Fatigue Crack Arrest Induced by Localized Compressive Deformation

Abstract

1. Introduction

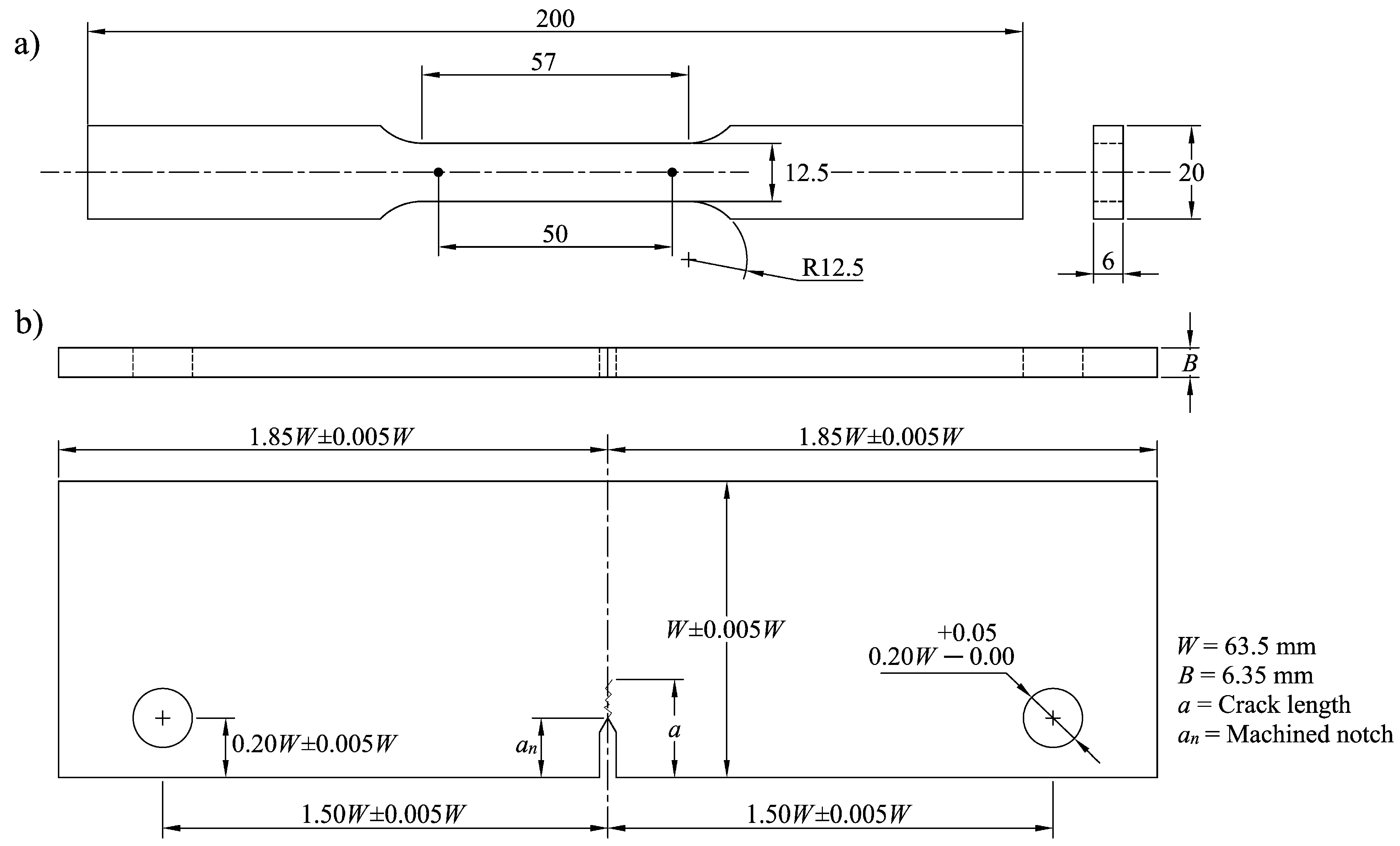

2. Materials and Methods

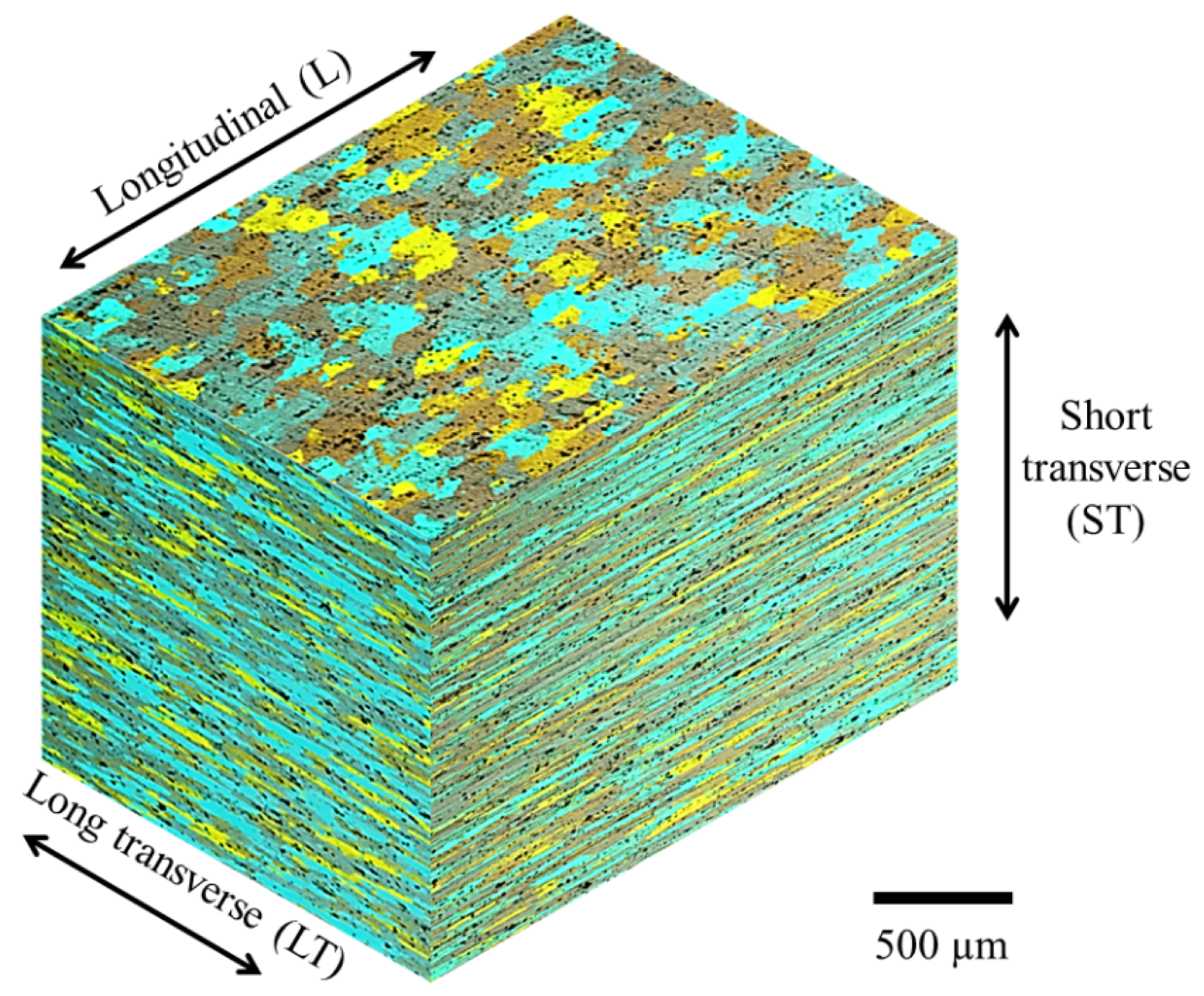

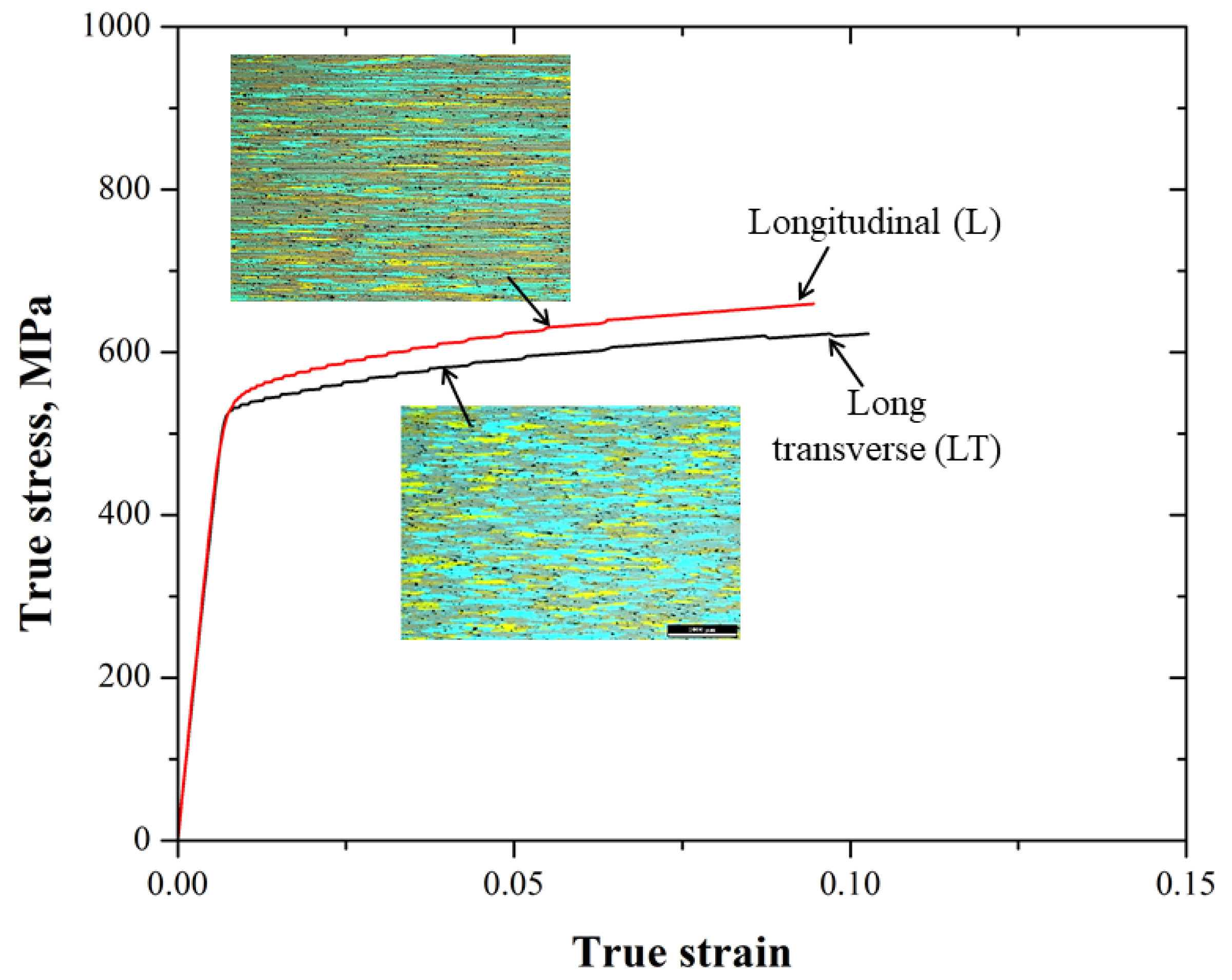

