Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres

Abstract

1. Introduction

- Will the bridging effect occur in cementitious mortars with the addition of the recently developed basalt fibres, as it has been discovered for other fibre-reinforced materials (e.g., concrete)?

- Will the addition of basalt fibres to cementitious mortar change the value of flexural strength?

- How do the curing conditions’ parameters (humidity, time and temperature) influence the flexural performance of cementitious mortars with the addition of basalt fibres?

- Is there any relation between the mixture proportions parameters (such as water to cement ratio, fibre dosage, presence of micro-silica and plasticiser) and the flexural performance of cementitious mortars with the addition of basalt fibres?

2. Materials

3. Methods

3.1. Flexural Strength Tests

3.2. Density Determination

4. Results

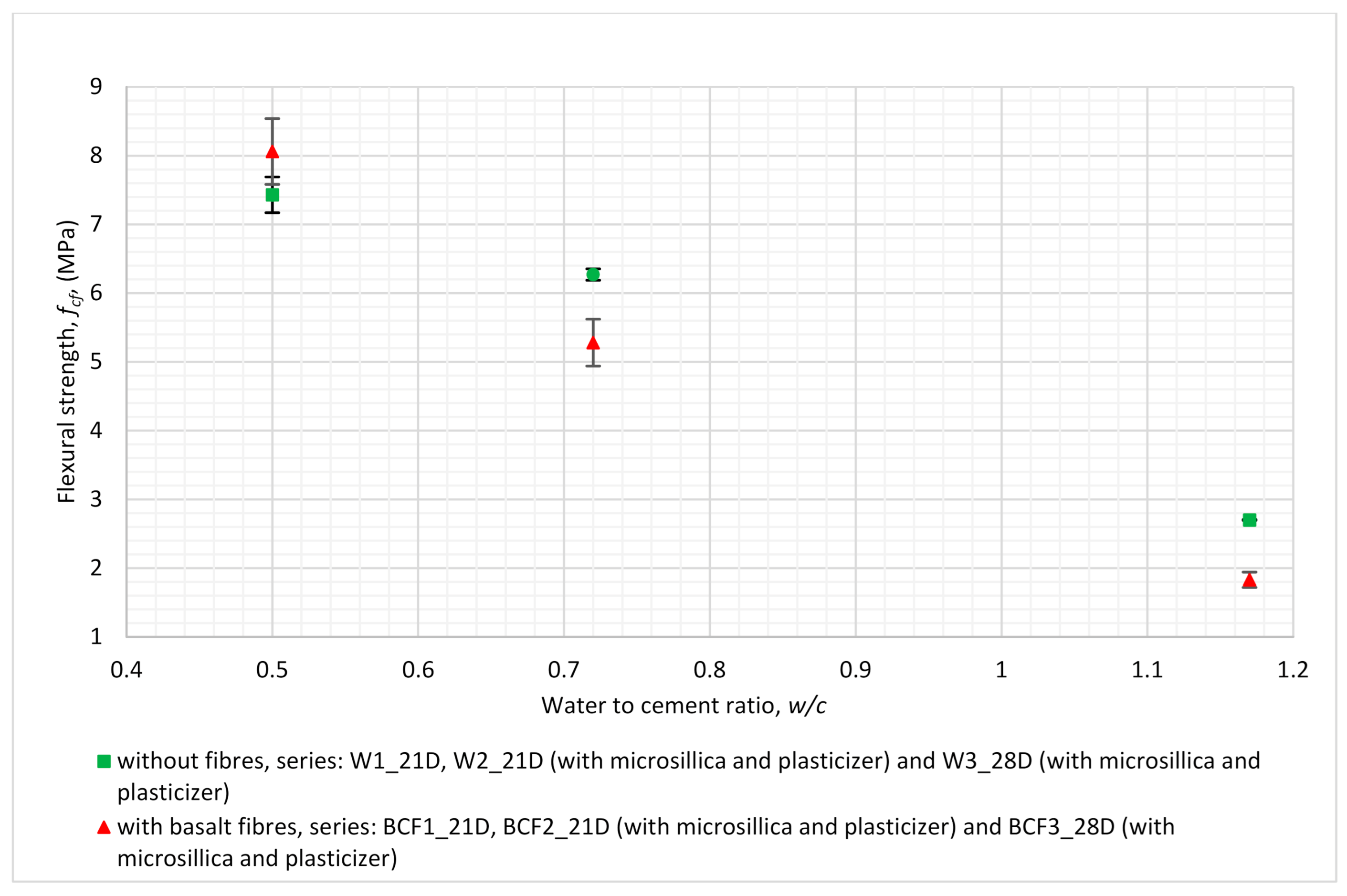

4.1. The Influence of Mixture Proportions

4.2. The Influence of Specimen Conditioning

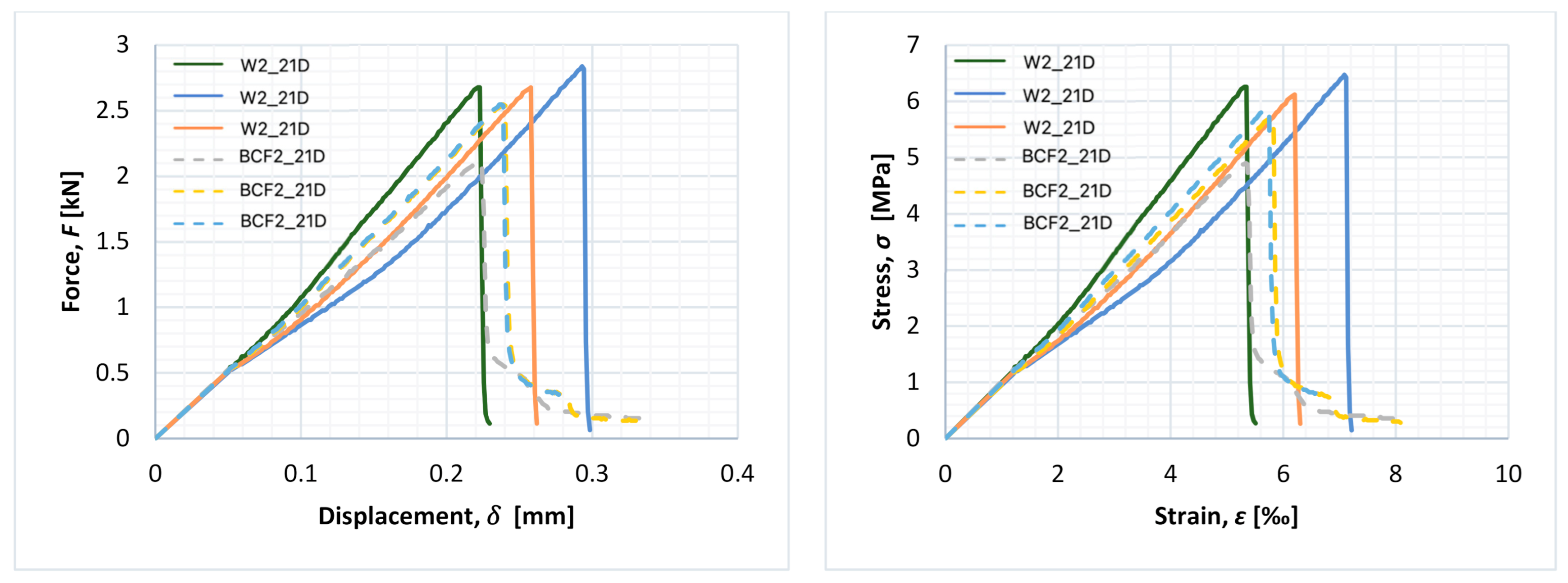

4.3. Post-Critical States Analysis

5. Discussion

- (1)

- Influence of mixture proportions (water to cement ratio and addition of micro-silica and plasticiser);

- (2)

- Issues related to specimen drying, the reduction of water inside the pores and other curing condition parameters (e.g., time);

- (3)

- Comparison to reference polypropylene fibres.

6. Summary and Conclusions

- (1)

- The bridging effect is among the biggest advantages of fibre-reinforced cementitious materials. In the case of cementitious mortars reinforced with basalt fibres examined in this research programme, however, this was observed only for mortars with a relatively low amount of cement and high w/c ratio. Additionally, for the series with the same mixture proportions, the effect occurred in tests carried out after 1 day from demoulding, while it did not occur after 21 days from demoulding, probably due to the fact that the highly alkaline environment inside the cementitious matrix strongly influences basalt fibre performance, especially after longer periods of time.

