Modeling Dynamic Recrystallization Behavior in a Novel HIPed P/M Superalloy during High-Temperature Deformation

Abstract

:1. Introduction

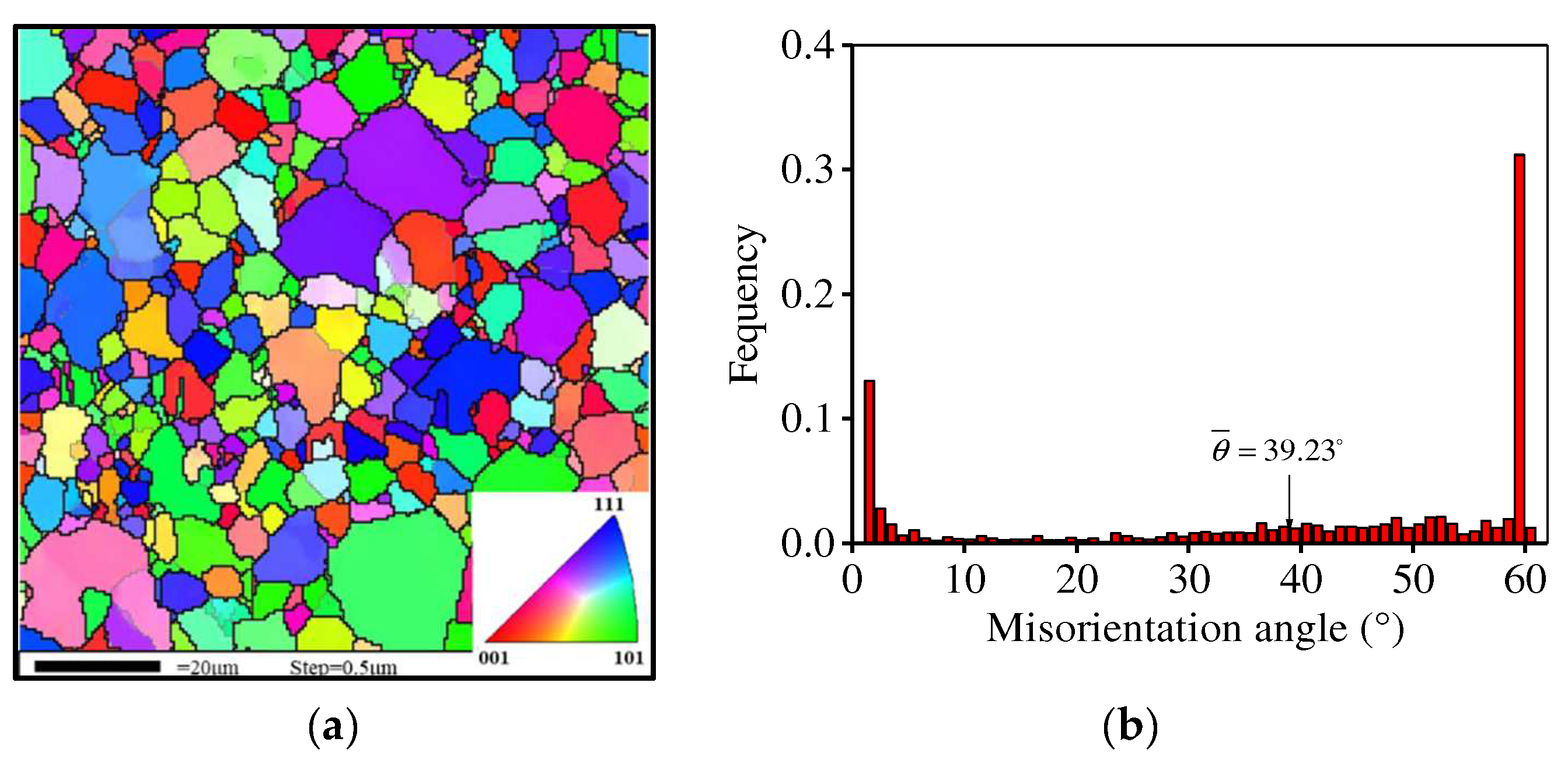

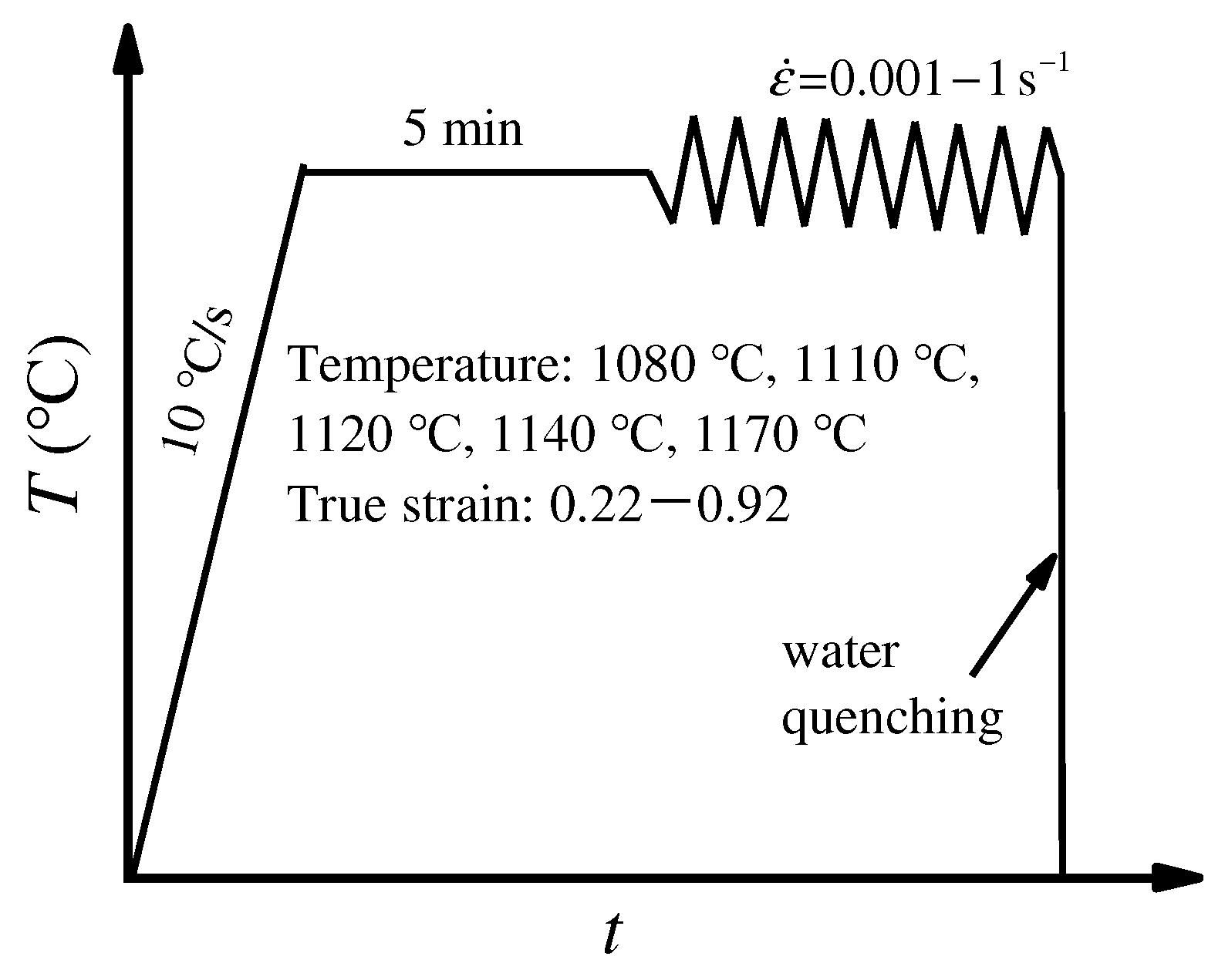

2. Material and Experiment Procedures

3. Results and Discussion

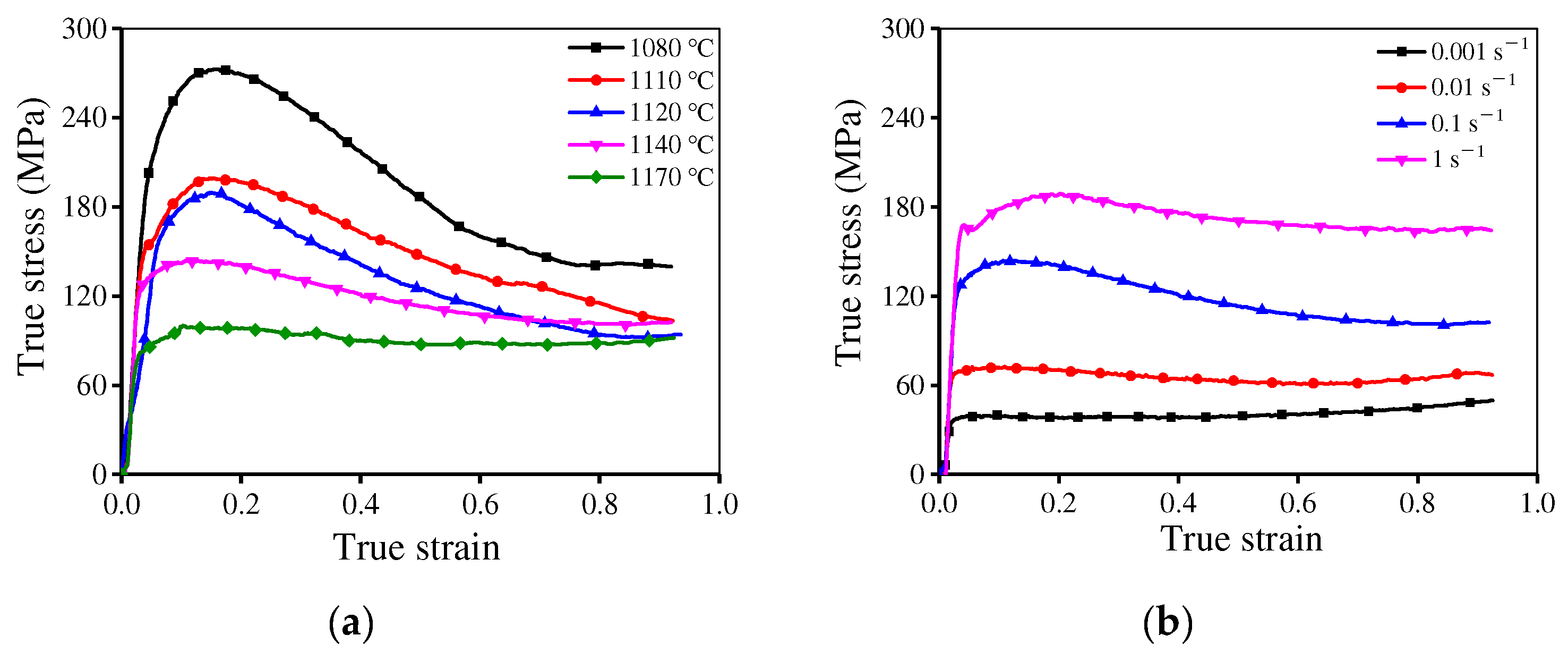

3.1. Rheological Characteristics and Deformation Mechanisms

3.2. The Evolution of Microstructure

3.2.1. Influence of True Strain on DRX Behavior and Grain Dimension

3.2.2. Influence of Strain Rate on the DRX Behavior and Grain Dimension

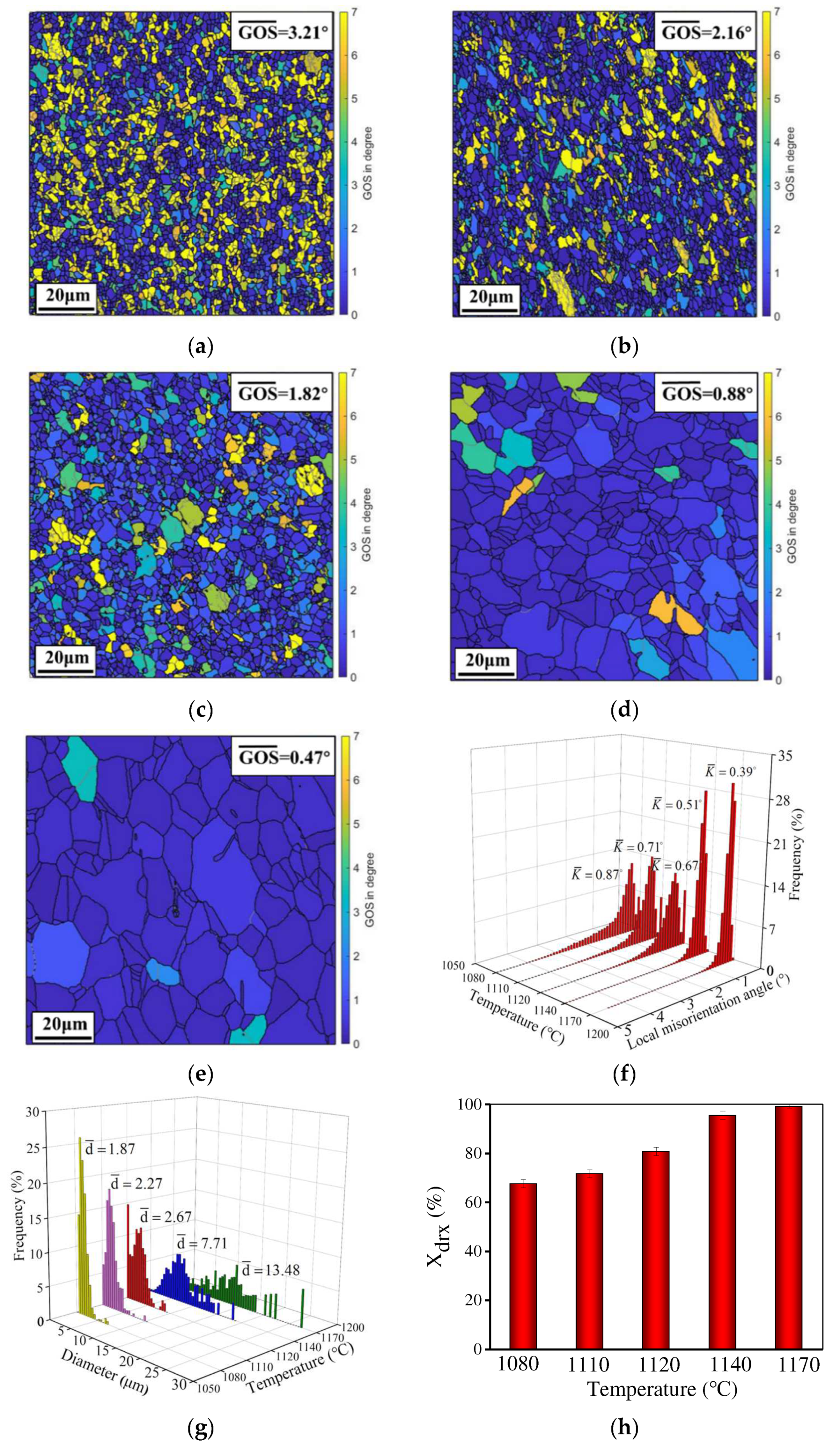

3.2.3. Influence of Temperature on the DRX Behavior and Grain Dimension

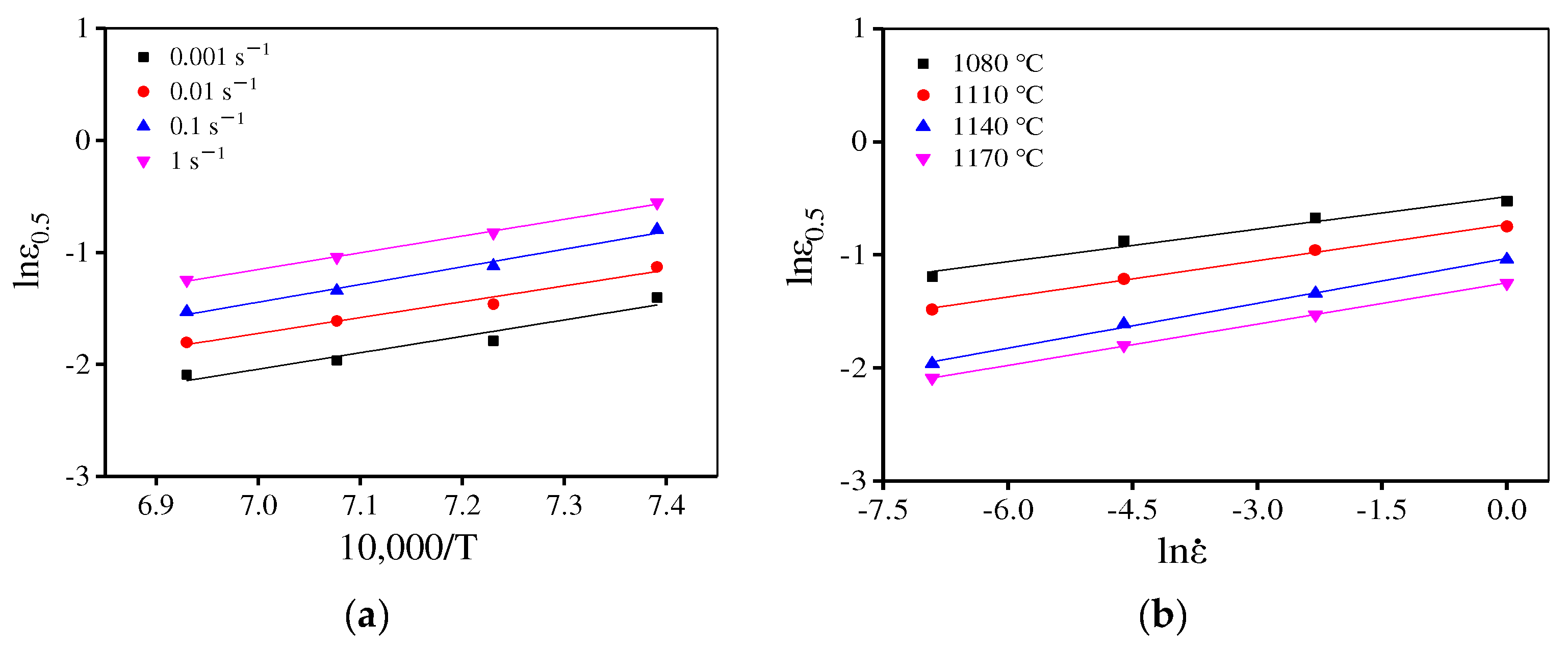

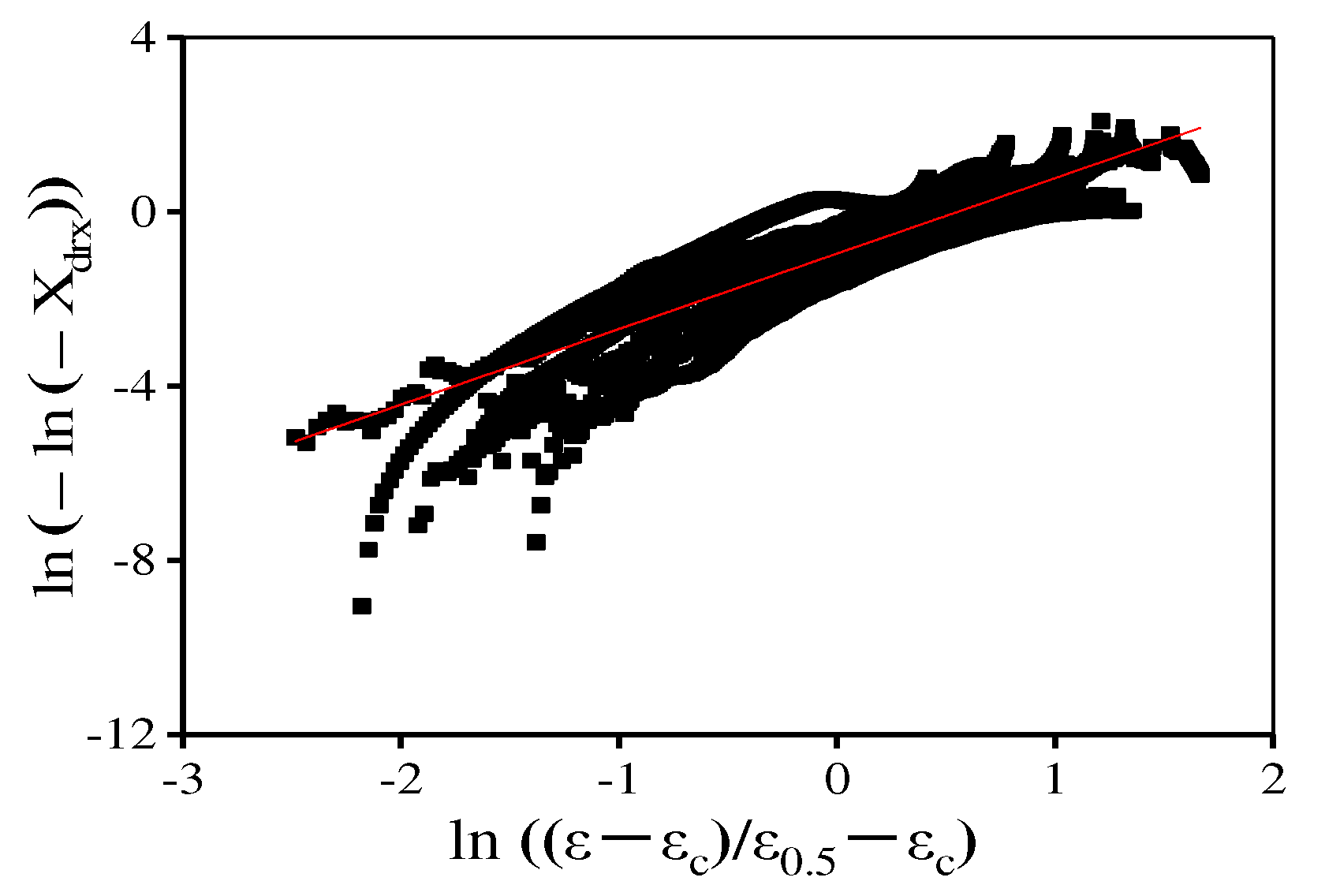

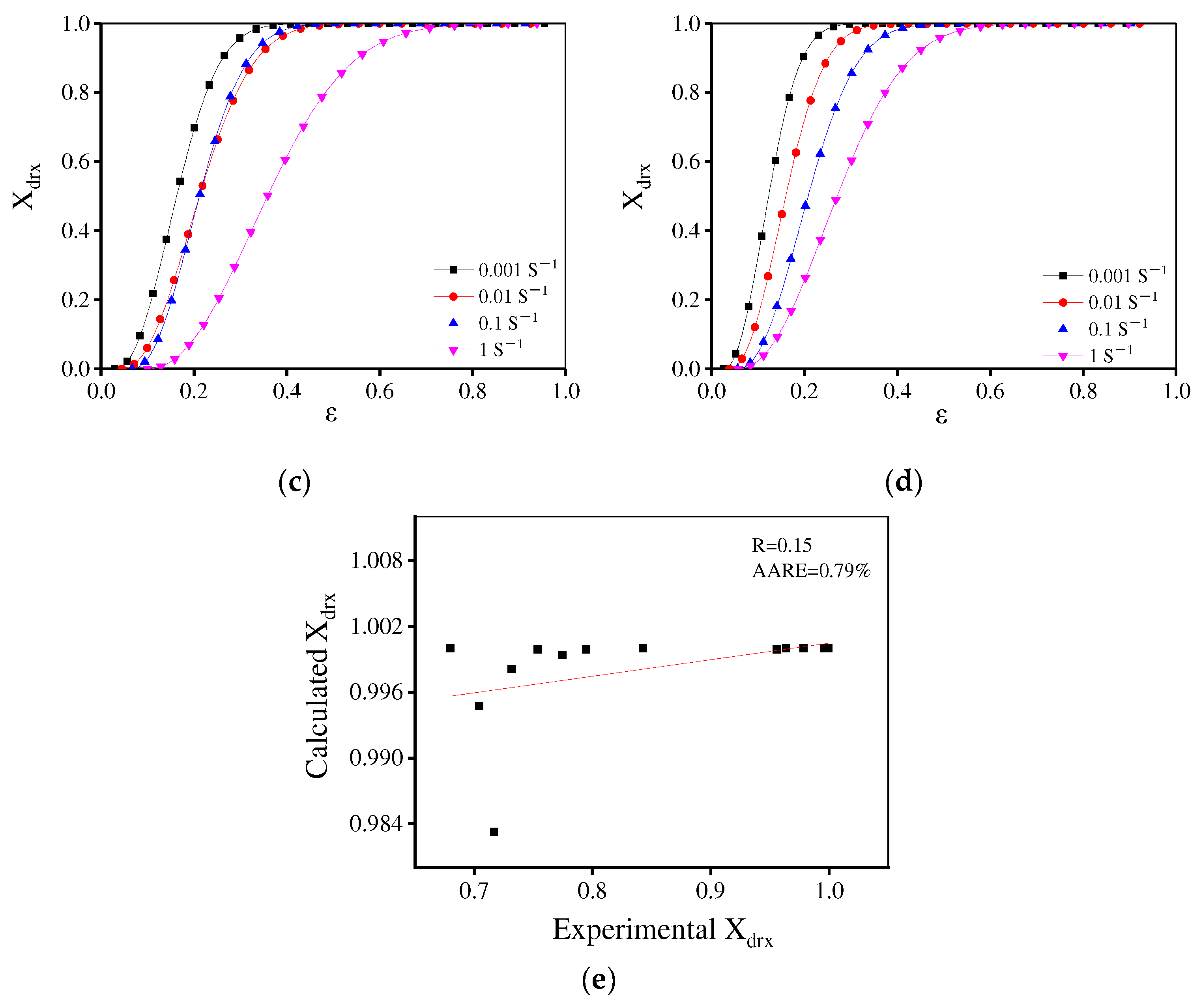

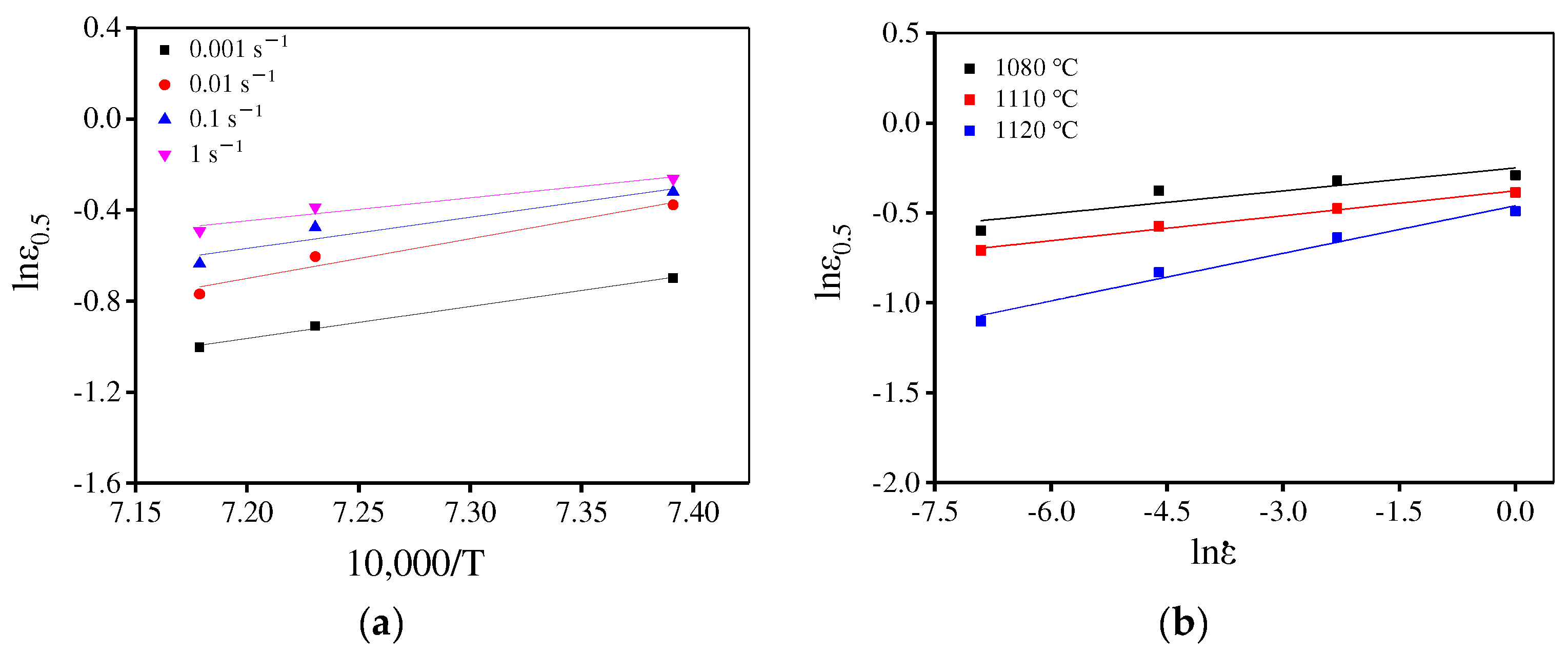

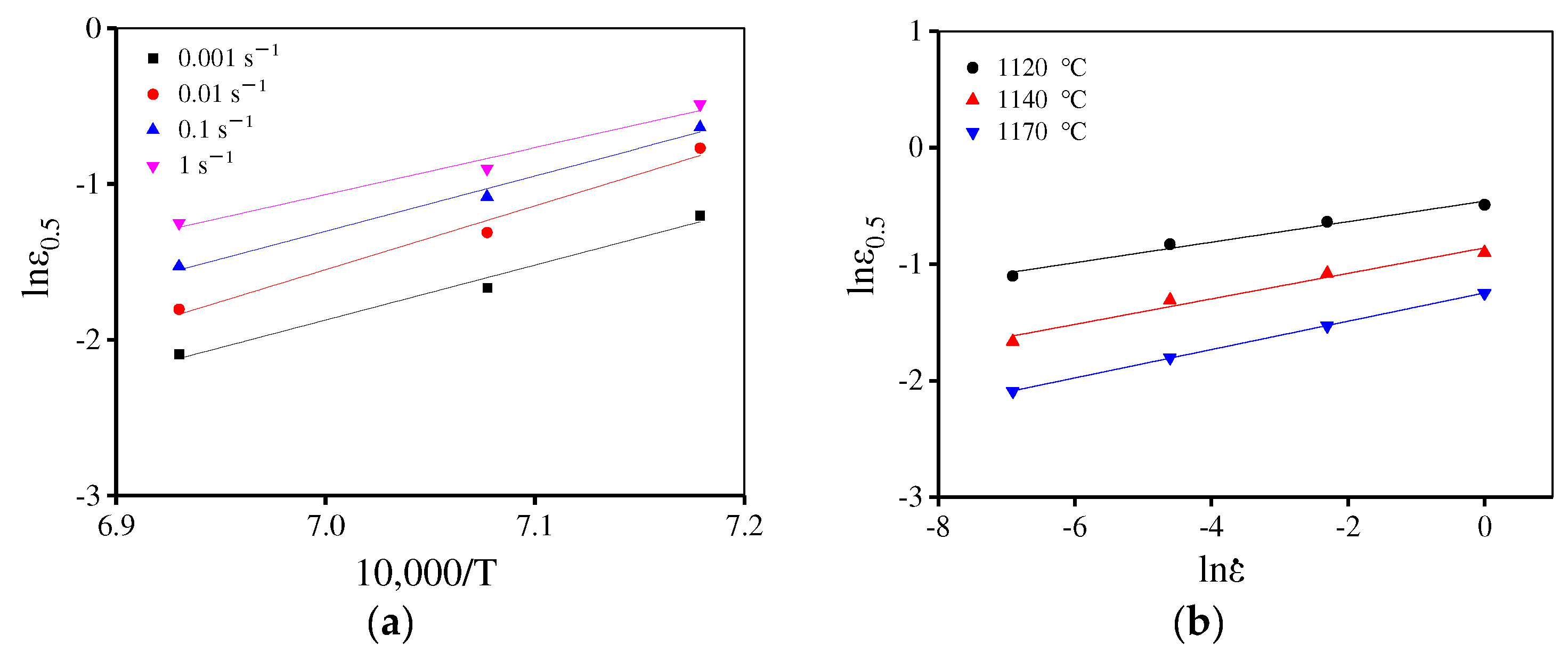

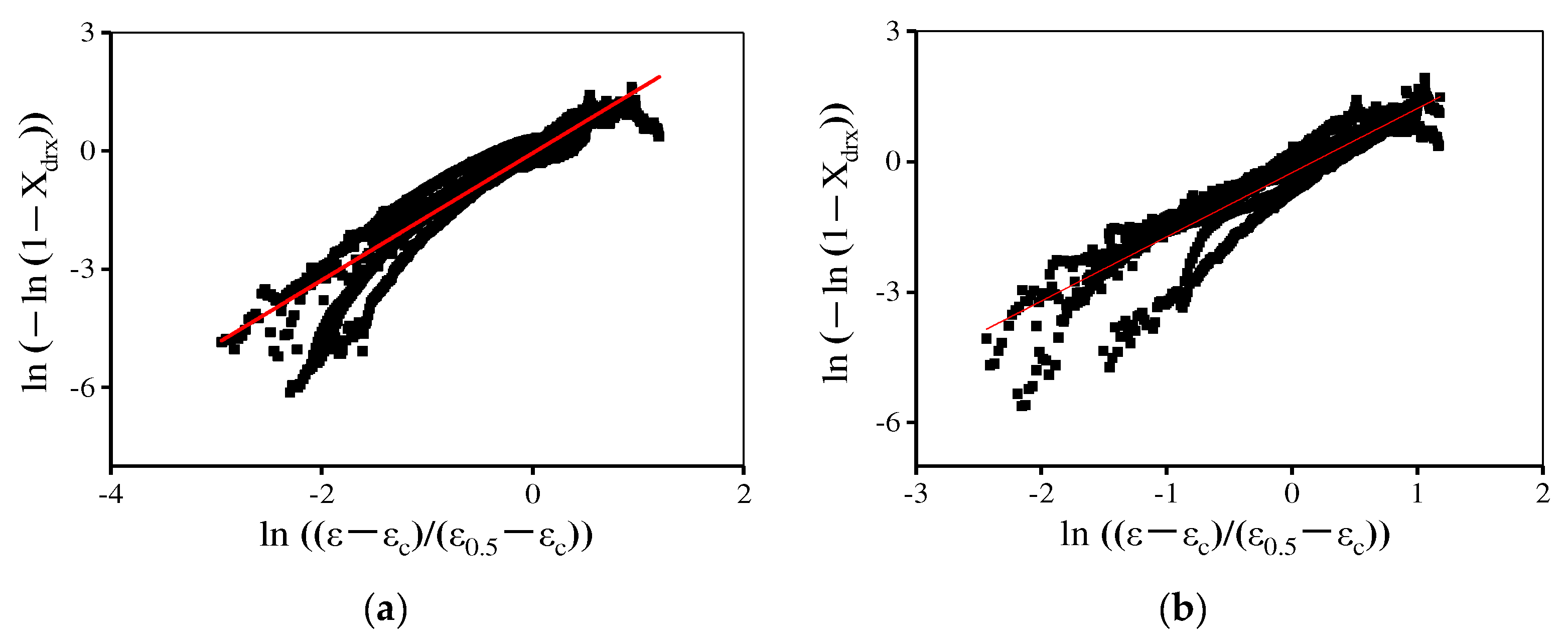

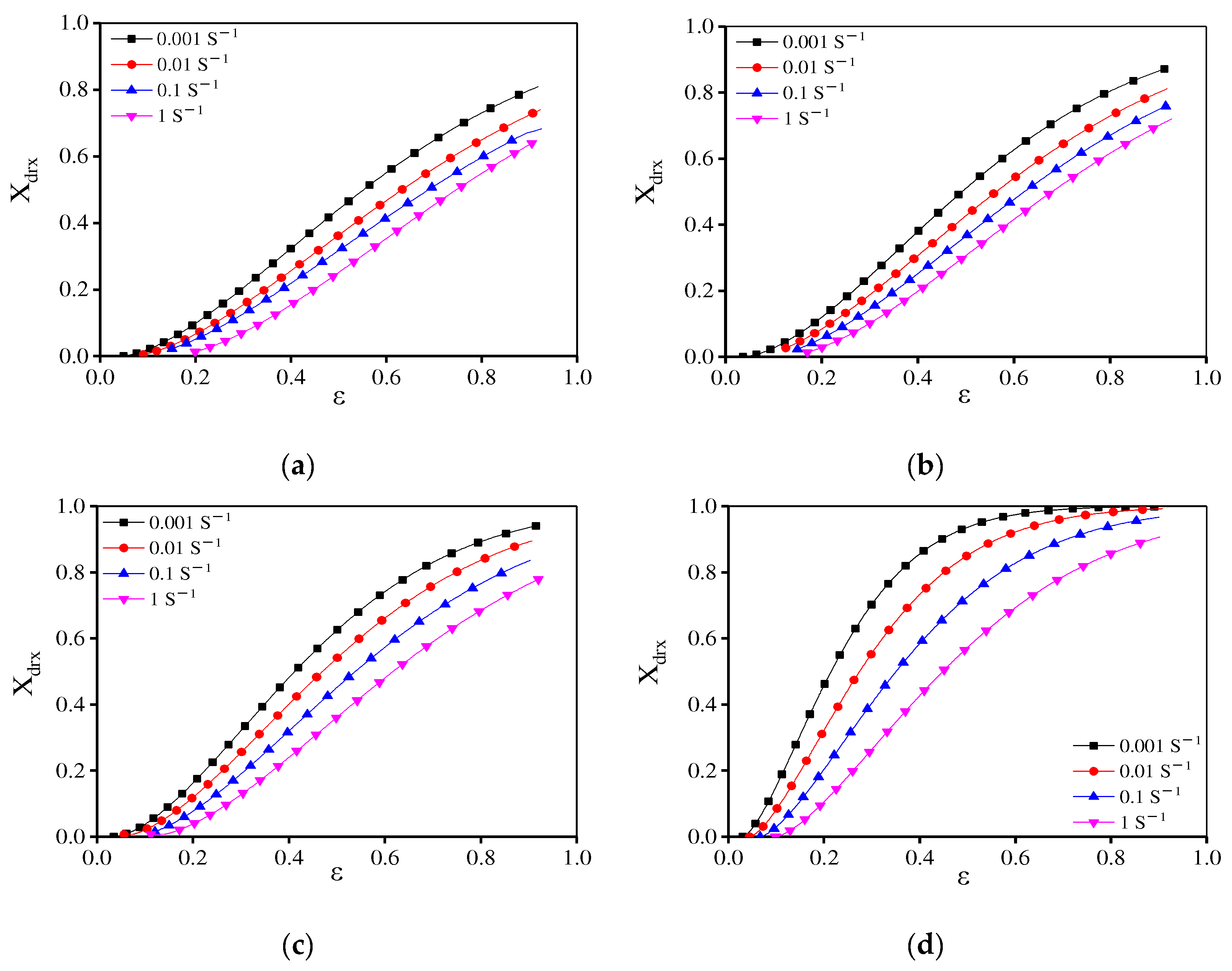

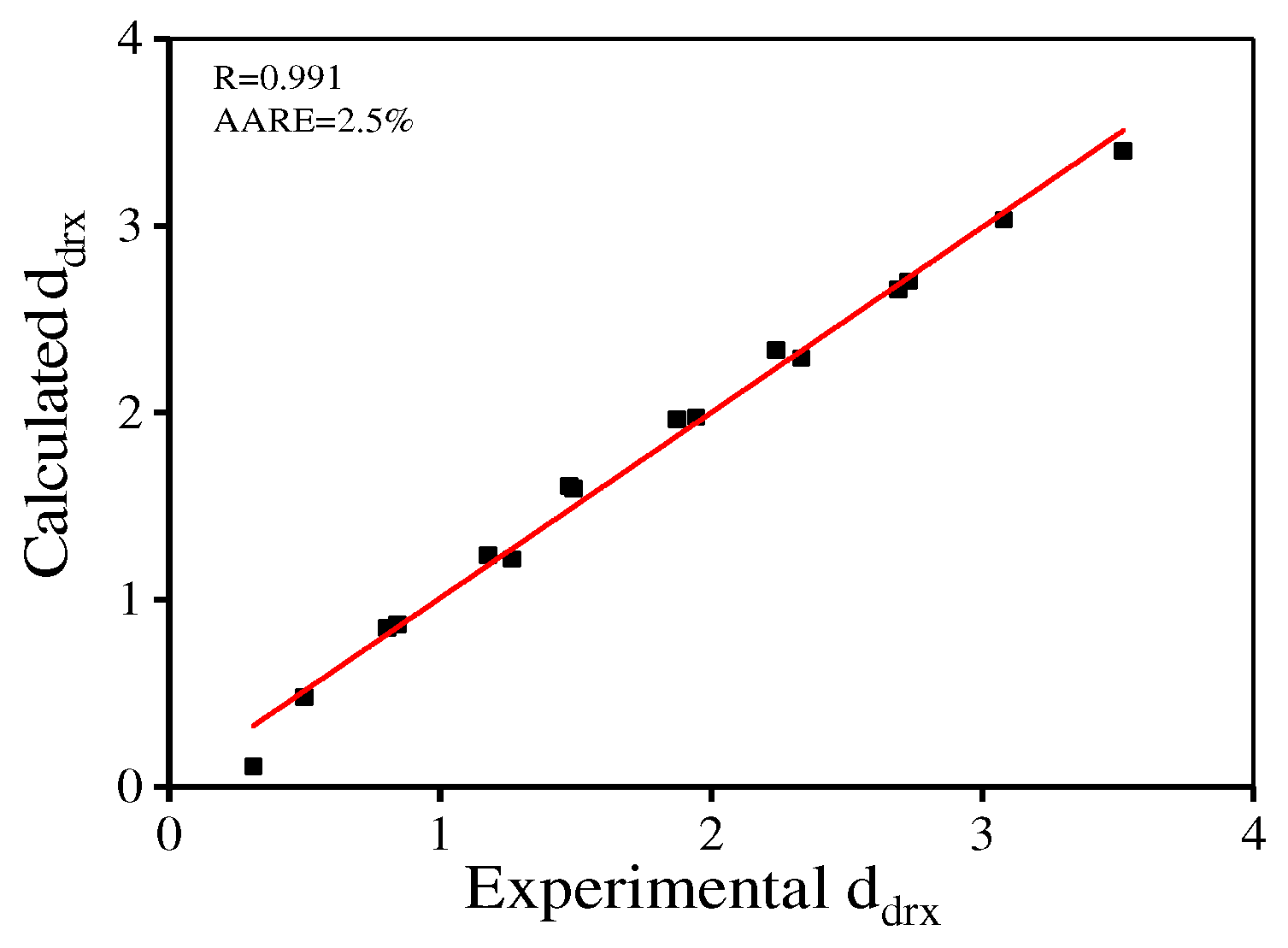

3.3. DRX Kinetics Model

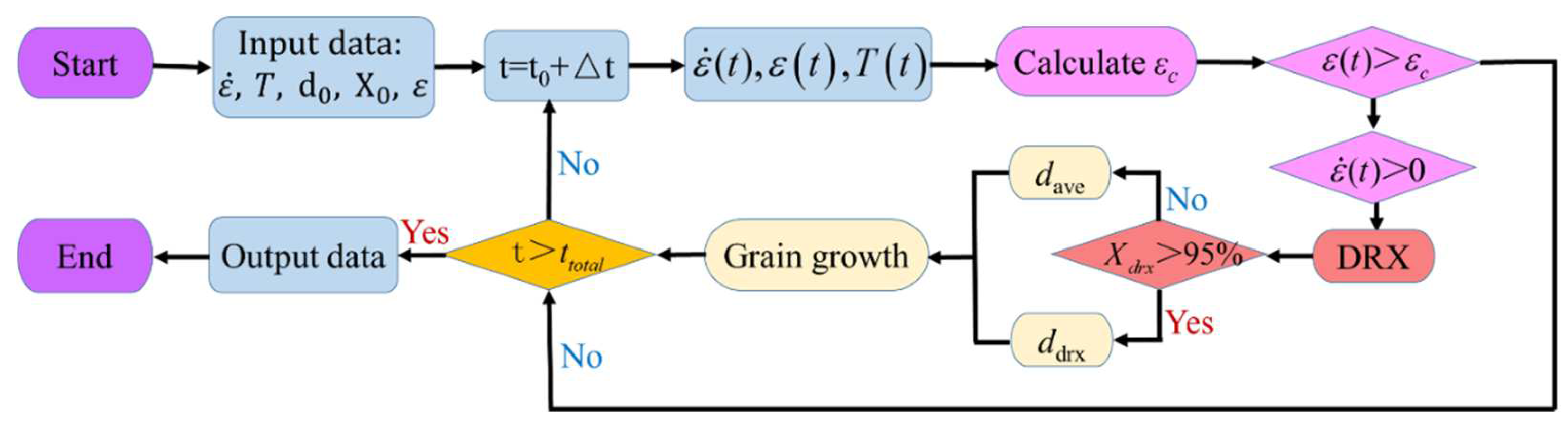

