High Power Impulse Magnetron Sputtering of In2O3/Sn Cold Sprayed Composite Target

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Targets Preparation

2.3. Magnetron Sputtering Process

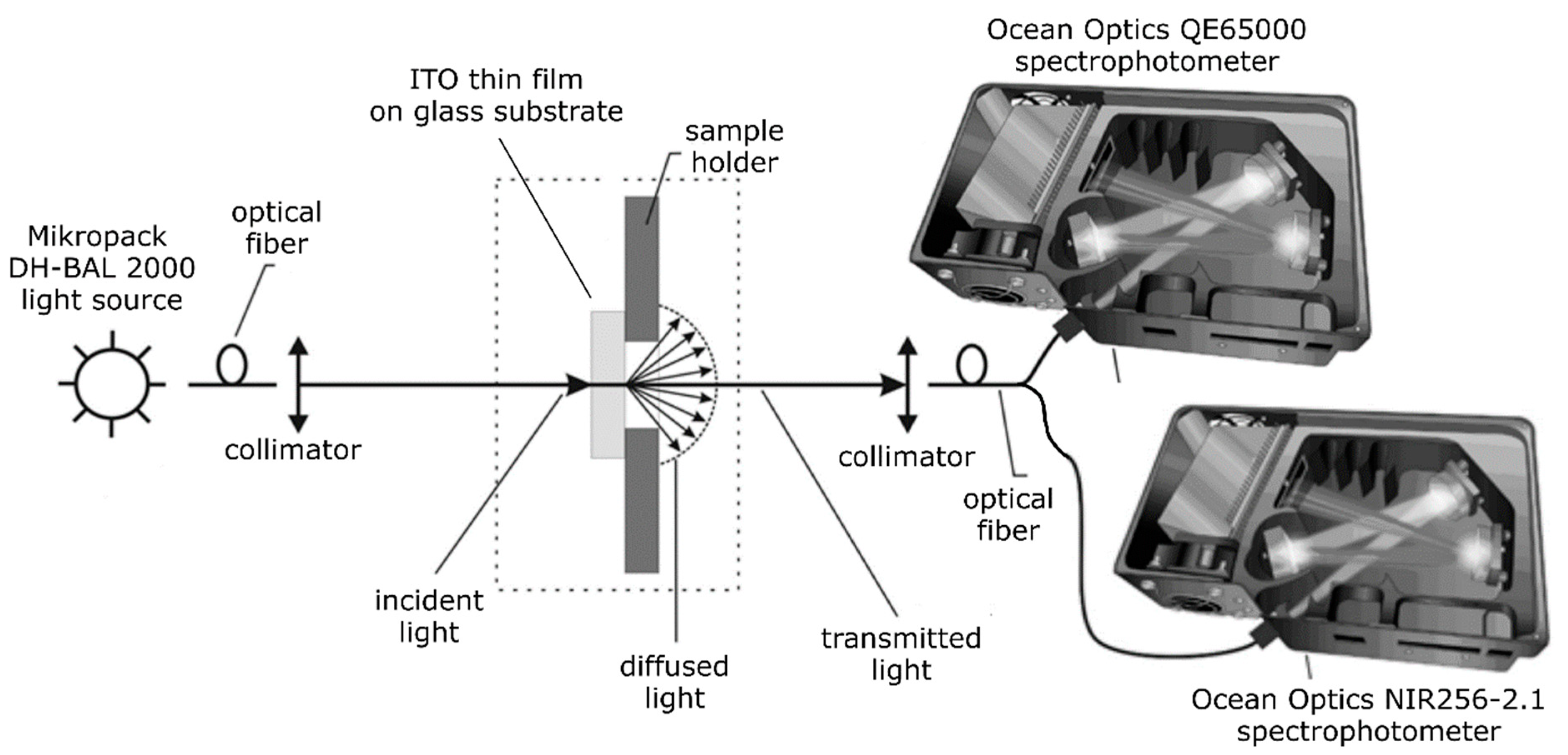

