The Study of New NiTi Actuators to Reinforce the Wing Movement of Aircraft Systems

Abstract

:1. Introduction

2. Experimental Procedure

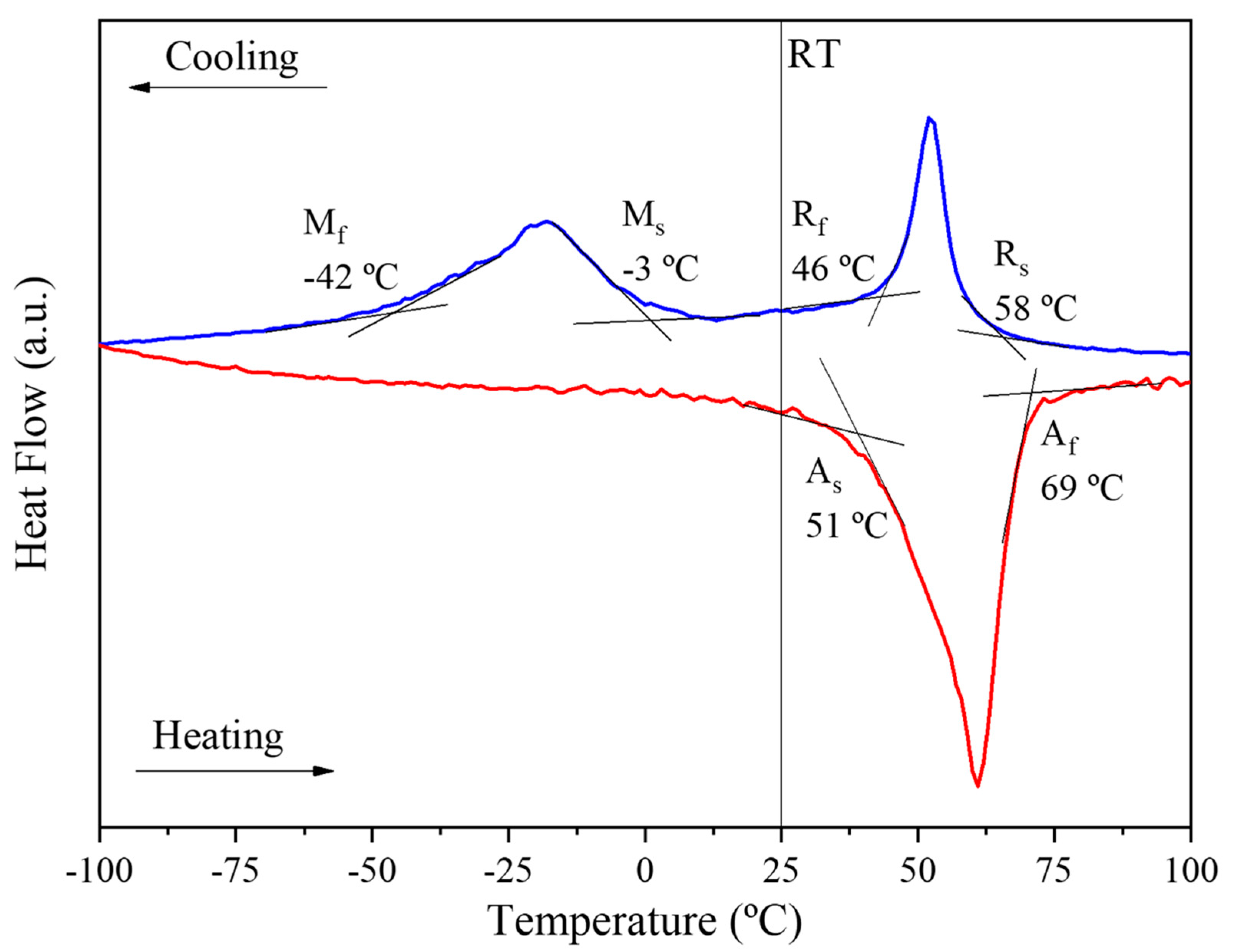

2.1. Material

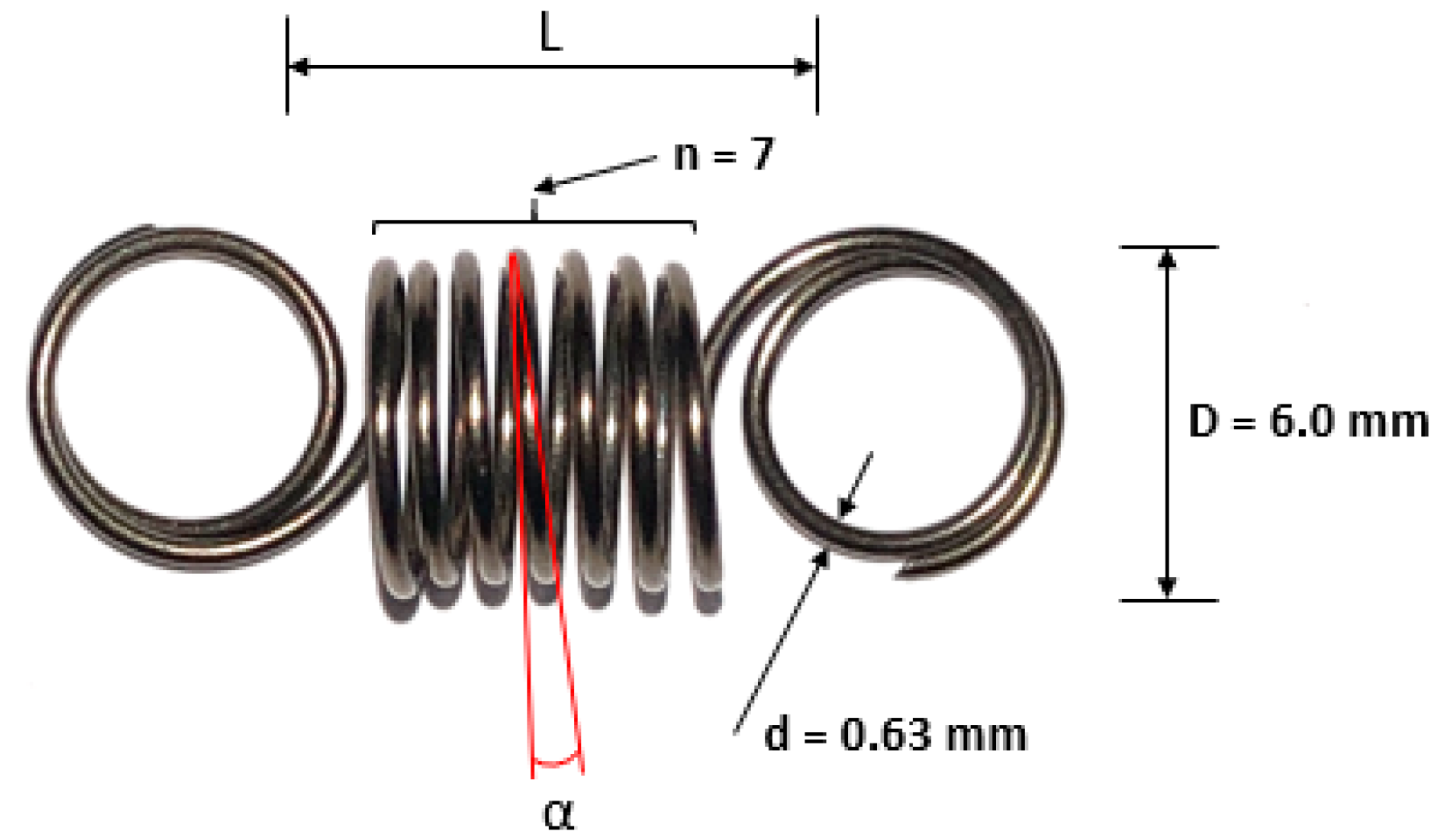

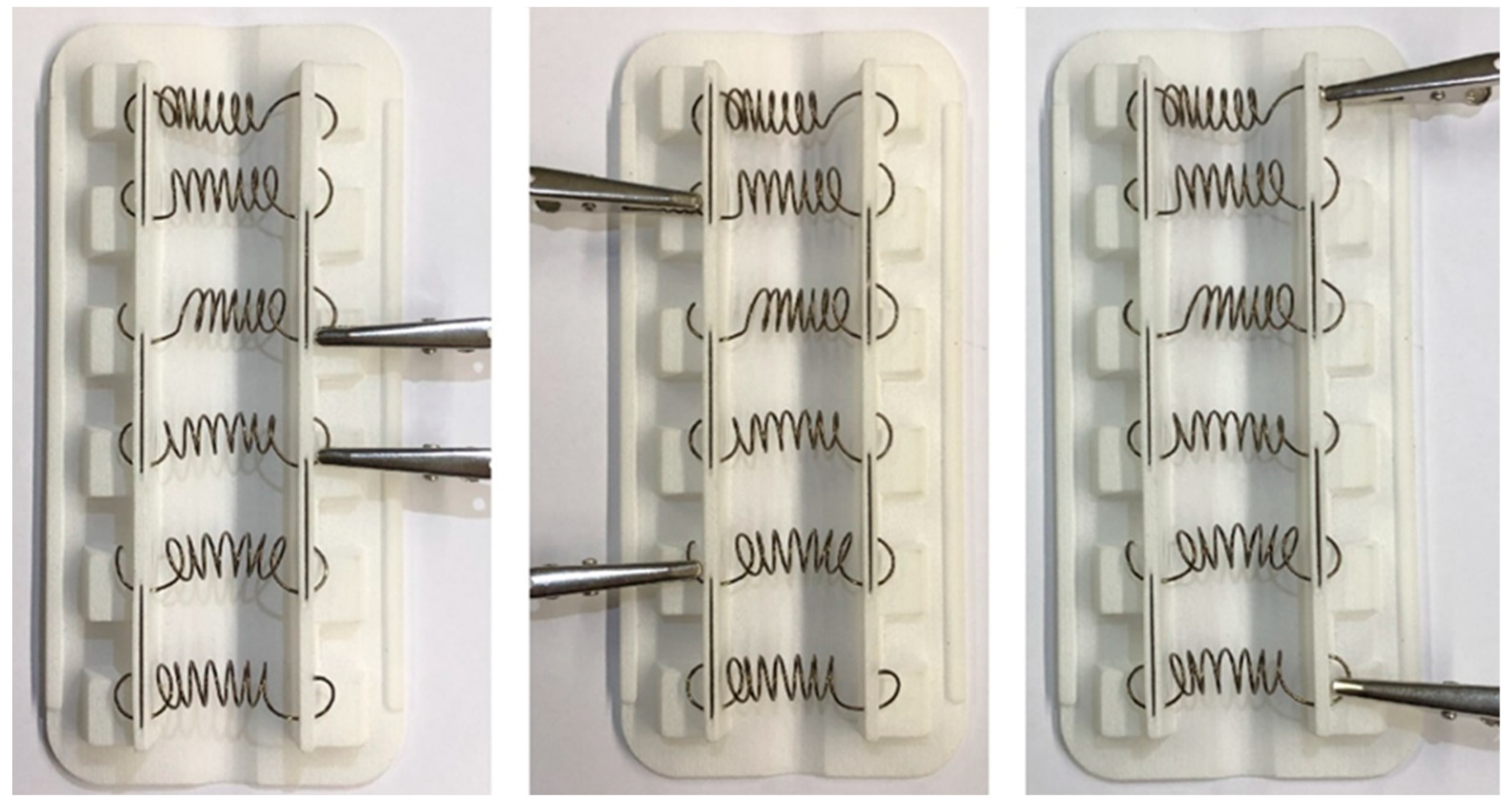

2.1.1. Spring and Wire

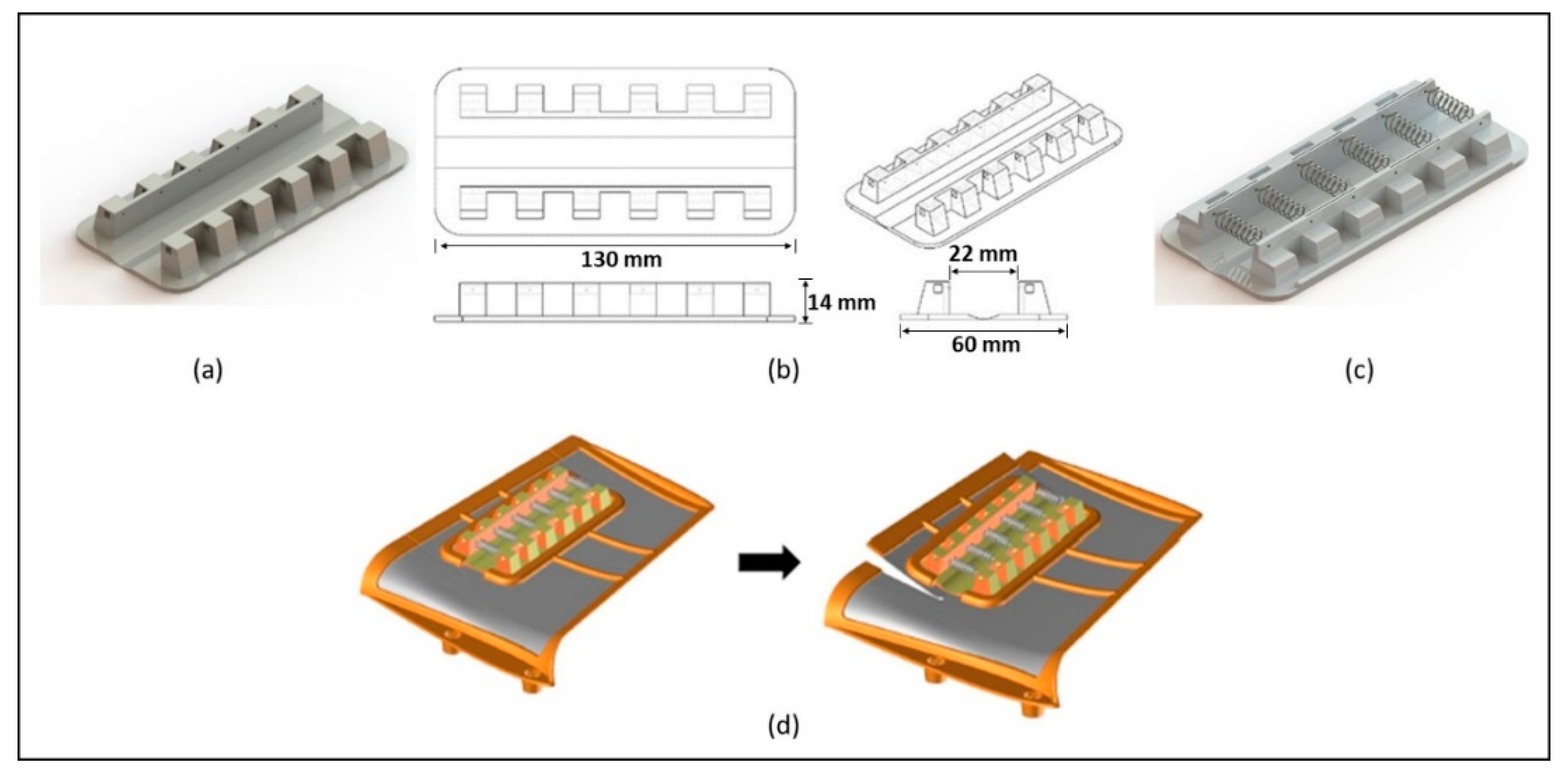

