Comparisons of Dy Utilization Efficiency by DyHx Grain Boundary Addition and Surface Diffusion Methods in Nd-Y-Fe-B Sintered Magnet

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Procedure

2.2. Characterization and Analysis Methods

3. Results and Discussion

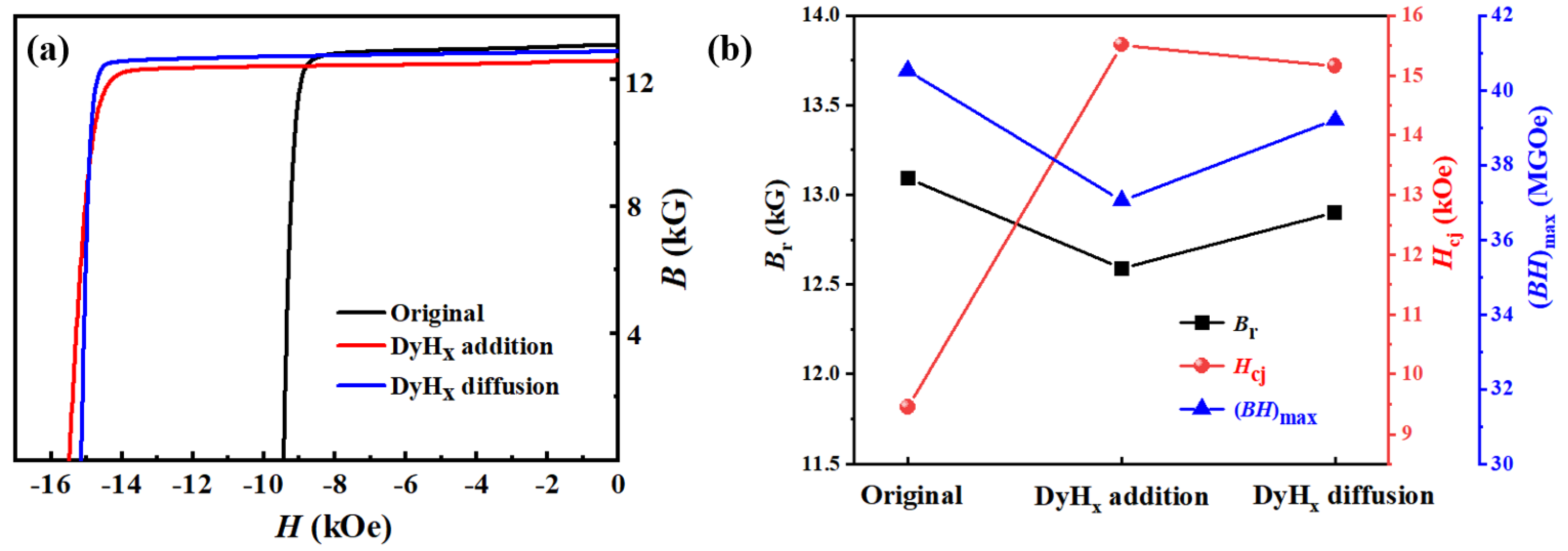

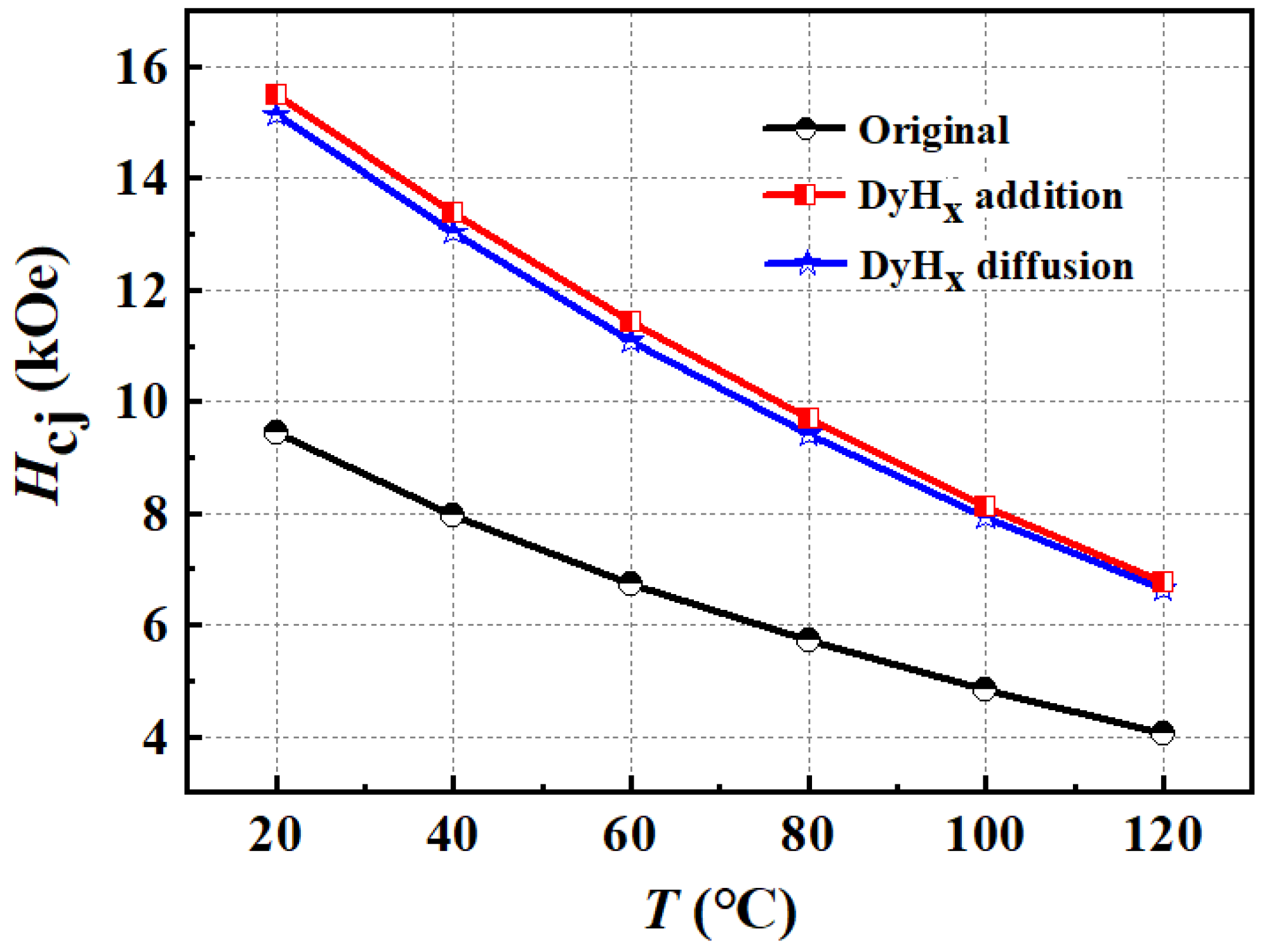