2.4. Coatings and Thin Films Characterization Methods

3. Results

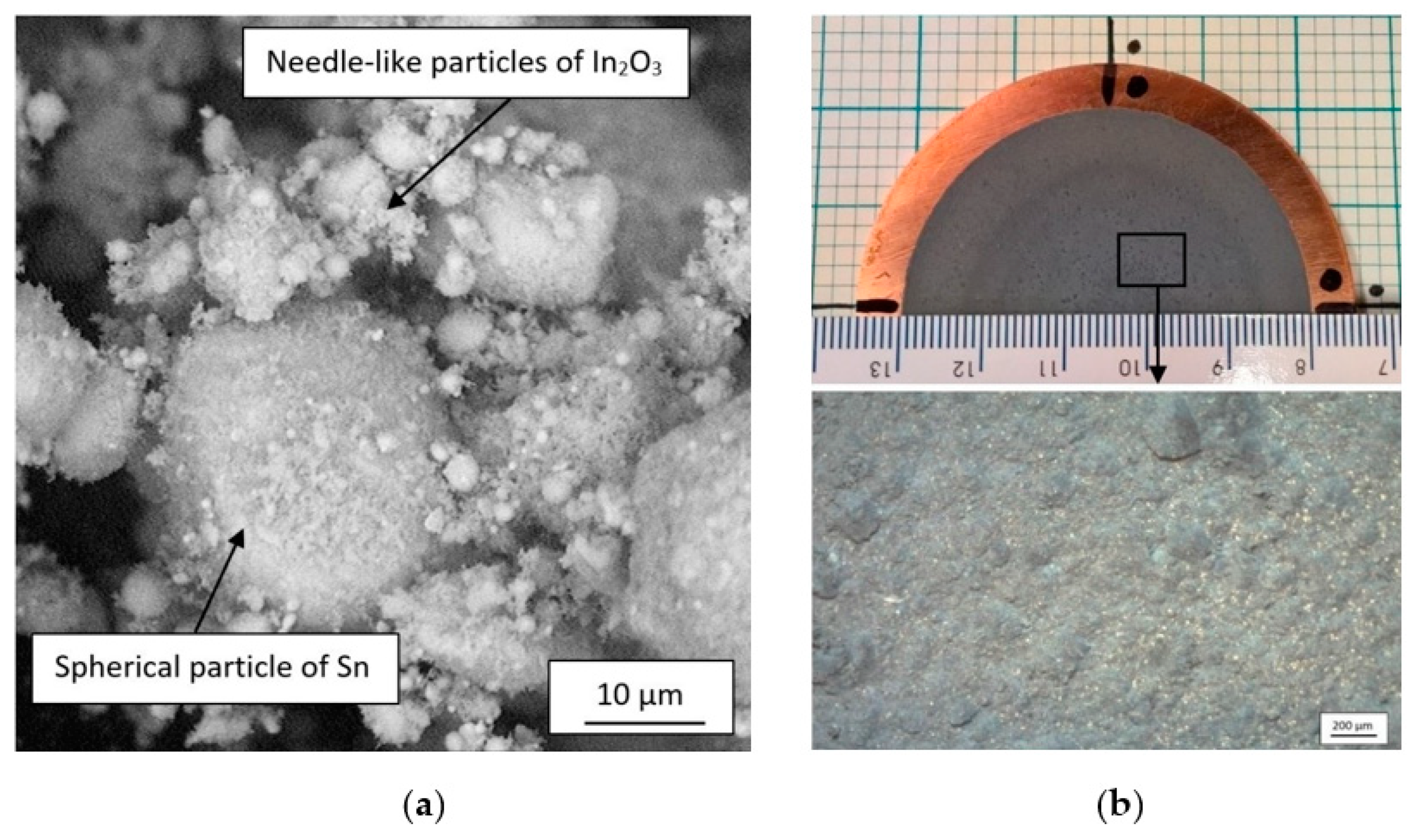