2.1. Microstructural and Mechanical Properties

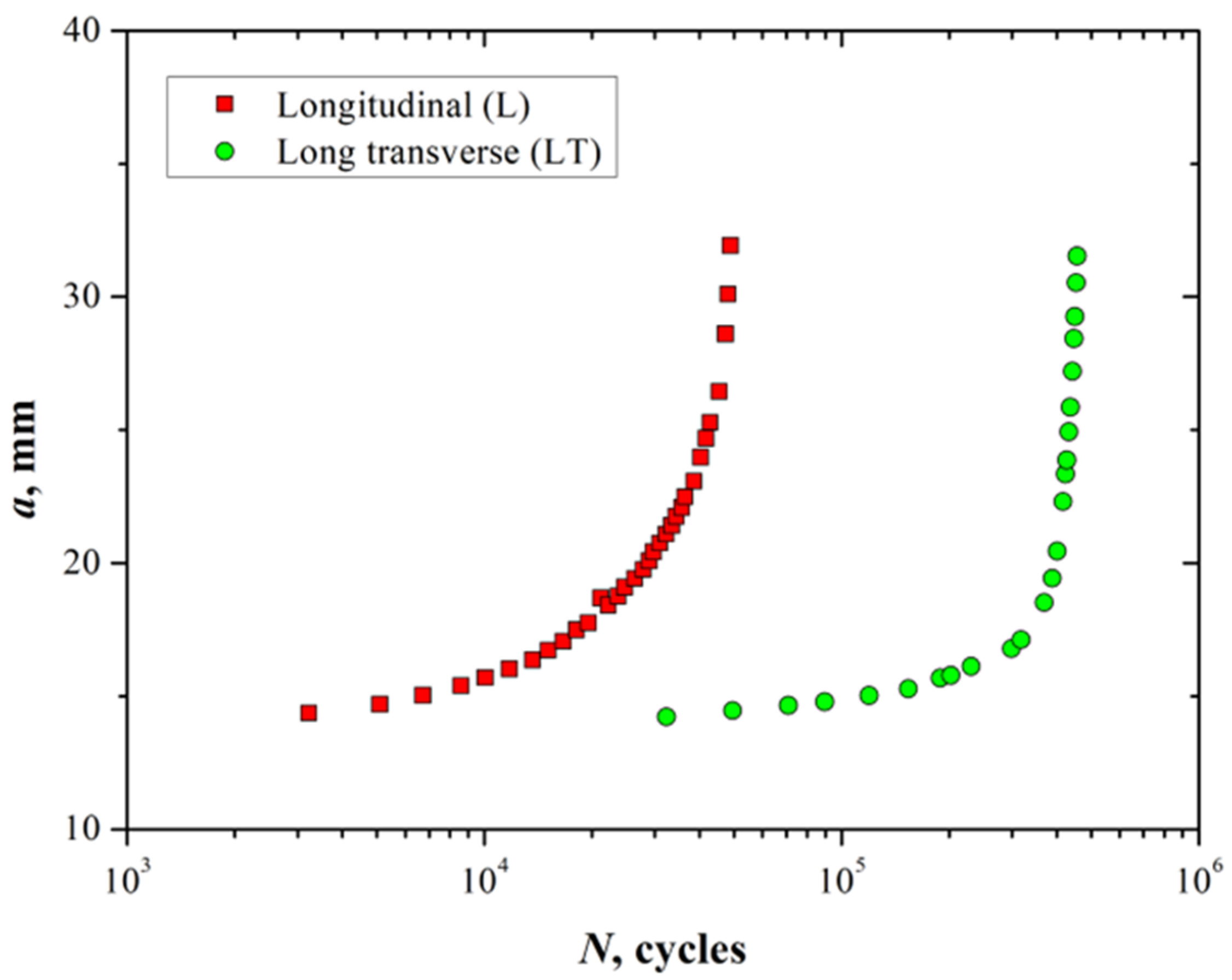

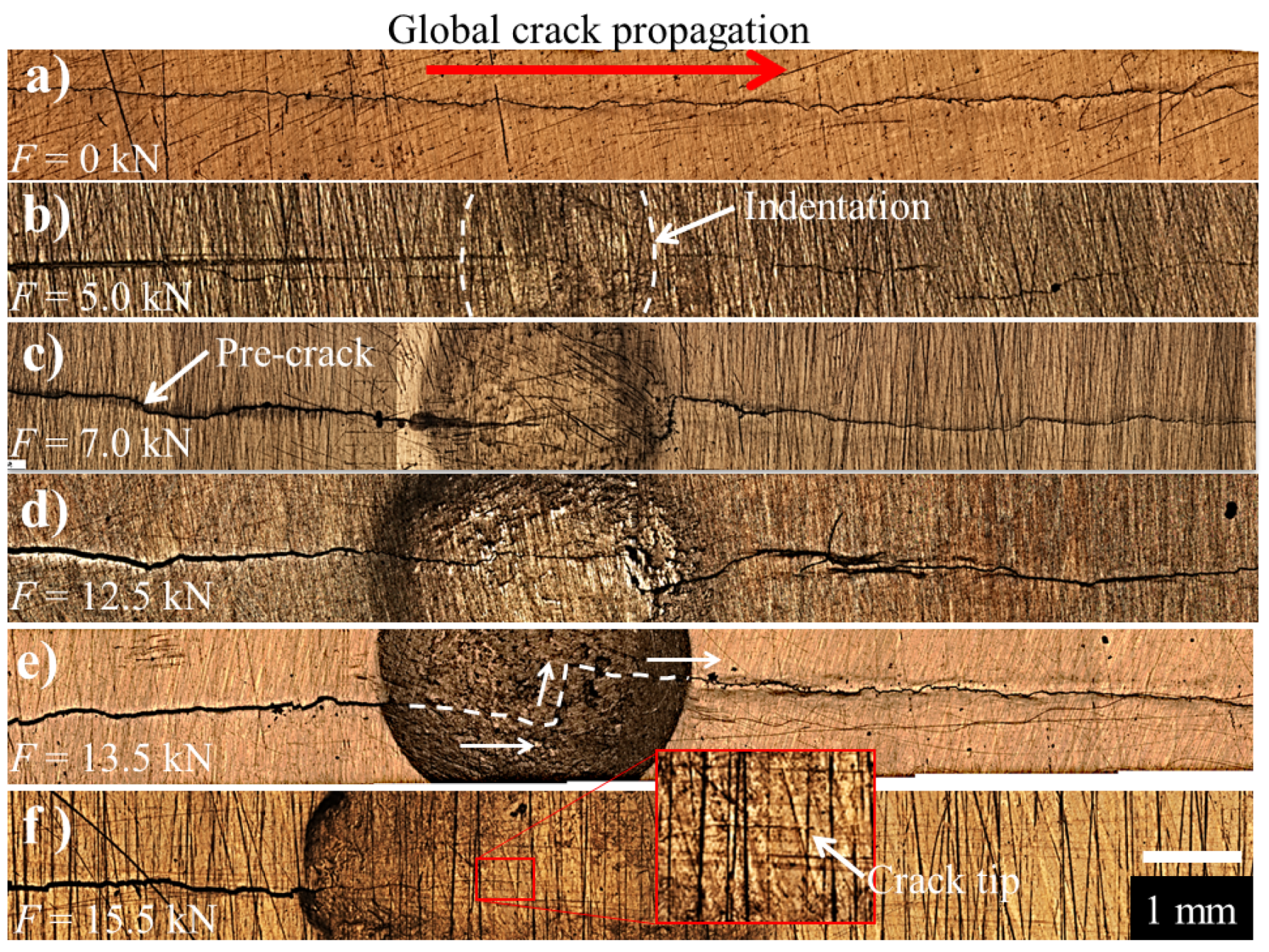

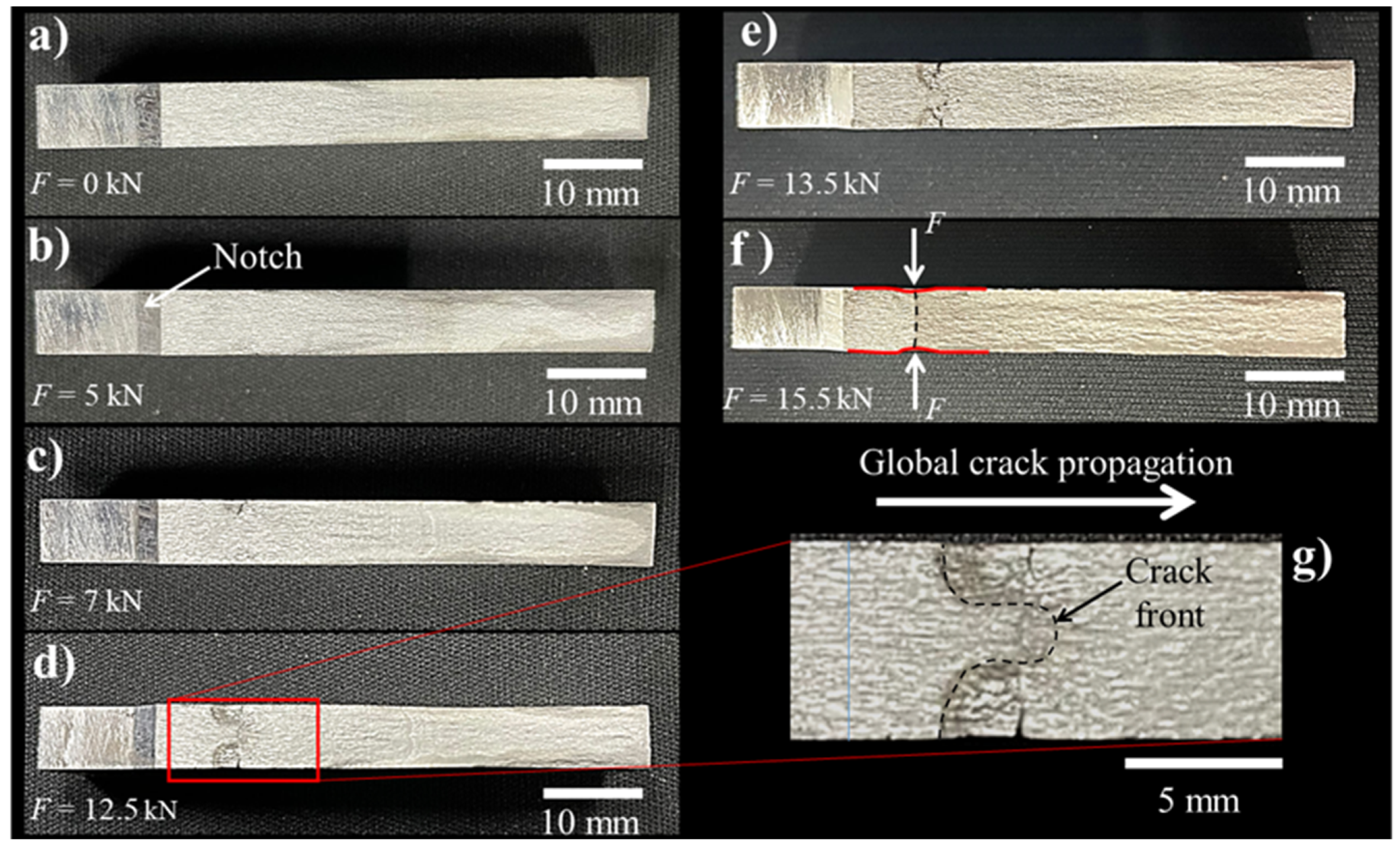

2.2. Localized Compressive Deformation (LCD) in Pre-Cracked Specimens

2.3. Residual Strain Measurements

