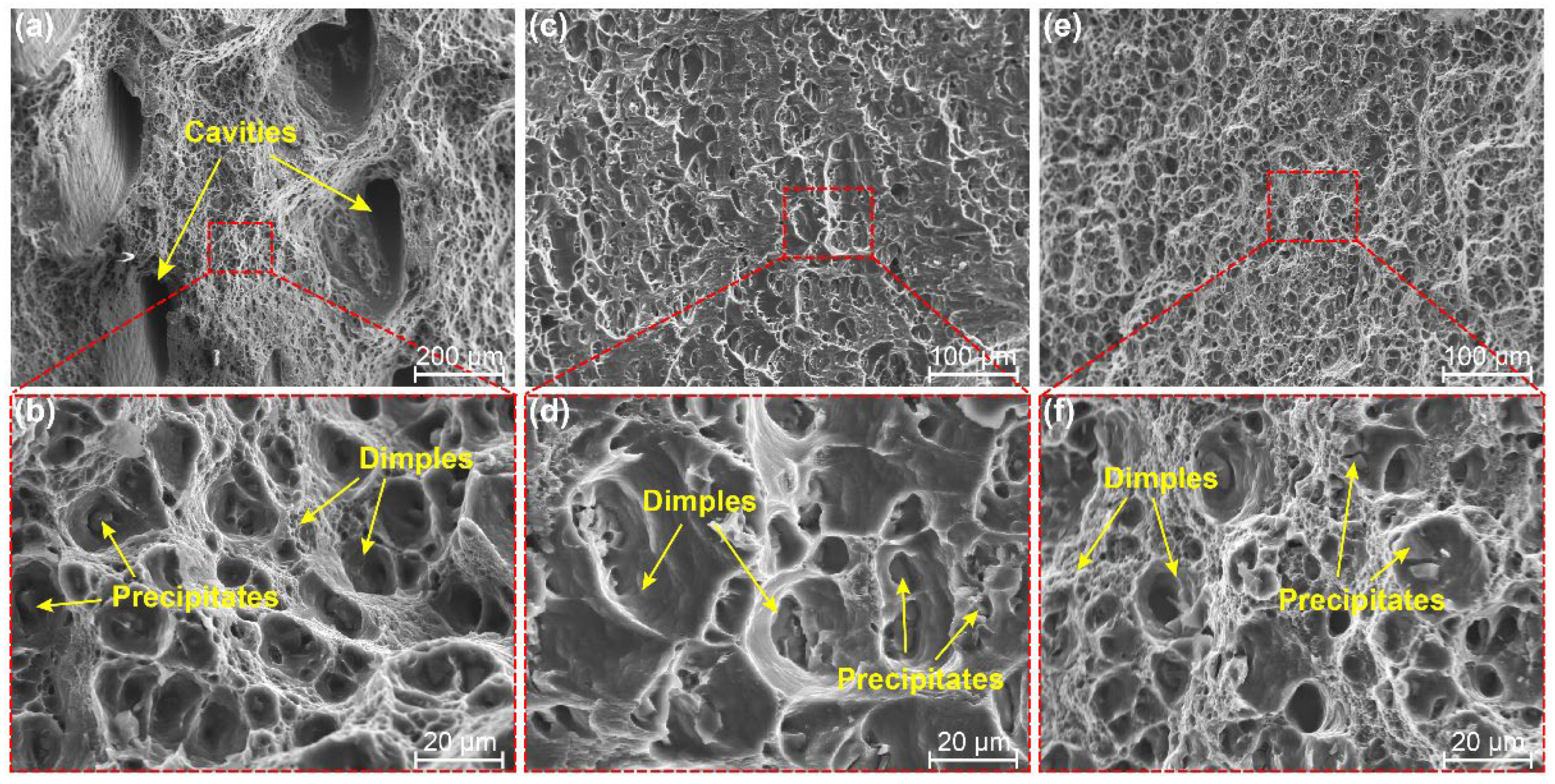

3.4.2. Tensile Properties

4. Conclusions

- The shoulder with a groove and a small plunge depth effectively prevented the overflow of plasticized materials. The weld thinning of all joints maintained a low level, with a minimum of 0.02 mm, which was 0.2% of the BM thickness;

