Effect of Accelerated Weathering on the Thermal, Tensile, and Morphological Characteristics of Polypropylene/Date Nanofiller Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Establishment of Nanofillers

2.2. Preparation of PP/DBF Biocomposites

2.3. Accelerated Weathering Test

2.4. Thermal Analysis

2.5. FTIR Analysis

2.6. Tensile Strength Analysis

2.7. Surface Morphological Analysis

3. Results and Discussion

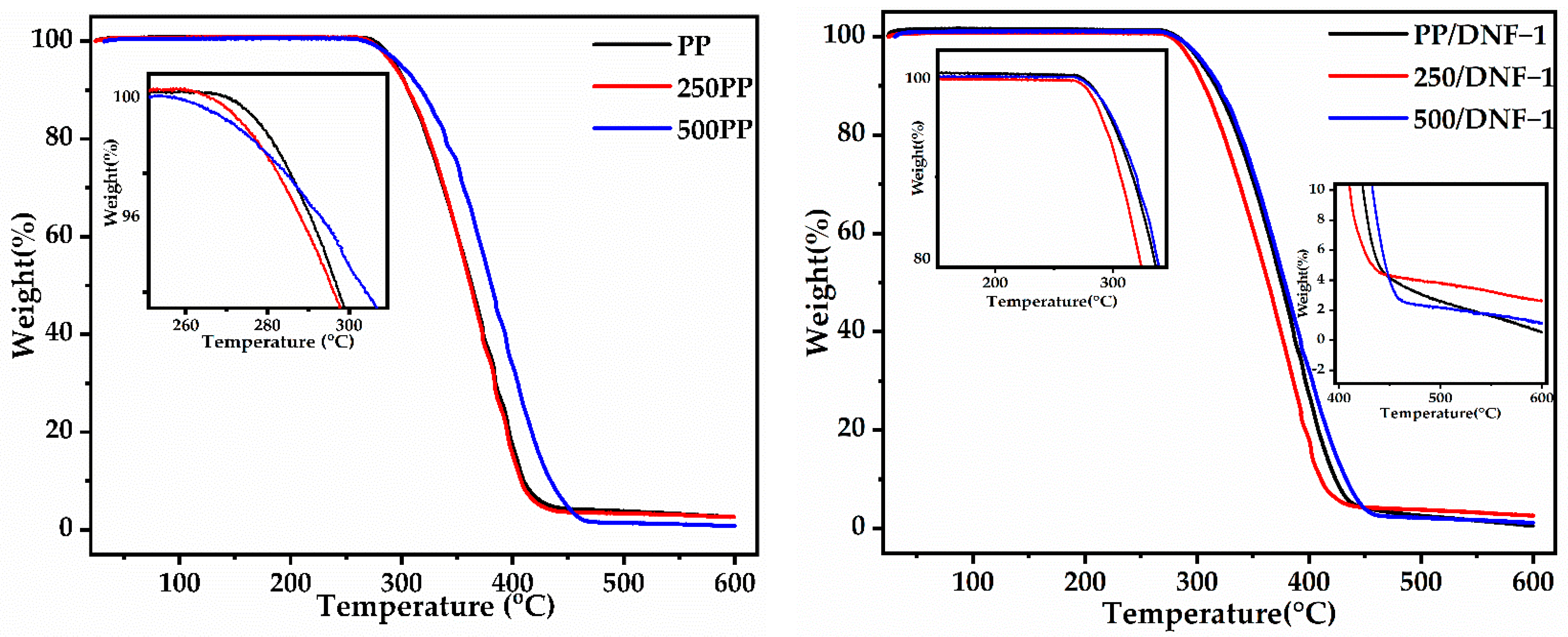

3.1. Thermal Analysis

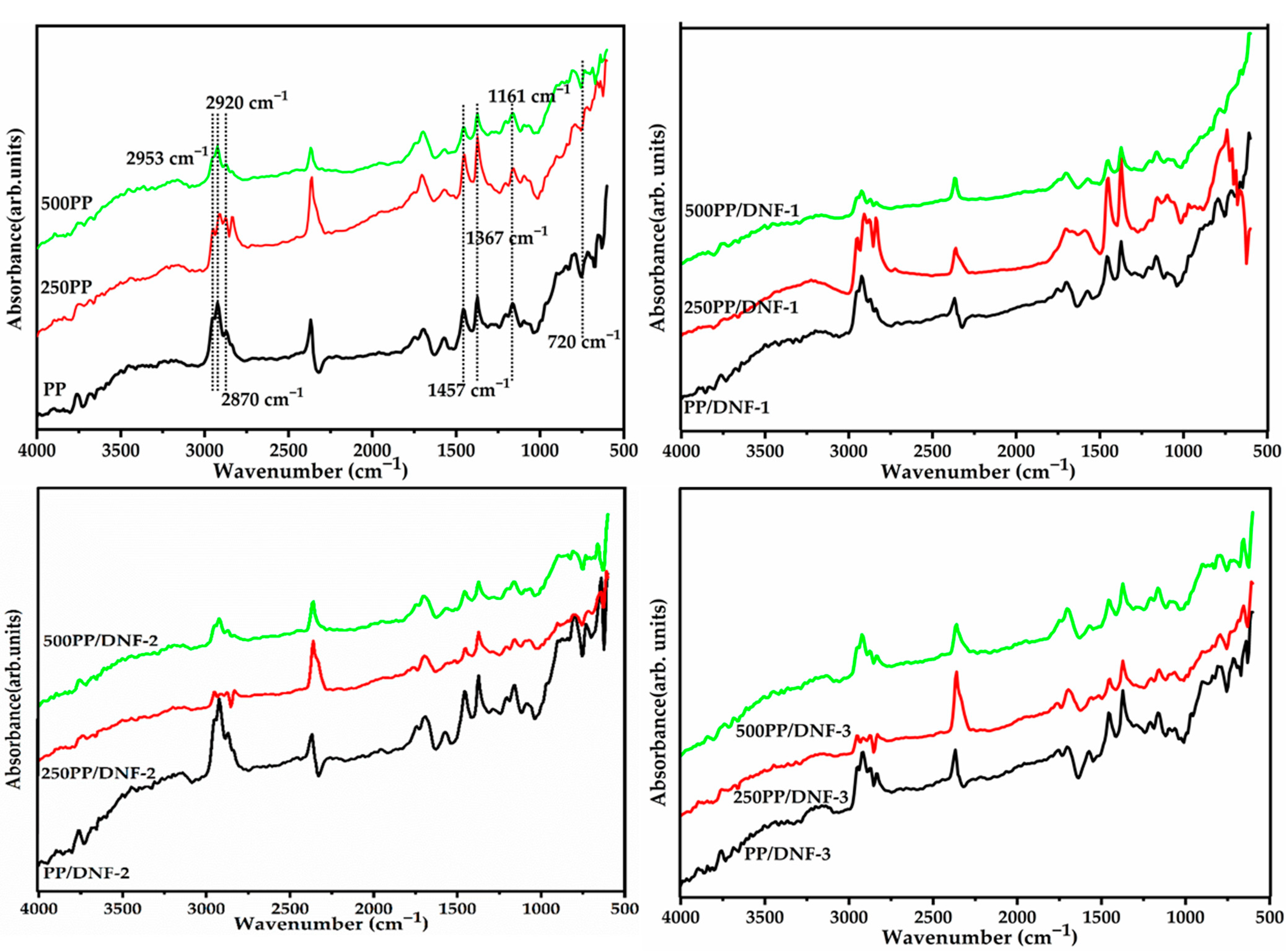

3.2. Functional Group Analysis

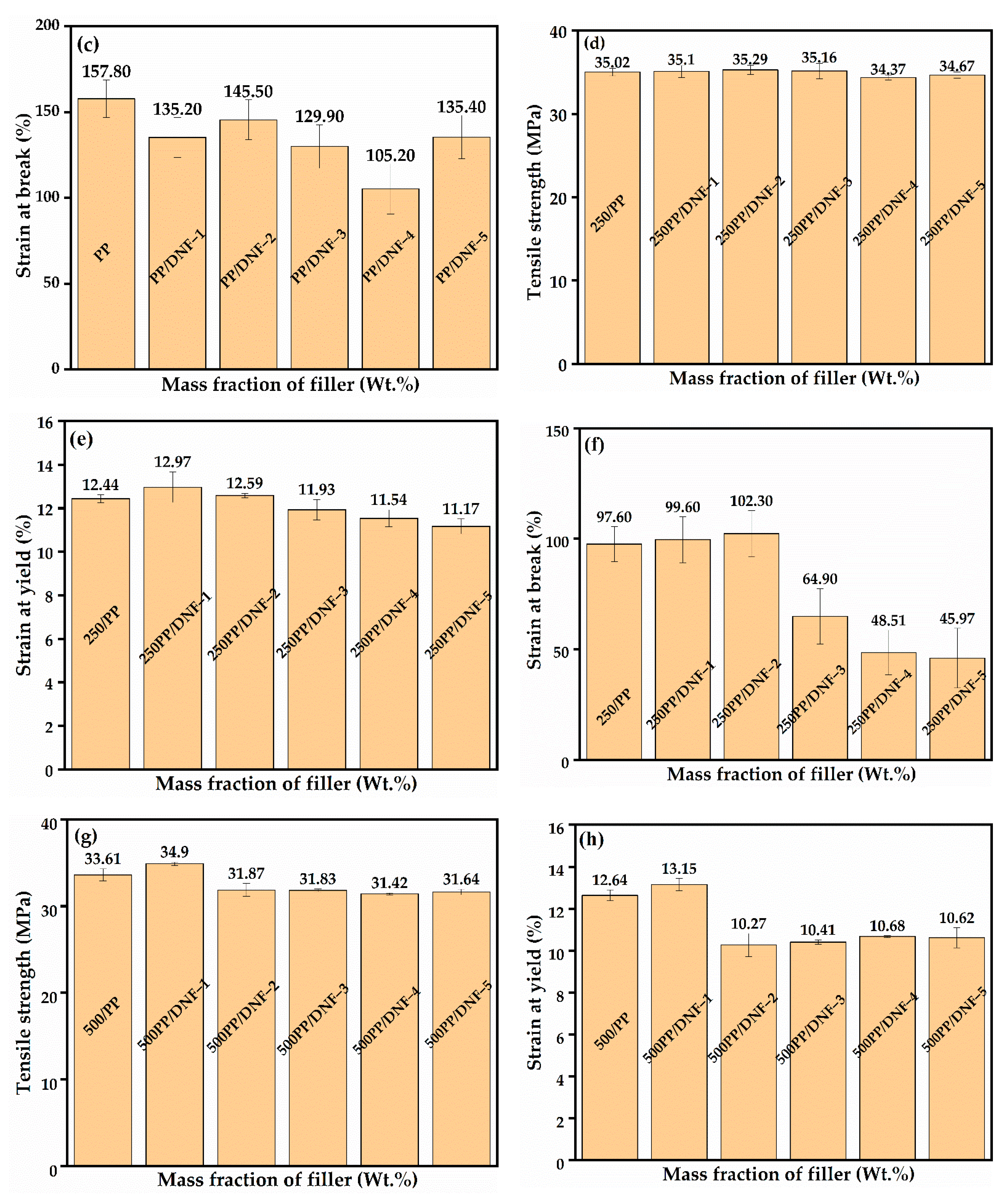

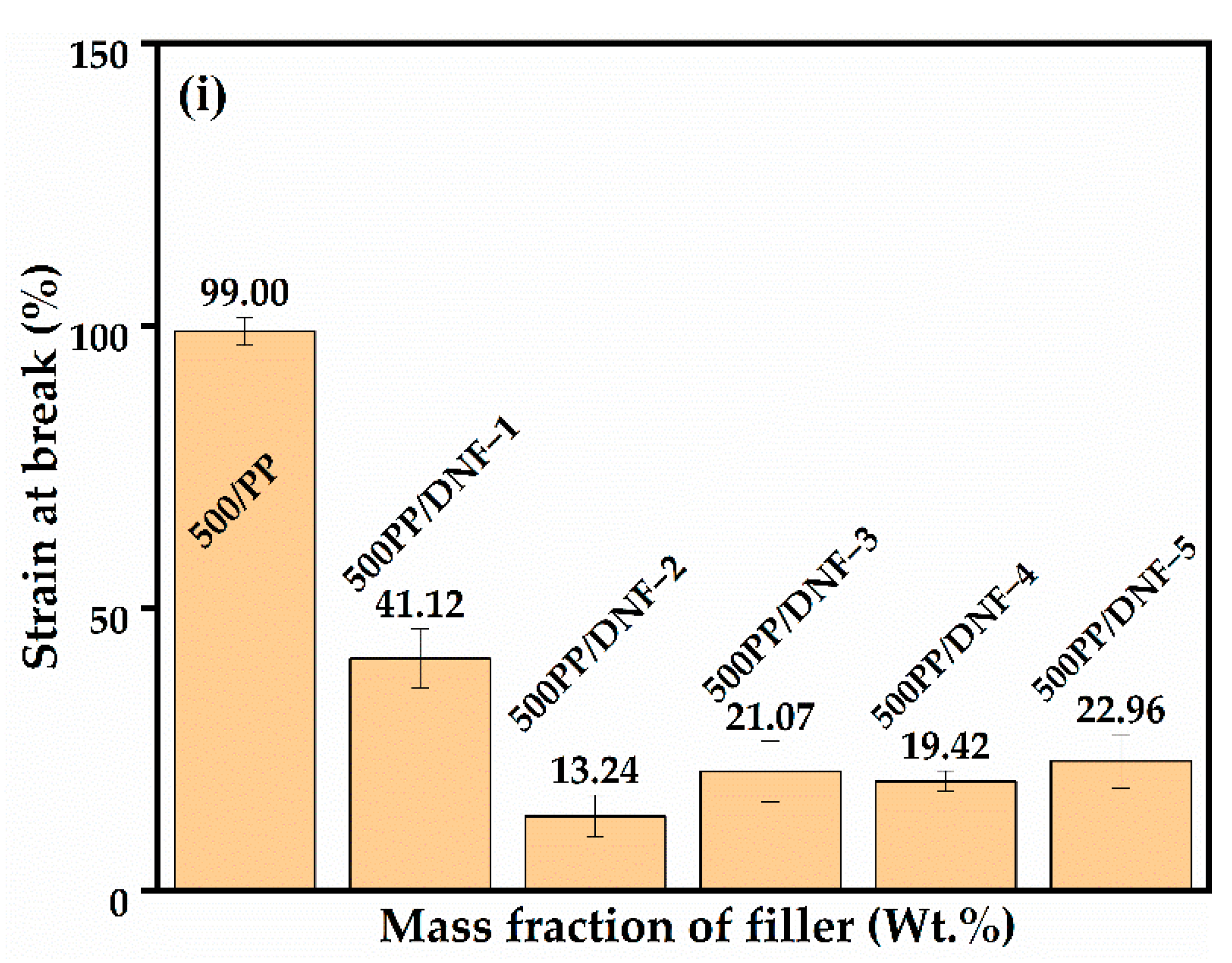

3.3. Mechanical Properties

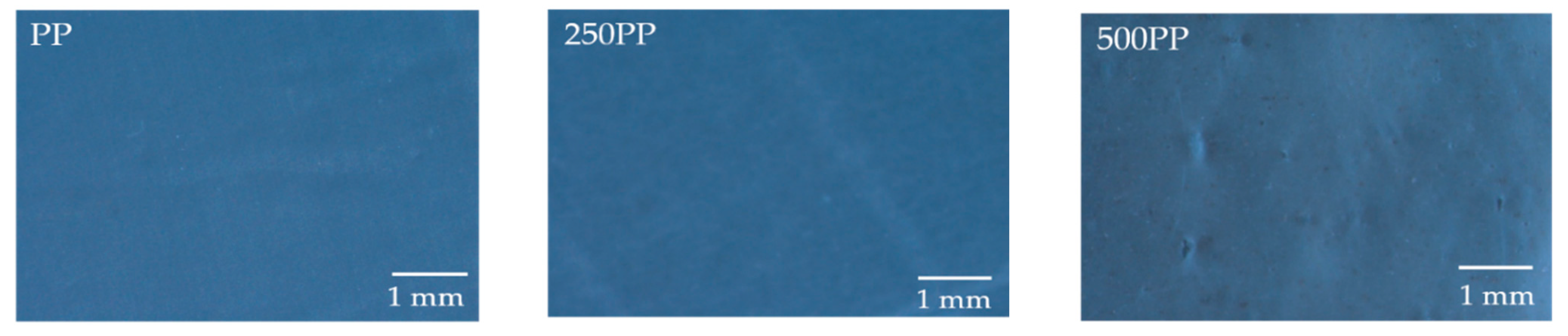

3.4. Surface Appearance and Morphological Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, G.; Wang, H.; Zhang, S.; Zhang, W.; Wu, H.; Li, C.; Xiao, Z. Multifunctional wood composites based on Camellia oleifera shell with harsh-weather and self-mildew resistance. Polym. Compos. 