Fatigue Property and Small Crack Propagation Mechanism of MIG Welding Joint of 6005A-T6 Aluminum Alloy

Abstract

:1. Introduction

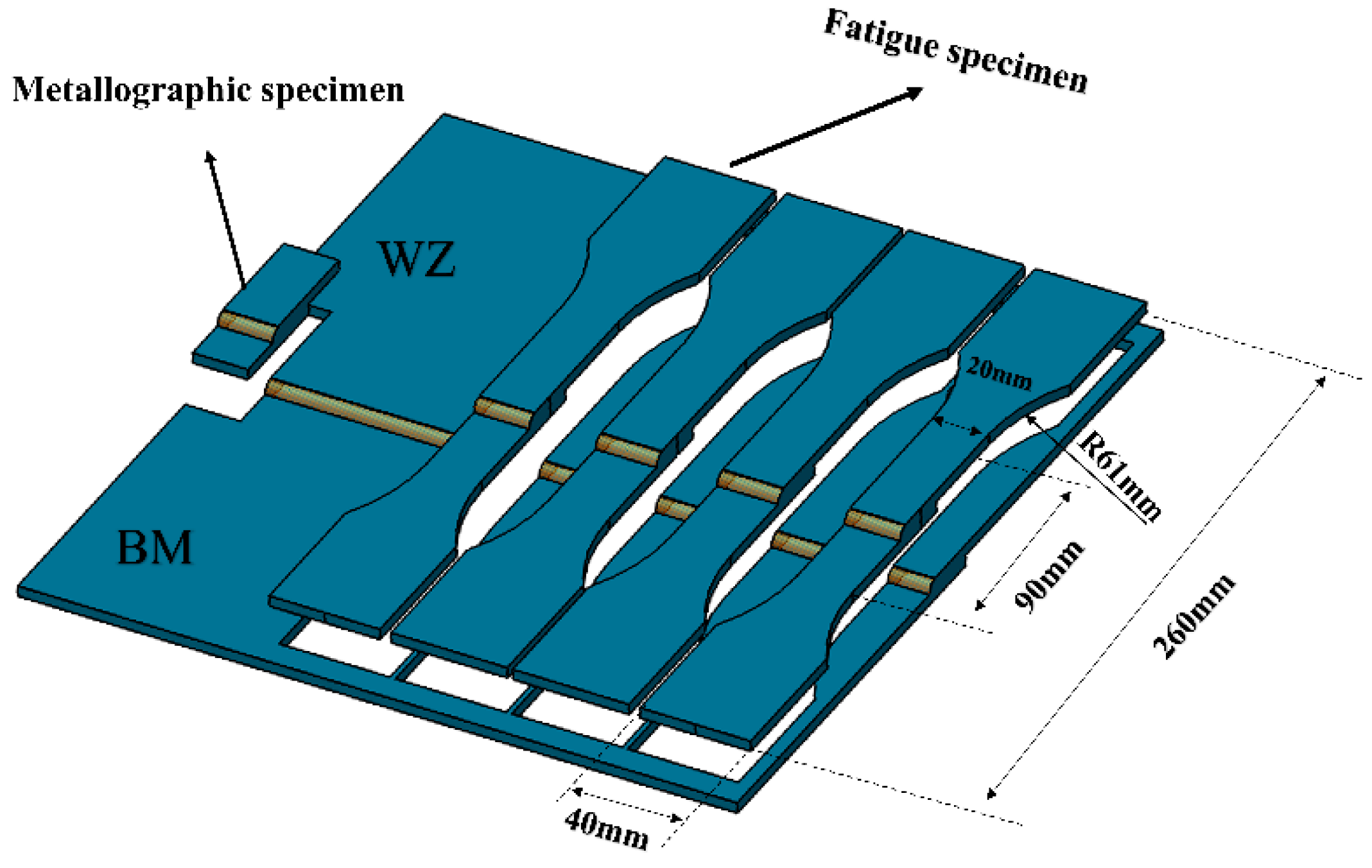

2. Experiments

2.1. Materials

2.2. Welding Procedure

2.3. Microscopic Observations

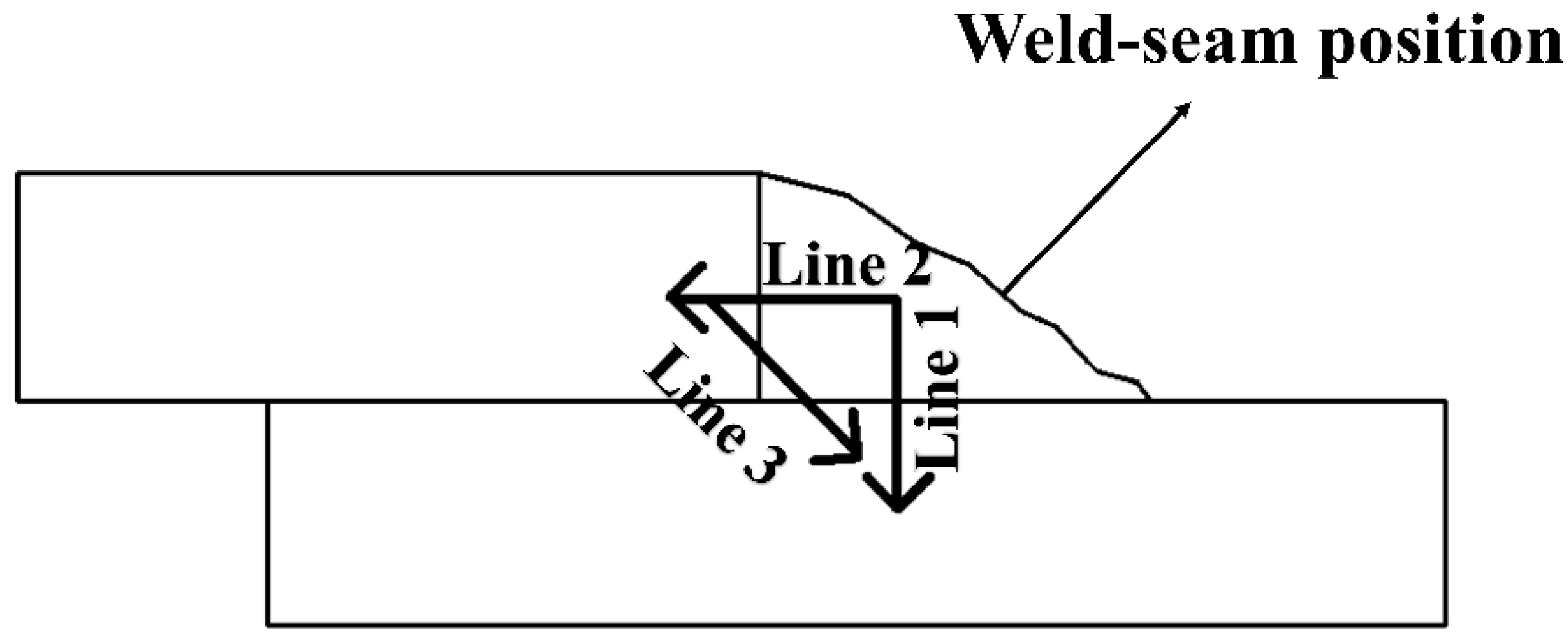

2.4. Hardness Test

2.5. Fatigue Test

3. Results and Discussion

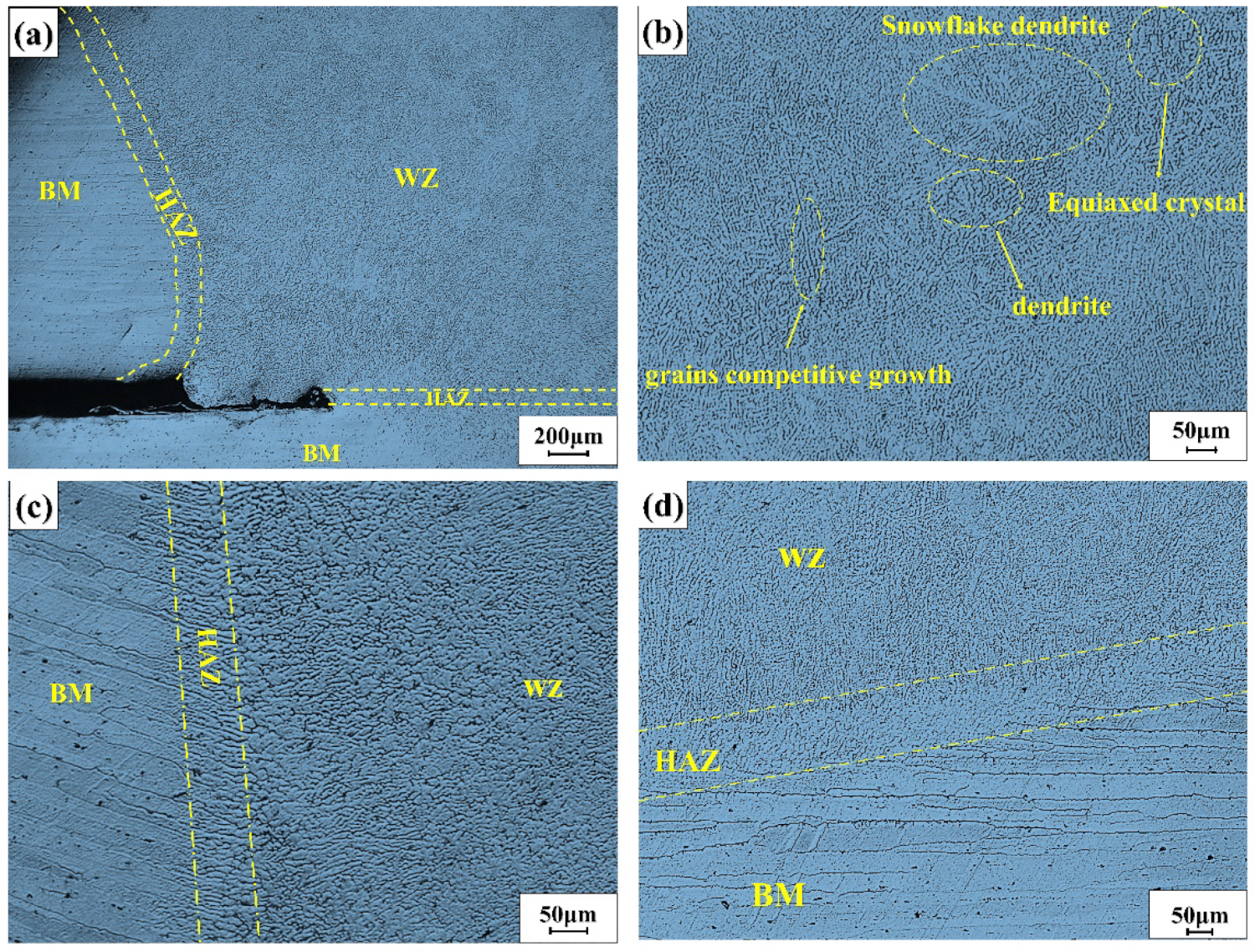

3.1. Microstructure Analysis

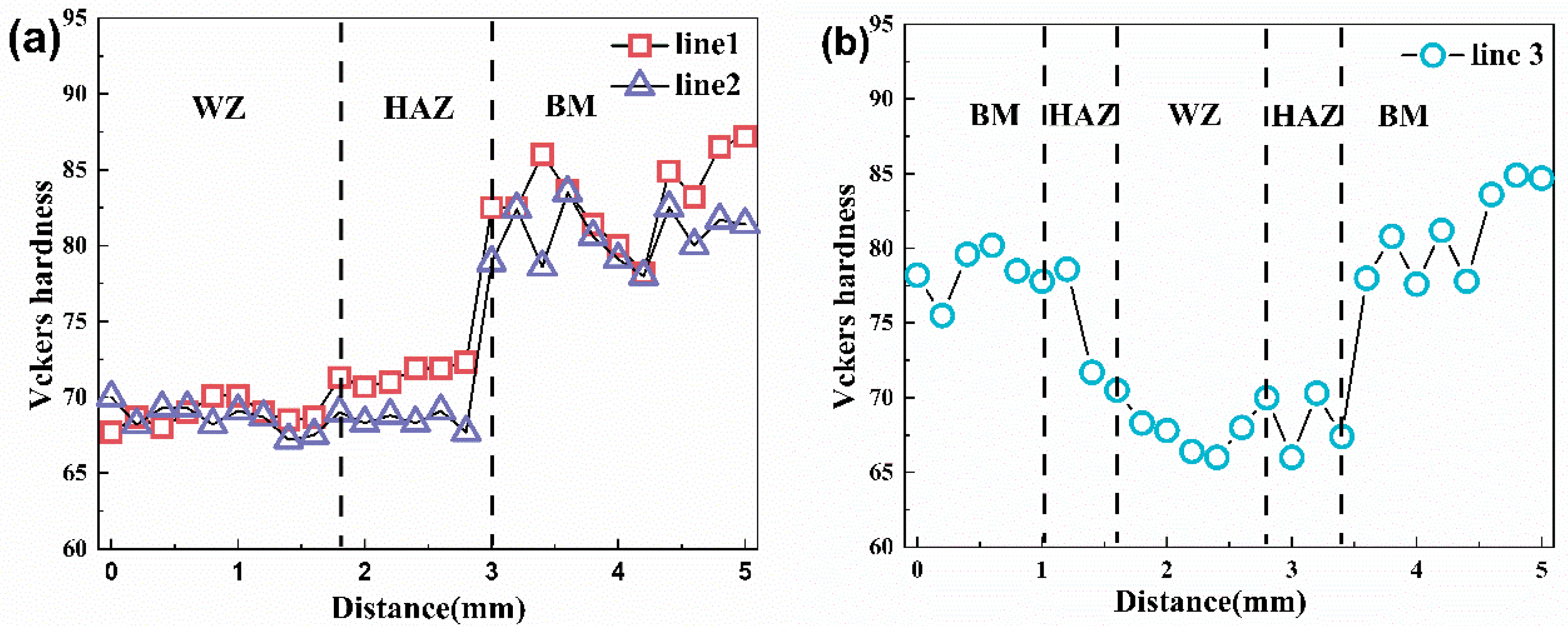

3.2. Microhardness Analysis

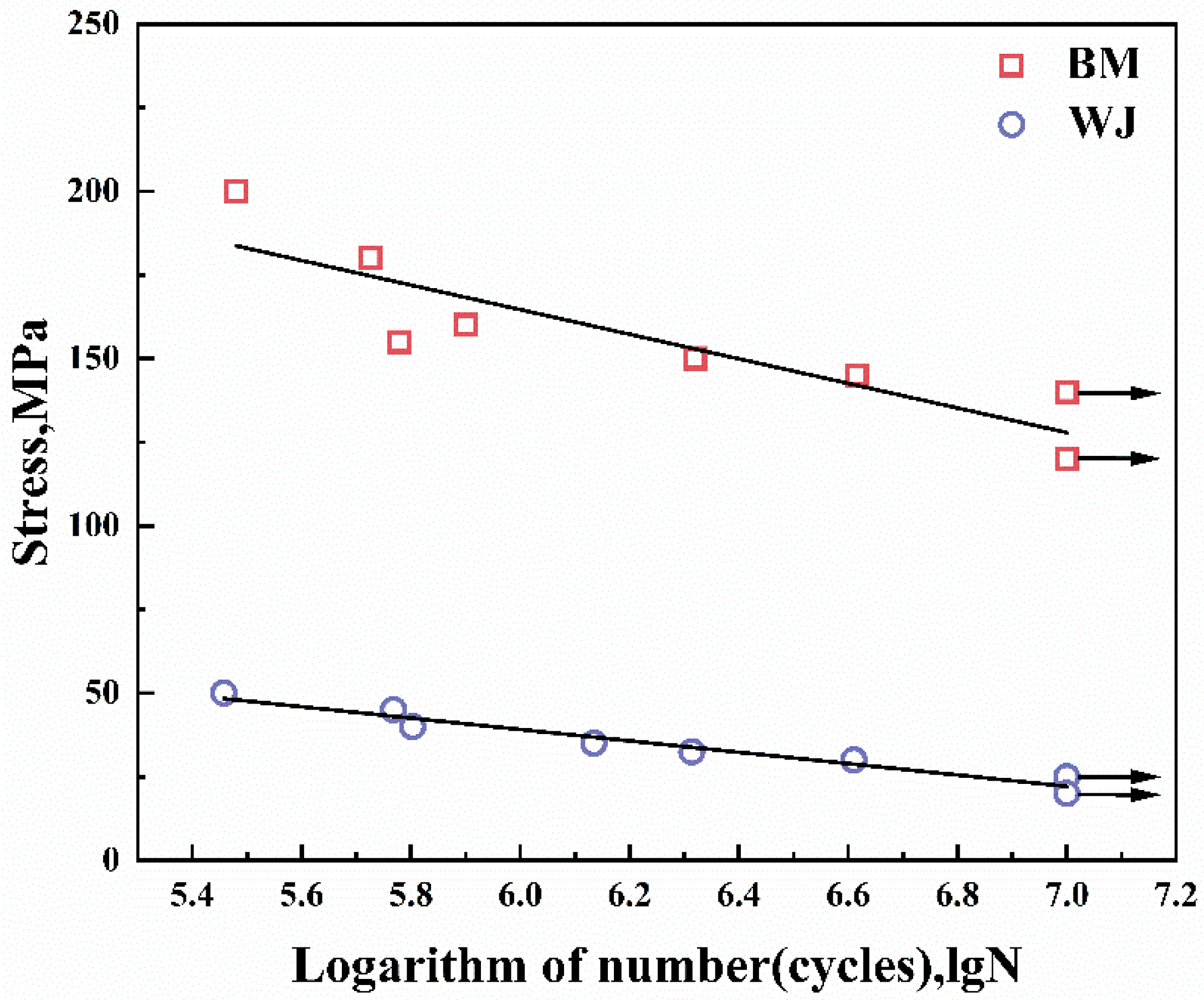

3.3. Fatigue Properties Analysis

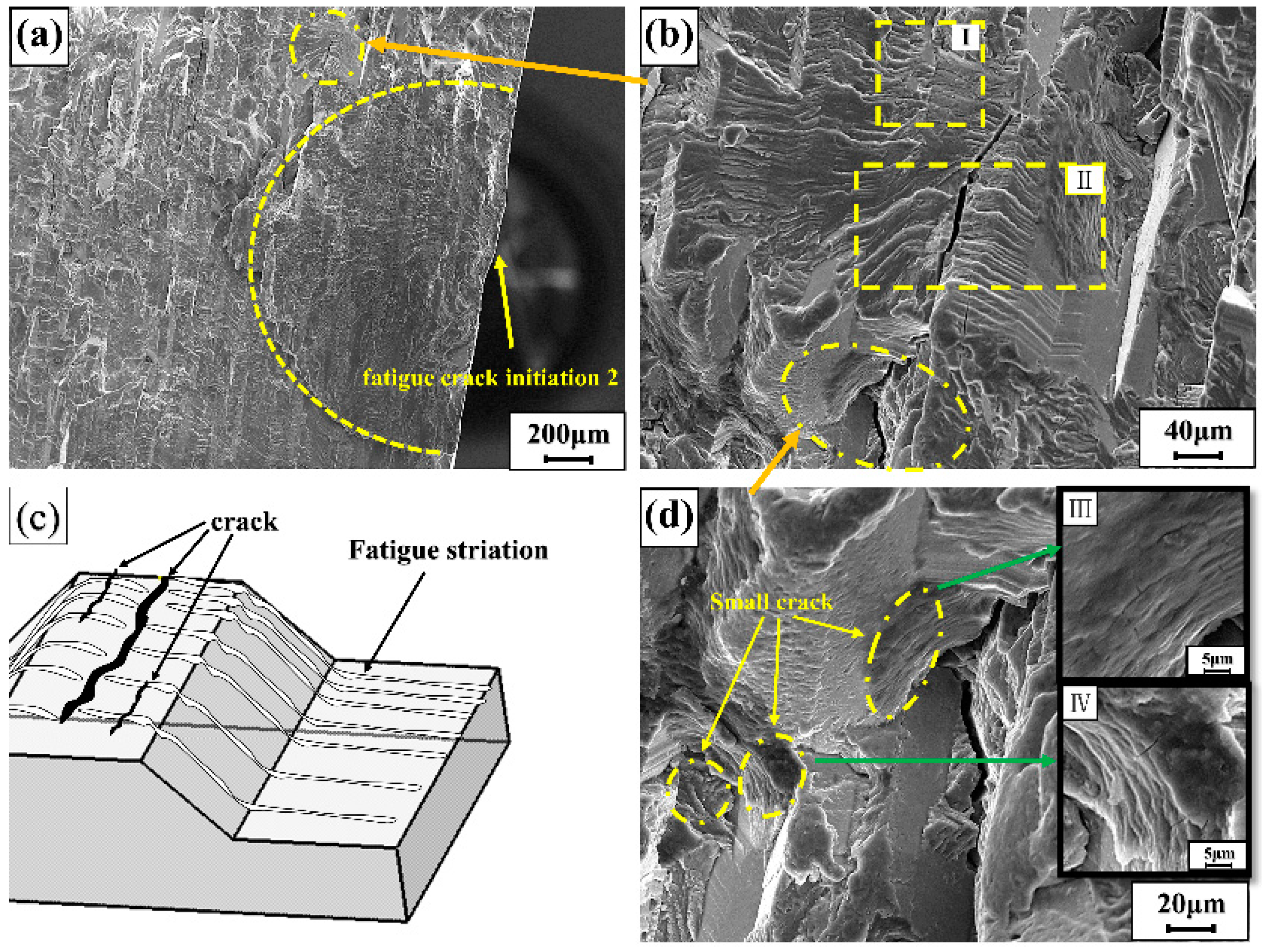

3.4. Fatigue Fracture Analysis

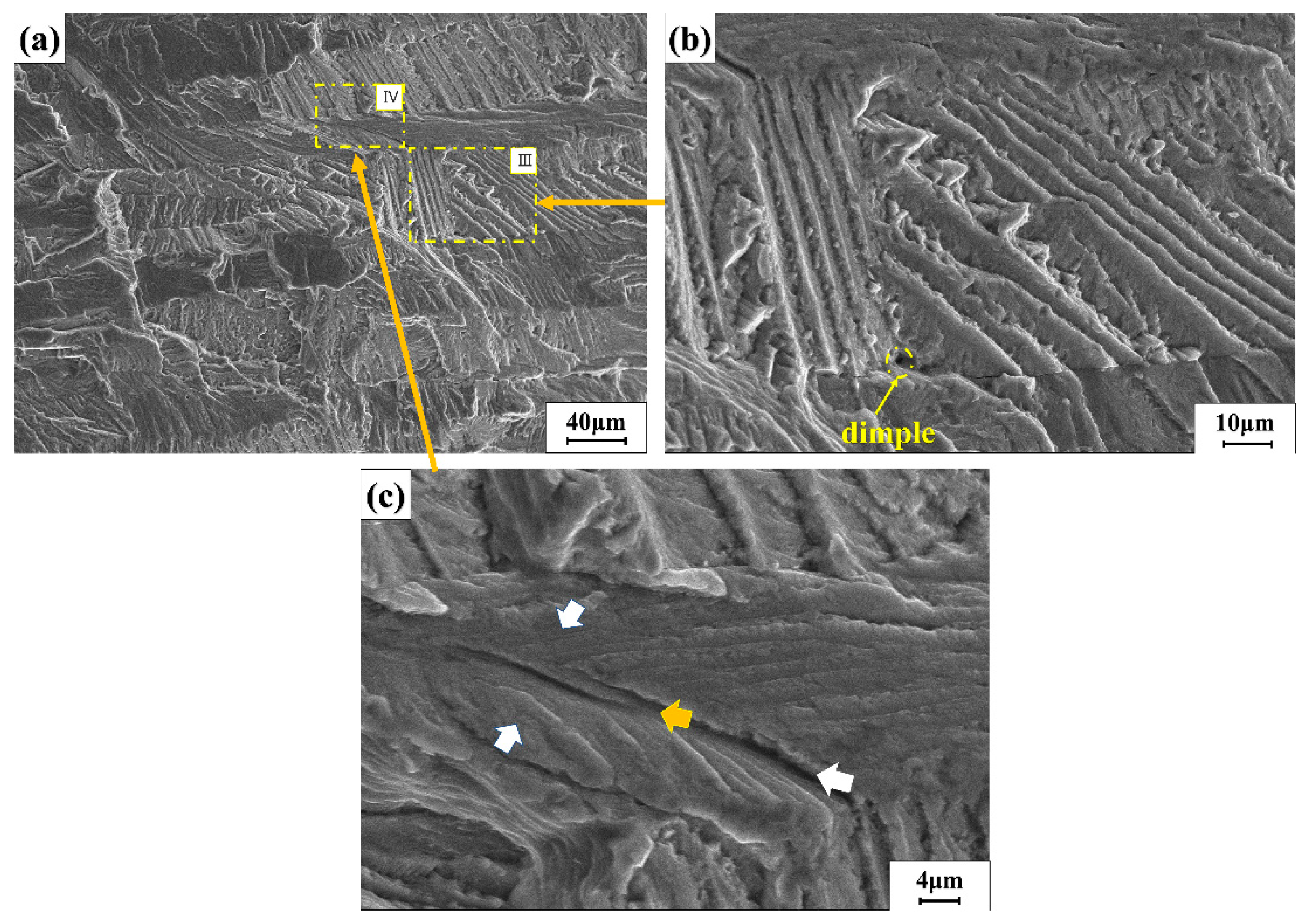

