Mechanical Performance of Bio-Based FRP-Confined Recycled Aggregate Concrete under Uniaxial Compression

Abstract

1. Introduction

- -

- The valorization of recycled sand in concrete mixtures without and with air entraining agent.

- -

- The formulation of concretes with a fully recycled granular skeleton.

- -

- An investigation on the effectiveness of unidirectional flax fiber-reinforced bio-sourced epoxy resin in confining air entrained recycled aggregates concrete.

- -

- A comparison between the effectiveness of bio-sourced FRP and the traditional CFRP.

- -

- A validation of the applicability of an analytical stress–strain model to confined air entrained recycled aggregates concrete with any type of fibers.

2. Materials and Methods

2.1. Concrete

- -

- Cement type CEM II/A-L 42.5N, Betocarb HP-OG,

- -

- Limestone fillers manufactured by OMYA SAS,

- -

- MC PowerFlow 3140 superplasticizer

- -

- Natural river sand called NS 0/4, two crushed natural gravels NG1 4/10 and NG2 6.3/20, and recycled aggregates provided from construction demolition wastes designed by RS0/4, RG1 4/10, and RG2 6.3/20.

2.2. Composites

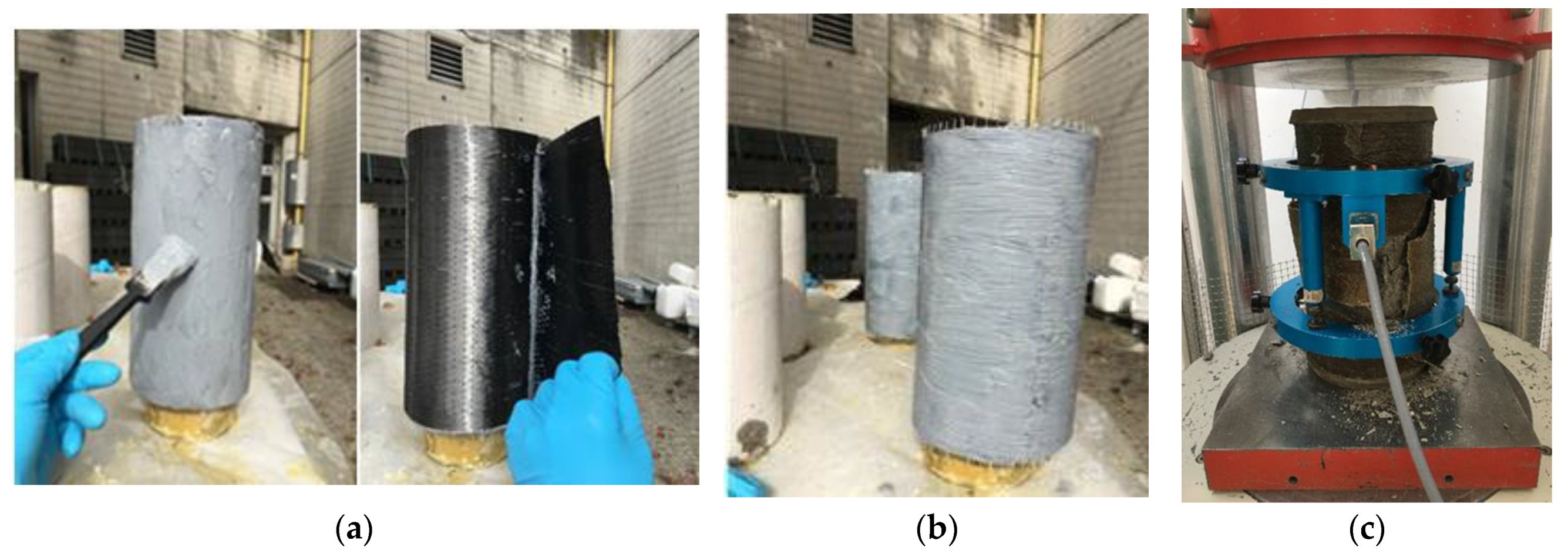

2.3. Specimen Preparation and Compressive Test

3. Results

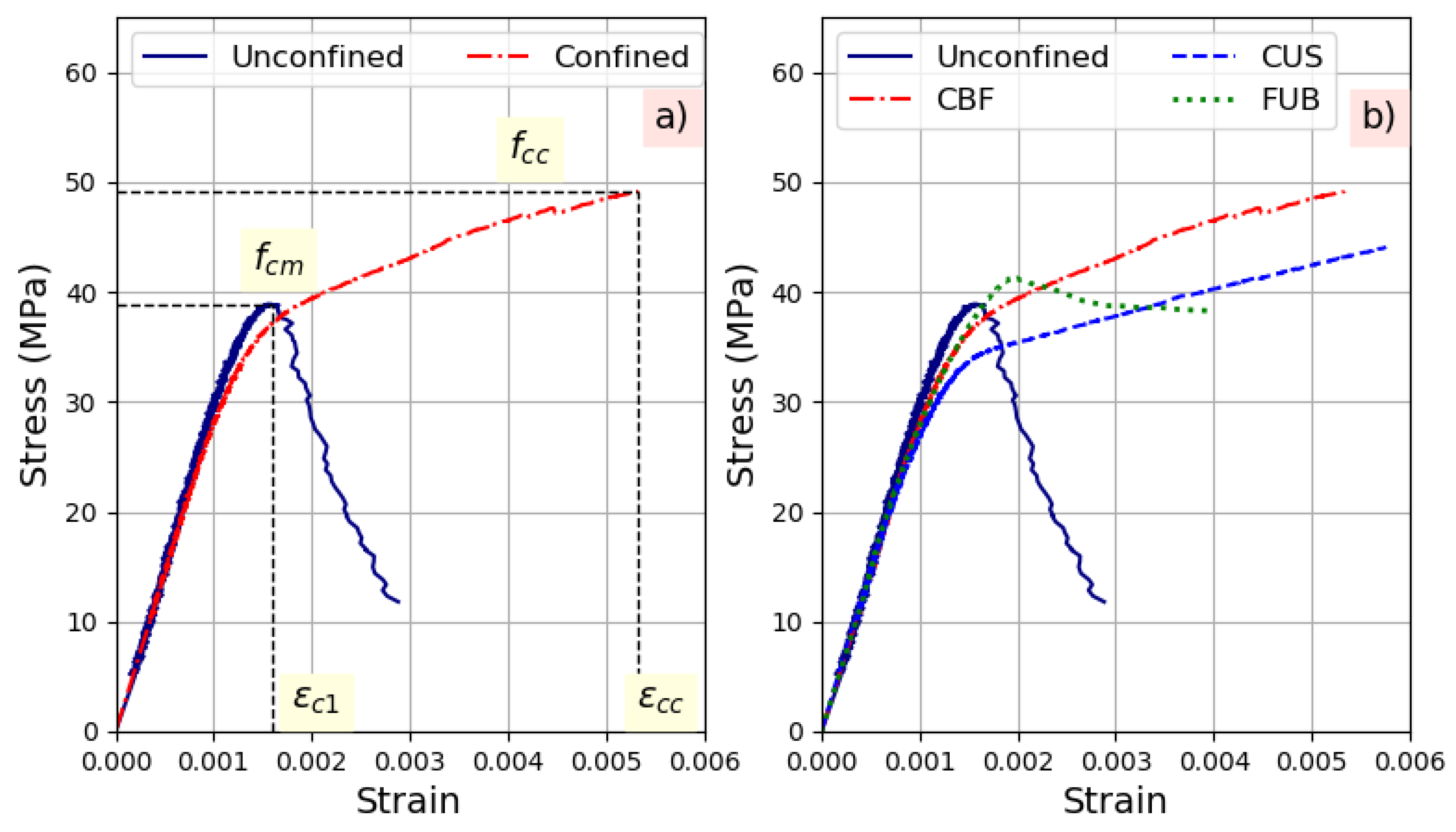

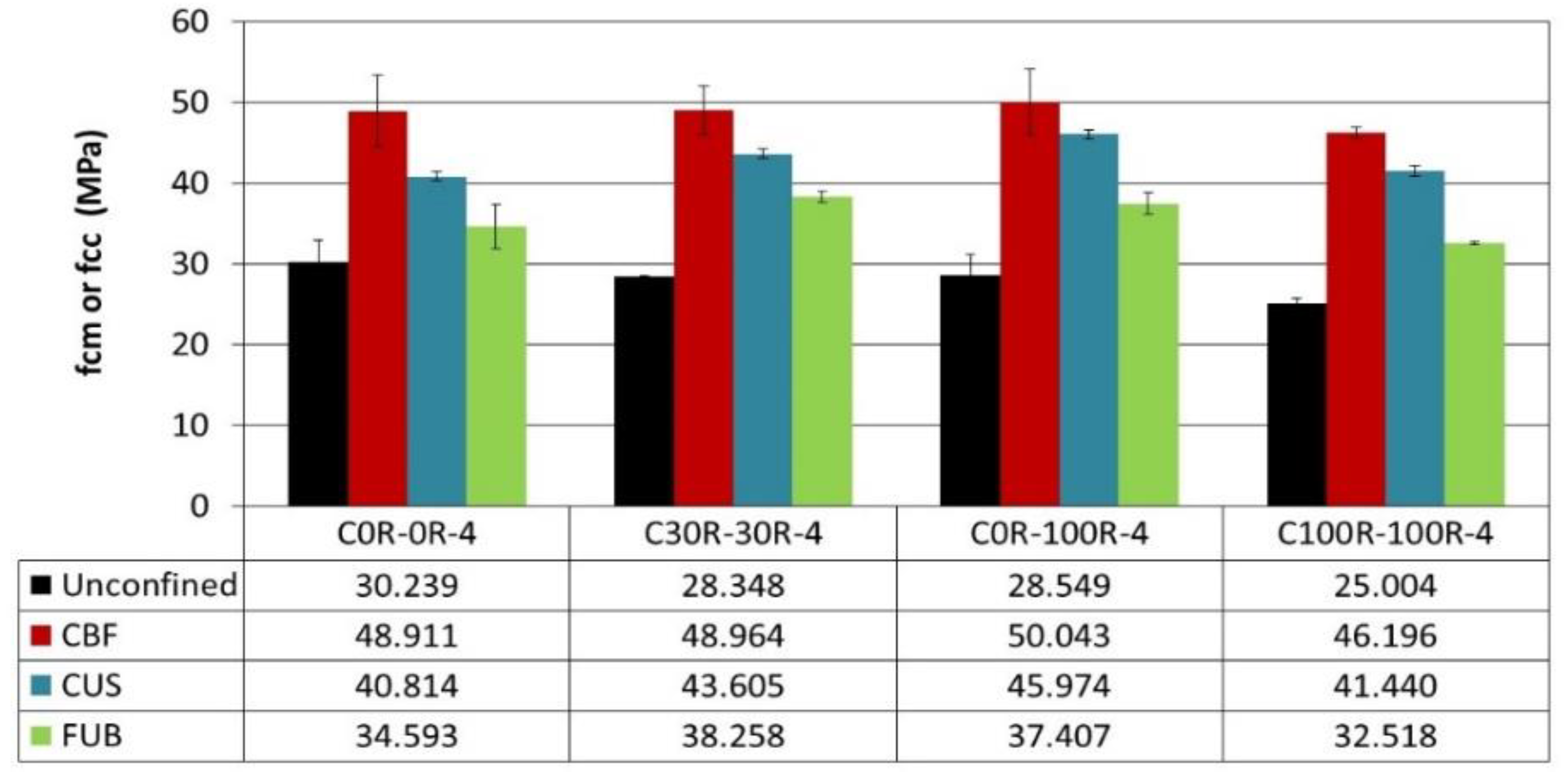

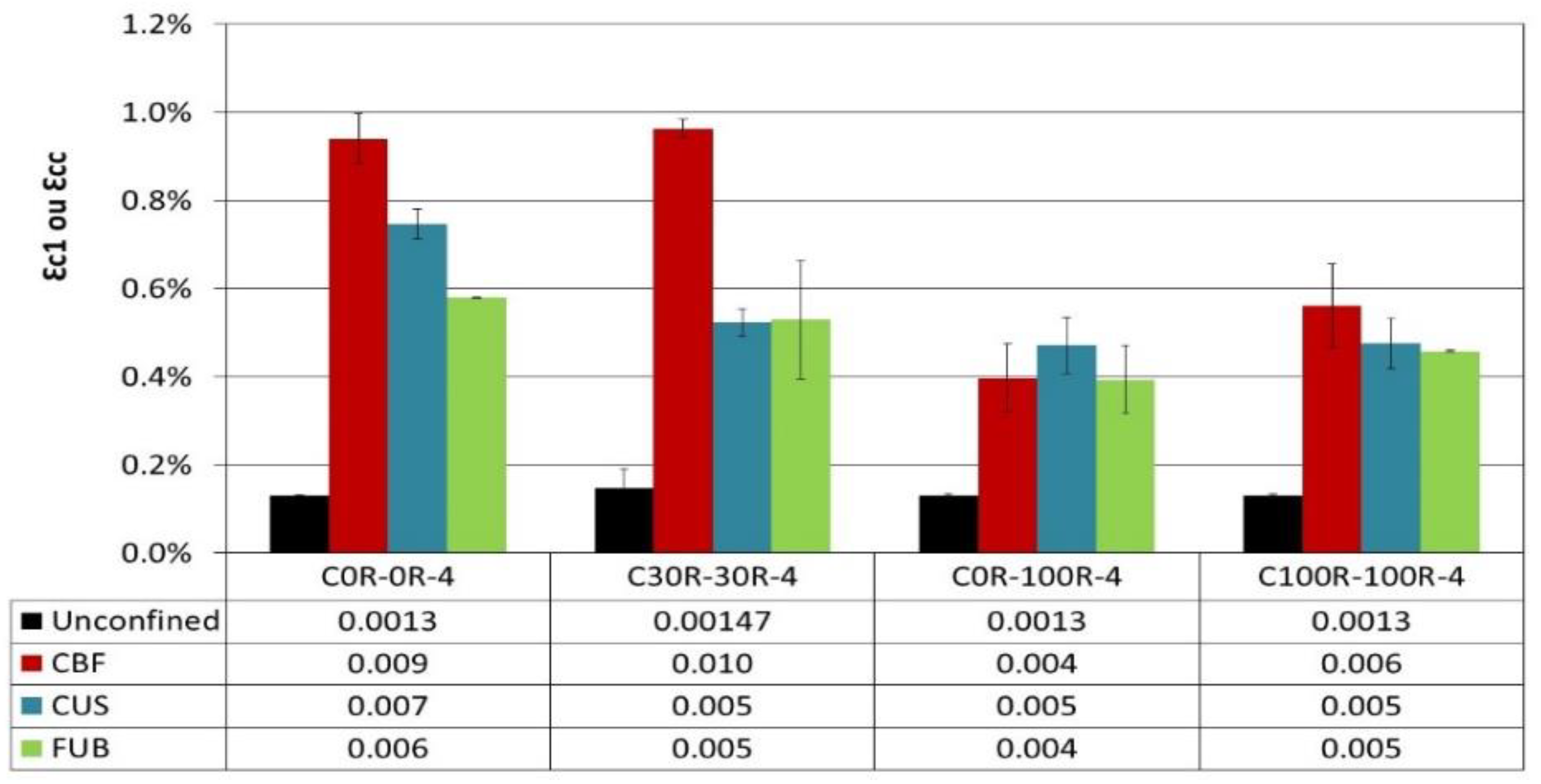

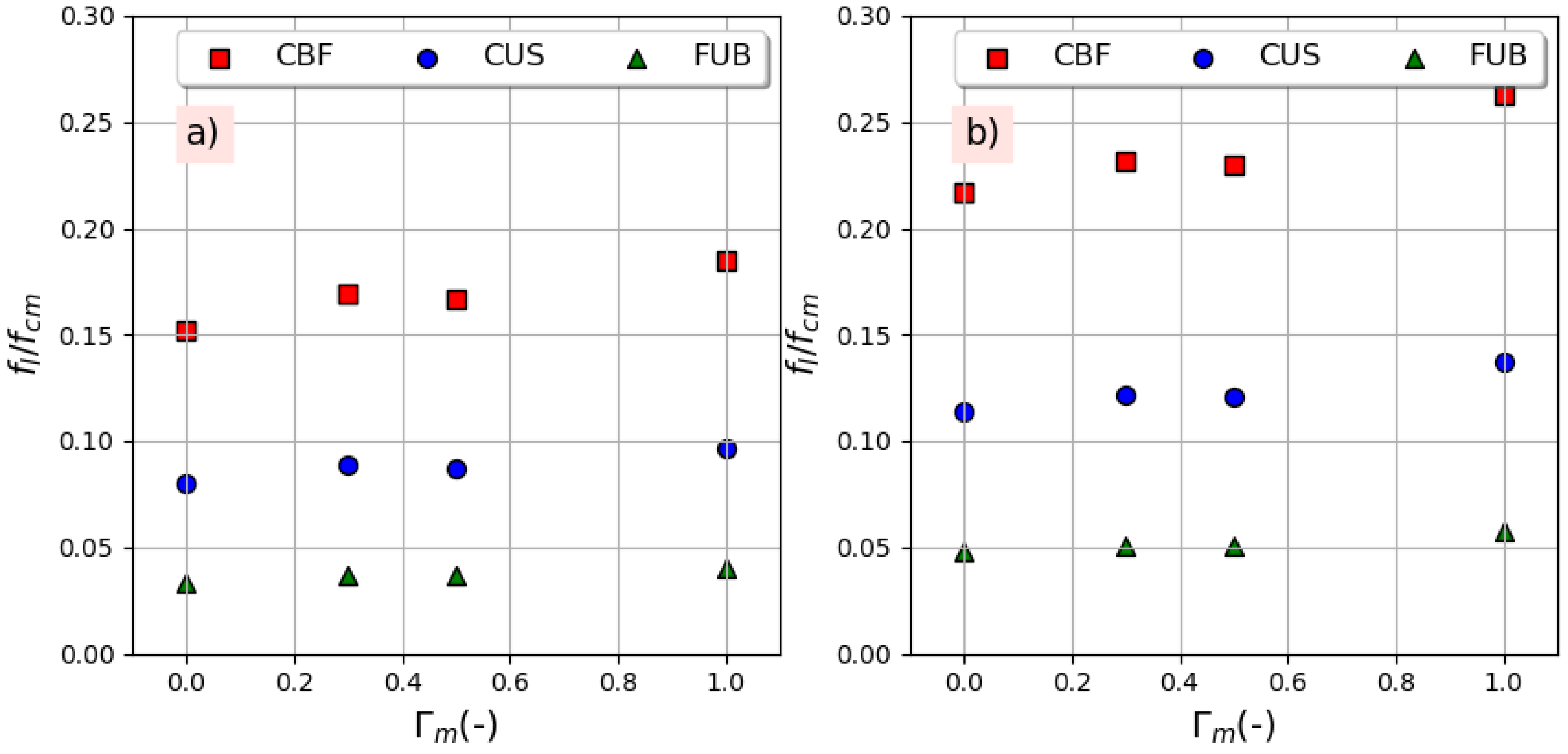

3.1. RAC without Air Entrainment Agent

