The Wear Performance of Cu-Based Composites Reinforced with Boron Nitride Nanosheets

Abstract

:1. Introduction

2. Experimental Section

2.1. Raw Materials

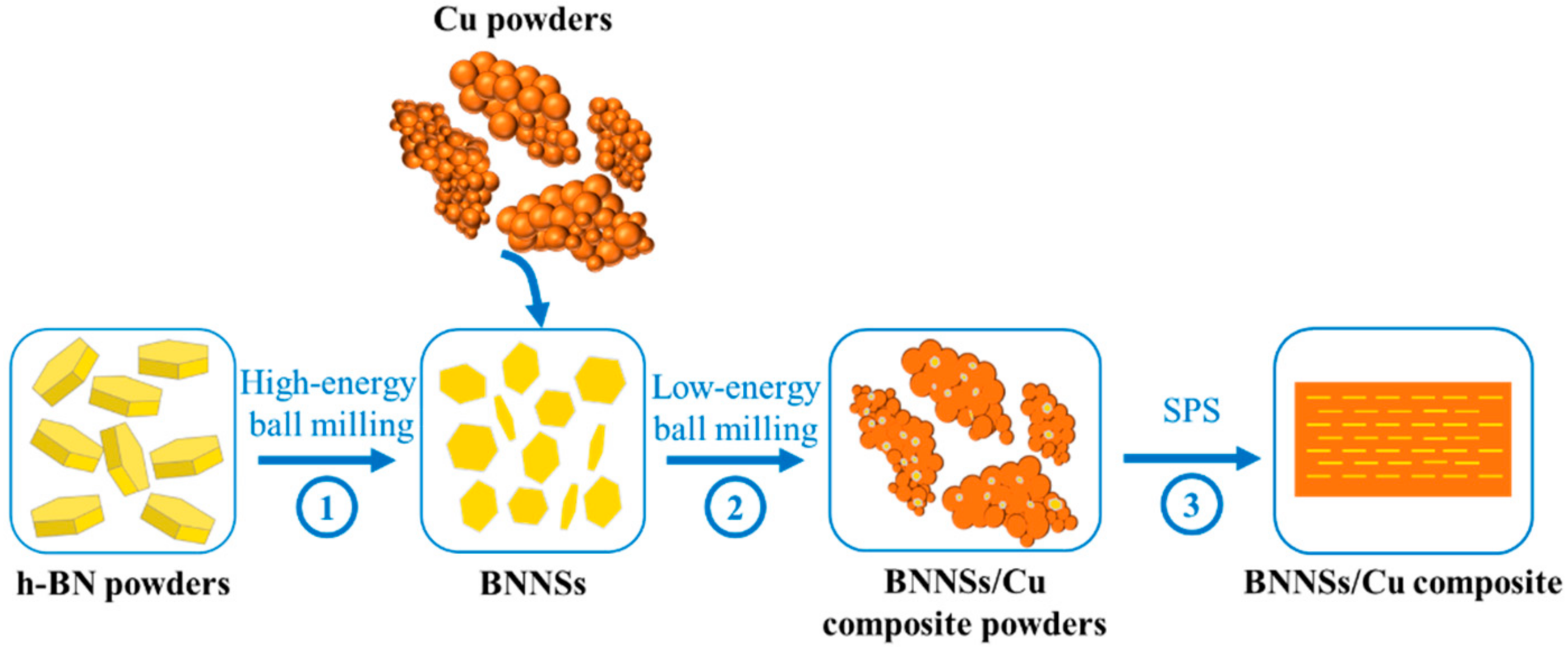

2.2. Preparation of Composites

2.3. Characterization

2.4. Microhardness Testing

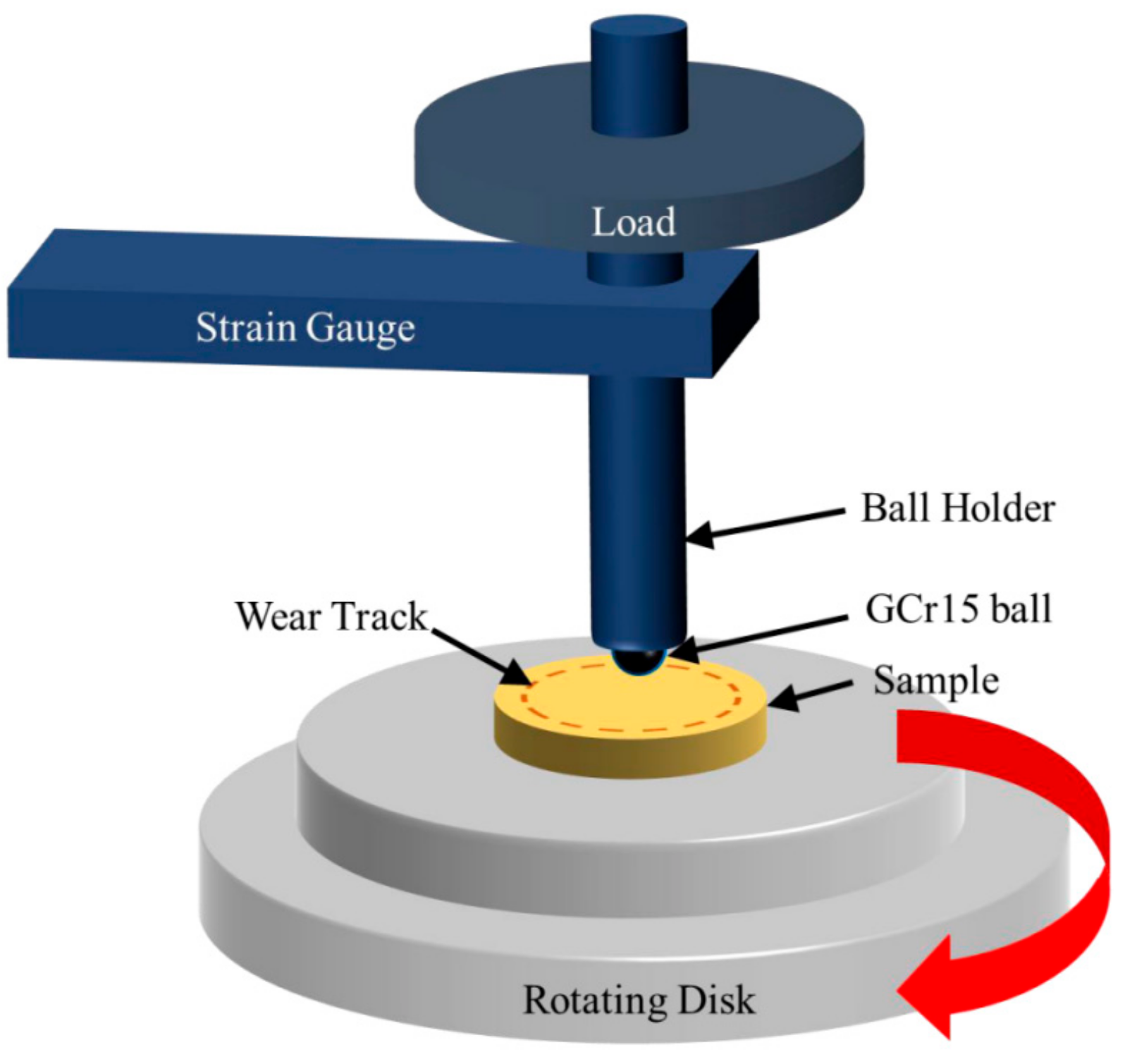

2.5. Wear Testing

3. Results and Discussion

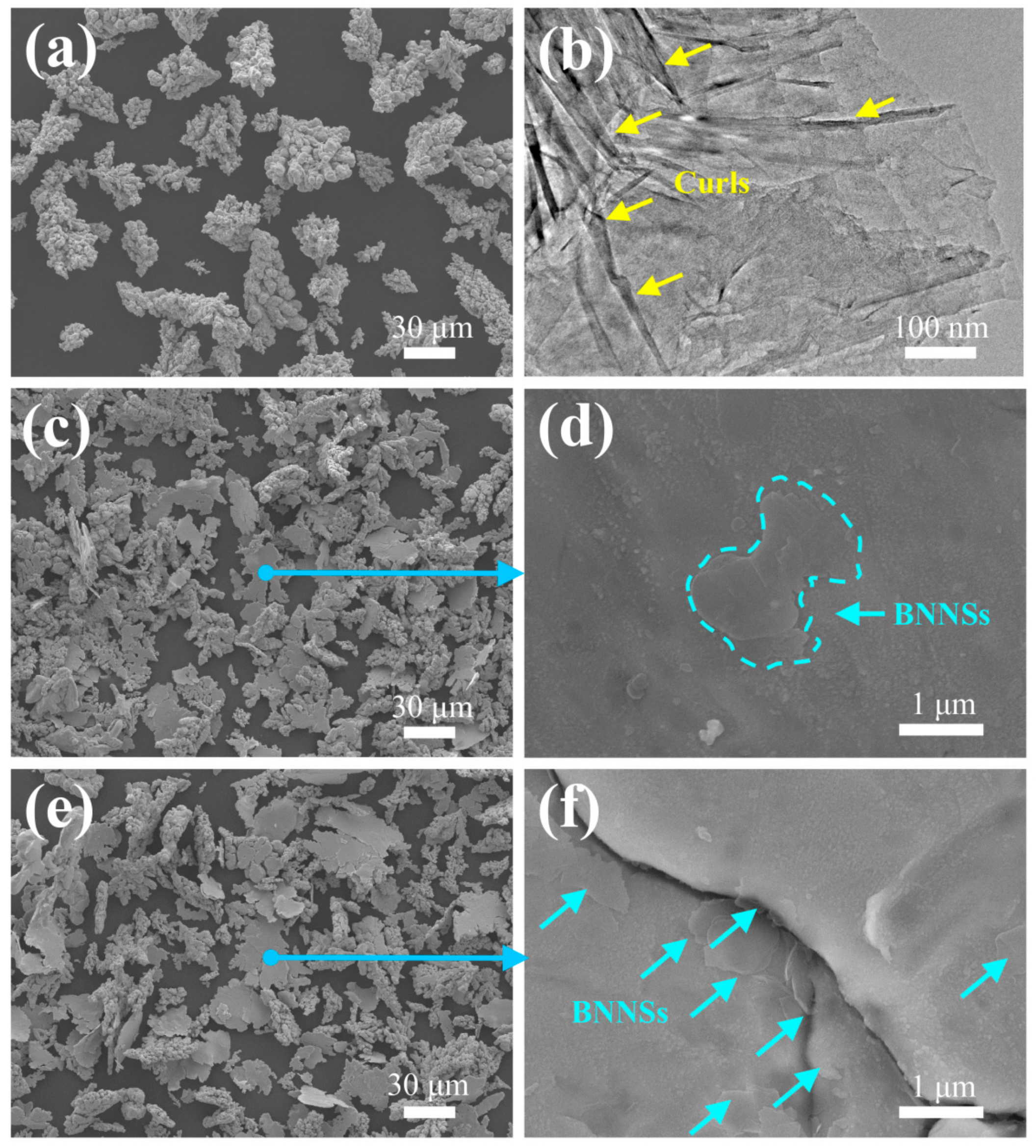

3.1. Morphology of Raw Materials

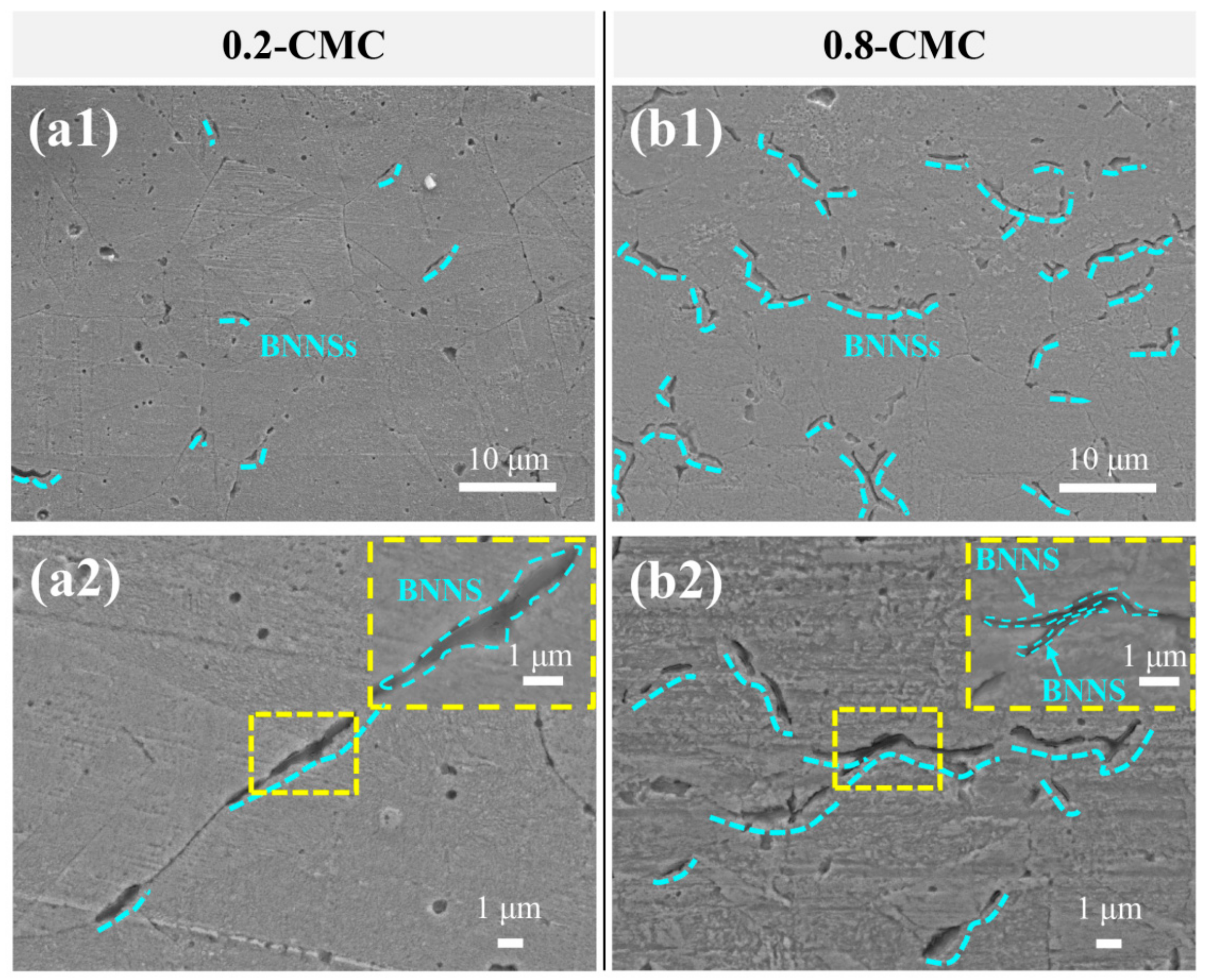

3.2. Characterization of the BNNSs/Cu Composites

