Effects of Forming Parameters on Fatigue Life in Incremental Sheet Punching

Abstract

:1. Introduction

2. Materials and Methods

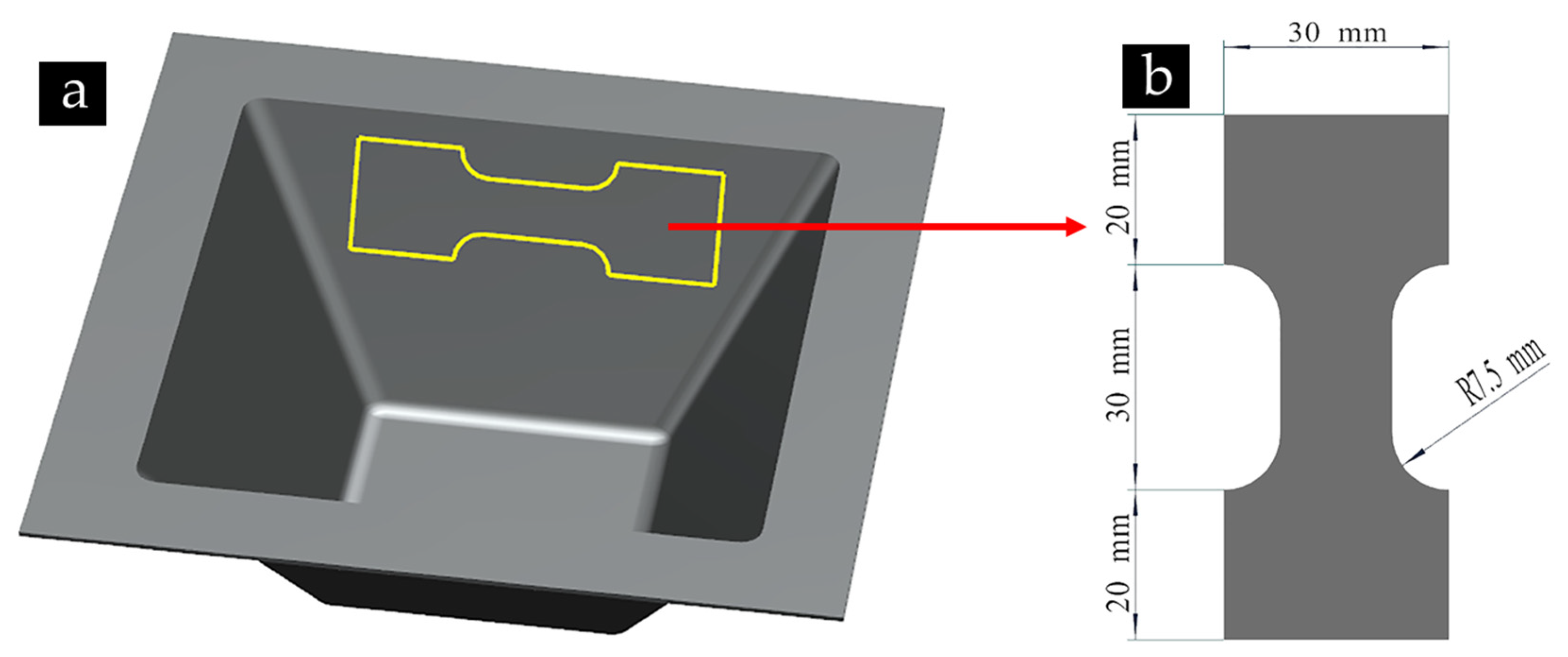

2.1. Blanks Preparation

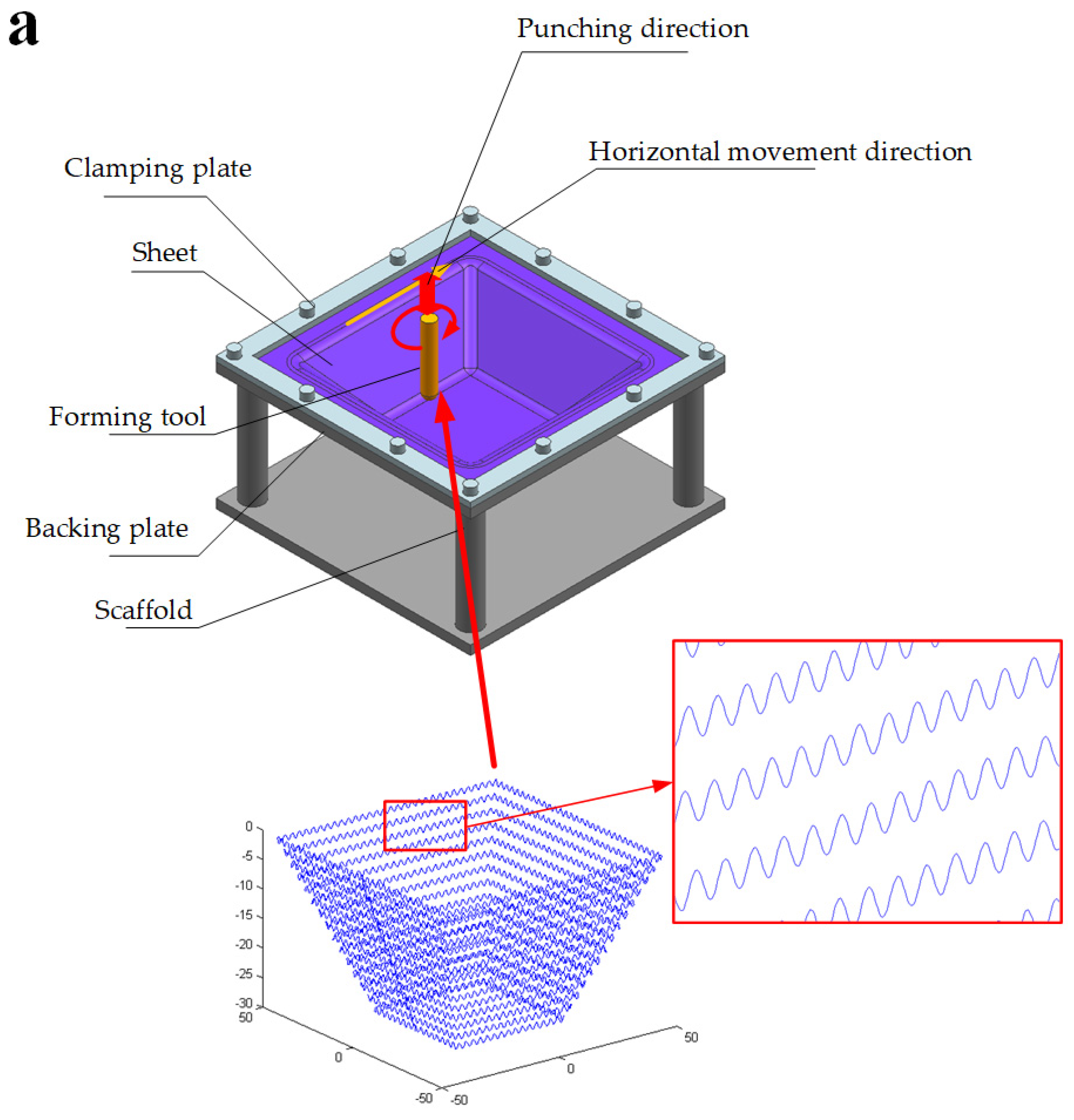

