The Effect of Clay on the Shear Strength of Microbially Cured Sand Particles

Abstract

:1. Introduction

2. Test Materials and Schemes

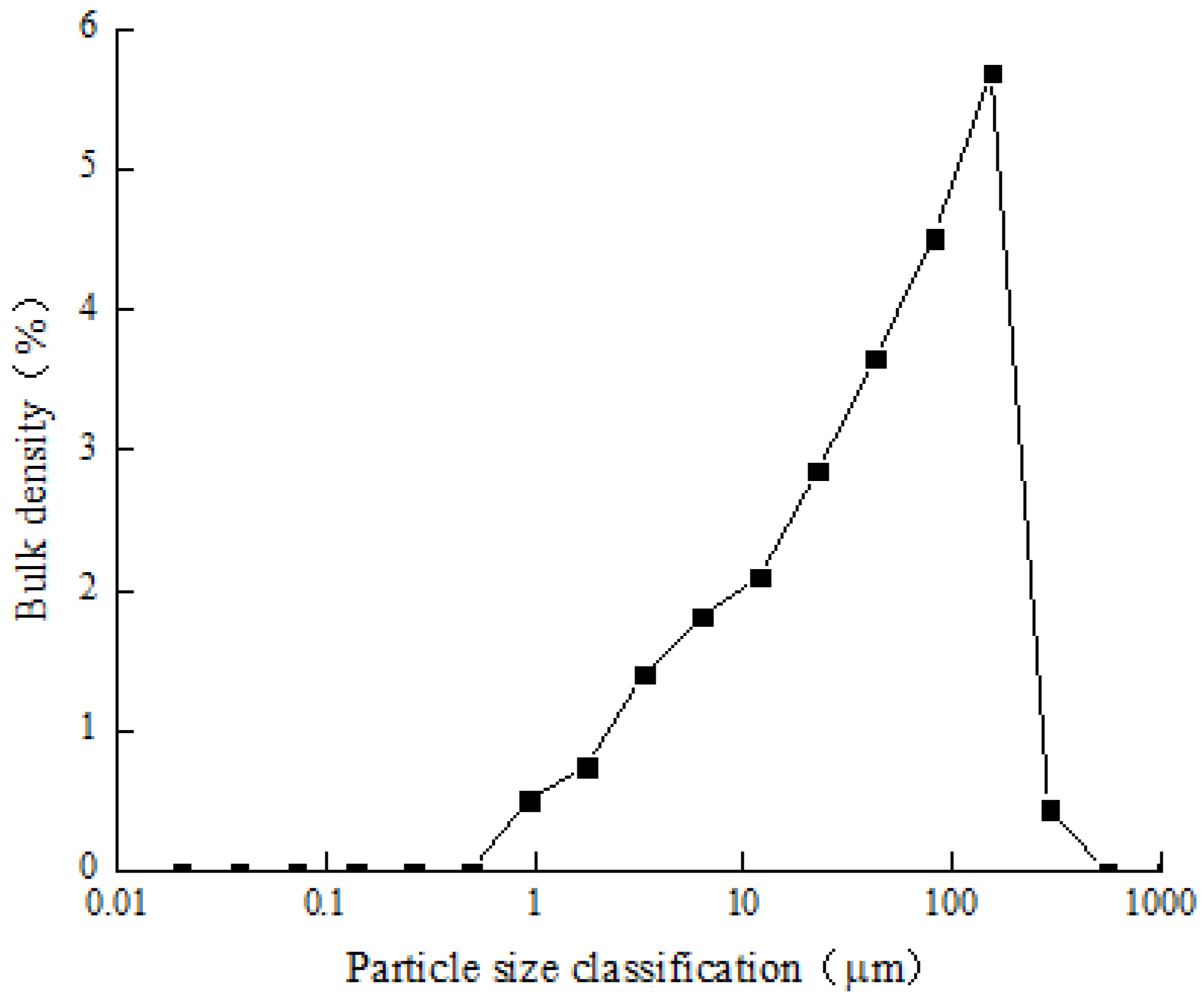

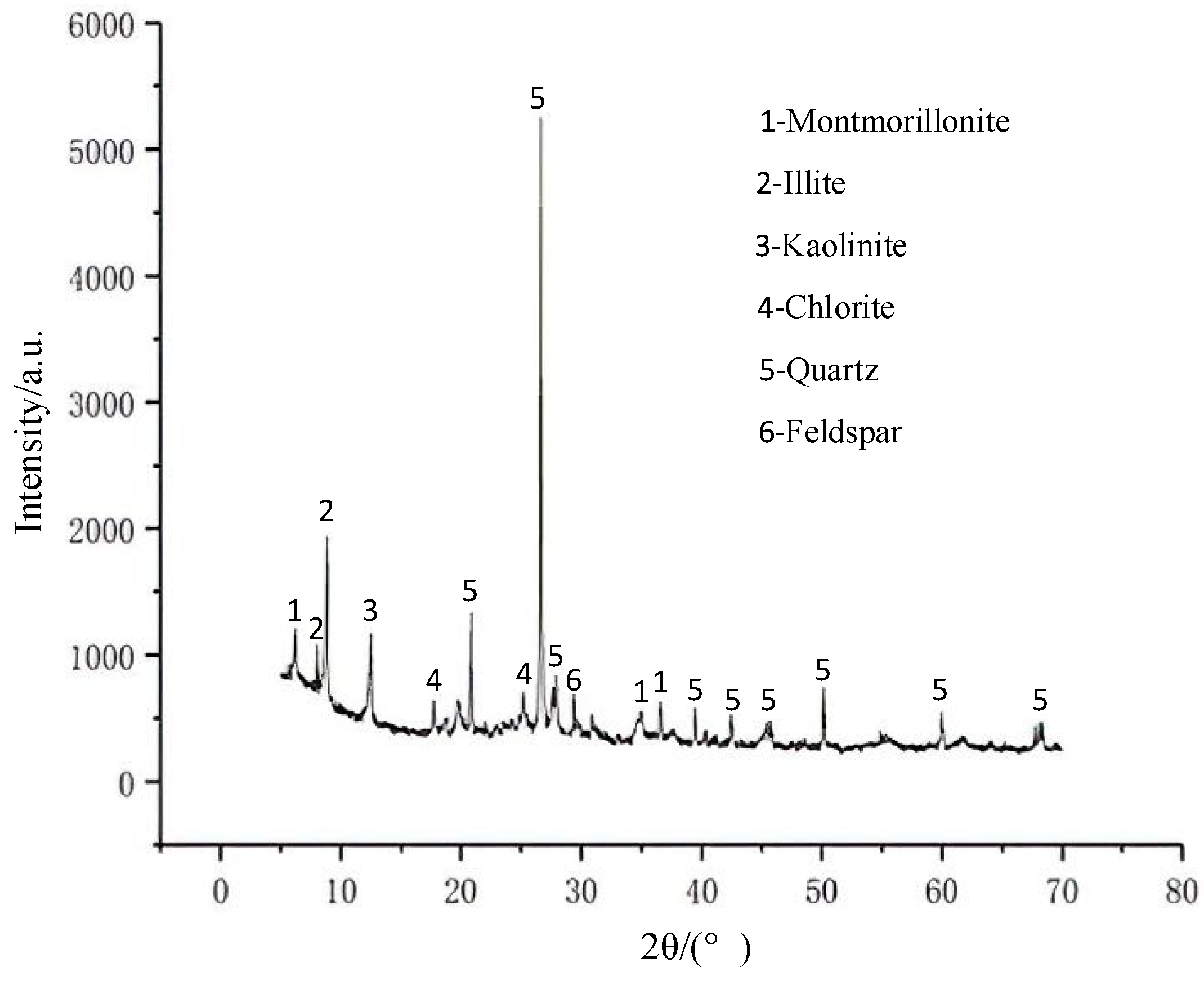

