Enhanced Energy Storage Performance in Na0.5Bi0.5TiO3-Based Relaxor Ferroelectric Ceramics via Compositional Tailoring

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

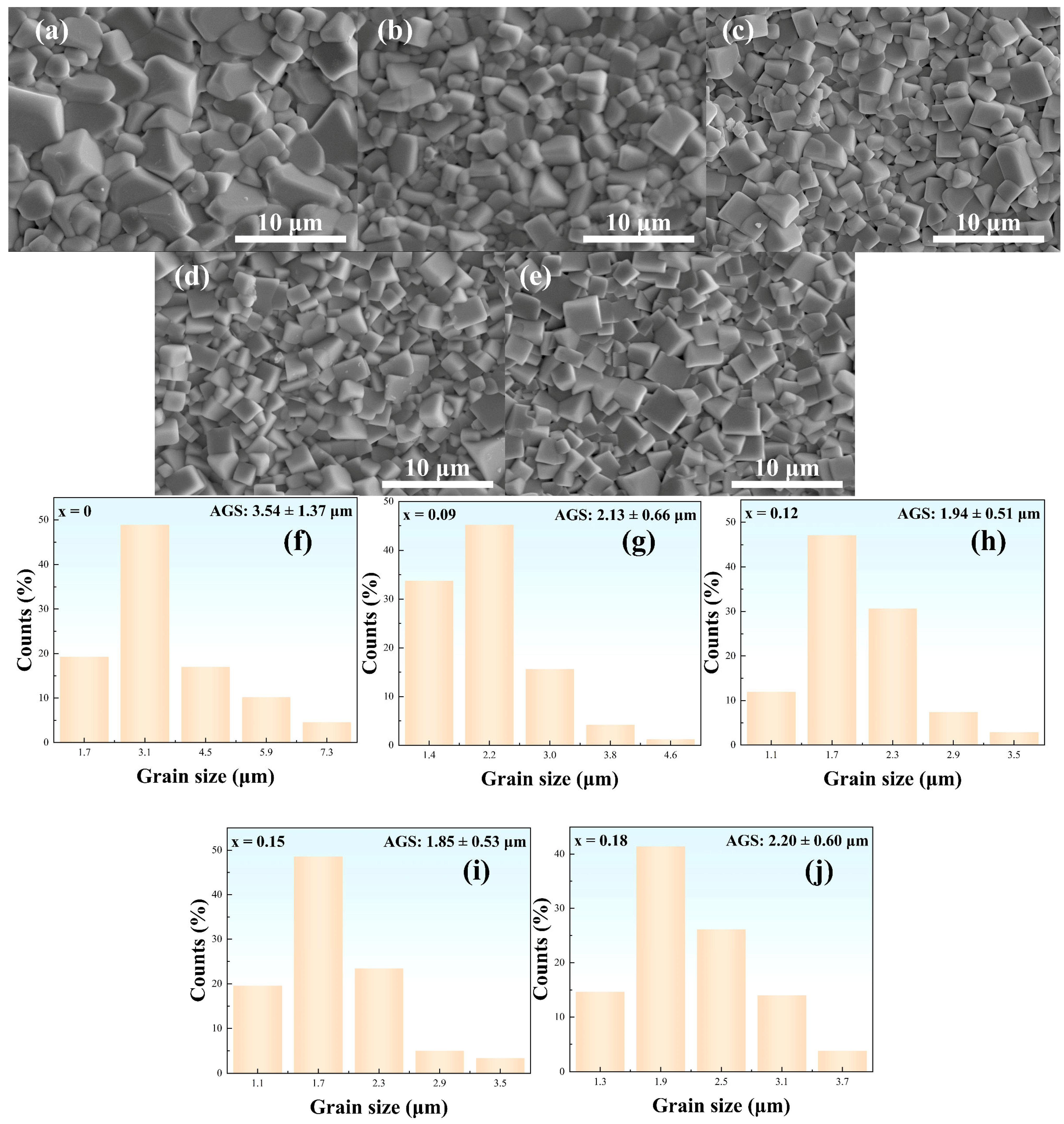