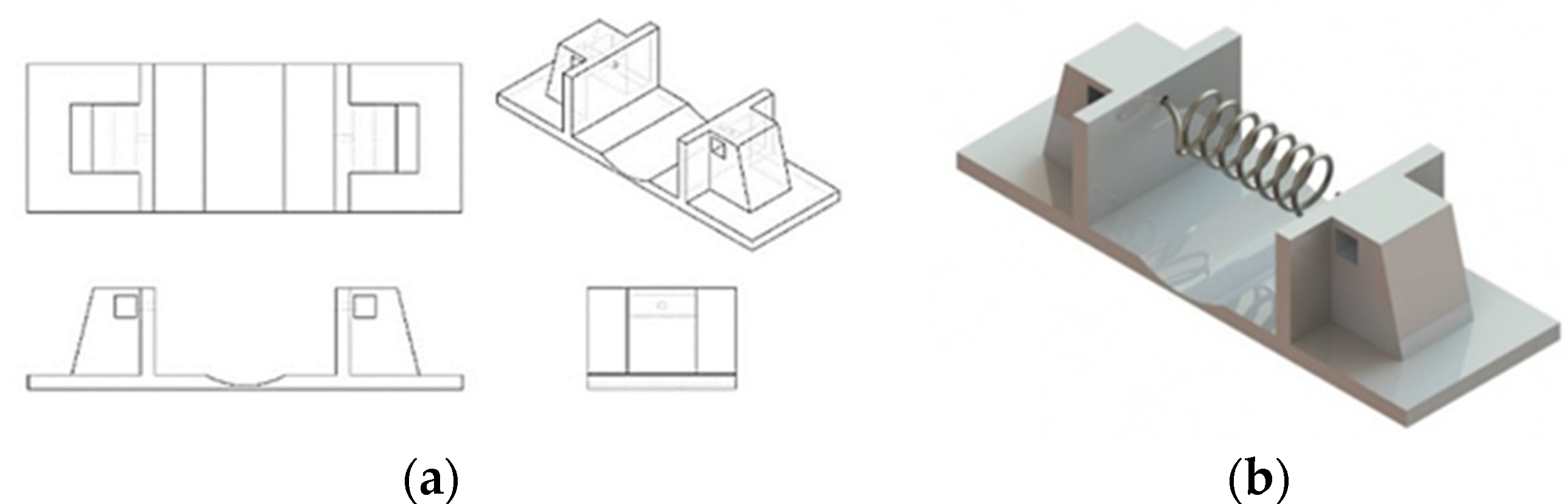

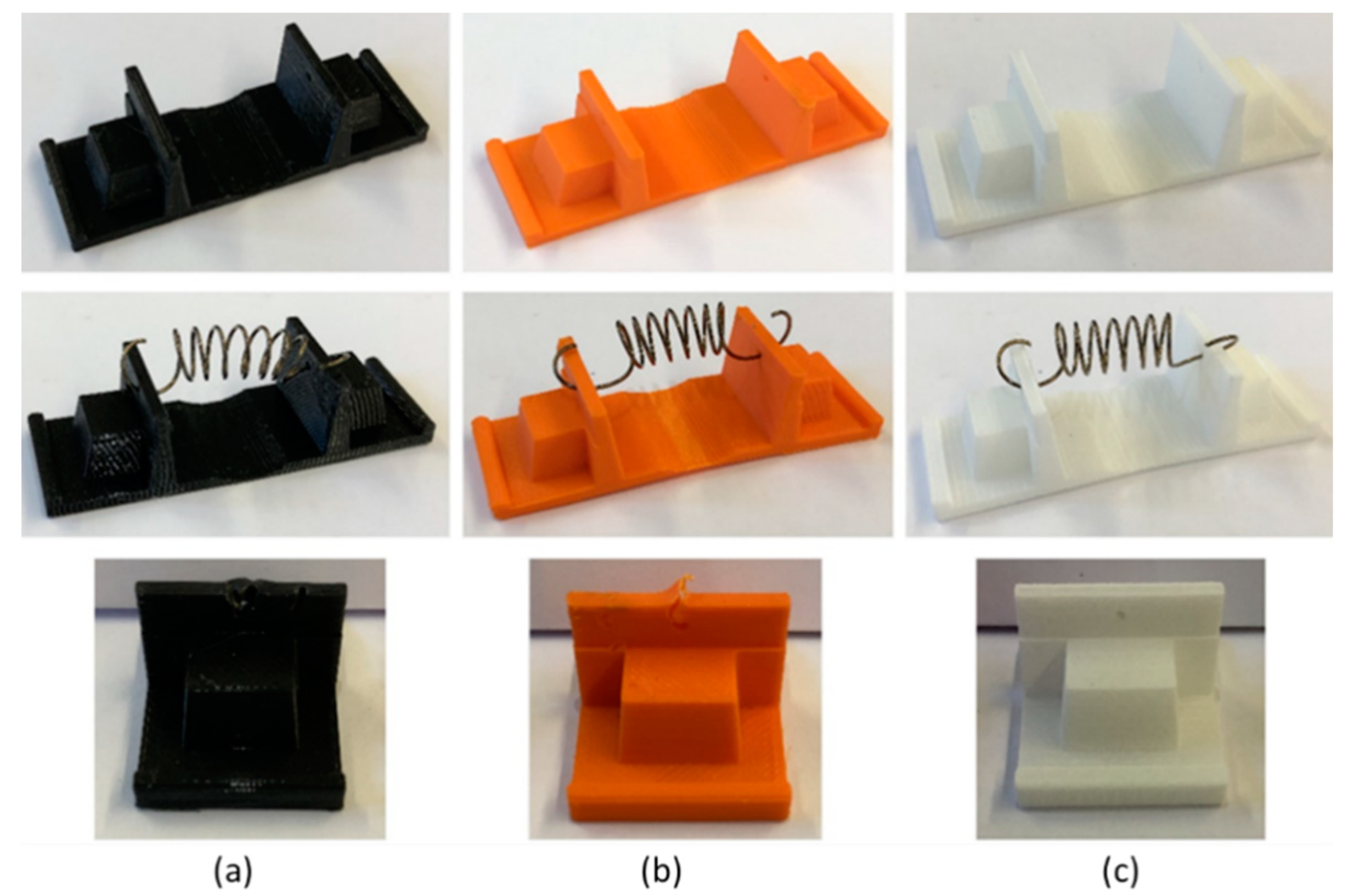

2.1.2. Support

2.2. Prototypes Fabrication

3. Results and Discussion

3.1. Prototype Details

3.1.1. Actuator

3.1.2. Support

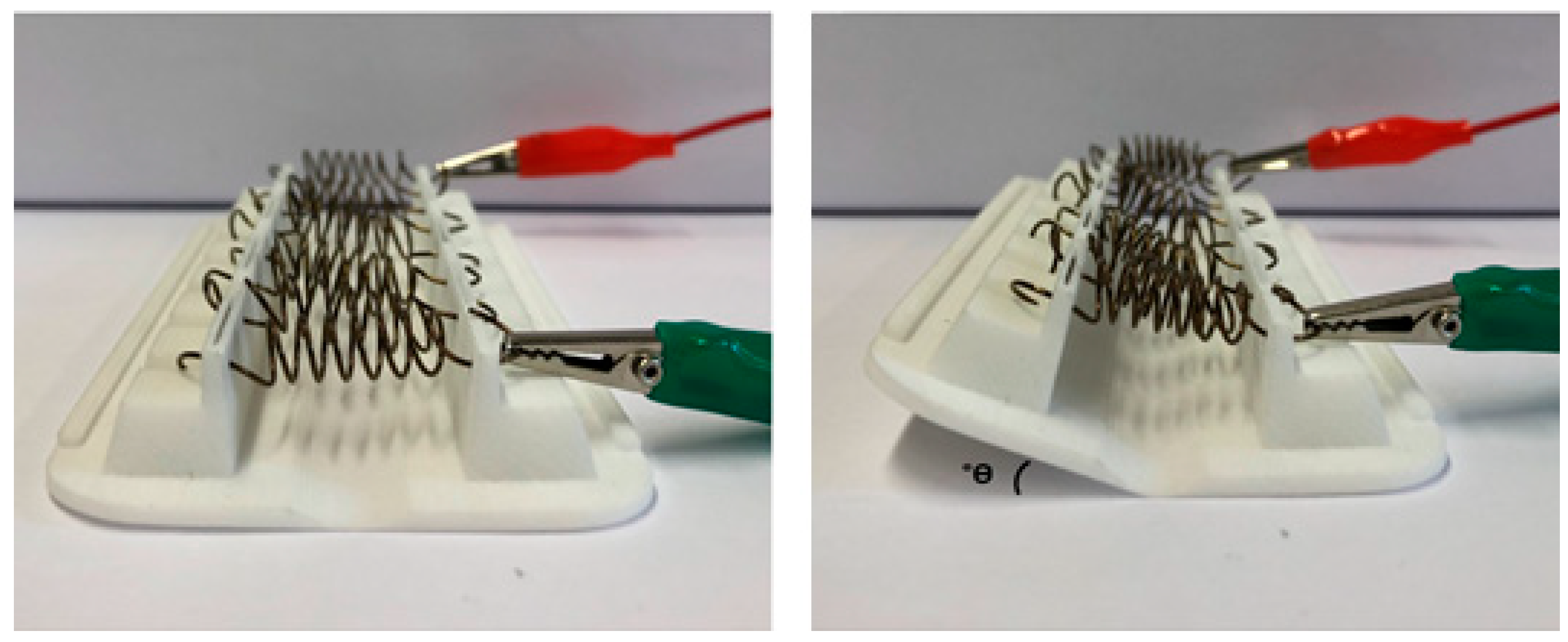

3.2. Prototype Tests

4. Conclusions

- −

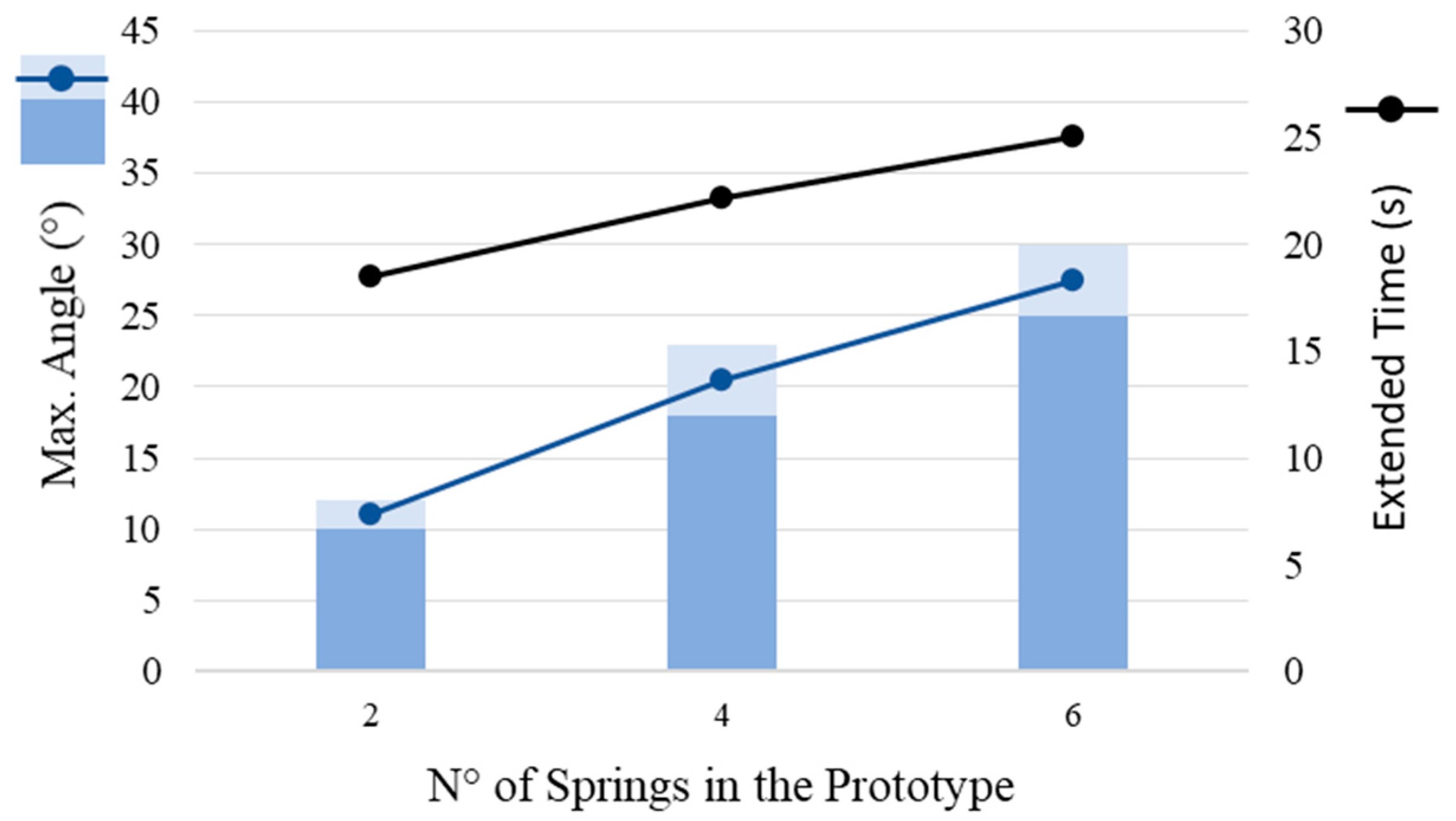