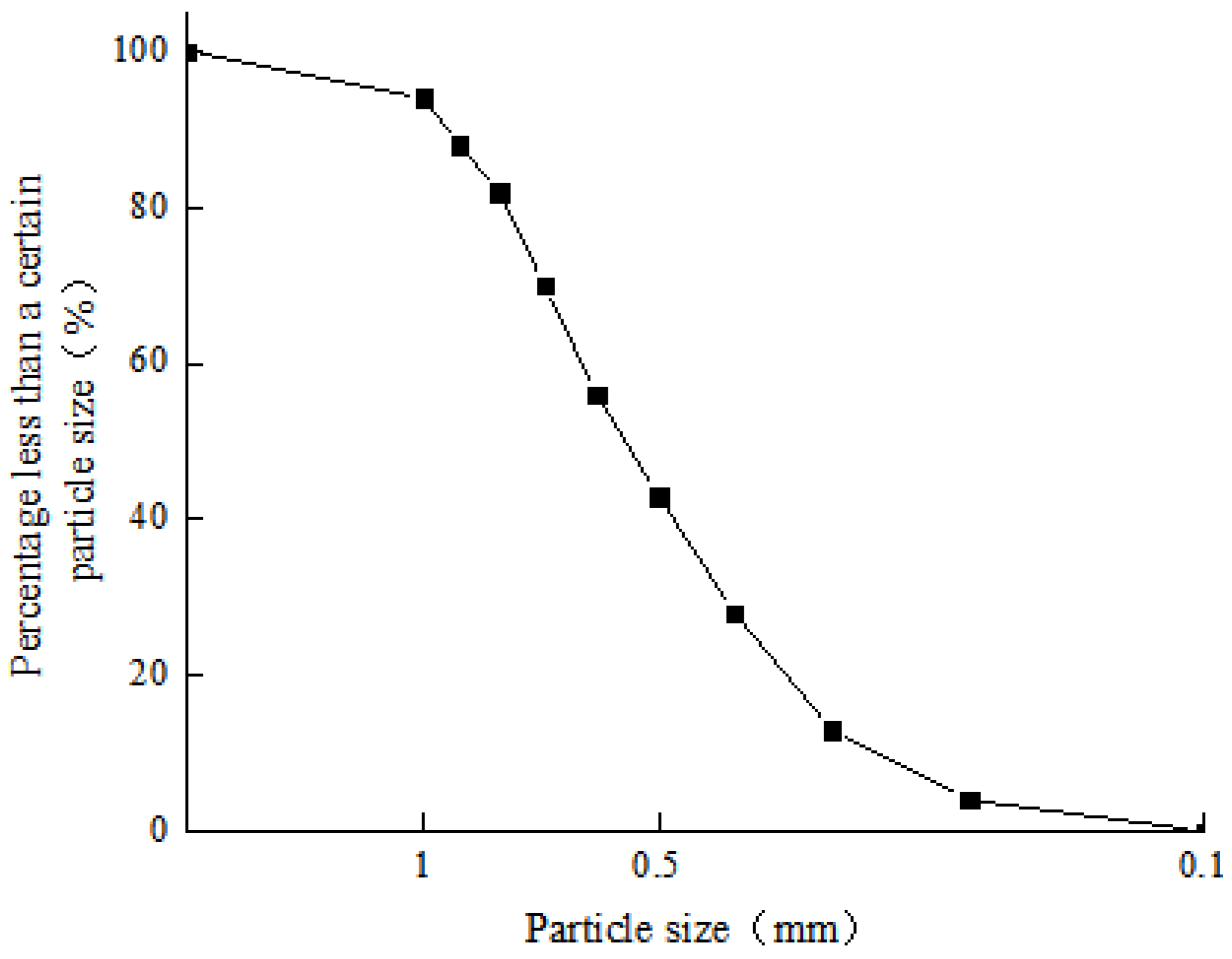

2.1. Test Materials

2.2. Test Scheme

3. Analysis of Test Results

3.1. The Influence of Clay Content on the Stress–Strain Curve

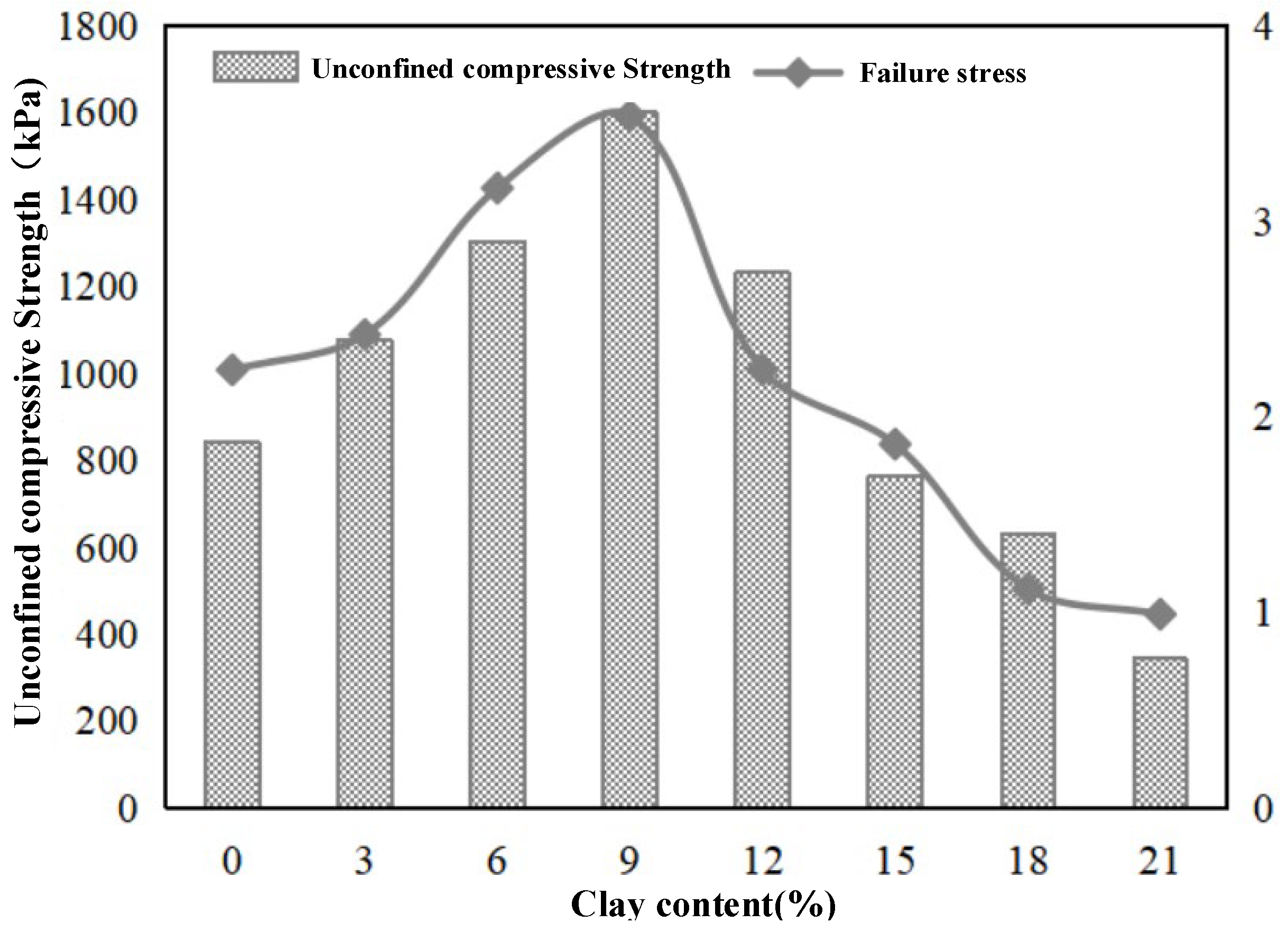