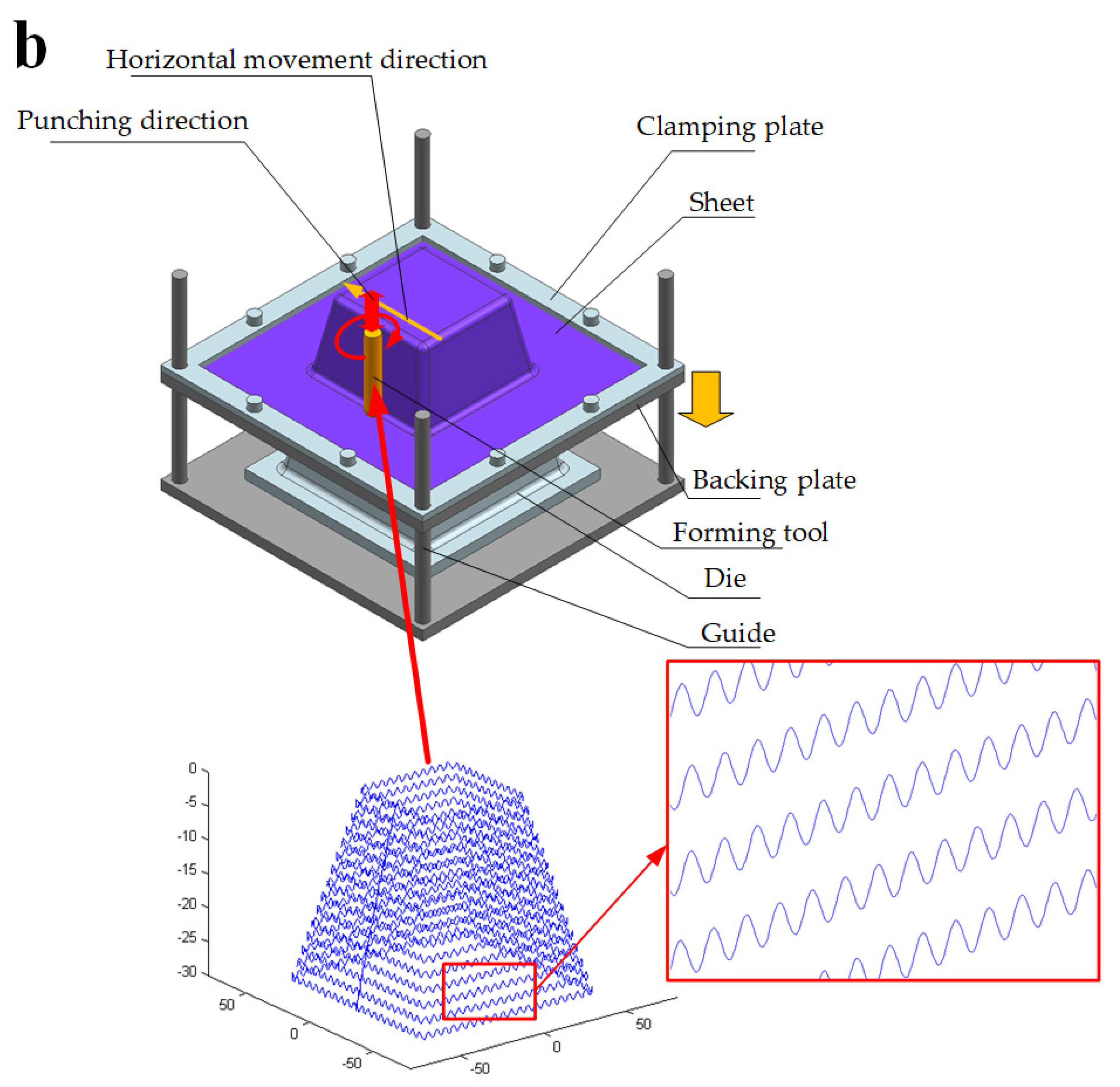

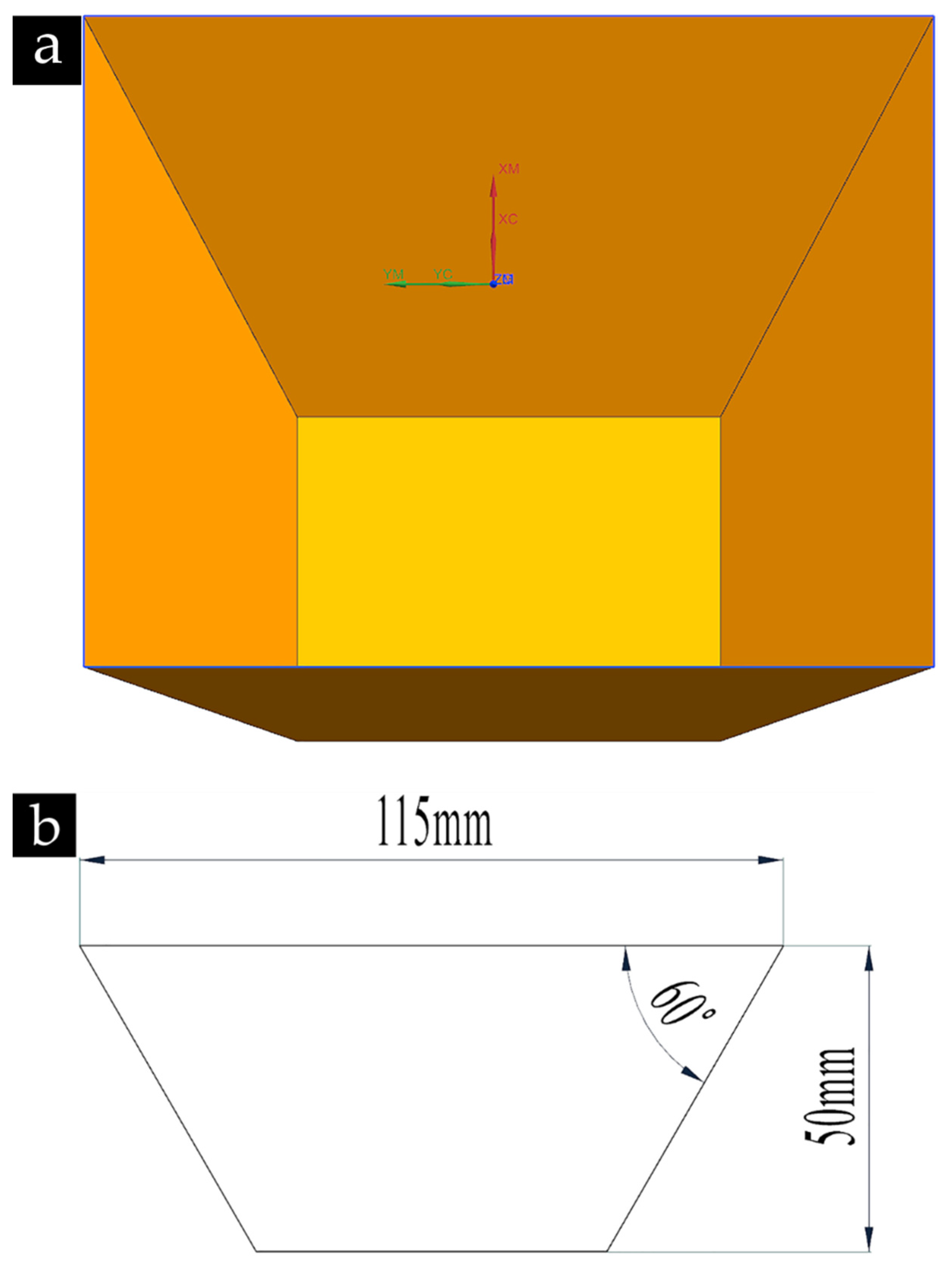

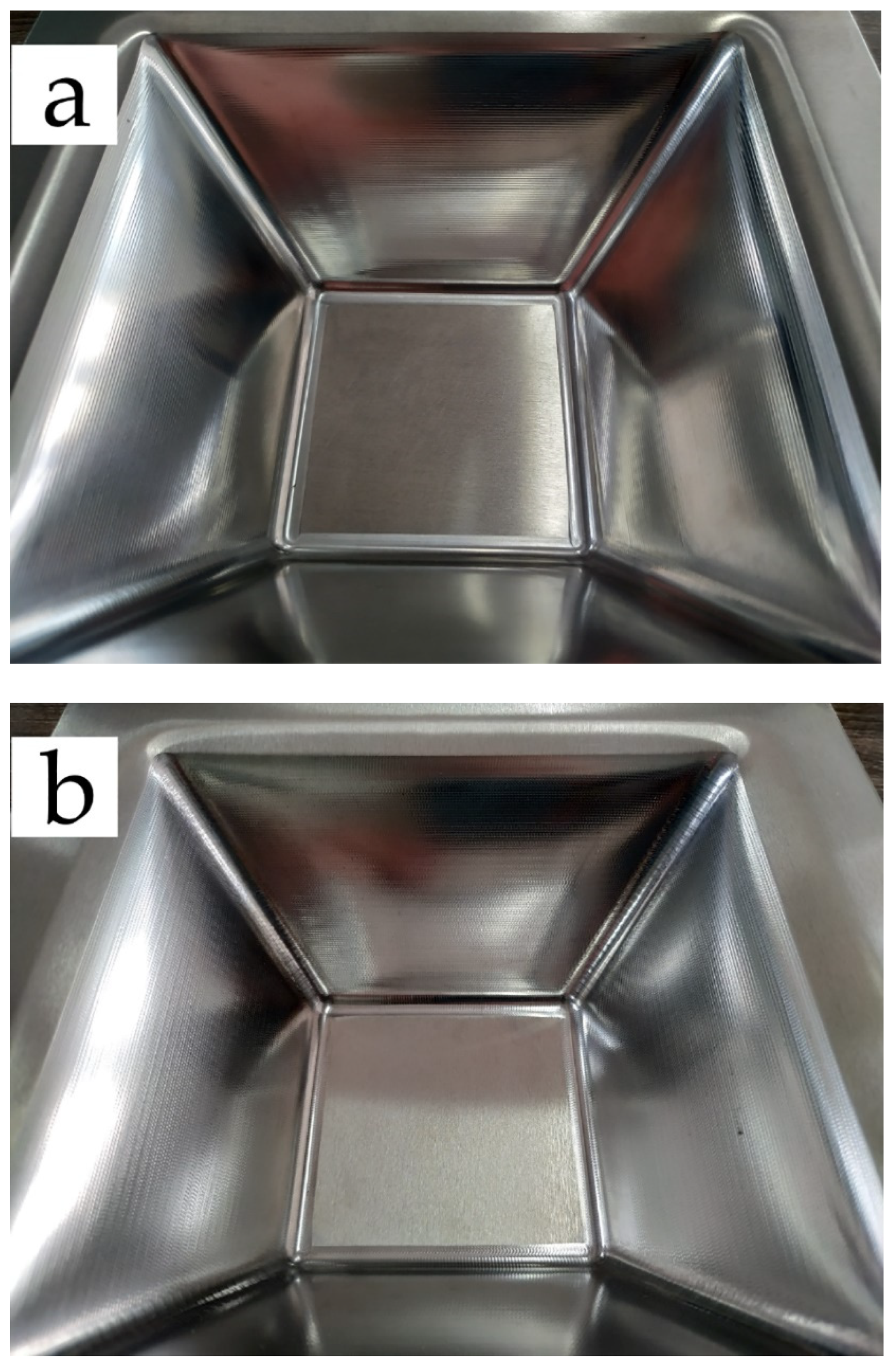

2.2. Incremental Sheet Punching

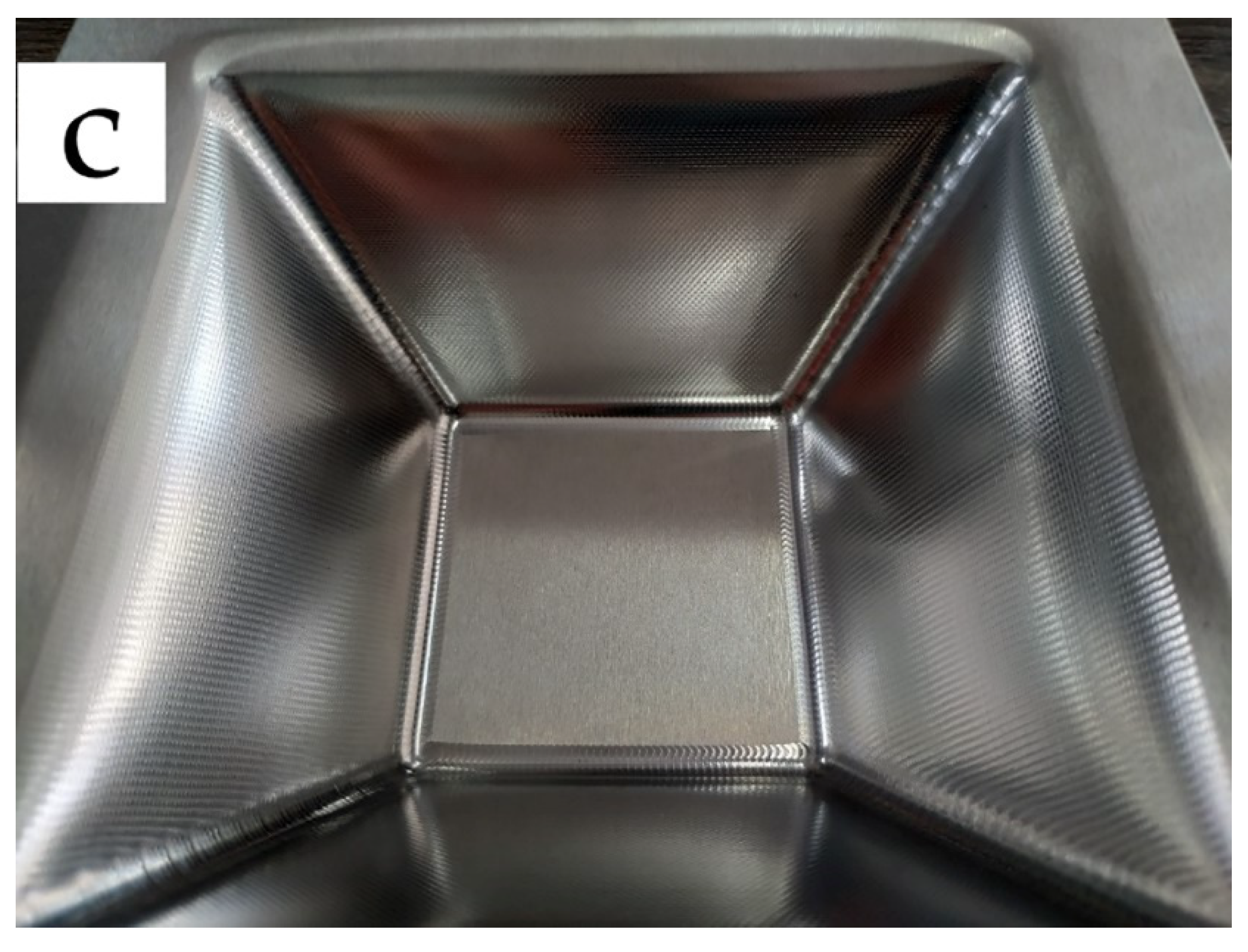

