The Significant Effect of Mechanical Treatment on Ceramic Coating for Biomedical Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. TiN Coating via Physical Vapor Deposition

2.3. Mechanical Treatment

2.4. Characterization

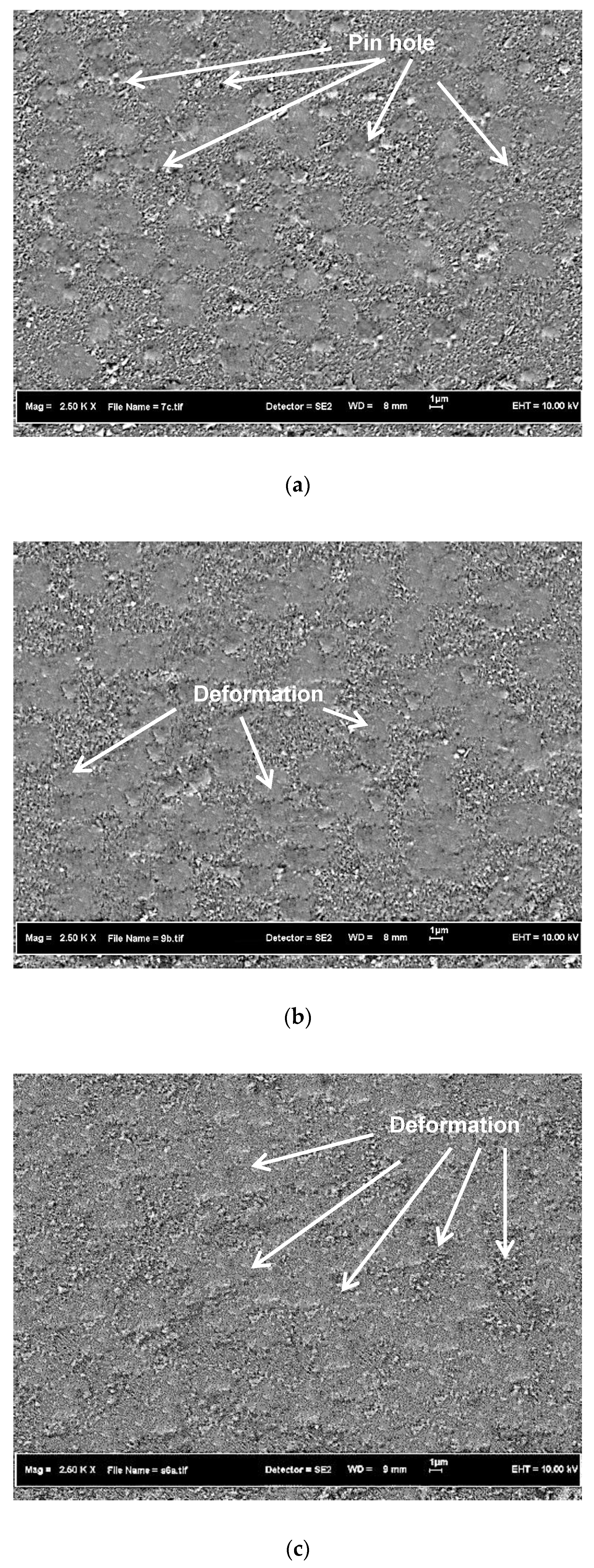

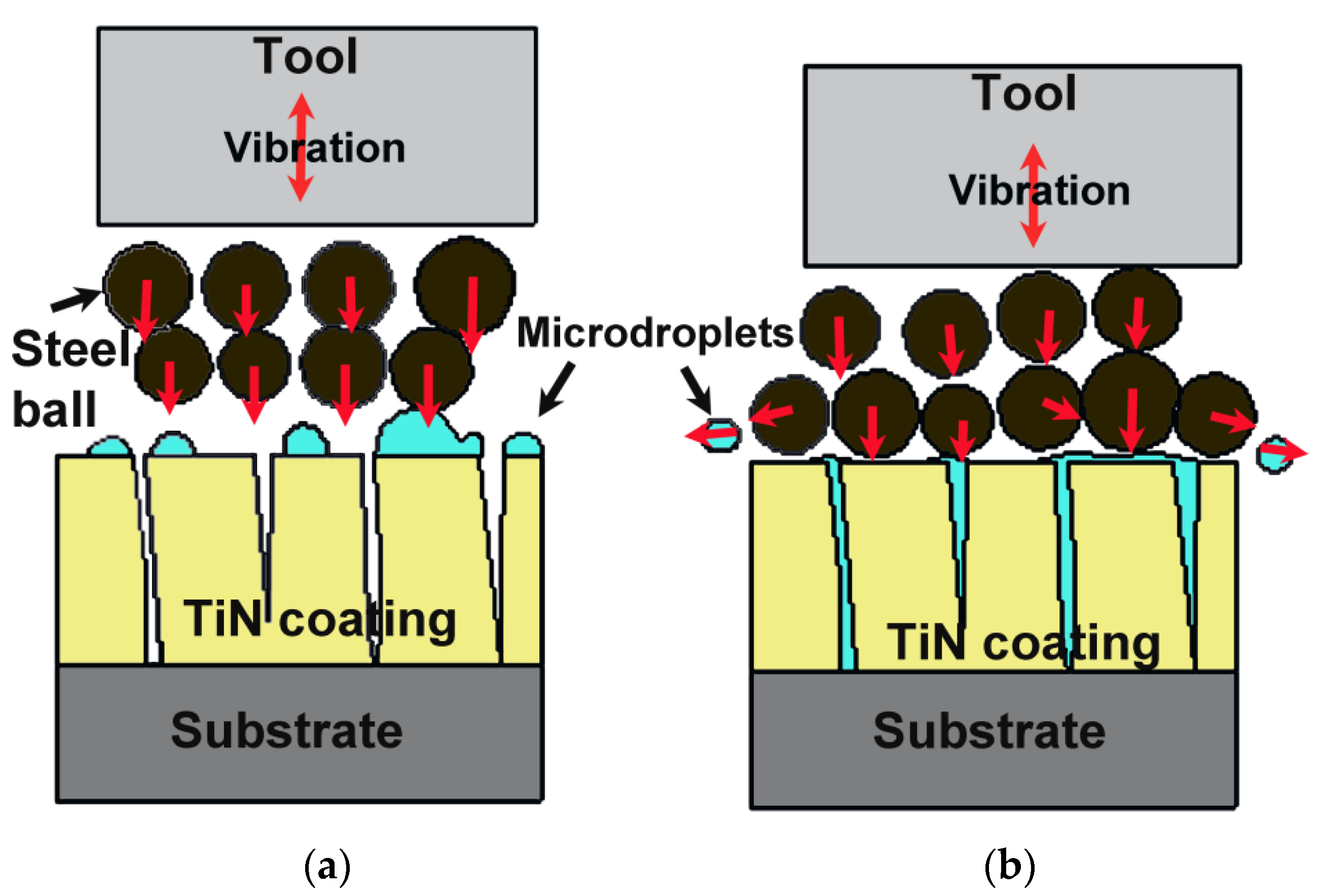

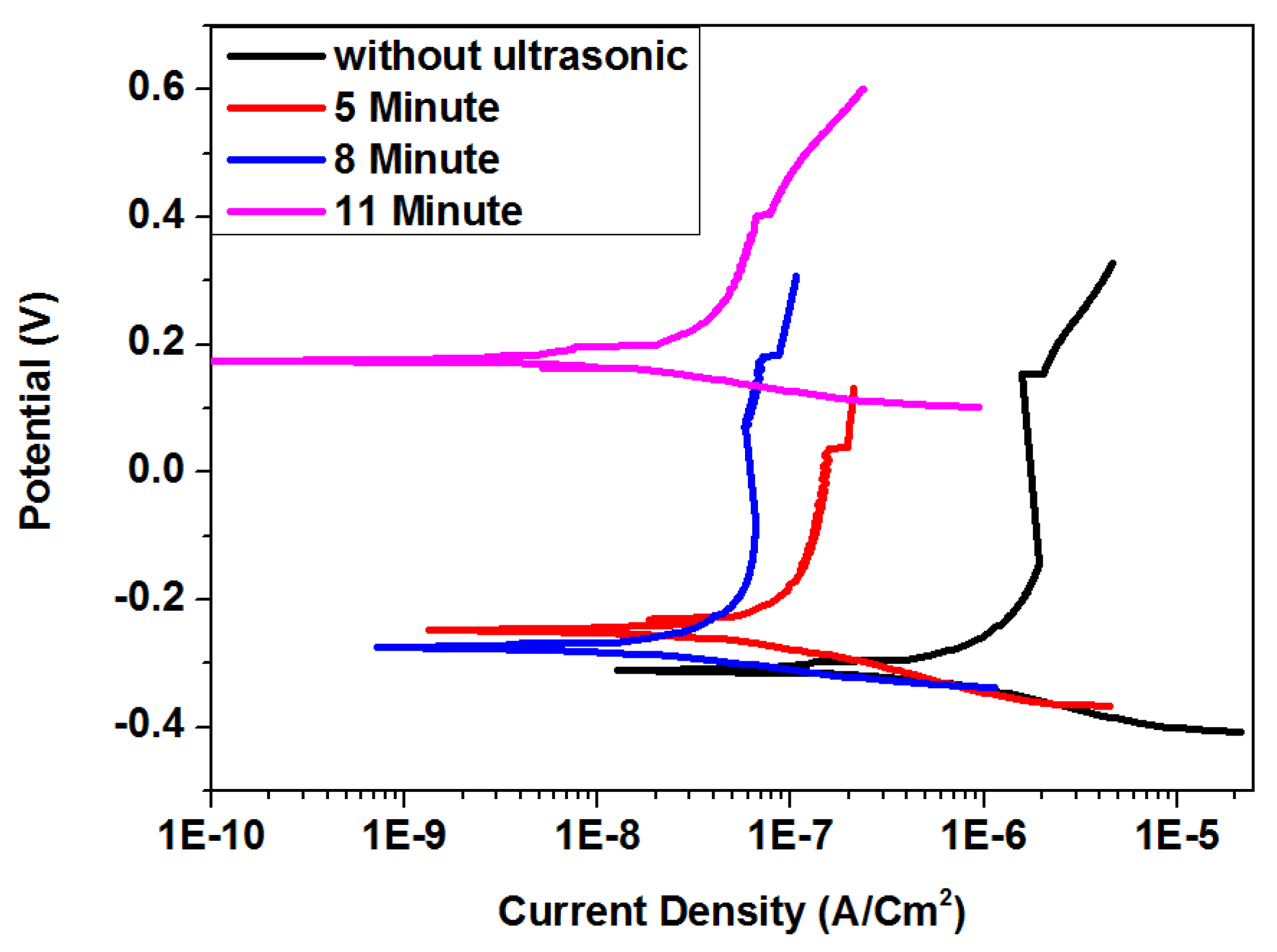

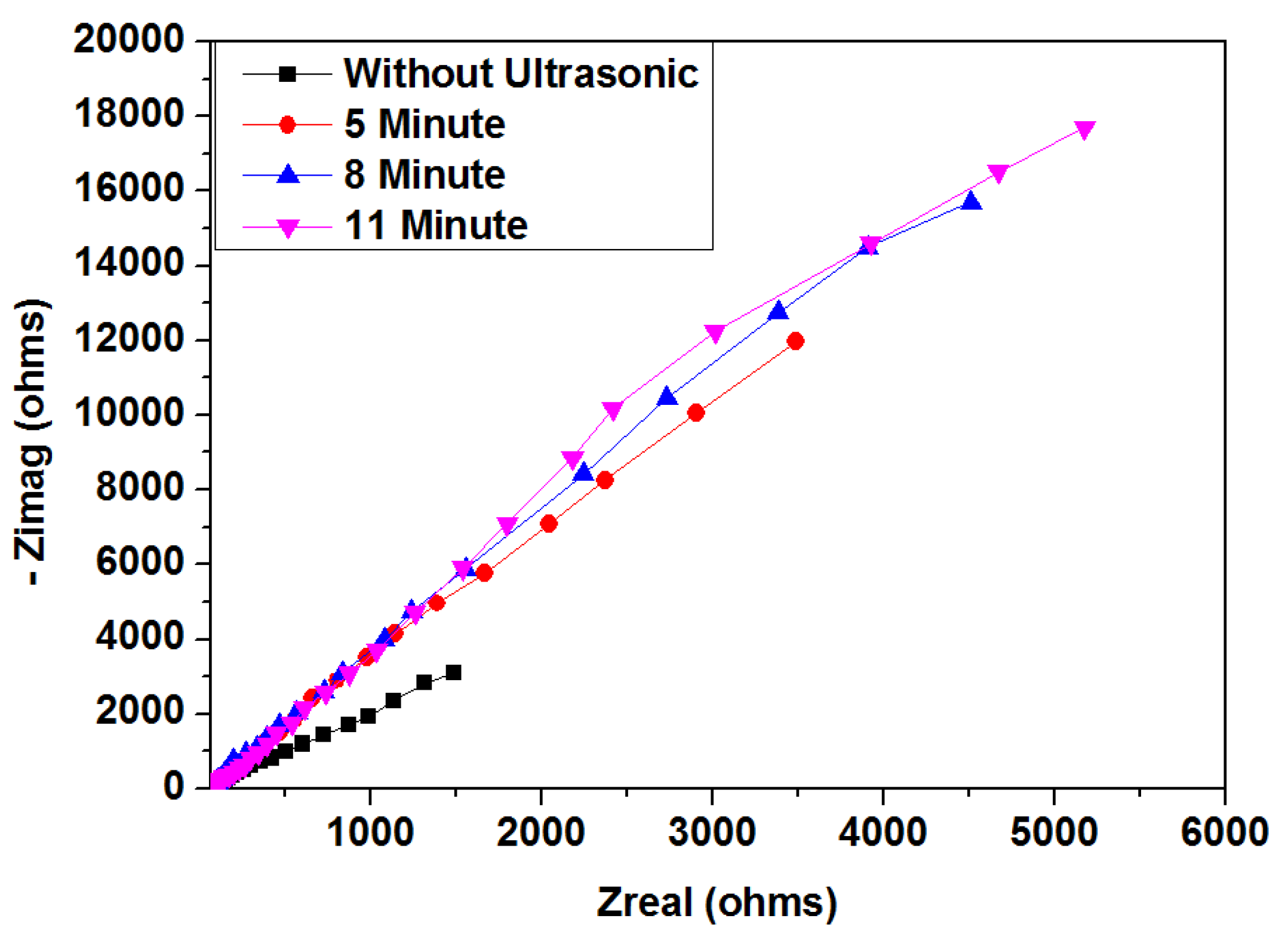

3. Results

4. Conclusions

- I.

- Ultrasonic frequency and exposure time directly affected the hardness of TiN-coated substrate. Increases in the TiN coating’s hardness were almost linear when both ultrasonic frequency and exposure time were increased. In contrast, the effect on the TiN coating’s thickness was enhanced by two ultrasonic parameters. Increased ultrasonic frequency and exposure time reduced the two responses; they compacted the coating layer from micro to nanoscale levels. The evidence shows a high elastic recovery in load vs. displacement curves.

- II.