3.2. The Effect of Different Clay Contents on Unconfined Compressive Strength

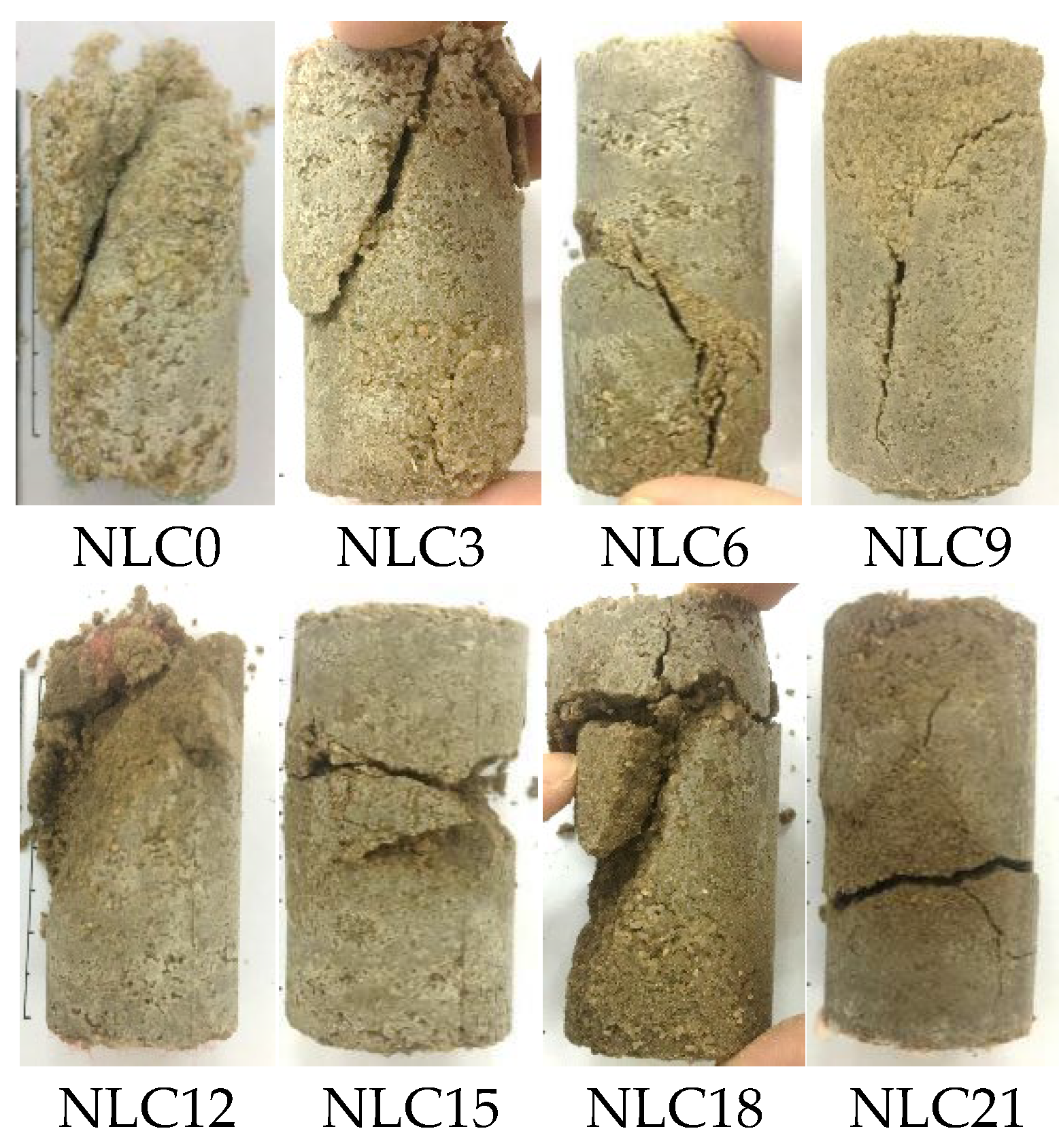

3.3. The Effect of Different Clay Contents on the Failure Mode of the Sample

