Study on an Epoxy Resin System Used to Improve the Elasticity of Oil-Well Cement-Based Composites

Abstract

:1. Introduction

2. Experiment and Method

2.1. Materials

2.2. Specimen Preparation

2.3. Thermogravimetric (TG) Analysis

2.4. Flexibility of the Pure Resin System

2.5. Mechanical Properties

2.6. X-ray Diffraction (XRD)

2.7. Scanning Electron Microscopy/Energy Dispersive Spectrometer (SEM/EDS)

3. Results and Discussion

3.1. Properties of Cured Resin System

3.1.1. Flexibility of Cured Resin System

3.1.2. Thermogravimetric Analysis

3.1.3. Micromorphology of Cured Resin System

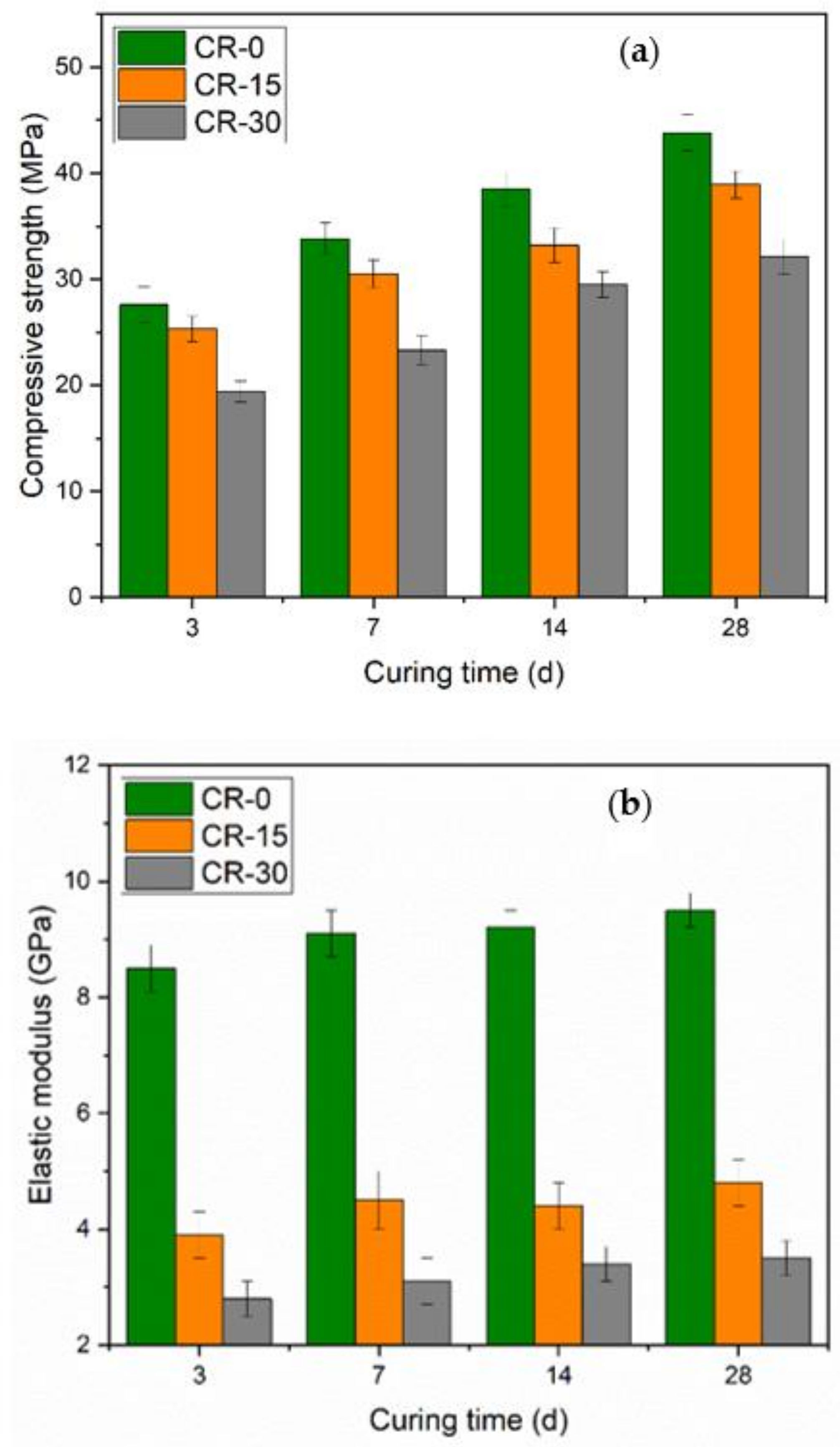

3.2. Mechanical Properties of Resin-Modified Cement-Based Composites

3.3. Structural Characteristics of Resin-Modified Cement-Based Composites

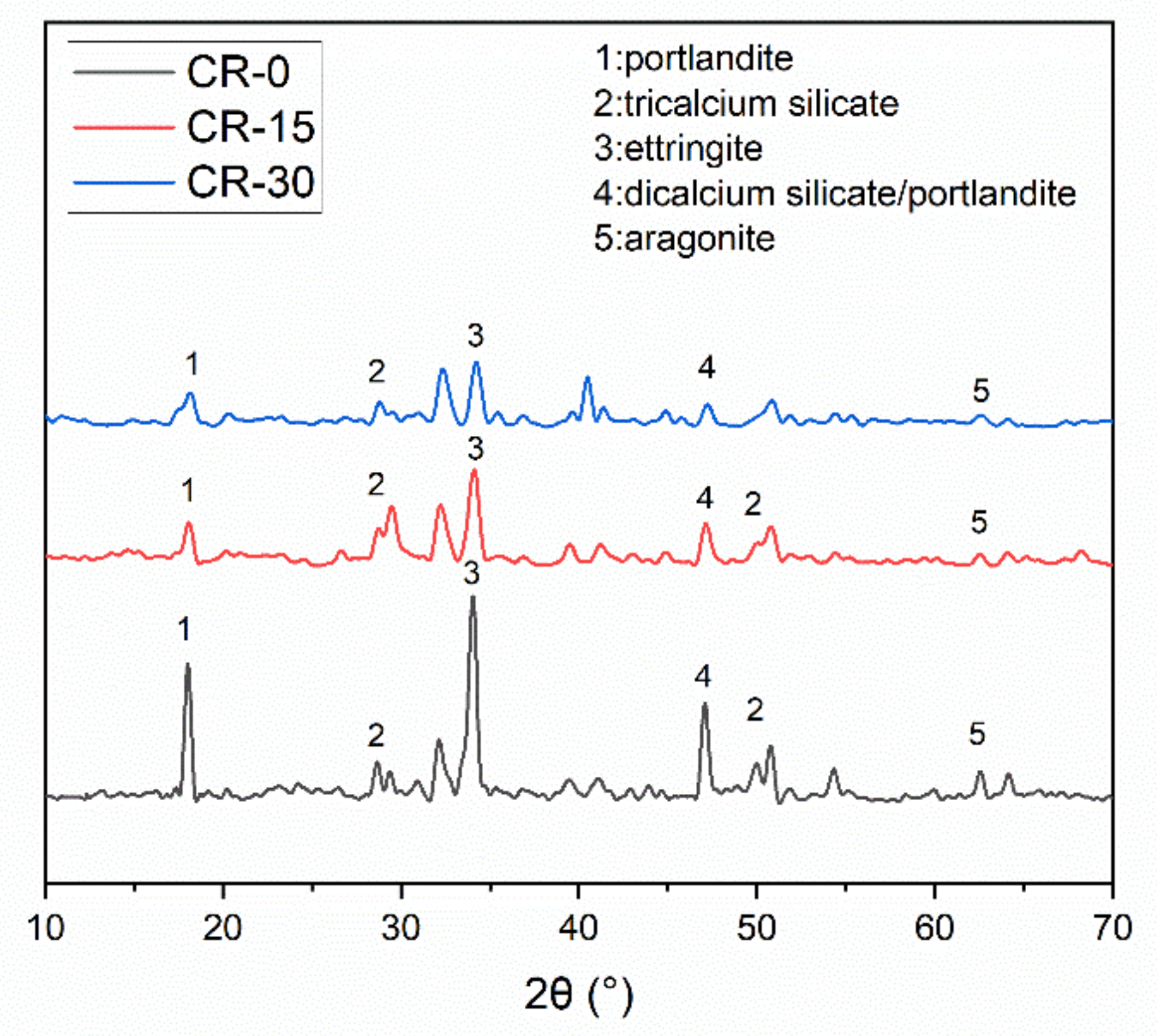

