Multidisciplinary Approach to Agricultural Biomass Ash Usage for Earthworks in Road Construction

Abstract

:1. Introduction

2. Materials and Methods

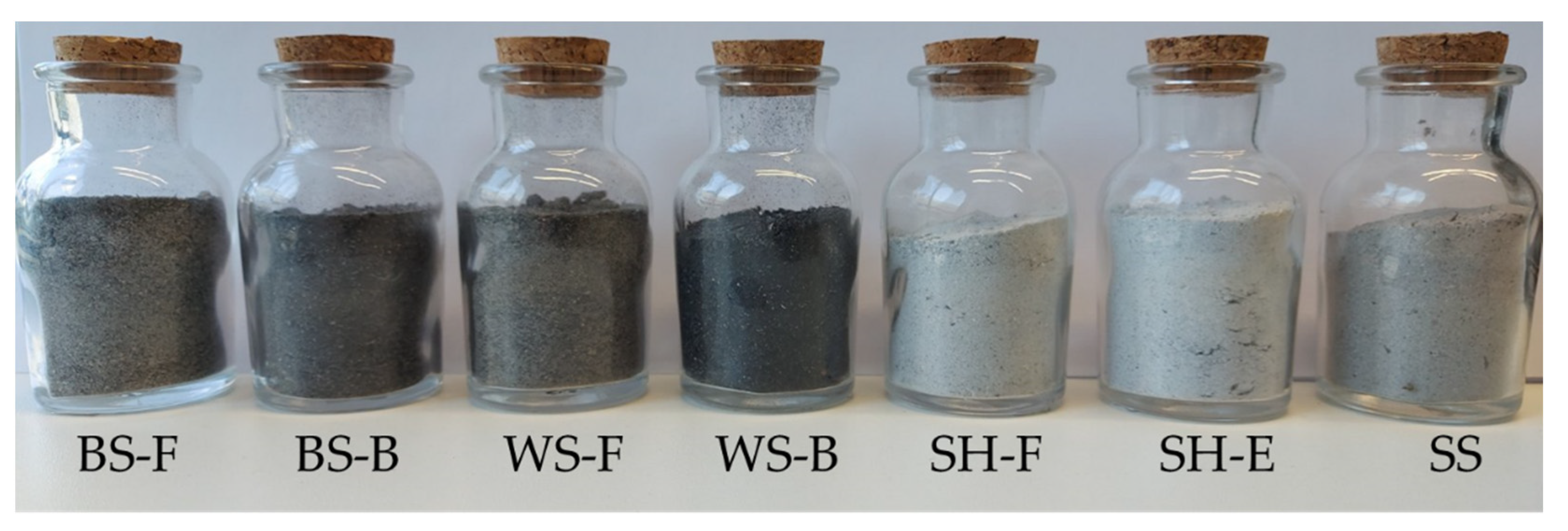

2.1. Biomass and Biomass Ash

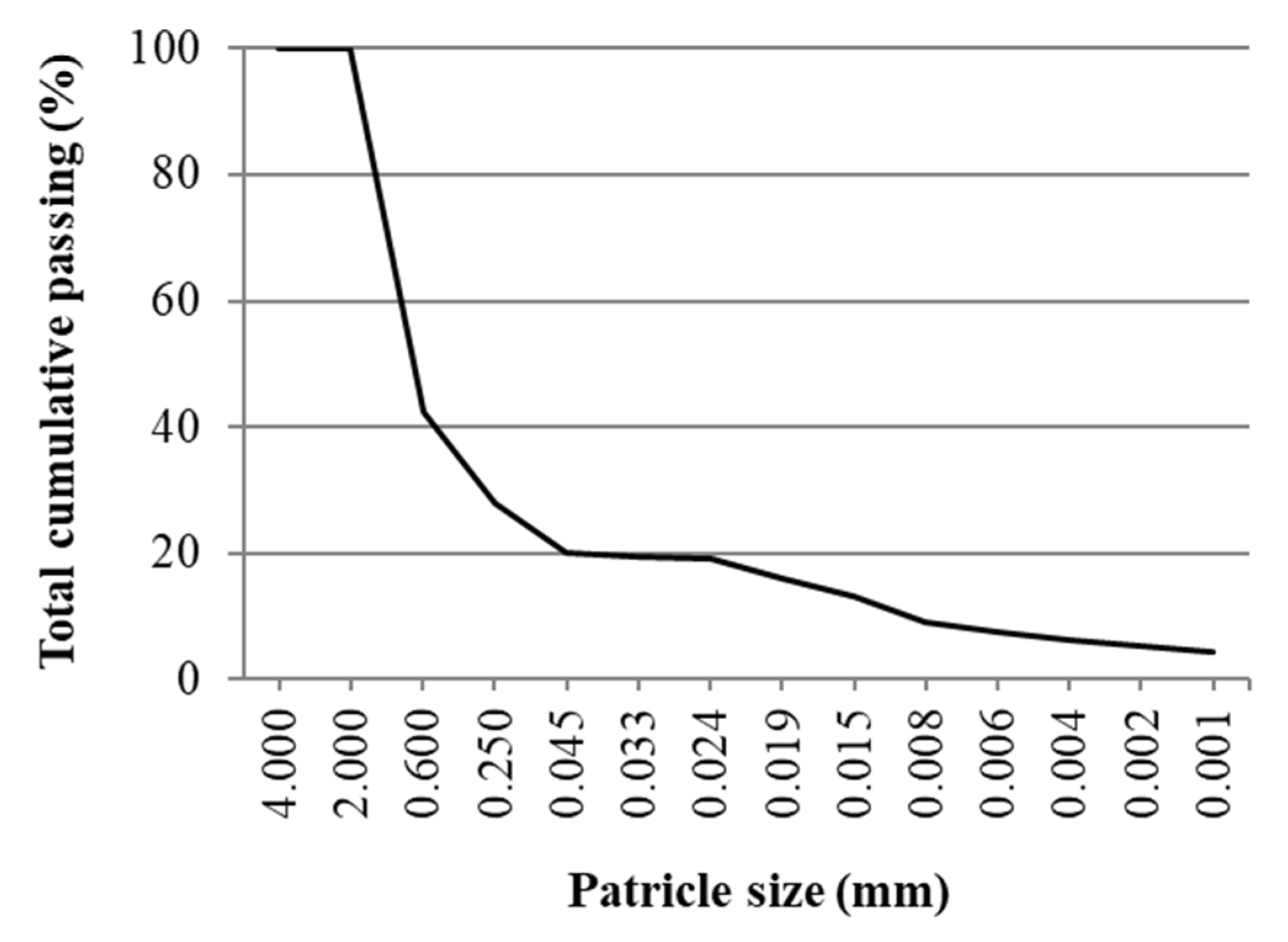

2.2. Stabilized Soil

2.3. Heavy Metal Content

2.4. Risk Assessment of ABA Leachate on Soil Organisms

2.4.1. Mortality and Molecular Biomarkers in Earthworm (Eisenia fetida)

2.4.2. Activity of Soil Microorganisms

3. Results and Discussion

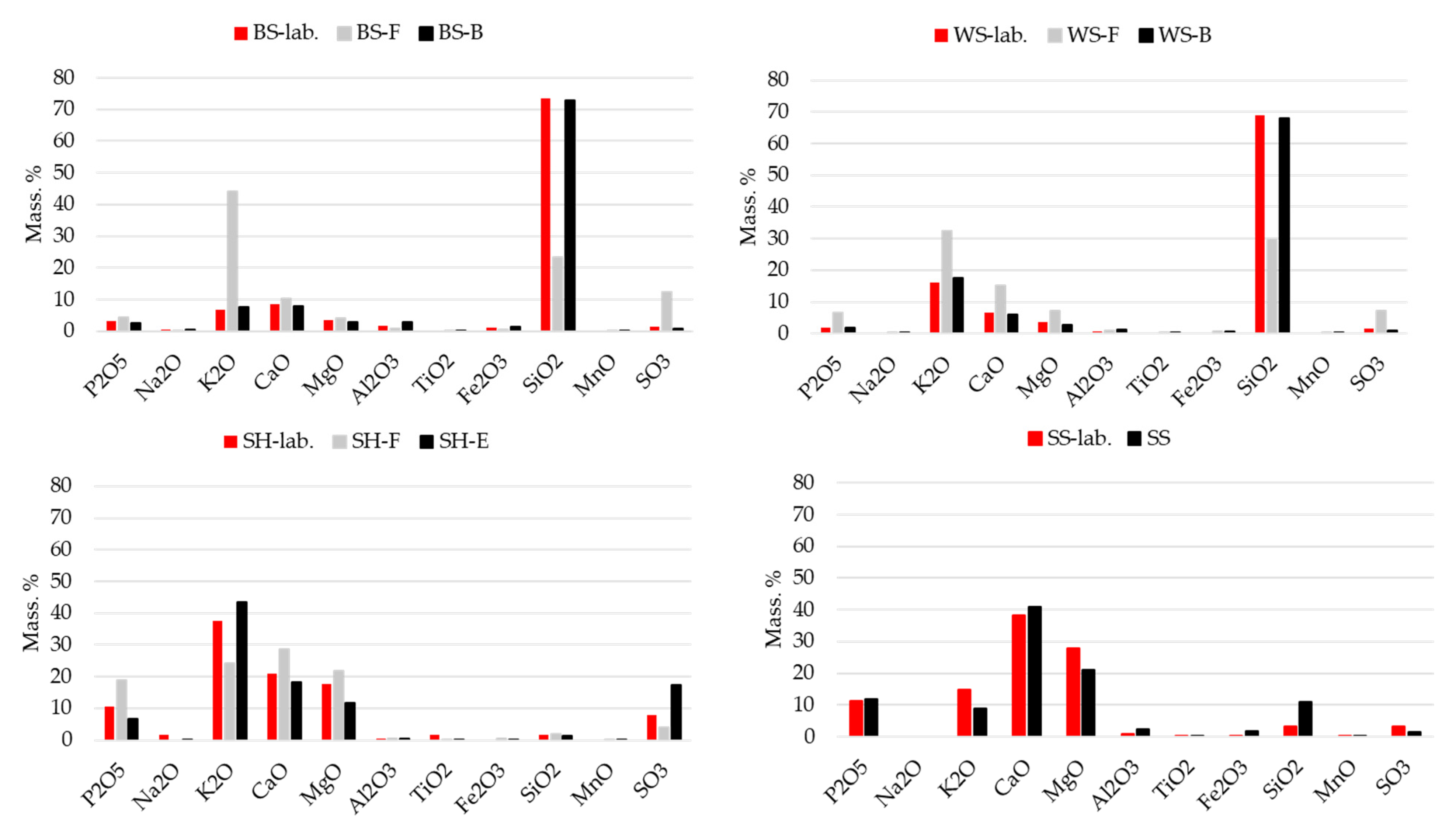

3.1. Characterstics of Agricultural Biomass and Agricultural Biomass Ash

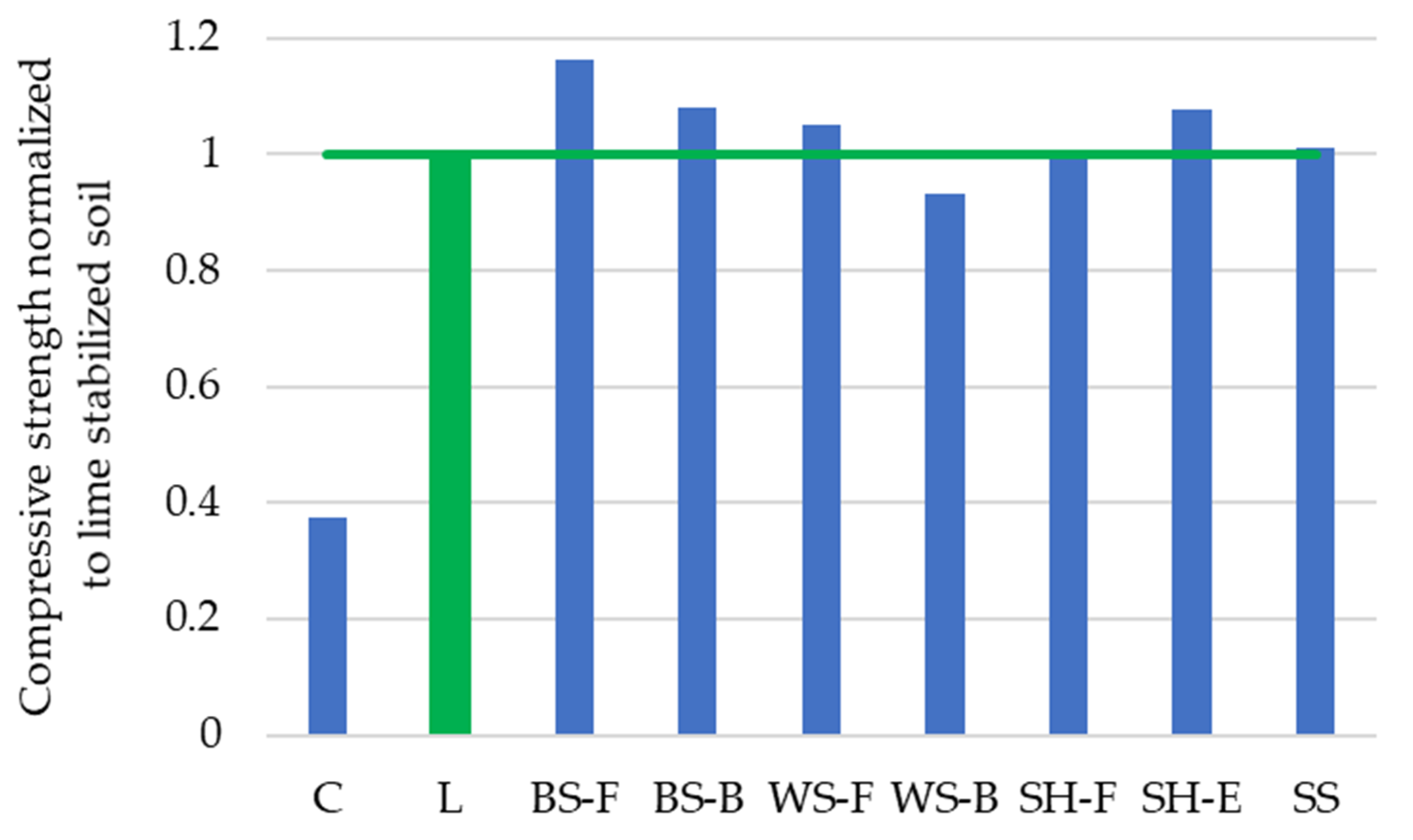

3.2. ABAs Influence on Stabilized Soil

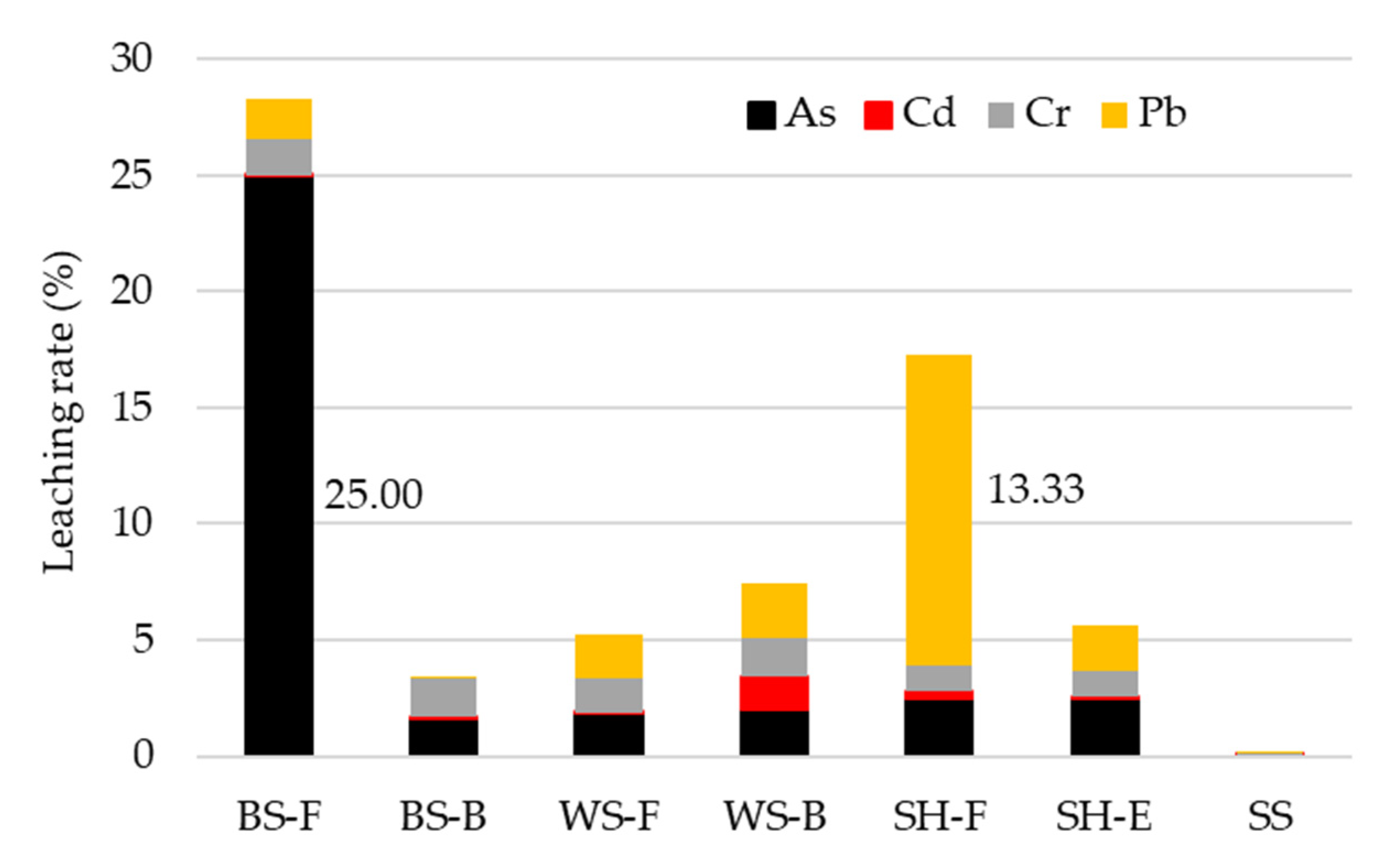

3.3. Heavy Metals and Leaching Potential

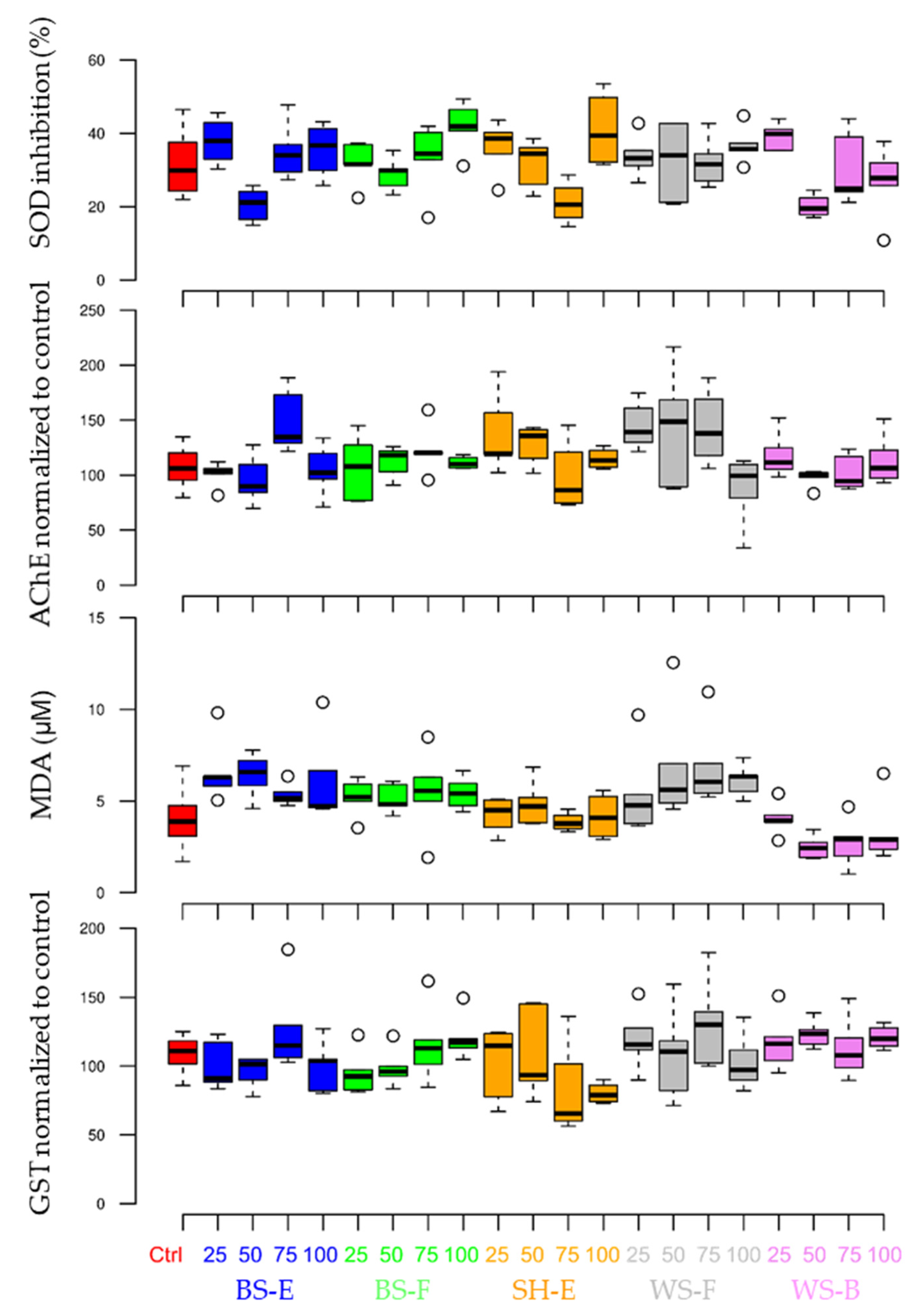

3.4. Mortality and Molecular Biomarkers in Earthworm (Eisenia fetida)

3.5. Activity of Soil Microorganisms

4. Conclusions

- Agricultural biomass presents a good potential for use as a fuel due to measured calorific values, but higher ash content and slagging (fouling) could be expected for certain biomasses. These