Formwork Pressure of a Heavyweight Self-Compacting Concrete Mix

Abstract

1. Introduction

2. Experimental Program

2.1. Materials and Mix Design

2.2. Test Methods

3. Test Results

3.1. Rheological Properties of the Self-Compacting Concrete

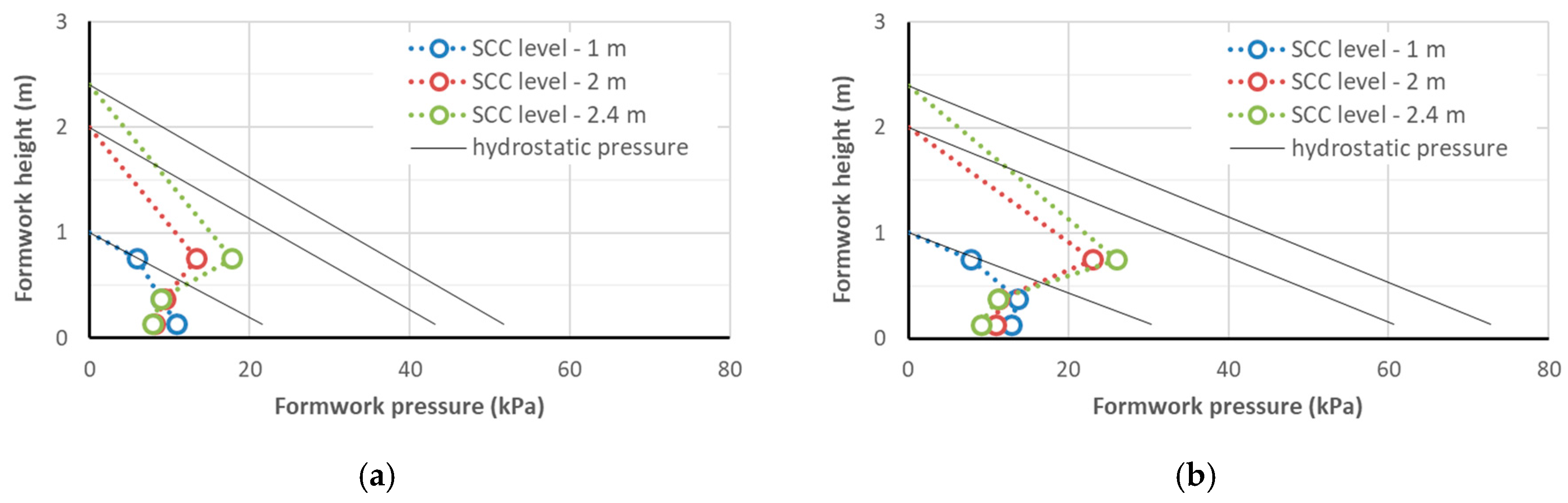

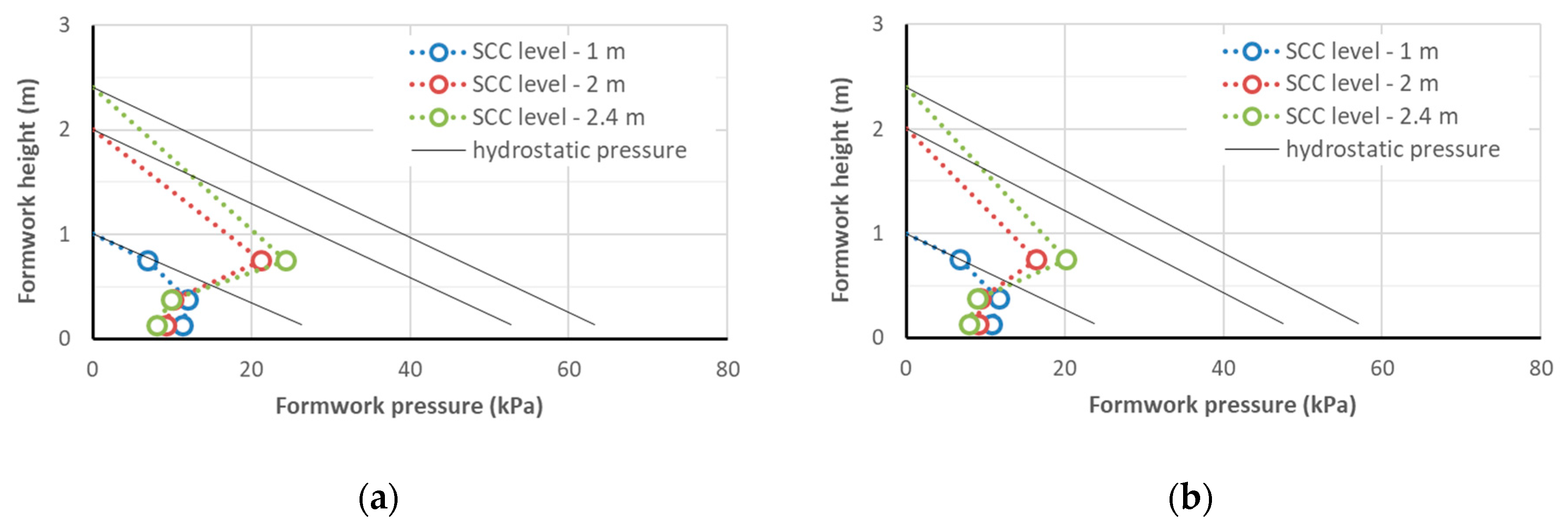

3.2. Lateral Pressure on the Formwork

3.3. Hardened Concrete Properties in the Columns

3.4. Properties of the Concrete Mixtures with Dry or Water-Saturated Serpentine

4. Discussion of the Results

4.1. Lateral Pressure on the Formwork

4.2. Lateral Pressure on the Formwork

4.3. Hardened Concrete Properties in the Columns

4.4. Properties of Concrete Mixtures with Dry or Water-Saturated Serpentine

5. Conclusions

- Heavyweight concrete mixes with a density of up to 3570 kg/m3 and mixtures with a chemically bound water content of 3–7% with self-compacting characteristics related to a slump flow from 55 to 65 cm were obtained using crushed magnetite and serpentine aggregates. A stable consistency was obtained for the magnetite aggregate, while the presence of serpentine aggregate resulted in a loss of slump flow by 10 cm. Both the yield stress and plastic viscosity of the self-compacting mixtures were increased with the use of magnetite and serpentine aggregates. The mixes exhibited resistance to the segregation of the SR2 class.