3.3.1. Phase Analysis

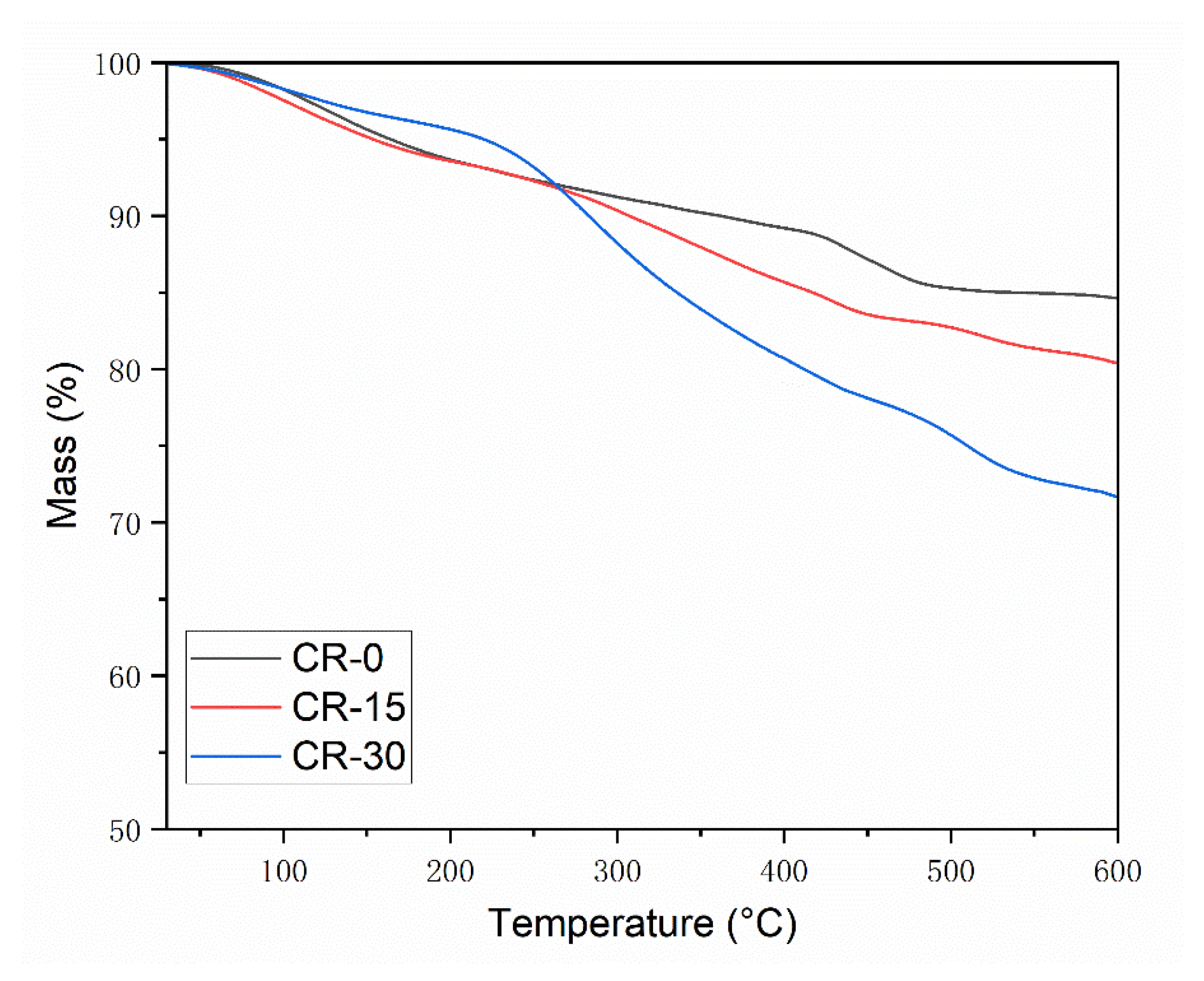

3.3.2. Thermogravimetric Analysis

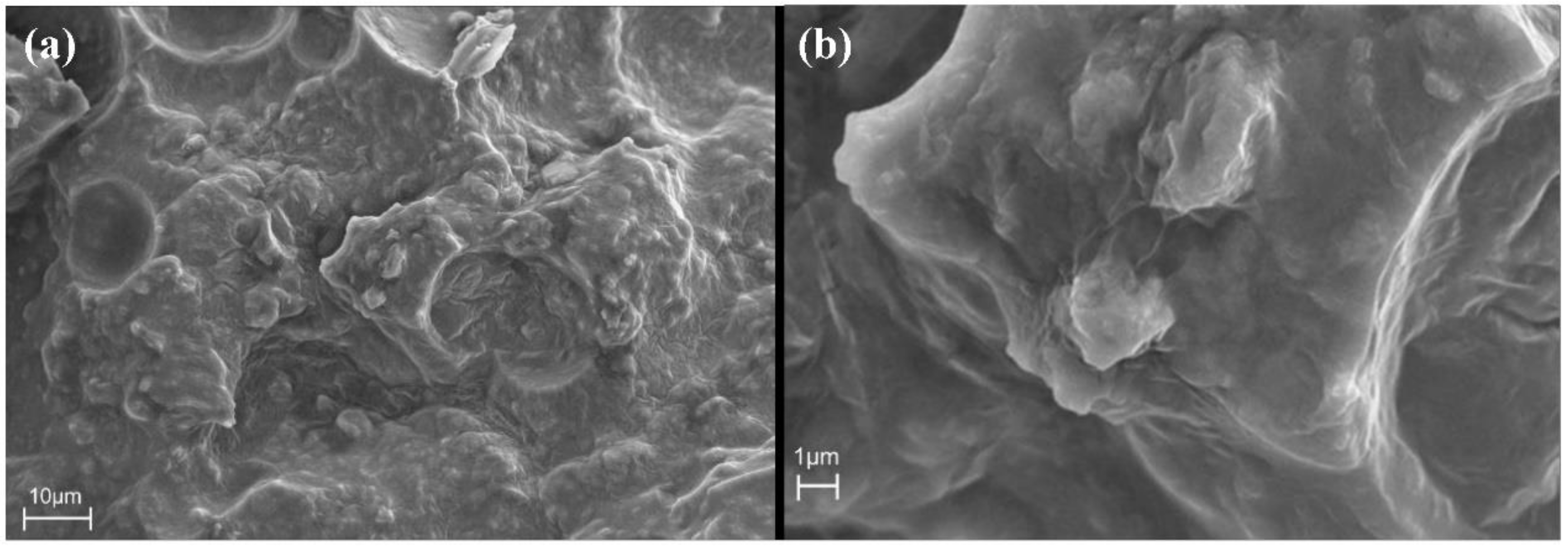

3.3.3. Micromorphology Analysis

4. Conclusions

- (1)

- The structure of cured resin is compact, and its thermal decomposition temperature is above 243.9 °C, which is higher than the application temperature of cement slurry. The shape recovery rate of cured resin elastomer is nearly 100% after being subjected to large compressive strain.

- (2)

- After the resin system mixed with oil-well cement, the compressive strength and elastic modulus of cement stone containing 30% resin decreased by 26.7% and 63.2%, respectively, compared with the blank cement stone. The decrease in elastic modulus is much larger than that of the compressive strength, and the elasticity of the cement stone obviously improved.