- The maximum inclination angle of the support is a linear function of the number of springs;

- −

- Cooling of the prototype has significant importance regarding prototype recovery time;

- −

- The maximum inclination angle of the prototype is a linear function of the temperature imposed on the spring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Abdullah, E.J.; Gaikwad, P.S.; Azid, N.; Abdul Majid, D.L.; Mohd Rafie, A.S. Temperature and strain feedback control for shape memory alloy actuated composite plate. Sens. Actuators A Phys. 2018, 283, 134–140. [Google Scholar] [CrossRef]

- Bertacchini, O.W.; Lagoudas, D.C.; Calkins, F.T.; Mabe, J.H. Thermomechanical cyclic loading and fatigue life characterization of nickel rich NiTi shape-memory alloy actuators. Behavior and Mechanics of Multifunctional and Composite Materials. Proc. SPIE 2008, 6929, 692916. [Google Scholar] [CrossRef]

- Mabe, J.H.; Calkins, F.T.; Bushnell, G.S.; Bieniawski, S.R. Aircraft Systems with Shape Memory Alloy (SMA) Actuators, and Associated Methods. U.S. Patent 7878459B2, 1 February 2011. [Google Scholar]

- Antonucci, V.; Martone, A. Phenomenology of Shape Memory Alloys. In Shape Memory Alloy Engineering: For Aerospace, Structural and Biomedical Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 33–56. [Google Scholar] [CrossRef]