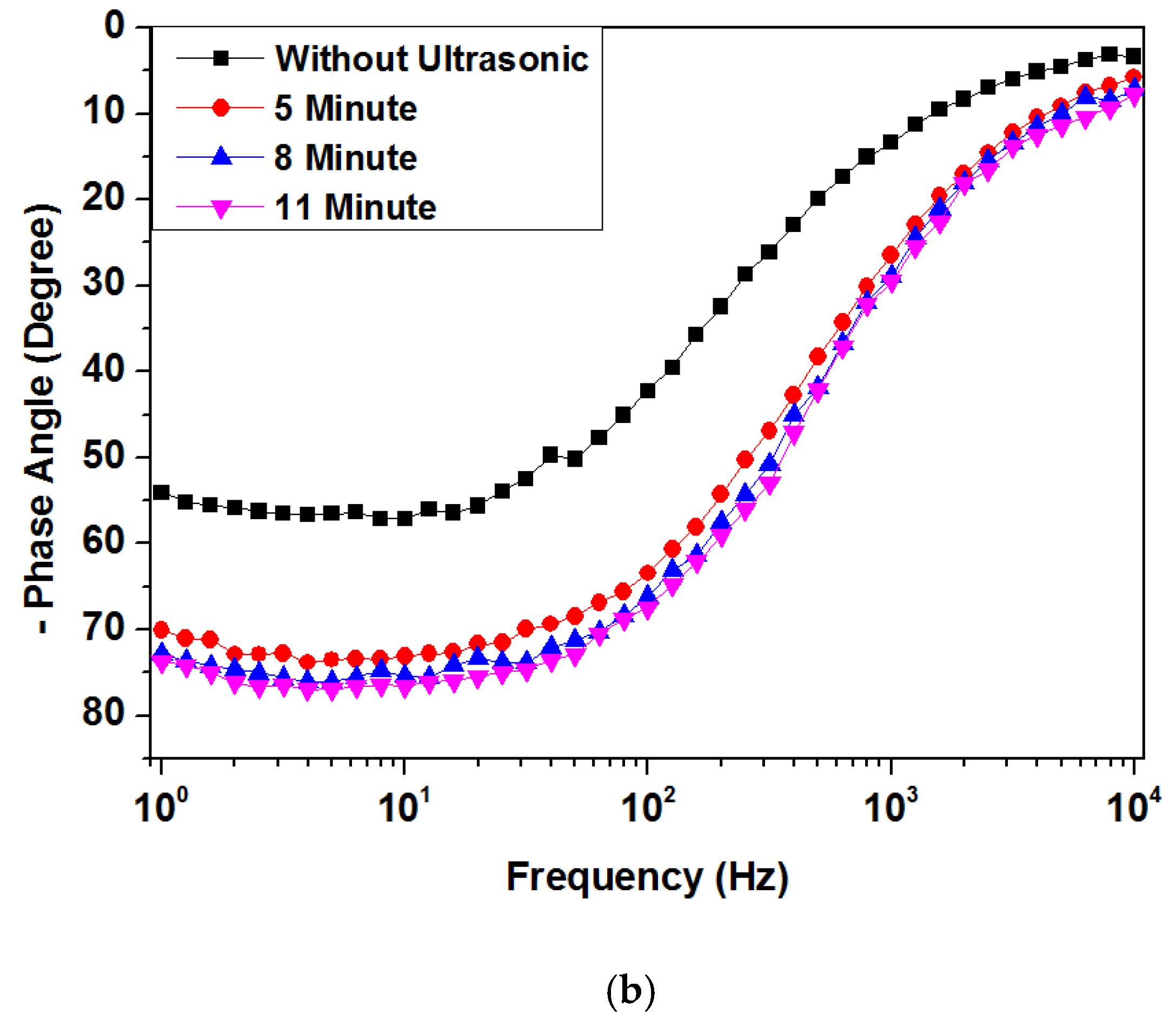

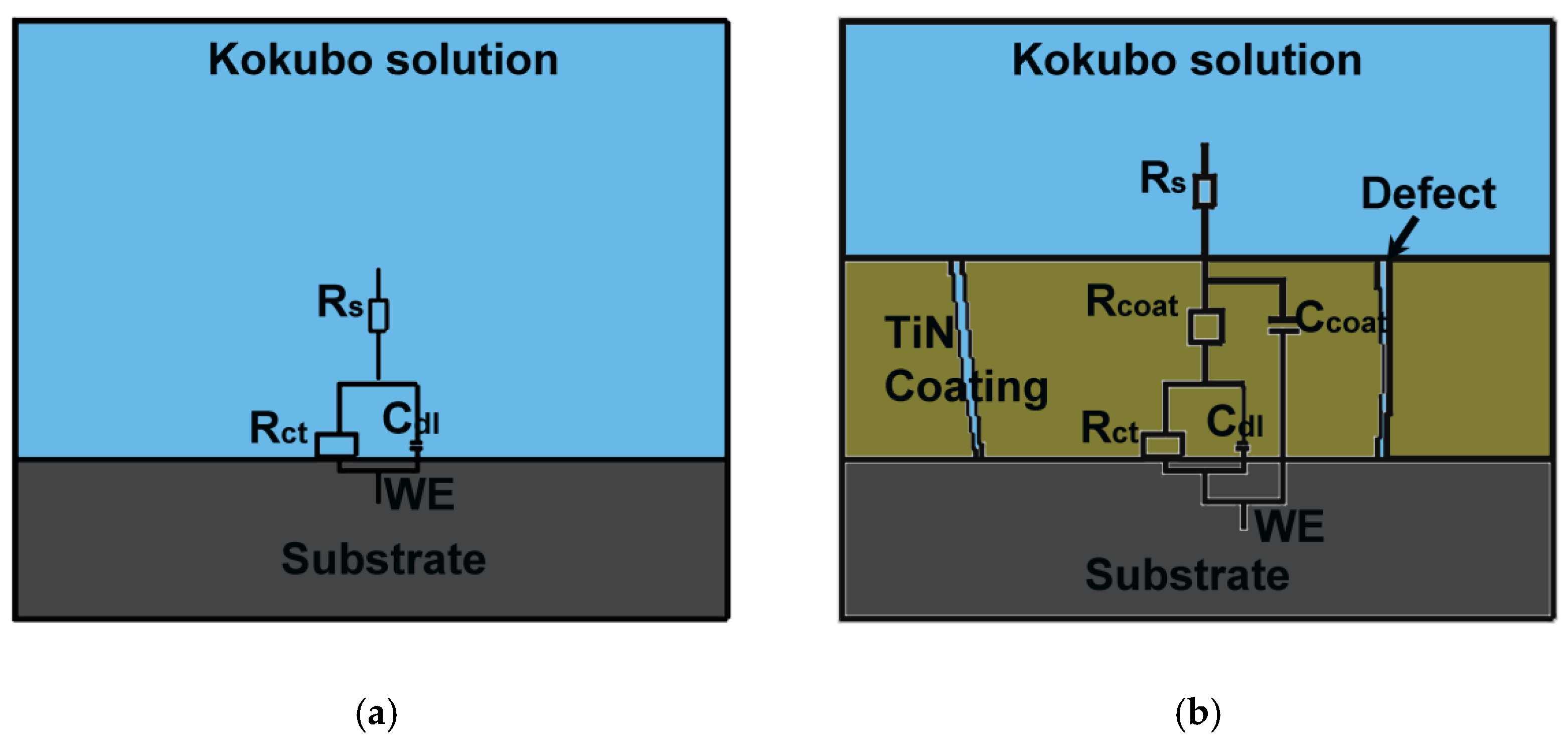

- Current density has an inverse effect on vibration frequencies and exposure time. Increased vibration frequency and exposure time reduced current densities of ultrasonically treated TiN-coated substrates. Pores and voids in TiN coatings were reduced when the vibration frequency and exposure time were increased, which led to an increased resistance to charge transfer Rct. Compared with the untreated sample, reducing Icorr values in ultrasonically treated TiN-coated substrates improved corrosion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prasad, K.; Bazaka, O.; Chua, M.; Rochford, M.; Fedrick, L.; Spoor, J.; Symes, R.; Tieppo, M.; Collins, C.; Cao, A.; et al. Metallic Biomaterials: Current Challenges and Opportunities. Materials 2017, 10, 884. [Google Scholar] [CrossRef] [PubMed]

- Çomakli, O. Influence of CrN, TiAlN monolayers and TiAlN/CrN multilayer ceramic films on structural, mechanical and tribological behavior of β-type Ti45Nb alloys. Ceram. Int. 2019, 46, 8185–8191. [Google Scholar] [CrossRef]

- Shah, A.; Izman, S.; Hassan, M.A. INFLUENCE OF NITROGEN FLOW RATE IN REDUCING TIN MICRODROPLETS ON BIOMEDICAL TI-13ZR-13NB ALLOY. J. Teknol. 2016, 78. [Google Scholar] [CrossRef][Green Version]