- (3)

- The addition of resin delays the hydration of cement and reduces the formation of hydration products, which is the reason for the decrease in compressive strength.

- (4)

- Due to the decomposition of resin, the mass loss of resin cement-based composites increases when the temperature is greater than 243.9 °C, and due to increased calcium hydroxide, the pure cement stone decreases sharply at 420–510 °C.

- (5)

- In the hydration products filled with resin particles, the morphology is consistent with that of the cured resin in the vicinity of the resin particles, and the hydration products are covered with polymer film. These effects reduce the elastic modulus of the cement-based composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Deng, Y. Mechanical properties of hybrid short fibers reinforced oil well cement by polyester fiber and calcium carbonate whisker. Constr. Build. Mater. 2018, 182, 258–272. [Google Scholar] [CrossRef]

- Jafariesfad, N.; Sangesland, S.; Gawel, K.; Torsæter, M. New materials and technologies for life-lasting cement sheath: A review of recent advances. SPE Drill. Complet. 2020, 35, 262–278. [Google Scholar] [CrossRef]

- Li, Y.; Dong, S.F.; Ahmed, R.; Zhang, L.; Han, B. Improving the mechanical characteristics of well cement using botryoid hybrid nano-carbon materials with proper dispersion. Constr. Build. Mater. 2020, 270, 121464. [Google Scholar] [CrossRef]

- Paiva, L.C.M.; Ferreira, I.M.; Martinelli, A.E.; Freitas, J.C.D.O.; Bezerra, U.T. Milled basalt fiber reinforced Portland slurries for oil well applications. J. Pet. Sci. Eng. 2018, 175, 184–189. [Google Scholar] [CrossRef]