3.1. Phase Structure and Microstructure

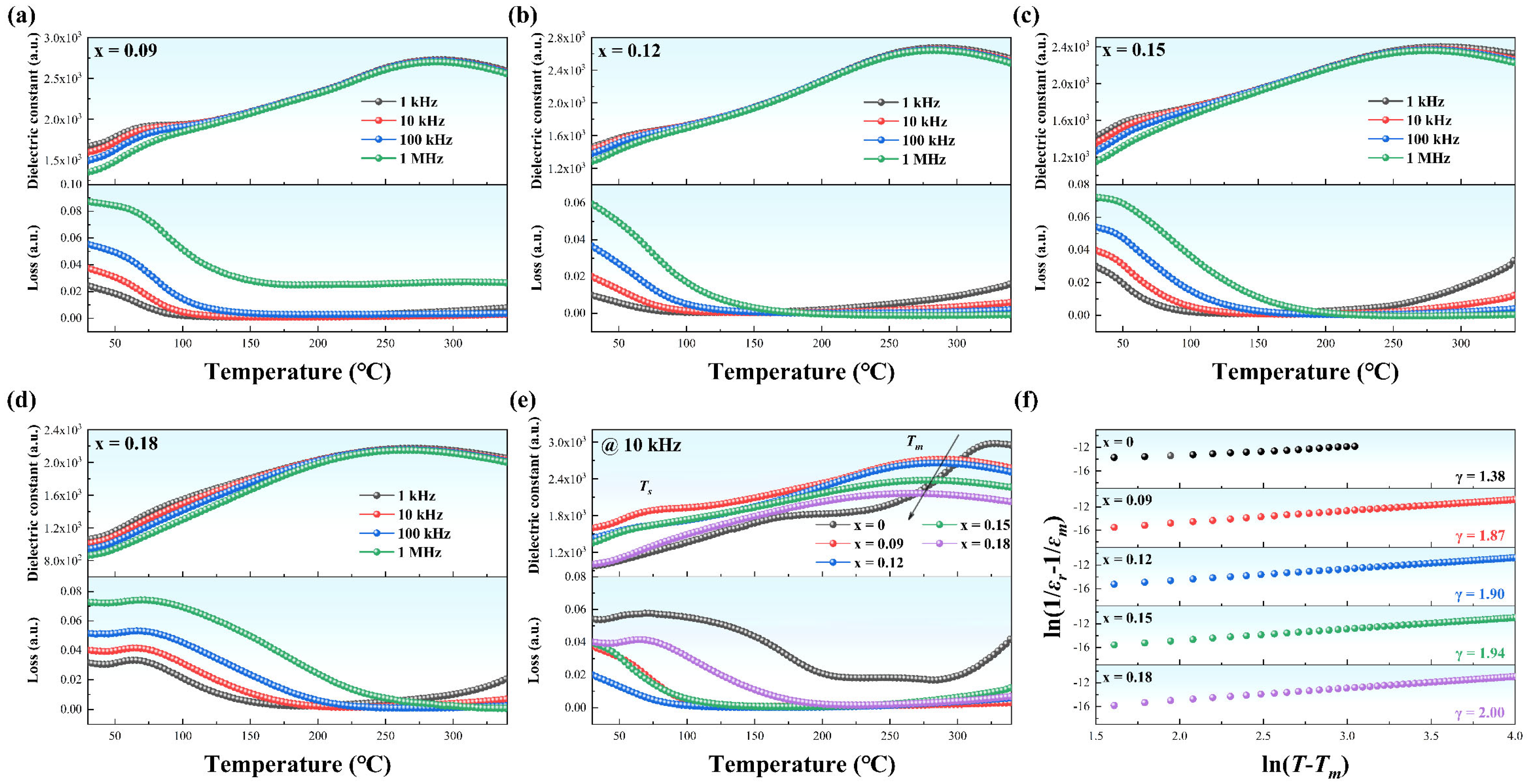

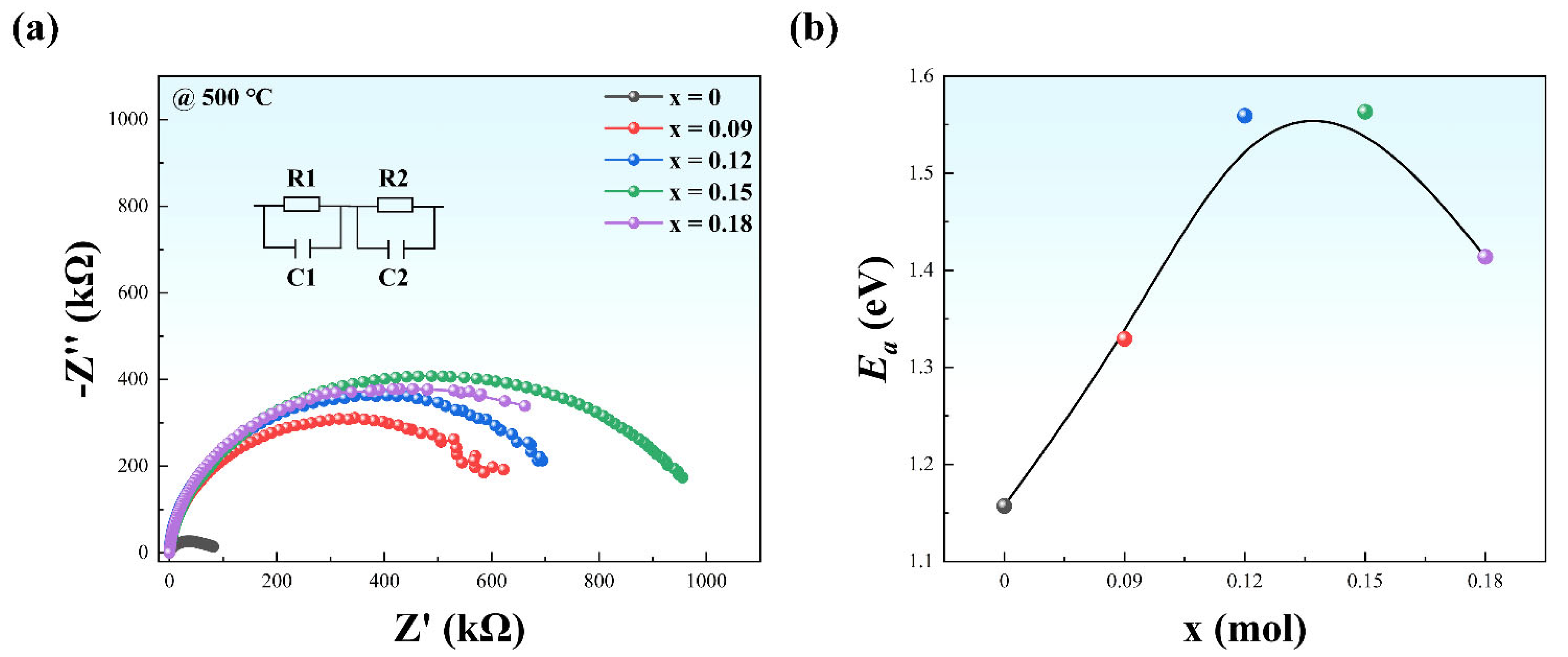

3.2. Dielectric Properties

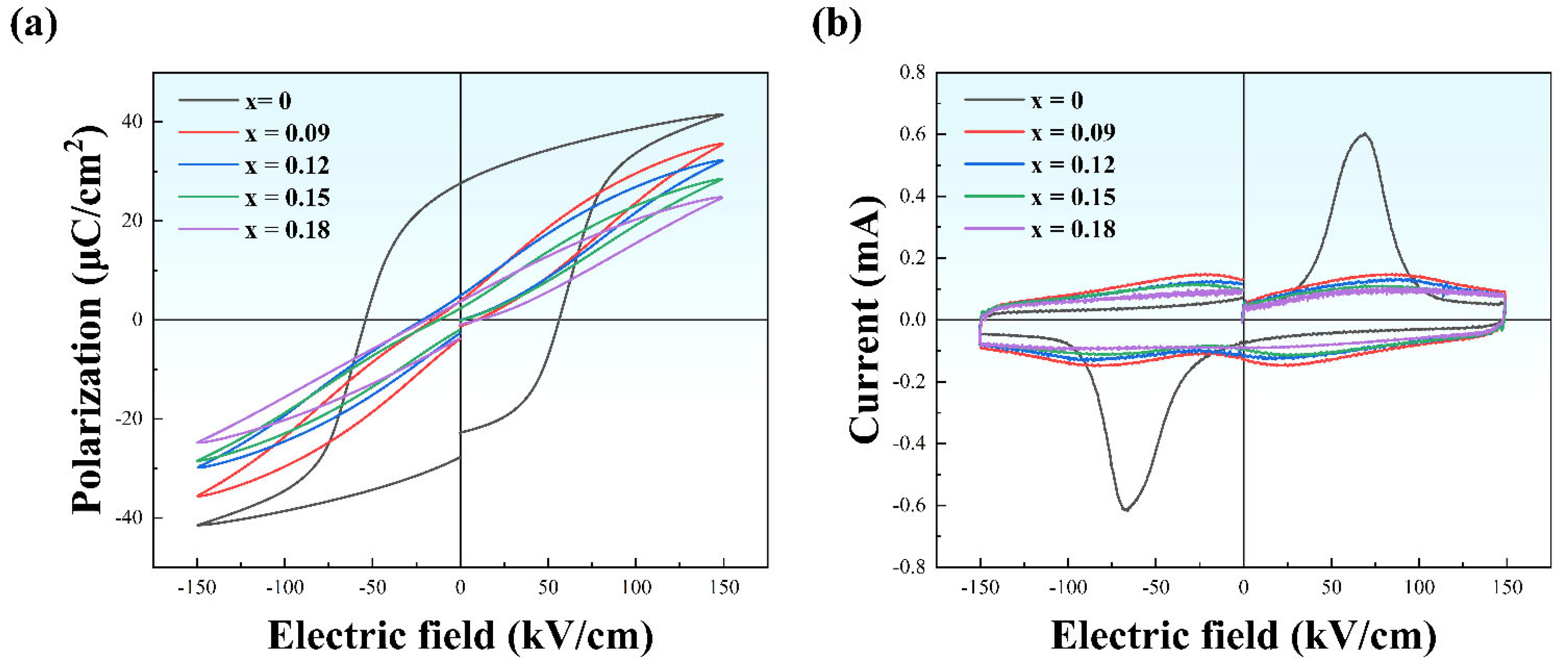