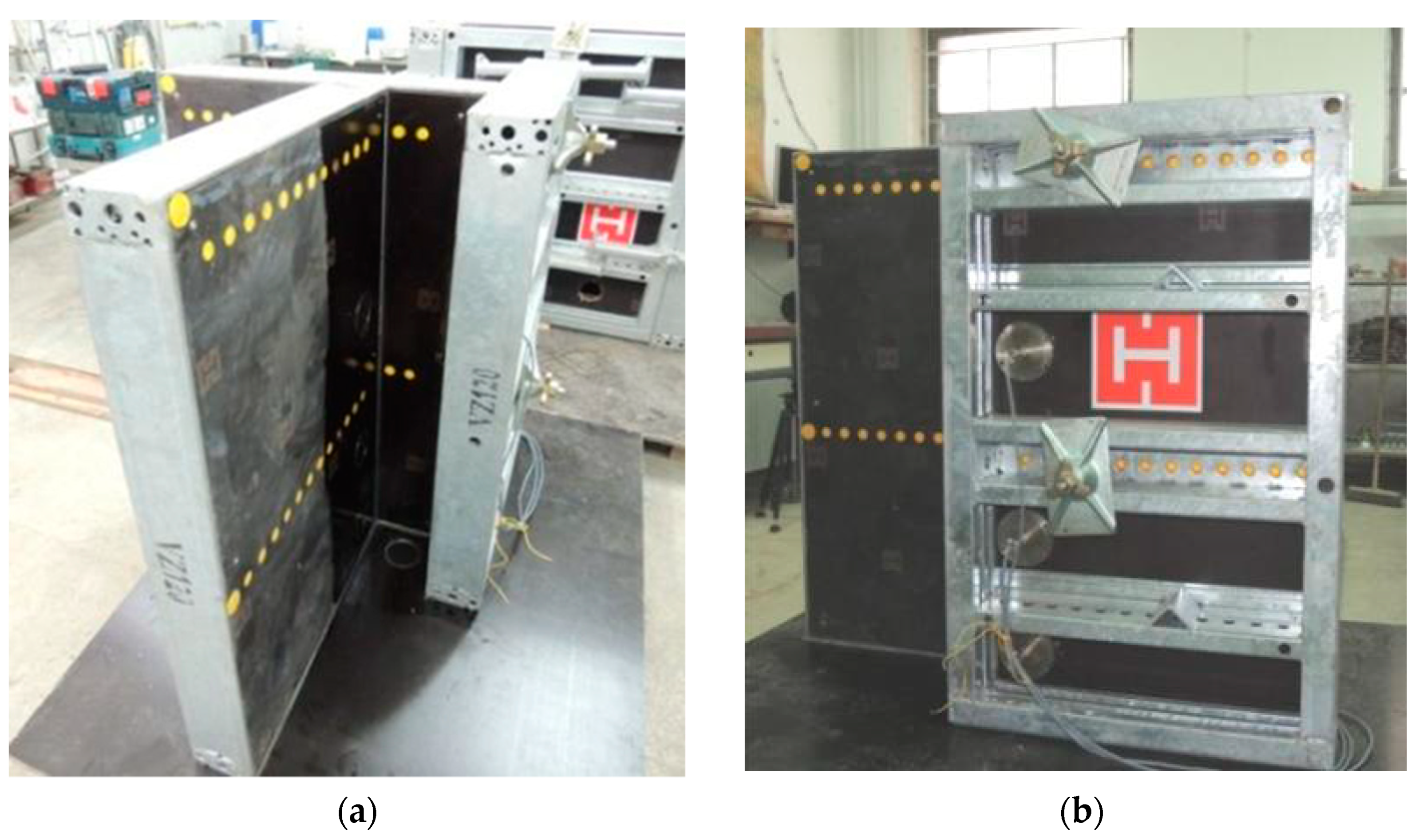

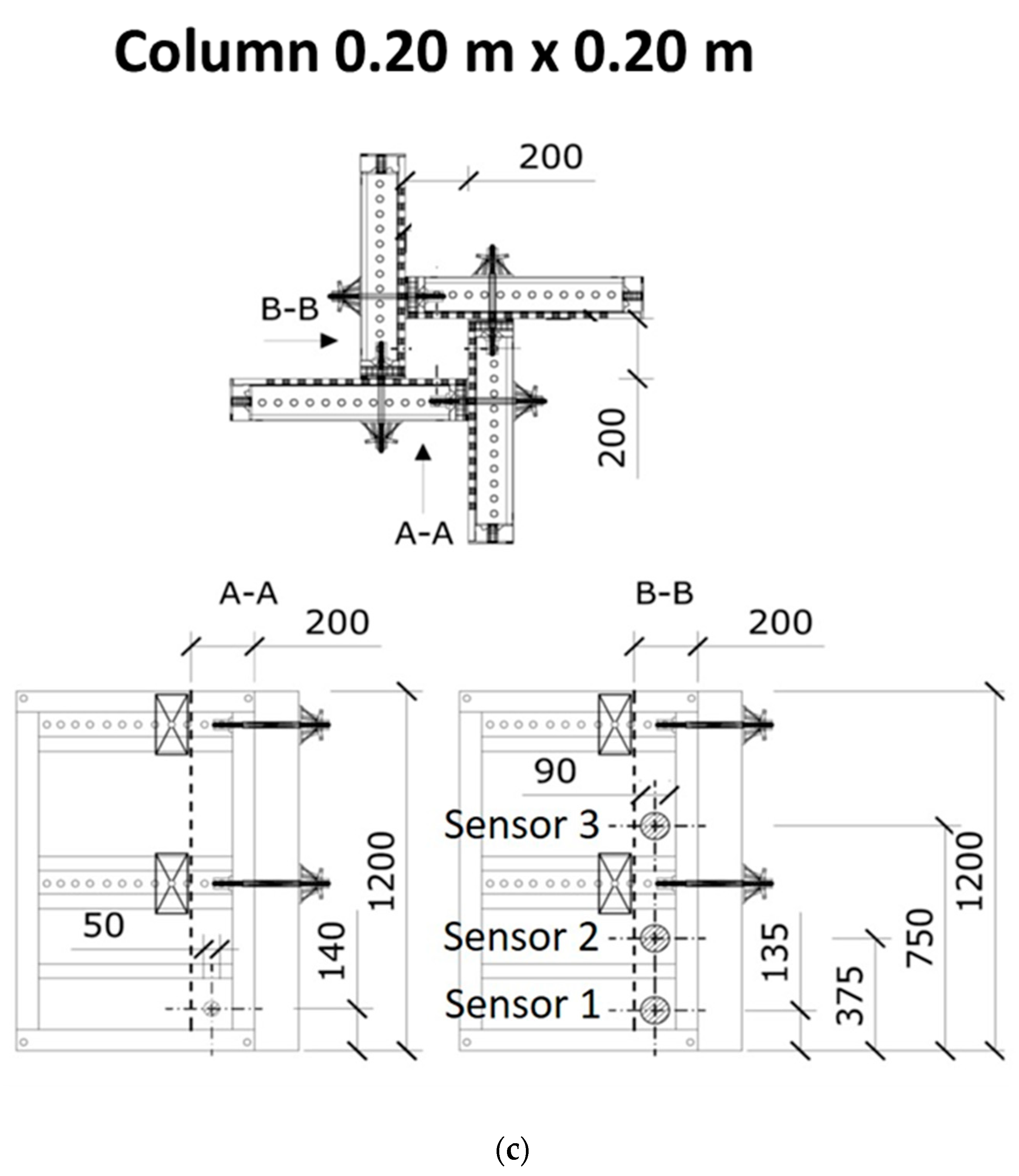

- An original test setup was developed for the determination of lateral pressure on the square column formwork with pressure measurements carried out using six strain gauge pressure transducers located on two opposite formwork walls. The setup was found to be adequate for heavyweight concrete mixtures when testing up to the density of 3570 kg/m3.