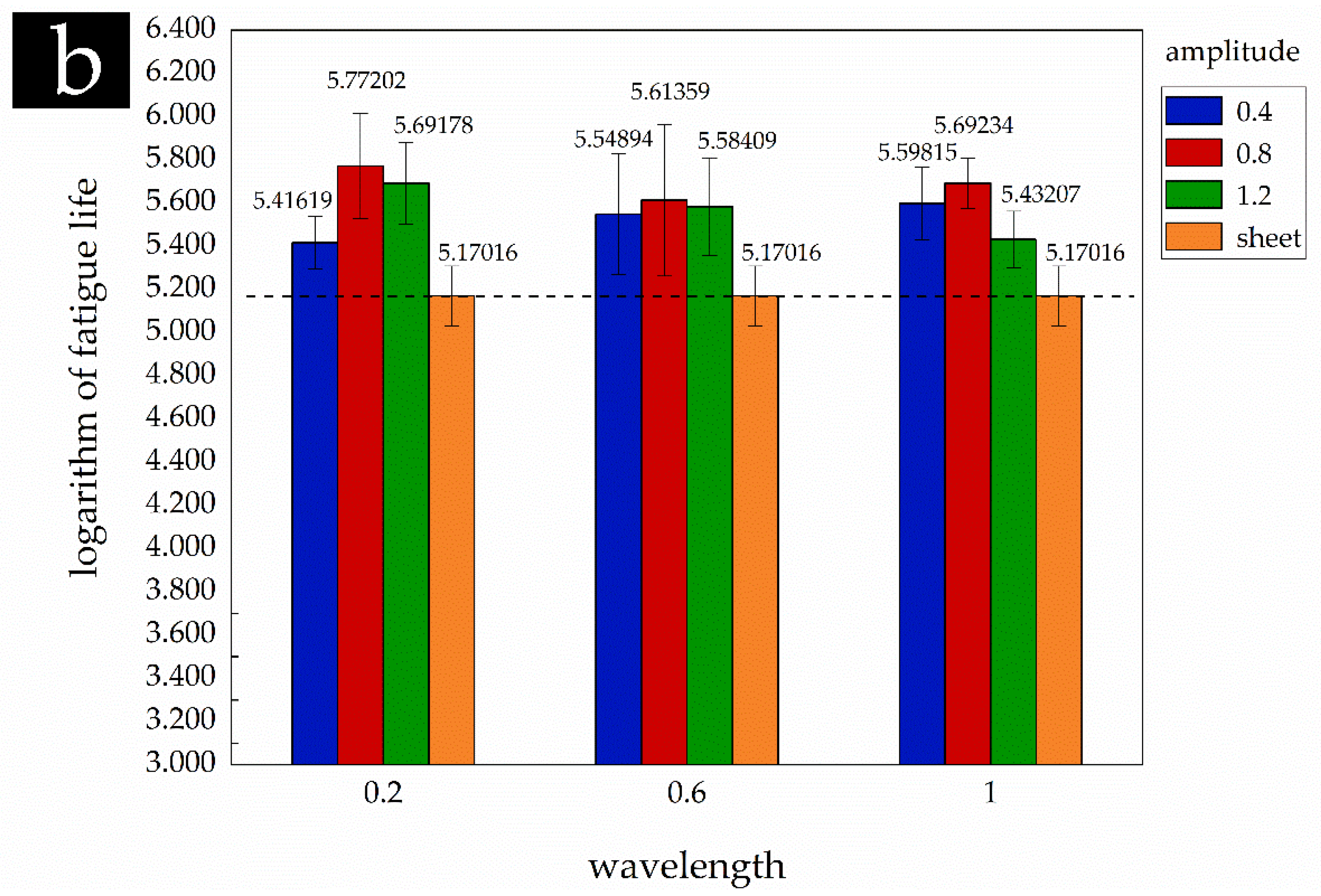

2.3. Fatigue Comparative Test

2.4. Statistical Analysis

2.4.1. ANOVA

2.4.2. Tukey Test

2.4.3. t-Test

3. Results and Discussion

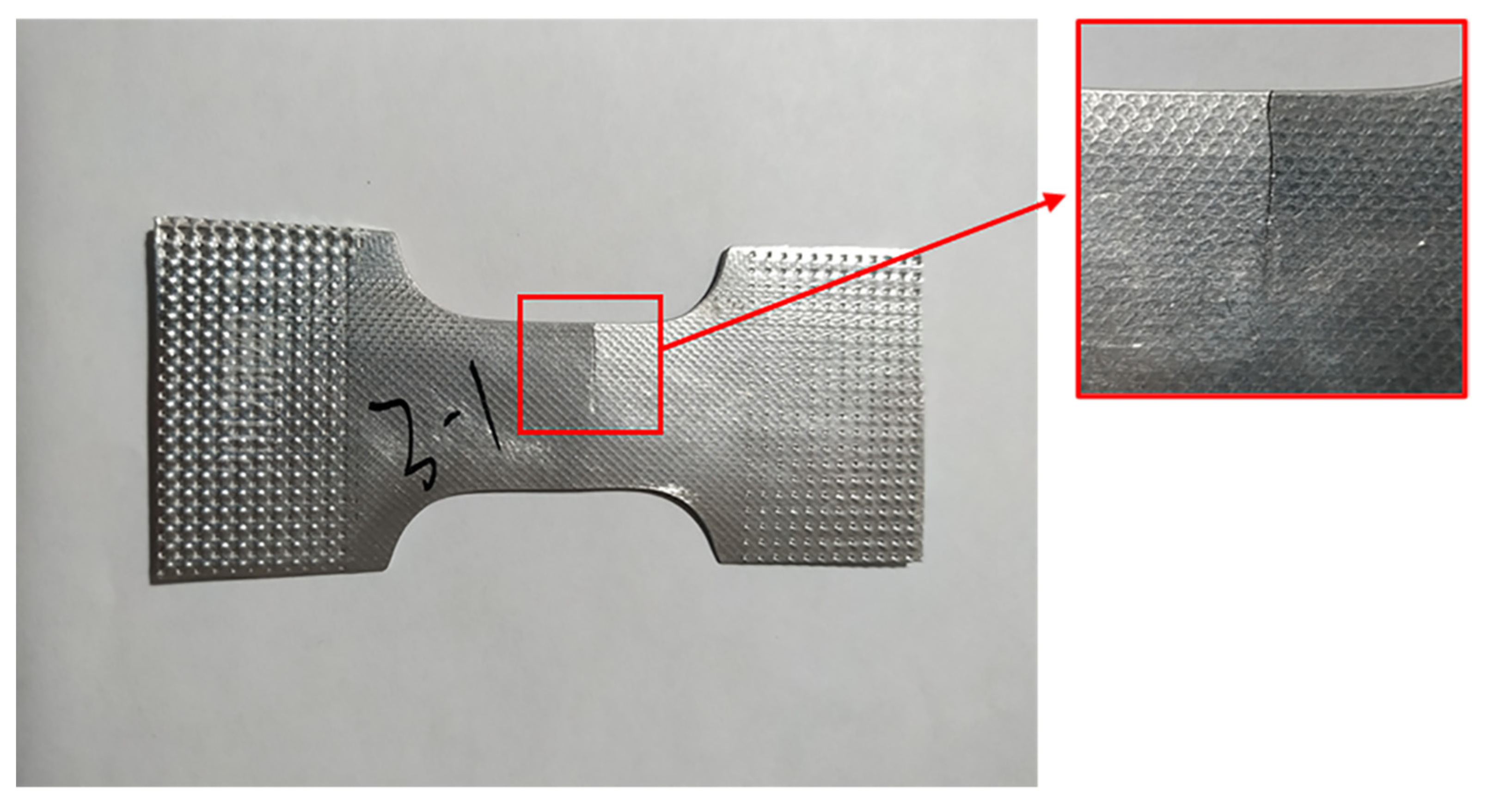

3.1. Results of Fatigue Test

3.2. Statistical Analysis Results of Fatigue Contrast Test

3.2.1. Test of Normality

3.2.2. Levene Homogeneity of Variance Test

3.2.3. Results of ANOVA

3.2.4. Results of Tukey Test

3.2.5. Results of t-Test

4. Conclusions

- (1)

