Effect of Varying Working Distances between Sandblasting Device and Composite Substrate Surface on the Repair Bond Strength

Abstract

1. Introduction

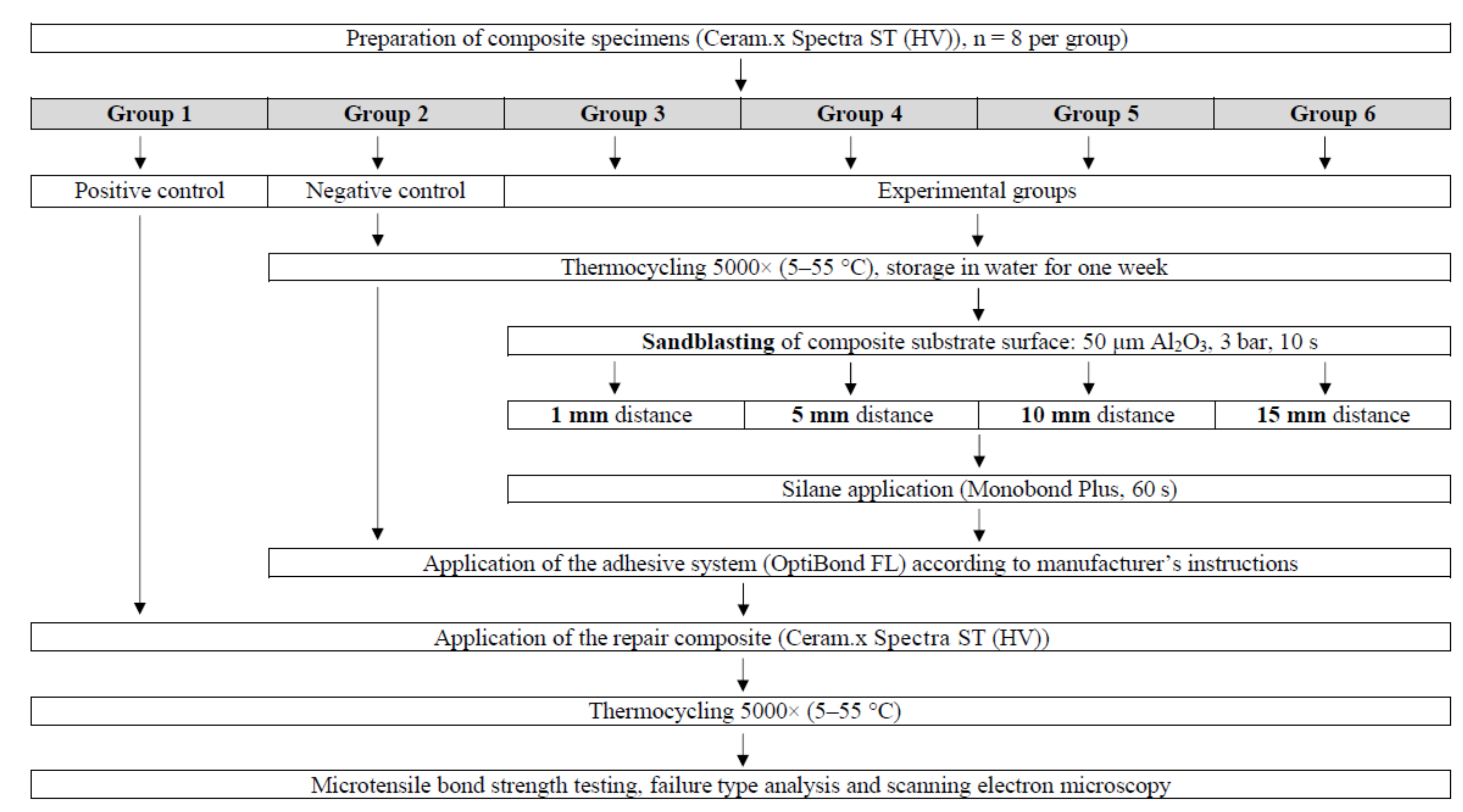

2. Materials and Methods

2.1. Specimen Preparation