3.1. Magnetic Properties

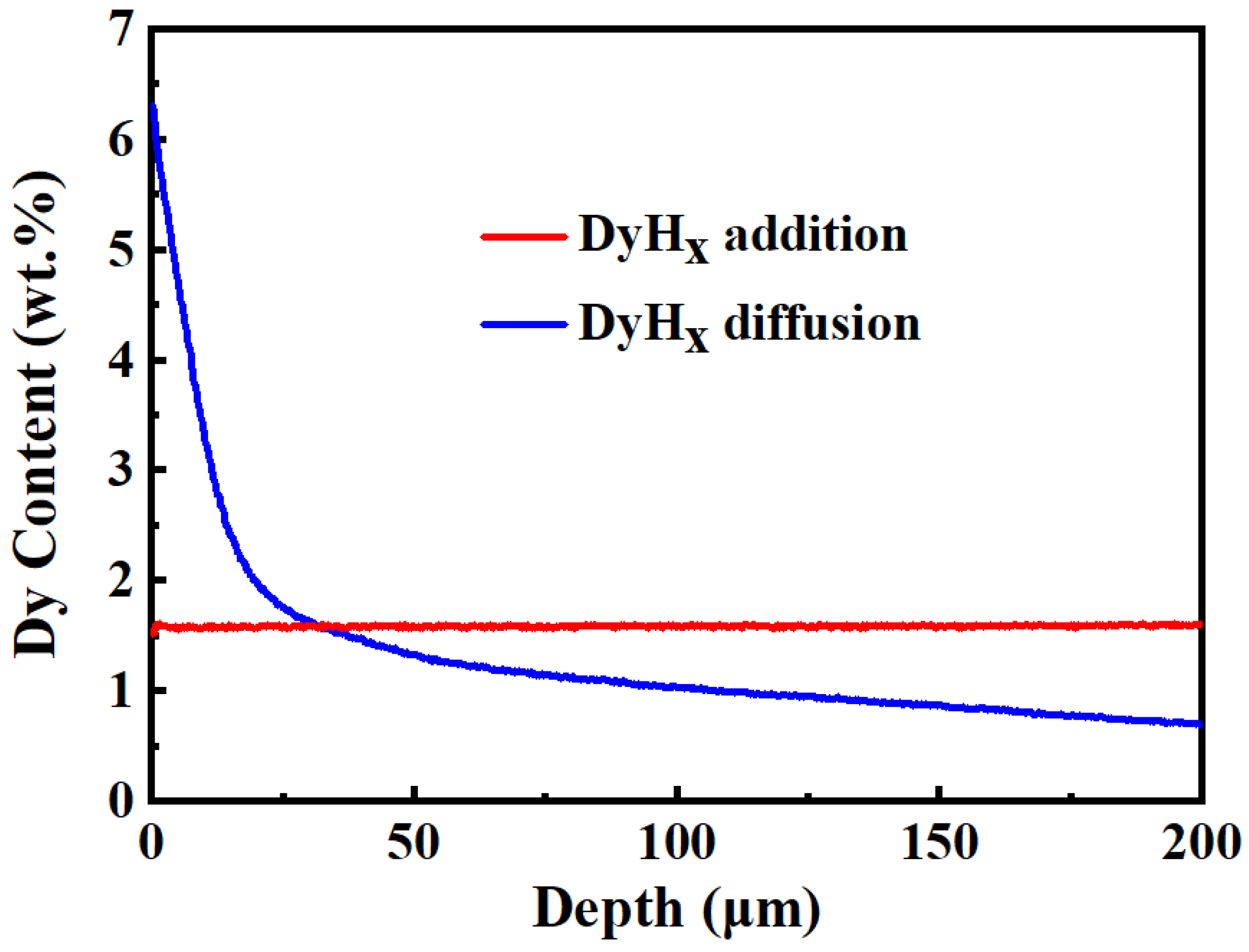

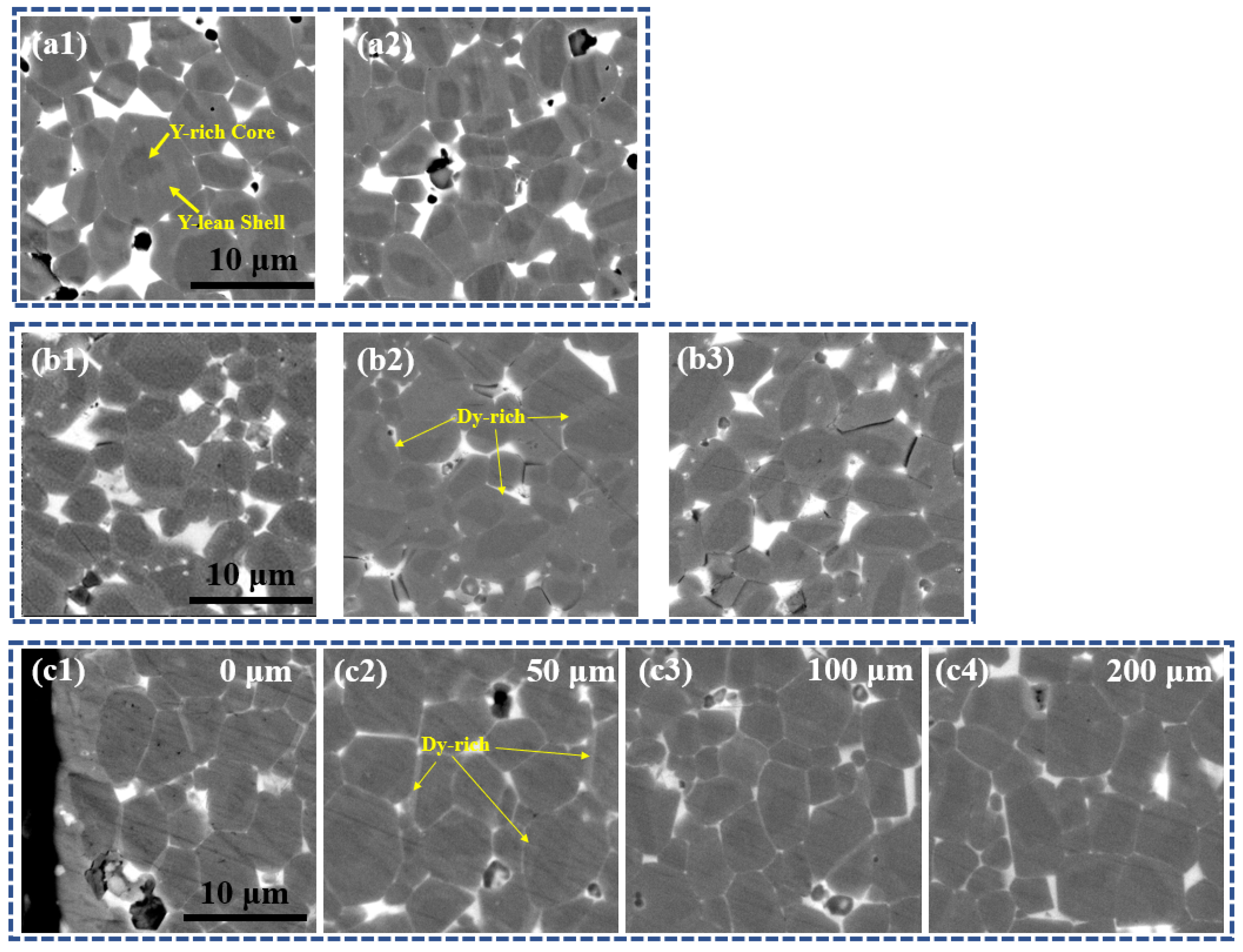

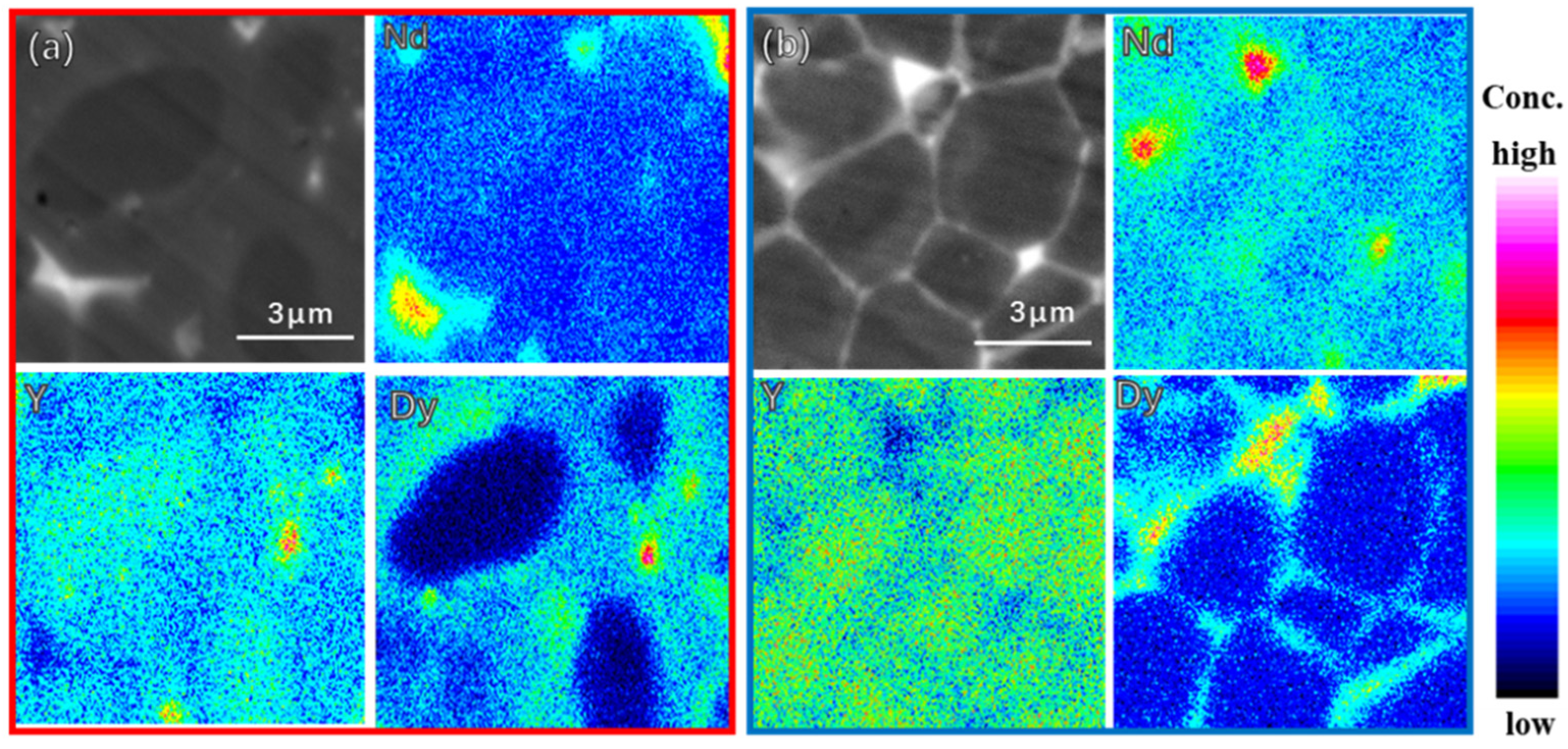

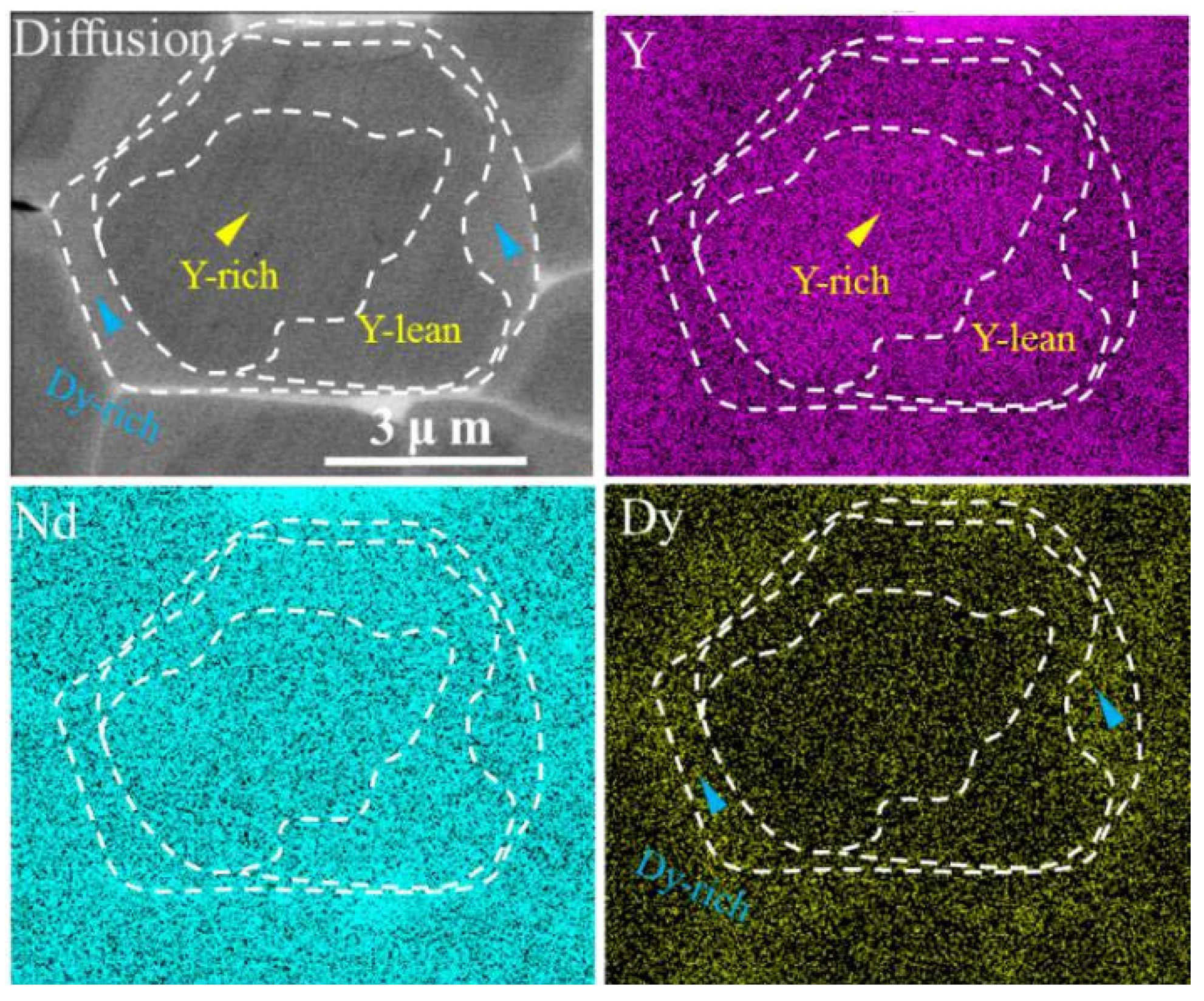

3.2. Microstructure and Elemental Distribution

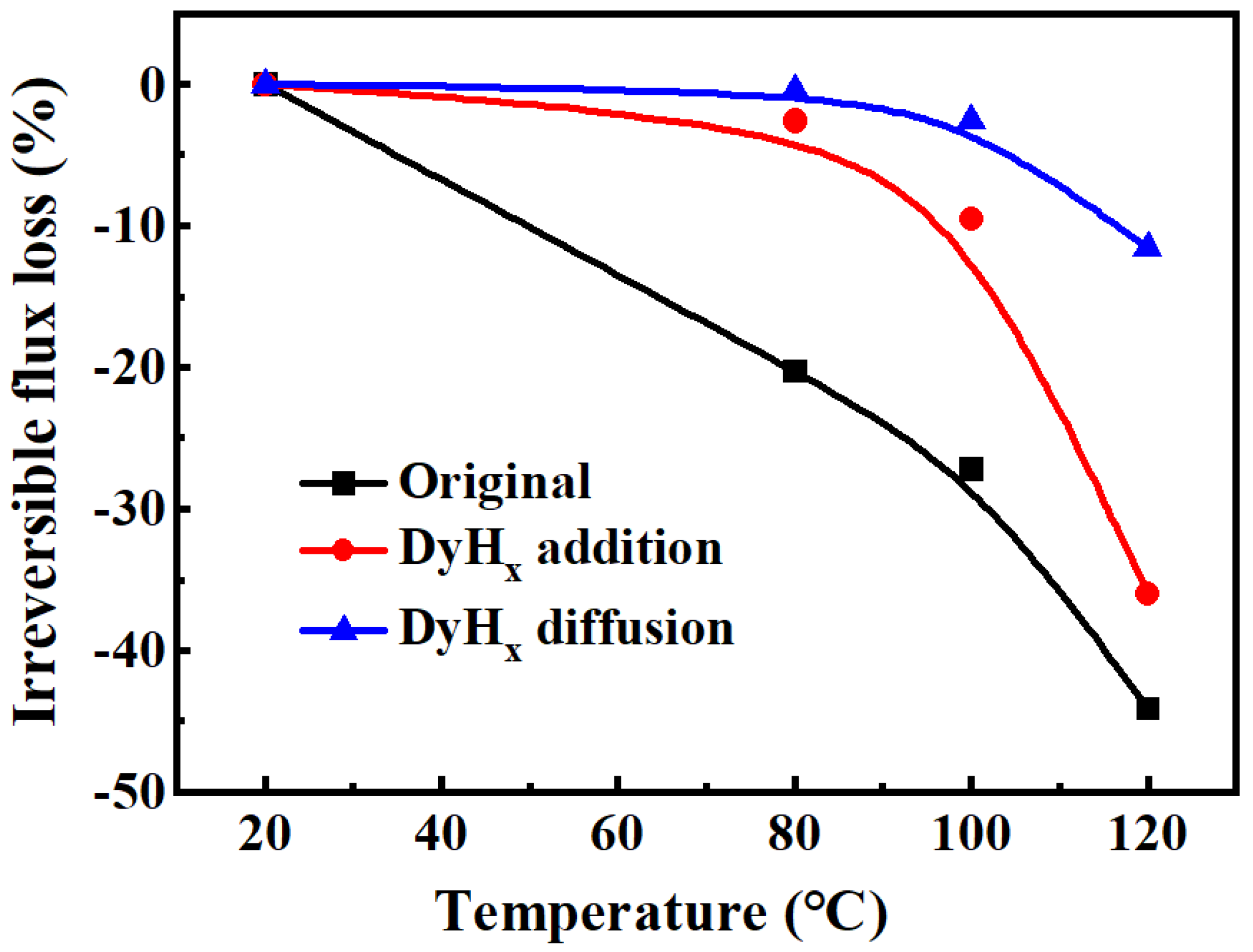

3.3. Thermal Stability

3.4. Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jones, N. The