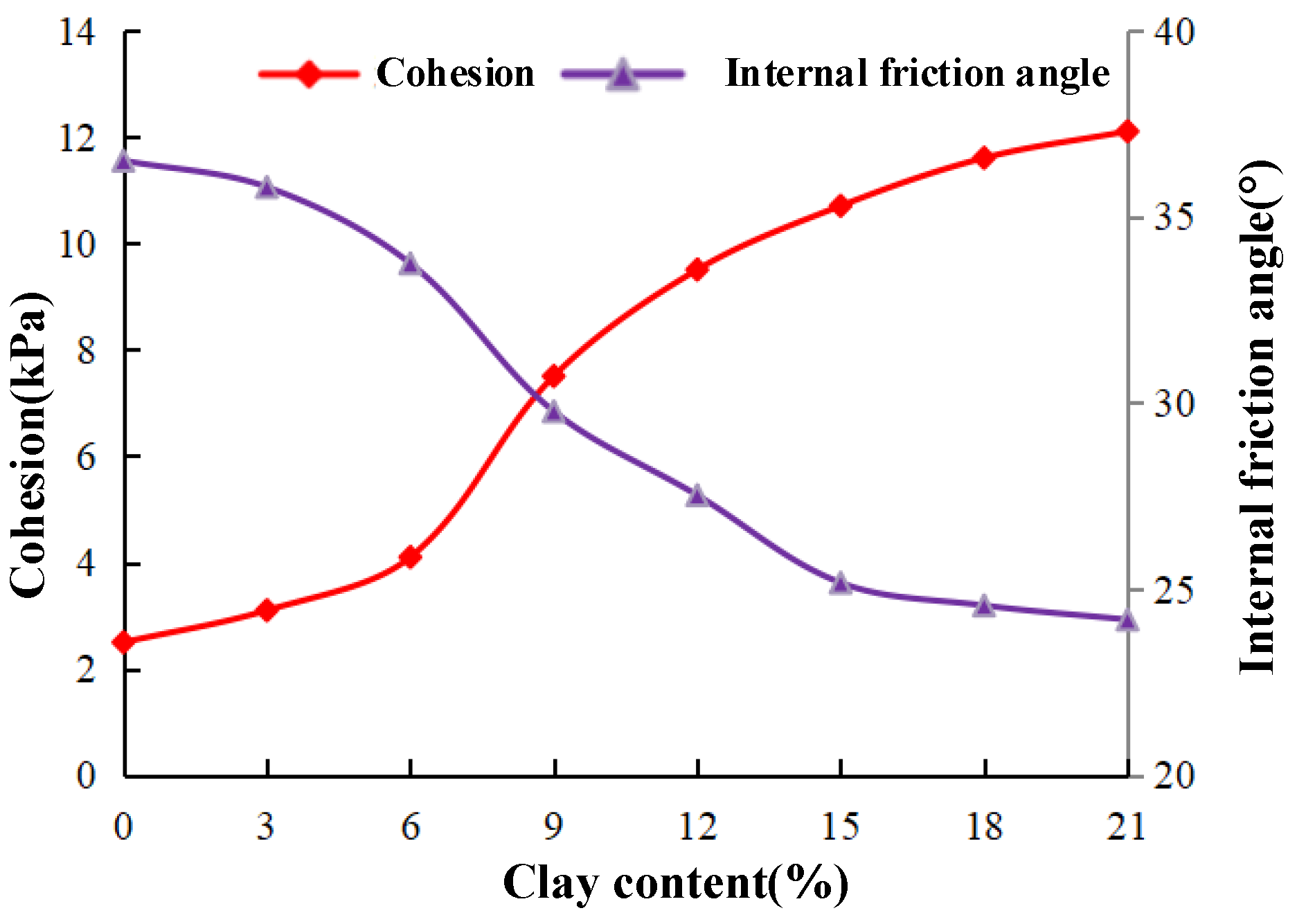

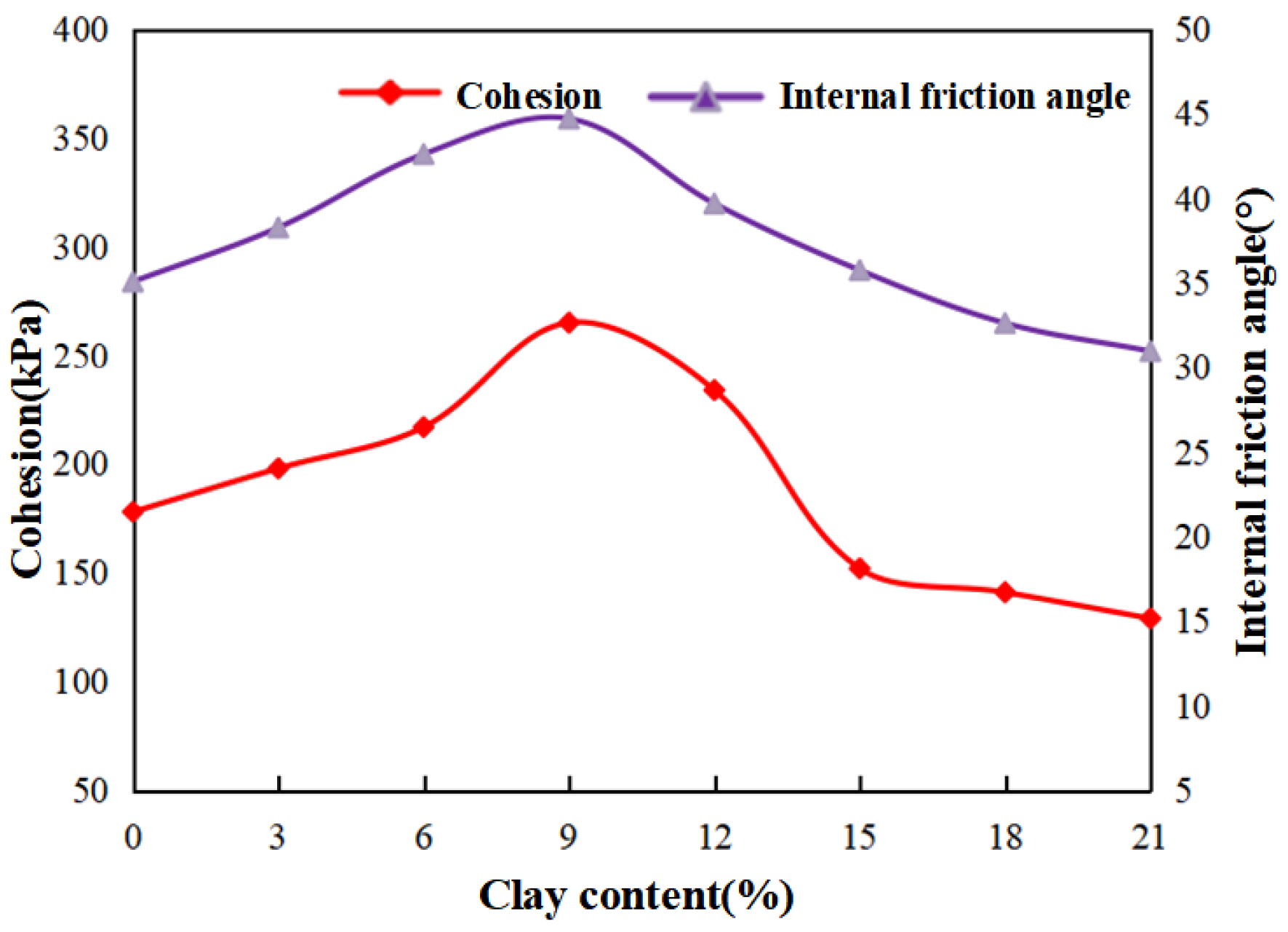

3.4. The Effects of Different Clay Contents on Cohesion and Internal Friction Angle under the Consolidated Undrained Test