2.2. Aluminum Oxide Sandblasting

2.3. Application of Repair Composite

2.4. Microtensile Bond Strength Test

2.5. Assessment of Failure Mode

2.6. SEM and EDX Analysis of the Substrate Surfaces

2.7. Statistical Analysis

3. Results

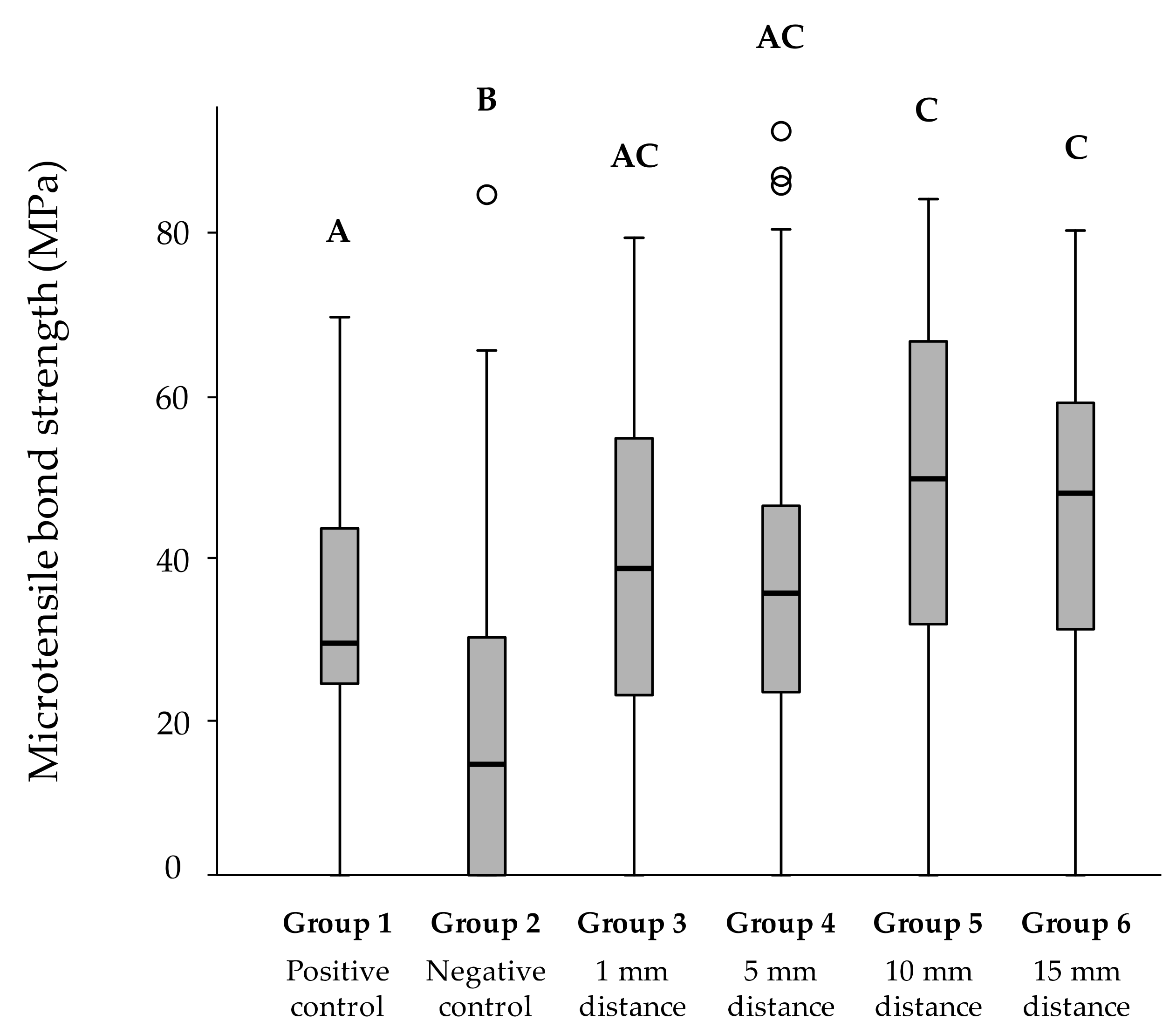