- The low peak temperature and weak material flow at the bottom weld caused by the small-tip pin were not favorable to the flow of plasticized materials to AS, which led to the susceptibility to defects at the bottom of the weld, as well as low microhardness and strength;

- The large-tip pin increased heat input and material flow at the bottom weld. The temperature difference between the top and bottom was reduced by 67.5% compared to the small-tip pin. The material flow was enhanced in both horizontal and thickness directions, effectively suppressing the generation of root defects;

- The large-tip pin increased the welding speed of defect-free joints from 100 mm/min to 500 mm/min, which significantly increased productivity. The ultimate tensile strength and elongation of the joint reached 247 MPa and 8.7%, respectively, equivalent to 80% and 65% of the BM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Yang, Z.; Domblesky, J.P.; Han, J.; Li, Z.; Liu, X. Investigation of through thickness microstructure and mechanical properties in friction stir welded 7N01 aluminum alloy plate. Mater. Sci. Eng. A 2019, 760, 316–327. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Tra, T.H.; Okazaki, M.; Suzuki, K. Fatigue crack propagation behavior in friction stir welding of AA6063-T5: Roles of residual stress and microstructure. Int. J. Fatigue 2012, 43, 23–29. [Google Scholar] [CrossRef]

- Huang, Y.; Xie, Y.; Meng, X.; Li, J.; Zhou, L. Joint formation mechanism of high depth-to-width ratio friction stir welding. J. Mater. Sci. Technol. 2019, 35, 1261–1269. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Z. Numerical simulation of vortex- friction stir welding based on internal friction between identical materials. Int. J. Heat Mass Transf. 2022, 185, 122418. [Google Scholar] [CrossRef]

- Nasir, T.; Kalaf, O.; Asmael, M.; Zeeshan, Q.; Safaei, B.; Hussain, G.; Motallebzadeh, A. The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties. Nanotechnol. Rev. 2021, 10, 401–413. [Google Scholar] [CrossRef]

- Xu, W.; Liu, J.; Chen, D.; Luan, G.; Yao, J. Change of microstructure and cyclic deformation behavior along the thickness in a friction-stir-welded aluminum alloy. Scr. Mater. 2012, 66, 5–8. [Google Scholar] [CrossRef]

- Xu, W.; Luo, Y.; Fu, M. Microstructure evolution in the conventional single side and bobbin tool friction stir welding of thick rolled 7085-T7452 aluminum alloy. Mater. Charact. 2018, 138, 48–55. [Google Scholar] [CrossRef]

- Silva-Magalhães, A.; De Backer, J.; Martin, J.; Bolmsjö, G. In-situ temperature measurement in friction stir welding of thick section aluminium alloys. J. Manuf. Process. 2019, 39, 12–17. [Google Scholar] [CrossRef]

- Martinez, N.; Kumar, N.; Mishra, R.S.; Doherty, K.J. Microstructural variation due to heat gradient of a thick friction stir welded aluminum 7449 alloy. J. Alloy. Compd. 2017, 713, 51–63. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.F.; Ma, G.N.; Wu, L.H.; Zhang, X.M.; He, G.Z.; Xue, P.; Ni, D.R.; Xiao, B.L.; Wang, K.S.; et al. Microstructure and mechanical properties of double-side friction stir welded 6082Al ultra-thick plates. J. Mater. Sci. Technol. 2020, 41, 105–116. [Google Scholar] [CrossRef]

- Wang, X.; Lados, D.A. Friction Stir Welding of Similar Aluminum Alloys Thick Plates: Understanding the Material Flow, Microstructure Evolution, Defect Formation, and Mechanical Properties. Materialia 2022, 24, 101508. [Google Scholar] [CrossRef]