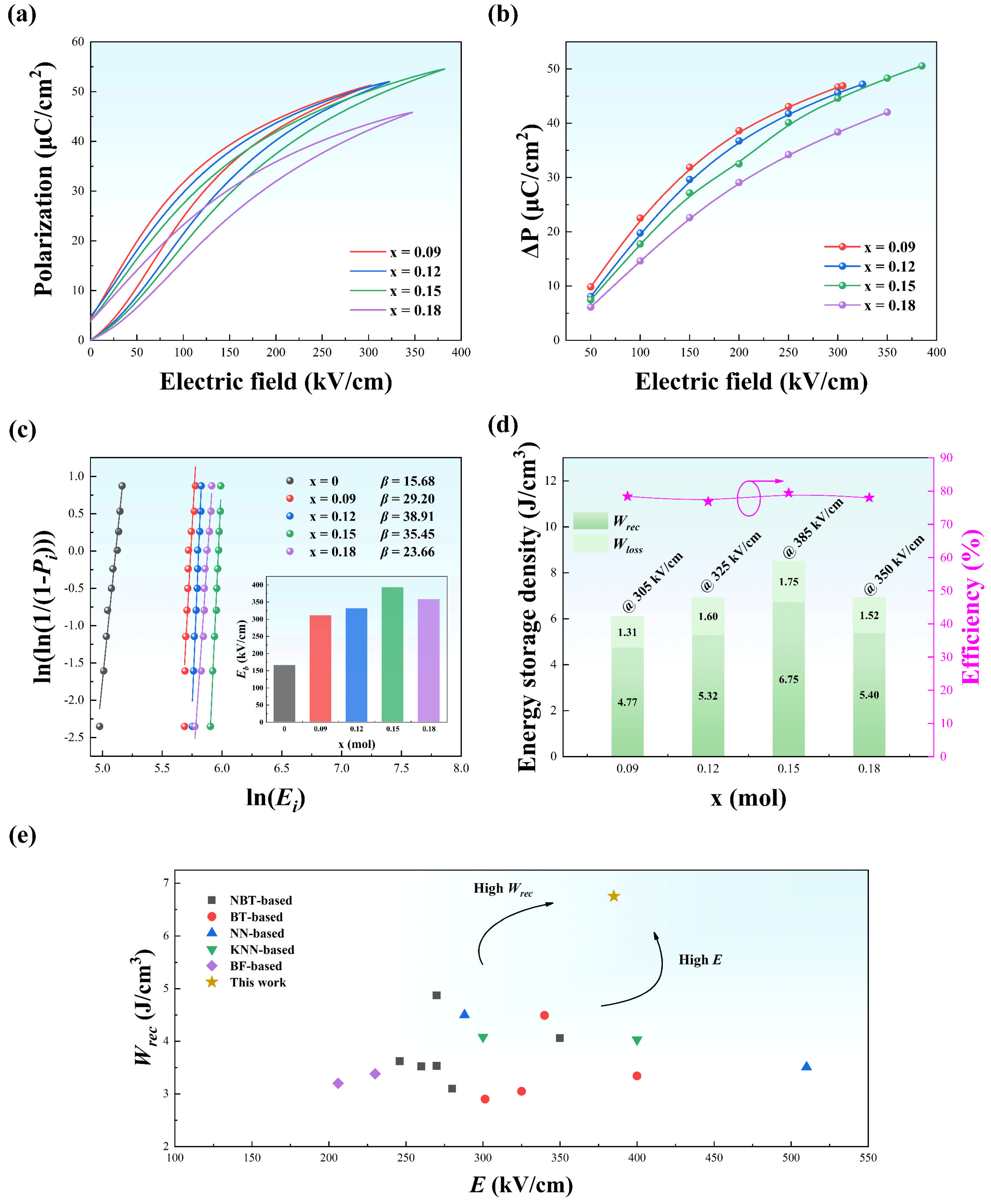

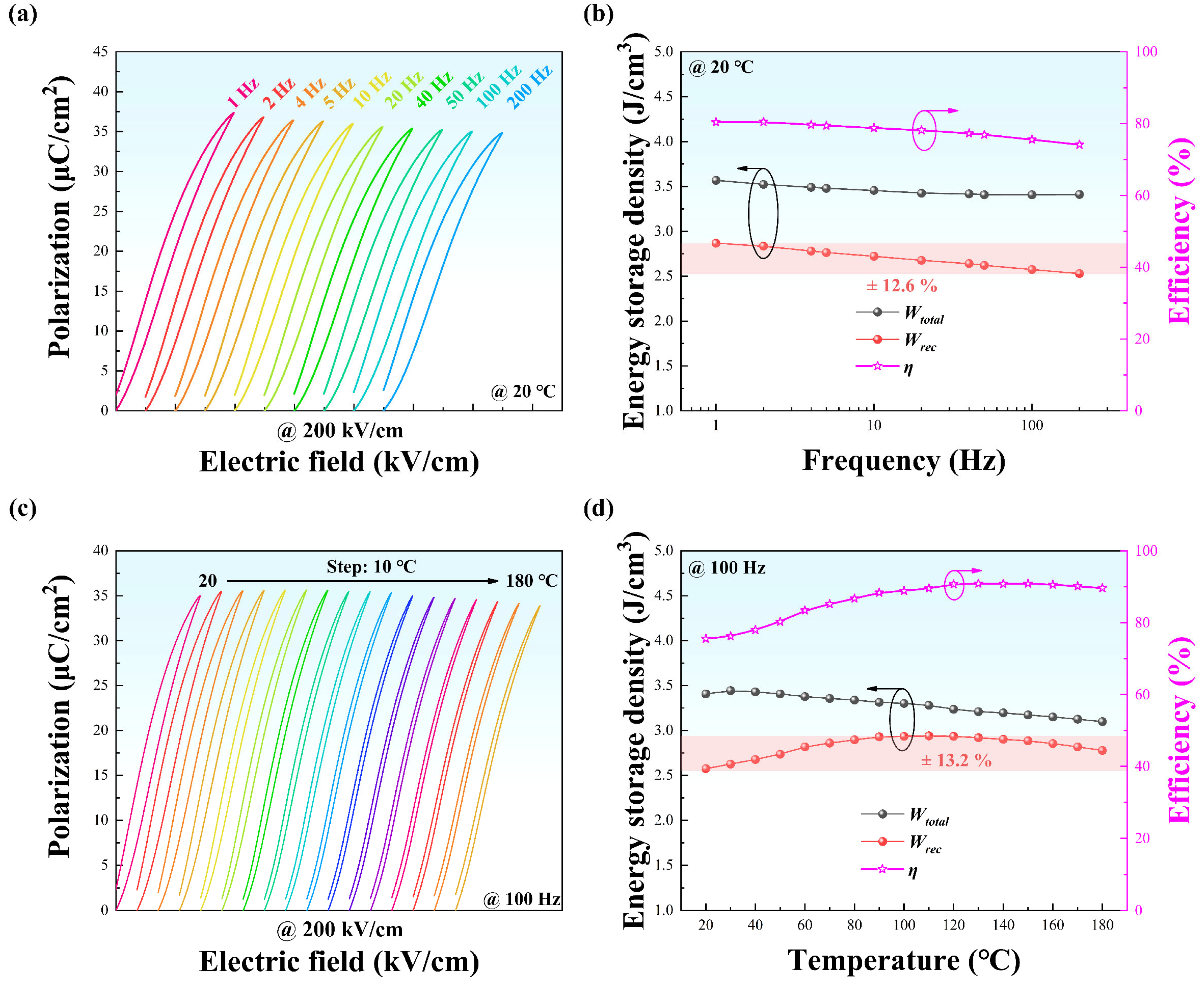

3.3. Ferroelectric and ESP

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Du, H.; Jin, L.; Poelman, D. High-performance lead-free bulk ceramics for electrical energy storage applications: Design strategies and challenges. J. Mater. Chem. A 2021, 9, 18026–18085. [Google Scholar] [CrossRef]

