Effect of Cd on Mechanical Properties of Al-Si-Cu-Mg Alloys under Different Multi-Stage Solution Heat Treatment

Abstract

1. Introduction

2. Experimental Procedure

3. Results

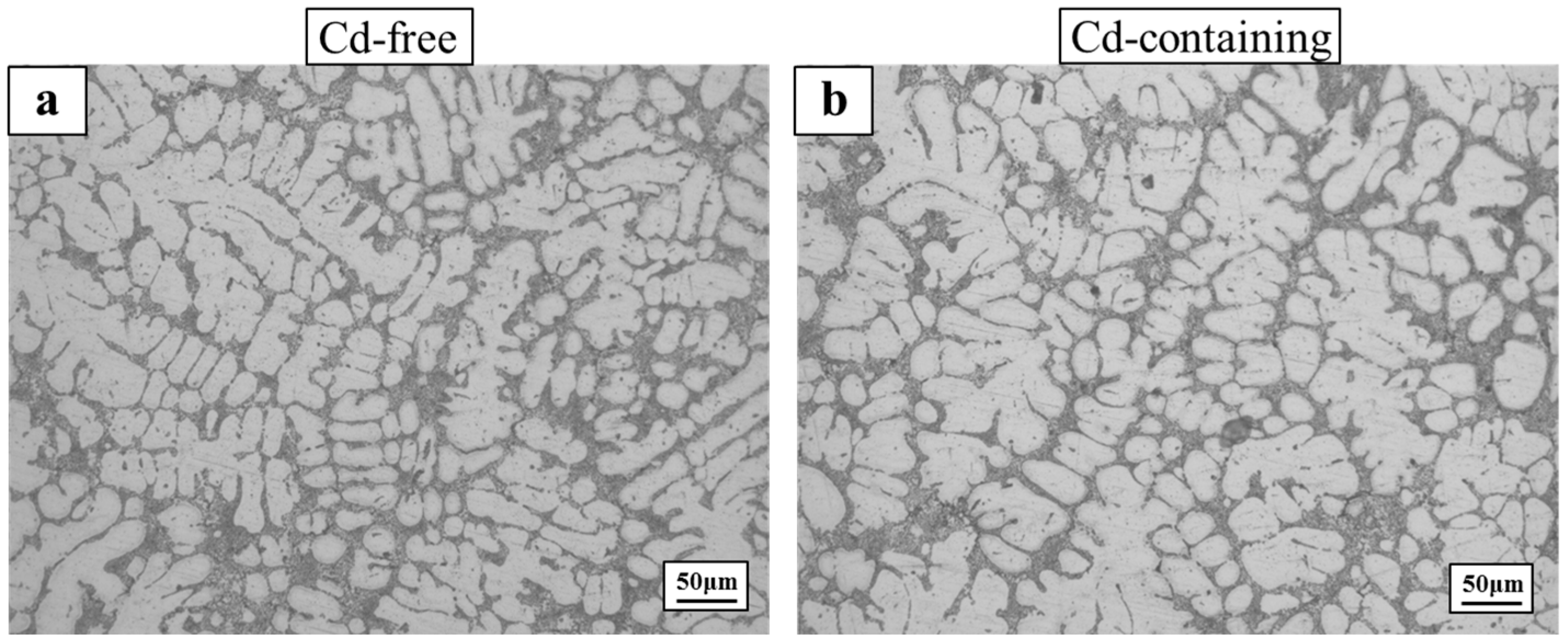

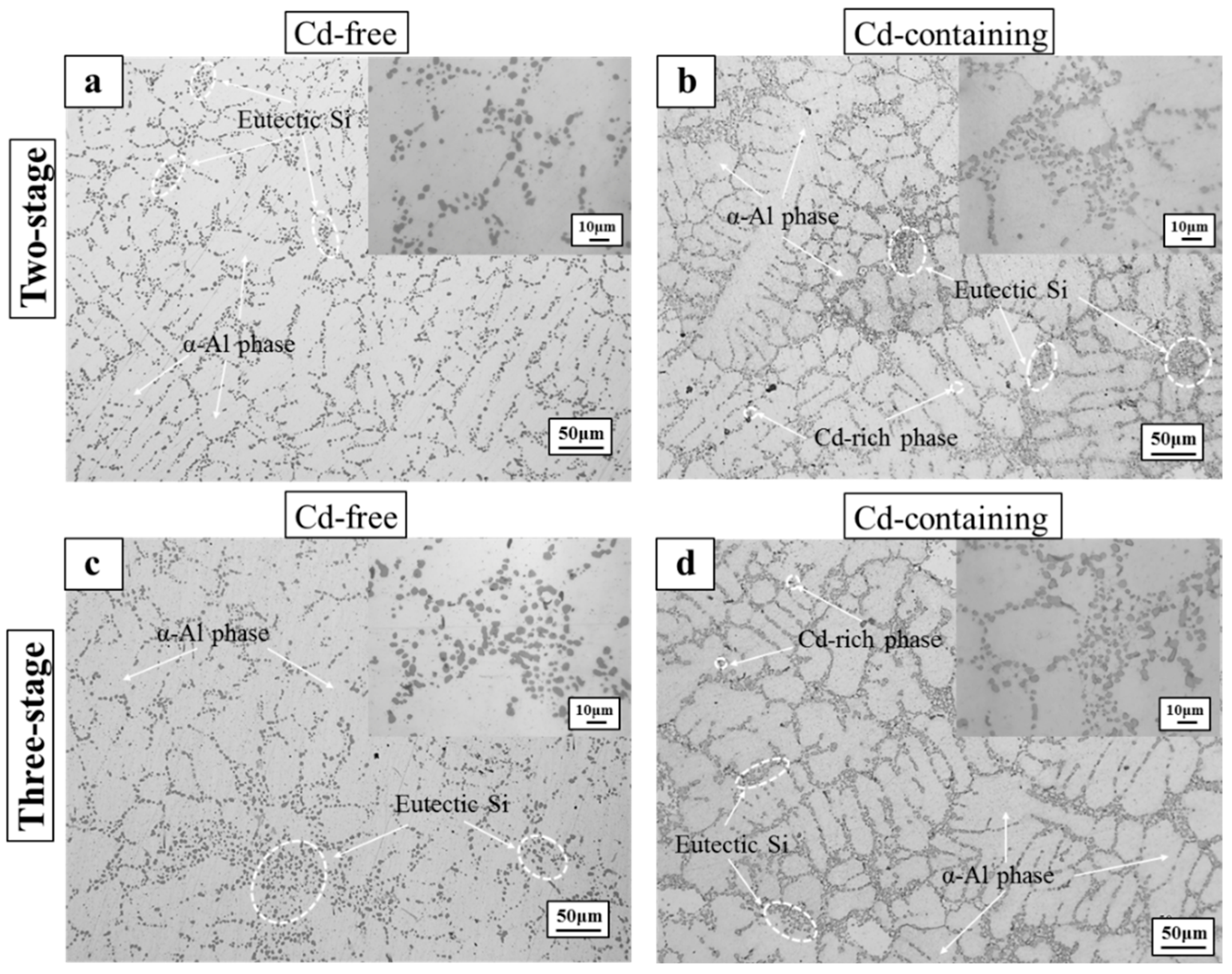

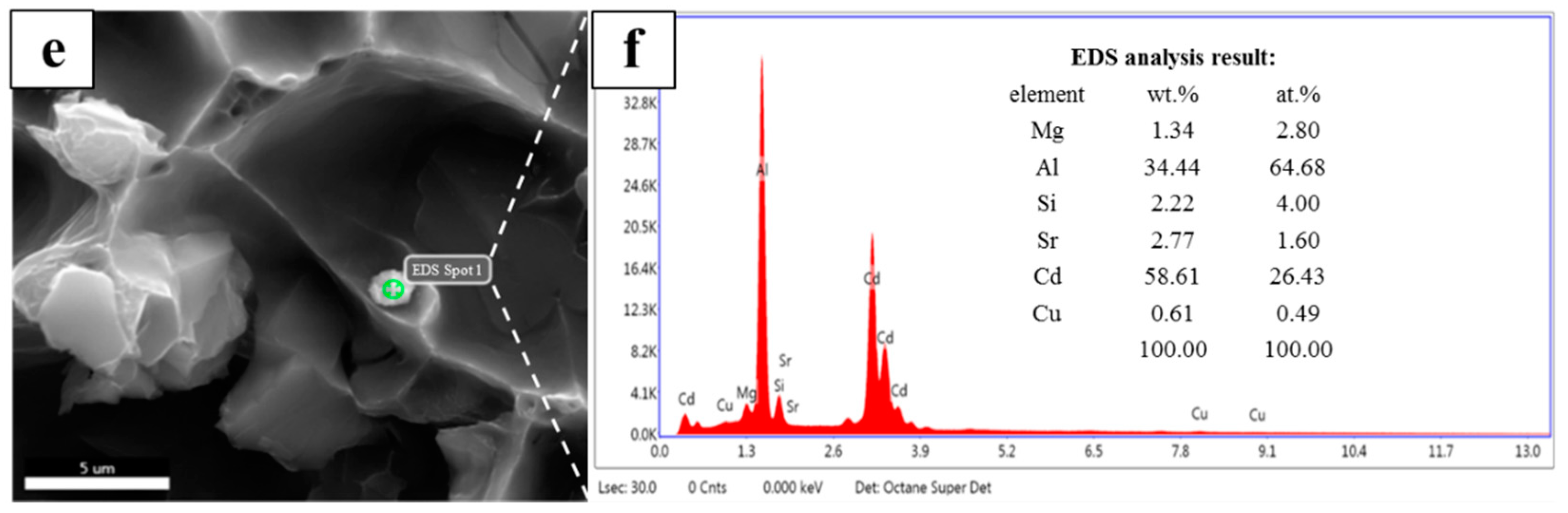

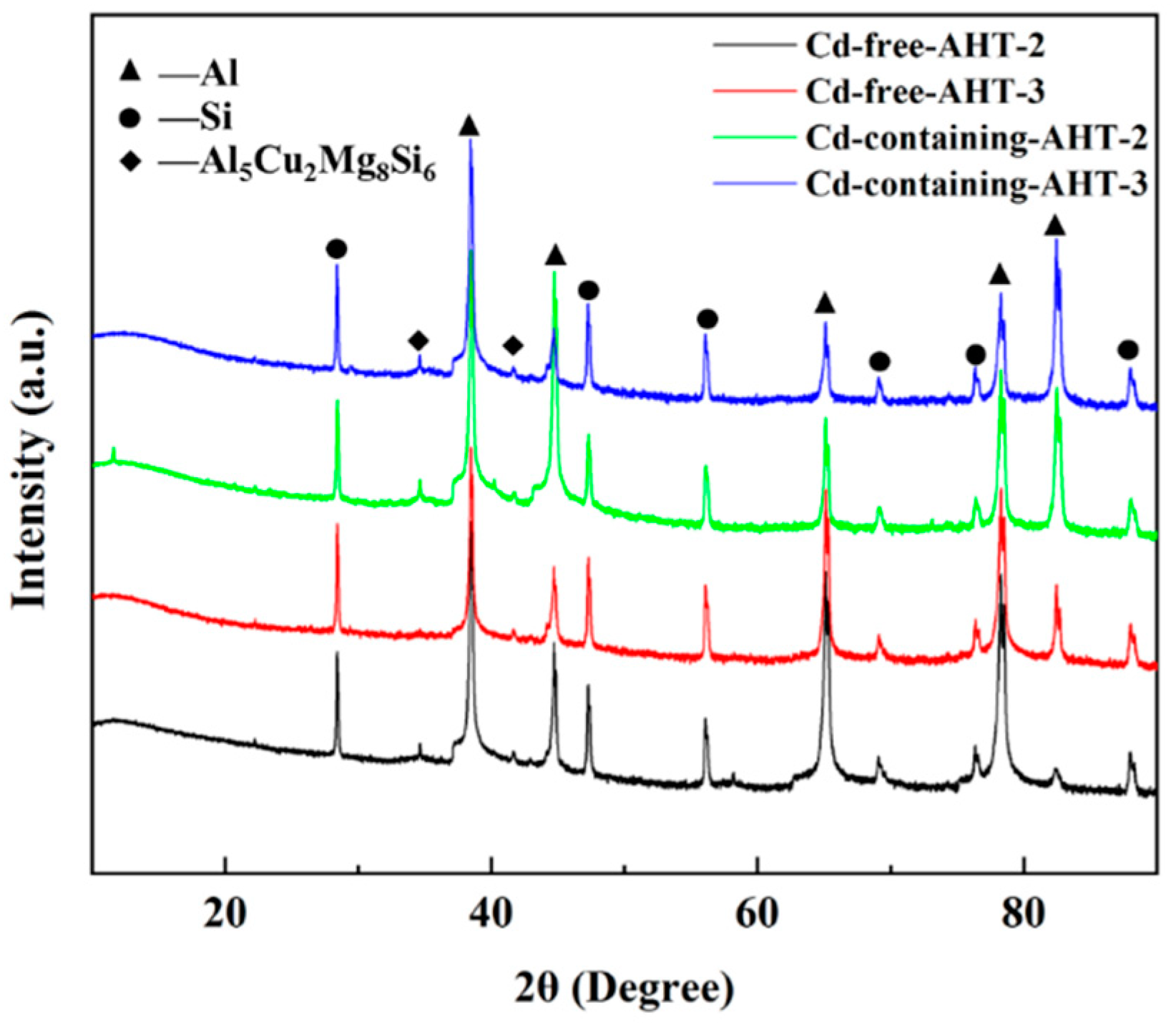

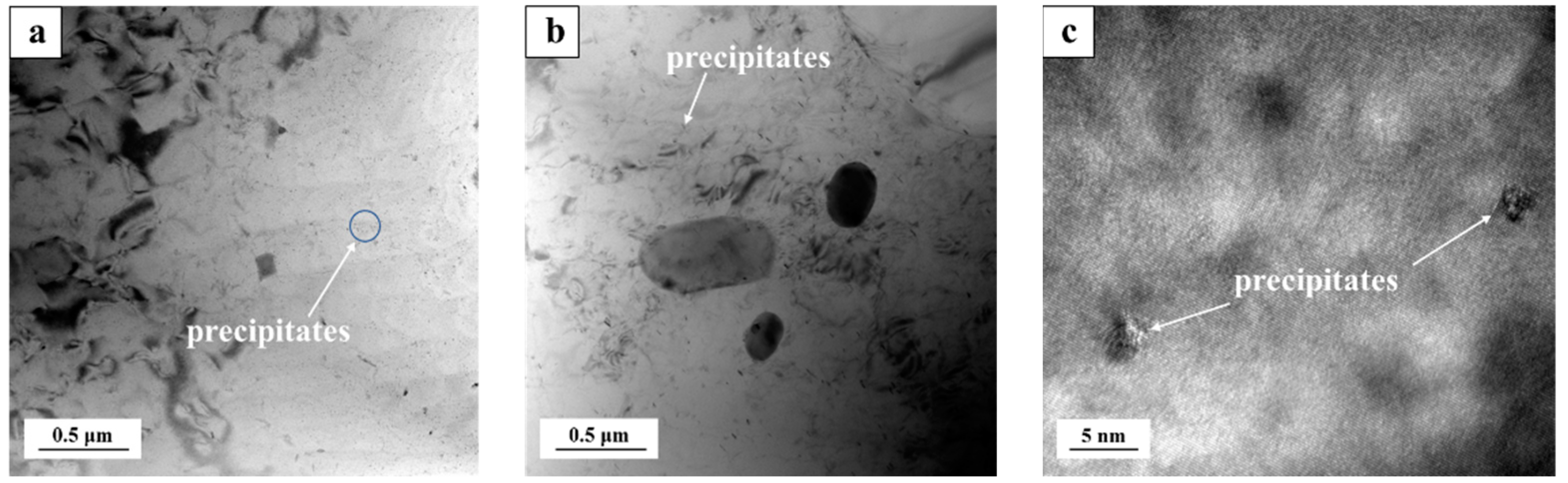

3.1. Microstructure

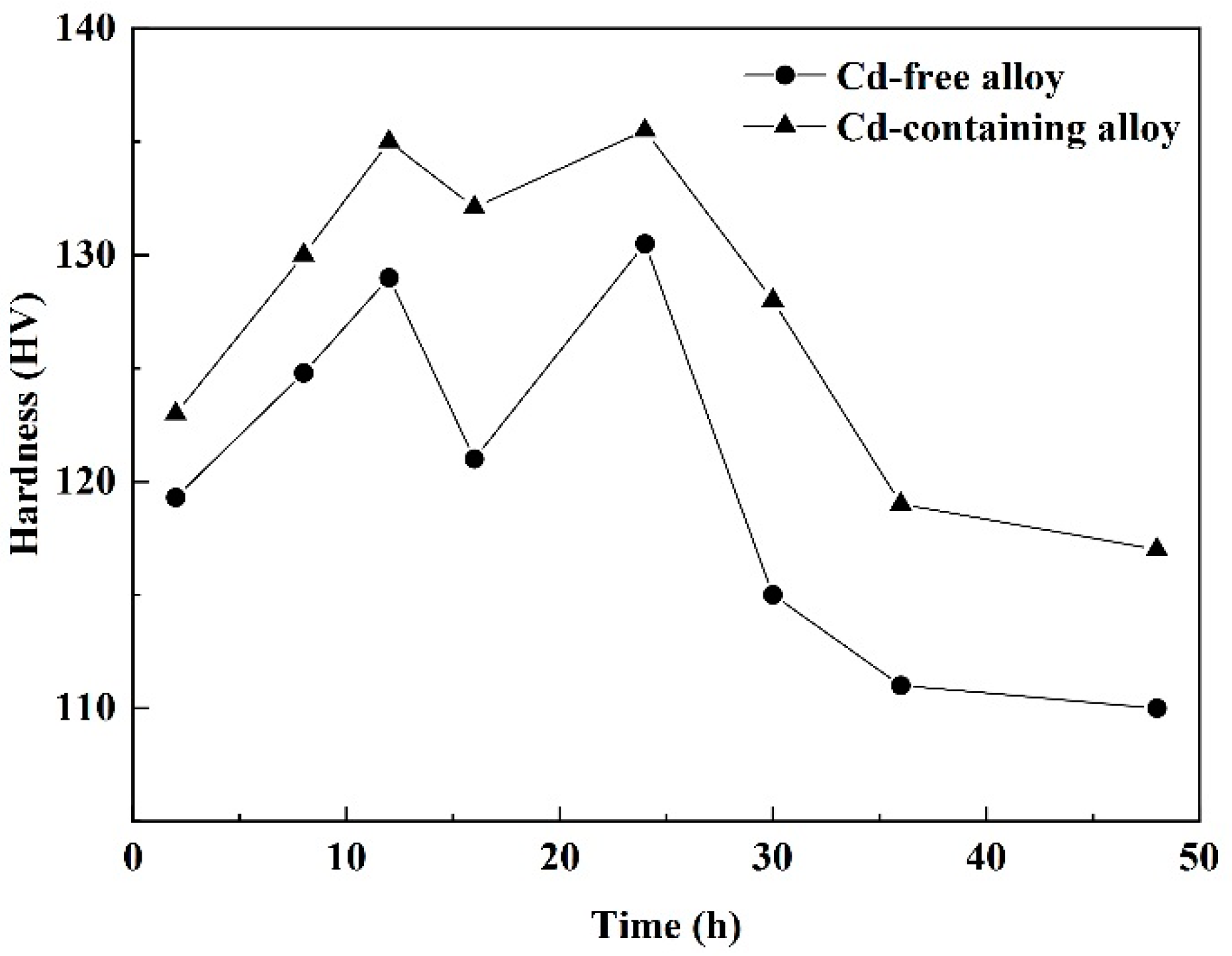

3.2. Aging Hardness

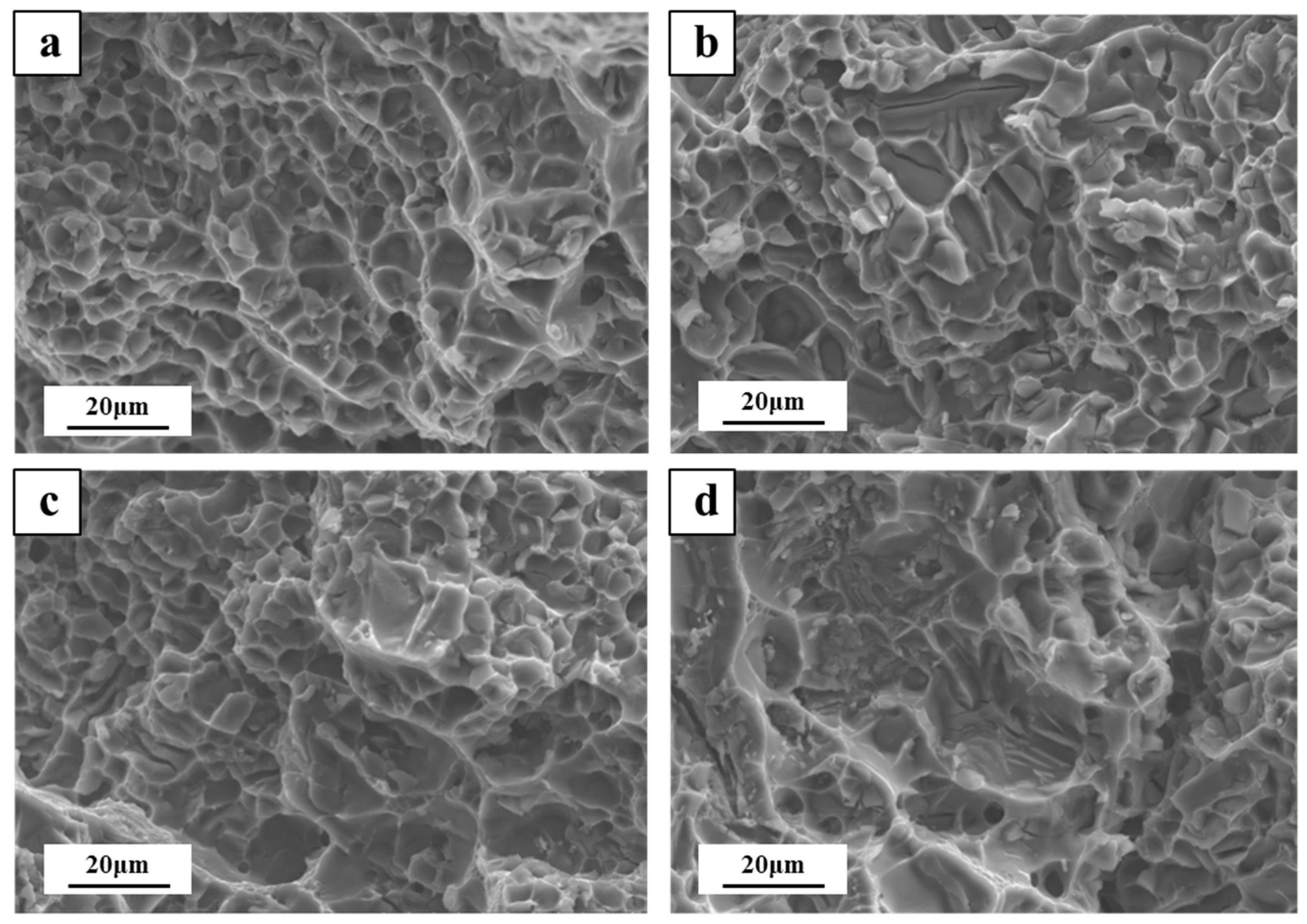