3.1. Microtensile Repair Bond Strength

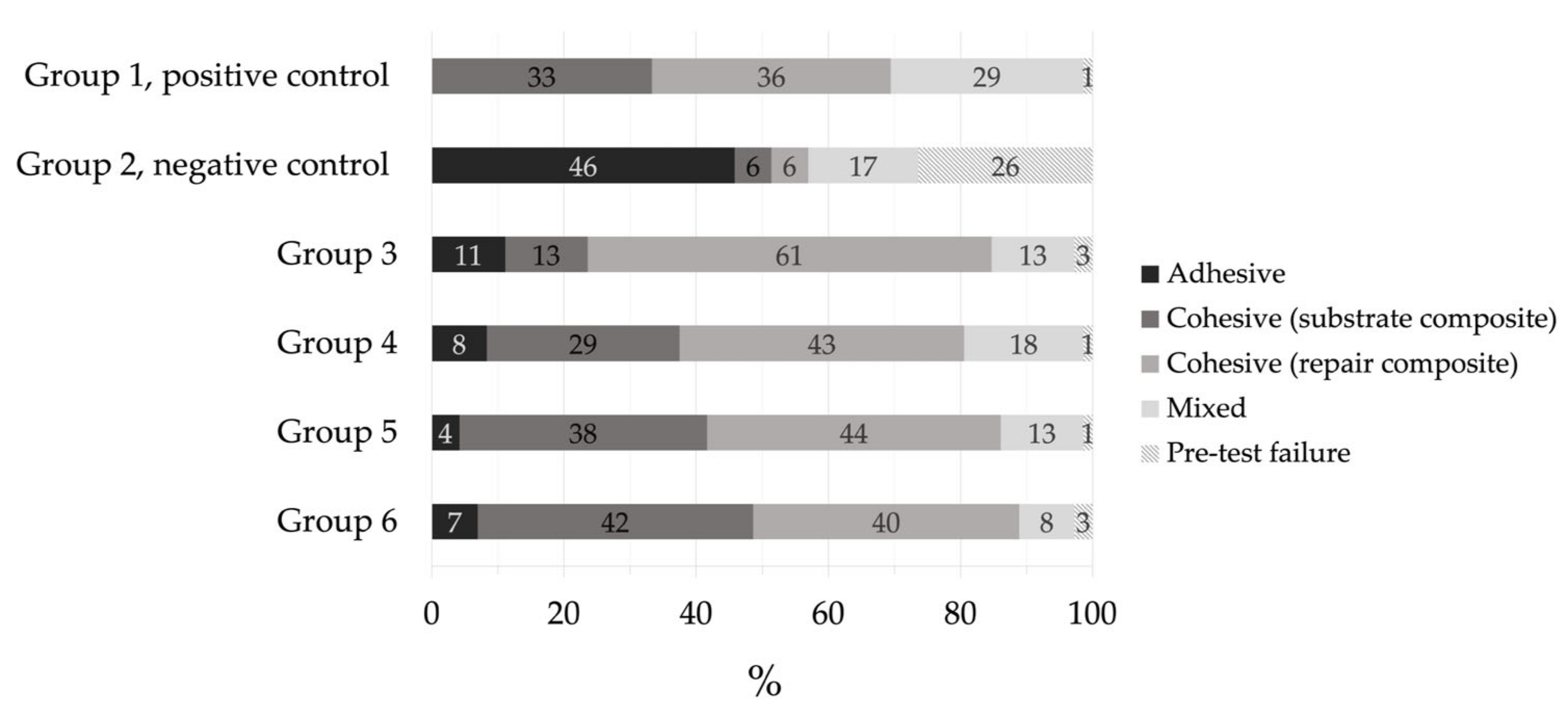

3.2. Failure Mode Distribution

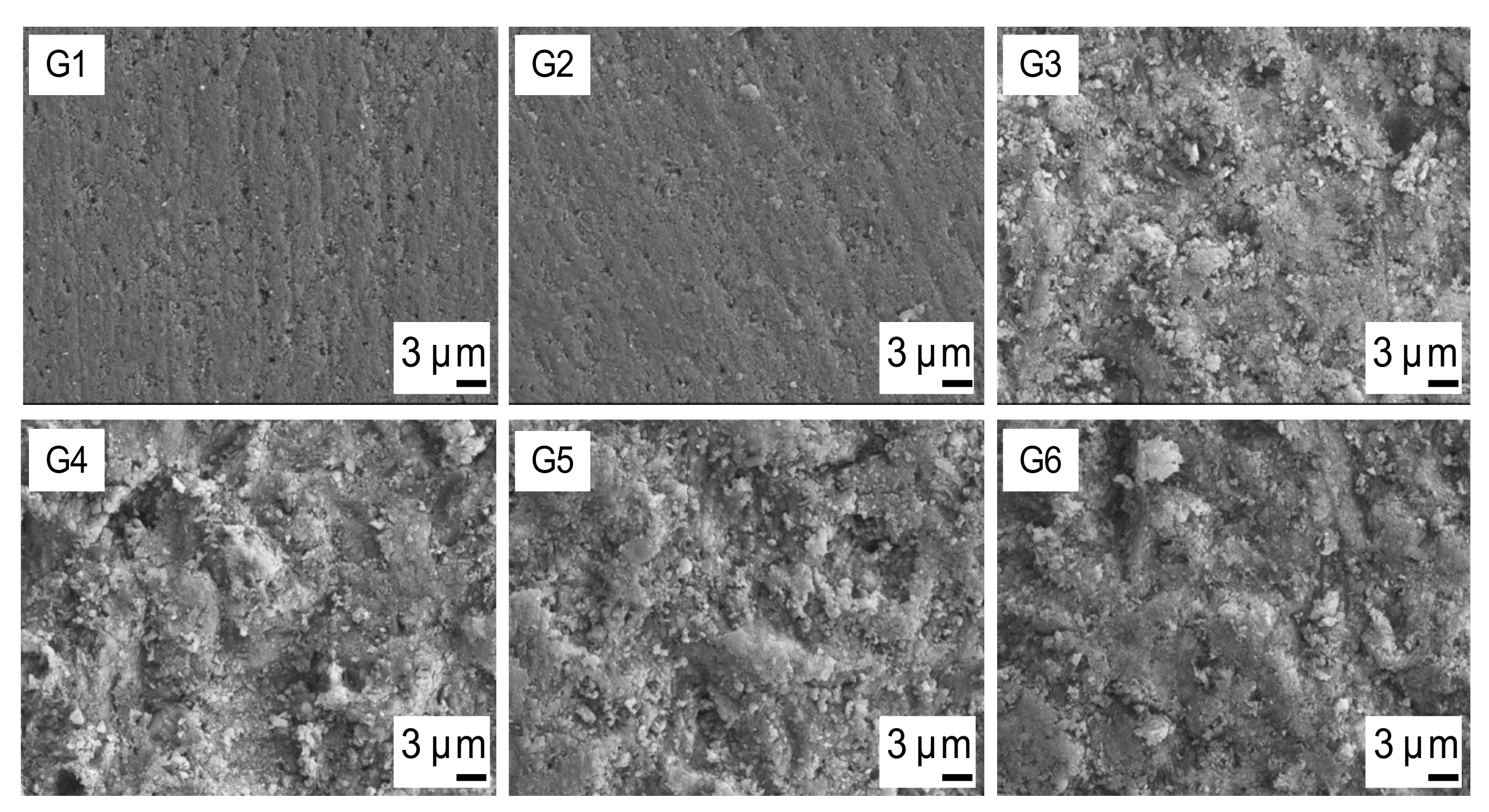

3.3. SEM Analysis of the Substrate Surfaces

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Estay, J.; Martín, J.; Viera, V.; Valdivieso, J.; Bersezio, C.; Vildosola, P.; Mjor, I.A.; Andrade, M.F.; Moraes, R.R.; Moncada, G. 12 years of repair of amalgam and composite resins: A clinical study. Oper. Dent. 2018, 43, 12–21. [Google Scholar] [CrossRef]