- (2)

- Mortars with the addition of basalt fibres demonstrated higher values of flexural strength than reference mortars with polypropylene fibres (the same percentage dosage by the mass of the binder). Nevertheless, the bridging effect in that case was obtained only for polypropylene fibres.

- (3)

- Drying out specimens until they reached a stable mass caused an improvement of flexural strength at a range of 70% to 86%; however, it did not influence the bridging effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Kulesza, M.; Dębski, D.; Fangrat, J.; Michalak, J. Effect of redispersible polymer powders on selected mechanical properties of thin-bed cementitious mortars. Cem. Wapno Beton 2020, 2020, 168–177. [Google Scholar]

- Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, S.; Zhu, Y.; Lin, Y.; Chen, D. Effect of polypropylene and basalt fiber on the behavior of mortars for repair applications. Adv. Mater. Sci. Eng. 2016, 2016, 14–16. [Google Scholar] [CrossRef]

- Iorfida, A.; Verre, S.; Candamano, S.; Ombres, L. Tensile and direct shear responses of basalt-fibre reinforced mortar based materials. RILEM Bookseries 2018, 15, 544–552. [Google Scholar]

- Asprone, D.; Cadoni, E.; Iucolano, F.; Prota, A. Analysis of the strain-rate behavior of a basalt fiber reinforced natural hydraulic mortar. Cem. Concr. Compos. 2014, 53, 52–58. [Google Scholar] [CrossRef]

- Santarelli, M.L.; Sbardella, F.; Zuena, M.; Tirillò, J.; Sarasini, F. Basalt fiber reinforced natural hydraulic lime mortars: A potential bio-based material for restoration. Mater. Des. 2014, 63, 398–406. [Google Scholar] [CrossRef]

- Rawat, S.; Narula, R.; Upasani, N.; Muthukumar, G. A relook on dosage of basalt chopped fibres and its influence on characteristics of concrete. In Advances in Sustainable Construction Materials and Geotechnical Engineering; Springer: Singapore, 2020; pp. 87–96. [Google Scholar]

- Li, V.C.; Lin, Z.L.; Matsumoto, T. Influence of fiber bridging on structural size-effect. Int. J. Solids Struct. 1998, 35, 4223–4238. [Google Scholar] [CrossRef]

- Abed, F.; Alhafiz, A.R. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- Tiberti, G.; Minelli, F.; Plizzari, G. Cracking behavior in reinforced concrete members with steel fibers: A comprehensive experimental study. Cem. Concr. Res. 2015, 68, 24–34. [Google Scholar] [CrossRef]

- Deng, M.; Han, J.; Liu, H.; Qin, M.; Liang, X. Analysis of Compressive Toughness and Deformability of High Ductile Fiber Reinforced Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 384902. [Google Scholar] [CrossRef]

- Chang, J.; Cui, K.; Zhang, Y. Effect of hybrid steel fibers on the mechanical performances and microstructure of sulphoaluminate cement-based reactive powder concrete. Constr. Build. Mater. 2020, 261, 120502. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Lee, Y.H.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-reinforced foamed concretes: A review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.A.G.; Šavija, B. Effect of fibers on durability of concrete: A practical review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef] [PubMed]

- Li, V.C.; Stang, H.; Krenchel, H. Micromechanics of crack bridging in fibre-reinforced concrete. Mater. Struct. 1993, 26, 486–494. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Vallini, P. Evaluation of crack width in FRC structures and application to tunnel linings. Mater. Struct. Constr. 2009, 42, 339–351. [Google Scholar] [CrossRef]

- Zheng, D.; Song, W.; Fu, J.; Xue, G.; Li, J.; Cao, S. Research on mechanical characteristics, fractal dimension and internal structure of fiber reinforced concrete under uniaxial compression. Constr. Build. Mater. 2020, 258, 120351. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-ul-Hassan, M.; Khan, M.; Zhang, J.L. Efficiency of Supplementary Cementitious Materials and Natural Fiber on Mechanical Performance of Concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Wang, H.; Zhang, M. Behaviour of recycled tyre polymer fibre reinforced concrete under dynamic splitting tension. Cem. Concr. Compos. 2020, 114, 103764. [Google Scholar] [CrossRef]