- Zhao, P.; Cai, Z.; Wu, L.; Zhu, C.; Li, L.; Wang, X. Perspectives and challenges for lead-free energy-storage multilayer ceramic capacitors. J. Adv. Ceram. 2021, 10, 1153–1193. [Google Scholar] [CrossRef]

- Lin, Y.; Li, D.; Zhang, M.; Yang, H. (Na0.5Bi0.5)0.7Sr0.3TiO3 modified by Bi(Mg2/3Nb1/3) O3 ceramics with high energy-storage properties and an ultrafast discharge rate. J. Mater. Chem. C 2020, 8, 2258–2264. [Google Scholar] [CrossRef]

- Zhou, S.; Pu, Y.; Zhao, X.; Ouyang, T.; Ji, J.; Zhang, Q.; Zhang, C.; Sun, S.; Sun, R.; Li, J.; et al. Dielectric temperature stability and energy storage performance of NBT-based ceramics by introducing high-entropy oxide. J. Am. Ceram. Soc. 2022, 105, 4796–4804. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, Y.; Chen, M. Influence of BaZrO3 additive on the energy-storage properties of 0.775Na0.5Bi0.5TiO3-0.225 BaSnO3 relaxor ferroelectrics. J. Alloy. Compd. 2019, 775, 342–347. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Hao, X. Ultra-high energy-storage density and fast discharge speed of (Pb0.98−xLa0.02Srx)(Zr0.9Sn0.1)0.995O3 antiferroelectric ceramics prepared via the tape-casting method. J. Mater. 2019, 7, 11858–11866. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, Y.; Ren, W.; Niu, M.; Hu, W.; Ma, H.; Ouyang, J. Rhombohedral BiFeO3 thick films integrated on Si with a giant electric polarization and prominent piezoelectricity. Acta Mater. 2020, 200, 305–314. [Google Scholar] [CrossRef]

- Wang, G.; Lu, Z.; Li, Y.; Li, L.; Ji, H.; Feteira, A.; Zhou, D.; Wang, D.; Zhang, S.; Reaney, I.M. Electroceramics for high-energy density capacitors: Current status and future perspectives. Chem. Rev. 2021, 121, 6124–6172. [Google Scholar] [CrossRef]

- Cao, W.P.; Sheng, J.; Qiao, Y.L.; Jing, L.; Liu, Z.; Wang, J.; Li, W.L. Optimized strain with small hysteresis and high energy-storage density in Mn-doped NBT-ST system. J. Eur. Ceram. Soc. 2019, 39, 4046–4052. [Google Scholar] [CrossRef]

- Lv, J.; Li, Q.; Li, Y.; Tang, M.; Jin, D.; Yan, Y.; Fan, B.; Jin, L.; Liu, G. Significantly improved energy storage performance of NBT-BT based ceramics through domain control and preparation optimization. Chem. Eng. J. 2021, 420, 129900. [Google Scholar] [CrossRef]

- Kong, X.; Yang, L.; Cheng, Z.; Zhang, S. Bi-modified SrTiO3-based ceramics for high-temperature energy storage applications. J. Am. Ceram. Soc. 2020, 103, 1722–1731. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, R.; Zhang, L.; Mao, P.; Sun, Q.; Kang, F.; Wang, J. Remarkably enhanced energy-storage density and excellent thermal stability under low electric fields of (Na0.5Bi0.5)TiO3-based ceramics via composition optimization strategy. J. Eur. Ceram. Soc. 2021, 41, 1917–1924. [Google Scholar] [CrossRef]

- Yang, H.; Tian, J.; Lin, Y.; Ma, J. Realizing ultra-high energy storage density of lead-free 0.76Bi0.5Na0.5TiO3-0.24SrTiO3-Bi (Ni2/3Nb1/3) O3 ceramics under low electric fields. Chem. Eng. J. 2021, 418, 129337. [Google Scholar] [CrossRef]

- Liu, Z.G.; Li, M.D.; Tang, Z.H.; Tang, X.G. Enhanced energy storage density and efficiency in lead-free Bi(Mg1/2Hf1/2) O3-modified BaTiO3 ceramics. Chem. Eng. J. 2021, 418, 129379. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, H.; Li, D.; Ma, L.; Lin, Y. Giant energy storage efficiency and high recoverable energy storage density achieved in K0.5Na0.5NbO3-Bi(Zn0.5Zr0.5)O3 ceramics. J. Mater. Chem. C 2020, 8, 8777–8785. [Google Scholar] [CrossRef]

- Guo, B.; Yan, Y.; Tang, M.; Wang, Z.; Li, Y.; Zhang, L.; Liu, G. Energy storage performance of Na0.5Bi0.5TiO3 based lead-free ferroelectric ceramics prepared via non-uniform phase structure modification and rolling process. Chem. Eng. J. 2021, 420, 130475. [Google Scholar] [CrossRef]

