TEM Study of the Microstructure of an Alumina/Al Composite Prepared by Gas-Pressure Infiltration

Abstract

1. Introduction

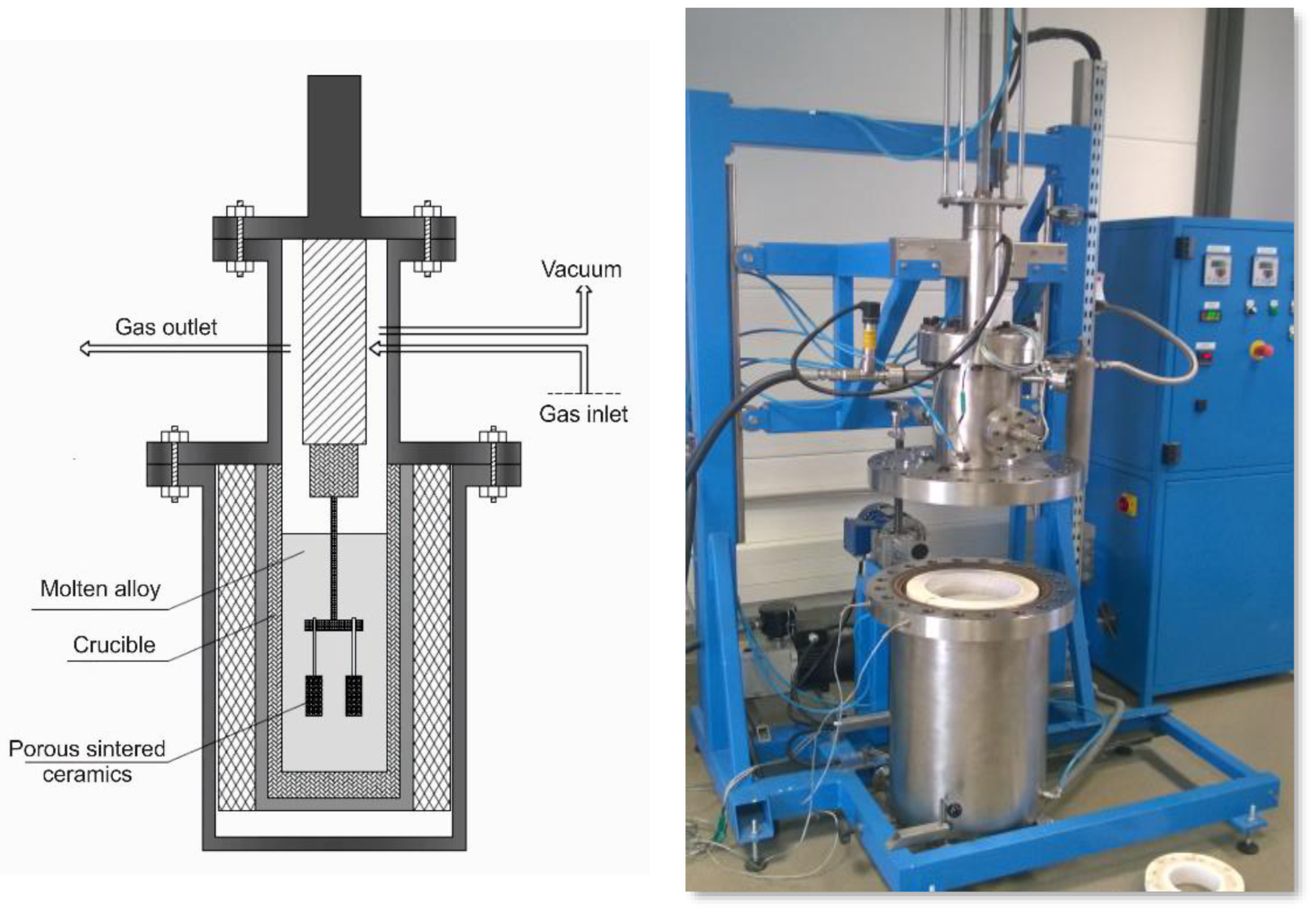

2. Materials and Methods

3. Results

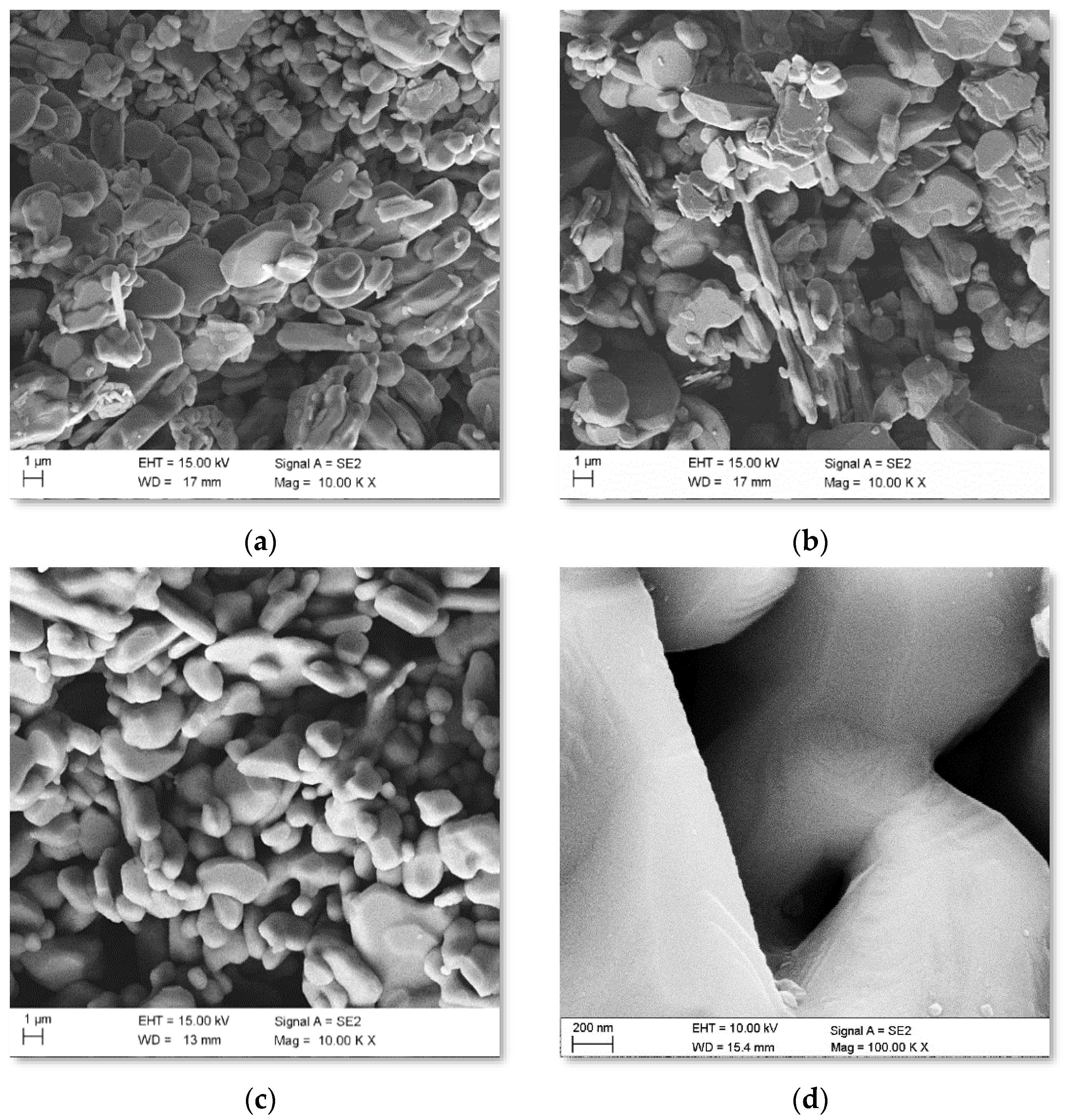

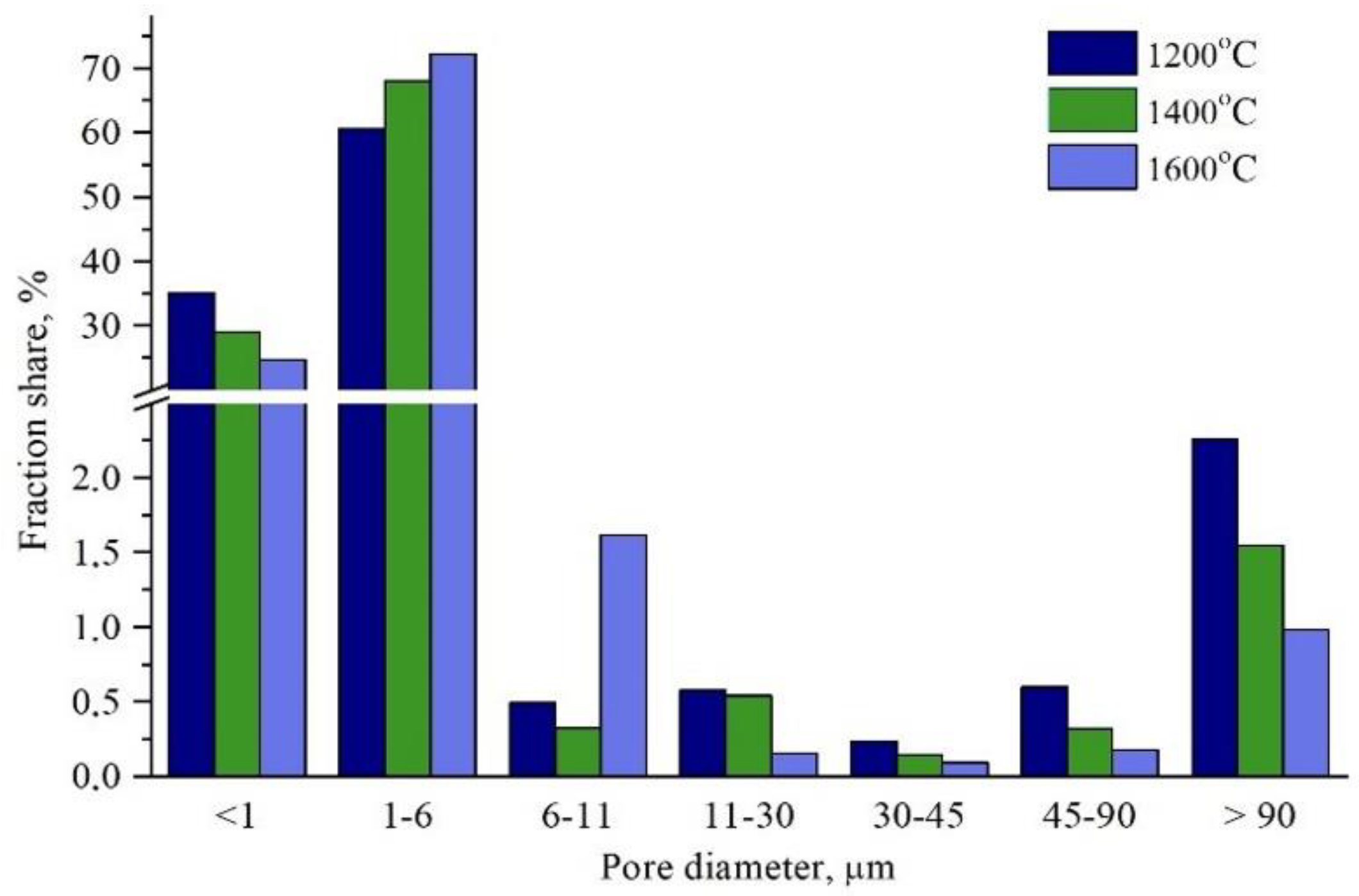

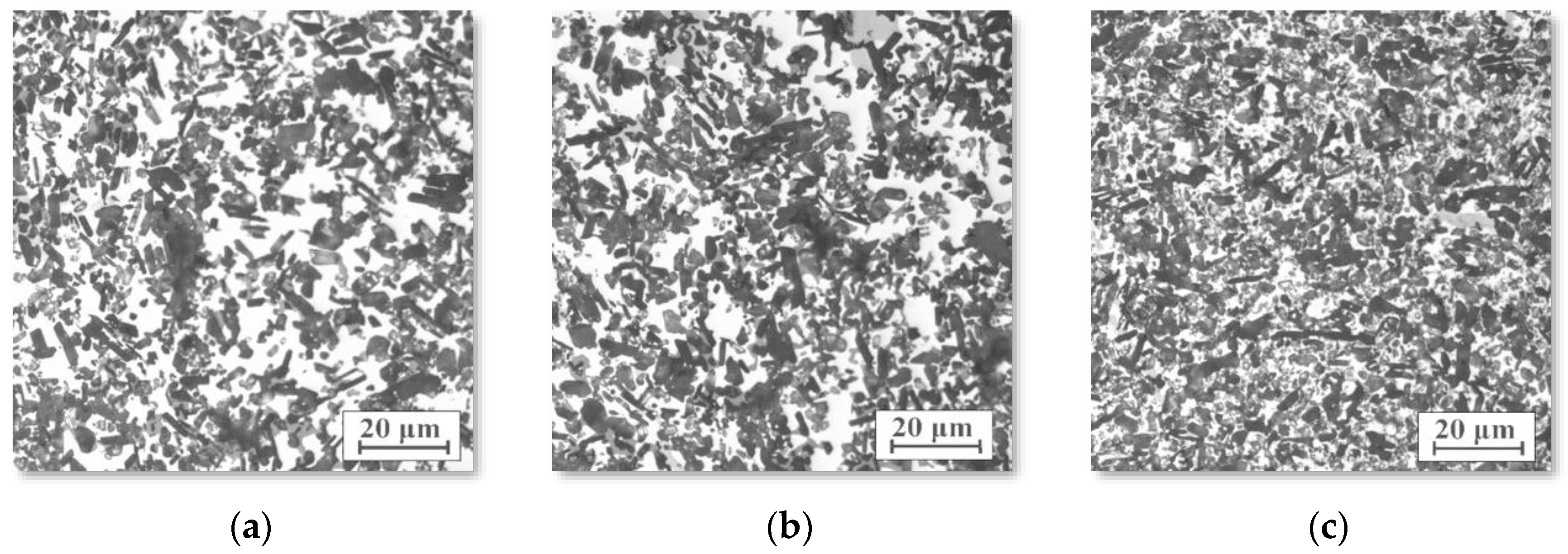

3.1. Microstructure of Porous Sintered Ceramics

3.2. Porosity and Density

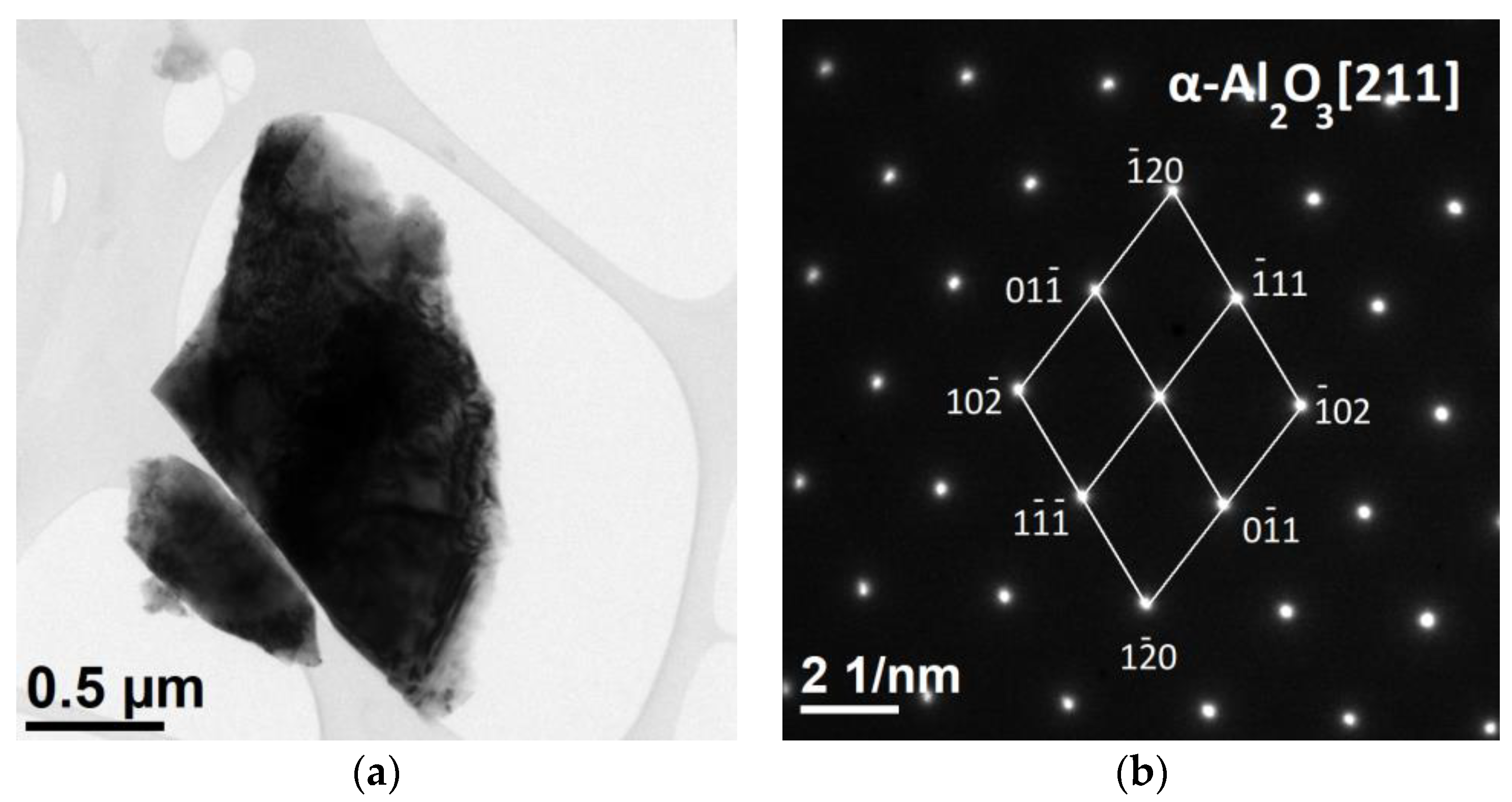

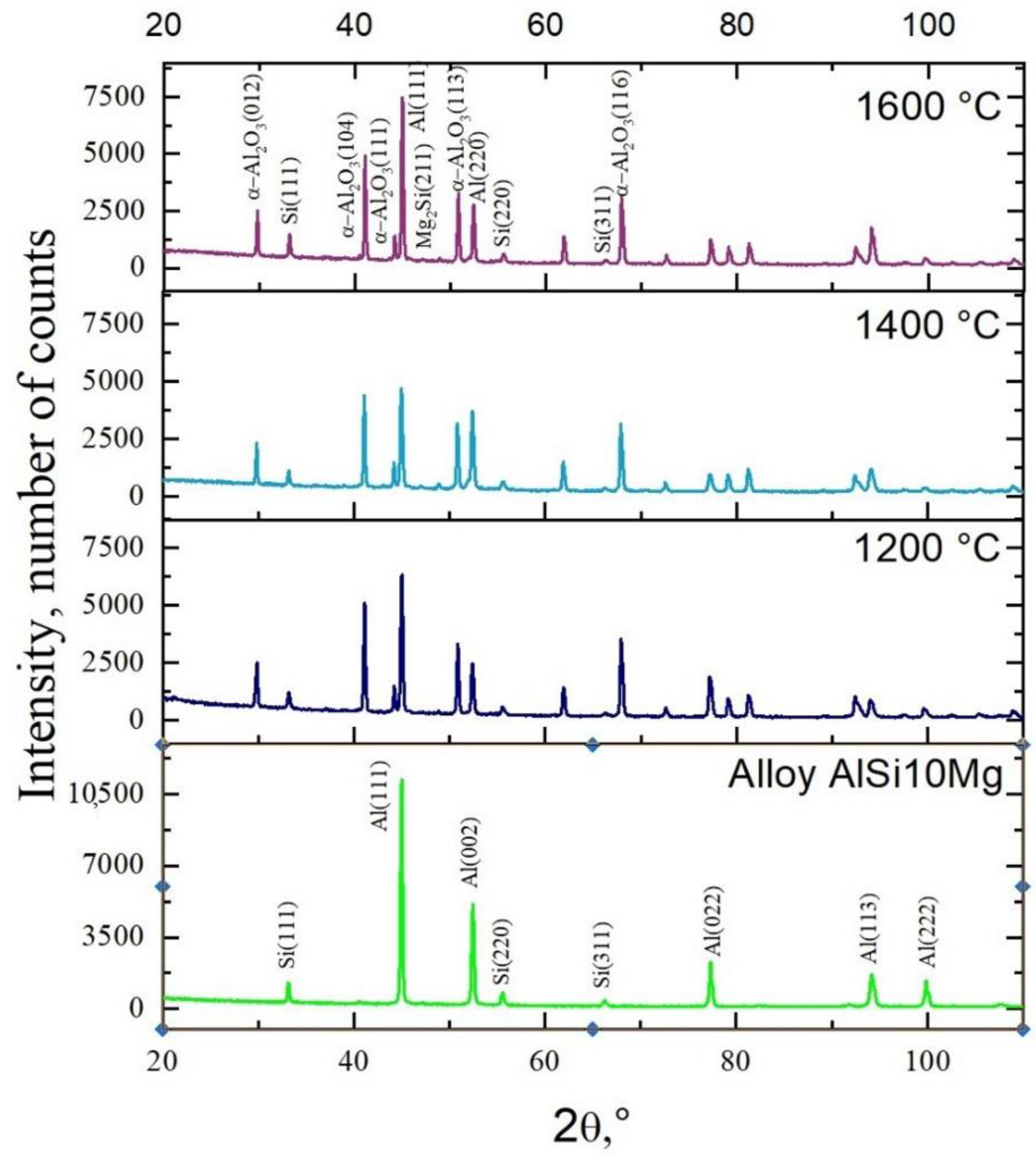

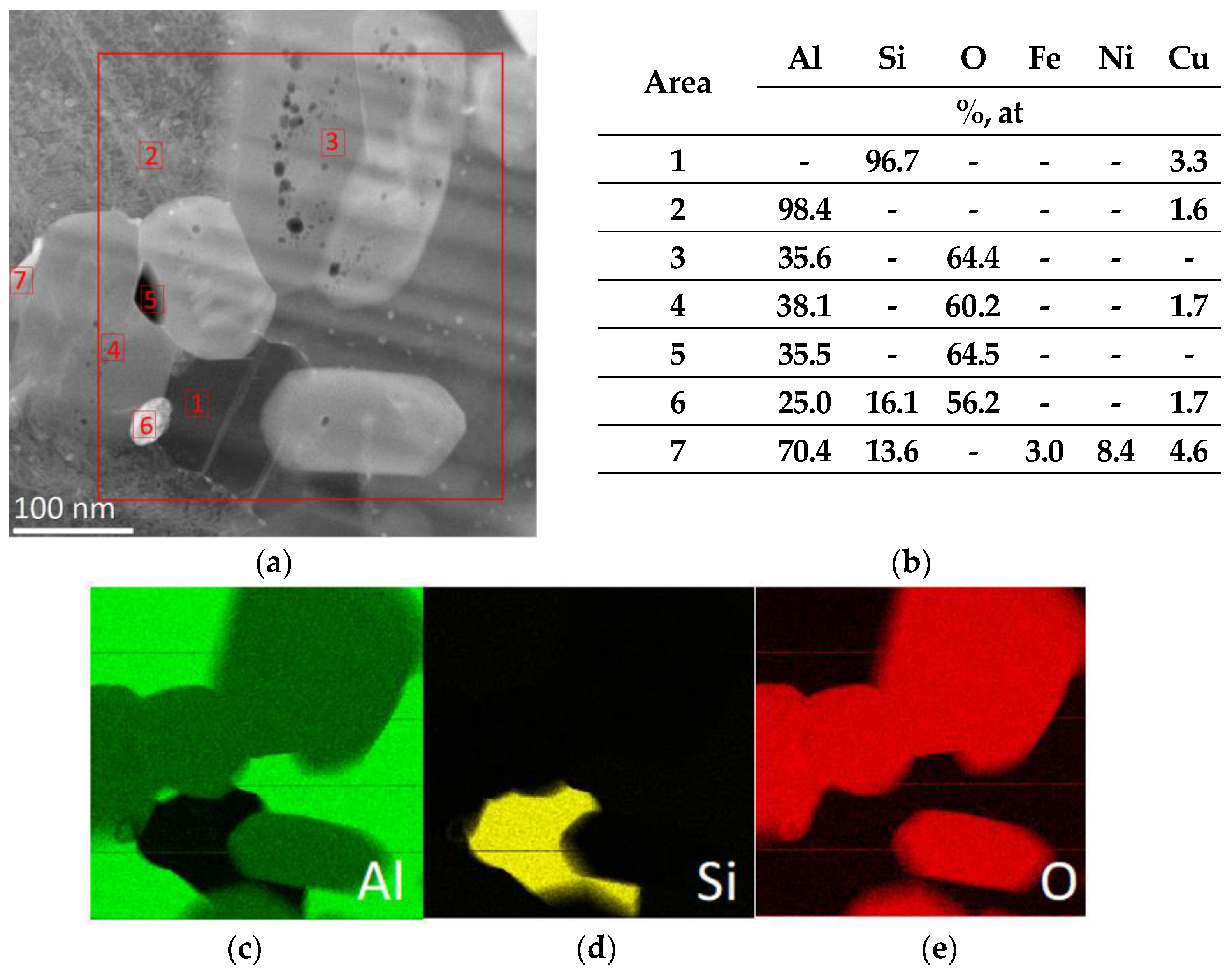

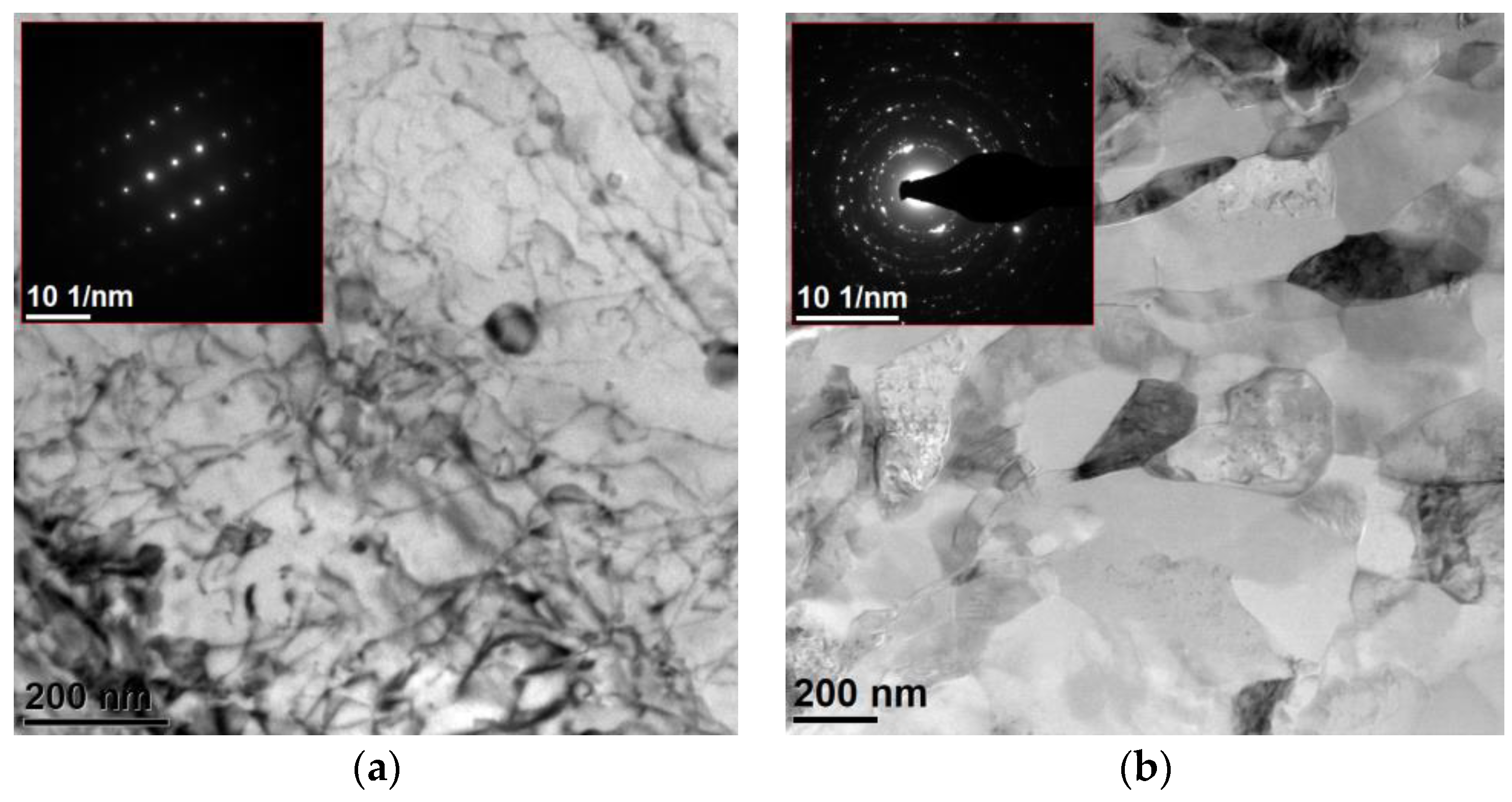