- Lau, C.K.; Chegenizadeh, A.; Htut, T.N.S.; Nikraz, H. Performance of the steel fibre reinforced rigid concrete pavement in fatigue. Buildings 2020, 10, 186. [Google Scholar] [CrossRef]

- Zareei, S.A.; Ameri, F.; Bahrami, N.; Shoaei, P.; Musaeei, H.R.; Nurian, F. Green high strength concrete containing recycled waste ceramic aggregates and waste carpet fibers: Mechanical, durability, and microstructural properties. J. Build. Eng. 2019, 26, 100914. [Google Scholar] [CrossRef]

- Carvalho, M.R.; Barros, J.A.O.; Zhang, Y.; Dias-da-Costa, D. A computational model for simulation of steel fibre reinforced concrete with explicit fibres and cracks. Comput. Methods Appl. Mech. Eng. 2020, 363, 112879. [Google Scholar] [CrossRef]

- Tailhan, J.L.; Rossi, P.; Daviau-Desnoyers, D. Probabilistic numerical modelling of cracking in steel fibre reinforced concretes (SFRC) structures. Cem. Concr. Compos. 2015, 55, 315–321. [Google Scholar] [CrossRef]

- Tarasovs, S.; Krūmiņš, J.; Tamužs, V. Modelling of the fracture toughness anisotropy in fiber reinforced concrete. Frattura ed Integrità Strutturale 2016, 10, 271–277. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, L.; Yu, H.S. Constitutive modeling of steel-polypropylene hybrid fiber reinforced concrete using a non-associated plasticity and its numerical implementation. Compos. Struct. 2014, 111, 497–509. [Google Scholar] [CrossRef]

- Bernardi, P.; Cerioni, R.; Michelini, E. Analysis of post-cracking stage in SFRC elements through a non-linear numerical approach. Eng. Fract. Mech. 2013, 108, 238–250. [Google Scholar] [CrossRef]

- Ito, H.; Watanabe, K.; Todoroki, S.; Suemori, H.; Shinjyo, R. Study on performance of PVA fiber reinforced concrete exposed for 10 years to seawater spray. J. Adv. Concr. Technol. 2018, 16, 159–169. [Google Scholar] [CrossRef]

- Kim, M.O.; Bordelon, A.C.; Lee, N.K. Early-age crack widths of thin fiber reinforced concrete overlays subjected to temperature gradients. Constr. Build. Mater. 2017, 148, 492–503. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Zhuge, Y.; Vijay, P.V.; Pettigrew, J. Experimental and numerical evaluations on the behaviour of structures repaired using prefabricated FRP composites jacket. Eng. Struct. 2020, 210, 110358. [Google Scholar] [CrossRef]

- Al-Rubaye, M.; Manalo, A.; Alajarmeh, O.; Ferdous, W.; Lokuge, W.; Benmokrane, B.; Edoo, A. Flexural behaviour of concrete slabs reinforced with GFRP bars and hollow composite reinforcing systems. Compos. Struct. 2020, 236, 111836. [Google Scholar] [CrossRef]

- Jiang, C.; Fan, K.; Wu, F.; Chen, D. Experimental study on the mechanical properties and microstructure of chopped basalt fibre reinforced concrete. Mater. Des. 2014, 58, 187–193. [Google Scholar] [CrossRef]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Borinaga-Treviño, R.; Orbe, A.; Norambuena-Contreras, J.; Canales, J. Effect of microwave heating damage on the electrical, thermal and mechanical properties of fibre-reinforced cement mortars. Constr. Build. Mater. 2018, 186, 31–41. [Google Scholar] [CrossRef]

- Bilotta, A.; Lignola, G.P. Effects of Defects on Bond Behavior of Fiber Reinforced Cementitious Matrix Materials. Materials 2020, 13, 164. [Google Scholar] [CrossRef]

- Padalu, P.K.V.R.; Singh, Y.; Das, S. Efficacy of basalt fibre reinforced cement mortar composite for out-of-plane strengthening of unreinforced masonry. Constr. Build. Mater. 2018, 191, 1172–1190. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; de Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Prota, A.; et al. Performance assessment of basalt FRCM for retrofit applications on masonry. Compos. Part B Eng. 2017, 128. [Google Scholar] [CrossRef]

- Li, L.G.; Zeng, K.L.; Ouyang, Y.; Kwan, A.K.H. Basalt fibre-reinforced mortar: Rheology modelling based on water film thickness and fibre content. Constr. Build. Mater. 2019, 229, 116857. [Google Scholar] [CrossRef]