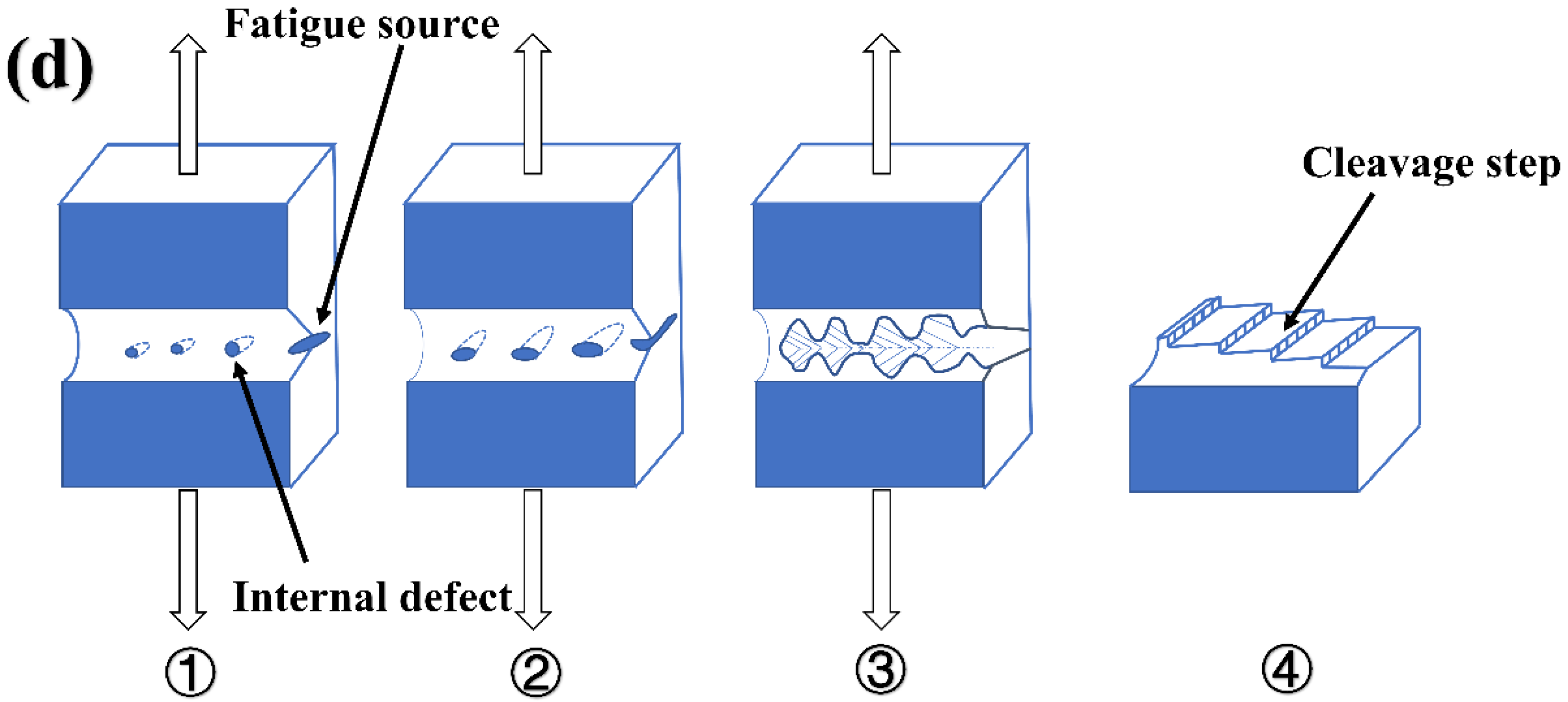

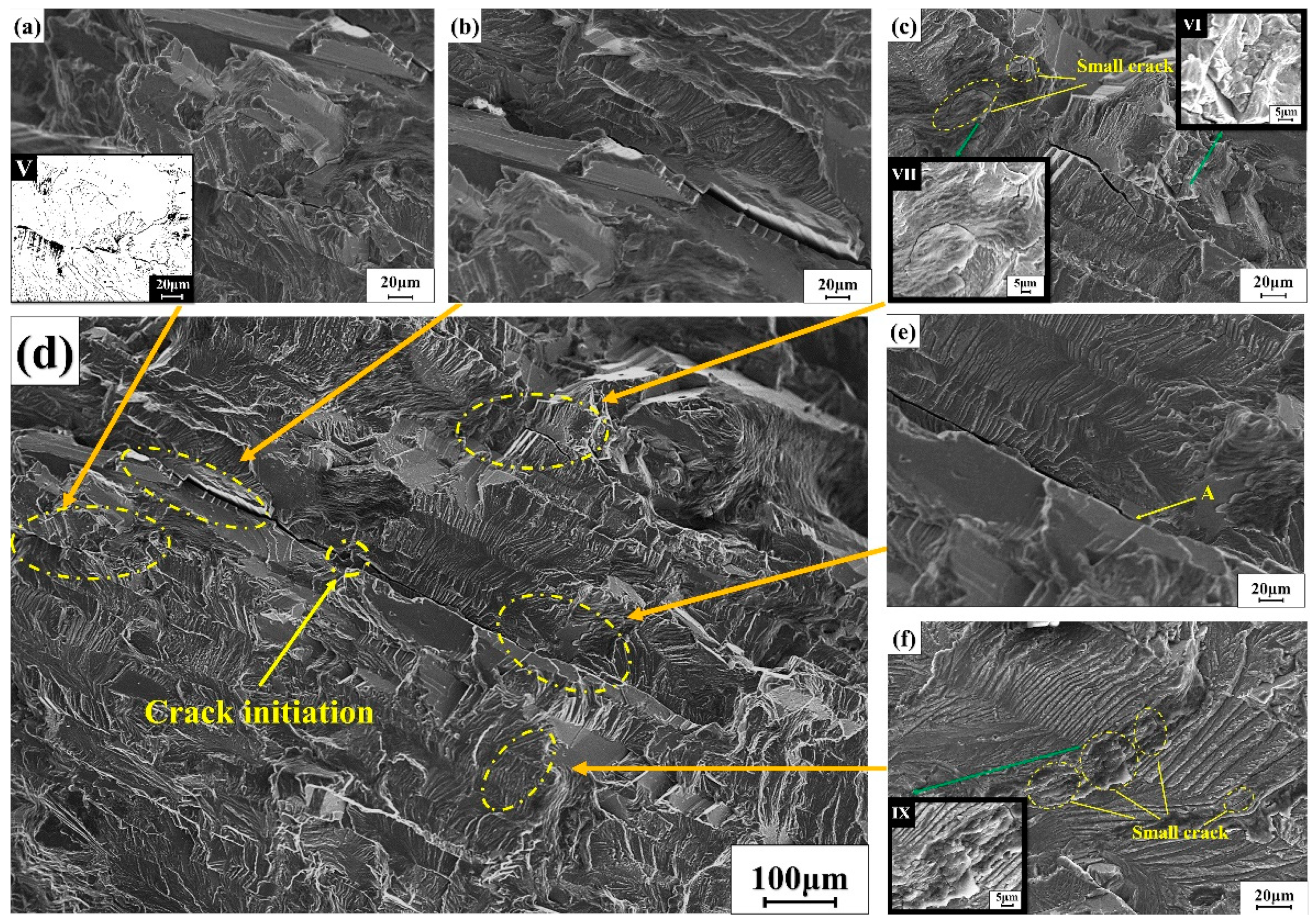

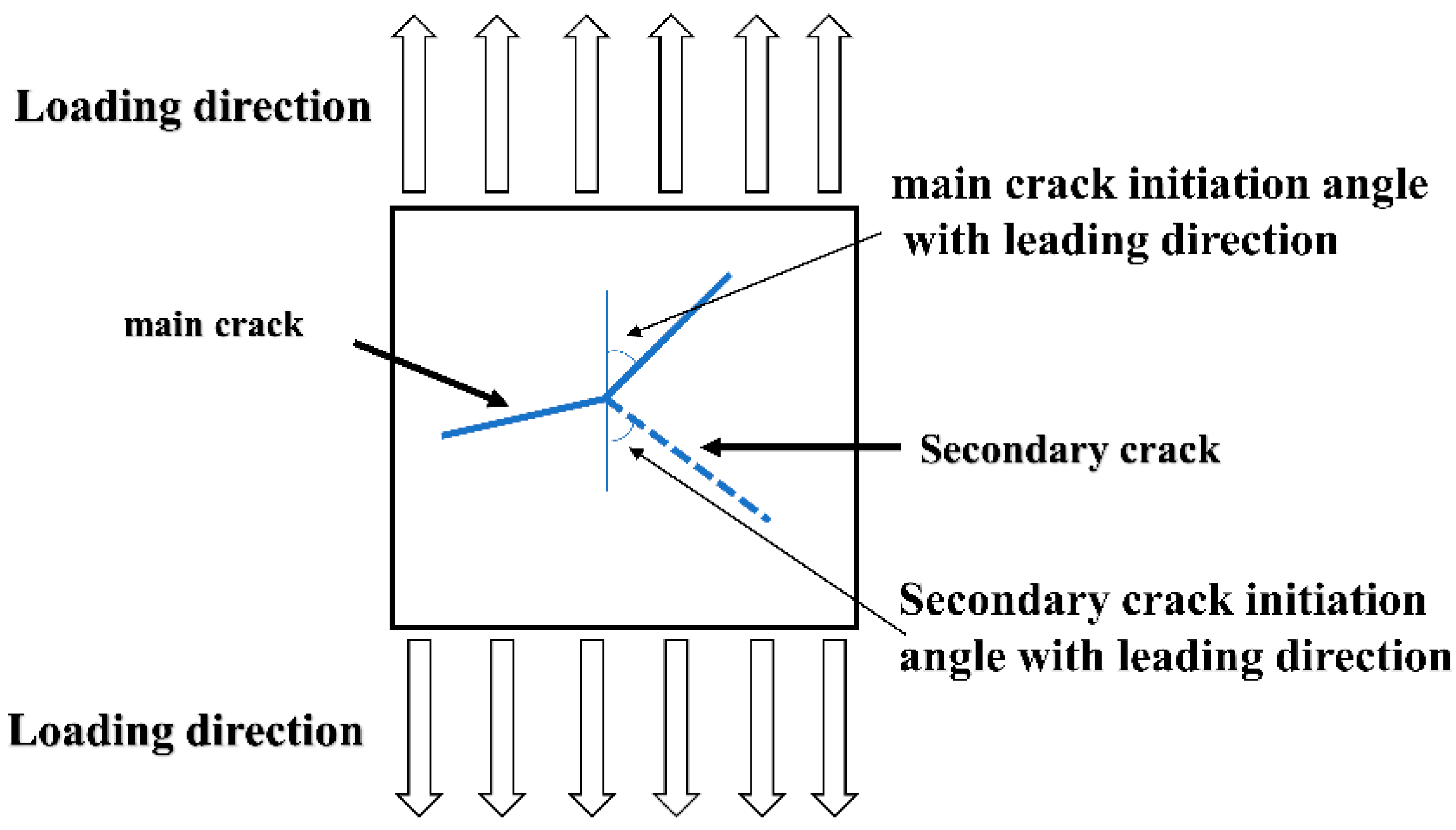

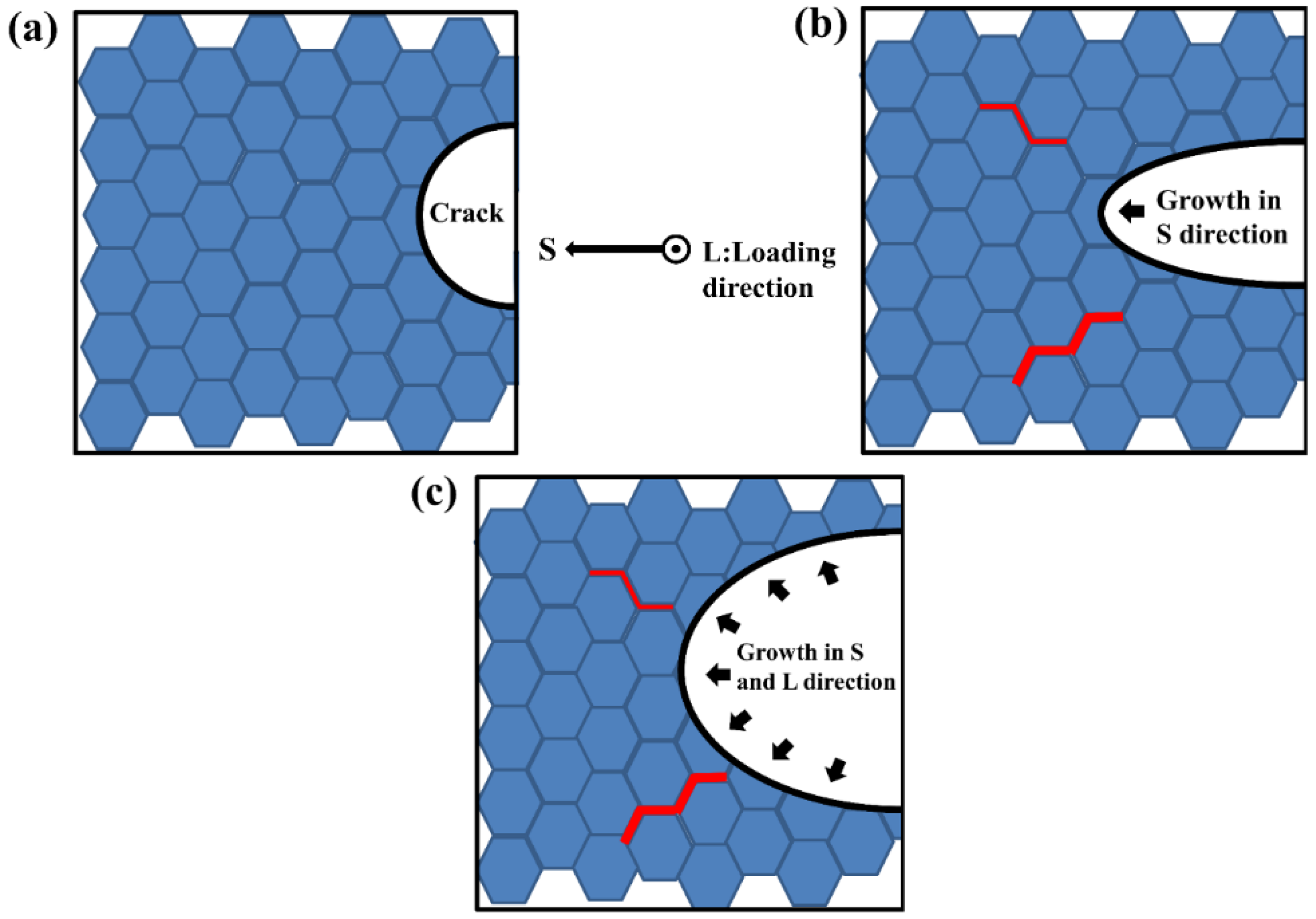

3.5. Mechanism of Fatigue Crack Propagation

3.6. Discussion

4. Conclusions

- Due to factors such as heat input, the precipitation phase in the WZ region was reduced, and the hardness of the WZ region was greatly reduced. Fatigue fracture occurred at the lap joint. Using post-treatment means to optimize the welding samples will give the welded joints better mechanical properties.

- In the stable crack propagation stage, grain orientation and other factors would hinder the crack propagation and change the crack propagation path. In the stable propagation stage, crack closure induced by oxides was also observed.