3.3. Tensile Properties and Fracture Analysis

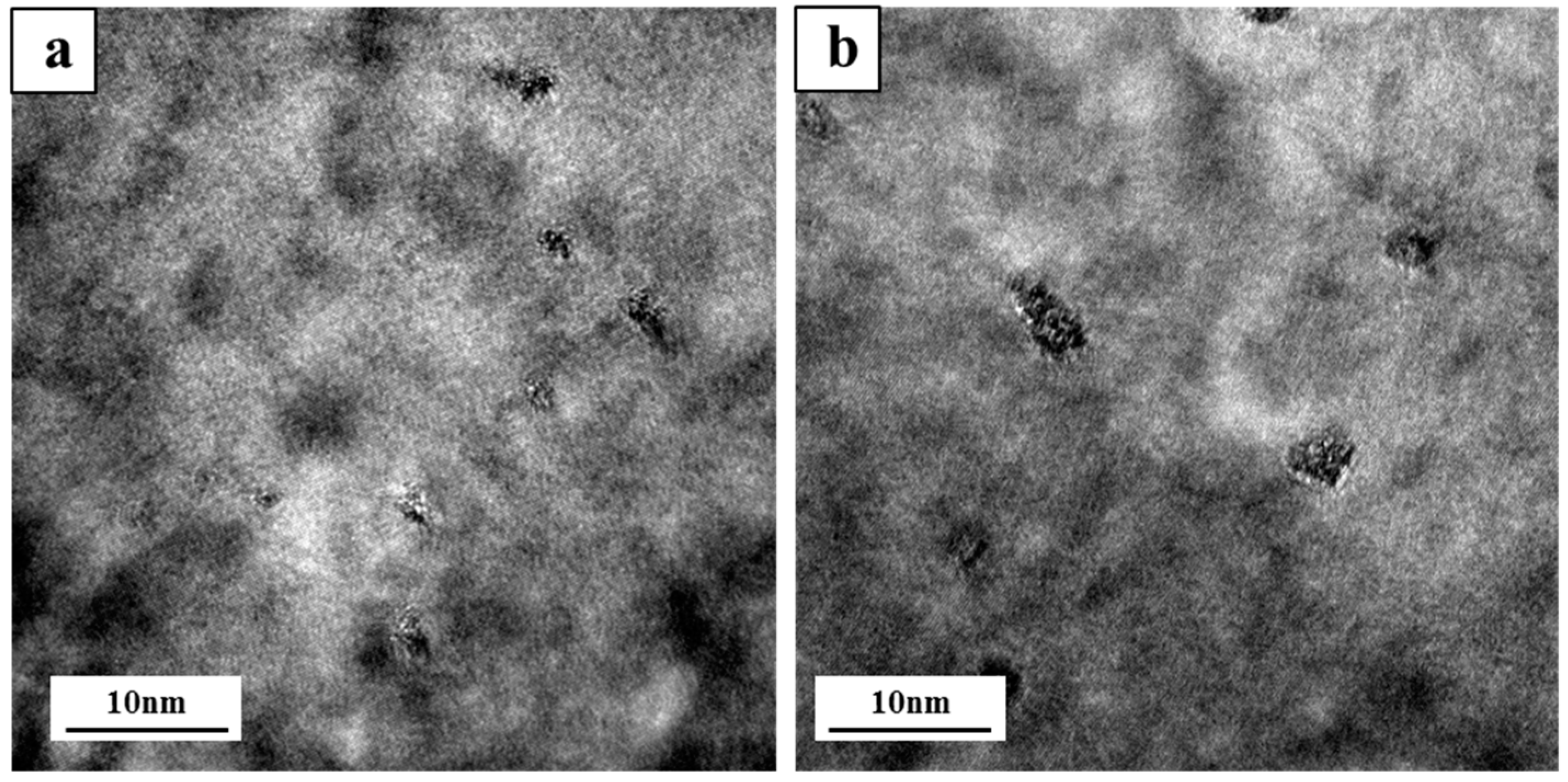

4. Discussion

4.1. Equilibrium Phase Diagram Analysis

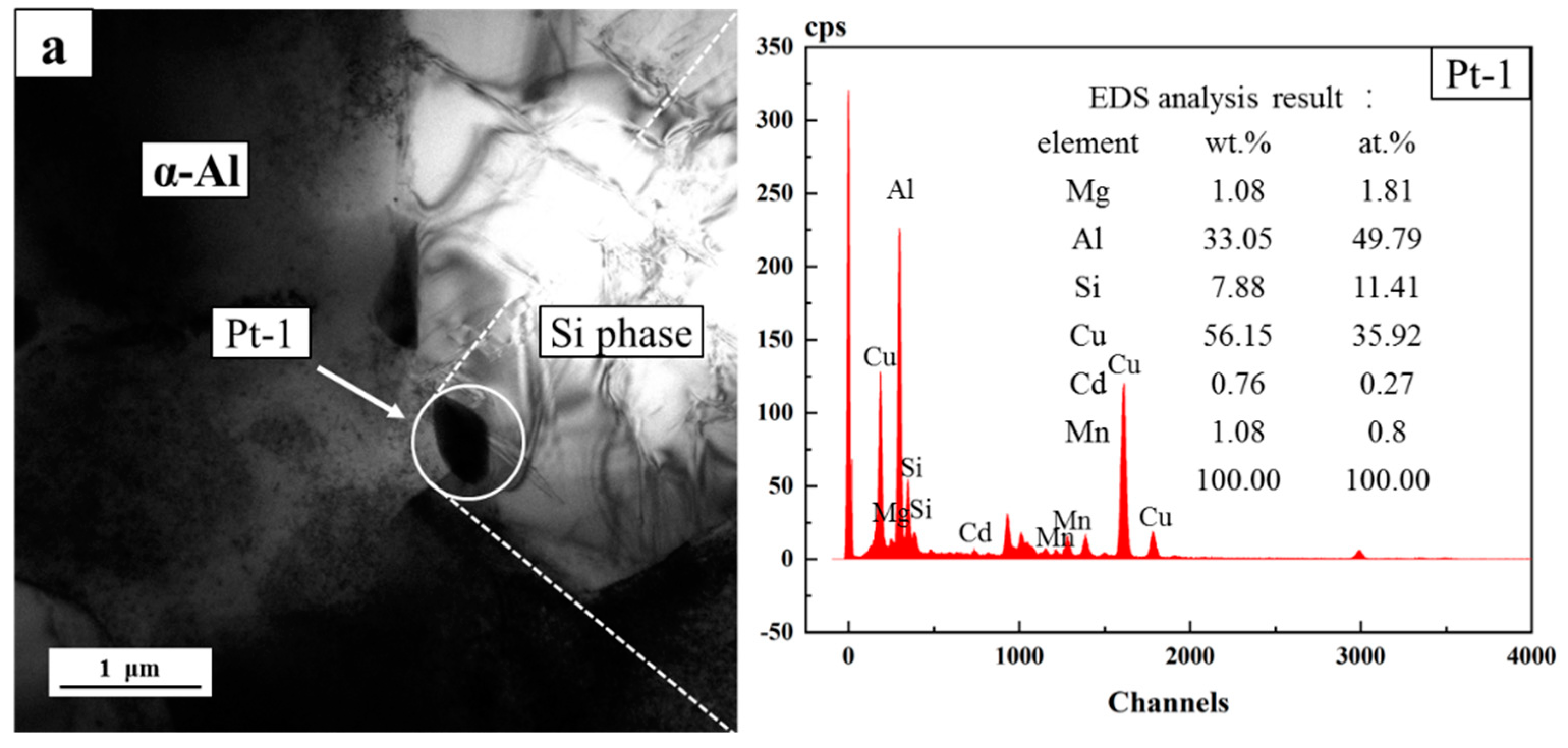

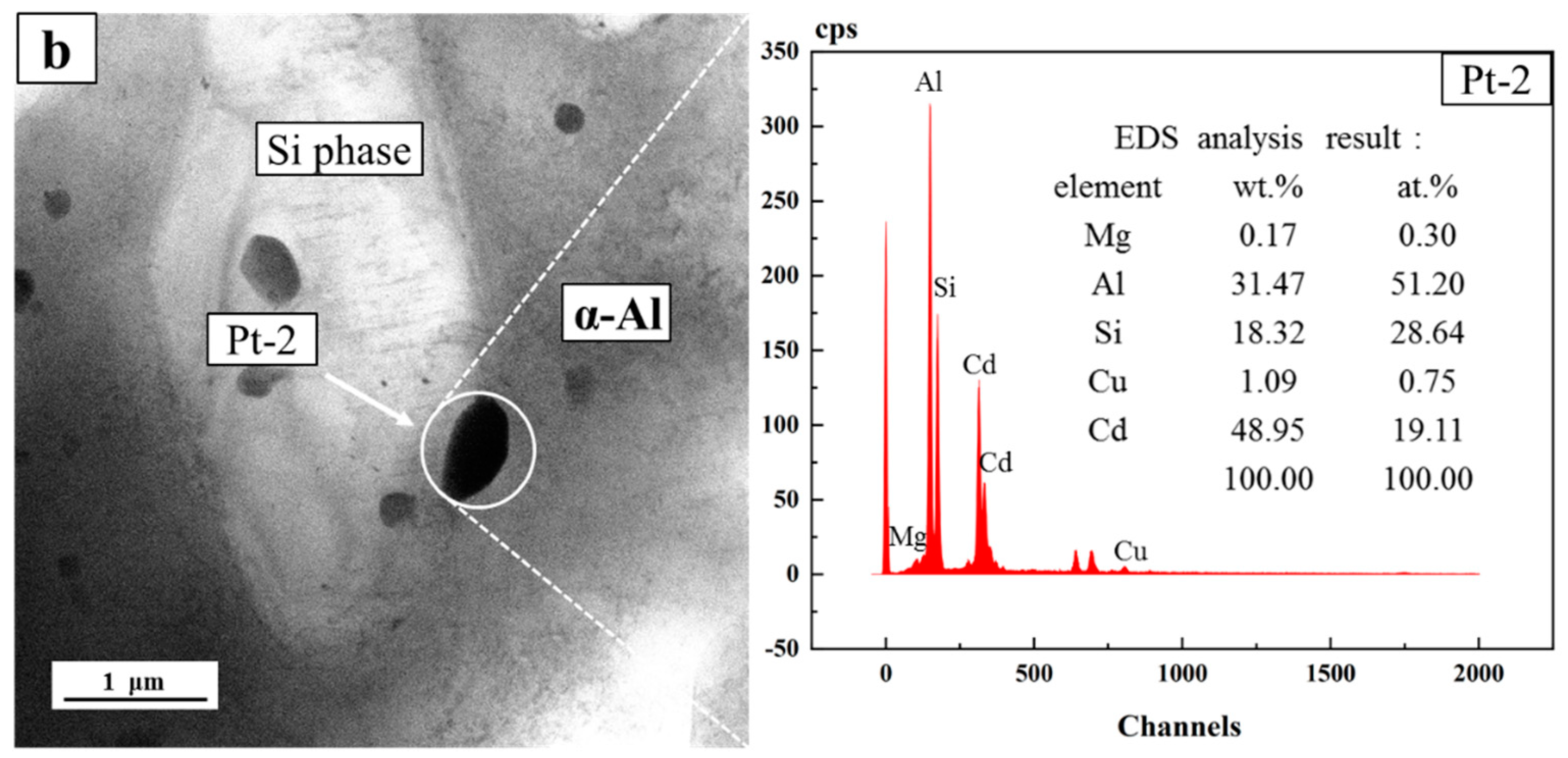

4.2. Low-Melting Cd Phase

5. Conclusions

- YS and UTS of Cd-containing alloys are stronger than Cd-free alloys, but the elongation is lower than the Cd-free alloys.

- The addition of Cd promotes the precipitation of the θ″ phase in the Al-Si-Cu-Mg alloy and improves the mechanical properties of the alloy.