2022, 43, 3531–3543. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Sasikala, G.; Balaji, D.; Saravanakumar, A.; Bhuvaneswari, V.; Bhoopathi, R. A Critical Review on Wood-Based Polymer Composites: Processing, Properties, and Prospects. Polymers 2022, 14, 589. [Google Scholar] [CrossRef] [PubMed]

- Partanen, A.; Carus, M. Wood and natural fiber composites current trend in consumer goods and automotive parts. Reinf. Plast. 2016, 60, 170–173. [Google Scholar] [CrossRef]

- Friedrich, D. Using PVC-Based Wood-Plastic Composites in Window Frames–Studying Performance and Benefits. In Proceedings of the Profiles: International Conference on Plastic Profiles for Construction Application, Cologne, Germany, 12–13 November 2019. [Google Scholar]

- Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Ozbakkaloglu, T. Lignocellulosic fiber reinforced composites: Progress, performance, properties, applications, and future perspectives. Polym. Compos. 2022, 43, 645–691. [Google Scholar] [CrossRef]

- Verma, D.; Dogra, V.; Chaudhary, A.K.; Mordia, R. 5-Advanced biopolymer-based composites: Construction and structural applications. In Sustainable Biopolymer Composites; Verma, D., Sharma, M., Goh, K.L., Jain, S., Sharma, H., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 113–128. [Google Scholar] [CrossRef]

- Yi, X.; Zhao, D.; Ou, R.; Ma, J.; Chen, Y.; Wang, Q. A Comparative Study of the Performance of Wood-Plastic Composites and Typical Substrates as Heating Floor. BioResources 2017, 12, 14. [Google Scholar] [CrossRef]