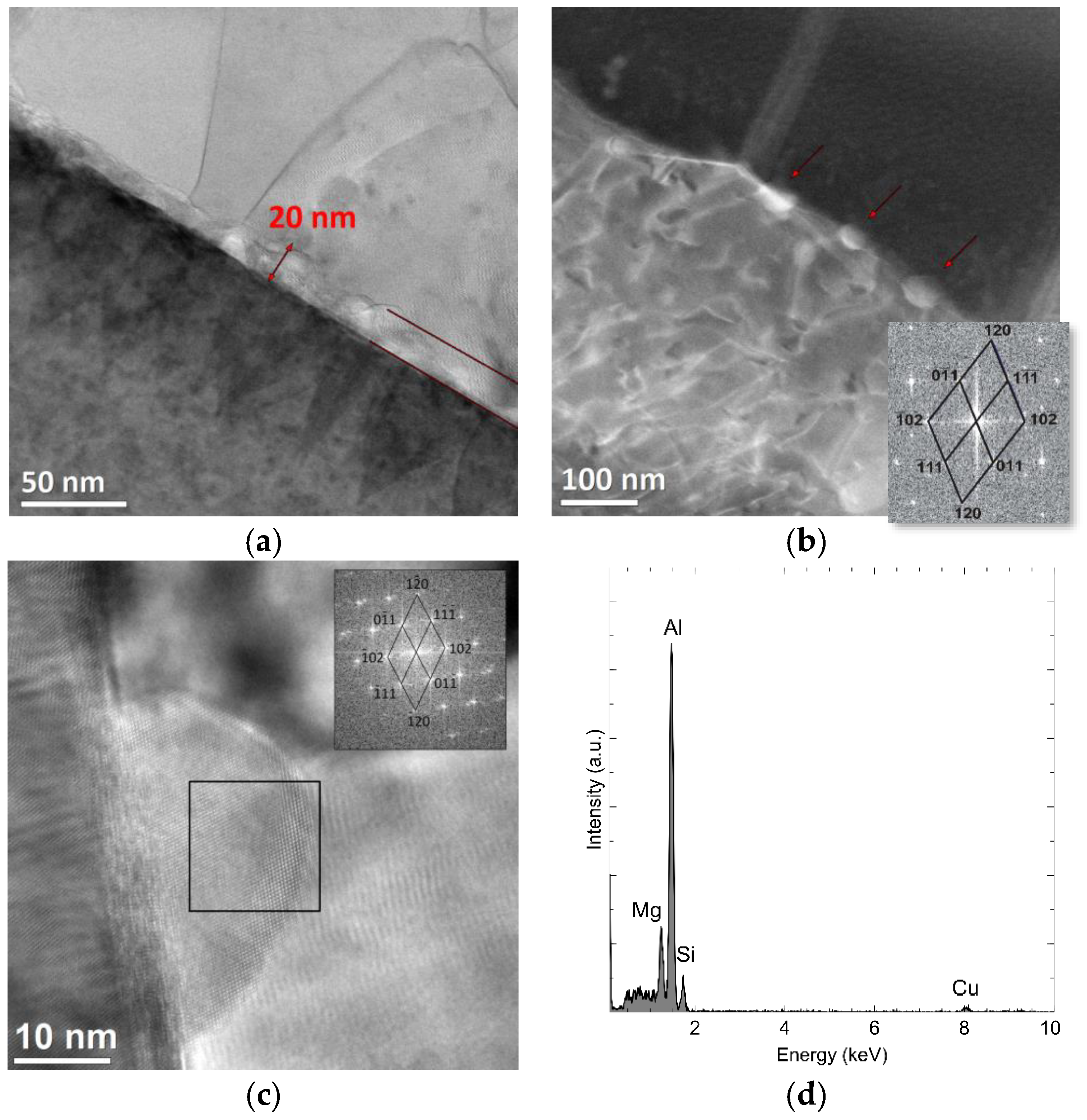

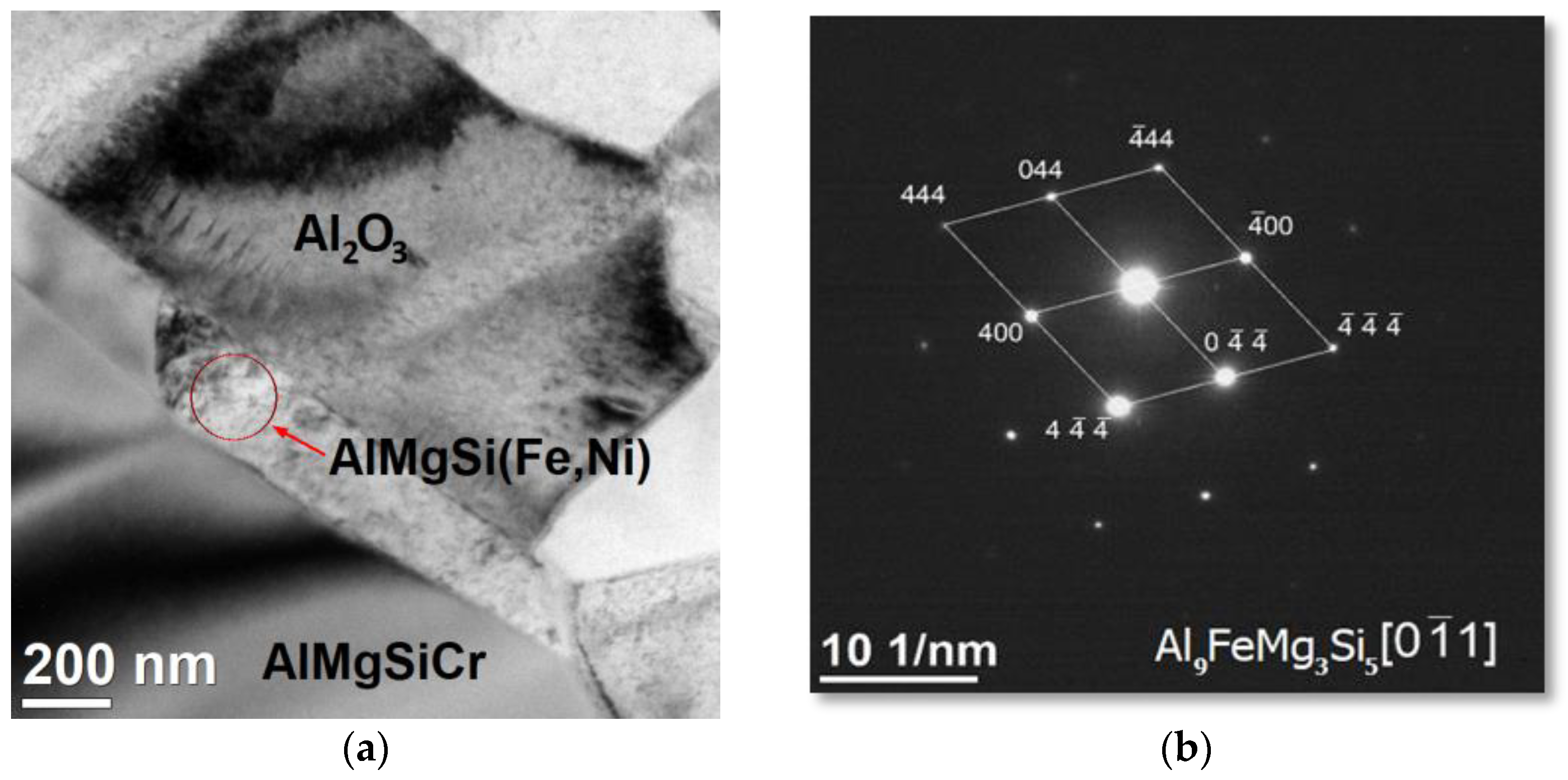

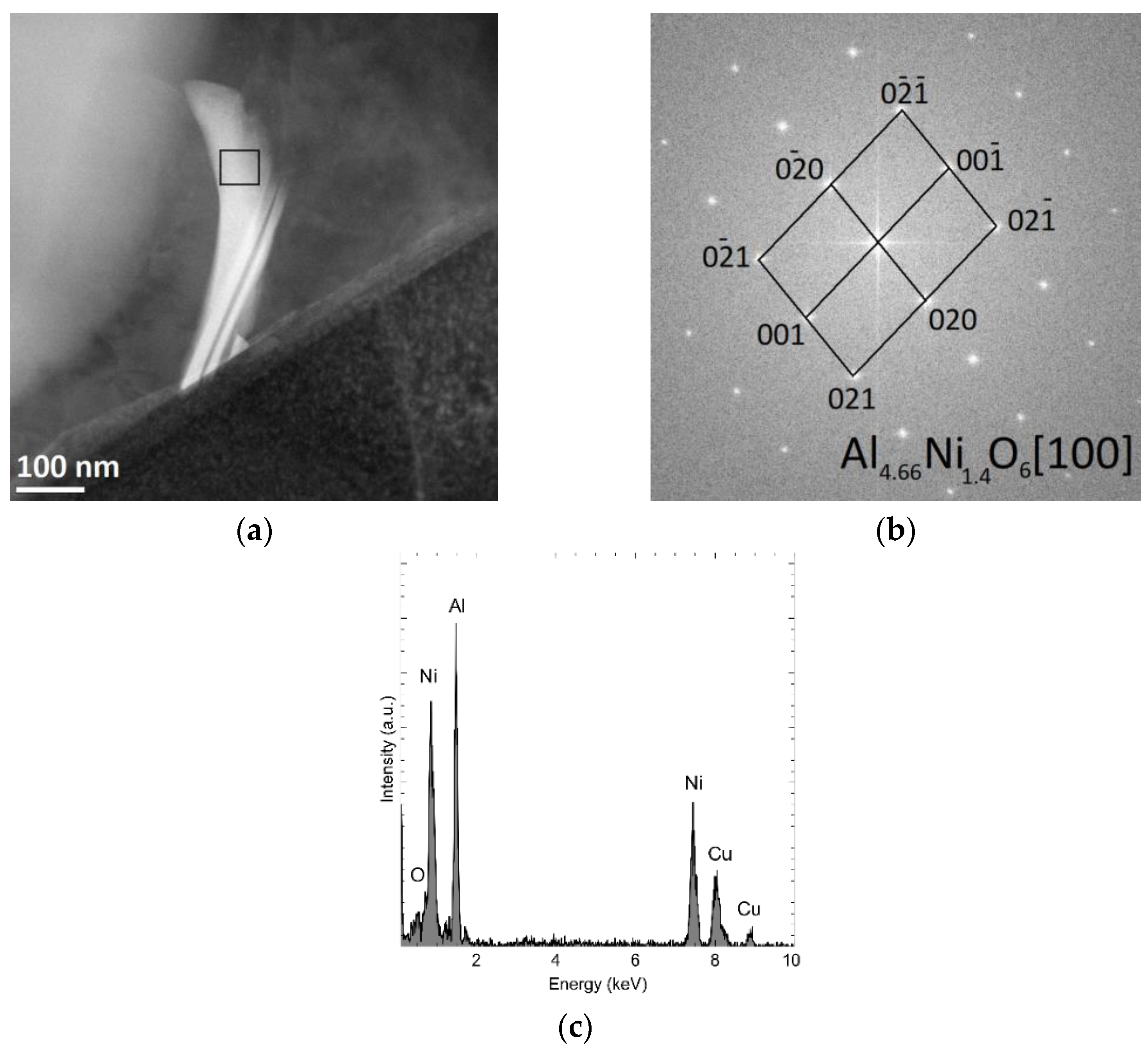

3.3. Microstructure and Phase X-ray Diffraction Analysis

3.4. Bending Strength

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Agrawal, P.; Sun, C.T. Fracture in metal–ceramic composites. Compos. Sci. Technol. 2004, 64, 1167–1178. [Google Scholar] [CrossRef]

- Wang, X.; Li, J.; Zhang, Y.; Wang, Y. Improvement of interfacial bonding and mechanical properties of Cu-Al2O3 composite by Cr-nanoparticle-induced interfacial modification. J. Alloy. Compd. 