- Das, S.; Guha, S.; Das, P.P.; Ghadai, R.K. Analysis of morphological, microstructural, electrochemical and nano mechanical characteristics of TiCN coatings prepared under N2 gas flow rate by chemical vapour deposition (CVD) process at higher temperature. Ceram. Int. 2020, 46, 10292–10298. [Google Scholar] [CrossRef]

- Mas-Ayu, H.; Daud, R.; Shah, A.; Hazwan, H.; Tomadi, S.H.; Salwani, M. Effect of Thermal Oxidation and Carbon Concentrations on Co-Cr-Mo Alloy in Enhanced Corrosion Protection. Mater. Sci. Forum 2018, 916, 170–176. [Google Scholar] [CrossRef]

- Ayu, H.M.; Izman, S.; Daud, R.; Shah, A.; Anwar, M.; Krishnamurithy, G.; Kamarul, T. IN-VITRO BIOCOMPATIBILITY STUDY OF HYDROXYAPATITE COATED ON CO-CR-MO WITH OXIDE INTERLAYER. J. Teknol. 2017, 80. [Google Scholar] [CrossRef][Green Version]

- Dong, M.; Zhu, Y.; Wang, C.; Shan, L.; Li, J. Structure and tribocorrosion properties of duplex treatment coatings of TiSiCN/nitride on Ti6Al4V alloy. Ceram. Int. 2019, 45, 12461–12468. [Google Scholar] [CrossRef]

- Chenakin, S.; Filatova, V.; Makeeva, I.; Vasylyev, M. Ultrasonic impact treatment of CoCrMo alloy: Surface composition and properties. Appl. Surf. Sci. 2017, 408, 11–20. [Google Scholar] [CrossRef]

- Tiringer, U.; Kovač, J.; Milošev, I. Effects of mechanical and chemical pre-treatments on the morphology and composition of surfaces of aluminium alloys 7075-T6 and 2024-T3. Corros. Sci. 2017, 119, 46–59. [Google Scholar] [CrossRef]

- Zhang, S.; Zou, B.; Liu, Y.; Wang, Y.; Huang, C.; Liu, Z. Edge passivation and quality of carbide cutting inserts treated by wet micro-abrasive blasting. Int. J. Adv. Manuf. Technol. 2018, 96, 2307–2318. [Google Scholar] [CrossRef]

- Sun, S.; Wu, G.; Sun, L.; Shan, X.; Li, M.; Ji, S. Effects of different surface treatments of aluminum alloy 5083 on interlaminar strength and anticorrosion properties of FMLs. Mater. Res. Express 2018, 5, 116506. [Google Scholar] [CrossRef]

- Toboła, D.; Morgiel, J.; Maj, Ł. TEM analysis of surface layer of Ti-6Al-4V ELI alloy after slide burnishing and low-temperature gas nitriding. Appl. Surf. Sci. 2020, 515, 145942. [Google Scholar] [CrossRef]

- Bouzakis, K.; Skordaris, G.; Bouzakis, E.; Tsouknidas, A.; Makrimallakis, S.; Gerardis, S.; Katirtzoglou, G. Optimization of wet micro-blasting on PVD films with various grain materials for improving the coated tools’ cutting performance. CIRP Ann. 2011, 60, 587–590. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Skordaris, G.; Mirisidis, I.; Mesomeris, G.; Michailidis, N.; Pavlidou, E.; Erkens, G. Micro-blasting of PVD Films, an Effective Way to Increase the Cutting Performance of Coated Cemented Carbide Tools. CIRP Ann. 2005, 54, 95–98. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Gerardis, S.; Skordaris, G.; Katirtzoglou, G.; Makrimallakis, S.; Klocke, F.; Bouzakis, E. Effect of dry mi-cro-blasting on PVD-film properties, cutting edge geometry and tool life in milling. Surf. Coat. Technol. 2009, 204, 1081–1086. [Google Scholar] [CrossRef]

- Bouzakis, K.D.; Klocke, F.; Skordaris, G.; Bouzakis, E.; Gerardis, S.; Katirtzoglou, G.; Makrimallakis, S. Influence of dry mi-cro-blasting grain quality on wear behaviour of TiAlN coated tools. Wear 2011, 271, 783–791. [Google Scholar] [CrossRef]