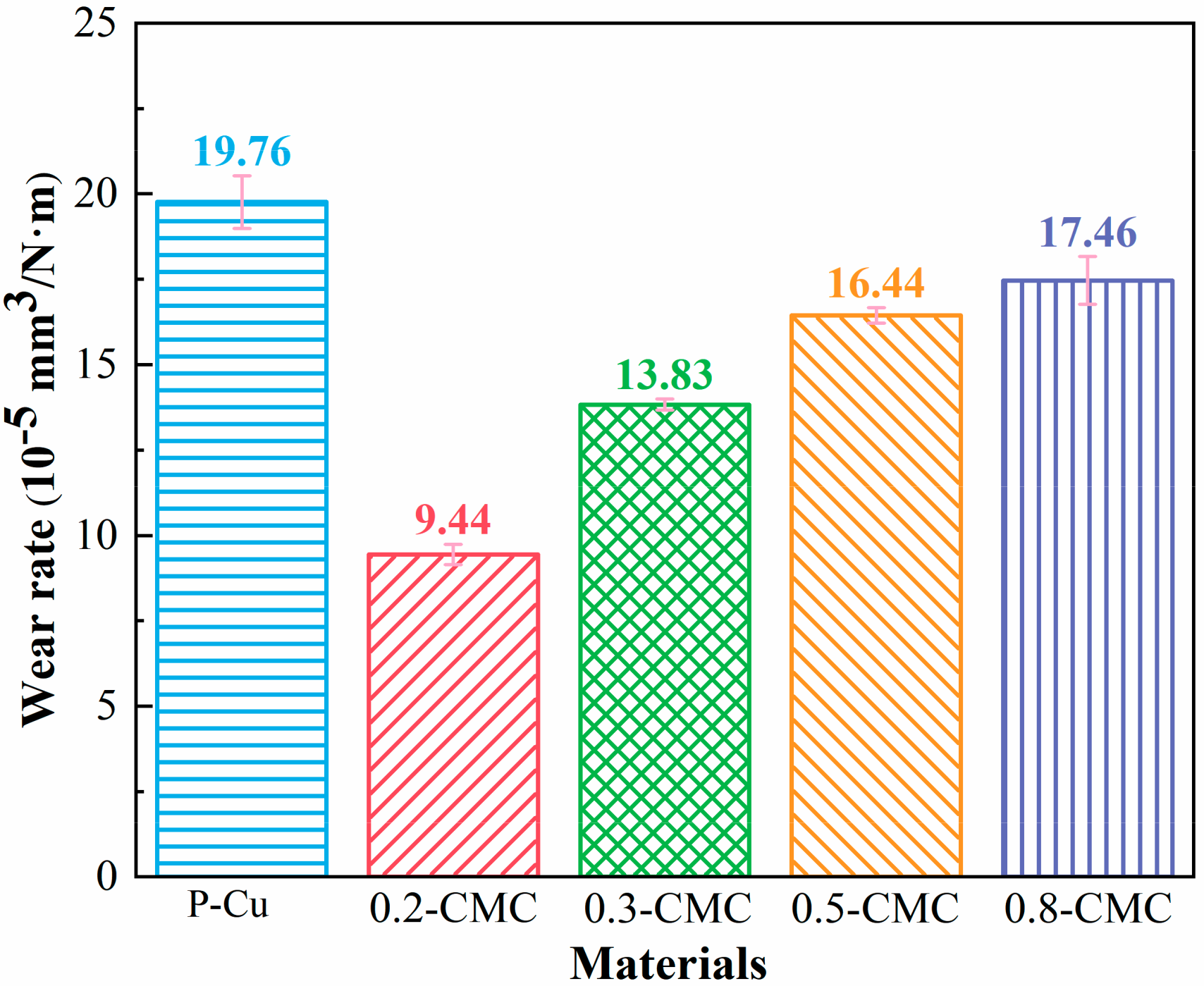

3.3. Microhardness and Wear Resistance

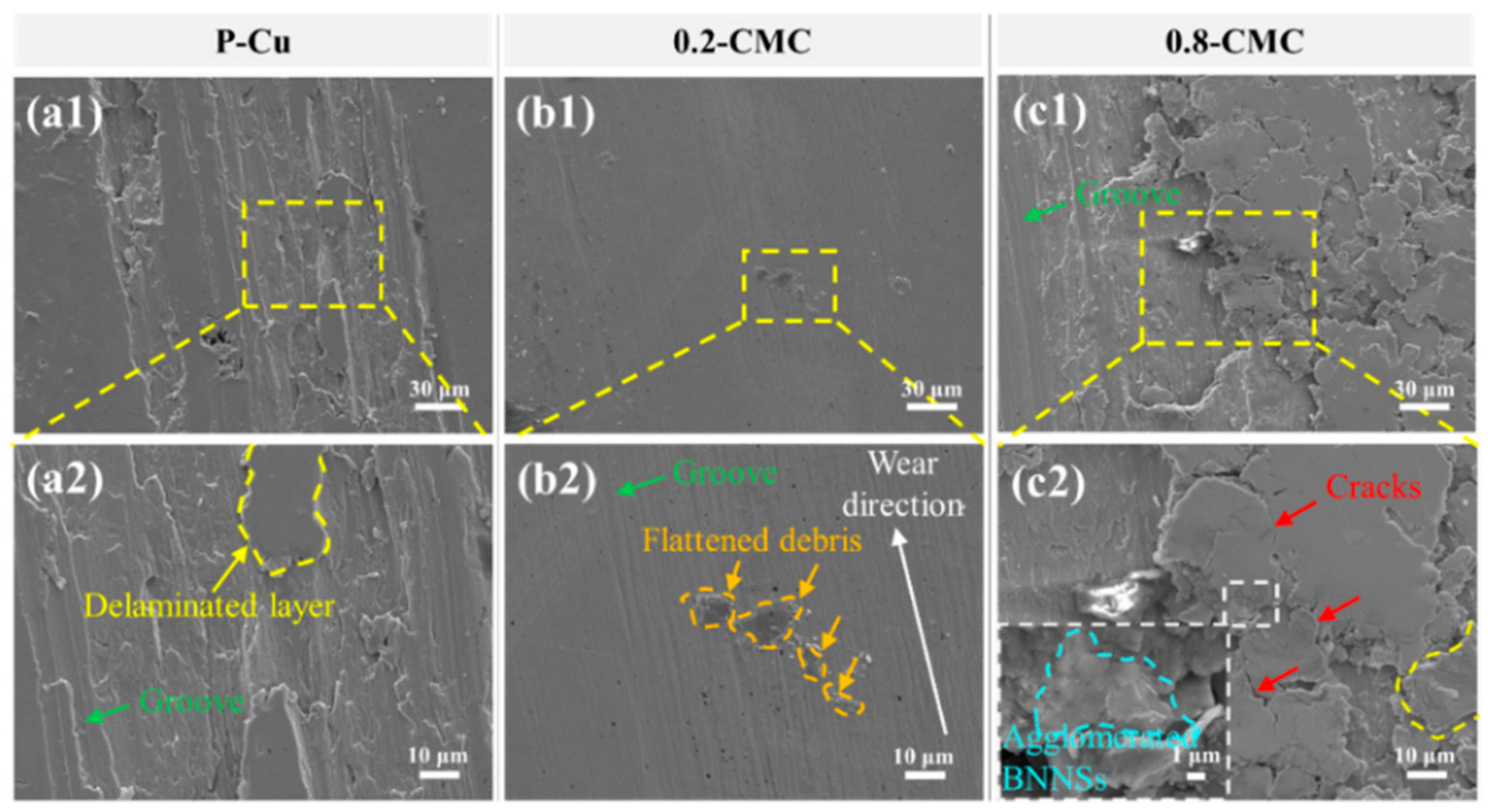

3.4. Wear Mechanisms of BNNSs/Cu Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, Y.; Fan, J.; Wu, S.; Liu, J.; Zhang, C.; Li, Y. Effect of carbon-fibre powder on friction and wear properties of copper-matrix composites. Mater. Sci. Technol. 2019, 36, 92–99. [Google Scholar] [CrossRef]

- Yang, Z.; Ge, Y.; Zhang, X.; Shangguan, B.; Zhang, Y.; Zhang, J. Effect of Carbon Content on Friction and Wear Properties of Copper Matrix Composites at