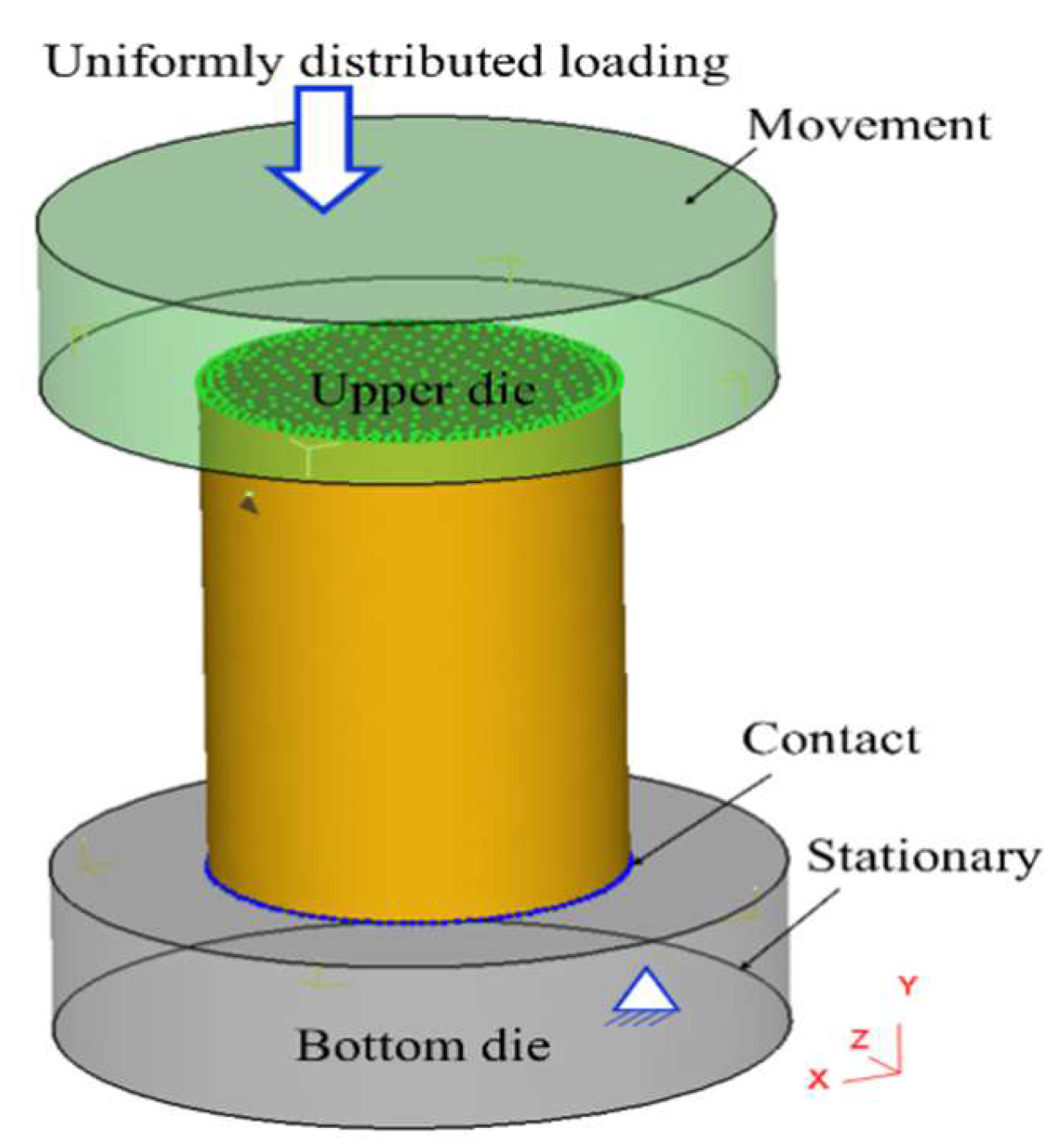

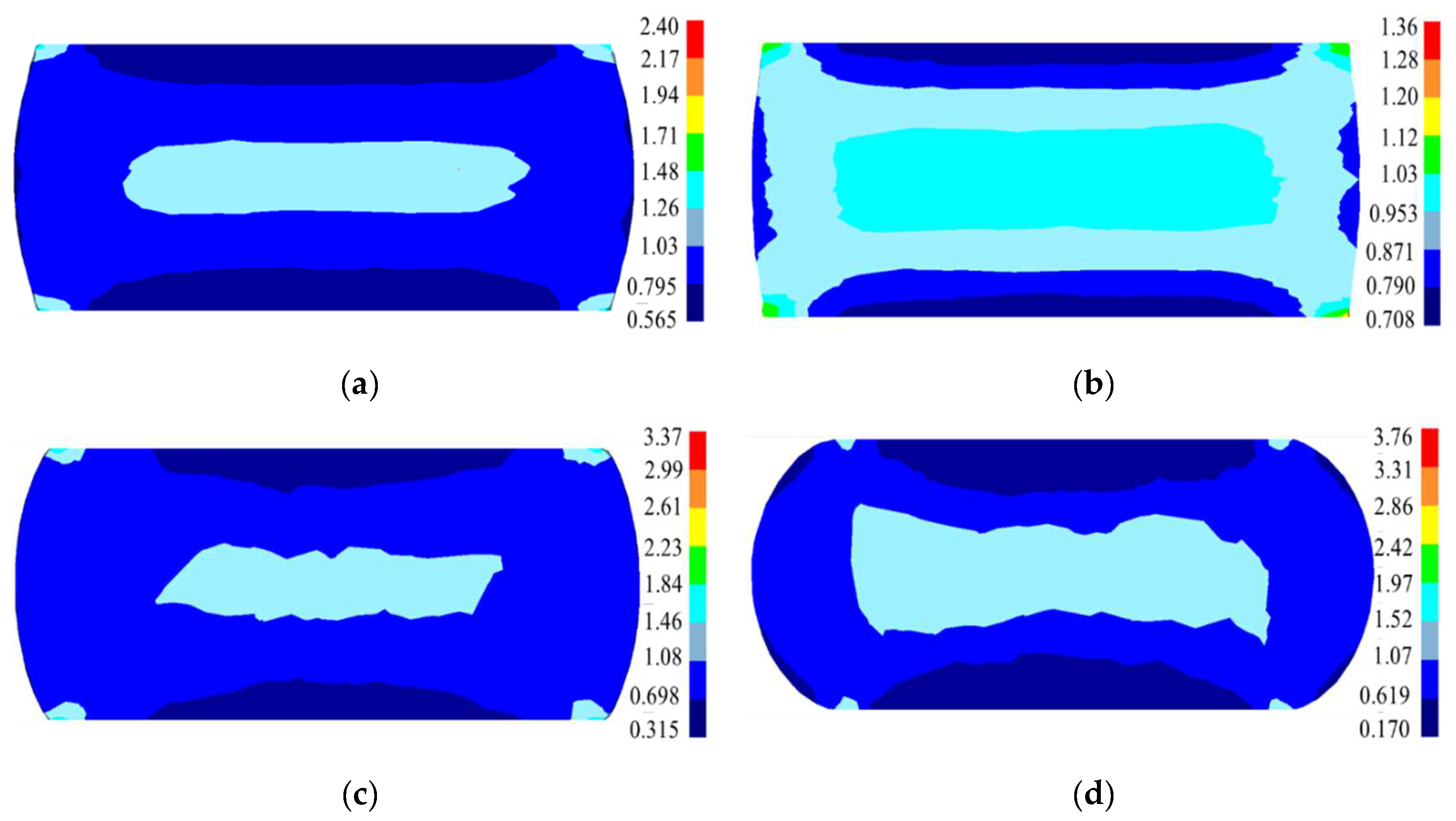

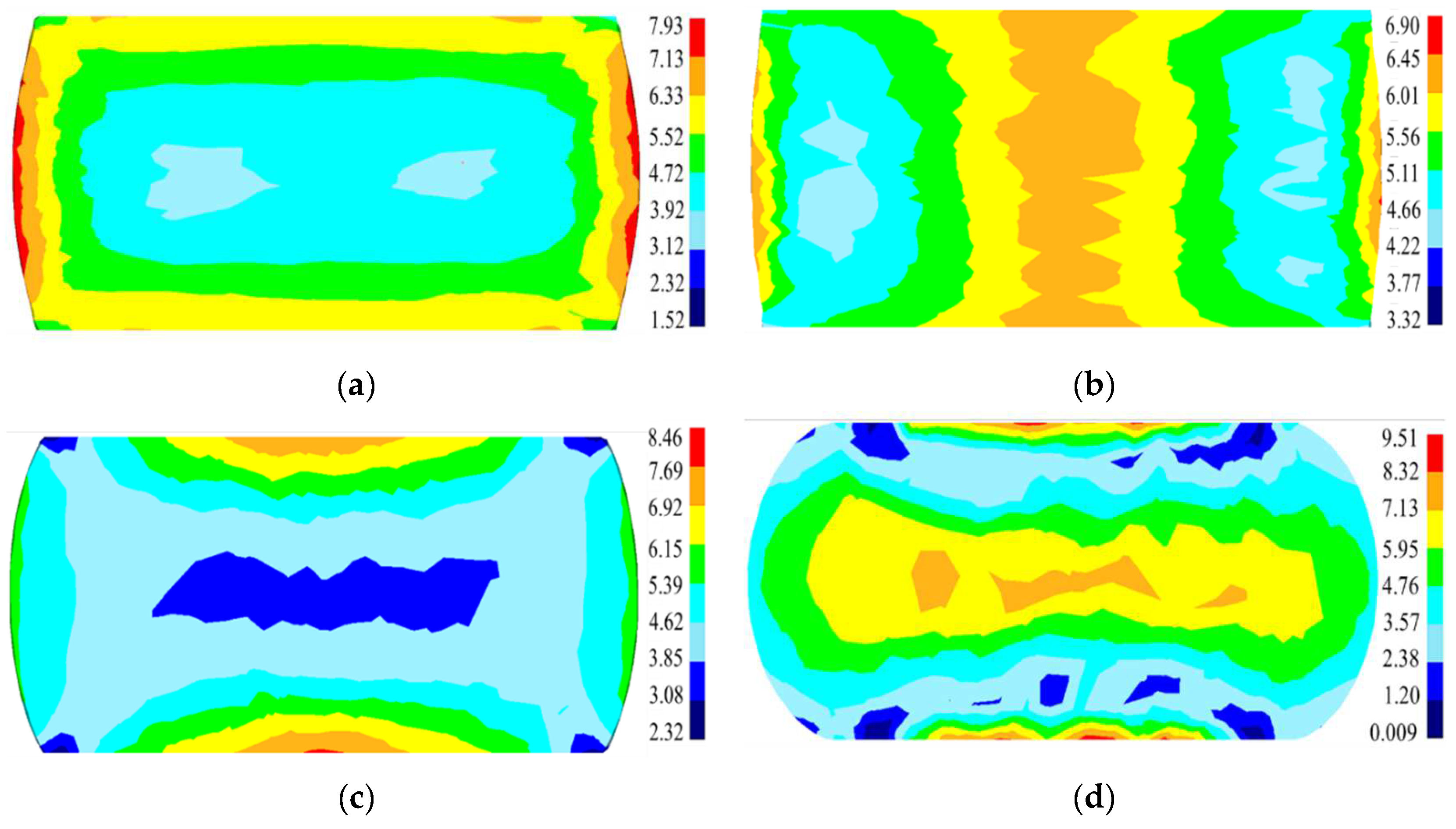

3.4. Finite-Element Simulation of DRX Behavior and Grain-Dimension Evolution

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, Y.T.; Li, C.; Xia, X.C.; Liang, H.Y.; Qi, Q.Q.; Liu, Y.C. Precipitate coarsening and its effects on the hot deformation behavior of the recently developed γ′-strengthened superalloys. J. Mater. Sci. Technol. 2021, 67, 95–104. [Google Scholar] [CrossRef]

- Kumar, S.S.S.; Raghu, T.; Bhattacharjee, P.P.; Rao, G.A.; Borah, U. Work hardening characteristics and microstructural evolution during hot deformation of a nickel superalloy at moderate strain rates. J. Alloys Compd. 2017, 709, 394–409. [Google Scholar] [CrossRef]

- Wu, H.X.; Ge, C.C.; Yan, Q.Z.; Xia, M.; Tian, T.; Zhu, Z.L.; Hu, Q.P. Plastic deformation behavior of spray formed superalloy FGH100. Mater. Sci. Eng. A 2017, 699, 156–164. [Google Scholar] [CrossRef]