pull of stronger magnets. Nature 2011, 472, 22. [Google Scholar] [CrossRef] [PubMed]

- Sagawa, M.; Fujimura, S.; Togawa, N.; Yamamoto, H.; Matsuura, Y. New material for permanent magnets on a base of Nd and Fe. J. Appl. Phys. 1984, 55, 2083. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic materials and devices for the 21st century: Stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821. [Google Scholar] [CrossRef]

- Herbst, J.F. Re2Fe14B materials: Intrinsic properties and technological aspects. Rev. Mod. Phys. 1991, 63, 819. [Google Scholar] [CrossRef]

- Ding, G.F.; Guo, S.; Chen, L.; Ding, J.H.; Song, J.; Chen, R.J.; Lee, D.; Yan, A. Coercivity enhancement in Dy-free sintered Nd-Fe-B magnets by effective structure optimization of grain boundaries. J. Alloys Compd. 2018, 735, 795. [Google Scholar] [CrossRef]

- Coey, J.M.D. Hard magnetic materials: A perspective. IEEE Trans. Magn. 2011, 47, 4671. [Google Scholar] [CrossRef]

- Cao, X.J.; Chen, L.; Li, X.B.; Yi, P.P.; Yan, A.R.; Yan, G.L. Coercivity enhancement of sintered Nd-Fe-B magnets by efficiently diffusing DyF3 based on electrophoretic deposition. J. Alloys Compd. 2015, 631, 315. [Google Scholar] [CrossRef]

- Ding, G.F.; Guo, S.; Chen, L.; Di, J.H.; Chen, K.; Chen, R.J.; Lee, D.; Yan, A. Effects of the grain size on domain structure and thermal stability of sintered Nd-Fe-B magnets. J. Alloys Compd. 2018, 735, 1176–1180. [Google Scholar] [CrossRef]