- Three evolution models were proposed: fishbone step evolution (model 1), secondary crack initiation evolution (model 2) and secondary crack evolution in main crack propagation (model 3). Model 1 explained the formation of step shape in crack propagation. Models 2 and 3 explained the propagation and interaction of secondary cracks. Model 3 explained the inhibitory effect of the main crack on the secondary crack. The small crack near the crack was easy to be hindered by the main crack propagation, and it was difficult to continue to when the size was small, the expansion stopped.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Simar, A.; Bréchet, Y.; de Meester, B.; Denquin, A.; Pardoen, T. Microstructure, local and global mechanical properties of friction stir welds in aluminium alloy 6005A-T6. Mater. Sci. Eng. A 2008, 486, 85–95. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tokaji, K.; Shibata, H.; Tozaki, Y.; Ohmune, T. Fatigue behaviour of friction stir welds without neither welding flash nor flaw in several aluminium alloys. Int. J. Fatigue 2009, 31, 1443–1453. [Google Scholar] [CrossRef]

- Liu, H.; Yang, S.; Xie, C.; Zhang, Q.; Cao, Y. Mechanisms of fatigue crack initiation and propagation in 6005A CMT welded joint. J. Alloy. Compd. 2018, 741, 188–196. [Google Scholar] [CrossRef]