issues need to be analysed for each individual biomass when introducing it as a new energy source, and chemical composition and empirical indices are helpful mechanisms.

- Lime/ABA binder improved geotechnical characteristics of low-plasticity clay, and it can be potentially used as a road construction material. When evaluating the potential application of ABA within road works, the chemical composition needs to be considered since it imposes a potential application (binder substitute or filler) and chemical reactions responsible for improving strength characteristics of stabilized soil can be predicted.

- The total heavy metal content in ABA is not an appropriate measure for predicting leaching potential and potential adverse environmental influence.

- Materials embedded in road embankment and subgrade are in direct contact with the surrounding soil, and appropriate environmental risk assessment needs to be conducted. There is a lack of proper legislation addressing the limiting values of potentially harmful substances within civil construction industry. Wastewater limit values are not appropriate since imbedding material changes the environment, which highly influences the leaching potential.

- Soil microbial activity was not substantially changed. The biofilm forming ability was decreased by barley and wheat fly ashes. The hydrolytic activity was decreased by adding lime instead of ashes, while the dehydrogenase activity was stimulated by all tested ash samples.

- The amount of ABAs added to the soil for roadworks should not have adverse effects on the soil fauna in the surrounding environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Environmental and Energy Study Institute. Fossil Fuels. Available online: https://www.eesi.org/topics/fossil-fuels/description (accessed on 18 February 2022).

- Ritchie, H.; Roser, M. Fossil Fuels. Available online: https://ourworldindata.org/fossil-fuels (accessed on 18 February 2022).

- World Bioenergy Association. Global Bioenergy Statistics 2021. Available online: https://www.worldbioenergy.org/uploads/211214%20WBA%20GBS%202021.pdf (accessed on 19 April 2022).

- Scarlat, N.; Martinov, M.; Dallemand, J.-F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Škrbić, S.; Ašonja, A.; Prodanović, R.; Ristić, V.; Stevanović, G.; Vulić, M.; Janković, Z.; Radosavac, A.; Igić, S. Analysis of Plant-Production-Obtained Biomass in Function of Sustainable Energy. Sustainability 2020, 12, 5486. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical characteristics of biomass ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef] [Green Version]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Benefcial management of biomass combustion ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Melotti, R.; Santagata, E.; Bassani, M.; Salvo, M.; Rizzo, S. A preliminary investigation into the physical and chemical properties of biomass ashes used as aggregate fillers for bituminous mixtures. Waste Manag. 2013, 33, 1906–1917. [Google Scholar] [CrossRef] [PubMed]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Tahami, S.A.; Arabani, M.; Mirhosseini, A.F. Usage of two biomass ashes as filler in hot mix asphalt. Constr. Build. Mater. 2018, 170, 547–556. [Google Scholar] [CrossRef]

- Shrivas, A.; Jain, D.; Joshi, R. Application of Different Waste in Concrete as a Partial Replacement of Cement. Int. J. Sci. Technol. Eng. 2015, 2, 89–107. [Google Scholar]