2017, 695, 2124–2130. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Su, Y.; Qu, Z. Synergetic strengthening effects on copper matrix induced by Al2O3 particle revealed from micro-scale mechanical deformation and microstructure evolutions. Ceram. Int. 2019, 45, 14889–14895. [Google Scholar] [CrossRef]

- Cabeza, M.; Feijoo, I.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Effect of high energy ball milling on the morphology, microstructure and properties of nano-sized TiC particle-reinforced 6005A aluminium alloy matrix composite. Powder Technol. 2017, 321, 31–34. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Pan, B.; Pan, D.; Liu, L.; Hou, X.; Chu, M.; Kondoh, K.; Zhao, M. Regulation of interface between carbon nanotubes-aluminum and its strengthening effect in CNTs reinforced aluminum matrix nanocomposites. Carbon 2019, 155, 686–696. [Google Scholar] [CrossRef]

- Bahl, S. Numerical simulation of the debonding behavior of fiber reinforced metal matrix composites. Mater. Today Proc. 2020, 28, 1328–1334. [Google Scholar] [CrossRef]

- Sha, J.-J.; Lu, Z.-Z.; Sha, R.-Y.; Zu, Y.-F.; Dai, J.-X.; Xian, Y.-Q.; Zhang, W.; Cui, D.; Yan, C.-L. Improved wettability and mechanical properties of metal coated carbon fiber-reinforced aluminum matrix composites by squeeze melt infiltration technique. Trans. Nonferrous Met. Soc. China 2021, 31, 317–330. [Google Scholar] [CrossRef]

- Garces, G.; Bruno, G.; Wanner, A. Load transfer in short fibre reinforced metal matrix composites. Acta Mater. 2007, 55, 5389–5400. [Google Scholar] [CrossRef]

- Arsenault, R.J.; Wang, L.; Feng, C.R. Strengthening of composites due to microstructural changes in the matrix. Acta Metall. Mater. 1991, 39, 47–57. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.K.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Stress in the interfaces of metal matrix composites (MMCs) in thermal and tensile loading. In Interfaces in Particle and Fibre Reinforced Composites; Woodhead Publishing: Sawston, UK, 2020; pp. 455–471. [Google Scholar]

- Maurya, P.; Kota, N.; Gibmeier, J.; Wanner, A.; Roy, S. Review on study of internal load transfer in metal matrix composites using diffraction techniques. Mater. Sci. Eng. A 2022, 840, 142973. [Google Scholar] [CrossRef]