- SreeArravind, M.; Kumar, S.R.; RaviShankar, B.; Kumar, S.S. Low cycle fatigue behavior of aluminium 6063 alloy under the cyclic frequency of 0.2 Hz. Mater. Today Proc. 2020, 27, 2376–2380. [Google Scholar] [CrossRef]

- McCullough, R.R.; Jordon, J.B.; Allison, P.G.; Rushing, T.; Garcia, L. Fatigue crack nucleation and small crack growth in an extruded 6061 aluminum alloy. Int. J. Fatigue 2019, 119, 52–61. [Google Scholar] [CrossRef]

- Gao, Y.K.; Wu, X.R. Experimental investigation and fatigue life prediction for 7475-T7351 aluminum alloy with and without shot peening-induced residual stresses. Acta Mater. 2011, 59, 3737–3747. [Google Scholar] [CrossRef]

- Brochu, M.; Verreman, Y.; Ajersch, F.; Bouchard, D. Propagation of short fatigue cracks in permanent and semi-solid mold 357 aluminum alloy. Int. J. Fatigue 2012, 36, 120–129. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.; Yang, S.; Huang, Y.; Fang, Y.; Gu, J.; Xiong, Q.; Duan, C. Microstructure characterization and mechanism of fatigue crack propagation of 6082 aluminum alloy joints. Mater. Chem. Phys. 2021, 257, 123734. [Google Scholar] [CrossRef]

- Duan, C.; Yang, S.; Liu, H.; Gu, J.; Xiong, Q.; Wang, Y. Formation and fatigue property of MIG welded high-speed train 6005A-T6 aluminum alloy. Mater. Res. Express 2019, 6, 056532. [Google Scholar] [CrossRef]

- Rometsch, P.A.; Cao, L.F.; Xiong, X.Y.; Muddle, B.C. Atom probe analysis of early-stage strengthening behaviour in an Al–Mg–Si–Cu alloy. Ultramicroscopy 2011, 111, 690–694. [Google Scholar] [CrossRef]

- Zedan, Y.; Houria, M.I.; Vanderesse, N.; Atmani, F.; Mirakhorli, F.; Nadeau, F.; Demers, V.; Bocher, P. Fatigue properties of continuous wave and pulsed wave laser cold-wire welding of thick section AA6005-T6 aluminum alloys. Int. J. Fatigue 2021, 147, 106184. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Wang, B.; Ma, M.; Yi, D. Influence of surface enhanced treatment on microstructure and fatigue performance of 6005A aluminum alloy welded joint. J. Manuf. Processes 2020, 60, 563–572. [Google Scholar] [CrossRef]