- Kabay, N. Abrasion resistance and fracture energy of concretes with basalt fiber. Constr. Build. Mater. 2014, 50, 95–101. [Google Scholar] [CrossRef]

- Lipatov, Y.V.; Gutnikov, S.I.; Manylov, M.S.; Zhukovskaya, E.S.; Lazoryak, B.I. High alkali-resistant basalt fiber for reinforcing concrete. Mater. Des. 2015, 73, 60–66. [Google Scholar] [CrossRef]

- Simões, T.; Costa, H.; Dias-da-Costa, D.; Júlio, E. Influence of type and dosage of micro-fibres on the physical properties of fibre reinforced mortar matrixes. Constr. Build. Mater. 2018, 187, 1277–1285. [Google Scholar] [CrossRef]

- Li, L.G.; Zhuo, H.X.; Zhu, J.; Kwan, A.K.H. Packing density of mortar containing polypropylene, carbon or basalt fibres under dry and wet conditions. Powder Technol. 2019, 342, 433–440. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Łagód, G.; Fic, S.; Jarosz-Hadam, M. Effect of polysiloxanes on roughness and durability of basalt fibres-reinforced cement mortar. Polymers 2018, 10, 420. [Google Scholar] [CrossRef]

- Atiyeh, M.; Aydin, E. Carbon-Fiber Enriched Cement-Based Composites for Better Sustainability. Materials 2020, 13, 1899. [Google Scholar] [CrossRef] [PubMed]

- Pereira, M.V.; Fujiyama, R.; Darwish, F.; Alves, G.T. On the strengthening of cement mortar by natural fibers. Mater. Res. 2015, 18, 177–183. [Google Scholar] [CrossRef]

- Pareek, K.; Saha, P. Basalt fiber and its composites: An overview. In Proceedings of the National Conference on Advances in Structural Technologies (CoAST-2019), Silchar, India, 1–3 February 2019. [Google Scholar]

- Li, Z.; Ma, J.; Ma, H.; Xu, X. Properties and applications of basalt fiber and its composites. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 012052. [Google Scholar] [CrossRef]

- Cheng, Y.; Li, L.; Zhou, P.; Zhand, Y.; Liu, H. Multi-Objective Optimization Design and Test of Compound Diatomite and Basalt Fibre Asphalt Mixture. Materials 2019, 12, 1461. [Google Scholar] [CrossRef]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental study on basic mechanical properties of basalt fiber reinforced concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef] [PubMed]

- Hanafi, M.; Aydin, E.; Ekinci, A. Engineering properties of basalt fiber-reinforced bottom ash cement paste composites. Materials 2020, 13, 1952. [Google Scholar] [CrossRef] [PubMed]

- Ralegaonkar, R.; Gavali, H.; Aswath, P.; Abolmaali, S. Application of chopped basalt fibers in reinforced mortar: A review. Constr. Build. Mater. 2018, 164, 589–602. [Google Scholar] [CrossRef]

- van Gemert, D.; Czarnecki, L.; Maultzsch, M.; Schorn, H.; Beeldens, A.; Łukowski, P.; Knapen, E. Cement concrete and concrete-polymer composites: Two merging worlds: A report from 11th ICPIC Congress in Berlin, 2004. Cem. Concr. Compos. 2005, 27, 926–933. [Google Scholar] [CrossRef]

- Kubissa, W.; Simon, T.; Jaskulski, R.; Reiterman, P.; Supera, M. Ecological high performance concrete. Procedia Eng. 2017, 172, 595–603. [Google Scholar] [CrossRef]

- Ipbüker, C.; Nulk, H.; Gulik, V.; Biland, A.; Tkaczyk, A.H. Radiation shielding properties of a novel cement-basalt mixture for nuclear energy applications. Nucl. Eng. Des. 2015, 284, 27–37. [Google Scholar] [CrossRef]

- Lee, J.J.; Song, J.; Kim, H. Chemical stability of basalt fiber in alkaline solution. Fibers Polym. 2014, 15, 2329–2334. [Google Scholar] [CrossRef]