- Roy, S.; Gibmeier, J.; Schell, K.G.; Bucharsky, E.C.; Weidenmann, K.A.; Wanner, A.; Hoffmann, M.J. Internal load transfer in an interpenetrating metal/ceramic composite material studied using energy dispersive synchrotron X-ray diffraction. Mater. Sci. Eng. A 2019, 753, 247–252. [Google Scholar] [CrossRef]

- Hossein-Zadeh, M.; Mirzaee, O.; Saidi, P. Structural and mechanical characterization of Al-based composite reinforced with heat treated Al2O3 particles. Mater. Des. (1980–2015) 2014, 54, 245–250. [Google Scholar] [CrossRef]

- Jue, J.; Gu, D.; Chang, K.; Dai, D. Microstructure evolution and mechanical properties of Al-Al2O3 composites fabricated by selective laser melting. Powder Technol. 2017, 310, 80–91. [Google Scholar] [CrossRef]

- Konopka, K.; Szafran, M. Fabrication of Al2O3–Al composites by infiltration method and their characteristic. J. Mater. Processing Technol. 2006, 175, 266–270. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, P.; Shaga, A.; Guo, R.; Jiang, Q. Preparation of nacre-like composites by reactive infiltration of a magnesium alloy into porous silicon carbide derived from ice template. Mater. Lett. 2016, 183, 299–302. [Google Scholar] [CrossRef]

- Chang, H.; Binner, J.; Higginson, R. Dry sliding wear behaviour of Al(Mg)/Al2O3 interpenetrating composites produced by a pressureless infiltration technique. Wear 2010, 268, 166–171. [Google Scholar] [CrossRef]

- Kursa, M.; Kowalczyk-Gajewska, K.; Petryk, H. Multi-objective optimization of thermo-mechanical properties of metal-ceramic composites. Compos. Part B Eng. 2014, 60, 586–596. [Google Scholar] [CrossRef]

- Leon-Patiño, C.A.; Drew, R.A.L. Role of metal interlayers in the infiltration of metal–ceramic composites. Curr. Opin. Solid State Mater. Sci. 2005, 9, 211–218. [Google Scholar] [CrossRef]

- Sazgar, A.; Movahhedy, M.R.; Mahnama, M.; Sohrabpour, S. A molecular dynamics study of bond strength and interface conditions in the metal–ceramic composites. Comput. Mater. Sci. 2015, 109, 200–208. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, X.; Wu, G. Interfacial microstructure of SiCp/Al composite produced by the pressureless infiltration technique. Ceram. Int. 2013, 39, 4893–4897. [Google Scholar] [CrossRef]

- Liu, J.; Binner, J.; Higginson, R.; Zhou, Z. Interfacial reactions and wetting in Al-Mg/oxide ceramic interpenetrating composites made by a pressureless infiltration technique. Compos. Sci. Technol. 2012, 72, 886–893. [Google Scholar] [CrossRef]

- Bleyan, D.; Hausnerova, B.; Svoboda, P. The development of powder injection moulding binders: A quantification of individual components’ interactions. Powder Technol. 2015, 286, 84–89. [Google Scholar] [CrossRef]

- Medvedovski, E.; Peltsman, M. Low pressure injection moulding mass production technology of complex shape advanced ceramic components. Adv. Appl. Ceram. 2012, 111, 333–344. [Google Scholar] [CrossRef]

- Herranz, G.; Matula, G.; Romero, A. Effects of chromium carbide on the microstructures and wear resistance of high speed steel obtained by powder injection moulding route. Powder Metall. 2017, 60, 120–130. [Google Scholar] [CrossRef]

- Chan, T.Y.; Lin, S.T. Effects of Stearic Acid on the Injection Molding of Alumina. J. Am. Ceram. Soc. 1995, 78, 2746–2752. [Google Scholar] [CrossRef]

- Bakan, H.I. Injection Moulding of Alumina with Partially Water Soluble Binder System and Solvent Debinding Kinetics. Mater. Sci. Technol. 2007, 23, 787–791. [Google Scholar] [CrossRef]

- Takahashi, M.; Masuda, Y.; Suzuki, S. Compaction and Sintering Behavior of a High Purity Alumina Powder Treated with Coupling Agents. J. Ceram. Soc. Jpn. 1993, 101, 569–574. [Google Scholar] [CrossRef][Green Version]

- Sathiyakumar, M.; Gnaman, F.D. Influence of MnO and TiO2 Additives on Density, Microstructure and Mechanical Properties of Al2O3. Ceram. Int. 2002, 28, 195–200. [Google Scholar] [CrossRef]

- Vielma-Thomas, P.; Cervera, A.; Levenfeld, B.; Vàrez, A. Production of alumina parts by powder injection molding with a binder system based on high density polyethylene. J. Eur. Ceram. Soc. 2008, 28, 763–771. [Google Scholar] [CrossRef]

- Ani Md, S.; Muchtar, A.; Muhamad, N.; Ghani, J.A. Binder removal a two-stage debinding process for ceramic injection molding parts. Ceram. Int. 2014, 40, 2819–2824. [Google Scholar] [CrossRef]

- Yang, W.-W.; Yang, K.-Y.; Hon, M.-H. Effects of PEG molecular weights on rheological behavior of alumina injection molding feedstocks. Mater. Chem. Phys. 2003, 78, 416–424. [Google Scholar] [CrossRef]

- Trunec, M.; Cihlar, J. Thermal removal of multicomponent binder from ceramic injection mouldings. J. Eur. Ceram. Soc. 2002, 22, 2231–2241. [Google Scholar] [CrossRef]

- Wei, W.C.; Wu, R.Y.; Ho, S.J. Effects of Pressure Parameters on Alumina made by Powder Injection Moulding. J. Eur. Ceram. Soc. 2000, 20, 1301–1310. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, T.; Rufner, J.F.; LaGrange, T.B.; Campbell, G.H.; Lavernia, E.J.; Schoenung, J.M.; van Benthem, K. Metal/ceramic interface structures and segregation behavior in aluminium-based composites. Acta Mater. 2015, 95, 254–263. [Google Scholar] [CrossRef]

- Guo, R.; Shen, P.; Sun, C.; Wang, Y.; Shaga, A.; Jiang, Q. Processing and mechanical properties of lamellar-structured Al–7Si–5Cu/TiC composites. Mater. Des. 2016, 106, 446–453. [Google Scholar] [CrossRef]

- Pilania, G.; Thijsse, B.J.; Hoagland, R.G.; Lazić, I.; Valone, S.M.; Liu, X.-Y. Revisiting the Al/Al2O3 Interface: Coherent Interfaces and Misfit Accommodation. Sci. Rep. 2014, 4, 4485. [Google Scholar] [CrossRef]

- Young, M.L.; Rao, R.; Almer, J.D.; Haeffner, D.R.; Lewis, J.A.; Dunand, D.C. Load partitioning in Al2O3–Al composites with three-dimensional periodic architecture. Acta Mater. 2009, 57, 2362–2375. [Google Scholar] [CrossRef]

- Matula, G.; Krzysteczko, J.; Lipowska, B. Ceramic injection moulding process of alumina. J. Achiev. Mater. Manuf. Eng. 2014, 67, 32–38. [Google Scholar]

- Matula, G.; Krzysteczko, J. Porous material produced by ceramic injection moulding. J. Achiev. Mater. Manuf. Eng. 2015, 71, 14–21. [Google Scholar]