- Abu-Sharkh, B.F.; Hamid, H. Degradation study of date palm fibre/polypropylene composites in natural and artificial weathering: Mechanical and thermal analysis. Polym. Degrad. Stab. 2004, 85, 967–973. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 243947. [Google Scholar] [CrossRef]

- Channalli, M.; Siddeswarappa, D. Effect of Alkali Treatments on Natural Filler Content Performance of Polymer Composites. Int. J. Eng. Res. 2015, 4, 11–16. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Pach, J.; Kozlowski, R. Use of Natural Fibres as Fillers for Polymer Composites. Int. Polym. Sci. Technol. 2007, 34, 45–50. [Google Scholar] [CrossRef]

- Lavanya, N.; Vallinayagam, S.; Rajendran, K. 12-Biodegradation of timber industry-based waste materials. In Biodegradation and Biodeterioration at the Nanoscale; Iqbal, H.M.N., Bilal, M., Nguyen, T.A., Yasin, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 261–281. [Google Scholar] [CrossRef]

- Thybring, E.E.; Kymäläinen, M.; Rautkari, L. Experimental techniques for characterising water in wood covering the range from dry to fully water-saturated. Wood Sci. Technol. 2018, 52, 297–329. [Google Scholar] [CrossRef]

- Aydemir, D.; Alsan, M.; Can, A.; Altuntaş, E.; Sivrikaya, H. Accelerated Weathering and Decay Resistance of Heat-Treated Wood Reinforced Polypropylene Composites. Drv. Ind. 2019, 70, 279–285. [Google Scholar] [CrossRef]

- Shimizu, K.; Tokuta, Y.; Oishi, A.; Kuriyama, T.; Kunioka, M. Weatherability of Polypropylene by Accelerated Weathering Tests and Outdoor Exposure Tests in Japan. J. Polym. 2016, 2016, 6539567. [Google Scholar] [CrossRef]

- Lv, Y.; Huang, Y.; Yang, J.; Kong, M.; Yang, H.; Zhao, J.; Li, G. Outdoor and accelerated laboratory weathering of polypropylene: A comparison and correlation study. Polym. Degrad. Stab. 2015, 112, 145–159. [Google Scholar] [CrossRef]