- Kim, T.H.; Lee, S.R.; Kim, H.J.; Lee, M.W.; Jiang, T.S. Simultaneous application of Dy-X (X = F or H) powder doping and dip-coating processes to Nd-Fe-B sintered magnets. Acta Mater. 2015, 93, 95–104. [Google Scholar] [CrossRef]

- Li, W.F.; Sepehri-Amin, H.; Ohkubo, T.; Hase, N.; Hono, K. Distribution of Dy in high-coercivity (Nd, Dy)-Fe-B sintered magnet. Acta Mater. 2011, 59, 3061. [Google Scholar] [CrossRef]

- Zhang, M.; Li, Z.B.; Shen, B.G.; Hu, F.X.; Sun, J.R. Permanent magnetic properties of rapidly quenched (La,Ce)2Fe14B nanomaterials based on La-Ce mischmetal. J. Alloys Comp. 2015, 651, 144. [Google Scholar] [CrossRef]

- Pathak, A.K.; Khan, M.; Gschneidner, J.K.A.; McCallum, R.W.; Zhou, L.; Sun, K.; Dennis, K.W.; Zhou, C.; Pinkerton, F.E.; Kramer, M.J.; et al. Cerium: An unlikely replacement of Dysprosium in high performance Nd-Fe-B permanent magnets. Adv. Mater. 2015, 27, 2663. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.J.; Guo, S.; Chen, R.J.; Lee, D.; Yan, A.R. Enhanced magnetic properties of sintered Ce-Fe-B based magnets by optimizing the microstructure of strip-casting alloys. IEEE Trans. Magn. 2014, 50, 2104604. [Google Scholar] [CrossRef]

- Ma, T.Y.; Wu, B.; Zhang, Y.J.; Jin, J.Y.; Wu, K.Y.; Tao, S.; Xia, W.; Yan, M. Enhanced coercivity of NdCe-Fe-B sintered magnets by adding (Nd, Pr)-H powders. J. Alloys Compd. 2017, 721, 1. [Google Scholar] [CrossRef]

- Fan, X.D.; Ding, G.F.; Chen, K.; Guo, S.; You, C.Y.; Chen, R.J.; Lee, D.; Yan, A. Whole process metallurgical behavior of the high-abundance rare-earth elements LRE (La, Ce and Y) and the magnetic performance of Nd0.75LRE0.25-Fe-B sintered magnets. Acta Mater. 2018, 154, 343–354. [Google Scholar] [CrossRef]

- Ding, G.F.; Liao, S.C.; Di, J.H.; Zheng, B.; Guo, S.; Chen, R.J.; Yan, A. Microstructure of core-shell NdY-Fe-B sintered magnets with a high coercivity and excellent thermal stability. Acta Mater. 2020, 194, 547–557. [Google Scholar] [CrossRef]

- Fan, X.D.; Chen, K.; Guo, S.; Chen, R.J.; Lee, D.; Yan, A.; You, C.Y. Core–shell Y-substituted Nd–Ce–Fe–B sintered magnets with enhanced coercivity and good thermal stability. Appl. Phys. Lett. 2017, 110, 172405. [Google Scholar] [CrossRef]

- Yang, F.; Guo, L.C.; Li, P.; Zhao, X.Z.; Sui, Y.L.; Guo, Z.M.; Gao, X.X. Boundary structure modification and magnetic properties of Nd-Fe-B sintered magnets by co-doping with Dy2O3/S powders. J. Magn. Magn. Mater. 2017, 429, 117–123. [Google Scholar] [CrossRef]

- Cui, X.G.; Cui, C.Y.; Cheng, X.N.; Xu, X.J. Effect of Dy2O3 intergranular addition on thermal stability and corrosion resistance of Nd-Fe-B magnets. Intermetallics 2014, 55, 118–122. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, H.B.; Li, A.H.; Li, W. Microstructural and magnetic property evolutions with diffusion time in TbHx diffusion processed Nd-Fe-B sintered magnets. J. Magn. Magn. Mater. 2020, 515, 167272. [Google Scholar] [CrossRef]

- Liu, P.; Ma, T.Y.; Wang, X.H.; Zhang, Y.J.; Yan, M. Role of hydrogen in Nd–Fe–B sintered magnets with DyHx addition. J. Alloys Compd. 2015, 628, 282–286. [Google Scholar] [CrossRef]

- Wang, C.G.; Yue, M.; Zhang, D.T.; Liu, W.Q.; Zhang, J.X. Structure and magnetic properties of hot deformed Nd2Fe14B magnets doped with DyHx nanoparticles. J. Magn. Magn. Mater. 2016, 404, 64–67. [Google Scholar] [CrossRef]