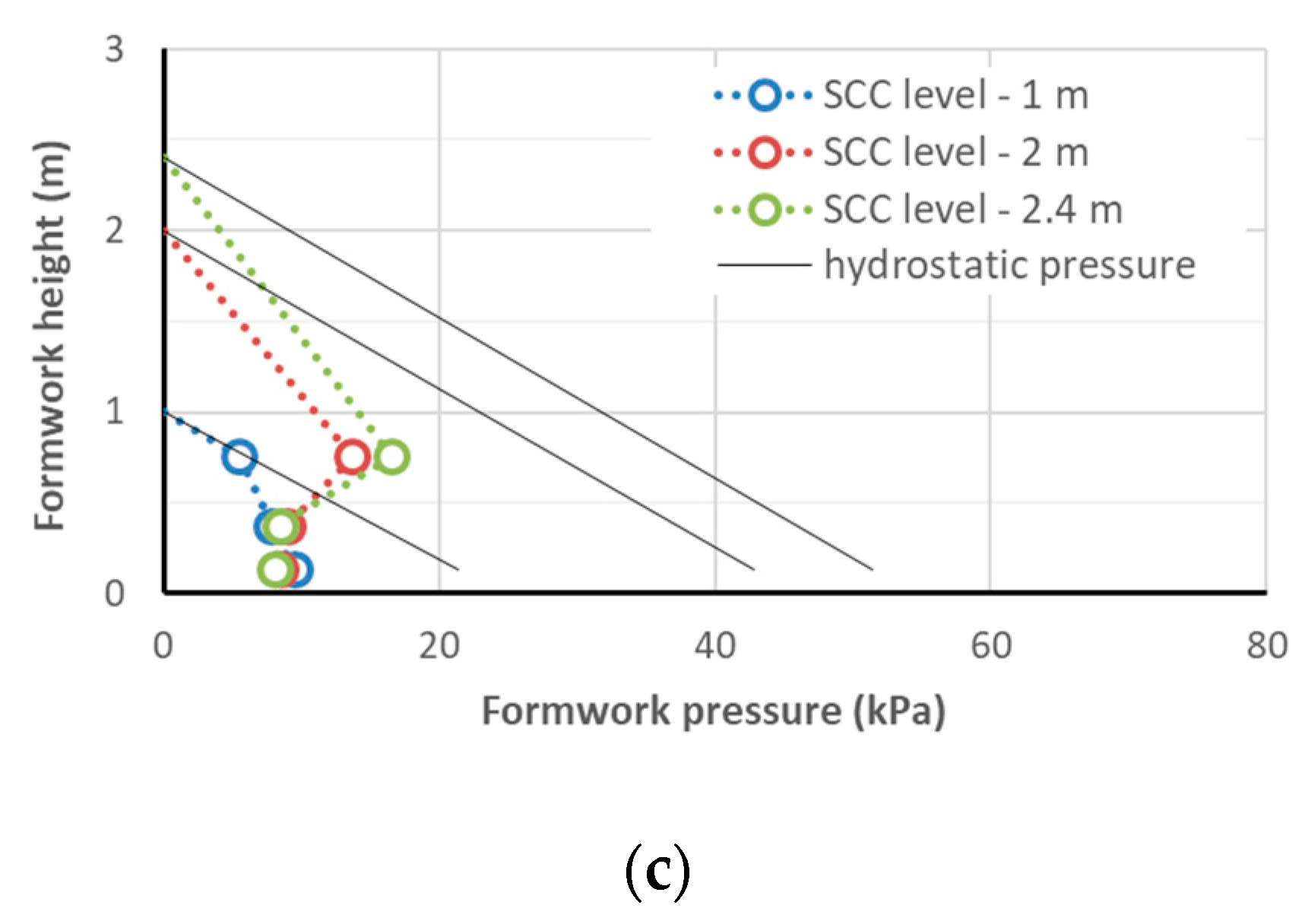

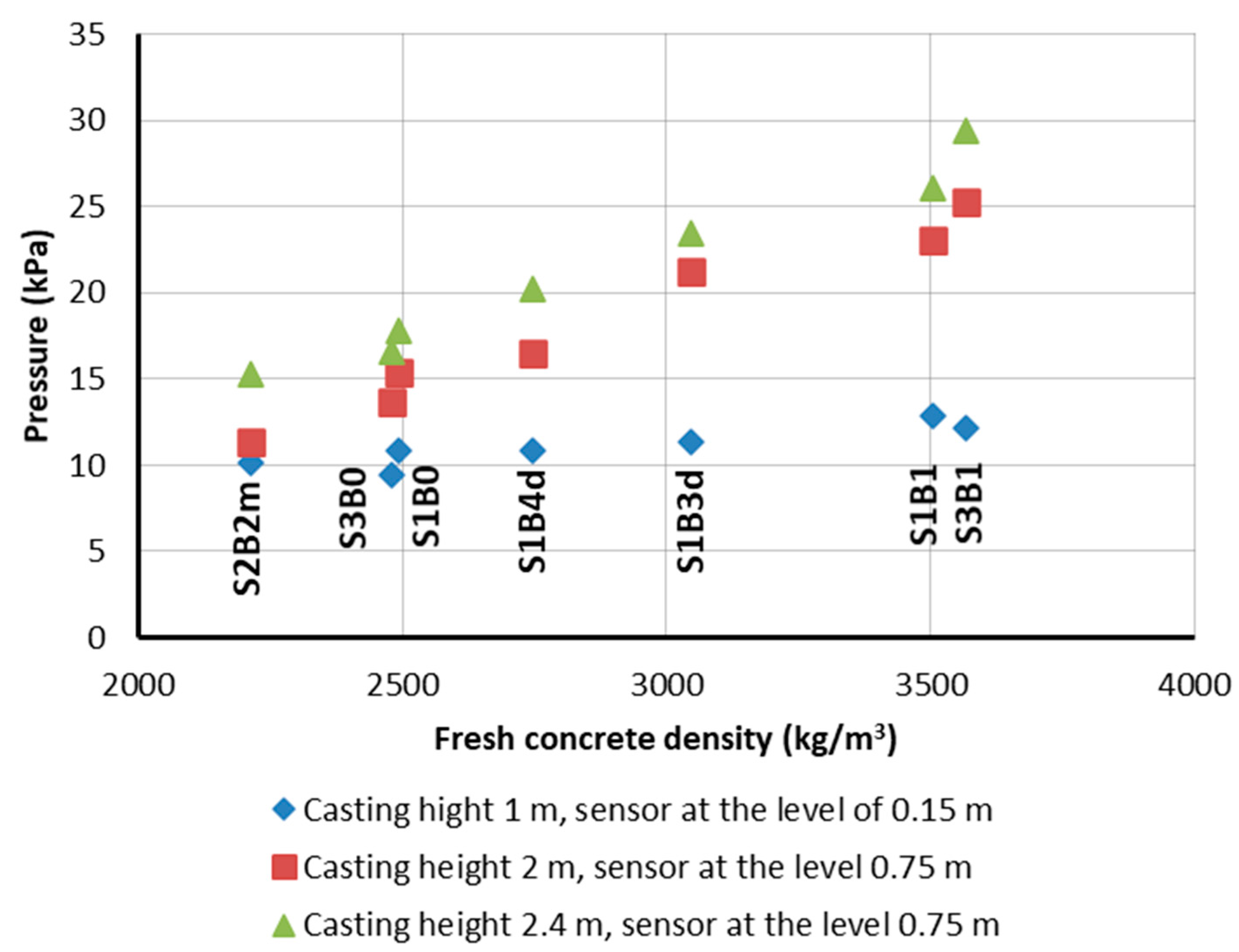

- Similar to conventional concrete, at the same casting rate and mix consistency, the maximum lateral pressure was directly proportional to the density of the self-compacting radiation-shielding concrete mixes. The maximum values of the lateral pressure recorded in the test at a casting speed of 1.5 m/h did not exceed 27 kPa and 55% of the hydrostatic pressure. Concrete mixtures with basalt, magnetite, and magnetite/serpentine blended aggregates were able to develop shear strength after casting for proper stability during concreting.

- At the casting speed of 1.5 m/h, the maximum pressure was registered 1.5 m below the concreting level. The pressure on the formwork was changed or even decreased at deeper levels, despite the progress of concreting. The mixture with the serpentine aggregate showed a lower load-carrying capacity, where in this case, despite the lowest density, the highest pressure on the formwork was observed at the level of the bottom sensor.

- The dependencies determined for normal concrete that allow for the prediction of pressure on the formwork can also be used for radiation-shielding concrete after taking into consideration their different densities.