- Su, G.; Yun, Z.; Lin, Y.-C.; He, D.-G.; Zhang, S.; Chen, Z.-J. Microstructure evolution and a unified constitutive model of Ti-55511 alloy compressed at stepped strain rates. Materials 2021, 14, 6750. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-C.; He, D.-G.; Chen, M.-S.; Chen, X.-M.; Zhao, C.-Y.; Ma, X.; Long, Z.-L. EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel-based superalloy during hot compressive deformation. Mater. Des. 2016, 97, 13–24. [Google Scholar] [CrossRef]

- Páramo-Kañetas, P.; Özturk, U.; Calvo, J.; Cabrera, J.M.; Guerrero-Mata, M. High-temperature deformation of delta-processed Inconel 718. J. Mater. Process. Technol. 2018, 255, 204–211. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chen, X.-M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Kumar, S.S.S.; Raghu, T.; Bhattacharjee, P.P.; Appa Rao, G.; Borah, U. Evolution of microstructure and microtexture during hot deformation in an advanced P/M nickel base superalloy. Mater. Charact. 2018, 146, 217–236. [Google Scholar] [CrossRef]

- Tan, L.M.; Li, Y.P.; He, G.A.; Liu, F.; Nie, Y.; Jiang, L. Optimized hot workability of a powder metallurgy nickel-base superalloy. Mater. Charact. 2019, 147, 340–352. [Google Scholar] [CrossRef]