- Bae, K.-H.; Kim, T.-H.; Lee, S.-R.; Kim, H.-J.; Lee, M.-W.; Jang, T.-S. Magnetic and microstructural characteristics of DyF3/DyHx dip-coated Nd–Fe–B sintered magnets. J. Alloys Compd. 2014, 612, 183–188. [Google Scholar] [CrossRef]

- Wang, C.; Luo, Y.; Wang, Z.L.; Yan, W.L.; Zhao, Y.Y.; Quan, N.T.; Peng, H.J.; Wu, K.W.; Ma, Y.H.; Zhao, C.L.; et al. Effect of MgCl2 on electrophoretic deposition of TbF3 powders on Nd-Fe-B sintered magnet. J. Rare Earths 2022, in press. [Google Scholar] [CrossRef]

- Oono, N.; Sagawa, M.; Kasada, R.; Matsui, H.; Kimura, A. Production of thick high-performance sintered neodymium magnets by grain boundary diffusion treatment with dysprosium–nickel–aluminum alloy. J. Magn. Magn. Mater. 2011, 323, 297–300. [Google Scholar] [CrossRef]

- Xu, F.; Wang, J.; Dong, X.P.; Zhang, L.T.; Wu, J.S. Grain boundary microstructure in DyF3 -diffusion processed Nd–Fe–B sintered magnets. J. Alloys Compd. 2011, 509, 7909–7914. [Google Scholar] [CrossRef]

- Lv, M.; Kong, T.; Zhang, W.H.; Zhu, M.Y.; Jin, H.M.; Li, W.X.; Li, Y. Progress on modification of microstructures and magnetic properties of Nd- Fe-B magnets by the grain boundary diffusion engineering. J. Magn. Magn. Mater. 2021, 517, 167278. [Google Scholar] [CrossRef]

- Soderžnik, M.; Korent, M.; Soderžnik, K.Ž.; Katter, M.; Üstüner, K.; Kobe, S. High-coercivity Nd-Fe-B magnets obtained with the electrophoretic deposition of sub-micron TbF3 followed by the grain-boundary diffusion process. Acta Mater. 2016, 115, 278–284. [Google Scholar] [CrossRef]

- Löewe, K.; Brombacher, C.; Katter, M.; Gutfleisch, O. Temperature-dependent Dy diffusion processes in Nd–Fe–B permanent magnets. Acta Mater. 2015, 83, 248–255. [Google Scholar] [CrossRef]

- Sepehri-Amin, H.; Ohkubo, T.; Hono, K. The mechanism of coercivity enhancement by the grain boundary diffusion process of Nd–Fe–B sintered magnets. Acta Mater. 2013, 61, 1982–1990. [Google Scholar] [CrossRef]

| Sample | Br (kG) | Hcj (kOe) | (BH)max (MGOe) |

|---|---|---|---|

| Original | 13.09 | 9.45 | 40.52 |

| DyHx addition | 12.59 | 15.51 | 37.05 |

| DyHx diffusion | 12.90 | 15.15 | 39.20 |

| Magnets | β (%/°C) |

|---|---|

| Original | −0.5968 |

| DyHx addition | −0.5632 |

| DyHx diffusion | −0.5614 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Liao, S.; Fan, X.; Ding, G.; Zheng, B.; Chen, R.; Yan, A. Comparisons of Dy Utilization Efficiency by DyHx Grain Boundary Addition and Surface Diffusion Methods in Nd-Y-Fe-B Sintered Magnet. Materials 2022, 15, 5964. https://doi.org/10.3390/ma15175964

Guo S, Liao S, Fan X, Ding G, Zheng B, Chen R, Yan A. Comparisons of Dy Utilization Efficiency by DyHx Grain Boundary Addition and Surface Diffusion Methods in Nd-Y-Fe-B Sintered Magnet. Materials. 2022; 15(17):5964. https://doi.org/10.3390/ma15175964

Chicago/Turabian StyleGuo, Shuai, Shicong Liao, Xiaodong Fan, Guangfei Ding, Bo Zheng, Renjie Chen, and Aru Yan. 2022. "Comparisons of Dy Utilization Efficiency by DyHx Grain Boundary Addition and Surface Diffusion Methods in Nd-Y-Fe-B Sintered Magnet" Materials 15, no. 17: 5964. https://doi.org/10.3390/ma15175964

APA StyleGuo, S., Liao, S., Fan, X., Ding, G., Zheng, B., Chen, R., & Yan, A. (2022). Comparisons of Dy Utilization Efficiency by DyHx Grain Boundary Addition and Surface Diffusion Methods in Nd-Y-Fe-B Sintered Magnet. Materials, 15(17), 5964. https://doi.org/10.3390/ma15175964