- Aksoğan, O.; Binici, H.; Ortlek, E. Durability of concrete made by partial replacement of fine aggregate by colemanite and barite and cement by ashes of corn stalk, wheat straw and sunflower stalk ashes. Constr. Build. Mater. 2016, 106, 253–263. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash Part 2. Potential utilisation, technological and ecological advantages and challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Cherian, C.; Siddiqua, S. Engineering and environmental evaluation for utilization of recycled pulp mill fly ash as binder in sustainable road construction. J. Clean. Prod. 2021, 298, 126758. [Google Scholar] [CrossRef]

- Cabrera, M.; Rosales, J.; Ayuso, J.; Estaire, J.; Agrela, F. Feasibility of using olive biomass bottom ash in the sub-bases of roads and rural paths. Constr. Build. Mater. 2018, 181, 266–275. [Google Scholar] [CrossRef]

- Varaprasad, B.J.S.; Reddy, J.J.; Reddy, J.S. Exploratory study on argo-industrial wastes for improving geotechnical properties of expansive soil—As sustainable material. Mater. Today Proc. 2021, 45, 6665–6673. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Y.; Chang, C.-W.; Namdar, A.; She, Y.; Lin, C.-H.; Yuan, X. Stabilization of expansive soil using cementing material from rice husk ash and calcium carbide residue. Constr. Build. Mater. 2019, 221, 1–11. [Google Scholar] [CrossRef]

- Yadav, A.K.; Gaurav, K.; Kishor, R.; Suman, S.K. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Chaunsali, P.; Uvegi, H.; Osmundsen, R.; Laracy, M.; Poinot, T.; Ochsendorf, J.; Olivetti, E. Mineralogical and microstructural characterization of biomass ash binder. Cem. Concr. Compos. 2018, 89, 41–51. [Google Scholar] [CrossRef]

- Singh, M.; Sharma, R. Soil stabilization using industrial waste (wheat husk and sugarcane straw ash). Int. Res. J. Eng. Technol. 2017, 4, 589–596. [Google Scholar]

- Netinger Grubeša, I.; Barišić, I. Environmental impact analysis of heavy metal concentrations in waste materials used in road construction. e-GFOS-Electron. J. Fac. Civ. Eng. Osijek 2016, 6, 23–29. [Google Scholar] [CrossRef]

- Barišić, I.; Netinger Grubeša, I.; Hackenberger Kutuzović, B. Multidisciplinary approach to the environmental impact of steel slag reused in road construction. Road Mater. Pavement Des. 2017, 18, 897–912. [Google Scholar] [CrossRef]

- Jagustyn, B.; Kmieć, M.; Smędowski, L.; Sajdak, M. The content and emission factors of heavy metals in biomass used for energy purposes in the context of the requirements of international standards. J. Energy Inst. 2017, 90, 704–714. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Y.; Hu, Z.; Zhang, L.; Yang, S.; Ruan, R.; Bai, S.; Tan, H. Characteristics of ash and slag from four biomass-fired power plants: Ash/slag ratio, unburned carbon, leaching of major and trace elements. Energy Convers. Manag. 2020, 214, 112897. [Google Scholar] [CrossRef]

- Li, L.; Yu, C.; Bai, J.; Wang, Q.; Luo, Z. Heavy metal characterization of circulating fluidized bed derived biomass ash. J. Hazard. Mater. 2012, 233–234, 41–47. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zou, D.; Zeng, X.; Li, L.; Wang, A.; Liu, F.; Wang, H.; Zeng, Q.; Xiao, Z. Effect of the direct use of biomass in agricultural soil on heavy metals__activation or immobilization? Environ. Pollut. 2021, 272, 115989. [Google Scholar] [CrossRef]

- Freire, M.; Lopes, H.; Tarelho, L.A.C. Critical aspects of biomass ashes utilization in soils: Composition, leachability, PAH and PCDD/F. Waste Manag. 2015, 46, 304–315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Y.; Wang, T.; Zhou, M.; Hou, H.; Xue, Y.; Wang, H. Rice husk and sewage sludge co-combustion ash: Leaching behavior analysis and cementitious property. Constr. Build. Mater. 2018, 163, 63–72. [Google Scholar] [CrossRef]

- Ogliari, A.J.; Zortéa, T.; Maccari, A.P.; Kraft, E.; de Oliveira Filho, L.C.I. Ecotoxicological Evaluation of Forest Biomass Ash on Springtails and Earthworms in Subtropical Soils of Brazil. J. Agric. Stud. 2020, 8, 208–226. [Google Scholar] [CrossRef] [Green Version]

- Qin, J.; Hovmand, M.F.; Ekelund, F.; Rønn, R.; Christensen, S.; de Groot, G.A.; Mortensen, L.H.; Skov, S.; Krogh, P.H. Wood ash application increases pH but does not harm the soil mesofauna. Environ. Pollut. 2017, 224, 581–589. [Google Scholar] [CrossRef]

- Chen, R.; Congress, S.S.C.; Cai, G.; Duan, W.; Liu, S. Sustainable utilization of biomass waste-rice husk ash as a new solidified material of soil in geotechnical engineering: A review. Constr. Build. Mater. 2021, 292, 123219. [Google Scholar] [CrossRef]

- Chen, C.; Bi, Y.; Huang, Y.; Huang, H. Review on slagging evaluation methods of biomass fuel combustion. J. Anal. Appl. Pyrolysis 2021, 155, 105082. [Google Scholar] [CrossRef]

- Vamvuka, D.; Kakaras, E. Ash properties and environmental impact of various biomass and coal fuels and their blends. Fuel Processing Technol. 2011, 92, 570–581. [Google Scholar] [CrossRef]

- EN ISO 17892-12:2018/A1:2021; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Liquid and Plastic Limits. European Committee for Standardization: Brusseles, Belgium, 2018.

- EN ISO 17892-4:2016; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. European Committee for Standardization: Brusseles, Belgium, 2004.

- prEN 13286-2; Unbound and Hydraulically Bound Mixtures—Part 2: Test Methods for Laboratory Reference Density and Water Content—Proctor Compaction. European Committee for Standardization: Brusseles, Belgium, 2010.

- EN 459-1:2015; Building Lime—Part 1: Definitions; Specifications and Conformity Criteria. European Committee for Standardization: Brusseles, Belgium, 2015.

- EN 1097-7:2008; Tests for Mechanical and Physical Properties of Aggregates—Part 7: Determination of the Particle Density of Filler—Pyknometer Method. European Committee for Standardization: Brusseles, Belgium, 2008.

- ISO 9277:2016; Determination of the Specific Surface Area of Solids by Gas Adsorption—BET Method. European Committee for Standardization: Brusseles, Belgium, 2016.