- Liu, G.W.; Mao, C.L.; Ding, R.; Yu, L.M.; Liu, C.X.; Liu, Y.C. The kinetics of dynamic recrystallization and construction of constitutive modeling of RAFM steel in the hot deformation process. J. Nucl. Mater. 2021, 557, 153285. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Aghaie-Khafri, M.; Cabrera, J.M.; Calvo, J. Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater. Sci. Eng. A 2016, 678, 137–152. [Google Scholar] [CrossRef] [Green Version]

- Fang, B.; Tian, G.F.; Ji, Z.; Wang, M.Y.; Jia, C.C.; Yang, S.W. Study on the thermal deformation behavior and microstructure of FGH96 heat extrusion alloy during two-pass hot deformation. Int. J. Min. Metall. Mater. 2019, 26, 657–663. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, L.W.; Li, M.F.; Shen, W.F.; Gu, S.D. Effects of microstructure and γ′ distribution on the hot deformation behavior for a powder metallurgy superalloy FGH96. J. Mater. Res. 2014, 29, 2799–2808. [Google Scholar] [CrossRef]

- Wang, S.Y.; Fang, S.; Shi, Z.S.; Jiang, J.Y.; Zhou, X.M.; Lin, J.G. Direct powder forging of PM nickel-based superalloy: Densification and recrystallisation. Int. J. Adv. Manuf. Technol. 2017, 88, 2661–2670. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.J.; Li, F.G.; Wang, L.; Wang, S.Y. Investigations of inhomogeneous mechanical properties and plastic deformations in HIPed P/M nickel-base superalloy FGH96 by using micro-indentation methods. Mater. Sci. Eng. A 2012, 556, 233–245. [Google Scholar] [CrossRef]

- Sreenu, B.; Sarkar, R.; Kumar, S.S.S.; Chatterjee, S.; AppaRao, G. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater. Sci. Eng. A 2020, 797, 140254. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mirzadeh, H. Estimation of homogenisation time for superalloys based on a new diffusional model. Mater. Sci. Technol. 2020, 36, 380–384. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Lin, Y.-C.; Wang, G.Q.; Pang, G.D.; Chen, M.S.; Huang, Z.C. Microstructure evolution and a unified constitutive model for a Ti-55511 alloy deformed in β region. J. Alloys Compd. 2021, 870, 159534. [Google Scholar] [CrossRef]