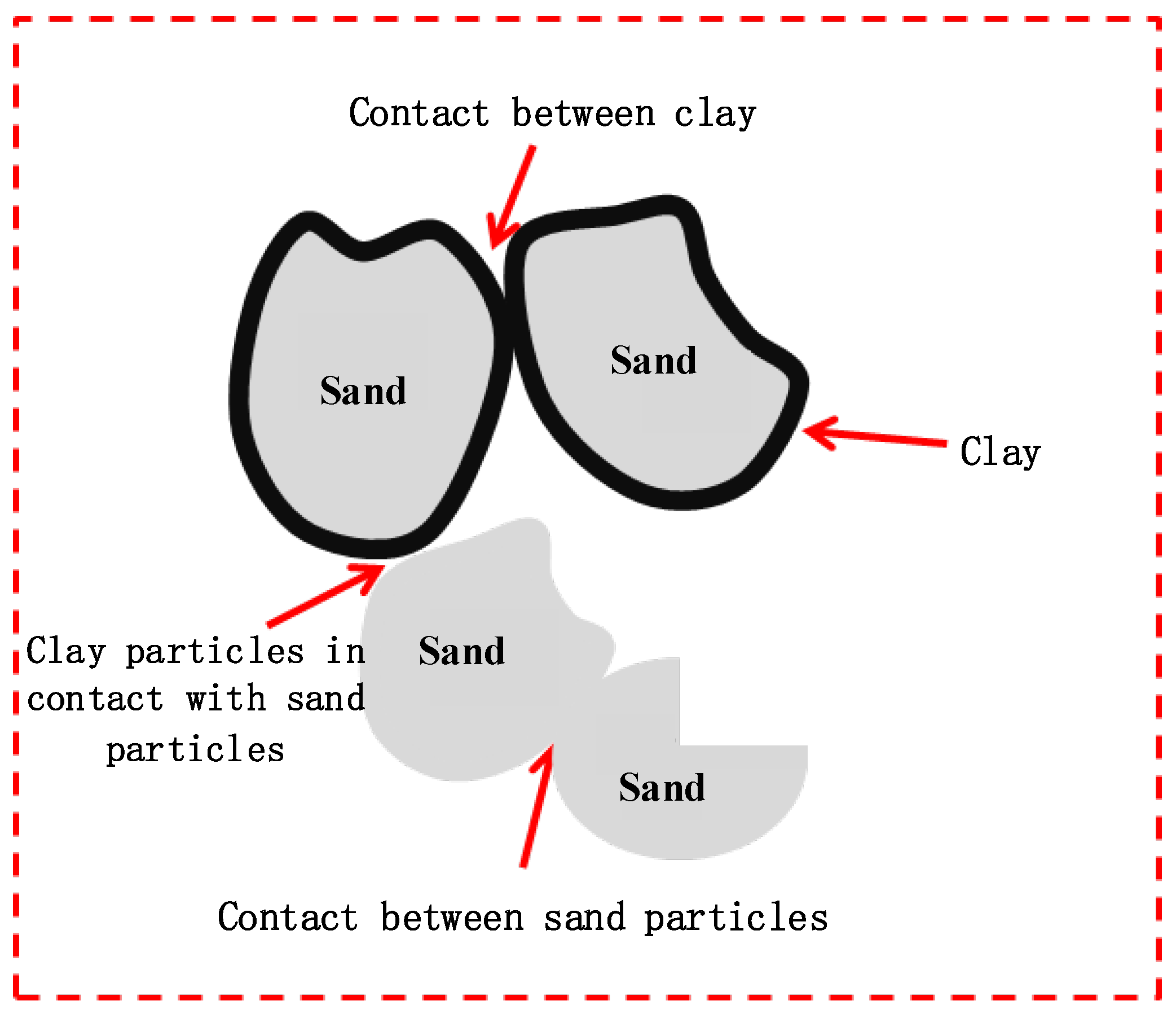

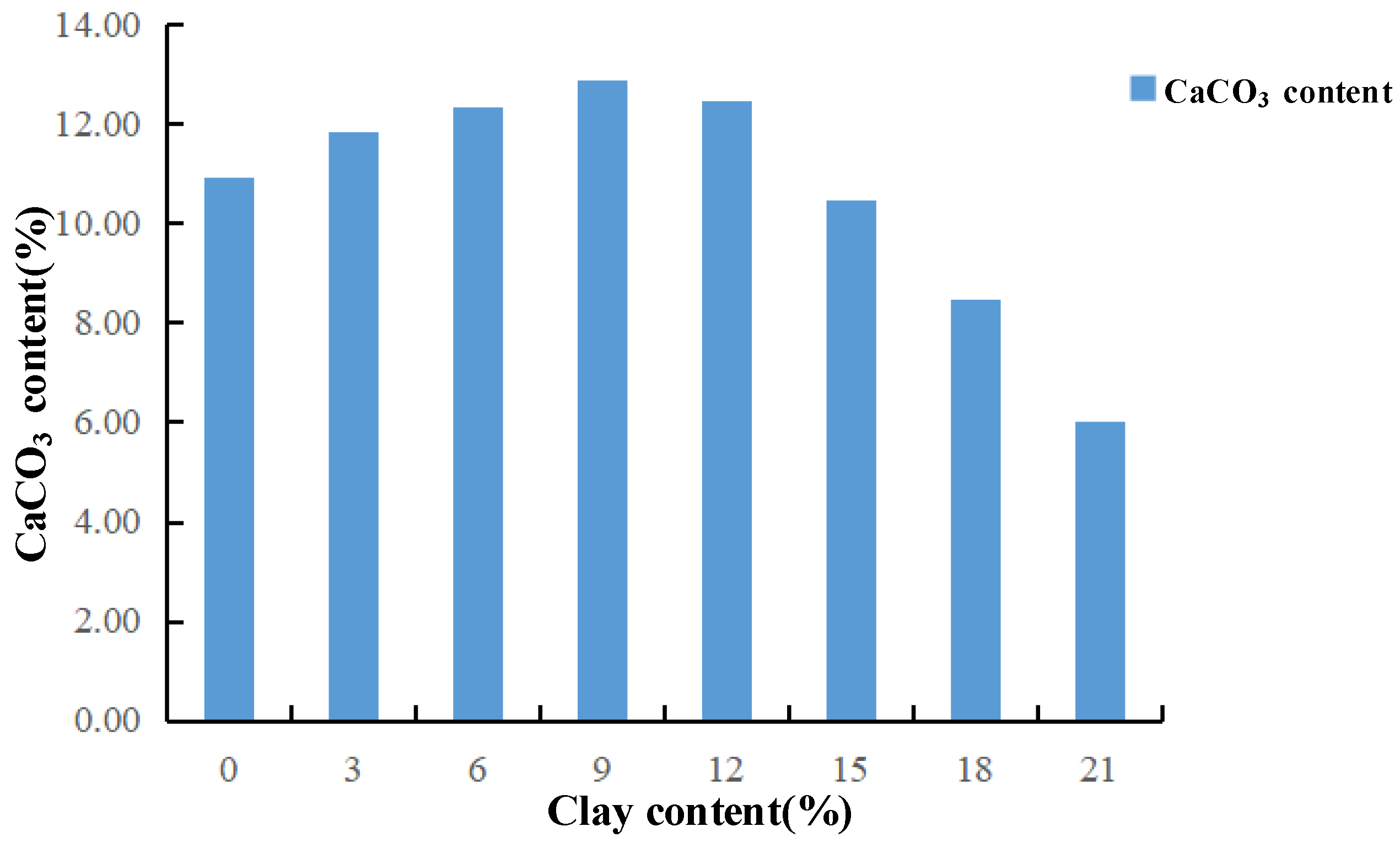

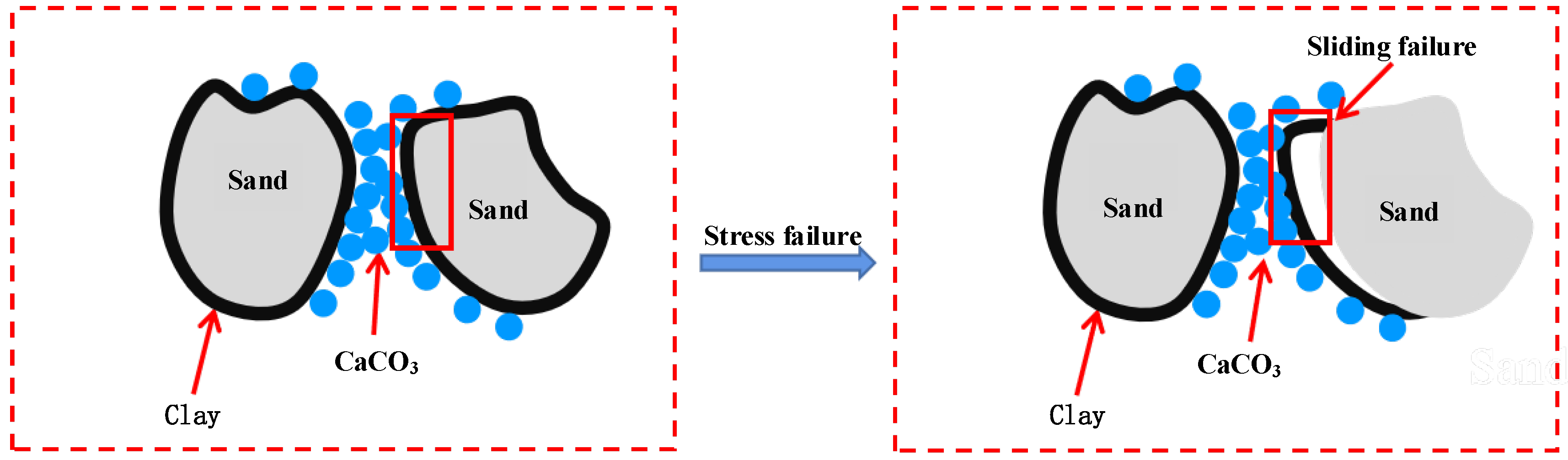

4. Mechanism Analysis of the Influence of Clay Content on Microbial Curing

4.1. Mechanism Analysis of the Influence of Different Clay Contents on Unconfined Compressive Strength

- (1)