- Tewari, M.; Jadoun, R.S.; Kumar, S. Effect of process parameters on tensile strength of Friction stir welded butt joints of thick AA1350 aluminum plates using Taguchi experimental design. Mater. Today Proc. 2021, 44, 2721–2725. [Google Scholar] [CrossRef]

- Gu, C.; Yang, X.; Tang, W.; Luo, T.; Wang, R. Softening behavior of stationary shoulder friction stir welded joint for thick-plate Al–Li–Cu alloy. J. Mater. Res. Technol. 2022, 20, 3008–3024. [Google Scholar] [CrossRef]

- Mao, Y.; Ke, L.; Liu, F.; Chen, Y.; Xing, L. Investigations on temperature distribution, microstructure evolution, and property variations along thickness in friction stir welded joints for thick AA7075-T6 plates. Int. J. Adv. Manuf. Technol. 2016, 86, 141–154. [Google Scholar] [CrossRef]

- Mastanaiah, P.; Sharma, A.; Reddy, G.M. Role of hybrid tool pin profile on enhancing welding speed and mechanical properties of AA2219-T6 friction stir welds. J. Mater. Process. Technol. 2018, 257, 257–269. [Google Scholar] [CrossRef]

- Zhang, W.; Mao, Y.; Yang, P.; Li, N.; Ke, L.; Chen, Y. Effect of Welding Speed on Microstructure Evolution and Mechanical Properties of Friction Stir Welded 2198 Al-Cu-Li Alloy Joints. Materials 2022, 15, 969. [Google Scholar] [CrossRef]

- Ma, X.; Meng, X.; Xie, Y.; Zhao, Y.; Peng, X.; Liang, M.; Mao, D.; Wan, L.; Huang, Y. Elimination of root kissing bond in friction stir welding of thick plates. Mater. Lett. 2022, 328, 133148. [Google Scholar] [CrossRef]

- Soori, M.; Asmael, M.; Solyalı, D. Recent Development in Friction Stir Welding Process: A Review. SAE Int. J. Mater. Manuf. 2020, 14, 63–80. [Google Scholar] [CrossRef]

- Ji, S.; Li, Z.; Zhou, Z.; Wu, B. Effect of Thread and Rotating Speed on Material Flow Behavior and Mechanical Properties of Friction Stir Lap Welding Joints. J. Mater. Eng. Perform. 2017, 26, 5085–5096. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Huang, Y. Entire-Process Simulation of Friction Stir Welding—Part 2: Implementation of Neural Networks. Weld. J. 2022, 101, 172–177. [Google Scholar] [CrossRef]

- Meng, X.; Xie, Y.; Ma, X.; Liang, M.; Peng, X.; Han, S.; Kan, L.; Wang, X.; Chen, S.; Huang, Y. Towards Friction Stir Remanufacturing of High-Strength Aluminum Components. Acta Metall. Sin. Engl. Lett. 2022. [Google Scholar] [CrossRef]

- Chupradit, S.; Bokov, D.O.; Suksatan, W.; Landowski, M.; Fydrych, D.; Abdullah, M.E.; Derazkola, H.A. Pin Angle Thermal Effects on Friction Stir Welding of AA5058 Aluminum Alloy: CFD Simulation and Experimental Validation. Materials 2021, 14, 7565. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Andersson, J.; Yang, X. A novel approach to measure three-dimensional surface topography for stationary shoulder friction stir processing. J. Mater. Res. Technol. 2021, 15, 5608–5614. [Google Scholar] [CrossRef]

- Ma, X.; Xie, Y.; Meng, X.; Chen, H.; Wang, F.; Jiang, Y.; Wan, L.; Huang, Y. Stepped-shoulder friction stir welding to alleviate weld thinning for dissimilar AA2195-T8/AA2219-T6 alloys. Sci. Technol. Weld. Join. 2021, 26, 599–605. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, Y.; Mi, S. A dynamic prediction method of transient temperature in friction stir welding process. Measurement 2022, 200, 111632. [Google Scholar] [CrossRef]