- Ahmadi, H.; Ashtiani, H.R.R.; Heidari, M. A comparative study of phenomenological, physically-based and artificial neural network models to predict the Hot flow behavior of API 5CT-L80 steel. Mater. Today Commun. 2020, 25, 101528. [Google Scholar] [CrossRef]

- He, D.-G.; Lin, Y.-C.; Chen, M.-S.; Li, L. Kinetics equations and microstructural evolution during metadynamic recrystallization in a nickel-based superalloy with δ phase. J. Alloys Compd. 2017, 690, 971–978. [Google Scholar] [CrossRef]

- Bobbili, R.; Ramudu, B.V.; Madhu, V. A physically-based constitutive model for hot deformation of Ti-10-2-3 alloy. J. Alloys Compd. 2017, 696, 295–303. [Google Scholar] [CrossRef]

- Badrish, A.; Morchhale, A.; Kotkunde, N.; Singh, S.K. Influence of material modeling on warm forming behavior of nickel based super alloy. Int. J. Mater. Form. 2020, 13, 445–465. [Google Scholar] [CrossRef]

- Rezaei Ashtiani, R.; Shahsavari, P. Constitutive modeling of flow behavior of precipitation-hardened AA7022-T6 aluminum alloy at elevated temperature. Trans. Nonferrous Met. Soc. China 2020, 30, 2927–2940. [Google Scholar] [CrossRef]