- ASTM D6276-99a; Standard Test Method for Using pH to Estimate the Soil-Lime Proportion Requirement for Soil Stabilization. ASTM International: West Conshohocken, PA, USA, 1999.

- EN 13286-41; Unbound and Hydraulically Bound Mixtures—Part 41: Test Method for Determination of the Compressive Strength of Hydraulically Bound Mixtures. European Committee for Standardization: Brusseles, Belgium, 2003.

- Barišić, I.; Netinger Grubeša, I.; Dokšanović, T.; Marković, B. Feasibility of Agricultural Biomass Fly Ash Usage for Soil Stabilisation of Road Works. Materials 2019, 12, 1375. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- EN 14332:2005; Foodstuffs—Determination of trace Elements—Determination of Arsenic in Seafood by Graphite Furnace Atomic Absorption Spectrometry (GFAAS) after Microwave Digestion. European Committee for Standardization: Brusseles, Belgium, 2004.

- EN 14084:2005; Foodstuffs—Determination of Trace Elements—Determination of Lead, Cadmium, Zink, Copper and Iron by Atomic Absorption Spectrometry (AAS) after Microwave Digestion. European Committee for Standardization: Brusseles, Belgium, 2005.

- EN 12457-2:2002; Characterisation of Waste. Leaching. Compliance Test for Leaching of Granular Waste Materials and Sludges. One Stage Batch Test at a Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size below 4 mm (without or with Size Reduction). European Committee for Standardization: Brussels, Belgium, 2002.

- EN ISO 15586:2008; Water Quality—Determination of Trace Elements Using Atomic Absorption Spectrometry with Graphite Furnace. European Committee for Standardization:: Brusseles, Belgium, 2008.

- Organization for Economic Cooperation and Development. Test No. 207: Earthworm, Acute Toxicity Tests, OECD Guidelines for the Testing of Chemicals, Section 2; OECD Publishing: Paris, France, 1984. [Google Scholar] [CrossRef]

- Organization for Economic Cooperation and Development. Test No. 222: Earthworm Reproduction Test (Eisenia fetida/Eisenia andrei), OECD Guidelines for the Testing of Chemicals, Section 2; OECD Publishing: Paris, France, 2016. [Google Scholar] [CrossRef]

- Ellman, G.L.; Courtney, K.D.; Andreas Jr., V.; Featherstone, R.M. A new and rapid colorimetric determination of acetylcho-linesterase activity. Biochem. Pharmacol. 1961, 7, 88–90. [Google Scholar] [CrossRef]

- Habig, W.H.; Pabst, M.J.; Jakobi, W. Glutathione S-Transferases the first enzymatic step in mercapturic acid formation. J. Biol. Chem. 1974, 249, 7130–7139. [Google Scholar] [CrossRef]

- McCord, J.M.; Fridovich, I. Superoxide dismutase. An enzymic function for erythrocuprein (hemocuprein). J. Biol. Chem. 1969, 244, 6049–6055. [Google Scholar] [CrossRef]

- Gagné, F. Biochemical Ecotoxicology: Principles and Methods; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Lowry, O.; Rosebrough, N.; Farr, A.; Randall, R. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- Golby, S.; Ceri, H.; Gieg, L.M.; Chatterjee, I.; Marques, L.L.R.; Turner, R.J.F.M.E. Evaluation of microbial biofilm communi-ties from an Alberta oil sands tailings pond. FEMS Microbiol. Ecol. 2012, 79, 240–250. [Google Scholar] [CrossRef] [Green Version]

- Adam, G.; Duncan, H. Development of a sensitive and rapid method for the measurement of total microbial activity using fluorescein diacetate (FDA) in a range of soils. Soil Biol. Biochem. 2001, 33, 943–951. [Google Scholar] [CrossRef] [Green Version]

- ISO 23753-2:2019; Soil Quality—Determination of Dehydrogenases Activity in Soils—Part 2: Method Using Iodonitrotetrazolium Chloride (INT). International Organization for Standardization: Geneva, Switzerland, 2019.

- Kramar, S.; Ducman, V. Evaluation of Ash Pozzolanic Activity by Means of the Strength Activity Index Test, Frattini Test and DTA/TG Analysis. Tehnički vjesnik-Technical Gazette 2018, 25, 1746–1752. [Google Scholar] [CrossRef]

- Ministry of Environmental Protection and Energy. Ordinance on Emission Limit Values for Wastewater Discharges (in Croatian). Official Gazette 26/20: Zagreb, Croatia, 2020. Available online: https://narodne-novine.nn.hr/clanci/sluzbeni/2020_03_26_622.html (accessed on 26 June 2022).

- Bahiru, D.B. Determination of Heavy Metals in Wastewater and Their Toxicological Implications around Eastern Industrial Zone, Central Ethiopia. J. Environ. Chem. Ecotoxicol. 2020, 12, 72–79. [Google Scholar] [CrossRef]

- Agency, E.U.S.E.P. Effluent Limitations Guidelines and Standards (ELG) Database. Available online: https://owapps.epa.gov/elg/ (accessed on 18 February 2022).

- Noor, N.M.; Othman, R.; Mubarak, N.M.; Abdullah, E.C. Agricultural biomass-derived magnetic adsorbents: Preparation and application for heavy metals removal. J. Taiwan Inst. Chem. Eng. 2017, 78, 168–177. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Dijkstra, J.J.; Comans, R.N.J. Assessment of biomass ash applications in soil and cement mortars. Chemosphere 2019, 223, 425–437. [Google Scholar] [CrossRef] [PubMed]

- Jänsch, S.; Amorim, M.J.; Römbke, J. Identification of the ecological requirements of important terrestrial ecotoxicological test species. Environmental Reviews. Environ. Rev. 2005, 13, 51–53. [Google Scholar] [CrossRef]

- Brami, C.; Pérès, G.; Menasseri-Aubry, S.; Byers-Woods, J.D.; Jacquet, T.; Lowe, C.N. Effect of Miscanthus× giganteus ash on survival, biomass, reproduction and avoidance behaviour of the endogeic earthworm Aporrectodea caliginosa. Ecotoxicology 2021, 30, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Kishor, P.; Ghosh, A.K.; Kumar, D. Use of flyash in agriculture: A way to improve soil fertility and its productivity. Asian J. Agric. Res. 2010, 4, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Pukalchik, M.; Mercl, F.; Terekhova, V.; Tlustoš, T. Biochar, wood ash and humic substances mitigating trace ele-ments stress in contaminated sandy loam soil: Evidence from an integrative approach. Chemosphere 2018, 203, 228–238. [Google Scholar] [CrossRef]