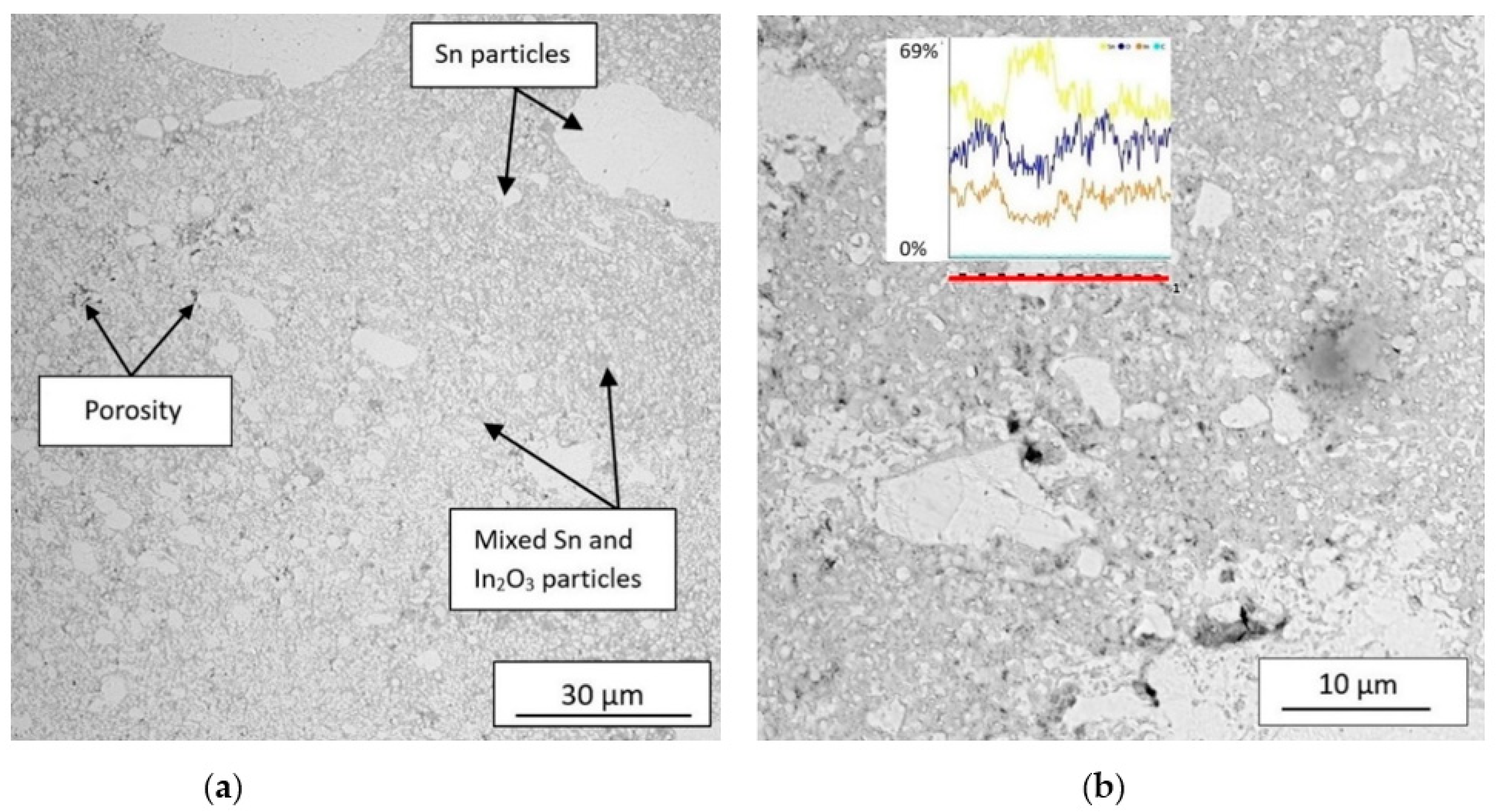

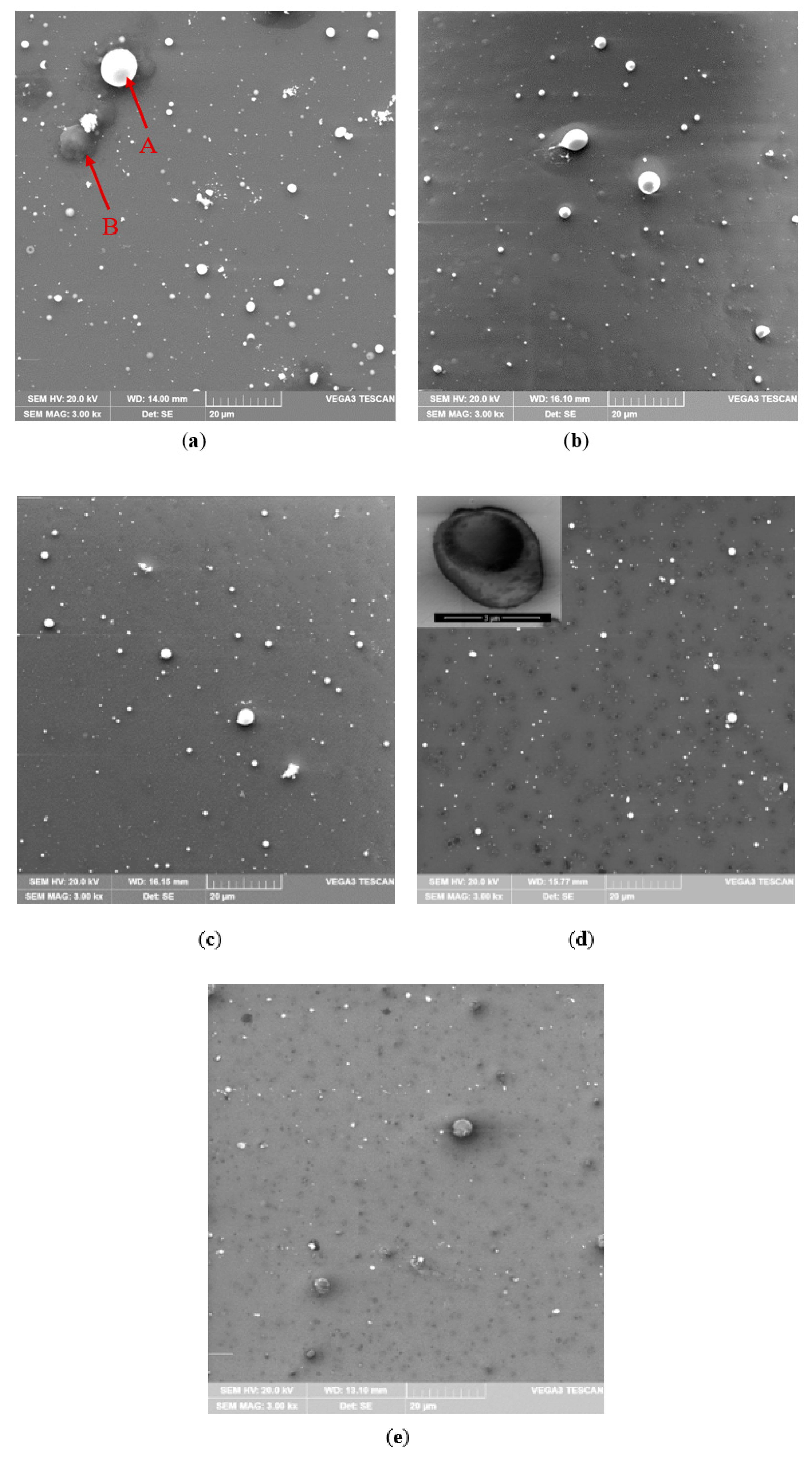