- No flowable concrete mixes with a dry serpentine aggregate were obtained. For a presaturated serpentine aggregate with water in the amount corresponding to its water absorption, concrete mixtures with an S3–S4 consistency could be obtained while avoiding a significant reduction in the strength of the concrete. For proper workability control, it is more beneficial to replace the 0–2 mm fraction of the serpentine aggregate with ordinary quartz sand.

- It is possible to obtain concrete mixtures with magnetite aggregate with an S4 consistency S4 that is stable over time and mixtures with serpentine and magnetite aggregates blended in various proportions with an S3–S4 consistency. For a higher dose of superplasticizer, an increased loss of workability was observed, which was more pronounced for CEM III/A cement than for CEM I cement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bouniol, P. Bétons spéciaux de protection. Tech. l’Ingénieur 2001, BN3, BN3740. [Google Scholar]

- Kurtis, K.E.; Xi, Y.; Glinicki, M.A.; Provis, J.; Giannini, E.R.; Fu, T. Can we design concrete to survive nuclear environments? Concr. Int. 2017, 39, 29–35. [Google Scholar]

- Yang, K.-H.; Mun, J.-S.; Lee, H. Workability and mechanical properties of heavyweight magnetite concrete. ACI Mater. J. 2014, 111, 273–282. [Google Scholar] [CrossRef]

- Ferreira, M.; Bohner, E.; Sjöblom, V.; Al-Neshawy, F.; Ojala, T. Construction of realistic NPP containment wall mock-up for challenging NDE methods. In Proceedings of the Fib Symposium 2019: Concrete—Innovations in Materials, Design and Structures, Krakow, Poland, 27–29 May 2019; pp. 1651–1658. [Google Scholar]

