Green Conversion of the Hazardous Cathode Ray Tube and Red Mud into Radiation Shielding Concrete

Abstract

:1. Introduction

2. Materials

2.1. Cement and Red Mud

2.2. Aggregates

2.3. Chemical Additives

2.4. Concrete Mix Design

3. Methodology

3.1. Mechanical Test

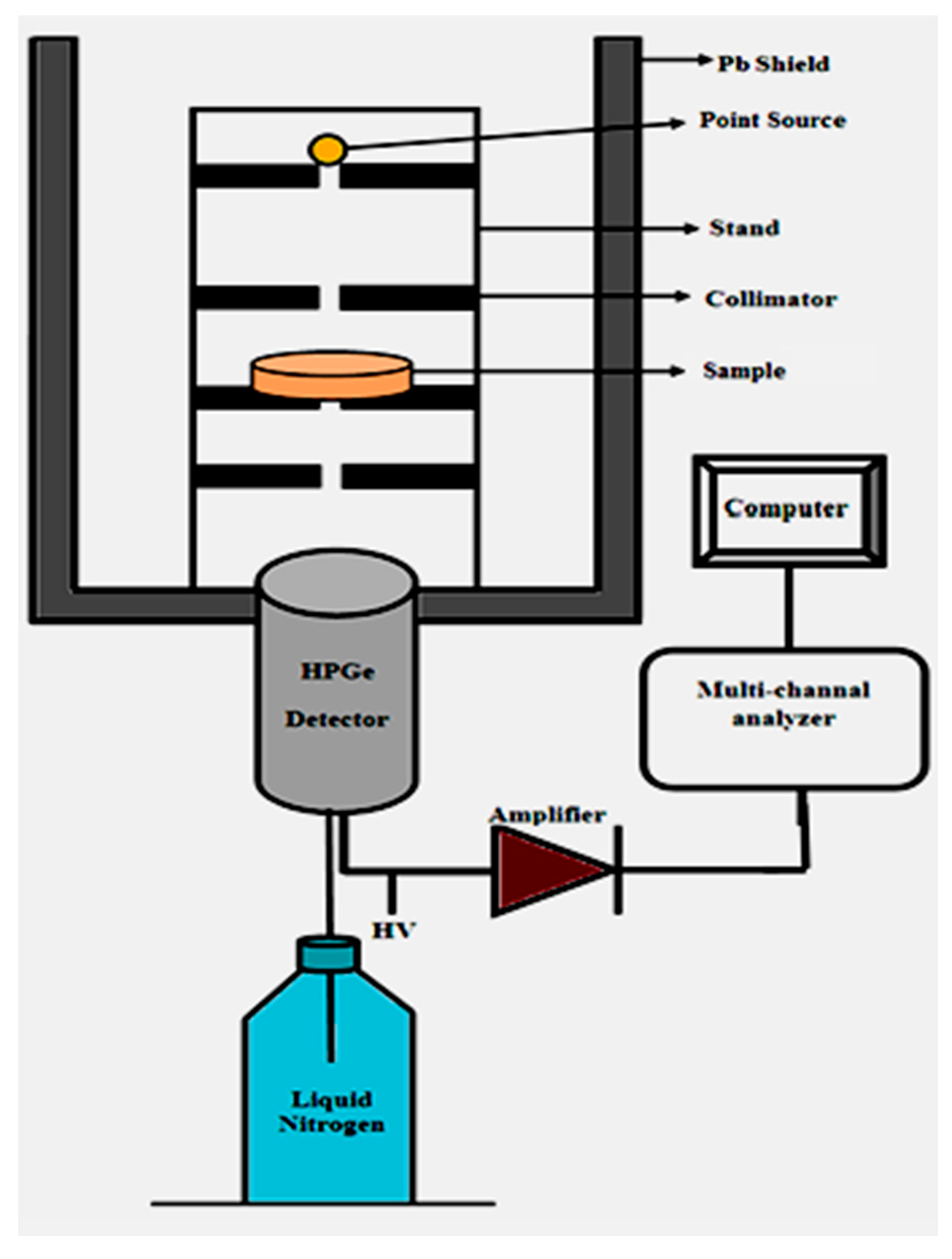

3.2. Shielding Test

4. Results and Discussion

4.1. Density Results

4.2. Compressive Strength Results

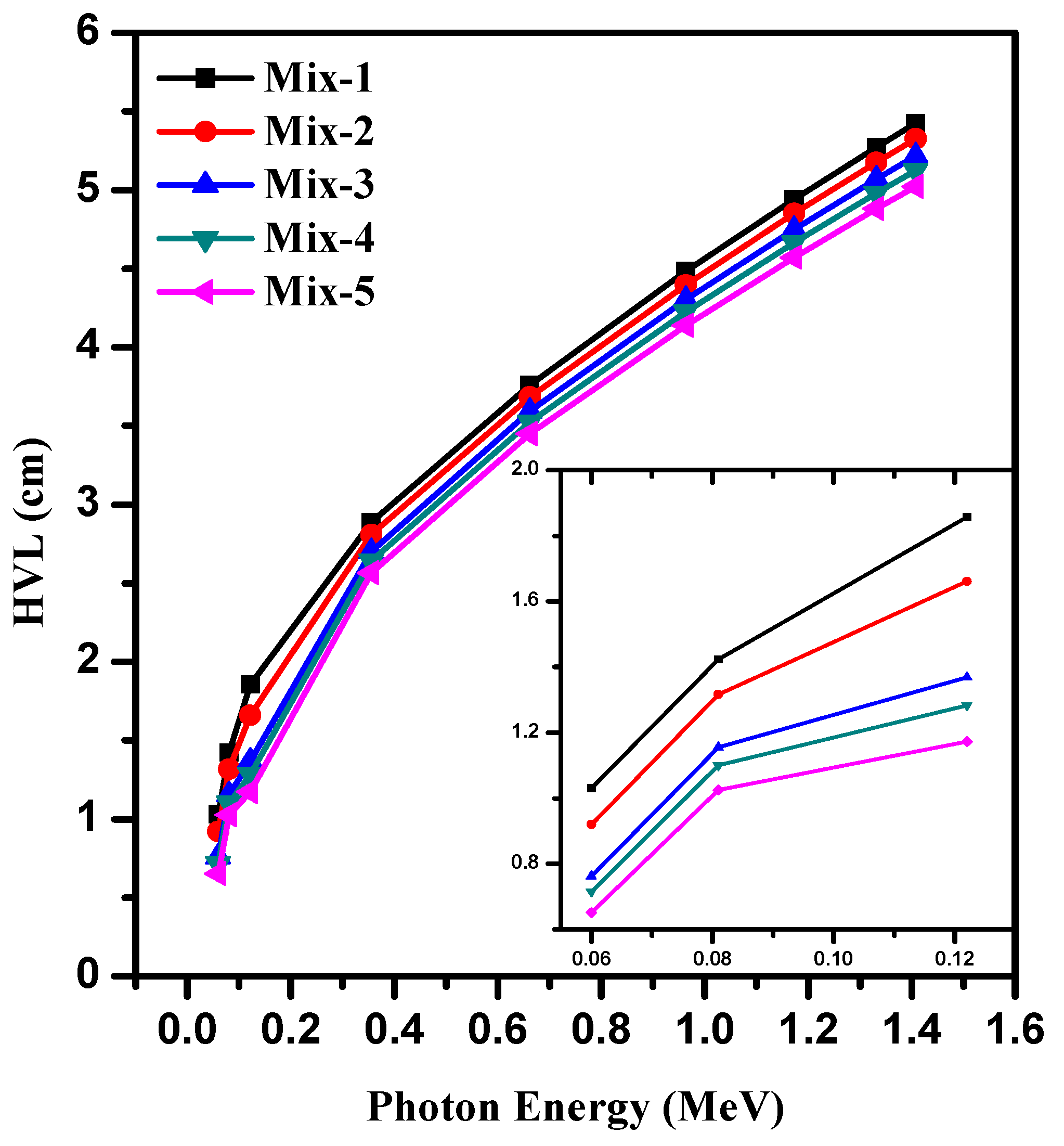

4.3. Gamma Ray Attenuation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamislioglu, M. An investigation into gamma radiation shielding parameters of the (Al:Si) and (Al+Na):Si-doped international simple glasses (ISG) used in nuclear waste management, deploying Phy-X/PSD and SRIM software. J. Mater. Sci. Mater. Electron. 2021, 32, 12690–12704. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Yang, H.; Liu, D.; Wang, C.; Li, Z. A novel comprehensive utilization of vanadium slag: As gamma ray shielding material. J. Hazard. Mater. 2016, 318, 751–757. [Google Scholar] [CrossRef] [PubMed]

- Dong, M.; Zhou, S.; Xue, X.; Sayyed, M.I.; Tishkevich, D.; Trukhanov, A.; Wang, C. Study of comprehensive shielding behaviors of chambersite deposit for neutron and gamma ray. Prog. Nucl. Energy 2022, 146, 104155. [Google Scholar] [CrossRef]

- Dong, M.; Xue, X.; Yang, H.; Li, Z. Highly cost-effective shielding composite made from vanadium slag and boron-rich slag and its properties. Radiat. Phys. Chem. 2017, 141, 239–244. [Google Scholar] [CrossRef]

- Kamislioglu, M. Research on the effects of bismuth borate glass system on nuclear radiation shielding parameters. Result Phys. 2021, 22, 103844. [Google Scholar] [CrossRef]