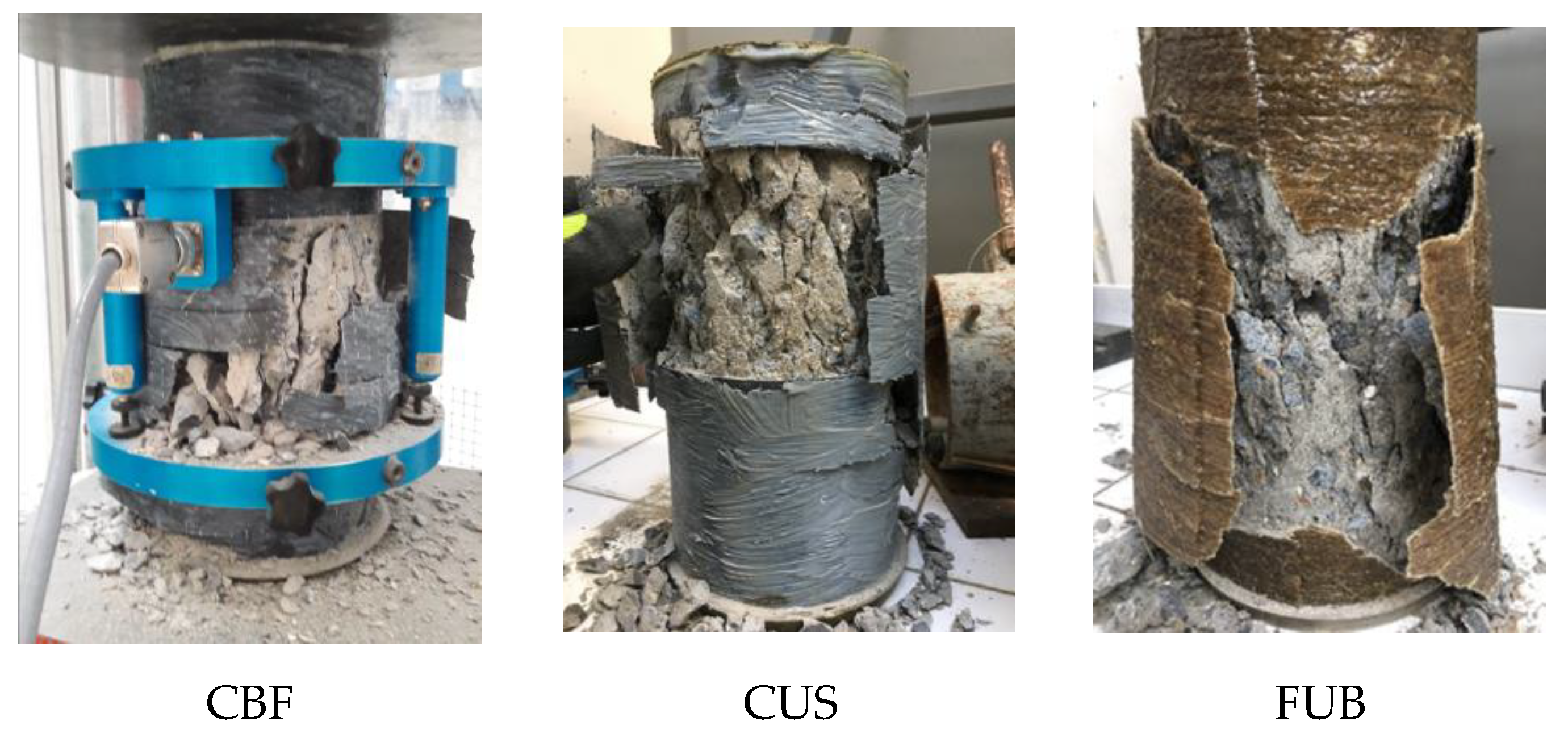

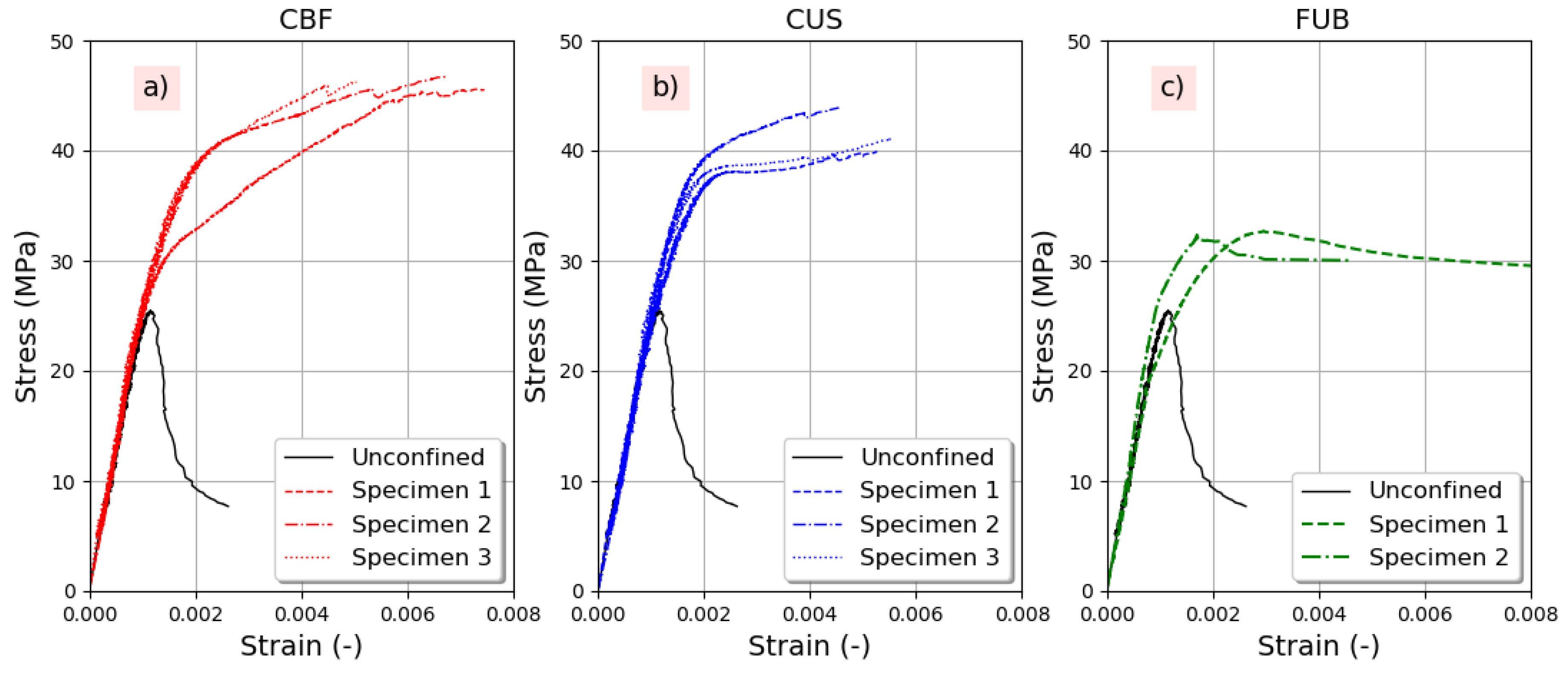

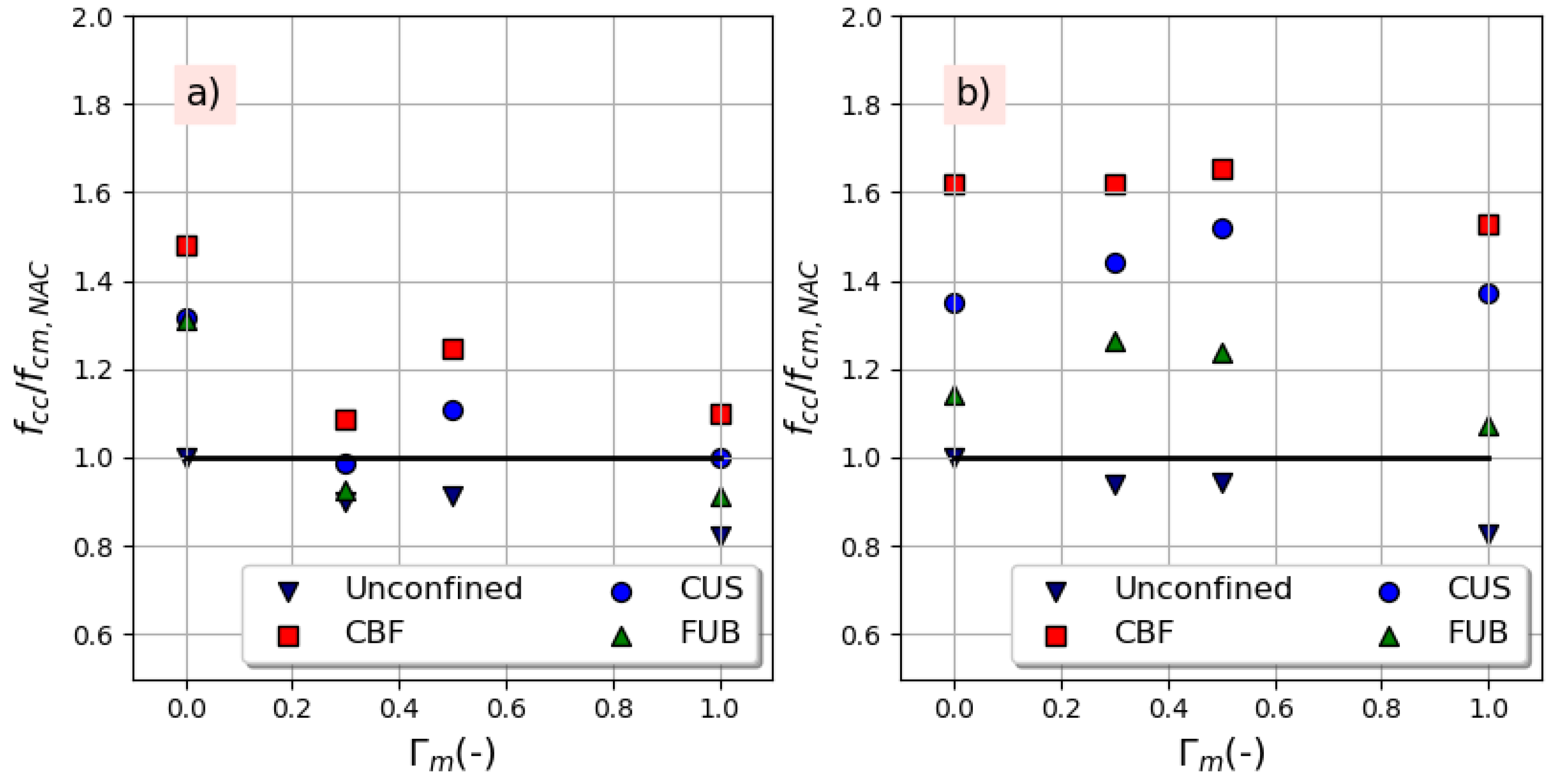

3.2. Strengthening Entrained Air RAC

3.3. Analytical Modeling

- SSE: the residual sum of squares

- SST: the total sum of squares

- n: the number of experimental points

- yi: the ith experimental measurement

- : the predicted value

- : the mean value.