- Nam, N.D.; Kim, J.G.; Hwang, W.-S. Effect of bias voltage on the electrochemical properties of TiN coating for polymer electrolyte membrane fuel cell. Thin Solid Films 2009, 517, 4772–4776. [Google Scholar] [CrossRef]

- Ali, R.; Alkhateeb, E.; Kellner, F.; Virtanen, S.; Popovska-Leipertz, N. Chemical vapor deposition of titanium based ceramic coatings on low carbon steel: Characterization and electrochemical evaluation. Surf. Coatings Technol. 2011, 205, 5454–5463. [Google Scholar] [CrossRef]

- Subramanian, B.; Ananthakumar, R.; Jayachandran, M. Structural and tribological properties of DC reactive magnetron sputtered titanium/titanium nitride (Ti/TiN) multilayered coatings. Surf. Coatings Technol. 2011, 205, 3485–3492. [Google Scholar] [CrossRef]

- Pedrosa, P.; Alves, E.; Barradas, N.; Fiedler, P.; Haueisen, J.; Vaz, F.; Fonseca, C. TiNx coated polycarbonate for bio-electrode applications. Corros. Sci. 2012, 56, 49–57. [Google Scholar] [CrossRef]

| Sample Conditions | Maximum Depth (nm) | Hardness (GPa) | Elastic Modulus E (GPa) | H3/E2 Ratio |

|---|---|---|---|---|

| Without Ultrasonic | 306.315 | 3.871 | 121.316 | 0.0039 |

| 5 min, 16 kHz | 190.235 | 9.821 | 242.640 | 0.0161 |

| 8 min, 16 kHz | 165.213 | 12.122 | 256.998 | 0.0270 |

| 11 min, 16 kHz | 150.012 | 13.101 | 263.221 | 0.0325 |

| Sample Conditions | Ecorr (mv) | Icorr (µA/cm2) | Corrosion Rate (mm/Year) | Rct | Cdl |

|---|---|---|---|---|---|

| Without Ultrasonic | −311.92 | 0.421 | 8.8354 × 10−3 | 2536 | 1.685 × 10−5 |

| 5 min, 16 kHz | −282.17 | 0.065 | 1.3152 × 10−3 | 7505 | 1.952 × 10−6 |

| 8 min, 16 kHz | −122.07 | 0.0363 | 0.726 × 10−3 | 8950 | 0.3448 × 10−6 |

| 11 min, 16 kHz | 174.21 | 0.0100 | 0.2250 × 10−3 | 9500 | 3.248 × 10−7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdullah, A.S.; Mohd Nawi, M.N.; Othuman Mydin, M.A.; Sari, M.W.; Ahmad, R.; Abdullah, M.M.A.B. The Significant Effect of Mechanical Treatment on Ceramic Coating for Biomedical Application. Materials 2022, 15, 6550. https://doi.org/10.3390/ma15196550

Abdullah AS, Mohd Nawi MN, Othuman Mydin MA, Sari MW, Ahmad R, Abdullah MMAB. The Significant Effect of Mechanical Treatment on Ceramic Coating for Biomedical Application. Materials. 2022; 15(19):6550. https://doi.org/10.3390/ma15196550

Chicago/Turabian StyleAbdullah, Arman Shah, Mohd Nasrun Mohd Nawi, Md Azree Othuman Mydin, Marti Widya Sari, Romisuhani Ahmad, and Mohd Mustafa Al Bakri Abdullah. 2022. "The Significant Effect of Mechanical Treatment on Ceramic Coating for Biomedical Application" Materials 15, no. 19: 6550. https://doi.org/10.3390/ma15196550

APA StyleAbdullah, A. S., Mohd Nawi, M. N., Othuman Mydin, M. A., Sari, M. W., Ahmad, R., & Abdullah, M. M. A. B. (2022). The Significant Effect of Mechanical Treatment on Ceramic Coating for Biomedical Application. Materials, 15(19), 6550. https://doi.org/10.3390/ma15196550