- Saburi, T. Ti-Ni Shape memory Alloys. In Shape Memory Materials, 1st ed.; Wayman, C.M., Otsuka, K., Eds.; Cambridge University Press: New York, NY, USA, 1998; pp. 49–96. [Google Scholar]

- Schmahl, W.W.; Khalil-Allafi, J.; Hasse, B.; Wagner, M.; Heckmann, A.; Somsen, C. Investigation of the phase evolution in a super-elastic NiTi shape memory alloy (50.7 at.% Ni) under extensional load with synchrotron radiation. Mater. Sci. Eng. A 2004, 378, 81–85. [Google Scholar] [CrossRef]

- Miyazaki, S.; Imai, T.; Igo, Y.; Otsuka, K. Effect of Cyclic Deformation on the Pseudoelasticity Characteristics of Ti-Ni Alloys. Metall. Trans. A Phys. Metall. Mater. Sci. 1986, 17, 115–120. [Google Scholar] [CrossRef]

- Frenzel, J.; George, E.P.; Dlouhy, A.; Somsen, C.; Wagner, M.F.X.; Eggeler, G. Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater. 2010, 58, 3444–3458. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Light. Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Shimoga, G.; Kim, T.H.; Kim, S.Y. An Intermetallic NiTi-Based Shape Memory Coil Spring for Actuator Technologies. Metals 2021, 11, 1212. [Google Scholar] [CrossRef]

- Yuan, H.; Fauroux, J.C.; Chapelle, F.; Balandraud, X. A review of rotary actuators based on shape memory alloys. J. Intell. Mater. Syst. Struct. 2017, 28, 1863–1885. [Google Scholar] [CrossRef] [Green Version]

- Jani, J.M.; Leary, M.; Subic, A. Designing shape memory alloy linear actuators: A review. J. Intell. Mater. Syst. Struct. 2016, 28, 1699–1718. [Google Scholar] [CrossRef]

- Koh, J.S. Design of Shape Memory Alloy Coil Spring Actuator for Improving Performance in Cyclic Actuation. Materials 2018, 11, 2324. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ko, W.-S.; Maisel, S.B.; Grabowski, B.; Jeon, J.B.; Neugebauer, J. Atomic scale processes of phase transformations in nanocrystalline NiTi shape-memory alloys. Acta Mater. 2017, 123, 90–101. [Google Scholar] [CrossRef] [Green Version]

- Seok, S.; Onal, C.D.; Cho, K.J.; Wood, R.J.; Rus, D.; Kim, S. Meshworm: A peristaltic soft robot with antagonistic nickel titanium coil actuators. IEEE/ASME Trans. Mechatron. 2013, 18, 1485–1497. [Google Scholar] [CrossRef]

- Costanza, G.; Radwan, N.; Tata, M.E.; Varone, E. Design and characterization of linear shape memory alloy actuator with modular stroke. Procedia Struct. Integr. 2019, 18, 223–230. [Google Scholar] [CrossRef]

- Costanza, G.; Tata, M.E. Shape memory alloys for aerospace, recent developments, and new applications: A short review. Materials 2020, 13, 1856. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lima, P.C.; Rodrigues, P.F.; Ramos, A.S.; da Costa, J.D.M.; Braz Fernandes, F.M.; Vieira, M.T. Experimental Analysis of NiTi Alloy during Strain-Controlled Low-Cycle Fatigue. Materials 2021, 14, 4455. [Google Scholar] [CrossRef] [PubMed]

- Arunprasath, K.; Vijayakumar, M.; Ramarao, M.; Arul, T.G.; Pauldoss, S.P.; Selwin, M.; Radhakrishnan, B.; Manikandan, V. Dynamic mechanical analysis performance of pure 3D printed polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). Mater. Today Proc. 2021, 50, 1559–1562. [Google Scholar] [CrossRef]

- Yaagoubi, H.; Abouchadi, H.; Janan, M.T. Numerical simulation of heat transfer in the selective laser sintering process of Polyamide12. Energy Rep. 2021, 7, 189–199. [Google Scholar] [CrossRef]

- Mokrane, A.; Boutaous, M.; Xin, S. Process of selective laser sintering of polymer powders: Modeling, simulation, and validation. Comptes Rendus Mécanique 2018, 346, 1087–1103. [Google Scholar] [CrossRef]

| Material | Service Temperature (°C) | Fracture Toughness (MPa.m1/2) | Young’s Modulus (GPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| PLA | 45–55 | 0.70–1.10 | 3.45–3.83 | 48.0–60.0 |