- Matula, G.; Krzysteczko-Witek, J.; Tomiczek, B. Application of ceramic injection moulding and pressure infiltration to the manufacturing of alumina/AlSi10Mg composites. Arch. Metall. Mater. 2018, 63, 2101–2106. [Google Scholar]

- Bao, S.; Tang, K.; Kvithyld, A.; Tangstad, M.; Engh, T.A. Wettability of Aluminum on Alumina. Metall. Mater. Trans. B 2011, 42, 1358–1366. [Google Scholar] [CrossRef]

- Ksiazek, M.; Sobczak, N.; Mikulowski, B.; Radziwill, W.; Surowiak, I. Wetting and bonding strength in Al/Al2O3 system. Mater. Sci. Eng. A 2002, 324, 162–167. [Google Scholar] [CrossRef]

- Shen, P.; Fujii, H.; Matsumoto, T.; Nogi, K. Critical Factors Affecting the Wettability of α-Alumina by Molten Aluminum. J. Am. Ceram. Soc. 2004, 87, 2151–2159. [Google Scholar] [CrossRef]

- Yang, J.; Bao, S.; Akhtar, S.; Shen, P.; Li, Y. Influence of Grain Refiners on the Wettability of Al2O3 Substrate by Aluminum Melt. Metall. Mater. Trans. B 2021, 52, 382–392. [Google Scholar] [CrossRef]

- Klinter, A.J.; Mendoza-Suarez, G.; Drew, R.A.L. Wetting of pure aluminum and selected alloys on polycrystalline alumina and sapphire. Mater. Sci. Eng. A 2008, 495, 147–152. [Google Scholar] [CrossRef]

- Biggemann, J.; Stumpf, M.; Fey, T. Porous Alumina Ceramics with Multimodal Pore Size Distributions. Materials 2021, 14, 3294. [Google Scholar] [CrossRef] [PubMed]

- Selamat, M.Z.; Nasir, N.; Jumaidin, R.; Salleh, S.; Lau, K.T. Effect of Yeast Content as Pores Forming Agent on Porous Alumina Ceramic. Int. J. Nanoelectron. Mater. 2022, 15, 27–36. [Google Scholar]

- Rutkowski, P.; Klimczyk, P.; Jaworska, L.; Stobierski, L.; Dubiel, A. Thermal properties of pressure sintered alumina–graphene composites. J. Anal. Calorim. 2015, 122, 105–114. [Google Scholar] [CrossRef]

- Eom, J.-H.; Kim, Y.-W.; Jeong, D.-H.; Lee, S.-S. Thermal conductivity and compressive strength anisotropy in vermiculite–ceramic composites with layered structure. J. Ceram. Soc. Jpn. 2011, 119, 319–321. [Google Scholar] [CrossRef]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. J. Mater. Res. Technol. 2019, 8, 4924–4939. [Google Scholar]

- Senel, M.; Gurbuz, M. Investigation on Mechanical Properties and Microstructures of Aluminum Hybrid Composites Reinforced with Al2O3/GNPs Binary Particle. Arch. Metall. Mater. 2021, 66, 97–106. [Google Scholar]

- Etemadi, R.; Wang, B.; Pillai, K.M.; Niroumand, B.; Omrani, E.; Rohatgi, P. Pressure infiltration processes to synthesize metal matrix composites—A review of metal matrix composites, the technology and process simulation. Mater. Manuf. Processes 2018, 33, 1261–1290. [Google Scholar] [CrossRef]

- Pawlyta, M.; Tomiczek, B.; Dobrzański, L.A.; Kujawa, M.; Bierska-Piech, B. Transmission electron microscopy observations on phase transformations during aluminium/mullite composites formation by gas pressure infiltration. Mater. Charact. 2016, 114, 9–17. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Lee, S.; Ha, J.-H.; Lee, J.; Song, I.-H.; Moon, K.-S. Effect of the Sintering Temperature on the Compressive Strengths of Reticulated Porous Zirconia. Appl. Sci. 2021, 11, 5672. [Google Scholar] [CrossRef]

| Properties | Sintering Temperature, °C | ||

|---|---|---|---|

| 1200 | 1400 | 1600 | |

| Mercury intrusion volume, cm3/g | 0.272 | 0.267 | 0.223 |

| Specific surface area, m2/g | 1.09 | 0.97 | 0.76 |

| Median pore diameter (vol), μm | 1.30 | 1.37 | 1.39 |

| Apparent density, g/cm3 | 1.86 | 1.89 | 2.10 |

| True density, g/cm3 | 3.78 | 3.83 | 3.89 |

| Porosity, % | 50.71 | 50.61 | 46.49 |

| Permeability, m2·10−15 | 1.51 | 1.37 | 1.33 |

| Apparent density H, g/cm3 | 1.85 | 1.89 | 2.08 |

| Porosity H, % | 50.44 | 50.36 | 47.79 |

| Open porosity H, % | 49.01 | 47.52 | 44.45 |

| Closed porosity H, % | 1.43 | 2.84 | 3.34 |

| Sintering Temperature | 1200 | 1400 | 1600 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Infiltration pressure, MPa | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| True density, g/cm3 | 3.20 | 3.24 | 3.24 | 3.24 | 3.24 | 3.29 | 3.26 | 3.28 | 3.32 |

| Ceramic phase content, % | 49.29 | 49.29 | 49.29 | 49.39 | 49.39 | 49.39 | 53.51 | 53.51 | 53.51 |

| Metal phase content, % | 49.96 | 50.71 | 50.71 | 50.37 | 50.6 | 50.61 | 44.12 | 44.74 | 46.32 |

| Unfulfilled porosity, % | 0.75 | 0 | 0 | 0.24 | 0.01 | 0 | 2.37 | 1.75 | 0.17 |

| Sintering Temperature, °C | 1200 | 1400 | 1600 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Infiltration pressure, MPa | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 |

| Bending strength, MPa | 498.0 | 507.4 | 510.8 | 470.6 | 472.0 | 483.8 | 350.3 | 423.6 | 460.97 |

| Standard deviation | 3.01 | 3.36 | 2.12 | 3.25 | 3.59 | 3.67 | 2.31 | 3.16 | 1.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matus, K.; Matula, G.; Pawlyta, M.; Krzysteczko-Witek, J.; Tomiczek, B. TEM Study of the Microstructure of an Alumina/Al Composite Prepared by Gas-Pressure Infiltration. Materials 2022, 15, 6112. https://doi.org/10.3390/ma15176112

Matus K, Matula G, Pawlyta M, Krzysteczko-Witek J, Tomiczek B. TEM Study of the Microstructure of an Alumina/Al Composite Prepared by Gas-Pressure Infiltration. Materials. 2022; 15(17):6112. https://doi.org/10.3390/ma15176112

Chicago/Turabian StyleMatus, Krzysztof, Grzegorz Matula, Mirosława Pawlyta, Jagoda Krzysteczko-Witek, and Błażej Tomiczek. 2022. "TEM Study of the Microstructure of an Alumina/Al Composite Prepared by Gas-Pressure Infiltration" Materials 15, no. 17: 6112. https://doi.org/10.3390/ma15176112

APA StyleMatus, K., Matula, G., Pawlyta, M., Krzysteczko-Witek, J., & Tomiczek, B. (2022). TEM Study of the Microstructure of an Alumina/Al Composite Prepared by Gas-Pressure Infiltration. Materials, 15(17), 6112. https://doi.org/10.3390/ma15176112