- Zhu, J.; Wei, J.; Yu, Q.; Xu, M.; Luo, Y. Hybrid effect of wollastonite fiber and carbon fiber on the mechanical properties of oil well cement pastes. Adv. Mater. Sci. Eng. 2020, 2020, 4618035. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, M.; Liu, W.; Feng, J.; Zhang, H.; Liu, M.; Guo, J. Toughening effects of well-dispersed carboxylated styrene-butadiene latex powders on the properties of oil well cement. Constr. Build. Mater. 2022, 340, 127768. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, Z.; Gu, T.; Zeng, L.; Yao, L.; Chen, Z.; Huang, K.; Zhang, Z.; Zhang, C.; Liu, K.; et al. Study on the dynamic and static mechanical properties of microsphere rubber powder reinforced oil well cement composites. Constr. Build. Mater. 2021, 309, 125145. [Google Scholar] [CrossRef]

- Pang, B.; Zhang, Y.; Liu, G. Study on the effect of waterborne epoxy resins on the performance and microstructure of cement paste. Constr. Build. Mater. 2018, 167, 831–845. [Google Scholar] [CrossRef]

- Cestari, A.R.; Vieira, E.F.; Tavares, A.M.; Andrade, M.A. Cement–epoxy/water interfaces—Energetic, thermodynamic, and kinetic parameters by means of heat-conduction microcalorimetry. J. Colloid Interface Sci. 2010, 343, 162–167. [Google Scholar] [CrossRef]

- Du, J.; Bu, Y.; Shen, Z.; Hou, X.; Huang, C. Effects of epoxy resin on the mechanical performance and thickening properties of geopolymer cured at low temperature. Mater. Des. 2016, 109, 133–145. [Google Scholar] [CrossRef]

- Yami, A.; Buwaidi, H.; Al-Herz, A.; Mukherjee, T.S.; Bedford, D.; Viso, R.; Hugentobler, K. Application of heavy weight cement-resin blend system to prevent cca pressure in saudi arabia deep gas fields. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 4–6 April 2017; p. SPE-185337-MS. [Google Scholar] [CrossRef]

- Liu, Y.L.; Li, Z.Y.; Xue, Y.T.; Zhou, B.; Sun, H.; Su, D.H.; Sun, J.F. Study on mechanical properties of cementing waterborne epoxy cement. Bull. Chin. Ceram. Soc. 2019, 38, 339–343. [Google Scholar] [CrossRef]

- Cestari, A.R.; Vieira, E.F.; Silva, E.C.; Alves, F.J.; Andrade, M.A. Synthesis, characterization and hydration analysis of a novel epoxy/superplasticizer oilwell cement slurry—Some mechanistic features by solution microcalorimetry. J. Colloid Interface Sci. 2013, 392, 359–368. [Google Scholar] [CrossRef] [Green Version]

- Djouani, F.; Connan, C.; Chehimi, M.M.; Benzarti, K. Interfacial chemistry of epoxy adhesives on hydrated cement paste. Surf. Interface Anal. 2010, 40, 146–150. [Google Scholar] [CrossRef]

- Yu, Y.; Han, Z.; Zhu, X.C.; Li, H.R. Effect of the pore structure on the elastic modulus of crumb rubber cement mortar. Bull. Chin. Ceram. Soc. 2015, 34, 892–896. [Google Scholar] [CrossRef]

- Chaudhary, R.G.; Ali, P.; Gandhare, N.V.; Tanna, J.A.; Juneja, H.D. Thermal decomposition kinetics of some transition metal coordination polymers of fumaroyl bis (paramethoxyphenylcarbamide) using DTG/DTA techniques. Arab. J. Chem. 2019, 12, 1070–1082. [Google Scholar] [CrossRef] [Green Version]

- Xie, Q.Y.; Chen, D.D.; Ding, Y.W. Thermogravimetric analysis and its applications in polymer characterization. Acta Polym. Sin. 2022, 53, 193–210. [Google Scholar] [CrossRef]

- Al-Yami, A.; Wagle, V.; Jimenez, W.C.; Jones, P. Evaluation of epoxy resin thermal degradation and its effect on preventing sustained casing pressure in oil and gas wells. Arab. J. Sci. Eng. 2019, 44, 6109–6118. [Google Scholar] [CrossRef]

- Song, J.; Xu, M.; Liu, W.; Wang, X.; Xu, P.; Huang, F.; Pan, Y. Thermoplastic rubber (TPR) modified by a silane coupling agent and its influence on the mechanical properties of oil well cement pastes. Adv. Mater. Sci. Eng. 2019, 2019, 3587081. [Google Scholar] [CrossRef] [Green Version]