- Wang, M.; Feng, Q.; Luo, C.; Lan, Y.; Yuan, C.; Luo, N.; Zhou, C.; Fujita, T.; Xu, J.; Chen, G.; et al. Ultrahigh energy storage density and efficiency in Bi0.5Na0.5TiO3-based ceramics via the domain and bandgap engineering. ACS Appl. Mater. Interfaces 2021, 13, 51218–51229. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, H.; Li, X.; Zeng, F.; Wu, K.; Zheng, Q.; Fan, G.; Lin, D. Enhanced energy density and discharged efficiency of lead-free relaxor (1-x)[(Bi0.5Na0.5)0.94Ba0.06]0.98La0.02TiO3-xKNb0.6Ta0.4O3 ceramic capacitors. Chem. Eng. J. 2020, 394, 124879. [Google Scholar] [CrossRef]

- Huang, W.; Thatikonda, S.K.; Ke, Y.; Du, X.; Qin, N.; Hao, A.; Bao, D. High-recoverable energy-storage density and dielectric tunability in Eu3+-doped NBT-xSTO binary solid solution films. J. Am. Ceram. Soc. 2020, 103, 999–1009. [Google Scholar] [CrossRef]

- Jiao, Y.; Song, S.; Chen, F.; Zeng, X.; Wang, X.; Song, C.; Liu, G.; Yan, Y. Energy storage performance of 0.55Bi0.5Na0.5TiO3-0.45SrTiO3 ceramics doped with lanthanide elements (Ln = La, Nd, Dy, Sm) using a viscous polymer processing route. Ceram. Int. 2022, 48, 10885–10894. [Google Scholar] [CrossRef]

- Tripathy, S.N.; Mishra, K.K.; Sen, S.; Pradhan, D.K. Dielectric and Raman spectroscopic studies of Na0.5Bi0.5TiO3–BaSnO3 ferroelectric system. J. Am. Ceram. Soc. 2014, 97, 1846–1854. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, K.; Yan, Z.; Xie, B.; Fan, P.; Chen, S.-G.; Samart, C.; Salamon, D.; Tan, H.; Fan, Z.; et al. High energy storage efficiency of NBT-SBT lead-free ferroelectric ceramics. Ceram. Int. 2022, 48, 23266–23272. [Google Scholar] [CrossRef]

- Jo, W.; Schaab, S.; Sapper, E.; Schmitt, L.A.; Kleebe, H.J.; Bell, A.J.; Rödel, J. On the phase identity and its thermal evolution of lead free (Bi1/2Na1/2) TiO3-6 mol% BaTiO3. J. Appl. Phys. 2011, 110, 074106. [Google Scholar] [CrossRef]

- Zhao, P.; Tang, B.; Fang, Z.; Si, F.; Yang, C.; Zhang, S. Improved dielectric breakdown strength and energy storage properties in Er2O3 modified Sr0.35Bi0.35K0.25TiO3. Chem. Eng. J. 2021, 403, 126290. [Google Scholar] [CrossRef]

- Kang, R.; Wang, Z.; Lou, X.; Liu, W.; Shi, P.; Zhu, X.; Guo, X.; Li, S.; Sun, H.; Zhang, L.; et al. Energy storage performance of Bi0.5Na0.5TiO3-based relaxor ferroelectric ceramics with superior temperature stability under low electric fields. Chem. Eng. J. 2021, 410, 128376. [Google Scholar] [CrossRef]

- Chen, P.; Cao, W.; Li, T.; Zhao, B.; Zheng, J.; Wang, C. Outstanding energy-storage and charge–discharge performances in Na0.5Bi0.5TiO3 lead-free ceramics via linear additive of Ca0.85Bi0.1TiO3. Chem. Eng. J. 2022, 435, 135065. [Google Scholar] [CrossRef]

- Zhu, X.; Gao, Y.; Shi, P.; Kang, R.; Kang, F.; Qiao, W.; Zhao, J.; Wang, Z.; Yuan, Y.; Lou, X. Ultrahigh energy storage density in (Bi0.5Na0.5)0.65Sr0.35TiO3-based lead-free relaxor ceramics with excellent temperature stability. Nano Energy 2022, 98, 107276. [Google Scholar] [CrossRef]

- Qiao, X.; Sheng, A.; Wu, D.; Zhang, F.; Chen, B.; Liang, P.; Wang, J.; Chao, X.; Yang, Z. A novel multifunctional ceramic with photoluminescence and outstanding energy storage properties. Chem. Eng. J. 2021, 408, 127368. [Google Scholar] [CrossRef]

- Qiao, X.; Wu, D.; Zhang, F.; Chen, B.; Ren, X.; Liang, P.; Du, H.; Chao, X.; Yang, Z. Bi0.5Na0.5TiO3-based relaxor ferroelectric ceramic with large energy density and high efficiency under a moderate electric field. J. Mater. Chem. C 2019, 7, 10514–10520. [Google Scholar] [CrossRef]

- Hu, D.; Pan, Z.; He, Z.; Yang, F.; Zhang, X.; Li, P.; Liu, J. Significantly improved recoverable energy density and ultrafast discharge rate of Na0.5Bi0.5TiO3-based ceramics. Ceram. Int. 2020, 46, 15364–15371. [Google Scholar] [CrossRef]

- Hu, D.; Pan, Z.; Zhang, X.; Ye, H.; He, Z.; Wang, M.; Xing, S.; Zhai, J.; Fu, Q.; Liu, J. Greatly enhanced discharge energy density and efficiency of novel relaxation ferroelectric BNT–BKT-based ceramics. J. Mater. Chem. C 2020, 8, 591–601. [Google Scholar] [CrossRef]