- Liu, Y.H.; Ning, Y.Q.; Yang, X.M.; Yao, Z.K.; Guo, H.Z. Effect of temperature and strain rate on the workability of FGH4096 superalloy in hot deformation. Mater. Des. 2016, 95, 669–676. [Google Scholar] [CrossRef]

- Liu, Y.H.; Yao, Z.K.; Ning, Y.Q.; Nan, Y. Effect of deformation temperature and strain rate on dynamic recrystallized grain size of a powder metallurgical nickel-based superalloy. J. Alloys Compd. 2017, 691, 554–563. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, G.Q.; Wang, H.; Hu, B.F. Modeling of thermal deformation behavior near γ′ solvus in a Ni-based powder metallurgy superalloy. Comp. Mater. Sci. 2019, 156, 241–245. [Google Scholar] [CrossRef]

- Tan, G.; Li, H.-Z.; Wang, Y.; Qiao, S.-C.; Yang, L.; Huang, Z.-Q.; Cheng, T.-W.; Zhao, Z.-X. Effect of Zener-Hollomon parameter on microstructure evolution of a HEXed PM nickel-based superalloy. J. Alloys Compd. 2021, 874, 159889. [Google Scholar] [CrossRef]

- Yang, Q.-M.; Lin, Y.-C.; Guo, J.-Z.; Wang, C.; Chen, Z.-J.; Chen, K.-G.; Zhu, J.-C. Spheroidization and dynamic recrystallization mechanisms of a novel HIPed P/M superalloy during hot deformation. J. Alloys Compd. 2022, 910, 16490. [Google Scholar] [CrossRef]