| ABS | 62–77 | 1.90–2.10 | 2.00–2.90 | 30.0–50.0 |

| PA12 | 90–130 | 3.32–3.66 | 1.33–1.65 | 58.5–71.5 |

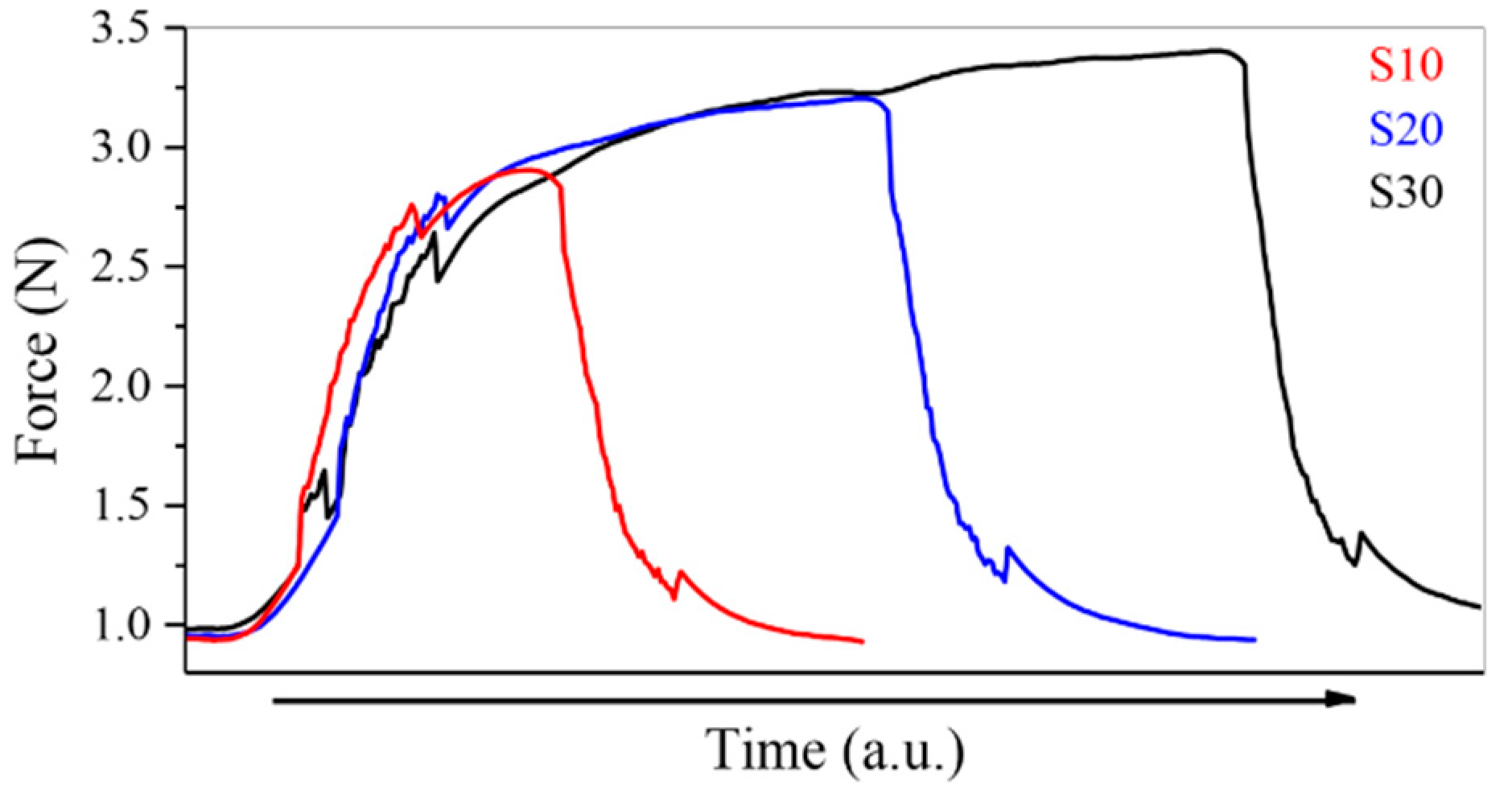

| Cycle Heating/Cooling | Maximum Force (N) |

|---|---|

| S10 | 2.1 |

| S20 | 2.2 |

| S30 | 2.3 |

| Number of Springs | Extended Time (s) | Retracted Time with Induced Cooling-Air (s) | Retracted Time without Induced Cooling-Air (s) | Maximum Angle (°) |

|---|---|---|---|---|

| 2 | ~19 | 20–35 | 75–90 | 10–12 |

| 4 | ~23 | 20–35 | 75–90 | 18–23 |

| 6 | ~25 | 20–35 | 75–90 | 25–30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Braga, R.; Rodrigues, P.F.; Cordeiro, H.; Carreira, P.; Vieira, M.T. The Study of New NiTi Actuators to Reinforce the Wing Movement of Aircraft Systems. Materials 2022, 15, 4787. https://doi.org/10.3390/ma15144787

Braga R, Rodrigues PF, Cordeiro H, Carreira P, Vieira MT. The Study of New NiTi Actuators to Reinforce the Wing Movement of Aircraft Systems. Materials. 2022; 15(14):4787. https://doi.org/10.3390/ma15144787

Chicago/Turabian StyleBraga, Rafael, Patrícia Freitas Rodrigues, Hélder Cordeiro, Pedro Carreira, and Maria Teresa Vieira. 2022. "The Study of New NiTi Actuators to Reinforce the Wing Movement of Aircraft Systems" Materials 15, no. 14: 4787. https://doi.org/10.3390/ma15144787

APA StyleBraga, R., Rodrigues, P. F., Cordeiro, H., Carreira, P., & Vieira, M. T. (2022). The Study of New NiTi Actuators to Reinforce the Wing Movement of Aircraft Systems. Materials, 15(14), 4787. https://doi.org/10.3390/ma15144787