- Chen, P.; Chu, B. Improvement of dielectric and energy storage properties in Bi(Mg1/2Ti1/2)O3-modified (Na1/2Bi1/2)0.92Ba0.08TiO3 ceramics. J. Eur. Ceram. Soc. 2016, 36, 81–88. [Google Scholar] [CrossRef]

- Hu, Q.; Tian, Y.; Zhu, Q.; Bian, J.; Jin, L.; Du, H.; Alikin, D.; Shur, V.Y.; Feng, Y.; Xu, Z.; et al. Achieve ultrahigh energy storage performance in BaTiO3–Bi(Mg1/2Ti1/2)O3 relaxor ferroelectric ceramics via nano-scale polarization mismatch and reconstruction. Nano Energy 2020, 67, 104264. [Google Scholar] [CrossRef]

- Yuan, Q.; Li, G.; Yao, F.-Z.; Cheng, S.-D.; Wang, Y.; Ma, R.; Mi, S.-B.; Gu, M.; Wang, K.; Li, J.-F.; et al. Simultaneously achieved temperature-insensitive high energy density and efficiency in domain engineered BaTiO3-Bi(Mg0.5Zr0.5)O3 lead-free relaxor ferroelectrics. Nano Energy 2018, 52, 203–210. [Google Scholar] [CrossRef]

- Dong, X.; Li, X.; Chen, H.; Sun, C.; Shi, J.; Pang, F.; Chen, X.; Zhou, H. Effective strategy to realise excellent energy storage performances in lead-free barium titanate-based relaxor ferroelectric. Ceram. Int. 2021, 47, 6077–6083. [Google Scholar] [CrossRef]

- Dai, Z.; Xie, J.; Liu, W.; Wang, X.; Zhang, L.; Zhou, Z.; Li, J.; Ren, X. Effective strategy to achieve excellent energy storage properties in lead-free BaTiO3-based bulk ceramics. ACS Appl. Ceram. Int. 2020, 12, 30289–30296. [Google Scholar] [CrossRef]

- Sun, C.; Chen, X.; Shi, J.; Pang, F.; Dong, X.; Chen, H.Y.; Wang, K.; Zhou, X.; Zhou, H. Simultaneously with large energy density and high efficiency achieved in NaNbO3-based relaxor ferroelectric ceramics. J. Eur. Ceram. Soc. 2021, 41, 1891–1903. [Google Scholar] [CrossRef]

- Wei, T.; Liu, K.; Fan, P.; Lu, D.; Ye, B.; Zhou, C.; Yang, H.; Tan, H.; Salamon, D.; Nan, B.; et al. Novel NaNbO3–Sr0.7Bi0.2TiO3 lead-free dielectric ceramics with excellent energy storage properties. Ceram. Int. 2021, 47, 3713–3719. [Google Scholar] [CrossRef]

- Yang, Z.; Du, H.; Qu, S.; Hou, Y.; Ma, H.; Wang, J.; Wang, J.; Wei, X.; Xu, Z. Significantly enhanced recoverable energy storage density in potassium–sodium niobate-based lead free ceramics. J. Mater. Chem. A 2016, 4, 13778–13785. [Google Scholar] [CrossRef]

- Shao, T.; Du, H.; Ma, H.; Qu, S.; Wang, J.; Wang, J.; Wei, X.; Xu, Z. Potassium–sodium niobate based lead-free ceramics: Novel electrical energy storage materials. J. Mater. Chem. A 2017, 5, 554–563. [Google Scholar] [CrossRef]

- Li, Q.; Ji, S.; Wang, D.; Zhu, J.; Li, L.; Wang, W.; Zeng, M.; Hou, Z.; Gao, X.; Lu, X.; et al. Simultaneously enhanced energy storage density and efficiency in novel BiFeO3-based lead-free ceramic capacitors. J. Eur. Ceram. Soc. 2021, 41, 387–393. [Google Scholar] [CrossRef]

- Yang, H.; Qi, H.; Zuo, R. Enhanced breakdown strength and energy storage density in a new BiFeO3-based ternary lead-free relaxor ferroelectric ceramic. J. Eur. Ceram. Soc. 2019, 39, 2673–2679. [Google Scholar] [CrossRef]

- Xu, Q.; Lanagan, M.T.; Huang, X.; Xie, J.; Zhang, L.; Hao, H.; Liu, H. Dielectric behavior and impedance spectroscopy in lead-free BNT–BT–NBN perovskite ceramics for energy storage. Ceram. Int. 2016, 42, 9728–9736. [Google Scholar] [CrossRef]

- Subramaniyan, R.; Bhaumik, I.; Ganesamoorthy, S.; Ramasamy, P.; Gupta, P.K. Growth and characterization of undoped and Mn doped lead-free piezoelectric NBT–KBT single crystals. Mater. Res. Bull. 2014, 53, 136–140. [Google Scholar] [CrossRef]

- Dong, X.; Li, X.; Chen, X.; Chen, H.; Sun, C.; Shi, J.; Pang, F.; Zhou, H. High energy storage density and power density achieved simultaneously in NaNbO3-based lead-free ceramics via antiferroelectricity enhancement. J. Mater. 2021, 7, 629–639. [Google Scholar] [CrossRef]

- Ma, W.; Zhu, Y.; Marwat, M.A.; Fan, P.; Xie, B.; Salamon, D.; Ye, Z.-G.; Zhang, H. Enhanced energy-storage performance with excellent stability under low electric fields in BNT–ST relaxor ferroelectric ceramics. J. Mater. Chem. C 2019, 7, 281–288. [Google Scholar] [CrossRef]