- For the Cd-free alloys, a long solution time is conducive to the full diffusion and homogenization of copper elements, thereby improving the precipitation-strengthening ability of the alloy. For the Cd-containing alloys, the Cd element is enriched in the Si-Al phase boundary, which reduces the precipitation-strengthening ability of Cd, resulting in the alloys’ mechanical properties after a three-stage heat treatment being lower than that of a two-stage heat treatment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- SjöLander, E.; Seifeddine, S. The heat treatment of Al-Si-Cu-Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Samuel, F.H. Incipient melting of Al5Mg8Si6Cu2 and Al2Cu intermetallics in unmodified and strontium-modified Al-Si-Cu-Mg (319) alloys during solution heat treatment. J. Mater. Sci. 1998, 33, 2283–2297. [Google Scholar] [CrossRef]

- Toda, H.; Nishimura, T.; Uesugi, K.; Suzuki, Y.; Kobayashi, M. Influence of high-temperature solution treatments on mechanical properties of an Al-Si-Cu aluminum alloy. Acta Mater. 2010, 58, 2014–2025. [Google Scholar] [CrossRef]

- Aguilera Luna, I.; Mancha Molinar, H.; Castro Román, M.J.; Escobedo Bocardo, J.C.; Herrera Trejo, M. Improvement of the tensile properties of an Al-Si-Cu-Mg aluminum industrial alloy by using multi stage solution heat treatments. Mater. Sci. Eng. A 2013, 561, 1–6. [Google Scholar] [CrossRef]

- Ma, Z.; Samuel, E.; Mohamed, A.; Samuel, A.M.; Samuel, F.H.; Doty, H.W. Influence of aging treatments and alloying additives on the hardness of Al-11Si-2.5Cu-Mg alloys. Mater. Des. 2010, 31, 3791–3803. [Google Scholar] [CrossRef]

- Amerioon, A.; Emamy, M.; Ashuri, G. Investigation the Effect of Al-5Ti-1B Grain Refiner and T6 Heat Treatment on Tensile Properties of Al-8%Mg. Procedia Mater. Sci. 2015, 11, 32–37. [Google Scholar] [CrossRef][Green Version]

- Hardy, H.K. The ageing characteristics of ternary aluminium-copper alloys with cadmium indium or tin. J. Inst. Met. 1952, 80, 483–492. [Google Scholar]