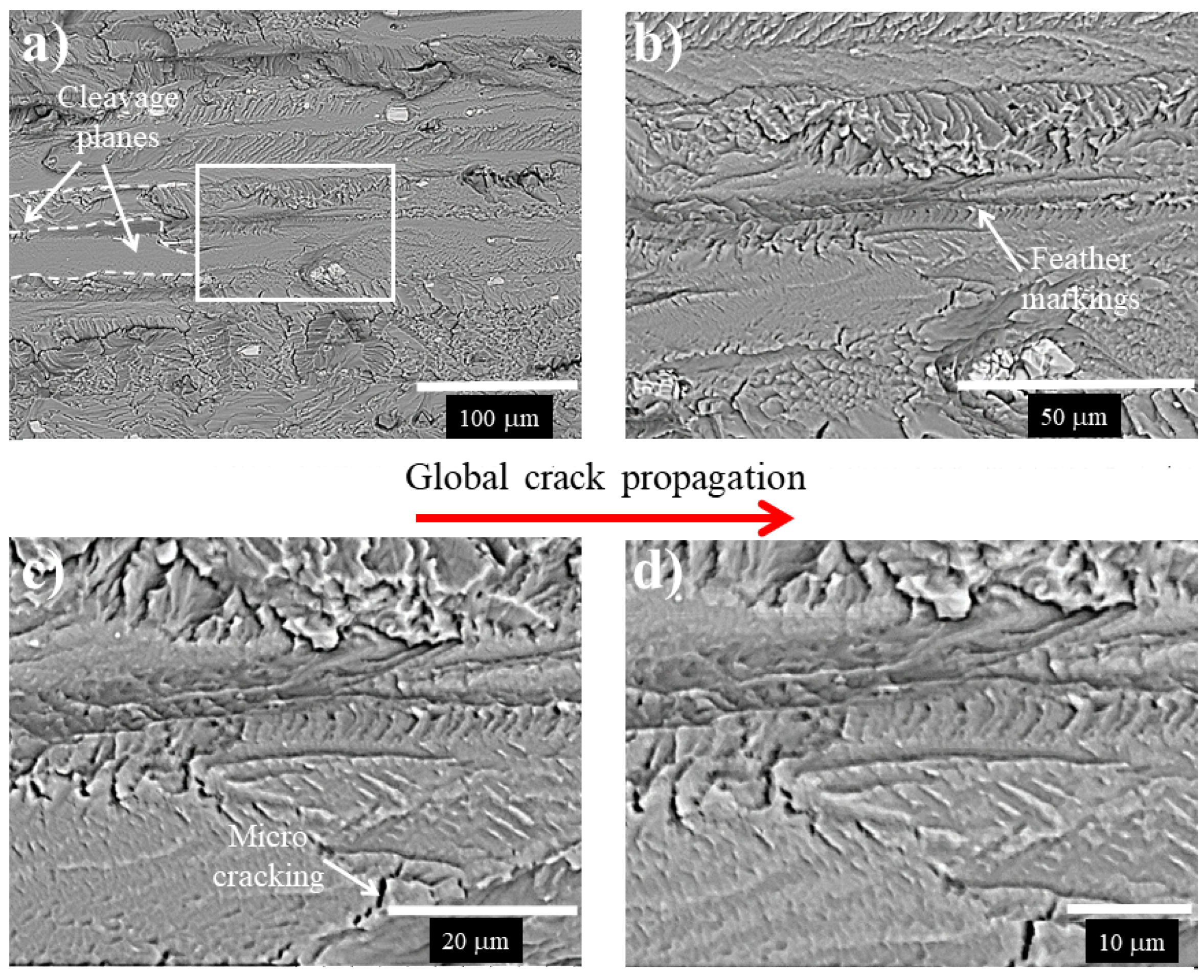

2.4. Fracture Surfaces

3. Results and Discussion

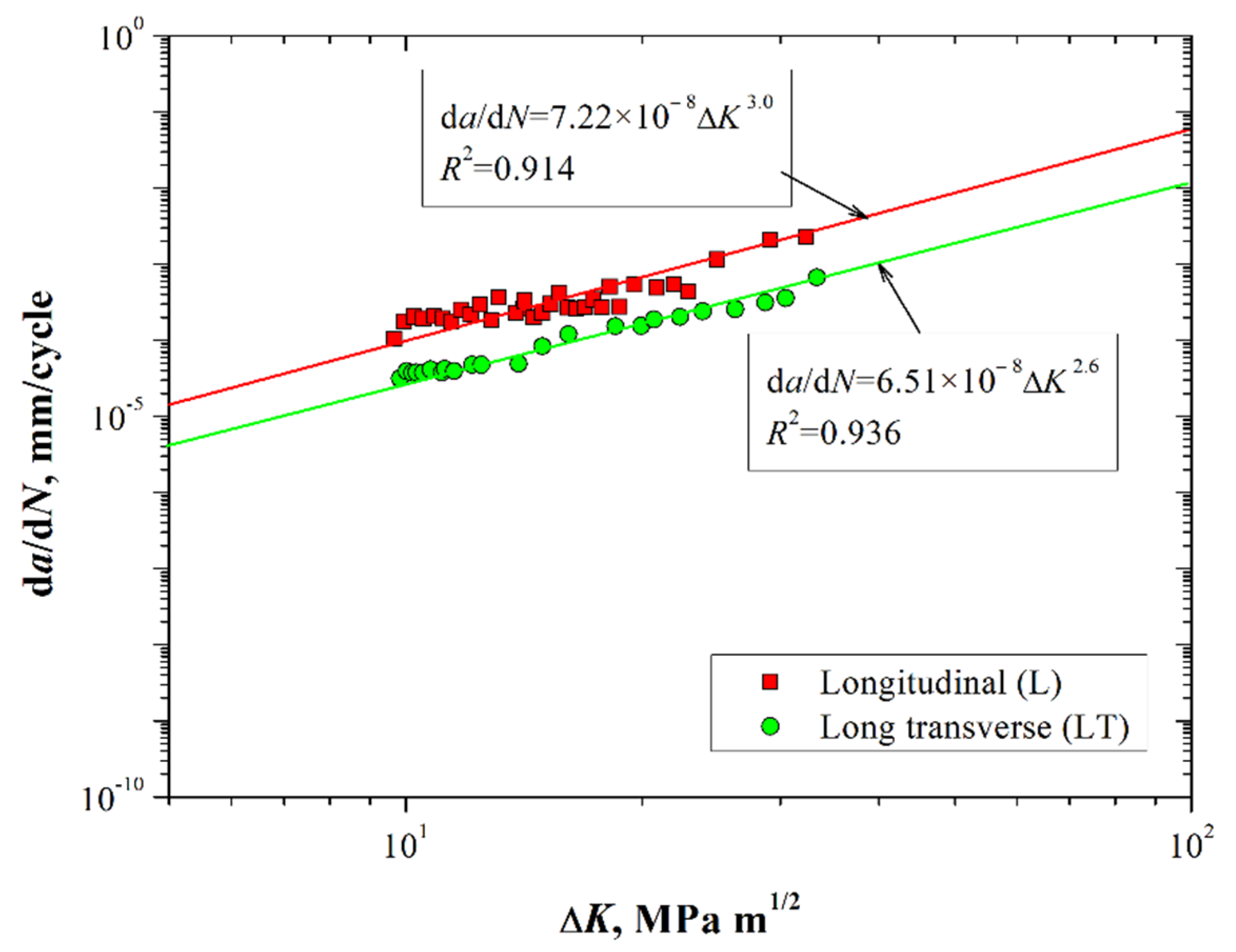

3.1. Material Characterization

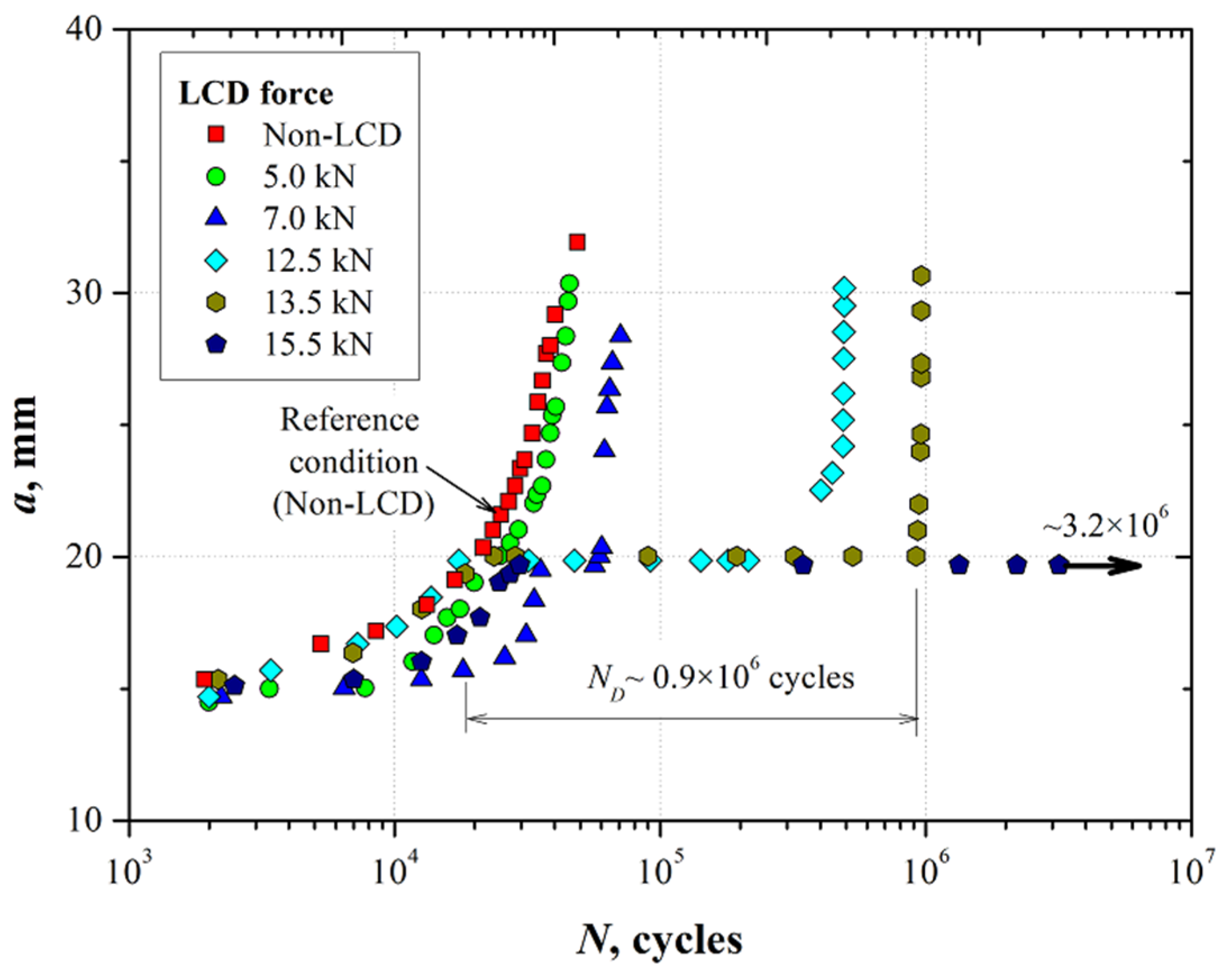

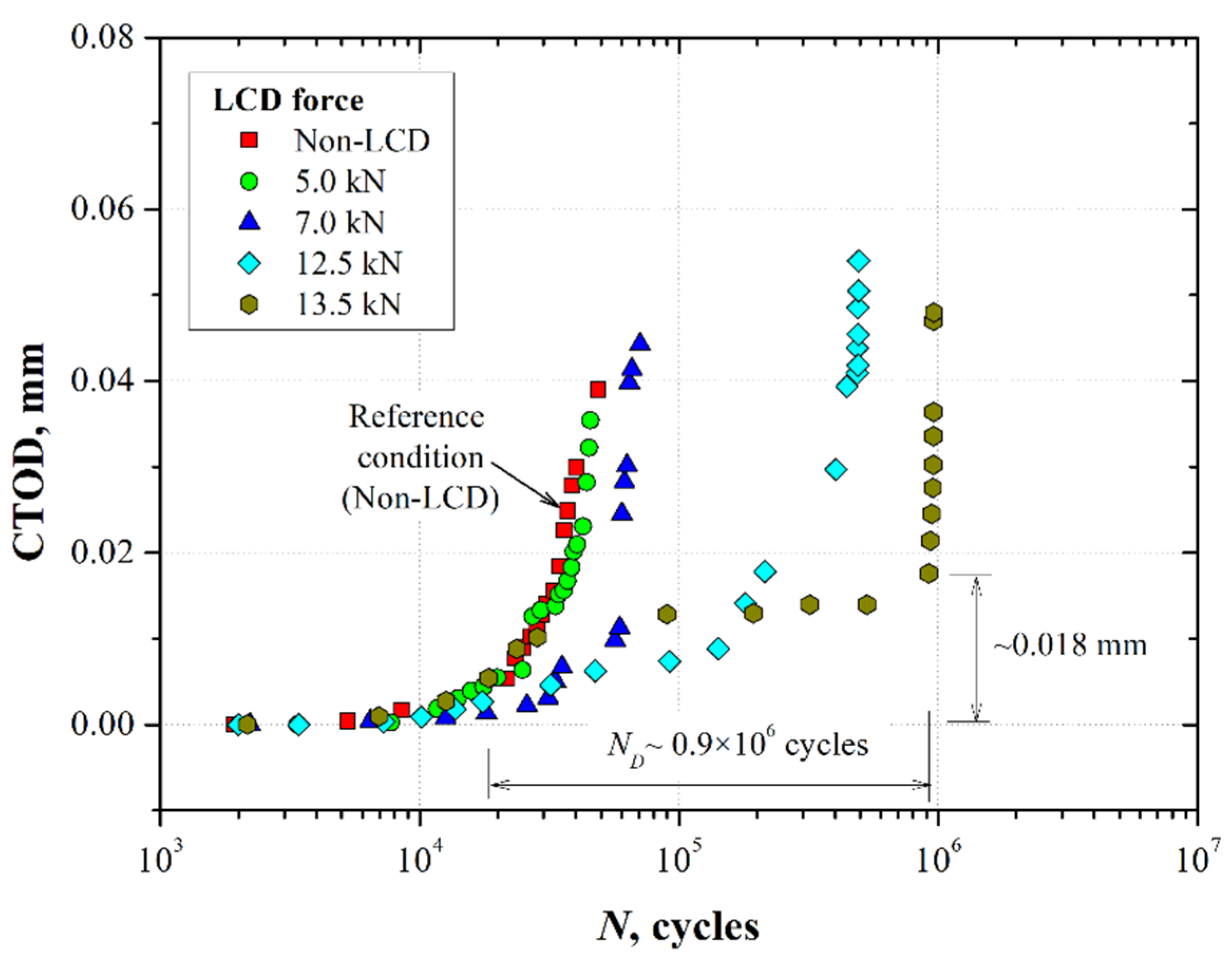