- Cauthen, C.; Anderson, K.V.; Avery, D.Z.; Baker, A.; Williamson, C.J.; Daniewicz, S.R.; Jordon, J.B. Fatigue crack nucleation and microstructurally small crack growth mechanisms in high strength aluminum alloys. Int. J. Fatigue 2020, 140, 105790. [Google Scholar] [CrossRef]

- Li, P.; Marchand, N.J. Crack initiation mechanisms in low cycle fatigue of aluminium alloy 7075 T6. Mater. Sci. Eng. A 1989, 119, 41–50. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agnew, S.R. Fatigue crack surface crystallography near crack initiating particle clusters in precipitation hardened legacy and modern Al–Zn–Mg–Cu alloys. Int. J. Fatigue 2011, 33, 1159–1174. [Google Scholar] [CrossRef]

- Indeck, J.; Demeneghi, G.; Mayeur, J.; Williams, C.; Hazeli, K. Influence of reversible and non-reversible fatigue on the microstructure and mechanical property evolution of 7075-T6 aluminum alloy. Int. J. Fatigue 2021, 145, 106094. [Google Scholar] [CrossRef]

- Pearson, S. Initiation of fatigue cracks in commercial aluminium alloys and the subsequent propagation of very short cracks. Eng. Fract. Mech. 1975, 7, 235–247. [Google Scholar] [CrossRef]

- Lankford, J. The growth of small fatigue cracks in 7075–T6 aluminum. Fatigue Fract. Eng. Mater. Struct. 1982, 5, 233–248. [Google Scholar] [CrossRef]

- Liu, H.; Yang, S.; Xie, C.; Zhang, Q.; Cao, Y. Microstructure characterization and mechanism of fatigue crack initiation near pores for 6005A CMT welded joint. Mater. Sci. Eng. A 2017, 707, 22–29. [Google Scholar] [CrossRef]

- Dong, P.; Li, H.; Sun, D.; Gong, W.; Liu, J. Effects of welding speed on the microstructure and hardness in friction stir welding joints of 6005A-T6 aluminum alloy. Mater. Des. 2013, 45, 524–531. [Google Scholar] [CrossRef]

- Gong, B.S.; Zhang, Z.J.; Hou, J.P.; Duan, Q.Q.; Wang, X.G.; Zhang, Z.F. Effect of aging state on corrosion fatigue properties of 7075 aluminum alloy. Int. J. Fatigue 2022, 161, 106916. [Google Scholar] [CrossRef]

- Selvamani, S.T. Microstructure and stress corrosion behaviour of CMT welded AA6061 T-6 aluminium alloy joints. J. Mater. Res. Technol. 2021, 15, 315–326. [Google Scholar] [CrossRef]

- Bianchetti, C.; Zheng, R.; Chromik, R.; Lévesque, M.; Brochu, M. Comparison of small and long fatigue crack growth behavior in AA 7050-T7451. Eng. Fract. Mech. 2018, 202, 20–32. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, S.; Shen, Z.; Cao, H.; Zhong, X.; Withers, P.J. Fine equiaxed zone induced softening and failure behavior of 7050 aluminum alloy hybrid laser welds. Mater. Sci. Eng. A 2021, 821, 141597. [Google Scholar] [CrossRef]

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Song, H.; Liu, C.; Zhang, H.; Du, J.; Yang, X.; Leen, S.B. In-situ SEM study of fatigue micro-crack initiation and propagation behavior in pre-corroded AA7075-T7651. Int. J. Fatigue 2020, 137, 105655. [Google Scholar] [CrossRef]

- Lei, X.; Nuam, V.L.; Bai, Y.; Dang, R.; Li, W.; Yao, W.; Wang, N. Investigation on laser beam remelted Al–Cu–Li alloy part I: Segregation and aging behavior at grain and dendrite boundaries. J. Alloy. Compd. 2021, 855, 157519. [Google Scholar] [CrossRef]

| Material | Mass Fraction/% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe | Cu | Si | Mn | Mg | Cr | Zn | Ti | Al | |

| 6005 | 0.35 | 0.30 | 0.60 | 0.50 | 0.40 | 0.30 | 0.20 | 0.10 | Balance |

| ER5356 | 0.40 | 0.10 | 0.25 | 0.35 | 4.80 | 0.15 | 0.10 | 0.13 | Balance |

| Welding Current/A | Welding Voltage/V | Welding Speed/(mm·s−1) | Protective Gas/(L·min−1) |

|---|---|---|---|

| 160 | 21 | 5.0 | 20 |

| Sample | Ordinal | Stress Range (MPa) | Fatigue Life (Cycle) | State |

|---|---|---|---|---|

| MIG | 1 | 50 | 286,854 | failure |

| 2 | 45 | 586,235 | failure | |

| 3 | 40 | 635,117 | failure | |

| 4 | 35 | 1,364,032 | failure | |

| 5 | 32.5 | 2,059,690 | failure | |

| 6 | 30 | 4,076,338 | failure | |

| 7 | 25 | 10,000,000 | runout | |

| 8 | 20 | 10,000,000 | runout | |

| BM | 1 | 200 | 302,481 | failure |

| 2 | 180 | 531,351 | failure | |

| 3 | 160 | 795,204 | failure | |

| 4 | 155 | 600,223 | failure | |

| 5 | 150 | 2,088,060 | failure | |

| 6 | 145 | 4,125,728 | failure | |

| 7 | 140 | 10,000,000 | runout | |

| 8 | 120 | 10,000,000 | runout |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Yang, S.; Wang, Z.; Gao, Z. Fatigue Property and Small Crack Propagation Mechanism of MIG Welding Joint of 6005A-T6 Aluminum Alloy. Materials 2022, 15, 4698. https://doi.org/10.3390/ma15134698

Peng Z, Yang S, Wang Z, Gao Z. Fatigue Property and Small Crack Propagation Mechanism of MIG Welding Joint of 6005A-T6 Aluminum Alloy. Materials. 2022; 15(13):4698. https://doi.org/10.3390/ma15134698

Chicago/Turabian StylePeng, Zeng, Shanglei Yang, Zhentao Wang, and Zihao Gao. 2022. "Fatigue Property and Small Crack Propagation Mechanism of MIG Welding Joint of 6005A-T6 Aluminum Alloy" Materials 15, no. 13: 4698. https://doi.org/10.3390/ma15134698

APA StylePeng, Z., Yang, S., Wang, Z., & Gao, Z. (2022). Fatigue Property and Small Crack Propagation Mechanism of MIG Welding Joint of 6005A-T6 Aluminum Alloy. Materials, 15(13), 4698. https://doi.org/10.3390/ma15134698