- Clay particles are evenly distributed in the pores of the sand column, thereby increasing the specific surface area of the sand particles and providing good “nuclear sites” and good living space for bacteria to produce abundant effective calcium carbonate;

- (2)

- Bacteria are negatively charged, whereas clay particles are positively charged so that they can better adsorb bacteria. The injected bacteria are retained in the sand column to avoid bacterial loss and generate abundant effective calcium carbonate to improve the strength of the sand column;

- (3)

- The contact mode among sand, clay, and calcium carbonate is mainly contact points 1 and 2. When subjected to load, contact points 1 and 2 can provide good friction resistance to prevent sample failure and improve sample strength. Meanwhile, calcium carbonate can limit the movement and deformation between sand particles and improve the unconfined compressive strength and failure strain of the sample.

4.2. Analysis of the Influence Mechanism of Different Clay Contents on Cohesion and Internal Friction Angle

5. Conclusions

- (1)

- The failure strain and unconfined compressive strength of the MICP-treated sand column increase initially and then decrease with the increase in clay content and reach the maximum when the clay content is 9%. A low clay content is beneficial to the microbial curing effect, the failure strain and unconfined compressive strength of the sample are significantly improved, and the integrity of the sample remains good after damage. A high clay content is not conducive to MICP sand curing, and brittle failure occurs in the sample;

- (2)

- With the increase in clay content in the sand–clay mixed soil, the peak strength of the sample under the same confining pressure gradually decreases, the internal friction angle of the mixed soil gradually decreases, and the cohesion gradually increases. After MICP treatment, the internal friction angle and cohesion of sand increase initially and then decrease with the increase in clay content, and the shear strength reaches the maximum when the clay content is 9%. The main reason is that a low clay content can promote the formation of calcium carbonate, enhance the mechanical biting action between particles, and increase the strength of samples;

- (3)

- When the clay content exceeds 9%, excessive clay will flow with the bacterial liquid and nutrient liquid, then accumulate at the bottom of the sand sample, which is not conducive to the growth of bacteria and the formation of calcium carbonate. At last, less calcium carbonate will be produced, and the content of available calcium carbonate will be low, finally resulting in low strength;

- (4)

- The influence of clay on mixed soil is mainly related to the soil matrix film. When clay and sand particles are mixed, the clay particles wrap around the sand particles to form a soil matrix film with a certain thickness, and this changes the contact form between sand particles, thus affecting the internal friction angle, cohesion, and strength of samples.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mujah, D.; Shahin, M.; Cheng, L. State-of-the-art review of bio-cementation by microbially induced calcite precipitation (MICP) for soil stabilization. Geomicrobiology 2016, 34, 524–537. [Google Scholar] [CrossRef]

- Sun, D.S.; Xu, W.Y.; Liu, K.W.; OuYang, J.Z.; Wang, A.G. Application Progress of MICP in Construction Field. Mater. Rep. 2021, 35, 11084–11091. (In Chinese) [Google Scholar]

- Liu, S.; Wen, K.; Armwood, C.; Bu, C.; Li, C.; Amini, F.; Li, L. Enhancement of MICP-Treated Sandy Soils against Environmental Deterioration. J. Mater. Civ. Eng. 2019, 31, 04019294. [Google Scholar] [CrossRef]

- Suk, L.Y.; Woojun, P. Current challenges and future directions for bacterial self-healing concrete. Appl. Microbiol. Biotechnol. 2018, 102, 3059–3070. [Google Scholar]

- Bu, C.; Wen, K.; Liu, S.; Ogbonnaya, U.; Li, L. Development of bio-cemented constructional materials through microbial induced calcite precipitation. Mater. Struct. 2018, 51, 30. [Google Scholar] [CrossRef]

- Choi, S.G.; Chang, I.; Lee, M.; Lee, J.H.; Han, J.T.; Kwon, T.H. Review on geotechnical engineering properties of sands treated by microbially induced calcium carbonate precipitation (MICP) and biopolymers. Constr. Build. Mater. 2020, 246, 118415. [Google Scholar] [CrossRef]

- Song, C.; Wang, C.; Elsworth, D.; Zhi, S. Compressive Strength of MICP-Treated Silica Sand with Different Particle Morphologies and Gradings. Geomicrobiol. J. 2022, 39, 148–154. [Google Scholar] [CrossRef]

- Montoya, B.M.; Dejong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- Yao-Jia, C.; Chao-Sheng, T.; Xiao-Hua, P.; Bo, L.; Yue-Han, X.; Qing, C.; Bin, S. Application of microbial induced carbonate precipitation for loess surface erosion control. Eng. Geol. 2021, 294, 106387. [Google Scholar]

- Han, Z.; Cheng, X.; Ma, Q. An experimental study on dynamic response for MICP strengthening liquefiable sands. Earthq. Eng. Eng. Vib. 2016, 15, 673–679. [Google Scholar] [CrossRef]

- Pan, Q.S.; Zhang, K.N.; Zhou, B. Analysis on Engineering Characteristics of Soft Soil in Nansha, Guangzhou. Geotech. Eng. 2006, 9, 46–48. (In Chinese) [Google Scholar]

- Kim, D.; Nam, B.H.; Youn, H. Effect of clay content on the shear strength of clay-sand mixture. Int. J. Geo-Eng. 2018, 9, 19. [Google Scholar] [CrossRef]