- Bian, S.; Yue, Z.; Shi, Y.; Zhang, J.; Feng, W. Ultrahigh energy storage density and charge-discharge performance in novel sodium bismuth titanate-based ceramics. J. Am. Ceram. Soc. 2021, 104, 936–947. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, T.; Ye, J.; Wang, G.; Dong, X.; Withers, R.; Liu, Y. Antiferroelectrics for energy storage applications: A review. Adv. Mater. Technol. 2018, 3, 1800111. [Google Scholar] [CrossRef]

- Zhao, X.; Bai, W.; Ding, Y.; Wang, L.; Wu, S.; Zheng, P.; Li, P.; Zhai, J. Tailoring high energy density with superior stability under low electric field in novel (Bi0.5Na0.5)TiO3-based relaxor ferroelectric ceramics. J. Eur. Ceram. Soc. 2020, 40, 4475–4486. [Google Scholar] [CrossRef]

- Shi, C.; Yan, F.; Ge, G.; Wei, Y.; Zhai, J.; Yao, W. Significantly enhanced energy storage performances and power density in (1 − x) BCZT-xSBT lead-free ceramics via synergistic optimization strategy. Chem. Eng. J. 2021, 426, 130800. [Google Scholar] [CrossRef]

- Dong, X.; Li, X.; Chen, H.; Dong, Q.; Wang, J.; Wang, X.; Pan, Y.; Chen, X.; Zhou, H. Realizing enhanced energy storage and hardness performances in 0.90NaNbO3 − 0.10Bi(Zn0.5Sn0.5)O3 ceramics. J. Adv. Ceram. 2022, 11, 729–741. [Google Scholar] [CrossRef]

| x | Space Group | Phase Fractions | Lattice Parameters (Å) | Volume (Å3) | R-Factors | ||||

|---|---|---|---|---|---|---|---|---|---|

| a | b | c | Rp(%) | Rwp(%) | χ2 | ||||

| 0 | R3c | 100.00 | 5.48944 | 5.48944 | 13.41966 | 350.209 | 6.27 | 8.10 | 4.29 |

| 0.09 | R3c | 92.63 | 5.53055 | 5.53055 | 13.53951 | 358.650 | 4.50 | 5.79 | 2.65 |

| P4bm | 7.37 | 5.51596 | 5.51596 | 3.94872 | 120.143 | ||||

| 0.12 | R3c | 82.67 | 5.53860 | 5.53860 | 13.55491 | 360.104 | 5.24 | 6.57 | 3.97 |

| P4bm | 17.33 | 5.52976 | 5.52976 | 3.91932 | 119.846 | ||||

| 0.15 | R3c | 75.48 | 5.54761 | 5.54761 | 13.60827 | 362.698 | 5.88 | 7.32 | 3.73 |

| P4bm | 24.52 | 5.53929 | 5.53929 | 3.94928 | 121.178 | ||||

| 0.18 | R3c | 60.33 | 5.55175 | 5.55175 | 13.58650 | 362.659 | 5.76 | 7.29 | 3.22 |

| P4bm | 39.67 | 5.54833 | 5.54833 | 3.93289 | 121.070 | ||||

| Composition | R1 (Ω) | C1 (F) | R2 (Ω) | C2 (F) |

|---|---|---|---|---|

| x = 0 | 12,944 | 6.76 × 10−10 | 54,458 | 1.32 × 10−9 |

| x = 0.09 | 177,600 | 8.90 × 10−10 | 501,600 | 9.05 × 10−10 |

| x = 0.12 | 245,490 | 6.92 × 10−10 | 535,090 | 8.03 × 10−10 |

| x = 0.15 | 98,490 | 3.29 × 10−11 | 850,890 | 5.19 × 10−11 |

| x = 0.18 | 19,437 | 3.17 × 10−10 | 798,390 | 8.30 × 10−10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Niu, X.; Liang, W.; Jian, X.; Shi, H.; Li, F.; Zhang, Y.; Wang, T.; Gong, W.; Zhao, X.; et al. Enhanced Energy Storage Performance in Na0.5Bi0.5TiO3-Based Relaxor Ferroelectric Ceramics via Compositional Tailoring. Materials 2022, 15, 5881. https://doi.org/10.3390/ma15175881

Jiang Y, Niu X, Liang W, Jian X, Shi H, Li F, Zhang Y, Wang T, Gong W, Zhao X, et al. Enhanced Energy Storage Performance in Na0.5Bi0.5TiO3-Based Relaxor Ferroelectric Ceramics via Compositional Tailoring. Materials. 2022; 15(17):5881. https://doi.org/10.3390/ma15175881

Chicago/Turabian StyleJiang, Yuleng, Xiang Niu, Wei Liang, Xiaodong Jian, Hongwei Shi, Feng Li, Yang Zhang, Ting Wang, Weiping Gong, Xiaobo Zhao, and et al. 2022. "Enhanced Energy Storage Performance in Na0.5Bi0.5TiO3-Based Relaxor Ferroelectric Ceramics via Compositional Tailoring" Materials 15, no. 17: 5881. https://doi.org/10.3390/ma15175881

APA StyleJiang, Y., Niu, X., Liang, W., Jian, X., Shi, H., Li, F., Zhang, Y., Wang, T., Gong, W., Zhao, X., Yao, Y., Tao, T., Liang, B., & Lu, S. (2022). Enhanced Energy Storage Performance in Na0.5Bi0.5TiO3-Based Relaxor Ferroelectric Ceramics via Compositional Tailoring. Materials, 15(17), 5881. https://doi.org/10.3390/ma15175881