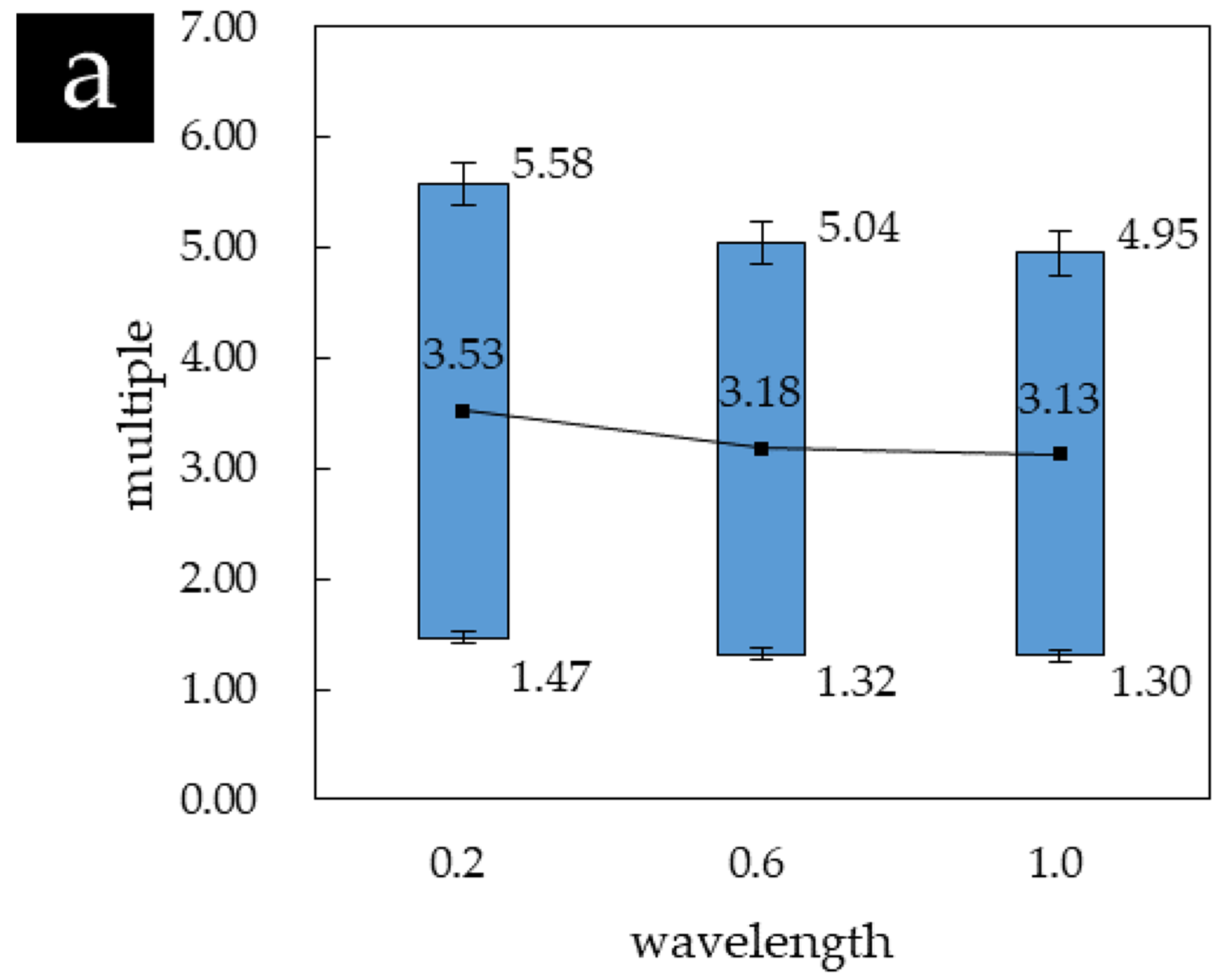

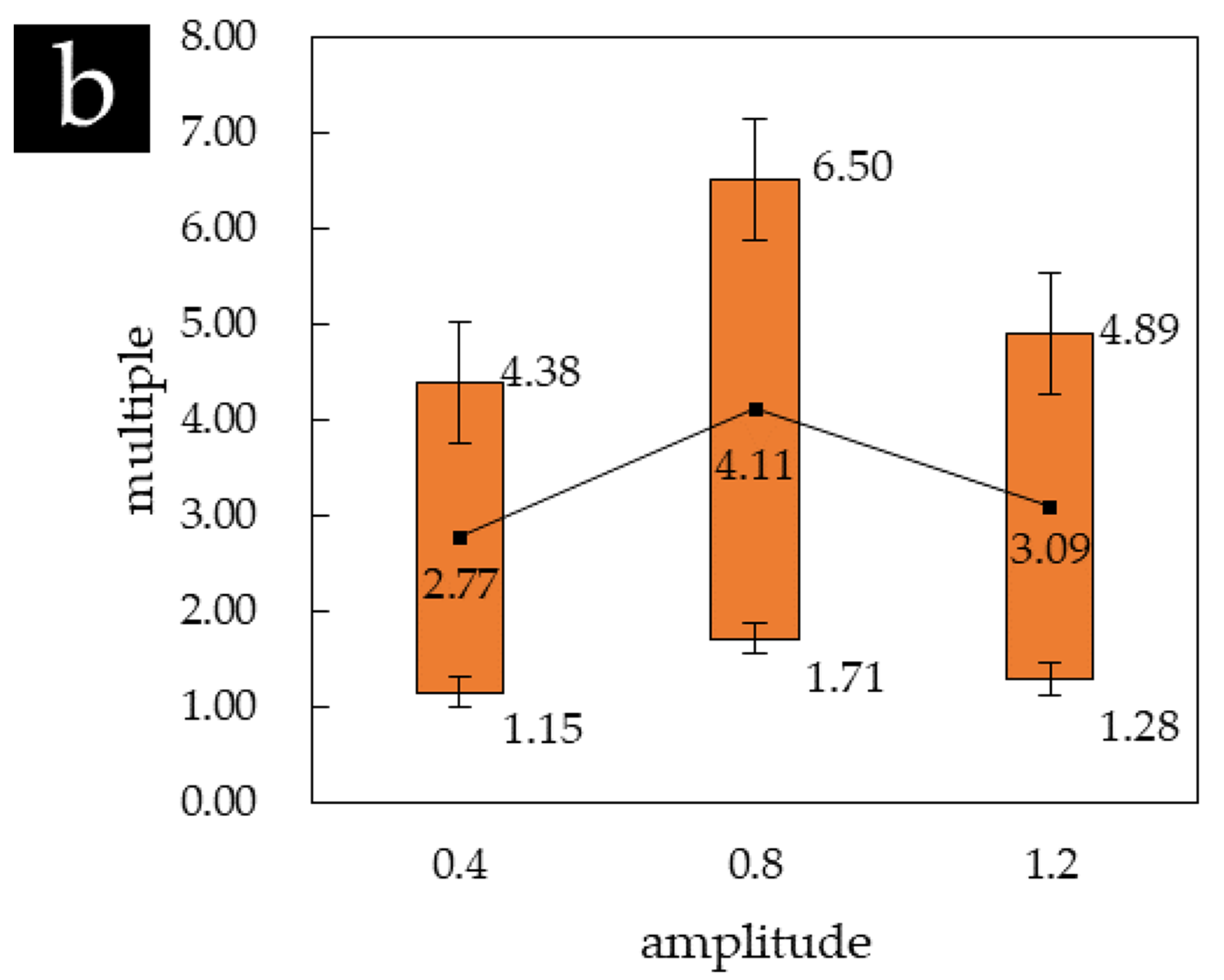

- ISP formed parts may have greater fatigue life under cyclic tension as compared to the virgin material. The improvement of fatigue life decreases with the increase of wavelength and increases with the increment of amplitude when it is less than a certain value, followed by decreasing.

- (2)

- Under the given parameter values, the maximum improvement of fatigue life was 1.47–5.58 times when wavelength