- Menadi, B.; Kenai, S.; Hammat, S.; Khatib, J. The Influence of the Fineness of Mineral Additions on Strength and Drying Shrinkage of Self-Compacting Mortars. Key Eng. Mater. 2014, 600, 367–374. [Google Scholar] [CrossRef]

- Herki, B.M.; Khatib, J. Structural behaviour of reinforced concrete beams containing a novel lightweight aggregate. Int. J. Struct. Eng. 2015, 7, 1. [Google Scholar] [CrossRef] [Green Version]

- Khatib, J.; Jefimiuk, A.; Khatib, S. Flexural Behaviour of Reinforced Concrete Beams Containing Expanded Glass as Lightweight Aggregates. Slovak J. Civ. Eng. 2015, 23, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Herki, B.M.; Khatib, J. Valorisation of waste expanded polystyrene in concrete using a novel recycling technique. Eur. J. Environ. Civ. Eng. 2017, 21, 1384–1402. [Google Scholar] [CrossRef]

- Khatib, J.; Jahami, A.; Baalbaki, O. Flexural Characteristics of Reinforced Concrete Beams Containing Lightweight Aggregate in the Tensile Zone. SSRN Electron. J. 2019. [Google Scholar] [CrossRef]

- Asim, N.; Alghoul, M.; Mohammad, M.; Amin, M.; Akhtaruzzaman, M.; Amin, N.; Sopian, K. Emerging sustainable solutions for depollution: Geopolymers. Constr. Build. Mater. 2019, 199, 540–548. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Dhir, R.K.; Brito, J.D.; Ghataora, G.; Lye, C.Q. Production and Properties of Glass Cullet. Sustain. Constr. Mater. 2018, 35–96. [Google Scholar] [CrossRef]

- Olukotun, S.F.; Gbenu, S.T.; Ibitoye, F.I.; Oladejo, O.F.; Shittu, H.; Fasasi, M.K.; Balogun, F.A. Investigation of gamma radiation shielding capability of two clay materials. Nucl. Eng. Technol. 2018, 50, 957–962. [Google Scholar] [CrossRef]

- Mann, H.S.; Brar, G.S.; Mudahar, G.S. Gamma-ray shielding effectiveness of novel light-weight clay-flyash bricks. Radiat. Phys. Chem. 2016, 127, 97–101. [Google Scholar] [CrossRef]

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM: West Conshohocken, PA, USA, 2005.

- ACI 211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete 607 Institute: Farmington Hills, MI, USA, 2009.

- Hover, K.C. Part 116: Method for determination of compressive strength of concrete cubes. Concr. Constr.-World Concr. 2005, 50, 37–41. [Google Scholar]

- Eid, M.S.; Bondouk, I.I.; Saleh, H.M.; Omar, K.M.; Sayyed, M.I.; El-Khatib, A.M.; Elsafi, M. Implementation of Waste Silicate Glass into Composition of Ordinary Cement for Radiation Shielding Applications. Nuclear Engineering and Technology. Available online: https://www.sciencedirect.com/science/article/pii/S173857332100591X (accessed on 10 October 2021).

- Elsafi, M.; Sayyed, M.I.; Almuqrin, A.H.; Gouda, M.M.; El-khatib, A.M. Analysis of particle size on mass dependent attenuation capability of bulk and nanoparticle PbO radiation shields. Results Phys. 2021, 26, 104458. [Google Scholar] [CrossRef]

- Alabsy, M.T.; Alzahrani, J.S.; Sayyed, M.I.; Abbas, M.I.; Tishkevich, D.I.; El-Khatib, A.M. Mohamed Elsafi Gamma-Ray Attenuation and Exposure Buildup Factor of Novel Polymers in Shielding Using Geant4 Simulation. Materials 2021, 14, 5051. [Google Scholar] [CrossRef]

- El-Khatib, A.M.; Elsafi, M.; Almutiri, M.N.; Mahmoud, R.M.M.; Alzahrani, J.S.; Sayyed, M.I.; Abbas, M.I. Enhancement of Bentonite Materials with Cement for Gamma-Ray Shielding Capability. Materials 2021, 14, 4697. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Albarzan, B.; Almuqrin, A.H.; El-Khatib, A.M.; Kumar, A.; Tishkevich, D.I.; Trukhanov, A.V.; Elsafi, M. Experimental and Theoretical Study of Radiation Shielding Features of CaO K2O-Na2O-P2O5 Glass Systems. Materials 2021, 14, 3772. [Google Scholar] [CrossRef]

- Elsafi, M.; El-Nahal, M.A.; Sayyed, M.I.; Saleh, I.H.; Abbas, M.I. Effect of bulk and nanoparticle Bi2O3 on attenuation capability of radiation shielding glass. Ceram. Int. 2021, 47, 19651–19658. [Google Scholar] [CrossRef]