3.2. Localized Compressive Deformation (LCD) in Pre-Cracked Specimens

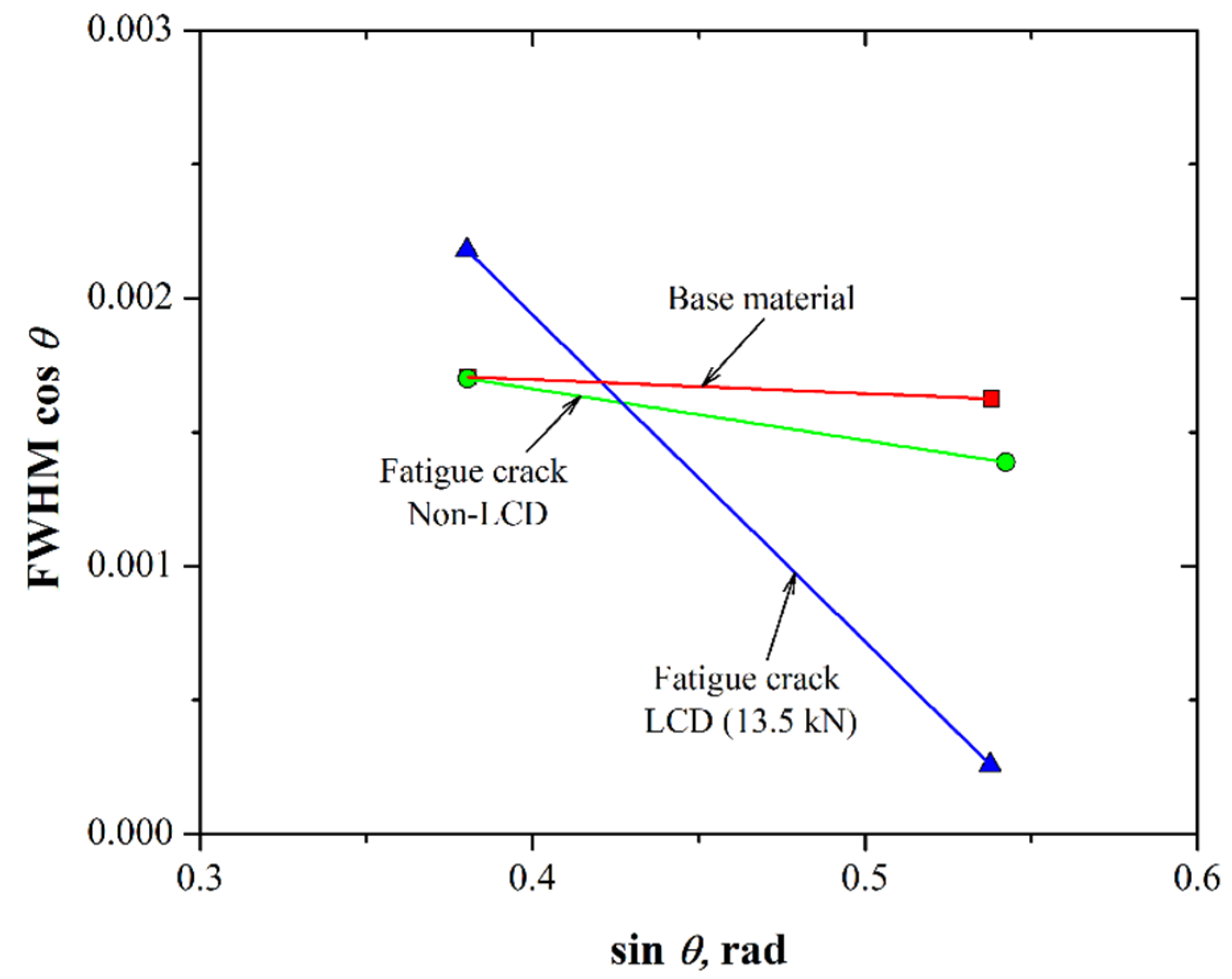

3.3. Residual Strain Measurements

3.4. Fracture Surfaces

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, B.; Liu, B.; Zhang, S. The Advancement of 7XXX Series Aluminum Alloys for Aircraft Structures: A Review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Soltani Tajabadi, M. Metallurgical Failure Analysis of a Cracked Aluminum 7075 Wing Internal Angle. Case Stud. Eng. Fail. Anal. 2016, 7, 9–16. [Google Scholar] [CrossRef][Green Version]

- Ritchie, R.O. Mechanisms of Fatigue Crack Propagation in Metals, Ceramics and Composites: Role of Crack Tip Shielding. Mater. Sci. Eng. 1988, A113, 15–28. [Google Scholar] [CrossRef]

- Soyama, H.; Chighizola, C.R.; Hill, M.R. Effect of Compressive Residual Stress Introduced by Cavitation Peening and Shot Peening on the Improvement of Fatigue Strength of Stainless Steel. J. Mater. Process. Technol. 2021, 288, 116877. [Google Scholar] [CrossRef]