- Glinicki, M.A. Dlugotrwala Funkcjonalnosc Betonu w Konstrukcjach Oslonowych Elektrowni Jadrowych (Longterm Performance of Concrete in Shielding Structures of Nuclear Power Plants); IPPT PAN: Warszawa, Poland, 2015; p. 64. [Google Scholar]

- Glinicki, M.; Antolik, A.; Gawlicki, M. Evaluation of compatibility of neutron-shielding boron aggregates with Portland cement in mortar. Constr. Build. Mater. 2018, 164, 731–738. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Andiç-Çakır, Ö. Bleeding characteristics of high consistency heavyweight concrete mixtures. Constr. Build. Mater. 2019, 194, 153–160. [Google Scholar] [CrossRef]

- Pei, Y.; Li, S.; Agostini, F.; Skoczylas, F.; Masson, B. Sealing of concrete confining structures of French nuclear reactors. Eng. Struct. 2019, 197, 343–352. [Google Scholar] [CrossRef]

- Glinicki, M.A.; Litorowicz, A. Crack system evaluation in concrete elements at mesoscale. Bull. Pol. Acad. Sci. Chem. 2006, 54, 371–379. [Google Scholar]

- Gökçe, H.; Öztürk, B.C.; Çam, N.; Andiç-Çakır, Ö. Gamma-ray attenuation coefficients and transmission thickness of high consistency heavyweight concrete containing mineral admixture. Cem. Concr. Compos. 2018, 92, 56–69. [Google Scholar] [CrossRef]

- ACI 347R-14: Guide to Formwork for Concrete; ACI Committee: Farmington Hills, MI, USA, 2014.

- Billberg, P.H.; Roussel, N.; Amziane, S.; Beitzel, M.; Charitou, G.; Freund, B.; Gardner, J.N.; Grampeix, G.; Graubner, C.-A.; Keller, L.; et al. Field validation of models for predicting lateral form pressure exerted by SCC. Cem. Concr. Compos. 2014, 54, 70–79. [Google Scholar] [CrossRef]

- Billberg, P. Form pressure generated by self-compacting concrete. In Proceedings of the 3rd International RILEM Symposium on Self-Compacting Concrete, RILEM PRO33, Reykjavik, Iceland, 17 August 2003; Wallevik, O., Nielsson, I., Eds.; pp. 271–280. [Google Scholar]

- Skarendahl, A.A.; Billberg, P. (Eds.) Casting of Self Compacting Concrete; RILEM Report 35; RILEM Publication S.A.R.L.: Bagneux, France, 2006; p. 42. [Google Scholar]

- Beitzel, M.; Beitzel, H.; Muller, H.S. Fresh concrete pressure of SCC on a vertical formwork. In Proceedings of the 3rd North American Conference on the Design and Use of Self-Consolidating Concrete, Chicago, IL, USA, 10–12 November 2008; p. 7. [Google Scholar]

- Oesterheld, S.; Mueller, F.V.; Wallevik, O.H. The Influence of workability loss and thixotropy on formwork pressure in SCC containing stabilizers. In Proceedings of the 3rd North American Conference on the Design and Use of Self-Consolidating Concrete, Chicago, IL, USA, 10–12 November 2008; p. 6. [Google Scholar]

- Billberg, P. Mechanisms behind reduced form pressure when casting with SCC. In Proceedings of the 1st International Symposium on Design, Performance and Use of Self-Consolidated Concrete SCC’2005, RILEM Proceedings PRO 42, Changsha, Hunan, China, 26–28 May 2005; Yu, Z., Shi, C., Khayat, K.H., Xie, Y., Eds.; pp. 589–598. [Google Scholar]

- Assaad, J.; Khayat, K.H. Kinetics of formwork pressure drop of self-consolidating concrete containing various types and contents of binder. Cem. Concr. Res. 2005, 35, 1522–1530. [Google Scholar] [CrossRef]

- Assaad, J.J.; Khayat, K.H. Effect of mixture consistency on formwork pressure exerted by highly flowable concrete. J. Mater. Civ. Eng. 2006, 18, 786–791. [Google Scholar] [CrossRef]

- Khayat, K.H.; Assaad, J. Influence of internal friction and cohesion on formwork pressure of self-compacting concrete. In Proceedings of the 1st International Symposium on Design, Performance and Use of Self-Consolidated Concrete SCC’2005, RILEM Proceedings PRO 42, Changsha, Hunan, China, 26–28 May 2005; Yu, Z., Shi, C., Khayat, K.H., Xie, Y., Eds.; pp. 607–616. [Google Scholar]

- DIN 18218: 2010 Pressure of Fresh Concrete on Vertical Formwork; German Institute for Standardisation: Berlin, Germany, 2010.

- Gołaszewski, J.; Drewniok, M. Dobór deskowań systemowych do wykonywania konstrukcji z betonu samozagęszczonego (Selection of system formworks when casting self-compacting concrete). Inżynieria Budownictwo 2009, 66, 23–26. [Google Scholar]

- Revuelta, D.; Barona, A.; Navarro, D. Medida de las principales propiedades en el estado fresco, y de la resistencia a la segregación, en un hormigón autocompactante de alta densidad fabricado con barita. Materiales Construcción 2009, 59, 31–44. [Google Scholar] [CrossRef]

- Volkman, D.E. Concrete for radiation shielding. In Significance of Tests and Properties of Concrete and Concrete-Making Materials; Lamond, J.F., Pielert, J.H., Eds.; ASTM STP 169C; ASTM International: West Conshohocken, PA, USA, 2006; pp. 570–577. [Google Scholar]

- Kubissa, W.; Glinicki, M.A. Influence of internal relative humidity and mix design of radiation shielding concrete on air permeability index. Constr. Build. Mater. 2017, 147, 352–361. [Google Scholar] [CrossRef]

- BS EN 197-1:2011 Cement. Composition, Specifications and Conformity Criteria for Common Cements; British Standards Institution: London, UK, 2011.