- Joseph, P.V.; Rabello, M.; Mattoso, L.H.C.; Joseph, K.; Thomas, S. Environmental effects on the degradation behavior of sisal fiber reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357–1372. [Google Scholar] [CrossRef]

- Tian, S.; Luo, Y.; Chen, J.; He, H.; Chen, Y.; Ling, Z. A Comprehensive Study on The Accelerated Weathering Properties of Polypropylene—Wood Composites with Non-Metallic Materials of Waste-Printed Circuit Board Powders. Materials 2019, 12, 876. [Google Scholar] [CrossRef] [PubMed]

- Peng, Y.; Liu, R.; Cao, J. Characterization of surface chemistry and crystallization behavior of polypropylene composites reinforced with wood flour, cellulose, and lignin during accelerated weathering. Appl. Surf. Sci. 2015, 332, 253–259. [Google Scholar] [CrossRef]

- La mantia, F.P.; Morreale, M. Accelerated weathering of polypropylene/wood flour composites. Polym. Degrad. Stab. 2008, 93, 1252–1258. [Google Scholar] [CrossRef]

- Kajaks, J.; Kalnins, K.; Matvejs, J. Accelerated aging of WPCs Based on Polypropylene and Birch plywood Sanding Dust. Open Eng. 2021, 11, 319–328. [Google Scholar] [CrossRef]

- Beg, H.; Pickering, K. Accelerated weathering of unbleached and bleached Kraft wood fibre reinforced polypropylene composites. Polym. Degrad. Stab. 2008, 93, 1939–1946. [Google Scholar] [CrossRef]

- Alothman, O.Y.; Shaikh, H.M.; Alshammari, B.A.; Jawaid, M. Structural, Morphological and Thermal Properties of Nano Filler Produced from Date Palm-Based Micro Fibers (Phoenix dactylifera L.). J. Polym. Environ. 2022, 30, 622–630. [Google Scholar] [CrossRef]

- Shaikh, H.M. Effect of carbon fiber as secondary filler on the electrical, thermal and rheological properties of carbon fiber/polypropylene composites. J. Polym. Eng. 2018, 38, 545–553. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, S.; Chen, Y.; Li, D. Thermal Properties of Wood-Plastic Composites with Different Compositions. Materials 2019, 12, 881. [Google Scholar] [CrossRef] [PubMed]

- Badji, C.; Soccalingame, L.; Garay, H.; Bergeret, A.; Bénézet, J.-C. Influence of weathering on visual and surface aspect of wood plastic composites: Correlation approach with mechanical properties and microstructure. Polym. Degrad. Stab. 2017, 137, 162–172. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T.H. Degradation Behavior of Polypropylene During Reprocessing and Its Biocomposites: Thermal and Oxidative Degradation Kinetics. Polymers 2020, 12, 1627. [Google Scholar] [CrossRef]

- Rasana, N.; Jayanarayanan, K.; Pegoretti, A. Non-isothermal crystallization kinetics of polypropylene/short glass fibre/multiwalled carbon nanotube composites. RSC Adv. 2018, 8, 39127–39139. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, L.; Cui, X.; Guo, W. Crystallization Behavior and Properties of Glass Fiber Reinforced Polypropylene Composites. Polymers 2019, 11, 1198. [Google Scholar] [CrossRef] [PubMed]

- Fang, J.; Zhang, L.; Sutton, D.; Wang, X.; Lin, T. Needleless Melt-Electrospinning of Polypropylene Nanofibres. J. Nanomater. 2012, 2012, 382639. [Google Scholar] [CrossRef]

- Shaikh, H.M.; Anis, A.; Poulose, A.M.; Al-Zahrani, S.M.; Madhar, N.A.; Alhamidi, A.; Aldeligan, S.H.; Alsubaie, F.S. Synthesis and Characterization of Cellulose Triacetate Obtained from Date Palm (Phoenix dactylifera L.) Trunk Mesh-Derived Cellulose. Molecules 2022, 27, 1434. [Google Scholar] [CrossRef]

- Zhou, Y.; Mallick, P.K. Effects of temperature and strain rate on the tensile behavior of unfilled and talc-filled polypropylene. Part I: Experiments. Polym. Eng. Sci. 2002, 42, 2449–2460. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Szulc, J.; Kloziński, A. Accelerated Weathering of Polylactide-Based Composites Filled with Linseed Cake: The Influence of Time and Oil Content within the Filler. Polymers 2019, 11, 1495. [Google Scholar] [CrossRef]