equaled 0.2 mm and was 1.71–6.50 times when amplitude equaled 0.8 mm.

- (3)

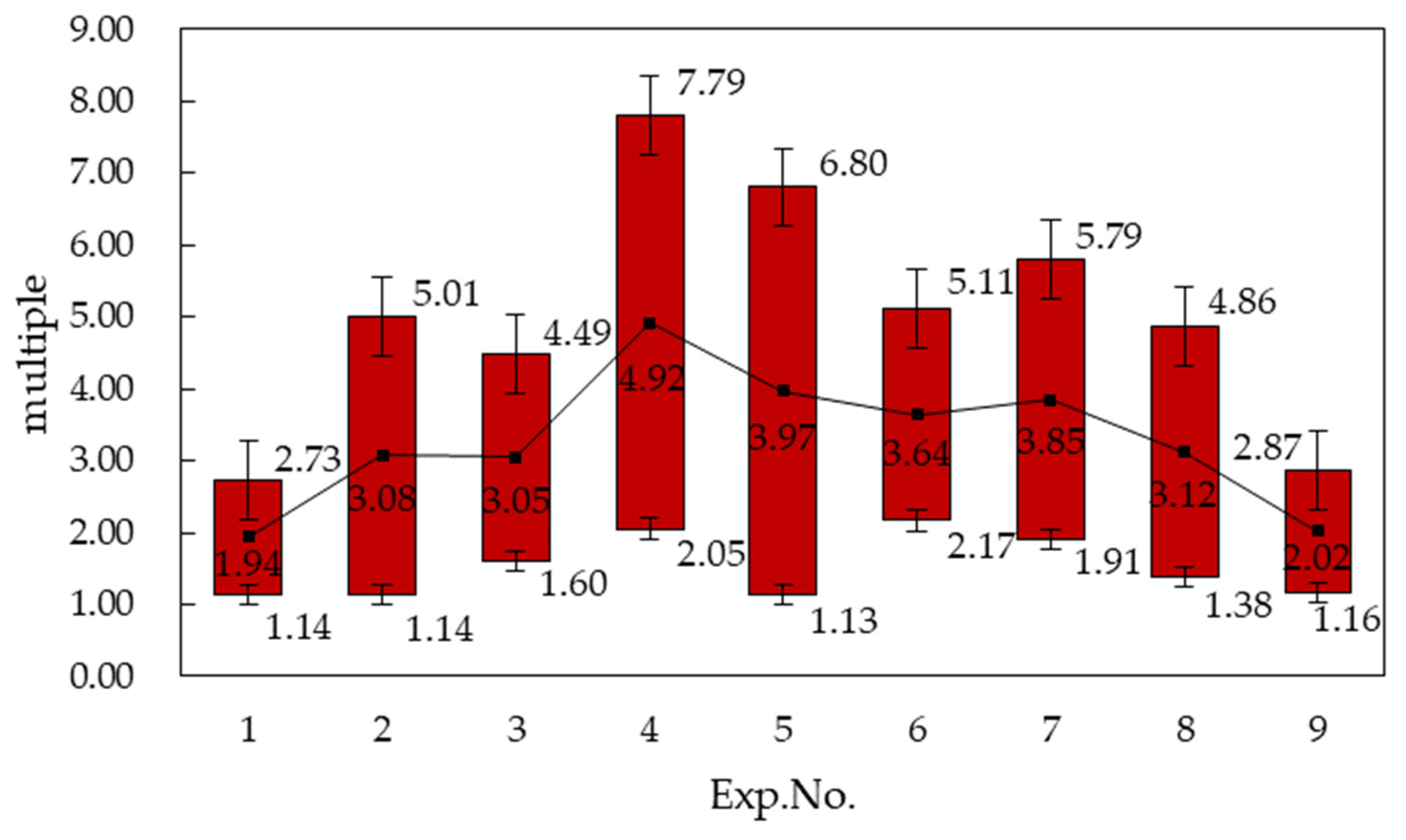

- The maximum improvement of fatigue life with interaction was 2.05–7.79 times when wavelength equaled 0.2 mm and the amplitude equaled 0.8 mm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jeswiet, J.; Adams, D.; Doolan, M.; McAnulty, T.; Gupta, P. Single point and asymmetric incremental forming. Adv. Manuf. 2015, 3, 253–262. [Google Scholar] [CrossRef]