- Nayak, A.K.; Raja, R.; Rao, K.S.; Shukla, A.K.; Mohanty, S.; Shahid, M.; Tripathi, R.; Panda, B.B.; Bhattacharyya, P.; Kumar, A.; et al. Effect of fly ash application on soil microbial response and heavy metal accumulation in soil and rice plan. Ecotoxicol. Environ. Saf. 2015, 114, 257–262. [Google Scholar] [CrossRef]

- Perucci, P.; Monaci, E.; Casucci, C.; Vischetti, C. Effect of recycling wood ash on microbiological and biochemical proper-ties of soils. Agron. Sustain. Dev. 2006, 26, 157–165. [Google Scholar] [CrossRef] [Green Version]

- Kohli, S.J.; Goyal, D. Effects of fly ash application on some soil physical properties and microbial activities. Acta Agrophys. 2010, 16, 327–335. [Google Scholar]

- Garcia-Sanchez, M.; Garcia-Romera, I.; Cajthaml, T.; Tlustos, P.; Szakov, J. Changes in soil microbial community functionality and structure in a metal-polluted site: The effect of digestate and fly ash applications. J. Environ. Manag. 2015, 162, 63–73. [Google Scholar] [CrossRef]

- Quirantes, M.; Romero, E.; Nogales, R. Nutrient Availability in a Calcareous Soil Amended with Different Types of Biomass Ash. Commun. Soil Sci. Plant Anal. 2016, 47, 2271–2280. [Google Scholar] [CrossRef]

- Wong, M.H.; Wong, J.W.C. Effects of Fly Ash on Soil Microbial Activity. Environ. Pollut. 1986, 40, 127–144. [Google Scholar] [CrossRef]

- Pichtel, J.R.; Hayes, J.M. Influence of fly ash on soil microbial activity and populations. J. Environ. Qual. 1990, 19, 593–597. [Google Scholar] [CrossRef]

- Pati, S.S.; Sahu, S.K. CO2 evolution and enzyme activities (dehydrogenase, protease and amylase) of fly ash amended soil in the presence and absence of earthworms (Drawida willsi Michaelsen) under labor-atory conditions. Geoderma 2004, 118, 289–301. [Google Scholar] [CrossRef]

| Characteristic | Standard | Condition | BS | WS | SH | SS |

|---|---|---|---|---|---|---|

| Moisture content (mass%) | EN ISO 18134-1 | as received | 7.7 | 8 | 11.2 | 11.5 |

| Ash content (mass%) | EN ISO 18122 | as received | 6 | 5.1 | 3.6 | 3.7 |

| dry | 6.5 | 5.5 | 4 | 4.2 | ||

| Sulfur content (mass%) | EN ISO 16994 | as received | 0.066 | 0.057 | 0.097 | 0.047 |

| dry | 0.072 | 0.062 | 0.109 | 0.053 | ||

| Chlorine content (mass%) | EN ISO 16994 | as received | 0.12 | 0.133 | 0.104 | 0.064 |

| dry | 0.134 | 0.145 | 0.117 | 0.072 | ||

| Carbon content (mass%) | EN ISO 16948 | as received | 42.9 | 42.8 | 46.3 | 42.5 |

| dry | 46.6 | 46.5 | 52 | 47.7 | ||

| Hydrogen content (mass%) | EN ISO 16948 | as received | 5.1 | 5.1 | 5.4 | 5.1 |

| dry | 5.5 | 5.6 | 6.2 | 5.7 | ||

| Nitrogen content (mass%) | EN ISO 16948 | as received | 0.43 | 0.31 | 0.85 | 0.57 |

| dry | 0.47 | 0.33 | 0.96 | 0.64 | ||

| Gross calorific value (MJ/kg) | EN ISO 18125 | as received | 17.03 | 17.1 | 18.97 | 16.56 |

| dry | 18.45 | 18.59 | 21.36 | 18.71 | ||

| Net calorific value (MJ/kg) | EN ISO 18125 | as received | 15.74 | 15.78 | 17.5 | 15.18 |

| dry | 17.25 | 17.37 | 20.01 | 17.47 |

| Oxides (Mass%) | BS-F | BS-B | WS-F | WS-B | SH-F | SH-E | SS |

|---|---|---|---|---|---|---|---|

| P2O5 | 4.4 | 2.69 | 6.7 | 1.9 | 18.71 | 6.83 | 11.8 |

| Na2O | 0.26 | 0.54 | 0.21 | 0.21 | <0.10 | 0.25 | <0.10 |

| K2O | 44.16 | 7.48 | 32.46 | 17.7 | 24.13 | 43.58 | 8.98 |

| CaO | 10.2 | 7.86 | 15.26 | 6.09 | 28.68 | 18.19 | 41.02 |

| MgO | 4.15 | 2.93 | 7.19 | 2.78 | 21.68 | 11.75 | 21.09 |

| Al2O3 | 0.68 | 3.01 | 0.86 | 1.24 | 0.52 | 0.52 | 2.5 |

| TiO2 | 0.03 | 0.35 | 0.05 | 0.34 | 0.01 | 0.01 | 0.22 |

| Fe2O3 | 0.38 | 1.43 | 0.63 | 0.54 | 0.31 | 0.19 | 1.71 |

| SiO2 | 23.38 | 72.86 | 29.49 | 68.05 | 1.96 | 1.24 | 11.07 |

| MnO | 0.03 | 0.04 | 0.05 | 0.06 | 0.08 | 0.04 | 0.05 |

| SO3 | 12.34 | 0.83 | 7.11 | 1.1 | 3.91 | 17.39 | 1.56 |

| Oxide (Mass%) | BS | WS | SH | SS |

|---|---|---|---|---|

| P2O5 | 3.32 | 1.82 | 10.45 | 11.2 |

| Na2O | 0.5 | 0.3 | 1.62 | <0.1 |

| K2O | 6.62 | 16.23 | 37.51 | 14.87 |

| CaO | 8.43 | 6.64 | 20.86 | 38.34 |

| MgO | 3.37 | 3.57 | 17.78 | 27.77 |

| Al2O3 | 1.73 | 0.72 | 0.49 | 0.79 |

| TiO2 | 0.15 | 0.02 | 1.67 | 0.03 |

| Fe2O3 | 1.15 | 0.23 | 0.26 | 0.28 |

| SiO2 | 73.39 | 68.97 | 1.58 | 3.3 |

| MnO | 0.04 | 0.07 | 0.05 | 0.03 |

| SO3 | 1.31 | 1.44 | 7.73 | 3.39 |

| Empirical Indices | BS | WS | SH | SS |

|---|---|---|---|---|

| B/A = (Fe2O3 + CaO + MgO)/(SiO2 + Al2O3) | 0.17-L | 0.15-L | 18.79-VH | 16.23-VH |