- El-Nahal, M.A.; Elsafi, M.; Sayyed, M.I.; Khandaker, M.U.; Osman, H.; Elesawy, B.H.; Saleh, I.H.; Abbas, M.I. Understanding the Effect of Introducing Micro- and Nanoparticle Bismuth Oxide (Bi2O3) on the Gamma Ray Shielding Performance of Novel Concrete. Materials 2021, 14, 6487. [Google Scholar] [CrossRef] [PubMed]

- Obaid, S.S.; Gaikwad, D.K.; Pawar, P.P. Determination of gamma ray shielding parameters of rocks and concrete. Radiat. Phys. Chem. 2018, 144, 356–360. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Almuqrin, A.H.; Kumar, A.; Jecong, J.F.M.; Akkurt, I. Optical, mechanical properties of TeO2-CdO-PbO-B2O3 glass systems and radiation shielding investigation using EPICS2017 library. Optik 2021, 242, 167342. [Google Scholar] [CrossRef]

- Ibrahim, A.M.; Mohamed, A.R.; El-Khatib, A.M.; Alabsy, M.T.; Elsalamawy, M. Effect of hematite and iron slag as aggregate replacement on thermal, mechanical, and gamma-radiation shielding properties of concrete. Constr. Build. Mater. 2021, 310, 125225. [Google Scholar] [CrossRef]

| Oxide Composition (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | Fe2O3 | CaO | MgO | TiO2 | SO3 | K2O | Na2O | L.O.I | |

| Cement | 4.88 | 21.38 | 5.86 | 58.22 | 2.66 | — | 2.87 | 0.32 | 0.41 | 3.40 |

| Red mud | 22.31 | 19.22 | 34.89 | 14.11 | 0.33 | 4.55 | — | — | 3.11 | 1.51 |

| Fine Aggregate | Course Aggregate | CRT Glass | |

|---|---|---|---|

| Relative density | 2.59 | 2.63 | 3.15 |

| Loose Unit Weight (t/m3) | 1.54 | 1.33 | 1.22 |

| Hardness index | 6.22 | 6.89 | — |

| Oxides | Chemical Composition (wt%) | ||

|---|---|---|---|

| Sand | Limestone | CRT Glass | |

| SiO2 | 99.38 | 14.53 | 51.24 |

| Al2O3 | — | 0.72 | 4.02 |

| Fe2O3 | — | 0.41 | — |

| CaO | 0.01 | 42.85 | 3.81 |

| MgO | — | 2.18 | 1.82 |

| SO3 | 0.04 | 0.03 | — |

| K2O | 0.07 | — | 7.81 |

| Na2O | — | — | 6.76 |

| BaSO4 | — | — | — |

| SrO | — | — | 0.51 |

| PbO | — | — | 22.18 |

| BaO | — | — | 0.52 |

| Sb2O3 | — | — | 0.28 |

| L.O.I | 0.5 | 39.28 | 1.05 |

| Mix Name | Cement (Kg/m3) | Red Mud (Kg/m3) | Water (Kg/m3) | Sand (Kg/m3) | CRT Glass (Kg/m3) | Limestone (Kg/m3) | SP (Kg/m3) |

|---|---|---|---|---|---|---|---|

| Mix-l | 400 | — | 180 | 830.0 | — | 995.0 | 9.8 |

| Mix-2 | 360 | 40.2 | 180 | 747.9 | 83.4 | 996.2 | 8.2 |

| Mix-3 | 320 | 81.5 | 180 | 671.7 | 162.2 | 998.5 | 7.9 |

| Mix-4 | 280 | 122.1 | 180 | 593.5 | 243.5 | 999.2 | 8.8 |

| Mix-5 | 240 | 163.2 | 180 | 502.3 | 332.4 | 999.8 | 9.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sayyed, M.I.; Almousa, N.; Elsafi, M. Green Conversion of the Hazardous Cathode Ray Tube and Red Mud into Radiation Shielding Concrete. Materials 2022, 15, 5316. https://doi.org/10.3390/ma15155316

Sayyed MI, Almousa N, Elsafi M. Green Conversion of the Hazardous Cathode Ray Tube and Red Mud into Radiation Shielding Concrete. Materials. 2022; 15(15):5316. https://doi.org/10.3390/ma15155316

Chicago/Turabian StyleSayyed, M. I., Nouf Almousa, and Mohamed Elsafi. 2022. "Green Conversion of the Hazardous Cathode Ray Tube and Red Mud into Radiation Shielding Concrete" Materials 15, no. 15: 5316. https://doi.org/10.3390/ma15155316

APA StyleSayyed, M. I., Almousa, N., & Elsafi, M. (2022). Green Conversion of the Hazardous Cathode Ray Tube and Red Mud into Radiation Shielding Concrete. Materials, 15(15), 5316. https://doi.org/10.3390/ma15155316