- Kanzow, P.; Wiegand, A. Retrospective analysis on the repair vs. replacement of composite restorations. Dent. Mater. 2020, 36, 108–118. [Google Scholar] [CrossRef]

- Krejci, I.; Lieber, C.M.; Lutz, F. Time required to remove totally bonded tooth-colored posterior restorations and related tooth substance loss. Dent. Mater. 1995, 11, 34–40. [Google Scholar] [CrossRef]

- Fernández, E.; Martín, J.; Vildósola, P.; Oliveira Junior, O.B.; Gordan, V.; Mjor, I.; Bersezio, C.; Estay, J.; de Andrade, M.F.; Moncada, G. Can repair increase the longevity of composite resins? Results of a 10-year clinical trial. J. Dent. 2015, 43, 279–286. [Google Scholar] [CrossRef]

- Kirsch, J.; Tchorz, J.; Hellwig, E.; Tauböck, T.T.; Attin, T.; Hannig, C. Decision criteria for replacement of fillings: A retrospective study. Clin. Exp. Dent. Res. 2016, 2, 121–128. [Google Scholar] [CrossRef]

- Beck, F.; Lettner, S.; Graf, A.; Bitriol, B.; Dumitrescu, N.; Bauer, P.; Moritz, A.; Schedle, A. Survival of direct resin restorations in posterior teeth within a 19-year period (1996–2015): A meta-analysis of prospective studies. Dent. Mater. 2015, 31, 958–985. [Google Scholar] [CrossRef]

- Fawzy, A.S.; El-Askary, F.S.; Amer, M.A. Effect of surface treatments on the tensile bond strength of repaired water-aged anterior restorative micro-fine hybrid resin composite. J. Dent. 2008, 36, 969–976. [Google Scholar] [CrossRef]

- Hahnel, S.; Henrich, A.; Bürgers, R.; Handel, G.; Rosentritt, M. Investigation of mechanical properties of modern dental composites after artificial aging for one year. Oper. Dent. 2010, 35, 412–419. [Google Scholar] [CrossRef]

- Wiegand, A.; Credé, A.; Tschammler, C.; Attin, T.; Tauböck, T.T. Enamel wear by antagonistic restorative materials under erosive conditions. Clin. Oral Investig. 2017, 21, 2689–2693. [Google Scholar] [CrossRef]

- Dieckmann, P.; Baur, A.; Dalvai, V.; Wiedemeier, D.B.; Attin, T.; Tauböck, T.T. Effect of composite age on the repair bond strength after different mechanical surface pretreatments. J. Adhes. Dent. 2020, 22, 365–372. [Google Scholar]

- Rathke, A.; Tymina, Y.; Haller, B. Effect of different surface treatments on the composite–composite repair bond strength. Clin. Oral Investig. 2009, 13, 317–323. [Google Scholar] [CrossRef]

- Kimyai, S.; Mohammadi, N.; Navimipour, E.J.; Rikhtegaran, S. Comparison of the effect of three mechanical surface treatments on the repair bond strength of a laboratory composite. Photomed. Laser Surg. 2010, 28 (Suppl. S2), S25–S30. [Google Scholar] [CrossRef]

- Da Costa, T.R.; Serrano, A.M.; Atman, A.P.; Loguercio, A.D.; Reis, A. Durability of composite repair using different surface treatments. J. Dent. 2012, 40, 513–521. [Google Scholar] [CrossRef]