- Baran, T.; Glinicki, M.A.; Jóźwiak-Niedźwiedzka, D. The properties of special cements for shielding concrete in nuclear power plants. Cement Wapno Beton 2016, 21, 207–216. [Google Scholar]

- BS EN 196-2:2013 Method of Testing Cement. Chemical Analysis of Cement; British Standards Institution: London, UK, 2013.

- BS EN 1097-6:2013 Tests for Mechanical and Physical Properties of Aggregates. Determination of Particle Density and Water Absorption; British Standards Institution: London, UK, 2013.

- BS EN 12350-2:2009 Testing Fresh Concrete. Slump-Test; British Standards Institution: London, UK, 2009.

- BS EN 12350-8:2010 Testing Fresh Concrete Self-Compacting Concrete. Slump-Flow Test; British Standards Institution: London, UK, 2010.

- BS EN 12350-7:2009 Testing Fresh Concrete. Air Content. Pressure Methods; British Standards Institution: London, UK, 2009.

- BS EN 12350-6:2009 Testing Fresh Concrete. Density; British Standards Institution: London, UK, 2009.

- BS EN 12350-11:2010 Testing Fresh Concrete. Self-Compacting Concrete. Sieve Segregation Test; British Standards Institution: London, UK, 2010.

- SCConcrete Rheometer BT2. Available online: http://www.schleibinger.com/cmsimple/downloads/bt2_us.pdf (accessed on 21 March 2021).

- Khayat, K.H.; Assaad, J.J. Measurement systems for determining formwork pressure of highly-flowable concrete. Mater. Struct. 2007, 41, 37–46. [Google Scholar] [CrossRef]

- BS EN 12390-3:2009 Testing Hardened Concrete. Compressive Strength of Test Specimens; British Standards Institution: London, UK, 2009.

- BS EN 12390-8:2009 Testing Hardened Concrete. Depth of Penetration of Water under Pressure; British Standards Institution: London, UK, 2009.

- BS EN 206 2013 Concrete. Specification, Performance, Production and Conformity; British Standards Institution: London, UK, 2013.

- Roussel, N. Understanding the Rheology of Concrete; Woodhead Publishing: Cambridge, UK, 2011; p. 384. [Google Scholar]

- Ovarlez, G.; Roussel, N. A physical model for the prediction of lateral stress exerted by self-compacting concrete on formwork. Mater. Struct. 2006, 39, 269–279. [Google Scholar] [CrossRef]

- De Schutter, G.; Bartos, P.J.M.; Domone, P.; Gibbs, J. Self Compacting Concrete; Whittles Publishing: Dunbeath, UK, 2008; p. 296. [Google Scholar]

- Jiao, D.; Shi, C.; Yuan, Q.; An, X.; Liu, Y.; Li, H. Effect of constituents on rheological properties of fresh concrete—A review. Cem. Concr. Compos. 2017, 83, 146–159. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Cygan, G.; Drewniok, M.; Kilijanek, A. Rheological properties of SCC in 544 terms of its thixotropic behaviour and its influence on formwork pressure. In Proceedings of the 5th International Conference—Non-Traditional Cement & Concrete, Brno, Czech Republic, 16–19 June 2014; Bilek, V., Kersner, Z., Eds.; Brno University of Technology: Brno, Czech Republic, 2014; pp. 75–78. [Google Scholar]

- Lomboy, G.R.; Wang, X.; Wang, K. Rheological behavior and formwork pressure of SCC, SFSCC, and NC mixtures. Cem. Concr. Compos. 2014, 54, 110–116. [Google Scholar] [CrossRef]

- Tuyan, M.; Ahari, R.S.; Erdem, T.K.; Çakır, Ö.A.; Ramyar, K. Influence of thixotropy determined by different test methods on formwork pressure of self-consolidating concrete. Constr. Build. Mater. 2018, 173, 189–200. [Google Scholar] [CrossRef]

- Teixeira, S.; Puente, I.; Santilli, A. Statistical model for predicting the maximum lateral pressure exerted by self-consolidating concrete on vertical formwork. J. Build. Eng. 2017, 12, 77–86. [Google Scholar] [CrossRef]

- Henschen, J.D.; Castaneda, D.I.; Lange, D.A. Formwork pressure model for self-consolidating concrete using a pressure decay signature. ACI Mater. J. 2018, 115, 339–348. [Google Scholar] [CrossRef]

- Beitzel, M. Modelling fresh concrete pressure of normal and self-compacting concrete. In Design, Production and Placement of Self-Consolidating Concrete, Proceedings of SCC2010, Montreal, QC, Canada, 26–29 September 2010; Khayat, K., Feys, D., Eds.; RILEM Bookseries; Springer: Dordrecht, The Netherlands, 2010; Volume 1, pp. 243–254. [Google Scholar]

- Kubissa, W.; Glinicki, M.A.; Dąbrowski, M. Permeability testing of radiation shielding concrete manufactured at industrial scale. Mater. Struct. 2018, 51, 83. [Google Scholar] [CrossRef]

| Component | CEM I 42.5N LH/SR3/NA | CEM III/A 42.5N LH/HSR/NA |

|---|---|---|

| SiO2 | 21.48 | 31.38 |

| Al2O3 | 4.80 | 5.98 |

| Fe2O3 | 2.62 | 2.09 |

| CaO | 65.60 | 52.51 |

| MgO | 0.87 | 3.73 |

| SO3 | 2.84 | 1.45 |

| K2O | 0.47 | 0.56 |

| Na2O | 0.12 | 0.34 |

| Cl | 0.008 | 0.058 |

| Loss on ignition | 1.12 | 0.12 |

| Cement Designation | Flow (cm) | Le-Cha Soundness (mm) | Water Demand (%) | Setting Time (min) | |||||

| Initial | Final | ||||||||

| CEM I 42.5N LH/SR3/NA | 18.1 | 1 | 28.0 | 185 | 250 | ||||

| CEM III/A 42.5N LH/HSR/NA | 15.4 | 0 | 34.0 | 200 | 345 | ||||

| Cement Designation | Blaine (cm2/g) | Density (g/cm3) | Bending Strength at Days (MPa) | Compressive Strength at Days (MPa) | |||||