- Yi, D.; Onuma, T.; Mironov, S.; Sato, Y.S.; Kokawa, H. Evaluation of heat input during friction stir welding of aluminium alloys. Sci. Technol. Weld. Join. 2017, 22, 41–46. [Google Scholar] [CrossRef]

- Huang, Y.; Xie, Y.; Meng, X.; Lv, Z.; Cao, J. Numerical design of high depth-to-width ratio friction stir welding. J. Mater. Process. Technol. 2018, 252, 233–241. [Google Scholar] [CrossRef]

- Zhai, M.; Wu, C.; Shi, L. Numerical simulation of friction stir lap welding of Al-to-Mg alloys under different lap configurations and pin lengths. J. Mater. Res. Technol. 2022, 20, 2889–2904. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Huang, Y. Entire-process simulation of friction stir welding, Part 1: Experiments and simulation. Weld. J. 2022, 5, 144-s–159-s. [Google Scholar] [CrossRef]

- Zou, Y.; Li, W.; Yang, X.; Patel, V.; Shen, Z.; Chu, Q.; Wang, F.; Tang, H.; Cui, F.; Chi, M. Characterizations of dissimilar refill friction stir spot welding 2219 aluminum alloy joints of unequal thickness. J. Manuf. Process. 2022, 79, 91–101. [Google Scholar] [CrossRef]

- Ma, Y.; Niu, S.; Liu, H.; Li, Y.; Ma, N. Microstructural evolution in friction self-piercing riveted aluminum alloy AA7075-T6 joints. J. Mater. Sci. Technol. 2021, 82, 80–95. [Google Scholar] [CrossRef]

- Xu, W.; Liu, J.; Zhu, H. A study on the hardness and elastic modulus of friction stir welded aluminum alloy thick plate joints using micro-indentation. J. Mater. Sci. 2011, 46, 1161–1166. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Chang, Y.; Mao, D.; Qin, Z.; Wan, L.; Huang, Y. Heteroatom Modification Enhances Corrosion Durability in High-Mechanical-Performance Graphene-Reinforced Aluminum Matrix Composites. Adv. Sci. 2022, 9, 2104464. [Google Scholar] [CrossRef] [PubMed]

| Mg | Zn | Si | Mn | Fe | Cr | Cu | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 1.10 | 0.31 | 0.81 | 0.15 | 0.75 | 0.07 | 0.23 | 0.19 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Xu, S.; Wang, F.; Zhao, Y.; Meng, X.; Xie, Y.; Wan, L.; Huang, Y. Effect of Temperature and Material Flow Gradients on Mechanical Performances of Friction Stir Welded AA6082-T6 Joints. Materials 2022, 15, 6579. https://doi.org/10.3390/ma15196579

Ma X, Xu S, Wang F, Zhao Y, Meng X, Xie Y, Wan L, Huang Y. Effect of Temperature and Material Flow Gradients on Mechanical Performances of Friction Stir Welded AA6082-T6 Joints. Materials. 2022; 15(19):6579. https://doi.org/10.3390/ma15196579

Chicago/Turabian StyleMa, Xiaotian, Shuangming Xu, Feifan Wang, Yaobang Zhao, Xiangchen Meng, Yuming Xie, Long Wan, and Yongxian Huang. 2022. "Effect of Temperature and Material Flow Gradients on Mechanical Performances of Friction Stir Welded AA6082-T6 Joints" Materials 15, no. 19: 6579. https://doi.org/10.3390/ma15196579

APA StyleMa, X., Xu, S., Wang, F., Zhao, Y., Meng, X., Xie, Y., Wan, L., & Huang, Y. (2022). Effect of Temperature and Material Flow Gradients on Mechanical Performances of Friction Stir Welded AA6082-T6 Joints. Materials, 15(19), 6579. https://doi.org/10.3390/ma15196579