4. Conclusions

- -

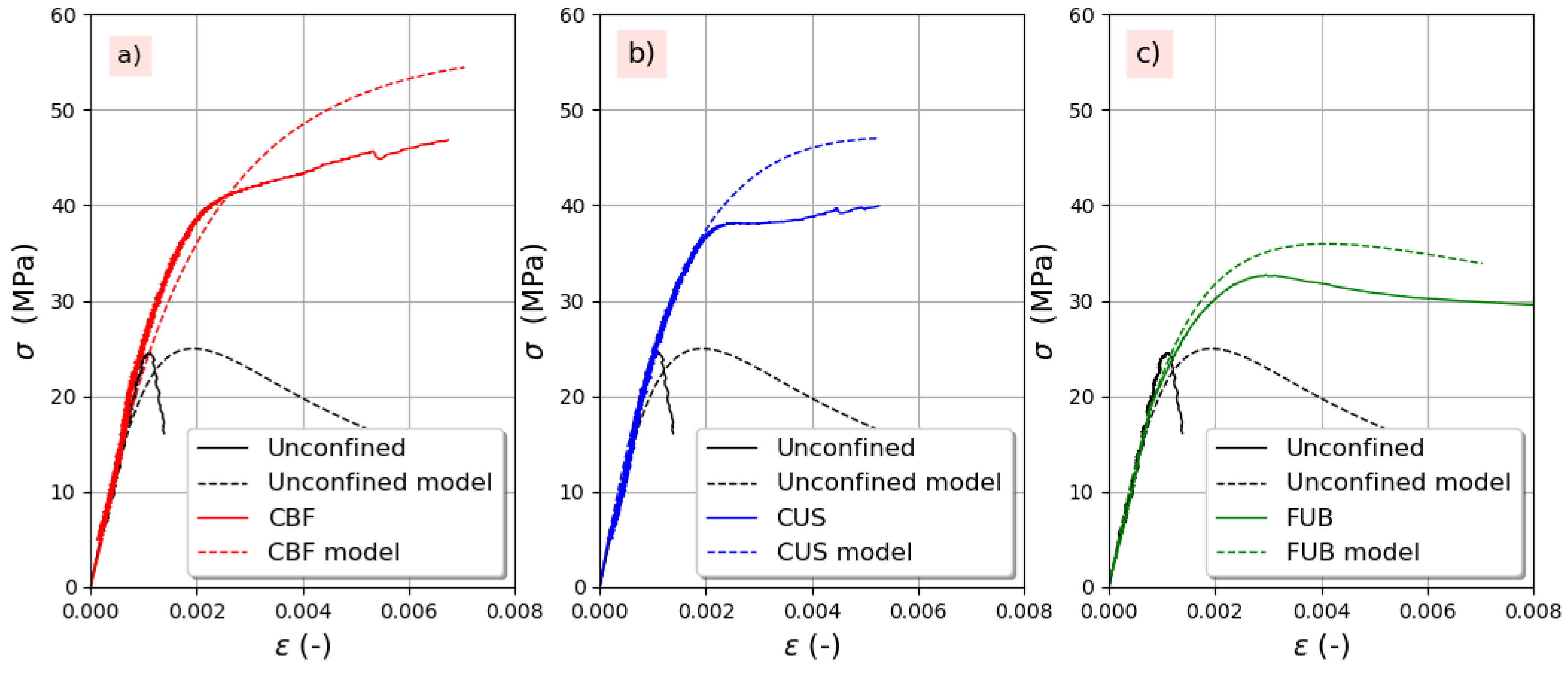

- Confining recycled aggregate concrete by the unidirectional flax fibers reinforced bio-sourced epoxy resin, FUB, is significant for 4% air-entrained recycled aggregates concrete, and its effectiveness is comparable to the effectiveness of traditional composites based on carbon fibers CBF and CUS.

- -

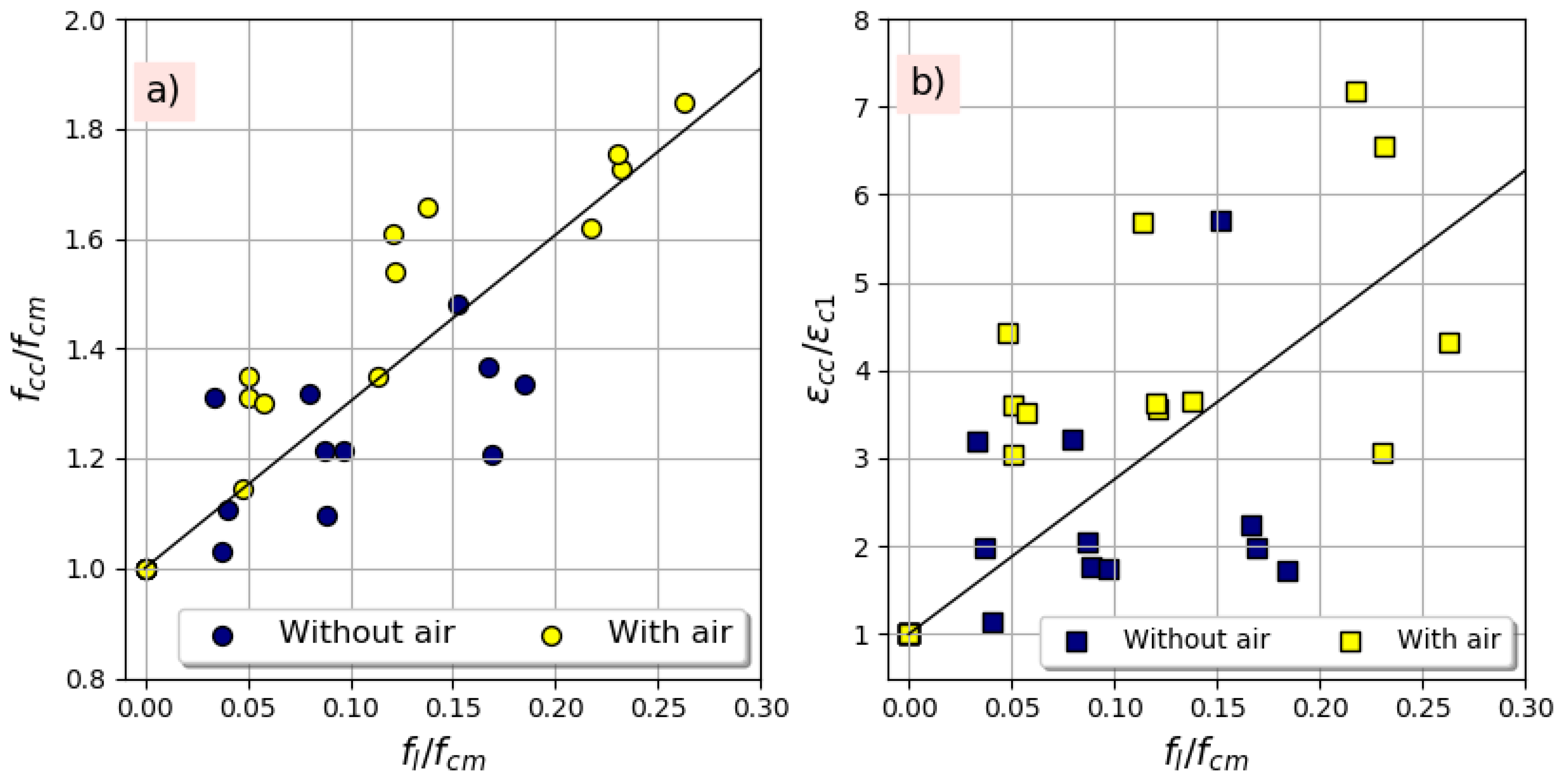

- For the same type of FRP and the same replacement ratio, the confining ratio is more important when an air-entraining agent is used.

- -

- The compressive strength and the strain enhancement obtained from FRP confinement are little affected by the replacement ratio.

- -

- Bio-based fiber, FUB, led to the recovery of the strength of the air-entrained concrete with an increase of 8% for the mixture C100R-100R-4. Moreover, for C100R-100R, a single layer of CUS and two layers of FUB fibers allowed restoring 100% and 91% of the NAC’s compressive strength.

- -

- The performance of the model developed by Ghorbel et al. is satisfactory to predict the full stress–strain curves for both series of studied concrete in unconfined and confined configurations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Comission. First Circular Economy Action Plan. 2015. Available online: https://ec.europa.eu/environment/circular-economy/first_circular_economy_action_plan.html (accessed on 3 April 2021).