| Sr = SiO2 100/(SiO2 + Fe2O3 + CaO + MgO) | 85.00-L | 86.85-L | 3.90-H | 4.74-H |

| Al = (K2O + Na2O)/GCV | 3.85-H | 8.89-H | 18.32-H | 7.96-H |

| Rb/a = (Fe2O3 + CaO + MgO + K2O + Na2O)/(SiO2 + TiO2 + Al2O3) | 0.27 | 0.39 | 20.86 | 19.72 |

| Property | Soil | Lime | BS-F | BS-B | WS-F | WS-B | SH-F | SH-E | SS |

|---|---|---|---|---|---|---|---|---|---|

| Density (g/cm3) | 2.74 | 2.65 | 2.40 | 2.40 | 2.40 | 2.40 | 2.40 | 2.40 | 2.40 |

| SSA (m2/g) | 0.98 | 1.67 | 3.41 | 3.10 | 3.69 | 3.29 | 3.37 | 4.77 | 10.35 |

| mg/kg | BS-F | BS-B | WS-F | WS-B | SH-F | SH-E | SS |

|---|---|---|---|---|---|---|---|

| As | 0.04 | 1.26 | 0.11 | 0.25 | 0.04 | <0.04 | 2.01 |

| Cd | 12.9 | 1.13 | 16.3 | 0.62 | 3.31 | 7.93 | 0.97 |

| Cr | 8.41 | 25.7 | 17.2 | 15.3 | 83.5 | 28.6 | 53.9 |

| Pb | 0.29 | 4.26 | 0.37 | 0.21 | <0.06 | 0.5 | 10.1 |

| mg/L | BS-F | BS-B | WS-F | WS-B | SH-F | SH-E | SS |

|---|---|---|---|---|---|---|---|

| As | 0.01 | 0.02 | 0.002 | 0.005 | <0.001 | <0.001 | <0.001 |

| Cd | 0.002 | 0.001 | 0.002 | 0.009 | 0.01 | 0.002 | 0.0002 |

| Cr | 0.13 | 0.43 | 0.26 | 0.25 | 0.94 | 0.32 | 0.02 |

| Pb | 0.005 | 0.003 | 0.007 | 0.005 | 0.008 | 0.01 | 0.003 |

| Element | Croatian Regulation (mg/L) [58] | WHO (mg/L) [59] | US EPA (mg/L) [60] |

|---|---|---|---|

| As | 0.1 * | - | 0.004 to 4 |

| Cd | 0.1 * | 0.003 | 0.0172 to 1.2 |

| Cr-total | 0.5 | 0.1 | 0.025 to 19 |

| Pb | 0.5 * | 0.05 | 0.057 to 3.4 |

| Preliminary Experiment | ||||

|---|---|---|---|---|

| ABA | Mortality (%) | Conductivity (μS/cm) | pH | |

| Control (dH2O) | 0 | 301.3 | 7.2 | |

| Lime | 20 | 8352.67 | 13.39 | |

| SH-F | 20 | 8448.00 | 13.35 | |

| SH-E | 40 | 9160.67 | 13.39 | |

| BS-F | 40 | 8837.67 | 13.35 | |

| BS-E | 60 | 8882.33 | 13.38 | |

| BS-B | 0 | 8056.67 | 13.41 | |

| WS-F | 40 | 8885.67 | 13.37 | |

| WS-B | 40 | 8141.00 | 13.36 | |

| SS | 20 | 8374.00 | 13.33 | |

| Final Experiment | ||||

| ABA | % of Eluate Added | Mortality (%) | Conductivity | pH |

| Control (dH2O) | 0 | 285.20 | 6.45 | |

| WS_F | 100 | 0 | 487.13 | 6.68 |

| 75 | 0 | 441.83 | 6.74 | |

| 50 | 0 | 419.80 | 6.73 | |

| 25 | 0 | 410.80 | 6.46 | |

| WS-B | 100 | 0 | 552.80 | 6.75 |

| 75 | 0 | 509.33 | 6.74 | |

| 50 | 0 | 421.10 | 6.73 | |

| 25 | 0 | 413.03 | 6.46 | |

| BS-E | 100 | 0 | 456.40 | 6.83 |

| 75 | 0 | 449.40 | 6.67 | |

| 50 | 0 | 415.77 | 6.67 | |

| 25 | 0 | 411.83 | 6.50 | |

| BS-F | 100 | 0 | 561.40 | 6.81 |

| 75 | 0 | 488.57 | 6.74 | |

| 50 | 0 | 449.73 | 6.74 | |

| 25 | 0 | 444.07 | 6.29 | |

| SH-E | 100 | 0 | 570.70 | 6.75 |

| 75 | 0 | 517.27 | 6.65 | |

| 50 | 0 | 498.30 | 6.52 | |

| 25 | 0 | 463.63 | 6.33 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barišić, I.; Netinger Grubeša, I.; Hackenberger, D.K.; Palijan, G.; Glavić, S.; Trkmić, M. Multidisciplinary Approach to Agricultural Biomass Ash Usage for Earthworks in Road Construction. Materials 2022, 15, 4529. https://doi.org/10.3390/ma15134529

Barišić I, Netinger Grubeša I, Hackenberger DK, Palijan G, Glavić S, Trkmić M. Multidisciplinary Approach to Agricultural Biomass Ash Usage for Earthworks in Road Construction. Materials. 2022; 15(13):4529. https://doi.org/10.3390/ma15134529

Chicago/Turabian StyleBarišić, Ivana, Ivanka Netinger Grubeša, Davorka K. Hackenberger, Goran Palijan, Stella Glavić, and Marija Trkmić. 2022. "Multidisciplinary Approach to Agricultural Biomass Ash Usage for Earthworks in Road Construction" Materials 15, no. 13: 4529. https://doi.org/10.3390/ma15134529

APA StyleBarišić, I., Netinger Grubeša, I., Hackenberger, D. K., Palijan, G., Glavić, S., & Trkmić, M. (2022). Multidisciplinary Approach to Agricultural Biomass Ash Usage for Earthworks in Road Construction. Materials, 15(13), 4529. https://doi.org/10.3390/ma15134529