- Wiegand, A.; Stawarczyk, B.; Buchalla, W.; Tauböck, T.T.; Özcan, M.; Attin, T. Repair of silorane composite–Using the same substrate or a methacrylate-based composite. Dent. Mater. 2012, 28, e19–e25. [Google Scholar] [CrossRef] [PubMed]

- Valente, L.L.; Silva, M.F.; Fonseca, A.S.; Münchow, E.A.; Isolan, C.P.; Moraes, R.R. Effect of diamond bur grit size on composite repair. J. Adhes. Dent. 2015, 17, 257–263. [Google Scholar] [PubMed]

- Kanzow, P.; Wiegand, A.; Schwendicke, F.; Göstemeyer, G. Same, same, but different? A systematic review of protocols for restoration repair. J. Dent. 2019, 86, 1–16. [Google Scholar] [CrossRef]

- Onisor, I.; Bouillaguet, S.; Krejci, I. Influence of different surface treatments on marginal adaptation in enamel and dentin. J. Adhes. Dent. 2007, 9, 297–303. [Google Scholar]

- Rodrigues, S.A.; Ferracane, J.L.; Della Bona, A. Influence of surface treatments on the bond strength of repaired resin composite restorative materials. Dent. Mater. 2009, 25, 442–451. [Google Scholar] [PubMed]

- Baena, E.; Vignolo, V.; Fuentes, M.V.; Ceballos, L. Influence of repair procedure on composite-to-composite microtensile bond strength. Am. J. Dent. 2015, 28, 255–260. [Google Scholar] [PubMed]

- Foitzik, M.; Attin, T. Filling revision—Possibilities and execution. Schweiz. Monatsschr. Zahnmed. 2004, 114, 1003–1011. [Google Scholar] [PubMed]

- Wendler, M.; Belli, R.; Panzer, R.; Skibbe, D.; Petschelt, A.; Lohbauer, U. Repair bond strength of aged resin composite after different surface and bonding treatments. Materials 2016, 9, 547. [Google Scholar] [CrossRef] [PubMed]

- Flury, S.; Dulla, F.A.; Peutzfeldt, A. Repair bond strength of resin composite to restorative materials after short- and long-term storage. Dent. Mater. 2019, 35, 1205–1213. [Google Scholar] [CrossRef] [PubMed]

- Dentsply Sirona. Scientific Manual Spectra ST Universal Composite Restorative. 2020. Available online: https://assets.dentsplysirona.com/flagship/en/explore/restorative/ceramx_spectra_st_hv_only/RES-SpectraST-Scientific%20Manual.pdf (accessed on 29 January 2020).

- Deari, S.; Wegehaupt, F.J.; Tauböck, T.T.; Attin, T. Influence of different pretreatments on the microtensile bond strength to eroded dentin. J. Adhes. Dent. 2017, 19, 147–155. [Google Scholar]

- Armstrong, S.; Breschi, L.; Özcan, M.; Pfefferkorn, F.; Ferrari, M.; Van Meerbeek, B. Academy of Dental Materials guidance on in vitro testing of dental composite bonding effectiveness to dentin/enamel using micro-tensile bond strength (μTBS) approach. Dent. Mater. 2017, 33, 133–143. [Google Scholar] [CrossRef]

- Brendeke, J.; Özcan, M. Effect of physicochemical aging conditions on the composite-composite repair bond strength. J. Adhes. Dent. 2007, 9, 399–406. [Google Scholar] [PubMed]

- Eliasson, S.T.; Tibballs, J.; Dahl, J.E. Effect of different surface treatments and adhesives on repair bond strength of resin composites after one and 12 months of storage using an improved microtensile test method. Oper. Dent. 2014, 39, E206–E216. [Google Scholar] [CrossRef]

- Ahmadizenouz, G.; Esmaeili, B.; Taghvaei, A.; Jamali, Z.; Jafari, T.; Amiri Daneshvar, F.; Khafri, S. Effect of different surface treatments on the shear bond strength of nanofilled composite repairs. J. Dent. Res. Dent. Clin. Dent. Prospects 2016, 10, 9–16. [Google Scholar] [CrossRef]