- Liao, J.; Brosse, N.; Pizzi, A.; Hoppe, S. Dynamically Cross-Linked Tannin as a Reinforcement of Polypropylene and UV Protection Properties. Polymers 2019, 11, 102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample ID | Composition of DNF (wt%) |

|---|---|

| Neat PP | 0% DNF (0) + PP (100) |

| PP/DNF-1 | 1% DNF (1) + PP (99) |

| PP/DNF-2 | 2% DNF (2) + PP (98) |

| PP/DNF-3 | 3% DNF (3) + PP (97) |

| PP/DNF-4 | 4% DNF (4) + PP (96) |

| PP/DNF-5 | 5% DNF (5) + PP (95) |

| Samples | Tonset | T5W%. | DTG (Tmax) | Residue (W%) |

|---|---|---|---|---|

| PP | 266.47 (±0.60) | 285.76 (±1.15) | 368.47 (±0.8) | 0.55 (±0.05) |

| PP/DNF-1 | 282.50 (±0.80) | 299.88 (±1.61) | 388.59 (±1.49) | 0.93 (±0.25) |

| PP/DNF-2 | 283.65 (±1.17) | 302.98 (±1.84) | 395.08 (±1.08) | 1.93 (±0.25) |

| PP/DNF-3 | 284.21 (±0.30) | 304.55 (±0.92) | 410.95 (±1.57) | 2.70 (±0.72) |

| PP/DNF-4 | 285.13 (±0.86) | 311.42 (±1.28) | 415.85 (±2.24) | 3.20 (±0.30) |

| PP/DNF-5 | 287.20 (±1.71) | 317.16 (±1.74) | 418.55 (±0.67) | 3.50 (±0.87) |

| 250PP | 270.64 (±0.75) | 293.53 (±0.60) | 350.26 (±1.20) | 0.75 (±0.20) |

| 250PP/DNF-1 | 278.90 (±1.40) | 295.45 (±1.26) | 377.43 (±0.71) | 1.20 (±0.47) |

| 250PP/DNF-2 | 281.48 (±0.71) | 304.57 (±1.58) | 387.76 (±2.14) | 1.84 (±0.85) |

| 250PP/DNF-3 | 283.87 (±0.35) | 308.73 (±1.32) | 392.08 (±1.72) | 2.76 (±0.55) |

| 250PP/DNF-4 | 286.01 (±0.57) | 305.41 (±1.02) | 402.51 (±1.95) | 3.83 (±0.70) |

| 250PP/DNF-5 | 291.31 (±0.71) | 300.34 (±0.71) | 412.71 (±2.71) | 4.23 (±0.35) |

| 500PP | 268.16 (±0.45) | 298.14 (±1.73) | 348.18 (±0.50) | 0.77 (±0.31) |

| 500PP/DNF-1 | 279.83 (±1.51) | 304.23 (±1.01) | 379.58 (±0.54) | 0.85 (±0.31) |

| 500PP/DNF-2 | 275.75 (±0.39) | 307.57 (±0.87) | 367.46 (±1.30) | 2.46 (±1.13) |

| 500PP/DNF-3 | 270.62 (±0.41) | 309.65 (±0.60) | 365.49 (±1.83) | 2.93 (±1.71) |

| 500PP/DNF-4 | 272.06 (±1.19) | 310.11 (±1.95) | 363.48 (±2.28) | 3.36 (±2.31) |

| 500PP/DNF-5 | 268.60 (±1.90) | 312.06 (±1.03) | 354.68 (±3.75) | 4.23 (±1.45) |

| Sample | Tm °C | ΔHm (J/g) | Tc °C | ΔHc (J/g) | Xc (%) |

|---|---|---|---|---|---|

| PP | 163.48 (±1.13) | 103.15 (±3.20) | 111.51 (±0.05) | 99.42 (±2.75) | 49.35 (±1.00) |

| PP/DNF-1 | 163.85 (±1.25) | 68.01 (±4.50) | 117.60 (±0.90) | 91.37 (±3.20) | 32.87 (±1.2) |

| PP/DNF-2 | 163.47 (±1.33) | 65.30 (±5.40) | 118.15 (±1.25) | 89.64 (±5.35) | 31.88 (±1.4) |

| PP/DNF-3 | 163.69 (±0.88) | 64.59 (±1.00) | 118.46 (±1.12) | 87.13 (±4.10) | 31.86 (±0.95) |