| 2 | 7 | 28 | 2 | 7 | 28 | ||||

| CEM I 42.5N LH/SR3/NA | 3800 | 3.15 | 3.6 | 6.0 | 8.1 | 20.7 | 33.7 | 52.6 | |

| CEM III/A 42.5N LH/HSR/NA | 4700 | 2.99 | 3.0 | 5.7 | 9.5 | 14.2 | 29.6 | 58.2 | |

| Type of Aggregate | Density (kg/dm3) | Water Absorption (%) |

|---|---|---|

| Crushed basalt | 3.0 | 0.80 |

| Crushed serpentine | 2.60 | 0/2 mm: 2.14 2/8 mm: 2.41 8/16 mm: 1.47 |

| Crushed magnetite | 4.80 | 0.40 |

| Concrete | Cement | Aggregate |

|---|---|---|

| S—self-compacting concrete V—vibrated concrete | 1—concrete with CEM I 3—concrete with CEM III/A | B0—basalt + magnetite B1—magnetite B2—serpentine B3—serpentine + magnetite 2:1 B4—serpentine + magnetite 1:2 d—dry serpentine aggregate m—water-saturated serpentine aggregate |

| Mix Constituents, w/c Ratio | Concrete Mix | |||||

|---|---|---|---|---|---|---|

| S1B0 S3B0 | S1B1 S3B1 | S3B2m (1) | S1B3d (2) | S1B4d (2) | ||

| Cement (CEM I or CEM III) | 350 | 350 | 350 | 350 | 350 | |

| Water | 168 | 168 | 211 | 168 | 168 | |

| w/c | 0.48 | 0.48 | 0.60 | 0.48 | 0.48 | |

| w/ceff | - | - | 0.48 | - | - | |

| Quartz sand 0/2 | 687 | 371 | 371 | 371 | 371 | |

| Crushed basalt 2/16 | 1001 | |||||

| Crushed magnetite 0/5 | 300 | 839 | 772 | 895 | ||

| Crushed magnetite 0/16 | 1846 | 1018 | ||||

| Crushed serpentine 0/2 | 273 | |||||

| Crushed serpentine 2/8 | 909 | 485 | 485 | |||

| Crushed serpentine 8/16 | 273 | 371 | 485 | |||

| HRWR (% mass of cement (%m.c.)) | CEM I CEM III/A | 0.36 0.2 | 0.3 0.2 | 1.4 | 2 | 1.6 |

| VMA (%m.c.) | CEM I | 0.15 | ||||

| Designed mix density | 2506 | 3574 | 2389 | 3537 | 2756 | |

| Mix Constituents, w/c Ratio | Concrete | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V1B0 V3B0 | V1B1 V3B1 | V1B2d1 | V1B2d2 | V1B2d3 | V1B2d4 | V1B2m1 | V1B2m2 | V3B2m3 | V3B2m4 | V1B3m | V1B3d V3B3d | V1B4m | V1B4d V3B4d | ||

| Cement (CEM I or CEM III) | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | 350 | |

| Water | 168 | 168 | 168 | 168 | 168 | 211 | 211 | 168 | 200 | 200 | 189 | 168 | 189 | 168 | |

| w/c | 0.48 | 0.48 | 0.48 | 0.48 | 0.48 | 0.60 | 0.60 | 0.48 | 0.57 | 0.57 | 0.54 | 0.48 | 0.54 | 0.48 | |

| w/ceff | - | - | 0.35 | 0.46 | 0.47 | 0.48 | 0.48 | 0.35 | 0.48 | 0.48 | 0.48 | - | 0.48 | - | |

| Quartz sand 0/2 | 687 | 371 | 371 | 510 | 654 | 371 | 371 | 371 | 371 | 371 | 371 | 371 | 371 | 371 | |

| Crushed basalt 2/16 | 1001 | ||||||||||||||

| Crushed magnetite 0/5 | 300 | 839 | 772 | 772 | 895 | 895 | |||||||||

| Crushed magnetite 0/16 | 1846 | 1018 | 1018 | ||||||||||||

| Crushed serpentine 0/2 | 273 | 136 | 273 | 273 | 273 | 273 | 273 | ||||||||

| Crushed serpentine 2/8 | 909 | 909 | 909 | 909 | 909 | 909 | 909 | 909 | 485 | 485 | 485 | 485 | |||

| Crushed serpentine 8/16 | 273 | 273 | 273 | 273 | 273 | 273 | 273 | 273 | 371 | 371 | 485 | 485 | |||

| HRWR (%m.c.) | CEM I CEM III/A | 0.2 0.15 | 0.2 0.15 | 1.2 | 1.5 | 1.0 | 0.5 | 0.5 | 2.0 | 0.5 | 1.66 | 0.3 | 0.3 0.2 | 0.48 | 0.57 0.4 |

| Remarks | (1) | (2) | (3) | (4) | (5) | (6) | (6) | (6) | (6) | ||||||

| Property | Cement CEM I | Cement CEM III | ||||||

|---|---|---|---|---|---|---|---|---|

| S1B0 | S1B1 | S1B3d | S1B4d | S3B0 | S3B1 | S3B2m | ||

| Slump flow (cm) | 5 min | 64 | 58 | 60 | 55 | 63 | 61.5 | 55 |

| 20 min | 62 | 52 | 50 | 43 | 58.5 | 53 | 42 | |

| Flow time T500 (s) | 5 min | 3.1 | 5.3 | 5.5 | 7 | 3.4 | 5.2 | 6.1 |

| 20 min | 4.6 | 13 | 11.6 | - | 6.9 | 5.3 | - | |

| Yield stress g (N·m) | 5 min | 0.35 | 1.18 | 0.95 | 1.12 | 0.36 | 1.08 | 0.53 |

| 20 min | 0.42 | 1.46 | 1.09 | 1.86 | 0.59 | 1.79 | 1.06 | |

| Plastic viscosity h (N·m·s) | 5 min | 2.7 | 11.19 | 11.79 | 10.46 | 8.54 | 12.37 | 5.75 |

| 20 min | 4.62 | 16.09 | 13.27 | 14.63 | 9.58 | 12.65 | 8.98 | |

| Air content Ac (%) | 3.8 | 5 | 3.8 | 3.0 | 3.6 | 2.6 | 6.8 | |

| Density of fresh concrete (kg/m3) | 2448 | 3503 | 3048 | 2745 | 2478 | 3568 | 2213 | |