- Michelotti, G.; Niedzwiecki, M.; Bidjan, D.; Dieckmann, P.; Deari, S.; Attin, T.; Tauböck, T.T. Silane effect of universal adhesive on the composite-composite repair bond strength after different surface pretreatments. Polymers 2020, 12, 950. [Google Scholar] [CrossRef]

- Özcan, M.; Barbosa, S.H.; Melo, R.M.; Galhano, G.A.; Bottino, M.A. Effect of surface conditioning methods on the microtensile bond strength of resin composite to composite after aging conditions. Dent. Mater. 2007, 23, 1276–1282. [Google Scholar] [CrossRef]

- Loomans, B.A.; Cardoso, M.V.; Roeters, F.J.; Opdam, N.J.; De Munck, J.; Huysmans, M.C.; Van Meerbeek, B. Is there one optimal repair technique for all composites. Dent. Mater. 2011, 27, 701–709. [Google Scholar] [CrossRef]

- Par, M.; Spanovic, N.; Tauböck, T.T.; Attin, T.; Tarle, Z. Degree of conversion of experimental resin composites containing bioactive glass 45S5: The effect of post-cure heating. Sci. Rep. 2019, 9, 17245. [Google Scholar] [CrossRef] [PubMed]

| Product | Composition | Lot no. | Manufacturer |

|---|---|---|---|

| Ceram.x Spectra ST (HV) | Matrix: methacrylic modified polysiloxane nanoparticles, dimethacrylate resin, ethyl-4-(dimethylamino)benzoate Filler: spherical, pre-polymerized SphereTEC fillers (particle size ≈ 15 μm), non-agglomerated barium glass, CQ 1, ytterbium fluoride Filler content: 78–80 wt%, 60–62 vol% | A4: 1907000298 A1: 1906000385 | Dentsply Sirona, Konstanz, Germany |

| Monobond Plus | Alcohol, silane methacrylate, 10-MDP 2, phosphoric acid methacrylate, sulphide methacrylate | Y24458 | Ivoclar Vivadent, Schaan, Liechtenstein |

| OptiBond FL | Primer: BHT 3, CQ, ethanol, GPDM 4, HEMA 5, PAMM 6, water Adhesive: Bis-GMA 7, CQ, GDM 8, HEMA, ODMAB 9, barium aluminoborosilicate, Na2SiF6, fumed silicon, dioxide, gamma-methacryloxypropyltrimethoxysilane | Primer: 6284132 Adhesive: 6496643 | Kerr, Orange, CA, USA |

| Group | Percentage of Aluminum |

|---|---|

| Group 1, positive control | 2.5 |

| Group 2, negative control | 2.7 |

| Group 3 | 4.1 |

| Group 4 | 3.7 |

| Group 5 | 4.0 |

| Group 6 | 3.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burrer, P.; Costermani, A.; Par, M.; Attin, T.; Tauböck, T.T. Effect of Varying Working Distances between Sandblasting Device and Composite Substrate Surface on the Repair Bond Strength. Materials 2021, 14, 1621. https://doi.org/10.3390/ma14071621

Burrer P, Costermani A, Par M, Attin T, Tauböck TT. Effect of Varying Working Distances between Sandblasting Device and Composite Substrate Surface on the Repair Bond Strength. Materials. 2021; 14(7):1621. https://doi.org/10.3390/ma14071621

Chicago/Turabian StyleBurrer, Phoebe, Amanda Costermani, Matej Par, Thomas Attin, and Tobias T. Tauböck. 2021. "Effect of Varying Working Distances between Sandblasting Device and Composite Substrate Surface on the Repair Bond Strength" Materials 14, no. 7: 1621. https://doi.org/10.3390/ma14071621

APA StyleBurrer, P., Costermani, A., Par, M., Attin, T., & Tauböck, T. T. (2021). Effect of Varying Working Distances between Sandblasting Device and Composite Substrate Surface on the Repair Bond Strength. Materials, 14(7), 1621. https://doi.org/10.3390/ma14071621