| PP/DNF-4 | 163.24 (±1.44) | 64.21 (±2.50) | 118.41 (±1.35) | 81.85 (±4.55) | 32.00 (±1.33) |

| PP/DNF-5 | 163.37 (±1.51) | 58.04 (±5.90) | 118.47 (±1.07) | 80.84 (±5.60) | 29.23 (±1.21) |

| 250PP | 161.89 (±1.26) | 73.33 (±2.15) | 109.16 (±2.15) | 95.68 (±1.26) | 35.09 (±2.25) |

| 250PP/DNF-1 | 161.58 (±1.35) | 73.17 (±1.65) | 115.05 (±2.80) | 92.08 (±3.90) | 35.36 (±1.09) |

| 250PP/DNF-2 | 161.71 (±2.01) | 70.16 (±4.45) | 116.48 (±1.10) | 89.91 (±3.23) | 34.25 (±3.21) |

| 250PP/DNF-3 | 162.57 (±2.22) | 69.77 (±3.70) | 116.89 (±0.50) | 87.25 (±5.30) | 34.42 (±2.20) |

| 250PP/DNF-4 | 161.77 (±1.52) | 67.44 (±2.25) | 116.31 (±0.75) | 86.26 (±3.55) | 33.61 (±1.44) |

| 250PP/DNF-5 | 162.45 (±2.33) | 67.07 (±3.30) | 116.43 (±1.00) | 84.31 (±2.45) | 33.78 (±2.50) |

| 500PP | 162.08 (±0.50) | 74.82 (±1.20) | 108.47 (±0.09) | 92.88 (±1.50) | 35.80 (±1.33) |

| 500PP/DNF-1 | 161.68 (±1.21) | 71.24 (±3.35) | 116.10 (±0.98) | 88.96 (±3.44) | 34.43 (±1.45) |

| 500PP/DNF-2 | 162.19 (±1.15) | 70.85 (±1.30) | 112.43 (±1.42) | 86.54 (±4.45) | 34.59 (±2.11) |

| 500PP/DNF-3 | 161.86 (±1.81) | 69.54 (±4.50) | 114.51 (±1.30) | 82.50 (±3.42) | 34.30 (±1.58) |

| 500PP/DNF-4 | 161.76 (±1.54) | 64.25 (±2.20) | 114.66 (±1.28) | 81.11 (±2.22) | 33.02 (±2.70) |

| 500PP/DNF-5 | 162.05 (±2.91) | 63.57 (±1.80) | 114.37 (±1.64) | 78.90 (±5.57) | 31.75 (±3.45) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshammari, B.A.; Alothman, O.Y.; Alhamidi, A.; Jawaid, M.; Shaikh, H.M. Effect of Accelerated Weathering on the Thermal, Tensile, and Morphological Characteristics of Polypropylene/Date Nanofiller Composites. Materials 2022, 15, 6053. https://doi.org/10.3390/ma15176053

Alshammari BA, Alothman OY, Alhamidi A, Jawaid M, Shaikh HM. Effect of Accelerated Weathering on the Thermal, Tensile, and Morphological Characteristics of Polypropylene/Date Nanofiller Composites. Materials. 2022; 15(17):6053. https://doi.org/10.3390/ma15176053

Chicago/Turabian StyleAlshammari, Basheer A., Othman Y. Alothman, Abdullah Alhamidi, Mohammad Jawaid, and Hamid M. Shaikh. 2022. "Effect of Accelerated Weathering on the Thermal, Tensile, and Morphological Characteristics of Polypropylene/Date Nanofiller Composites" Materials 15, no. 17: 6053. https://doi.org/10.3390/ma15176053

APA StyleAlshammari, B. A., Alothman, O. Y., Alhamidi, A., Jawaid, M., & Shaikh, H. M. (2022). Effect of Accelerated Weathering on the Thermal, Tensile, and Morphological Characteristics of Polypropylene/Date Nanofiller Composites. Materials, 15(17), 6053. https://doi.org/10.3390/ma15176053