- Raynor, G.V.; Lee, J.A. The tin-rich intermediate phases in the alloys of tin with cadmium, indium and mercury. Acta Mater. 1954, 2, 616–620. [Google Scholar] [CrossRef]

- Runxia, L.I.; Rongde, L.I.; Guan, H. Effect of Cd addition on the aging process of Al-Si-Cu-Mg cast alloy. Acta Mater. 2004, 40, 867–872. [Google Scholar]

- Sofyan, B.T.; Raviprasad, K.; Ringer, S.P. Effects of microalloying with Cd and Ag on the precipitation process of Al-4Cu-0.3Mg (wt%) alloy at 200 °C. Micron 2001, 32, 851–856. [Google Scholar] [CrossRef]

- Lu, G.; Sun, B.; Wang, J.; Liu, Y.; Liu, C. Enhanced high-temperature age-hardening behavior and mechanical properties of Al–Mg–Si alloys via microalloying with Cd. Mater. Sci. Eng. A 2021, 825, 141910. [Google Scholar] [CrossRef]

- Feng, Q.; Jin, S.; Gang, S.; Li, Y. Enhanced dispersoid precipitation and dispersion strengthening in an Al alloy by microalloying with Cd. Acta Mater. 2018, 157, 114–125. [Google Scholar]

- Gogoi, S.; Banerjee, S.; Kirtania, S.; Kashyap, S.; Bhadra, R. Computational modelling of tensile flow parameters for 2219Al alloys microalloyed with Cd. Int. J. Interact. Des. M 2022, 1–10. [Google Scholar] [CrossRef]

- Bourgeois, L.; Nie, J.F.; Muddle, B.C. Assisted nucleation of θ′ phase in Al–Cu–Sn: The modified crystallography of tin precipitates. Philos. Mag. 2005, 85, 3487–3509. [Google Scholar] [CrossRef]

- Ringer, S.P.; Hono, K.; Sakurai, T. The effect of trace additions of Sn on precipitation in Al-Cu alloys: An atom probe field ion microscopy study. Metall. Mater. Trans. A 1995, 26, 2207–2217. [Google Scholar] [CrossRef]

- Homma, T.; Moody, M.P.; Saxey, D.W.; Ringer, S.P. Effect of Sn Addition in Preprecipitation Stage in Al-Cu Alloys: A Correlative Transmission Electron Microscopy and Atom Probe Tomography Study. Metall. Mater. Trans. A 2012, 43, 2192–2202. [Google Scholar] [CrossRef]

- Marioara, C.D.; Andersen, S.J.; Stene, T.N.; Hasting, H.; Walmsley, J.; Helvoort, A.T.J.V.; Holmestad, R. The effect of Cu on precipitation in Al-Mg-Si alloys. Philos. Mag. 2007, 87, 3385–3413. [Google Scholar] [CrossRef]

- Zandbergen, M.W.; Xu, Q.; Cerezo, A.; Smith, G. Study of precipitation in Al-Mg-Si alloys by Atom Probe Tomography I. Microstructural changes as a function of ageing temperature. Acta Mater. 2015, 101, 136–148. [Google Scholar] [CrossRef]

- Kim, J.H.; Marioara, C.D.; Holmestad, R.; Kobayashi, E.; Sato, T. Effects of Cu and Ag additions on age-hardening behavior during multi-step aging in Al-Mg-Si alloys. Mater. Sci. Eng. A 2013, 560, 154–162. [Google Scholar] [CrossRef]

- MøRtsell, E.A.; Marioara, C.D.; Andersen, S.J.; RøYset, J.; Reiso, O.; Holmestad, R. Effects of Germanium, Copper, and Silver Substitutions on Hardness and Microstructure in Lean Al-Mg-Si Alloys. Metall. Mater. Trans. A 2015, 46, 4369–4379. [Google Scholar] [CrossRef]

- Wiengmoon, A.; Pearce, J.; Chairuangsri, T.; Isoda, S.; Kurata, H. HRTEM and HAADF-STEM of precipitates at peak ageing of cast A319 aluminium alloy. Micron 2013, 45, 32–36. [Google Scholar] [CrossRef] [PubMed]

- Bourgeois, L.; Dwyer, C.; Weyland, M.; Nie, J.F.; Muddle, B.C. The magic thicknesses of θ′ precipitates in Sn-microalloyed Al-Cu. Acta Mater. 2016, 60, 633–644. [Google Scholar] [CrossRef]

- Silcock, J.M.; Heal, T.J.; Hardy, H.K. Structural ageing characteristics of binary aluminium-copper alloys. J. Inst. Met. 1954, 2, 885–887. [Google Scholar]

- Biswas, A.; Siegel, D.J.; Wolverton, C.; Seidman, D.N. Precipitates in Al-Cu alloys revisited: Atom-probe tomographic experiments and first-principles calculations of compositional evolution and interfacial segregation. Acta Mater. 2011, 59, 6187–6204. [Google Scholar] [CrossRef]

- Costa, T.A.; Dias, M.; Gomes, L.G.; Rocha, O.L.; Garcia, A. Effect of solution time in T6 heat treatment on microstructure and hardness of a directionally solidified Al-Si-Cu alloy. J. Alloys Compd. 2016, 683, 485–494. [Google Scholar] [CrossRef]

- El-Menshawy, K.; El-Sayed, A.; El-Bedawy, M.E.; Ahmed, H.A.; El-Raghy, S.M. Effect of aging time at low aging temperatures on the corrosion of aluminum alloy 6061. Corros. Sci. 2012, 54, 167–173. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Toschi, S.; Johansson, S.; Seifeddine, S. Effect of microstructure and overaging on the tensile behavior at room and elevated temperature of C355-T6 cast aluminum alloy. Mater. Des. 2015, 83, 626–634. [Google Scholar] [CrossRef]

- Chen, K.; Liu, H.; Zhuo, Z.; Song, L.; Todd, R.I. The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments. J. Mater. Process. Technol. 2003, 142, 190–196. [Google Scholar] [CrossRef]

- Luo, Y.; Xiaojing, X.U.; Zhang, Y.; Zhang, Z. Effect of Enhanced-solid-solution on Intergranular Corrosion and Exfoliation Corrosion of 7075 Al Alloy. Hot Work. Technol. 2012, 6, 288–293. [Google Scholar]