| Segregation resistance (SR) | 11.2 | 1.4 | 6.4 | 1.8 | 5.3 | 3.4 | 8.9 | |

| SR class | SR 2 | |||||||

| Mixture | Density (kg/m3) | Level of the Sensor (m) | Pressure (kPa) after the End of Casting at a Height of | ||

|---|---|---|---|---|---|

| 1 m | 2 m | 2.4 m | |||

| S1B0 | 2448 | 0.75 | 6 | 15.35 | 17.8 |

| 0.375 | 8.85 | 9.35 | 8.9 | ||

| 0.135 | 9.25 | 8.15 | 7.8 | ||

| S1B1 | 3503 | 0.75 | 7.85 | 23.05 | 26.1 |

| 0.375 | 13.7 | 11.35 | 11.15 | ||

| 0.135 | 12.85 | 10.95 | 9.05 | ||

| S1B3 | 3048 | 0.75 | 7 | 21.2 | 24.4 |

| 0.375 | 12 | 10.1 | 9.85 | ||

| 0.135 | 11.35 | 9.25 | 8.1 | ||

| S1B4 | 2745 | 0.75 | 6.8 | 16.45 | 20.25 |

| 0.375 | 11.65 | 9.35 | 9 | ||

| 0.135 | 10.8 | 9.05 | 7.9 | ||

| S3B0 | 2478 | 0.75 | 5.45 | 12.7 | 15.6 |

| 0.375 | 7.8 | 9 | 8.4 | ||

| 0.135 | 8.45 | 8.5 | 8.1 | ||

| S3B1 | 3568 | 0.75 | 8.5 | 25.3 | 29.4 |

| 0.375 | 13.95 | 12.75 | 13.1 | ||

| 0.135 | 12.15 | 11.15 | 11.45 | ||

| S3B2m | 2213 | 0.75 | 5.05 | 11.35 | 15.3 |

| 0.375 | 9.35 | 12.35 | 15.7 | ||

| 0.135 | 10.13 | 12.65 | 14.85 | ||

| Concrete Mix | Position of Sample in the Column | Density (kg/m3) | Average Compressive Strength (MPa) | Depth of Water Penetration (mm) | |

|---|---|---|---|---|---|

| Parallel to Direction of Concreting | Perpendicular to Direction of Concreting | ||||

| S1B0 | Top | 2482 | 63.5 | 40 | 50 |

| Bottom | 2468 | ||||

| S1B1 | Top | 3595 | 58.2 | 60 | 55 |

| Bottom | 3570 | ||||

| S1B3 | Top | 3221 | 63.8 | 105 | 65 |

| Bottom | 3207 | ||||

| S1B4 | Top | 2764 | 55.6 | Water penetrated through the sample | |

| Bottom | 2762 | ||||

| S3B0 | Top | 2417 | 71.5 | 80 | 25 |

| Bottom | 2467 | ||||

| S3B1 | Top | 3582 | 75.4 | 60 | 45 |

| Bottom | 3536 | ||||

| S3B2m | Top | 2263 | 61.4 | 35 | 20 |

| Bottom | 2287 | ||||

| Property | Concrete Mix | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| V1B2d1 | V1B2d2 | V1B2d3 | V1B2d4 | V1B2m1 | V1B2m2 | V3B2m3 | V3B2m4 | ||

| Slump (cm) | 5 min | 3.0 | 4.0 | 22.0 | 21..5 | 14 | 1.0 | 14 | 25 |

| 60 min | - | 1.0 | 16.0 | 16.0 | 6.0 | - | 6 | 20 | |

| Air content (%) | 2.9 | 3.2 | 4.0 | 4.2 | 3.0 | 2.0 | 3.8 | 4.0 | |

| Density of fresh concrete (kg/m3) | 2380 | 2335 | 2289 | 2273 | 2378 | 2410 | 2303 | 2293 | |

| Density of concrete (kg/m3) | 2373 | 2366 | 2311 | 2280 | 2394 | 2424 | 2348 | 2284 | |

| Compressive strength of concrete (MPa) | 47.6 | 52.7 | 40.7 | 34.3 | 47.8 | 50.5 | 47.8 | 46.7 | |

| Property | Concrete Mix | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| V1B0 | V3B0 | V1B1 | V3B1 | V1B3d | V1B3m | V1B4d | V1B4m | V3B3d | V3B4d | ||

| Slump (cm) | 5 min | 20 | 20 | 22.0 | 20 | 21.0 | 21.0 | 19.5 | 26 | 19 | 21 |

| 60 min | 19 | 9 | 19 | 4 | 16 | 17.5 | 19.5 | 21 | 5 | 18 | |

| Air content (%) | 1.9 | 2.2 | 2.2 | 1.8 | 1.9 | 2.1 | 2.4 | 2.5 | 2.0 | 2.8 | |

| Density of fresh concrete (kg/m3) | 2421 | 2452 | 3587 | 3598 | 3191 | 3208 | 2783 | 2728 | 3195 | 2750 | |

| Compressive strength of concrete (MPa) | 48.0 | 46.2 | 54.0 | 55.3 | 53.7 | 48.1 | 52.6 | 37.5 | - | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Glinicki, M.A.; Gołaszewski, J.; Cygan, G. Formwork Pressure of a Heavyweight Self-Compacting Concrete Mix. Materials 2021, 14, 1549. https://doi.org/10.3390/ma14061549

Glinicki MA, Gołaszewski J, Cygan G. Formwork Pressure of a Heavyweight Self-Compacting Concrete Mix. Materials. 2021; 14(6):1549. https://doi.org/10.3390/ma14061549

Chicago/Turabian StyleGlinicki, Michał A., Jacek Gołaszewski, and Grzegorz Cygan. 2021. "Formwork Pressure of a Heavyweight Self-Compacting Concrete Mix" Materials 14, no. 6: 1549. https://doi.org/10.3390/ma14061549

APA StyleGlinicki, M. A., Gołaszewski, J., & Cygan, G. (2021). Formwork Pressure of a Heavyweight Self-Compacting Concrete Mix. Materials, 14(6), 1549. https://doi.org/10.3390/ma14061549