- Badrish, C.A.; Kotkunde, N.; Mahalle, G.; Singh, S.K.; Mahesh, K. Analysis of hot anisotropic tensile flow stress and strain hardening behavior for Inconel 625 alloy. J. Mater. Eng. Perform. 2019, 28, 7537–7553. [Google Scholar] [CrossRef]

- Wen, D.-X.; Lin, Y.-C.; Chen, J.; Chen, X.-M.; Zhang, J.-L.; Liang, Y.-J.; Li, L.-T. Work hardening behaviors of typical solution-treated and aged Ni-based superalloys during hot deformation. J. Alloys Compd. 2015, 618, 372–379. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Wen, D.-X.; Chen, M.-S.; Chen, X.-M. A novel unified dislocation density-based model for hot deformation behavior of a nickel-based superalloy under dynamic recrystallization conditions. Appl. Phys. A 2016, 122, 805. [Google Scholar] [CrossRef]

- Chen, Z.-J.; Lin, Y.-C.; He, D.-G.; Lou, Y.-M.; Chen, M.-S. A unified dislocation density-based model for an aged polycrystalline Ni-based superalloy considering the coupled effects of complicate deformation mechanisms and initial δ phase. Mater. Sci. Eng. A 2021, 827, 142062. [Google Scholar] [CrossRef]

- Momeni, A.; Abbasi, S.M.; Morakabati, M.; Badri, H. A comparative study on the hot working behavior of Inconel 718 and ALLVAC 718 plus. Metall. Mater. Trans. A 2017, 48, 1216–1229. [Google Scholar] [CrossRef]

- Xie, B.; Zhang, B.; Ning, Y.; Fu, M.W. Mechanisms of DRX nucleation with grain boundary bulging and subgrain rotation during the hot working of nickel-based superalloys with columnar grains. J. Alloys Compd. 2019, 786, 636–647. [Google Scholar] [CrossRef]

- Jia, D.; Sun, W.; Xu, D.; Yu, L.; Xin, X.; Zhang, W.; Qi, F. Abnormal dynamic recrystallization behavior of a nickel based superalloy during hot deformation. J. Alloys Compd. 2019, 787, 196–205. [Google Scholar] [CrossRef]

- Yin, X.-Q.; Park, C.-H.; Li, Y.-F.; Ye, W.-J.; Zuo, Y.-T.; Lee, S.-W.; Yeom, J.-T.; Mi, X.-J. Mechanism of continuous dynamic recrystallization in a 50Ti-47Ni-3Fe shape memory alloy during hot compressive deformation. J. Alloys Compd. 2017, 693, 426–431. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhang, K.F.; Zhou, H.P.; Lu, Z.; Zhao, C.H.; Yang, X.L. Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation. Mater. Des. 2015, 80, 51–62. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Mokdad, F.; Wells, M.A.; Chen, D.L. A new grain orientation spread approach to analyze the dynamic recrystallization behavior of a cast-homogenized Mg-Zn-Zr alloy using electron backscattered diffraction. Mater. Sci. Eng. A 2018, 709, 285–289. [Google Scholar] [CrossRef]

- Alvi, M.H.; Cheong, S.W.; Weiland, H.; Rollett, A.D. Recrystallization and texture development in hot rolled 1050 aluminum. Mater. Sci. Forum Trans. Tech. Publ. 2004, 467–470, 357–362. [Google Scholar]

- Lin, Y.-C.; Wu, X.-Y.; Chen, X.-M.; Chen, J.; Wen, D.-X.; Zhang, J.-L.; Li, L.-T. EBSD study of a hot deformed nickel-based superalloy. J. Alloys Compd. 2015, 640, 101–113. [Google Scholar]

- Annasamy, M.; Haghdadi, N.; Taylor, A.; Hodgson, P.; Fabijanic, D. Dynamic recrystallization behaviour of AlxCoCrFeNi high entropy alloys during high-temperature plane strain compression. Mater. Sci. Eng. A 2019, 745, 90–106. [Google Scholar] [CrossRef]

- Momeni, A.; Abbasi, S.M.; Morakabati, M.; Badri, H.; Wang, X. Dynamic recrystallization behavior and constitutive analysis of Incoloy 901 under hot working condition. Mater. Sci. Eng. A 2014, 615, 51–60. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Roostaei, M.; Parsa, M.H.; Mahmudi, R. Rate controlling mechanisms during hot deformation of Mg–3Gd–1Zn magnesium alloy: Dislocation glide and climb, dynamic recrystallization, and mechanical twinning. Mater. Des. 2015, 68, 228–231. [Google Scholar] [CrossRef]

- Xia, Y.-C.; Chen, X.-M.; Lin, Y.-C.; Lu, X.-Z. Evolution of annealing twins in a hot deformed nickel-based superalloy. Materials 2022, 15, 7. [Google Scholar] [CrossRef]

- Jiang, H.; Dong, J.X.; Zhang, M.C.; Yao, Z.H. A study on the effect of strain rate on the dynamic recrystallization mechanism of alloy 617B. Metall. Mater. Trans. A 2016, 47, 5071–5087. [Google Scholar] [CrossRef]

- Charpagne, M.A.; Franchet, J.M.; Bozzolo, N. Overgrown grains appearing during sub-solvus heat treatment in a polycrystalline γ-γ′ Nickel-based superalloy. Mater. Des. 2018, 144, 353–360. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.-Q.; Chen, M.-S.; Li, H.-B.; Lin, Y.-C.; Zeng, W.-D.; Ma, Y.-Y. Methods and mechanisms for uniformly refining deformed mixed and coarse grains inside a solution-treated Ni-based superalloy by two-stage heat treatment. J. Mater. Sci. Technol. 2021, 77, 47–57. [Google Scholar] [CrossRef]

- Poliak, E.I.; Jonas, J.J. A one-parameter approach to determining the critical conditions for the initiation of dynamic recrystallization. Acta Mater. 1996, 44, 127–136. [Google Scholar] [CrossRef]

- Chen, M.-S.; Lin, Y.-C.; Li, K.-K.; Zhou, Y. A new method to establish dynamic recrystallization kinetics model of a typical solution-treated Ni-based superalloy. Comput. Mater. Sci. 2016, 122, 150–158. [Google Scholar] [CrossRef]

- Huang, H.L.; Liu, G.Q.; Wang, H.; Ullah, A.; Hu, B.F. Dissolution behavior and kinetics of γ′ phase during solution treatment in powder metallurgy nickel-based superalloy. Metall. Mater. Trans. A 2020, 51, 1075–1084. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Wen, D.-X.; Chen, M.-S.; Liu, Y.-X.; Chen, X.-M.; Ma, X. Improved dislocation density based models for describing hot deformation behaviors of a Ni-based superalloy. J. Mater. Res. 2016, 31, 2415–2429. [Google Scholar] [CrossRef]

| Al | Ti | Nb | Co | Cr | W | Mo | Ta | Hf | Ni |

|---|---|---|---|---|---|---|---|---|---|

| 2.7–3.1 | 3.6–3.9 | 1.2–1.3 | 18–20 | 11.5–13.5 | 4.0–4.5 | 3.5–4.5 | 0.9–1.2 | 0.1–0.3 | Bal. |

| Temperature/Strain Rate | 0.001 s−1 | 0.01 s−1 | 0.1 s−1 | 1 s−1 |

|---|---|---|---|---|

| 1080 °C | 3.53 | 2.23 | 1.64 | 1.36 |

| 1110 °C | 6.98 | 4.37 | 3.24 | 2.32 |

| 1140 °C | 17.07 | 12.46 | 7.52 | 7.36 |

| 1170 °C | 33.75 | 21.73 | 14.73 | 10.29 |

| Tracked Points | DRX Fraction (%) | Tracked Points | Average Grain Size (μm) | ||

|---|---|---|---|---|---|

| Experiment | Simulation | Experiment | Simulation | ||

| P1 | 77.4 | 80 | P4 | 4.21 | 4.45 |

| P2 | 52.8 | 58 | P5 | 5.19 | 6.02 |

| P3 | 40.8 | 31 | P6 | 6.44 | 6.84 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.-M.; Lin, Y.-C.; Chen, M.-S.; Chen, Z.-J. Modeling Dynamic Recrystallization Behavior in a Novel HIPed P/M Superalloy during High-Temperature Deformation. Materials 2022, 15, 4030. https://doi.org/10.3390/ma15114030

Yang Q-M, Lin Y-C, Chen M-S, Chen Z-J. Modeling Dynamic Recrystallization Behavior in a Novel HIPed P/M Superalloy during High-Temperature Deformation. Materials. 2022; 15(11):4030. https://doi.org/10.3390/ma15114030

Chicago/Turabian StyleYang, Qiu-Mei, Yong-Cheng Lin, Ming-Song Chen, and Zi-Jian Chen. 2022. "Modeling Dynamic Recrystallization Behavior in a Novel HIPed P/M Superalloy during High-Temperature Deformation" Materials 15, no. 11: 4030. https://doi.org/10.3390/ma15114030

APA StyleYang, Q.-M., Lin, Y.-C., Chen, M.-S., & Chen, Z.-J. (2022). Modeling Dynamic Recrystallization Behavior in a Novel HIPed P/M Superalloy during High-Temperature Deformation. Materials, 15(11), 4030. https://doi.org/10.3390/ma15114030