High Speed Current-Carrying. Materials 2019, 12, 2881. [Google Scholar] [CrossRef] [Green Version]

- Gao, X.; Yue, H.; Guo, E.; Zhang, H.; Lin, X.; Yao, L.; Wang, B. Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites. Powder Technol. 2016, 301, 601–607. [Google Scholar] [CrossRef]

- Jamwal, A.; Mittal, P.; Agrawal, R.; Gupta, S.; Kumar, D.; Sadasivuni, K.K.; Gupta, P. Towards sustainable copper matrix composites: Manufacturing routes with structural, mechanical, electrical and corrosion behaviour. J. Compos. Mater. 2020, 54, 2635–2649. [Google Scholar] [CrossRef]

- Zhan, Y.; Zhang, G. The role of graphite particles in the high-temperature wear of copper hybrid composites against steel. Mater. Des. 2006, 27, 79–84. [Google Scholar] [CrossRef]

- Kumar, J.; Mondal, S. Microstructure and properties of graphite-reinforced copper matrix composites. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–10. [Google Scholar] [CrossRef]

- Tsai, P.-C.; Jeng, Y.-R.; Lee, J.-T.; Stachiv, I.; Sittner, P. Effects of carbon nanotube reinforcement and grain size refinement mechanical properties and wear behaviors of carbon nanotube/copper composites. Diam. Relat. Mater. 2017, 74, 197–204. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, L.; Li, J.; Shi, Z.; Wang, M.; Sheng, J.; Fei, W. Lateral size effect of reduced graphene oxide on properties of copper matrix composites. Mater. Sci. Eng. A 2021, 820, 141579. [Google Scholar] [CrossRef]

- Chen, F.; Ying, J.; Wang, Y.; Du, S.; Liu, Z.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Wang, M.; Liu, E.; Zhao, N.; Shi, C.; Lin, D.; Zhu, F.; He, C. A powder-metallurgy-based strategy toward three-dimensional graphene-like network for reinforcing copper matrix composites. Nat. Commun. 2020, 11, 2775. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Connell, J.W. Advances in 2D boron nitride nanostructures: Nanosheets, nanoribbons, nanomeshes, and hybrids with graphene. Nanoscale 2012, 4, 6908–6939. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ding, Y. Structural, electronic, and magnetic properties of the semifluorinated boron nitride bilayer: A first-principles study. J. Phys. Chem. C 2013, 117, 3114–3121. [Google Scholar] [CrossRef]