- Omary, S.; Ghorbel, E.; Wardeh, G. Relationships between recycled concrete aggregates characteristics and recycled aggregates concretes properties. Constr. Build. Mater. 2016, 108, 163–174. [Google Scholar] [CrossRef]

- Wardeh, G.; Ghorbel, E.; Gomart, H. Mix Design and Properties of Recycled Aggregate Concretes: Applicability of Eurocode 2. Int. J. Concr. Struct. Mater. 2015, 9, 1–20. [Google Scholar] [CrossRef]

- Omary, S.; Ghorbel, E.; Wardeh, G.; Nguyen, M.D. Mix Design and Recycled Aggregates Effects on the Concrete’s Properties. Int. J. Civ. Eng. 2018, 16, 973–992. [Google Scholar] [CrossRef]

- Silva, S.; Evangelista, L.; de Brito, J. Durability and shrinkage performance of concrete made with coarse multi-recycled concrete aggregates. Constr. Build. Mater. 2021, 272, 121645. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Durability of recycled aggregate concrete prepared with carbonated recycled concrete aggregates. Cem. Concr. Compos. 2017, 84, 214–221. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Barros, J.A.O.; Ferrara, L.; Martinelli, E. Recent Advances on Green Concrete for Structural Purposes. In The Contribution of the Eu-fp7 Project Encore; Springer International Publishing: New York, NY, USA, 2014. [Google Scholar]

- Bravo, M.; Duarte, A.P.C.; de Brito, J.; Evangelista, L.; Pedro, D. On the Development of a Technical Specification for the Use of Fine Recycled Aggregates from Construction and Demolition Waste in Concrete Production. Materials 2020, 13, 4228. [Google Scholar] [CrossRef] [PubMed]

- Al-Hamrani, M.; Kucukvar, W.; Alnahhal, E.; Mahdi, N.C. Onat, Green Concrete for a Circular Economy: A Review on Sustainability, Durability, and Structural Properties. Materials 2021, 14, 351. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; Murali, G.; Vatin, N.; Klyuev, S.; Ozbakkaloglu, T.; Vasilev, Y. Use of Recycled Concrete Aggregates in Production of Green Cement-Based Concrete Composites: A Review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; European Environment Agency European Topic Centre Waste and Materials in a Green Economy: Copenhagen, Denmark, 2020.

- Xiao, J.; Huang, Y.; Yang, J.; Zhang, C. Mechanical properties of confined recycled aggregate concrete under axial compression. Constr. Build. Mater. 2012, 26, 591–603. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, Z.P.; Xiao, Y.; Demartino, C.; Wang, J.H. Recycled Aggregate Concrete in FRP-confined columns: A review of experimental results. Compos. Struct. 2017, 174, 277–291. [Google Scholar] [CrossRef]

- Zhou, Y.; Hu, J.; Li, M.; Sui, L.; Xing, F. FRP-Confined Recycled Coarse Aggregate Concrete: Experimental Investigation and Model Comparison. Polymers 2016, 8, 375. [Google Scholar] [CrossRef]

- Choudhury, M.S.I.; Amin, A.F.M.S.; Islam, M.M.; Hasnat, A. Effect of confining pressure distribution on the dilation behavior in FRP-confined plain concrete columns using stone, brick and recycled aggregates. Constr. Build. Mater. 2016, 102, 541–551. [Google Scholar] [CrossRef]

- Xie, T.; Ozbakkaloglu, T. Behavior of recycled aggregate concrete-filled basalt and carbon FRP tubes. Constr. Build. Mater. 2016, 105, 132–143. [Google Scholar] [CrossRef]

- Chen, G.M.; He, Y.H.; Jiang, T.; Lin, C.J. Behavior of CFRP-confined recycled aggregate concrete under axial compression. Constr. Build. Mater. 2016, 111, 85–97. [Google Scholar] [CrossRef]

- Li, P.; Sui, L.; Xing, F.; Zhou, Y. Static and cyclic response of low-strength recycled aggregate concrete strengthened using fiber-reinforced polymer. Compos. Part B Eng. 2019, 160, 37–49. [Google Scholar] [CrossRef]

- Zhou, J.K.; Lin, G.; Teng, J.G. Stress-strain behavior of FRP-confined concrete containing recycled concrete lumps. Constr. Build. Mater. 2021, 267, 120915. [Google Scholar] [CrossRef]

- Nanni, A.; Bradford, N.M. FRP jacketed concrete under uniaxial compression. Constr. Build. Mater. 1995, 9, 115–124. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Alkinani, A.Q.; Fam, A. State-of-the-art of prefabricated FRP composite jackets for structural repair. Eng. Sci. Technol. Int. J. 2020, 23, 1244–1258. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; AlAjarmeh, O.; Mohammed, A.A.; Salih, C.; Yu, P.; Khotbehsara, M.M.; Schubel, P. Static behaviour of glass fibre reinforced novel composite sleepers for mainline railway track. Eng. Struct. 2021, 229, 111627. [Google Scholar] [CrossRef]

- Chen, J.; Chouw, N. Flexural behaviour of flax FRP double tube confined coconut fibre reinforced concrete beams with interlocking interface. Compos. Struct. 2018, 192, 217–224. [Google Scholar] [CrossRef]

- Ghalieh, L.; Awwad, E.; Saad, G.; Khatib, H.; Mabsout, M. Concrete Columns Wrapped with Hemp Fiber Reinforced Polymer—An Experimental Study. Procedia Eng. 2017, 200, 440–447. [Google Scholar] [CrossRef]

- Reddy, M.I.; Kumar, M.A.; Raju, C.R.B. Tensile and Flexural properties of Jute, Pineapple leaf and Glass Fiber Reinforced Polymer Matrix Hybrid Composites. Mater. Today Proc. 2018, 5, 458–462. [Google Scholar] [CrossRef]

- Sen, T.; Paul, A. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N.; Jayaraman, K. Experimental Investigation of Flax FRP Tube Confined Coconut Fibre Reinforced Concrete. Key Eng. Mater. 2014, 594, 416–420. [Google Scholar] [CrossRef]

- Zuccarello, B.; Marannano, G.; Mancino, A. Optimal manufacturing and mechanical characterization of high performance biocomposites reinforced by sisal fibers. Compos. Struct. 2018, 194, 575–583. [Google Scholar] [CrossRef]

- Limaiem, M.; Ghorbel, E.; Limam, O. Comparative experimental study of concrete reparation with carbon epoxy & bio-resourced composites. Constr. Build. Mater. 2019, 210, 312–323. [Google Scholar] [CrossRef]

- ECOREB ECO-Construction par le REcyclage du Béton dans le Béton. 2013. Available online: https://anr.fr/Projet-ANR-12-VBDU-0003 (accessed on 3 April 2021).