- Sun, Y.; Tang, L.; Lu, W.; Zhao, Z. Study of the shear properties of Granite residual soil in the Guangzhou area using different testing methods. Fresenius Environ. Bull. 2018, 27, 327–335. [Google Scholar]

- Li, C.S.; Kong, L.W.; Shu, R.; An, R. Disintegration characteristics in granite residual soil and their relationship with the collapsing gully in South China. Open Geosci. 2020, 12, 1116–1126. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Chen, R. Effects of Different Clay’s Percentages on Improvement of Sand-Clay Mixtures with Microbially f Induced Calcite Precipitation. Geomicrobiology 2019, 36, 810–818. [Google Scholar] [CrossRef]

- Ma, G.; He, X.; Jiang, X.; Liu, H.; Chu, J.; Xiao, Y. Strength and Permeability of Bentonite-Assisted Biocemented Coarse Sand. Can. Geotech. J. 2021, 58, 969–981. [Google Scholar] [CrossRef]

- Yue, J.; Zhao, L.; Zhang, B.; Kong, Q.; Wang, S.; Wang, H. Effect of Glutinous Rice Slurry on the Reinforcement of Silt in the Yellow River Basin by Microbially Induced Carbonate Precipitation (MICP): Mechanical Property and Microcosmic Structure. Adv. Mater. Sci. Eng. 2021, 2021, 5539854. [Google Scholar] [CrossRef]

- Ma, G.L.; He, X.; Lu, H.M.; Wu, H.R.; Liu, H.L.; Chu, J.; Xiao, R. Strength of hardening coarse sand by kaolin particle immobilization nucleating microorganism. Chin. J. Geotech. Eng. 2021, 43, 290–299. (In Chinese) [Google Scholar]

- Jiang, N.J.; Soga, K.; Kuo, M. Microbially Induced Carbonate Precipitation for Seepage-Induced Internal Erosion Control in Sand-Clay Mixtures. J. Geotech. Geoenviron. Eng. 2017, 143, 04016100. [Google Scholar] [CrossRef]

- Do, J.; Montoya, B.M.; Gabr, M.A. Microbially Induced Carbonate Precipitation Process for Soil Improvement Adjacent to Model Pile by Innovative Delivery System. In Proceedings of the Geo-Congress, Minneapolis, MN, USA, 25–28 February 2020; pp. 188–195. [Google Scholar]

- Lin, H.; Suleiman, M.T.; Jabbour, H.M.; Brown, D.G. Bio-grouting to enhance axial pull-out response of pervious concrete ground improvement piles. Can. Geotech. J. 2017, 55, 119–130. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.T.; Jabbour, H.M.; Brown, D.G.; Kavazanjian, E., Jr. Enhancing the Axial Compression Response of Pervious Concrete Ground Improvement Piles Using Biogrouting. J. Geotech. Geoenviron. Eng. 2016, 142, 04015066. [Google Scholar] [CrossRef]

- Hestera, H. Analysis of pedological factors and USCS in the contact area of Dakovo loess plateau and Dilj gora, Croatia. Rud.-Geol.-Naft. Zb. 2020, 35, 13–23. [Google Scholar] [CrossRef]

- Ozgan, E.; Serin, S.; Erturk, S.; Vural, I. Effects of freezing and thawing cycles on the engineering properties of soils. Soil Mech. Found. Eng. 2015, 52, 95–99. [Google Scholar] [CrossRef]

- Zhai, Q.; Rahardjo, H.; Satyanaga, A.; Zhu, Y.; Dai, G.; Zhao, X. Estimation of wetting hydraulic conductivity function for unsaturated sandy soil. Eng. Geol. 2021, 285, 106034. [Google Scholar] [CrossRef]

- Zhai, Q.; Rahardjo, H.; Satyanaga, A.; Dai, G. Estimation of tensile strength of sandy soil from soil-water characteristic curve. ACTA Geotech. 2020, 15, 3371–3381. [Google Scholar] [CrossRef]

- GB/T50123-2019; Specification of Soil Test. Ministry of Water Resources of People’s Republic of China: Beijing, China; China Planning Press: Beijing, China, 2019.

| Moisture Content/% | Density/g·cm−3 | Void Ratio | Liquid Limit/% | Plastic Limit/% | Liquidity Index | Plasticity Index |

|---|---|---|---|---|---|---|

| 69.28 | 1.67 | 1.74 | 52.84 | 38.14 | 2.12 | 14.7 |

| Parameter | Density/g·cm−3 | Specific Gravity | Average Particle Size/(mm) | Nonuniformity Coefficient | Maximum Void Ratio | Minimum Void Ratio |

|---|---|---|---|---|---|---|

| Numerical value | 1.92 | 2.653 | 0.68 | 1.56 | 2.00 | 0.08 |

| Number | Clay Content | Whether Processed by MICP or Not | Consolidated Undrained Test | Unconfined Compressive Strength Test |

|---|---|---|---|---|

| NL0 | 0% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL3 | 3% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL6 | 6% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL9 | 9% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL12 | 12% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL15 | 15% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL18 | 18% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NL21 | 21% | No | Confining pressures are 100, 200, and 300 kPa | No |

| NLC0 | 0% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC3 | 3% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC6 | 6% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC9 | 9% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC12 | 12% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC15 | 15% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC18 | 18% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

| NLC21 | 21% | Yes | Confining pressures are 100, 200, and 400 kPa | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, D.; Gao, H.; Li, Z.; Liang, S. The Effect of Clay on the Shear Strength of Microbially Cured Sand Particles. Materials 2022, 15, 3414. https://doi.org/10.3390/ma15103414

Feng D, Gao H, Li Z, Liang S. The Effect of Clay on the Shear Strength of Microbially Cured Sand Particles. Materials. 2022; 15(10):3414. https://doi.org/10.3390/ma15103414

Chicago/Turabian StyleFeng, Deluan, Haiqin Gao, Zhanlin Li, and Shihua Liang. 2022. "The Effect of Clay on the Shear Strength of Microbially Cured Sand Particles" Materials 15, no. 10: 3414. https://doi.org/10.3390/ma15103414

APA StyleFeng, D., Gao, H., Li, Z., & Liang, S. (2022). The Effect of Clay on the Shear Strength of Microbially Cured Sand Particles. Materials, 15(10), 3414. https://doi.org/10.3390/ma15103414