- Li, L.H.; Chen, Y. Atomically Thin Boron Nitride: Unique Properties and Applications. Adv. Funct. Mater. 2016, 26, 2594–2608. [Google Scholar] [CrossRef] [Green Version]

- Kvashnin, D.; Ghorbani-Asl, M.; Shtansky, D.; Golberg, D.; Krasheninnikov, A.; Sorokin, P. Mechanical properties and current-carrying capacity of Al reinforced with graphene/BN nanoribbons: A computational study. Nanoscale 2016, 8, 20080–20089. [Google Scholar] [CrossRef] [Green Version]

- Krasheninnikov, A.V.; Berseneva, N.; Kvashnin, D.G.; Enkovaara, J.; Björkman, T.R.; Sorokin, P.; Shtansky, D.; Nieminen, R.M.; Golberg, D. Toward stronger Al–BN nanotube composite materials: Insights into bonding at the Al/BN interface from first-principles calculations. J. Phys. Chem. C 2014, 118, 26894–26901. [Google Scholar] [CrossRef]

- Li, L.H.; Cervenka, J.; Watanabe, K.; Taniguchi, T.; Chen, Y. Strong oxidation resistance of atomically thin boron nitride nanosheets. ACS Nano 2014, 8, 1457–1462. [Google Scholar] [CrossRef]

- Yoo, S.C.; Kim, J.; Lee, W.; Hwang, J.Y.; Ryu, H.J.; Hong, S.H. Enhanced mechanical properties of boron nitride nanosheet/copper nanocomposites via a molecular-level mixing process. Compos. Part B 2020, 195, 108088. [Google Scholar] [CrossRef]

- Song, Y.; He, G.; Wang, Y.; Chen, Y. Tribological behavior of boron nitride nanoplatelet reinforced Ni3Al intermetallic matrix composite fabricated by selective laser melting. Mater. Des. 2019, 165, 107579. [Google Scholar] [CrossRef]

- Ma, Z.; Huang, R.; Kostyantyn, G.; Wang, Y.; Li, R.; Liu, Z.; Xu, J. Tribology Properties of Titanium-Based Metals Reinforced by BN Nanosheets. Adv. Eng. Mater. 2021, 23, 2001351. [Google Scholar] [CrossRef]

- Liu, Z.; Li, R.; Wang, Y.; Xu, Z.; Tian, L.; Hu, H.; Khor, K.A. High-performance titanium-based composite strengthened with in-situ network-distributed 3D reinforcements. Mater. Sci. Eng. A 2021, 802, 140572. [Google Scholar] [CrossRef]

- Tian, W.-M.; Li, S.-M.; Wang, B.; Chen, X.; Liu, J.-H.; Yu, M. Graphene-reinforced aluminum matrix composites prepared by spark plasma sintering. Int. J. Miner. Metall. Mater. 2016, 23, 723–729. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, C.; Li, R.; Liu, H.; Xu, Z.; Yu, C.; Li, H. Enhanced mechanical properties of boron nitride nanosheets/copper composites with a bioinspired laminated structure. Compos. Interfaces 2021, 1–14. [Google Scholar] [CrossRef]

- Honarpisheh, M.; Asemabadi, M.; Sedighi, M. Investigation of annealing treatment on the interfacial properties of explosive-welded Al/Cu/Al multilayer. Mater. Des. 2012, 37, 122–127. [Google Scholar] [CrossRef]

- Kucharski, S.; Mróz, Z. Identification of wear process parameters in reciprocating ball-on-disc tests. Tribol. Int. 2011, 44, 154–164. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Li, R.; Wang, H.; Tian, L.; Li, H. Microstructure and Wear Behavior of Cold-Sprayed Cu-BNNSs Composite Coating. J. Therm. Spray Technol. 2021, 30, 1482–1492. [Google Scholar] [CrossRef]

- Li, F.Z.; Tian, L.H.; Li, R.T.; Wang, Y.; Liu, Z.Q. Microstructure and wear resistance properties of Al/Al-Cu-Cr-Fe composites consolidated using spark plasma sintering. Compos. Interfaces 2019. [Google Scholar] [CrossRef]