- MICRO Matériaux Innovants Composites pour la Réparation d’Ouvrages. Approche Fiabiliste Du Dimensionnement Pour Leur Requalification Et La Prédiction De Leur Durabilité; MICRO: Paris, France, 2015. [Google Scholar]

- Sucharda; Mateckova, P.; Bilek, V. Non-Linear Analysis of an RC Beam Without Shear Reinforcement with a Sensitivity Study of the Material Properties of Concrete. Slovak J. Civ. Eng. 2020, 28, 33–43. [Google Scholar] [CrossRef]

- Wardeh, G.; Perrin, B. Identification of Liquid Pressure in Pores of Baked Clay Tiles During Freezing-Thawing Cycles. J. Build. Phys. 2006, 29, 269–279. [Google Scholar] [CrossRef]

- Wardeh, G.; Mohamed, M.A.S.; Ghorbel, E. Analysis of concrete internal deterioration due to frost action. J. Build. Phys. 2010, 35, 54–82. [Google Scholar] [CrossRef]

- Bisby, L.A.; Dent, A.J.; Green, M.F. Comparison of Confinement Models for Fiber-Reinforced Polymer-Wrapped Concrete. ACI Struct. J. 2005, 102. [Google Scholar] [CrossRef]

- Tamuzs, V.; Tepfers, R.; Zile, E.; Ladnova, O. Behavior of concrete cylinders confined by a carbon composite 3. Deformability and the ultimate axial strain. Mech. Compos. Mater. 2006, 42, 303–314. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Analysis-oriented stress–strain models for FRP–confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- Youssef, M.N.; Feng, M.Q.; Mosallam, A.S. Stress–strain model for concrete confined by FRP composites. Compos. Part B Eng. 2007, 38, 614–628. [Google Scholar] [CrossRef]

- Nisticò, N.; Monti, G. RC square sections confined by FRP: Analytical prediction of peak strength. Compos. Part B Eng. 2013, 45, 127–137. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Observed Stress-Strain Behavior of Confined Concrete. J. Struct. Eng. 1988, 114, 1827–1849. [Google Scholar] [CrossRef]

- Ghorbel, E.; Wardeh, G.; Fares, H. Mechanical and fracture properties of recycled aggregate concrete in design codes and empirical models. Struct. Concr. 2019, 20, 2156–2170. [Google Scholar] [CrossRef]

| Content (kg/m3) | Without Air-Entraining Agent | With Air-Entraining Agent | ||||||

|---|---|---|---|---|---|---|---|---|

| C0R-0R | C30R-30R | C0R-100R | C100R-100R | C0R-0R-4 | C30R-30R-4 | C0R-100R-4 | C100R-100R-4 | |

| (%) | 0 | 30 | 50 | 100 | 0 | 30 | 50 | 100 |

| Total | 185 | 220 | 238 | 284 | 178 | 171 | 175 | 163 |

| Cement | 299 | 321 | 336 | 381 | 287 | 299 | 310 | 339 |

| Limestone filler | 58 | 44 | 53 | 70 | 56 | 41 | 49 | 62 |

| NS (0/4) | 771 | 491 | 782 | 0 | 740 | 457 | 721 | 0 |

| RS (0/4) | 0 | 235.2 | 0 | 728.6 | 0 | 199 | 0 | 591 |

| NG1 (4/10) | 264 | 168 | 0 | 0 | 254 | 157 | 0 | 0 |

| RG1 (4/10) | 0 | 151.4 | 168.4 | 318.7 | 0 | 132 | 146 | 266 |

| NG2 (6.3/20) | 810 | 542 | 0 | 0 | 778 | 505 | 0 | 0 |

| RG2 (10/20) | 0 | 175.2 | 728.4 | 464.6 | 0 | 153 | 628 | 388 |

| Superplasticizer | 2.1 | 1.64 | 2.18 | 2.78 | 2 | 1.5 | 2 | 2.5 |

| Air-Entraining agent | 0 | 0 | 0 | 0 | 2.6 | 2 | 1.6 | 1.5 |

| Fresh properties | ||||||||

| Slump (cm) | 20 | 20 | 20 | 19 | 18 | 19 | 18 | 20 |

| Air content (%) | 1.8 ± 0.2 | 2.1 ± 0.1 | 2.4 ± 0.1 | 2.9 ± 0.1 | 4 ± 0.1 | 4 ± 0.1 | 4 ± 0.2 | 4 ± 0.2 |

| ≈2.5 | ≈4 | |||||||

| Properties | Without Air-Entraining Agent | With Air-Entraining Agent | ||||||

|---|---|---|---|---|---|---|---|---|

| C0R-0R | C30R-30R | C0R-100R | C100R-100R | C0R-0R-4 | C30R-30R-4 | C0R-100R-4 | C100R-100R-4 | |

| fcm (MPa) | 43.20 | 38.89 | 39.39 | 35.58 | 30.239 | 28.348 | 28.549 | 25.004 |

| Ec (GPa) | 32.21 | 29.75 | 26.08 | 26.03 | 29.540 | 28.806 | 26.424 | 24.536 |

| εc1 | 0.00160 | 0.00197 | 0.0021 | 0.0022 | 0.0013 | 0.00147 | 0.0013 | 0.0013 |

| Fiber Direction | Composite | Thickness (mm) | ft (MPa) | E (MPa) | εultimate | |||

|---|---|---|---|---|---|---|---|---|

| Average | SD | Average | SD | Average | SD | |||

| 0° | CBF | 0.48 | 1026.5 | 75.16 | 64,300 | 9300 | 0.018 | 0.005 |

| CUS | 0.129 | 2001 | 156.24 | 114,000 | 54,300 | 0.0212 | 0.008 | |

| FUB | 0.25 | 216.29 | 83.14 | 27,000 | 2670 | 0.01 | 0.0044 | |

| 90° | CBF | - | 938.75 | 100.2 | 27,600 | 3260 | 0.035 | 0.004 |

| CUS | 38.347 | 12.28 | 23,100 | 6060 | 0.002 | 0.0005 | ||

| FUB | 86.18 | 11.12 | 15,110 | 760 | 0.006 | 0.0009 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghorbel, E.; Limaiem, M.; Wardeh, G. Mechanical Performance of Bio-Based FRP-Confined Recycled Aggregate Concrete under Uniaxial Compression. Materials 2021, 14, 1778. https://doi.org/10.3390/ma14071778

Ghorbel E, Limaiem M, Wardeh G. Mechanical Performance of Bio-Based FRP-Confined Recycled Aggregate Concrete under Uniaxial Compression. Materials. 2021; 14(7):1778. https://doi.org/10.3390/ma14071778

Chicago/Turabian StyleGhorbel, Elhem, Mariem Limaiem, and George Wardeh. 2021. "Mechanical Performance of Bio-Based FRP-Confined Recycled Aggregate Concrete under Uniaxial Compression" Materials 14, no. 7: 1778. https://doi.org/10.3390/ma14071778

APA StyleGhorbel, E., Limaiem, M., & Wardeh, G. (2021). Mechanical Performance of Bio-Based FRP-Confined Recycled Aggregate Concrete under Uniaxial Compression. Materials, 14(7), 1778. https://doi.org/10.3390/ma14071778