- Grzybowski, M.; Wang, J.; Karihaloo, B. Technical Report: Single and Multiple Bridged Cracks: Application to Fibre-Reinforced Solids; The University of Sydney: Sydney, Australia, 1996. [Google Scholar]

- Yonggui, W.; Shuaipeng, L.; Hughes, P.; Yuhui, F. Mechanical properties and microstructure of basalt fibre and nano-silica reinforced recycled concrete after exposure to elevated temperatures. Constr. Build. Mater. 2020, 247, 118561. [Google Scholar] [CrossRef]

- Kooshafar, M. Influential Mechanisms and Potential Applications of Nano-Silicas in Cement Composites. Civ. Eng. Infrastruct. J. 2017, 50, 375–393. [Google Scholar]

- European Committee for Standardization. CEN-EN 196-1:2016 Methods of Testing Cement. Determination of Strength; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Kozłowski, M.; Kadela, M.; Kukiełka, A. Fracture energy of foamed concrete based on three-point bending test on notched beams. Procedia Eng. 2015, 108, 349–354. [Google Scholar] [CrossRef]

- America Concrete Institute. ACI 446 Fracture Toughness Testing of Concrete; America Concrete Institute: Farmington Hills, MI, USA, 2009. [Google Scholar]

- British Standards Institution. EN 14651 Test Method for Metallic Fibred Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual); British Standards Institution: London, UK, 2005. [Google Scholar]

- Ramakrishnan, V.; Tolmare, N.; Brik, V. Performance Evaluation of 3-D Basalt Fiber Reinforced Concrete and Basalt Rod Reinforced Concrete. Innovations Deserving Exploratory Analysis Programs (IDEA) Program Final Report; Transportation Research Board: Washington, DC, USA, 1998. [Google Scholar]

- Zhang, G.; Li, X.; Li, Z. Experimental Study on Static Mechanical Properties and Moisture Contents of Concrete Under Water Environment. Sustainability 2019, 11, 2962. [Google Scholar] [CrossRef]

- Deschner, F.; Lothenbach, B.; Winnefeld, F.; Neubauer, J. Effect of temperature on the hydration of Portland cement blended with siliceous fly ash. Cem. Concr. Res. 2013, 52, 169–181. [Google Scholar] [CrossRef]

- Martínez-Ramírez, S.; Frías, M. The effect of curing temperature on white cement hydration. Constr. Build. Mater. 2009, 23, 1344–1348. [Google Scholar] [CrossRef]

- del Bosque, I.F.S.; Martínez-Ramírez, S.; Blanco-Varela, M. Combined effect of amorphous nanosilica and temperature on white Portland cement hydration. Ind. Eng. Chem. Res. 2013, 52, 11866–11874. [Google Scholar] [CrossRef][Green Version]

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | Others | |

|---|---|---|---|---|---|---|---|---|

| Minima | 45 | 12 | 5 | 6 | 3 | 0.9 | 2.5 | 2.0 |

| Maxima | 60 | 19 | 15 | 12 | 7 | 2.0 | 6.0 | 3.5 |

| SiO2 | Al2O3 | CaO + MgO | K2O + Na2O | C | |

|---|---|---|---|---|---|

| Percentage of overall mass (%) | 89.00 | 0.49 | 2.30 | 3.62 | 2.5 |

| Series Symbol 1 | Cement (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Micro-Silica (kg/m3) | Plasticiser (kg/m3) | BCF Fibres | PP Fibres | w/c Ratio 2 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| By Weight (kg/m3) | Weight Percentage by Binder Mass (%) | Percentage of Overall Volume (%) | By Weight (kg/m3) | Weight Percentage by Binder Mass (%) | Percentage of Overall Volume (%) | |||||||