- Chen, X.; Song, R.; Li, J. Current Research Status and Development Trends of 7xxx Series Aluminum Alloys. Mater. Rev. 2009, 19, 1651–1662. [Google Scholar]

- Sokolowski, J.H.; Sun, X.C.; Byczynski, G.; Northwood, D.O.; Esseltine, A. The removal of copper-phase segregation and the subsequent improvement in mechanical properties of cast 319 aluminium alloys by a two-stage solution heat treatment. J. Mater. Process. Technol. 1995, 53, 385–392. [Google Scholar] [CrossRef]

- Han, Y.; Samuel, A.M.; Doty, H.W.; Valtierra, S.; Samuel, F.H. Optimizing the tensile properties of Al-Si-Cu-Mg 319-type alloys: Role of solution heat treatment. Mater. Des. 2014, 58, 426–438. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Samuel, F.H.; Al Kahtani, S. Influence of Mg and solution heat treatment on the occurrence of incipient melting in Al-Si-Cu-Mg cast alloys. Mater. Sci. Eng. A 2012, 543, 22–34. [Google Scholar] [CrossRef]

- Kang, H.G.; Kida, M.; Miyahara, H.; Ogi, K. Age-hardening characteristics of Al-Si-Cu-base cast alloys. J. Jpn. Foundry Eng. Soc. 1999, 107, 507–515. [Google Scholar]

- Li, R.; Chen, Y.; Yuan, X.; Yingdong, Q.; Rongde, L. Effects of Cd and Sn on double-peak age-hardening behaviors of Al-Si-Cu-Mg cast alloys. China Foundry 2010, 7, 1–5. [Google Scholar]

- Xiao, Q.; Liu, H.; Yi, D.; Yin, D.; Chen, Y.; Zhang, Y.; Wang, B. Effect of Cu content on precipitation and age-hardening behavior in Al-Mg-Si-xCu alloys. J. Alloys Compd. 2016, 695, 1005–1013. [Google Scholar] [CrossRef]

- Cai, Q.; Mendis, C.L.; Wang, S.; Chang, I.; Fan, Z. Effect of heat treatment on microstructure and tensile properties of die-cast Al-Cu-Si-Mg alloys. J. Alloys Compd. 2021, 881, 160559. [Google Scholar]

- Wang, D.; Liu, S.; Zhang, X.; Li, X.; Nagaumi, H. Fast aging strengthening by hybrid precipitates in high pressure die-cast Al-Si-Cu-Mg-Zn alloy. Mater. Charact. 2021, 179, 111312. [Google Scholar] [CrossRef]

- Zuo, L.; Ye, B.; Feng, J.; Kong, X.; Jiang, H. Effect of Q-Al5Cu2Mg8Si6 phase on mechanical properties of Al-Si-Cu-Mg alloy at elevated temperature. Mater. Sci. Eng. A 2017, 693, 26–32. [Google Scholar] [CrossRef]

- Alexander, W.B.; Slifkin, L.M. Diffusion of Solutes in Aluminum and Dilute Aluminum Alloys. Phys. Rev. B 1970, 1, 3274–3282. [Google Scholar] [CrossRef]

- Du, Y.; Chang, Y.A.; Huang, B. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Simonovic, D.; Sluiter, M.H.F. Impurity diffusion activation energies in Al from first principles. Phys. Rev. B Condens. Matter 2009, 79, 263–274. [Google Scholar] [CrossRef]

- Porter, D.A.; Easterling, K.E.; Sherif, M. Phase Transformations in Metals and Alloys (Revised Reprint); CRC Press: Boca Raton, FL, USA, 2009; ISBN 1439883572. [Google Scholar]

| Alloy | Si | Cu | Mg | Mn | Ti | Fe | Sr | Cd | Al |

|---|---|---|---|---|---|---|---|---|---|

| Cd-free | 7.52 | 1.63 | 0.25 | 0.25 | 0.18 | 0.05 | 0.06 | - | Balance |

| Cd-containing | 7.28 | 1.57 | 0.28 | 0.23 | 0.19 | 0.05 | 0.06 | 0.29 | Balance |

| Process of Treatment | Solid Solution Stages | Aging Stage | ||||||

|---|---|---|---|---|---|---|---|---|

| Stage 1 | Stage 2 | Stage 3 | ||||||

| T, (°C) | t, (h) | T, (°C) | t, (h) | T, (°C) | t, (h) | T, (°C) | t, (h) | |

| AHT-2 | 500 | 4 | 520 | 4 | - | - | 175 | - |

| AHT-3 | 490 | 4 | 500 | 6 | 520 | 8 | ||

| Alloys | YS (MPa) | UTS (MPa) | El (%) |

|---|---|---|---|

| two-stage-Cd-free | 240 ± 3 | 353 ± 9 | 11 ± 3 |

| three-stage-Cd-free | 279 ± 6 | 373 ± 7 | 10 ± 2 |

| two-stage-Cd-containing | 308 ± 5 | 390 ± 7 | 7 ± 2 |

| three-stage-Cd-containing | 295 ± 4 | 384 ± 4 | 10 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, H.; Bai, X.; Song, F.; Song, Y.; Jia, Z.; Xu, H.; Wang, Y. Effect of Cd on Mechanical Properties of Al-Si-Cu-Mg Alloys under Different Multi-Stage Solution Heat Treatment. Materials 2022, 15, 5101. https://doi.org/10.3390/ma15155101

Mao H, Bai X, Song F, Song Y, Jia Z, Xu H, Wang Y. Effect of Cd on Mechanical Properties of Al-Si-Cu-Mg Alloys under Different Multi-Stage Solution Heat Treatment. Materials. 2022; 15(15):5101. https://doi.org/10.3390/ma15155101

Chicago/Turabian StyleMao, Hongkui, Xiaoyu Bai, Feng Song, Yuewen Song, Zhe Jia, Hong Xu, and Yu Wang. 2022. "Effect of Cd on Mechanical Properties of Al-Si-Cu-Mg Alloys under Different Multi-Stage Solution Heat Treatment" Materials 15, no. 15: 5101. https://doi.org/10.3390/ma15155101

APA StyleMao, H., Bai, X., Song, F., Song, Y., Jia, Z., Xu, H., & Wang, Y. (2022). Effect of Cd on Mechanical Properties of Al-Si-Cu-Mg Alloys under Different Multi-Stage Solution Heat Treatment. Materials, 15(15), 5101. https://doi.org/10.3390/ma15155101