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J. Asymmetric Single Point Incremental Forming of Sheet Metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, H.S.; Long, T.; Wang, B.P. Study on experimental method of measuring forming limit diagram in incremental sheet forming. Forg. Stamp. Technol. 2013, 38, 34–36, 39. [Google Scholar]

- Zhang, S.; Jin, W.; Shi, J.; Zhang, X.; Zhang, Z. Incremental forming performance of retiary sheet metal. Forg. Stamp. Technol. 2016, 41, 48–52, 88. [Google Scholar]

- Schafer, T.; Schraft, R.D. Incremental sheet metal forming by industrial robots. Rapid Prototyp. J. 2005, 11, 278–286. [Google Scholar] [CrossRef]

- Vihtonen, L.; Puzik, A.; Katajarinne, T. Comparing two robot assisted incremental forming methods: Incremental forming by pressing and incremental hammering. Int. J. Mater. Form. 2008, 1, 1207–1210. [Google Scholar] [CrossRef]

- Luo, Y.; He, K.; Du, R. A new sheet metal forming system based on the incremental punching, part 1: Modeling and simulation. Int. J. Adv. Manuf. Technol. 2010, 51, 481–491. [Google Scholar] [CrossRef]

- Luo, Y.; He, K.; Du, R. A new sheet metal forming system based on incremental punching, part 2: Machine building and experiment results. Int. J. Adv. Manuf. Technol. 2010, 51, 493–506. [Google Scholar] [CrossRef]

- Sedighi, M.; Riahi, M.; Asgari, A. An analytical method for prediction of the incremental sheet metal punching process. Int. J. Adv. Manuf. Technol. 2015, 78, 231–238. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Jiang, H.; Zhang, Z.; Zhang, S. Incremental sheet punching on the base of sinusoidal tool path. Int. J. Adv. Manuf. Technol. 2017, 89, 3527–3534. [Google Scholar] [CrossRef]

- Zhang, Z.; Jin, W.; Li, L.; Jiang, H.; Bo, G.; Gao, S. Research on the method of motion trajectory of tool-head in incrementally pressing forming. Forg. Stamp. Technol. 2015, 40, 70–73. [Google Scholar]

- Jiang, H.; Xu, W.; Zhang, Z.; Jin, W.; Li, L.; Sun, S. Study on incremental punching time driven by wave tool path for sheet metal. Forg. Stamp. Technol. 2017, 42, 89–93. [Google Scholar]

- She, J.; Zhang, A. Research on Residual Stress of Revolving Type Metal Sheet Incremental Forming Parts. New Technol. New Process 2013, 1, 40–44. [Google Scholar]

- Agrawal, A.; Ziegert, J.; Smith, S.; Woody, B.; Cao, J. Study of Dimensional Repeatability and Fatigue Life for Deformation Machining Bending Mode. J. Manuf. Sci. Eng. 2012, 134, 61009. [Google Scholar] [CrossRef]

- Xu, R.; Shi, X.; Xu, D.; Malhotra, R.; Cao, J. A preliminary study on the fatigue behavior of sheet metal parts formed with accumulative-double-sided incremental forming. Manuf. Lett. 2014, 2, 8–11. [Google Scholar] [CrossRef]

- Zhentong, G. Fatigue Application Statistics; National Defense Industry Press: Beijing, China, 1986; pp. 288–336. [Google Scholar]

- Zhang, L.; Hou, Y.W. Effect of Plastic Deformation on Fatigue Life of 6061 Aluminum Alloy. Alum. Fabr. 2013, 2, 21–25. [Google Scholar]

- Subcommittee E08.05 on Cyclic Deformation and Fatigue Crack Formation. ASTM E466-2007, Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Jing, J.N.; Dong, L.H.; Wang, H.D.; Jin, G. Influences of Vacuum Ion-nitriding on Bending Fatigue Behaviors of 42CrMo4 Steel: Experiment Verification, Numerical Analysis and Statistical Approach. Int. J. Fatigue 2020, 145, 106104. [Google Scholar] [CrossRef]

- Shaw, R.G.; Mitchellolds, T. Anova for Unbalanced Data—An Overview. Ecology 1995, 74, 1638–1645. [Google Scholar] [CrossRef]

- Cai, L.; Lv, W. Segmented Testing of Improved Time Series Stationarity Test Based on Tukey. Stat. Decis. 2018, 34, 26–29. [Google Scholar]

- Zhang, B.; Zhen-Zhou, L.U. Reliability test of fatigue life of LY12 alloy sheet under low-energy impact loads. Exp. Technol. Manag. 2007, 10, 219–222. [Google Scholar]

- Cong, C.; Hua, F. Levene Homogeneity of Variance Test. Chin. J. Health Stat. 2005, 6, 408–420. [Google Scholar]

- Brown, M.B.; Forsythe, A.B. Robust Tests for the Equality of Variances. J. Am. Stat. Assoc. 1974, 69, 364–367. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, J.; Zhou, P.; Liu, Q. Effects of Wavelength on Incremental Pressing Forming of Sheet Metal. J. Netshape Form. Eng. 2017, 9, 98–101. [Google Scholar]

- Mattson, R.L.; Coleman, W.S., Jr. Effect of Shot-Peening Variables and Residual Stresses on the Fatigue Life of Leaf-Spring Specimens. SAE Trans. 1954, 62, 546–556. [Google Scholar]

- Scuracchio, B.G.; Lima, N.B.d.; Schön, C.G. Role of residual stresses induced by double peening on fatigue durability of automotive leaf springs. Mater. Des. 2013, 47, 672–676. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.Y.; Fang, X. Effect of Diameter and Velocity of Shooting Pellet on the Distribution Residual Stress of Shot Peening. J. Mater. Sci. Eng. 2013, 31, 588–591, 626. [Google Scholar]

- Li, Y.; Chen, X.; Li, F.; Sun, J.; Li, J.; Zhao, G. Research Development on Incremental Sheet Metal Forming Process. J. Netshape Form. Eng. 2017, 9, 1–9. [Google Scholar]

- Chen, Y.; Huang, Y.; Xue, C.; Hong, J. VIC-3D Static Analysis and Fatigue Test of Aeronautical Aluminum Alloy 2024. Nonferrous Met. Eng. 2016, 6, 35–39, 67. [Google Scholar]

| Mg | Si | Cu | Cr | Fe | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|

| 0.8–1.2 | 0.4–0.8 | 0.15–0.40 | 0.04–0.35 | 0.70 | 0.25 | 0.15 | other |

| Parameter | Value |

|---|---|

| Yield strength Rp0.2/MPa | 240 |

| Tensile strength Rm/MPa | 290 |

| Elongation A/% | 6 |

| Hardness /HBS | 95 |

| Elastic modulus E/GPa | 68.3 |

| Poisson ratio | 0.33 |

| Tool Diameter (mm) | Vertical Feed (mm) | Feed Speed (mm/min) | Hammer Angle (°) |