| W1_21D | 200 | 1862 | 234.5 | – | 2.8 | – | – | – | – | – | – | 1.17 |

| BCF1_21D | 200 | 1862 | 234.5 | – | 2.8 | 12.4 | 6.2 | 0.46 | – | – | – | 1.17 |

| W2_1D W2_21D | 300 | 1750 | 215 | 30 | 3.0 | – | – | – | – | – | – | 0.72 |

| BCF2_1D BCF2_21D | 300 | 1750 | 215 | 30 | 3.0 | 9.0 | 3.0 | 0.33 | – | – | – | 0.72 |

| W3_28D W3_28D_70 | 500 | 1500 | 250 | 50 | 5.0 | – | – | – | – | – | – | 0.50 |

| BCF3_28D BCF3_28D_70 | 500 | 1500 | 250 | 50 | 5.0 | 5.0 | 1.0 | 0.18 | – | – | – | 0.50 |

| PP3_28D PP3_28D_70 | 500 | 1500 | 250 | 50 | 5.0 | – | – | – | 5.0 | 1.0 | 0.54 | 0.50 |

| Conditioning Description | Series Symbol | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W1_21D | BCF1_21D | W2_1D | BCF2_1D | W2_21D | BCF2_21D | W3_28D | BCF3_28D | PP3_28D | W3_28D_70 | BCF3_28D_70 | PP3_28D_70 | |

| – specimens stored in forms—air temperature in the room: 20 °C | 0th–1st | 0th–1st | 0th–1st | 0th–1st | 0th–1st | 0th–1st | 0th–2nd | 0th–2nd | 0th–2nd | 0th–2nd | 0th–2nd | 0th–2nd |

| – specimens stored in air saturated with water vapour at a level not less than 95%—air temperature: 20 °C | 2nd–21st | 2nd–21st | – | – | 2nd–21st | 2n–21st | – | – | – | – | – | – |

| – specimens stored in water—water temperature: 20 °C | – | – | – | – | – | – | 3rd–21st | 3rd–21st | 3rd–21st | 3rd–21st | 3rd–21st | 3rd–21st |

| – air-dry conditions—air temperature in the room: 20 °C | – | – | – | – | – | – | 22nd–28th | 22nd–28th | 22nd–28th | – | – | – |

| – specimens stored inside the dryer—air temperature inside the dryer: 70 °C | – | – | – | – | – | – | – | – | – | 22nd–28th | 22nd–28th | 22nd–28th |

| W1_21D/BCF1_21D | W2_1D/BCF2_1D | W2_21D/BCF2_21D | |

|---|---|---|---|

| without fibres | 56.93 | 41.91 | 206.19 |

| with fibres | 85.51 | 101.95 | 174.86 |

| increase due to fibres addition | +50.2% | +143.3% | −15.2% |

| Series Symbol | Flexural Strength | Density | Fracture Energy | ||

|---|---|---|---|---|---|

| Mean Value (MPa) | Standard Deviation (MPa) | Mean Value (kg/m3) | Standard Deviation (kg/m3) | Mean Value (N/m) | |

| W1_21D | 2.70 | 0.006 | 2216.0 | 21.47 | 56.93 |

| BCF1_21D 1,2 | 1.83 | 0.112 | 2051.4 | 21.38 | 85.51 |

| W2_1D | 2.28 | 0.064 | 2137.1 | 6.88 | 41.91 |

| BCF2_1D 1,2 | 1.75 | 0.079 | 1962.4 | 14.11 | 101.95 |

| W2_21D | 6.27 | 0.083 | 2135.2 | 5.75 | 206.19 |

| BCF2_21D | 5.28 | 0.341 | 1949.6 | 4.23 | 174.86 |

| W3_28D | 7.43 | 0.260 | 2432.7 | 26.70 | - |

| BCF3_28D | 8.06 | 0.478 | 2329.5 | 17.76 | - |

| PP3_28D 1 | 7.38 | 0.251 | 2224.7 | 22.34 | - |

| W3_28D_70 | 13.82 | 0.855 | 2306.3 | 30.80 | - |

| BCF3_28D_70 | 13.76 | 0.811 | 2240.0 | 23.03 | - |

| PP3_28D_70 1 | 12.91 | 0.441 | 2111.0 | 13.91 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wydra, M.; Dolny, P.; Sadowski, G.; Fangrat, J. Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres. Materials 2021, 14, 1334. https://doi.org/10.3390/ma14061334

Wydra M, Dolny P, Sadowski G, Fangrat J. Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres. Materials. 2021; 14(6):1334. https://doi.org/10.3390/ma14061334

Chicago/Turabian StyleWydra, Małgorzata, Piotr Dolny, Grzegorz Sadowski, and Jadwiga Fangrat. 2021. "Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres" Materials 14, no. 6: 1334. https://doi.org/10.3390/ma14061334

APA StyleWydra, M., Dolny, P., Sadowski, G., & Fangrat, J. (2021). Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres. Materials, 14(6), 1334. https://doi.org/10.3390/ma14061334