- Maagi, M.T.; Jun, G. Effect of the particle size of nanosilica on early age compressive strength in oil-well cement paste. Constr. Build. Mater. 2020, 262, 120393. [Google Scholar] [CrossRef]

- Ouyang, X.; Shi, C.; Wu, Z.; Li, K.; Shan, B.; Shi, J. Experimental investigation and prediction of elastic modulus of ultra-high performance concrete (UHPC) based on its composition. Cem. Concr. Res. 2020, 138, 106241. [Google Scholar] [CrossRef]

- Moghadam, H.A.; Mirzaei, A.; Dehghi, Z.A. The relation between porosity, hydration degree and compressive strength of Portland cement pastes in the presence of aluminum chloride additive. Constr. Build. Mater. 2020, 250, 118884. [Google Scholar] [CrossRef]

- Liu, Z.; Sha, A.; Hu, L.; Zou, X. A laboratory study of Portland cement hydration under low temperatures. Road Mater. Pavement Des. 2017, 18, 12–22. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, J.; Shi, M. Quantitative Analysis of the Calcium Hydroxide Content of EVA-Modified Cement Paste Based on TG-DSC in a Dual Atmosphere. Materials 2022, 15, 2660. [Google Scholar] [CrossRef]

- Du, J.; Bu, Y.; Shen, Z. Interfacial properties and nanostructural characteristics of epoxy resin in cement matrix. Constr. Build. Mater. 2018, 164, 103–112. [Google Scholar] [CrossRef]

| Material | Content (wt%) |

|---|---|

| Neat resin | 100 |

| Hardener | 20 |

| Material | Content (wt%) |

|---|---|

| Cement | 100 |

| Freshwater | 44 |

| Filtration reducer | 2 |

| Dispersant | 1 |

| Micro silica | 1.5 |

| Sample Number | Cement Slurry Content (%) | Resin System Content (%) |

|---|---|---|

| CR-0 | 100 | 0 |

| CR-15 | 85 | 15 |

| CR-30 | 70 | 30 |

| Curing Time (d) | V (%) | H (%) |

|---|---|---|

| 3 | 50.0 | 100 |

| 7 | 50.0 | 98.6 |

| 14 | 50.0 | 99.2 |

| 28 | 50.0 | 100 |

| Element | wt% | Atomic% |

|---|---|---|

| C | 67.83 | 76.69 |

| O | 23.75 | 20.45 |

| Si | 0.33 | 0.16 |

| S | 0.39 | 0.17 |

| Cl | 2.35 | 0.81 |

| Ca | 4.28 | 1.58 |

| Zr | 1.07 | 0.14 |

| Total | 100.00 | 100.00 |

| Element | wt% | Atomic% |

|---|---|---|

| C | 15.02 | 28.06 |

| O | 25.82 | 36.22 |

| Na | 1.00 | 0.98 |

| Mg | 0.20 | 0.18 |

| Al | 0.92 | 0.76 |

| Si | 7.37 | 5.88 |

| S | 2.67 | 1.87 |

| Cl | 3.86 | 2.44 |

| K | 0.55 | 0.32 |

| Ca | 39.17 | 21.92 |

| Fe | 3.42 | 1.37 |

| Total | 100.00 | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Xu, M.; Tan, C.; You, F.; Wang, X.; Zhou, S. Study on an Epoxy Resin System Used to Improve the Elasticity of Oil-Well Cement-Based Composites. Materials 2022, 15, 5258. https://doi.org/10.3390/ma15155258

Song J, Xu M, Tan C, You F, Wang X, Zhou S. Study on an Epoxy Resin System Used to Improve the Elasticity of Oil-Well Cement-Based Composites. Materials. 2022; 15(15):5258. https://doi.org/10.3390/ma15155258

Chicago/Turabian StyleSong, Jianjian, Mingbiao Xu, Chunqin Tan, Fuchang You, Xiaoliang Wang, and Shanshan Zhou. 2022. "Study on an Epoxy Resin System Used to Improve the Elasticity of Oil-Well Cement-Based Composites" Materials 15, no. 15: 5258. https://doi.org/10.3390/ma15155258

APA StyleSong, J., Xu, M., Tan, C., You, F., Wang, X., & Zhou, S. (2022). Study on an Epoxy Resin System Used to Improve the Elasticity of Oil-Well Cement-Based Composites. Materials, 15(15), 5258. https://doi.org/10.3390/ma15155258