|---|---|---|---|

| 10 | 0.5 | 1000 | 90 |

| No. | Factor | |

|---|---|---|

| Wavelength(mm) | Amplitude(mm) | |

| 1 | 0.2 | 0.4 |

| 2 | 0.6 | 0.4 |

| 3 | 1.0 | 0.4 |

| 4 | 0.2 | 0.8 |

| 5 | 0.6 | 0.8 |

| 6 | 1.0 | 0.8 |

| 7 | 0.2 | 1.2 |

| 8 | 0.6 | 1.2 |

| 9 | 1.0 | 1.2 |

| No. | Cycle of Fatigue Life (×105) | ||||

|---|---|---|---|---|---|

| 1 | 1.897 | 2.019 | 2.804 | 3.053 | 3.675 |

| 2 | 1.547 | 2.732 | 2.964 | 5.510 | 8.048 |

| 3 | 2.472 | 3.311 | 3.556 | 5.030 | 6.687 |

| 4 | 3.504 | 4.096 | 4.323 | 9.476 | 12.325 |

| 5 | 1.240 | 3.940 | 4.144 | 4.801 | 12.030 |

| 6 | 3.793 | 3.970 | 4.495 | 6.367 | 6.718 |

| 7 | 2.730 | 3.740 | 5.249 | 6.758 | 7.943 |

| 8 | 2.384 | 2.504 | 3.629 | 4.489 | 8.562 |

| 9 | 1.915 | 2.380 | 2.535 | 2.918 | 4.291 |

| 10 a | 0.893 | 1.435 | 1.610 | 1.611 | 2.134 |

| No. | p(%) | μpi | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5.278 | 5.189 | 5.393 | 5.545 | 5.093 | 5.579 | 5.436 | 5.377 | 5.282 | 4.951 | 83.33 | −0.9685 |

| 2 | 5.305 | 5.436 | 5.520 | 5.612 | 5.595 | 5.599 | 5.573 | 5.399 | 5.377 | 5.157 | 66.67 | −0.4313 |

| 3 | 5.448 | 5.472 | 5.551 | 5.636 | 5.617 | 5.653 | 5.720 | 5.560 | 5.404 | 5.207 | 50.00 | 0.0000 |

| 4 | 5.485 | 5.741 | 5.702 | 5.977 | 5.681 | 5.804 | 5.830 | 5.652 | 5.465 | 5.207 | 33.33 | 0.4313 |

| 5 | 5.565 | 5.906 | 5.825 | 6.091 | 6.080 | 5.827 | 5.900 | 5.933 | 5.633 | 5.329 | 16.67 | 0.9685 |

| Source | Level | df | ||

|---|---|---|---|---|

| Wavelength | 0.2 | 0.958 | 15 | 0.666 |

| 0.6 | 0.984 | 15 | 0.989 | |

| 1.0 | 0.957 | 15 | 0.646 | |

| Amplitude | 0.4 | 0.969 | 15 | 0.849 |

| 0.8 | 0.889 | 15 | 0.065 | |

| 1.2 | 0.929 | 15 | 0.264 | |

| Treatment group | Sheet | 0.911 | 5 | 0.473 |

| Source | Based on | df1 | df2 | ||

|---|---|---|---|---|---|

| Logarithm of Fatigue life | Mean | 1.011 | 9 | 40 | 0.448 |

| Median | 0.588 | 9 | 40 | 0.799 | |

| trimmed mean | 0.990 | 9 | 40 | 0.463 |

| Source | Type III Sum of Squares | df | Mean Square | ||

|---|---|---|---|---|---|

| Corrected Model | 1.366 a | 9 | 0.152 | 3.448 | 0.003 |

| Wavelength | 0.024 | 2 | 0.012 | 0.272 | 0.763 |

| Amplitude | 0.235 | 2 | 0.117 | 2.667 | 0.082 |

| Wavelength × amplitude | 0.298 | 4 | 0.074 | 1.690 | 0.171 |

| Error | 1.761 | 40 | 0.044 | ||

| Total | 1544.326 | 50 | |||

| Corrected Total | 3.127 | 49 |

| (I) Wavelength | (J) Treatment Group | Mean Difference (I − J) | Std. Error | 95% Confidence Interval | ||

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 0.2 | Sheet | 0.45650 * | 0.108344 | 0.001 | 0.16609 | 0.74691 |

| 0.6 | 0.41204 * | 0.108344 | 0.003 | 0.12163 | 0.70245 | |

| 1.0 | 0.40402 * | 0.108344 | 0.003 | 0.11362 | 0.69443 | |

| Treatment Group | Wavelength | Multiple |

|---|---|---|

| Sheet | 0.2 | 1.47–5.58 |

| 0.6 | 1.32–5.04 | |

| 1.0 | 1.30–4.95 |

| (I) Amplitude | (J) Treatment Group | Mean Difference (I − J) | Std. Error | 95% Confidence Interval | ||

|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||

| 0.4 | Sheet | 0.35093 * | 0.108344 | 0.012 | 0.06052 | 0.64134 |

| 0.8 | 0.52249 * | 0.108344 | 0.000 | 0.23208 | 0.81289 | |

| 1.2 | 0.39915 * | 0.108344 | 0.004 | 0.10874 | 0.68956 | |

| Treatment Group | Amplitude | Multiple |

|---|---|---|

| Sheet | 0.4 | 1.15–4.38 |

| - | 0.8 | 1.71–6.50 |

| - | 1.2 | 1.28–4.89 |

| Treatment Group | Experimental Group | 95% Confidence Interval of the Difference | |||

|---|---|---|---|---|---|

| Lower | Upper | ||||

| Sheet | 1 | 2.988 | 0.017 | 0.056151 | 0.435908 |

| - | 2 | 2.718 | 0.026 | 0.057470 | 0.700078 |

| - | 3 | 4.403 | 0.002 | 0.203855 | 0.652125 |

| - | 4 | 4.792 | 0.001 | 0.312213 | 0.891508 |

| - | 5 | 2.628 | 0.030 | 0.054273 | 0.832573 |

| 6 | 6.474 | 0.000 | 0.336187 | 0.708156 | |

| - | 7 | 4.985 | 0.001 | 0.280337 | 0.762901 |

| - | 8 | 3.498 | 0.008 | 0.141032 | 0.686822 |

| - | 9 | 3.088 | 0.015 | 0.066308 | 0.457512 |

| Treatment Group | Experimental Group | Multiple |

|---|---|---|

| Sheet | 1 | 1.14–2.73 |

| - | 2 | 1.14–5.01 |

| - | 3 | 1.60–4.49 |

| - | 4 | 2.05–7.79 |

| - | 5 | 1.13–6.80 |

| - | 6 | 2.17–5.11 |

| - | 7 | 1.91–5.79 |

| - | 8 | 1.38–4.86 |

| - | 9 | 1.16–2.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, X.; Wang, Y.; Wang, M. Effects of Forming Parameters on Fatigue Life in Incremental Sheet Punching. Materials 2021, 14, 2308. https://doi.org/10.3390/ma14092308

Wang J, Wang X, Wang Y, Wang M. Effects of Forming Parameters on Fatigue Life in Incremental Sheet Punching. Materials. 2021; 14(9):2308. https://doi.org/10.3390/ma14092308

Chicago/Turabian StyleWang, Jin, Xu Wang, Yongqiang Wang, and Mengting Wang. 2021. "Effects of Forming Parameters on Fatigue Life in Incremental Sheet Punching" Materials 14, no. 9: 2308. https://doi.org/10.3390/ma14092308

APA StyleWang, J., Wang, X., Wang, Y., & Wang, M. (2021). Effects of Forming Parameters on Fatigue Life in Incremental Sheet Punching. Materials, 14(9), 2308. https://doi.org/10.3390/ma14092308