- Ezeilo, A. Comparison of Shot Peening Residual Stress Distributions in a Selection of Materials. In Proceedings of the 5th International Conference on Shot Peening, Oxford, UK, 13–17 September 1993; pp. 275–282. [Google Scholar]

- Vöhringer, O. Changes in the State of the Material by Shot Peening. In Proceedings of the 3rd International Conference on Shot Peening, Garmisch-Partenkirchen, Germany, September 1987; pp. 185–204. [Google Scholar]

- Uroš Zupanc, J.G. Surface Integrity of Shot Peened Aluminium Alloy 7075-T651. J. Mech. Eng. 2011, 57, 379–384. [Google Scholar] [CrossRef]

- Hatamleh, O.; Lyons, J.; Forman, R. Laser and Shoot Peening Effects on Fatigue Crack Growth in Friction Stir Welded 7075-T751 Aluminium Alloys. Int. J. Fatigue 2007, 29, 421–434. [Google Scholar] [CrossRef]

- Klemenz, M.; Schulze, V.; Rohr, I.; Löhe, D. Application of the FEM for the Prediction of the Surface Layer Characteristics after Shot Peening. J. Mater. Process. Technol. 2009, 209, 4093–4102. [Google Scholar] [CrossRef]

- Viveros, K.C.; Ambriz, R.R.; Amrouche, A.; Talha, A.; García, C.; Jaramillo, D. Cold Hole Expansion Effect on the Fatigue Crack Growth in Welds of a 6061-T6 Aluminum Alloy. J. Mater. Process. Technol. 2014, 214, 2606–2616. [Google Scholar] [CrossRef]

- Ambriz, R.R.; García, C.; Rodríguez-Reyna, S.L.; Ramos-Azpeitia, M.; Jaramillo, D. Synergy Effects in the Fatigue Crack Growth of Hole Cold Expanded Specimens under Variable Cyclic Loading. Int. J. Fatigue 2020, 140, 105807. [Google Scholar] [CrossRef]

- B209-14; Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate. ASTM International: West Conshohocken, PA, USA, 2014.

- E384-17; Standard Test Method for Microindentation Hardness of Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- B557M-15; Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products. ASTM International: West Conshohocken, PA, USA, 2015.

- E647-15e1; Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM International: West Conshohocken, PA, USA, 2016.

- Feijoo, I.; Cabeza, M.; Merino, P.; Pena, G.; Pérez, M.C.; Cruz, S.; Rey, P. Estimation of Crystallite Size and Lattice Strain in Nano-Sized TiC Particle-Reinforced 6005A Aluminium Alloy from X-Ray Diffraction Line Broadening. Powder Technol. 2019, 343, 19–28. [Google Scholar] [CrossRef]

- ASM International. Handbook, Volume 2B: Properties and Selection of Aluminum Alloys, 2nd ed.; Anderson, K., Weritz, J., Kaufman, J.G., Eds.; ASM International: West Conshohocken, PA, USA, 2019; Volume 2. [Google Scholar]

- Xue, Y.; el Kadiri, H.; Horstemeyer, M.F.; Jordon, J.B.; Weiland, H. Micromechanisms of Multistage Fatigue Crack Growth in a High-Strength Aluminum Alloy. Acta Mater. 2007, 55, 1975–1984. [Google Scholar] [CrossRef]

- E112-06; Standard Test Methods for Determining Average Grain Size. ASTM International: West Conshohocken, PA, USA, 2006.

- Ringer, S.P.; Hono, K. Microstructural Evolution and Age Hardening in Aluminium Alloys: Atom Probe Field-Ion Microscopy and Transmission Electron Microscopy Studies. Mater. Charact. 2000, 44, 101–131. [Google Scholar] [CrossRef]

- James, M.A.; Newman, J. The Effect of Crack Tunneling on Crack Growth: Experiments and CTOA Analyses. Eng. Fract. Mech. 2003, 70, 457–468. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics, 3rd ed.; CRC Press: Danvers, MA, USA, 2017; ISBN 9781315370293. [Google Scholar]

| Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others |

|---|---|---|---|---|---|---|---|---|---|

| 88.6 | 0.03 | 0.19 | 1.7 | 0.02 | 2.7 | 0.18 | 6.4 | 0.02 | 0.16 |

| Direction | E (GPa) | σ0.2 (MPa) | σuts (MPa) | H (MPa) | n | Tensile Toughness (MJ m−3) |

|---|---|---|---|---|---|---|

| Longitudinal | 72 | 549 | 600 | 729 | 0.07 | 74.7 |

| Long transverse | 72 | 530 | 568 | 794 | 0.08 | 64.3 |

| LCD Force (kN) | Crack Arrest Relationship at 20 mm (Cycles/N) |

|---|---|

| 7.0 | 2.85 |

| 12.5 | 22.4 |

| 13.5 | 66.6 |

| 7075-T651 Alloy | Constitutive Equation | |

|---|---|---|

| Base material | (5) | |

| Fatigue crack non-LCD | (6) | |

| Fatigue crack with LCD (13.5 kN) | (7) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barragán, E.R.; Ambriz, R.R.; Frutos, J.A.; García, C.J.; Gómora, C.M.; Jaramillo, D. Fatigue Crack Arrest Induced by Localized Compressive Deformation. Materials 2022, 15, 4553. https://doi.org/10.3390/ma15134553

Barragán ER, Ambriz RR, Frutos JA, García CJ, Gómora CM, Jaramillo D. Fatigue Crack Arrest Induced by Localized Compressive Deformation. Materials. 2022; 15(13):4553. https://doi.org/10.3390/ma15134553

Chicago/Turabian StyleBarragán, Edú R., Ricardo R. Ambriz, José A. Frutos, Christian J. García, César M. Gómora, and David Jaramillo. 2022. "Fatigue Crack Arrest Induced by Localized Compressive Deformation" Materials 15, no. 13: 4553. https://doi.org/10.3390/ma15134553

APA StyleBarragán, E. R., Ambriz, R. R., Frutos, J. A., García, C. J., Gómora, C. M., & Jaramillo, D. (2022). Fatigue Crack Arrest Induced by Localized Compressive Deformation. Materials, 15(13), 4553. https://doi.org/10.3390/ma15134553