- Saheb, N.; Iqbal, Z.; Khalil, A.; Hakeem, A.S.; Al Aqeeli, N.; Laoui, T.; Al-Qutub, A.; Kirchner, R. Spark Plasma Sintering of Metals and Metal Matrix Nanocomposites: A Review. J. Nanomater. 2012, 2012, 983470. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.X.; Huang, L.J.; Kaveendran, B.; Geng, L.; Cui, X.P.; Wei, S.L.; Yin, F.X. Tensile and bending behaviors and characteristics of laminated Ti-(TiBw/Ti) composites with different interface status. Compos. Part B 2017, 108, 377–385. [Google Scholar] [CrossRef]

- Veillere, A.; Heintz, J.-M.; Chandra, N.; Douin, J.; Lahaye, M.; Lalet, G.; Vincent, C.; Silvain, J.-F. Influence of the interface structure on the thermo-mechanical properties of Cu–X (X= Cr or B)/carbon fiber composites. Mater. Res. Bull. 2012, 47, 375–380. [Google Scholar] [CrossRef]

- Yusupov, K.U.; Corthay, S.; Bondarev, A.V.; Kovalskii, A.M.; Matveev, A.T.; Arkhipov, D.; Golberg, D.V.; Shtansky, D.V. Spark plasma sintered Al-based composites reinforced with BN nanosheets exfoliated under ball milling in ethylene glycol. Mater. Sci. Eng. A 2019, 745, 74–81. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, H.; Zhao, H.; Liu, L.; Wu, Y. Friction and wear properties of copper matrix composites reinforced with short carbon fibers. Mater. Des. 2008, 29, 257–261. [Google Scholar] [CrossRef]

- Sarmadi, H.; Kokabi, A.; Reihani, S.S. Friction and wear performance of copper–graphite surface composites fabricated by friction stir processing (FSP). Wear 2013, 304, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Xian, Y.; Zou, Z.; Tu, C.; Ding, Y.; Liao, T.; Zhang, F.; Luo, Q.; Wu, G.; Gao, G. Identifying the effects of cobalt addition in copper-graphene nanoplatelet composites towards improved tribological performance. J. Alloys Compd. 2020, 835, 155444. [Google Scholar] [CrossRef]

- Algul, H.; Tokur, M.; Ozcan, S.; Uysal, M.; Çetinkaya, T.; Akbulut, H.; Alp, A. The effect of graphene content and sliding speed on the wear mechanism of nickel–graphene nanocomposites. Appl. Surf. Sci. 2015, 359, 340–348. [Google Scholar] [CrossRef]

- Li, L.H.; Xing, T.; Chen, Y.; Jones, R. Boron Nitride Nanosheets for Metal Protection. Adv. Mater. Interfaces 2014, 1, 1300132. [Google Scholar] [CrossRef] [Green Version]

- Paul, T.; Zhang, C.; Denis, N.; Boesl, B.; Agarwal, A. Role of ultrasonic treatment on microstructure, mechanical and tribological behavior of 2D boron nitride reinforced aluminum composites. Mater. Sci. Eng. A 2021, 809, 140970. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.; Li, R.; Liu, H.; Liu, W.; He, P. High-performance aluminum-based matrix composites reinforced with high content of boron nitride nanosheets. J. Alloy Compd. 2022, 906, 164358. [Google Scholar] [CrossRef]

- Shu, R.; Jiang, X.; Sun, H.; Shao, Z.; Song, T.; Luo, Z. Recent researches of the bio-inspired nano-carbon reinforced metal matrix composites. Compos. Part A 2020, 131, 105816. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; Li, R. The Wear Performance of Cu-Based Composites Reinforced with Boron Nitride Nanosheets. Materials 2022, 15, 5282. https://doi.org/10.3390/ma15155282

Zhu C, Li R. The Wear Performance of Cu-Based Composites Reinforced with Boron Nitride Nanosheets. Materials. 2022; 15(15):5282. https://doi.org/10.3390/ma15155282

Chicago/Turabian StyleZhu, Changshun, and Ruitao Li. 2022. "The Wear Performance of Cu-Based Composites Reinforced with Boron Nitride Nanosheets" Materials 15, no. 15: 5282. https://doi.org/10.3390/ma15155282

APA StyleZhu, C., & Li, R. (2022). The Wear Performance of Cu-Based Composites Reinforced with Boron Nitride Nanosheets. Materials, 15(15), 5282. https://doi.org/10.3390/ma15155282