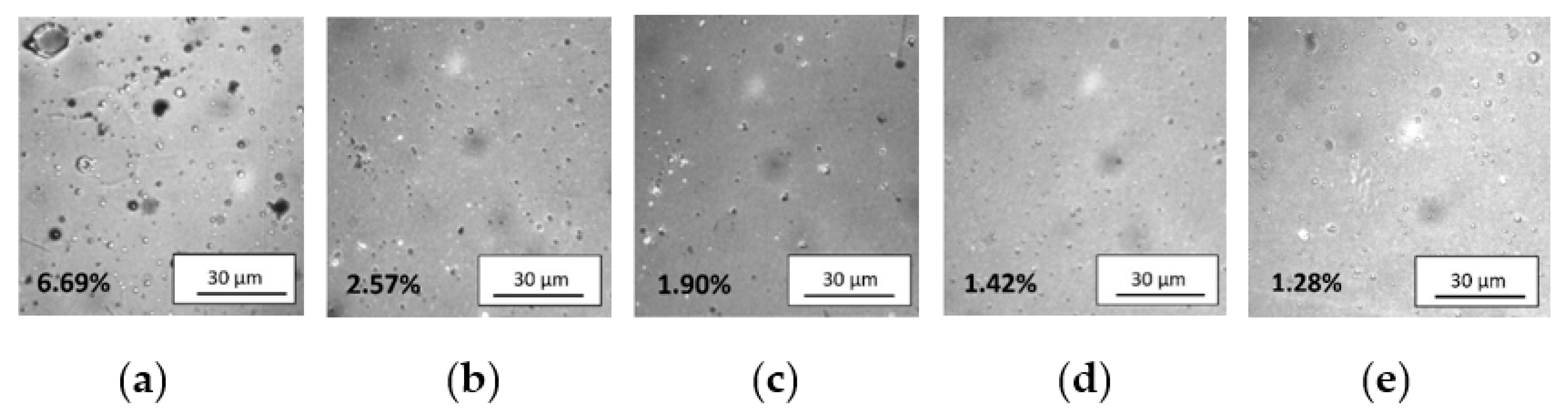

3.1. Cold-Sprayed Targets

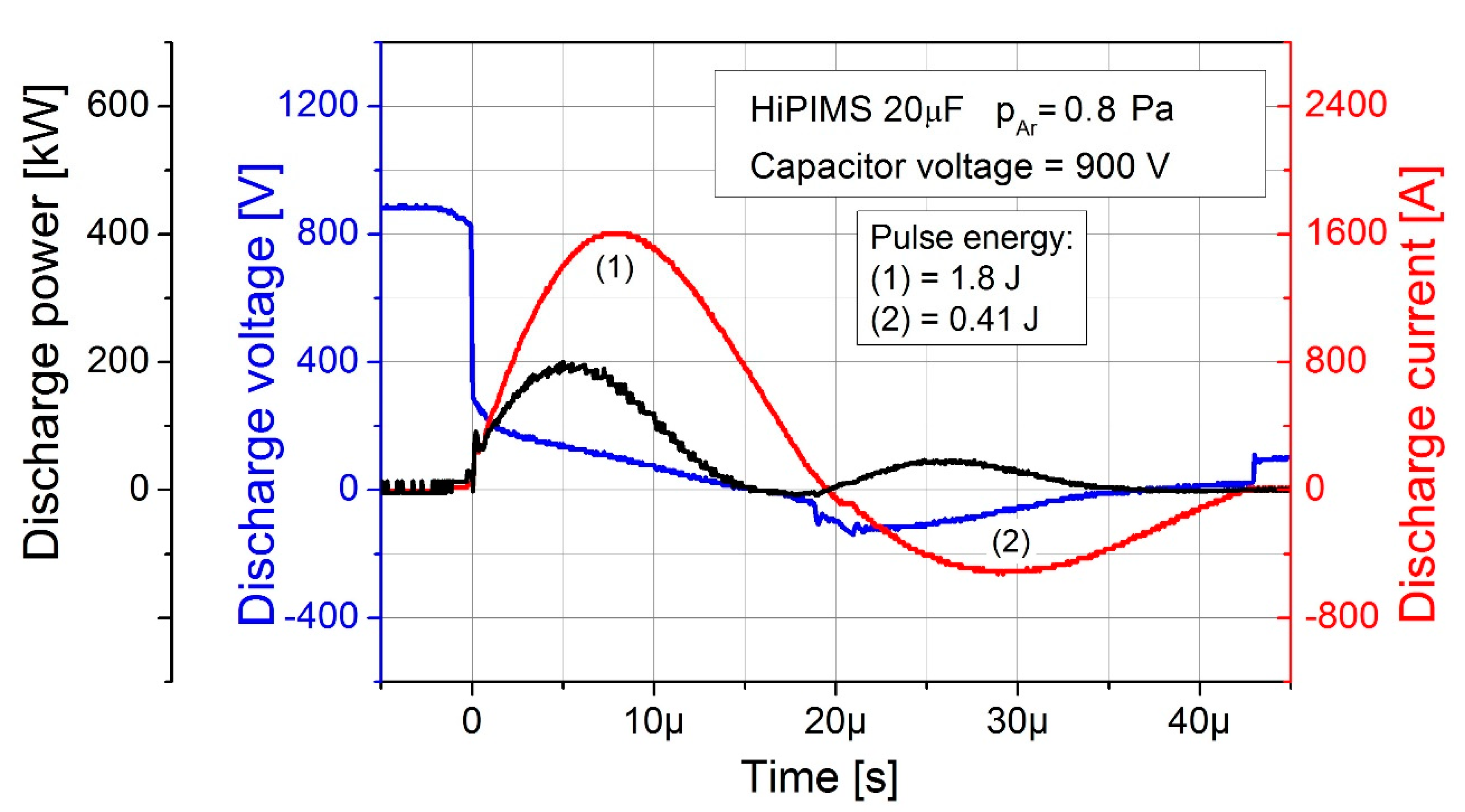

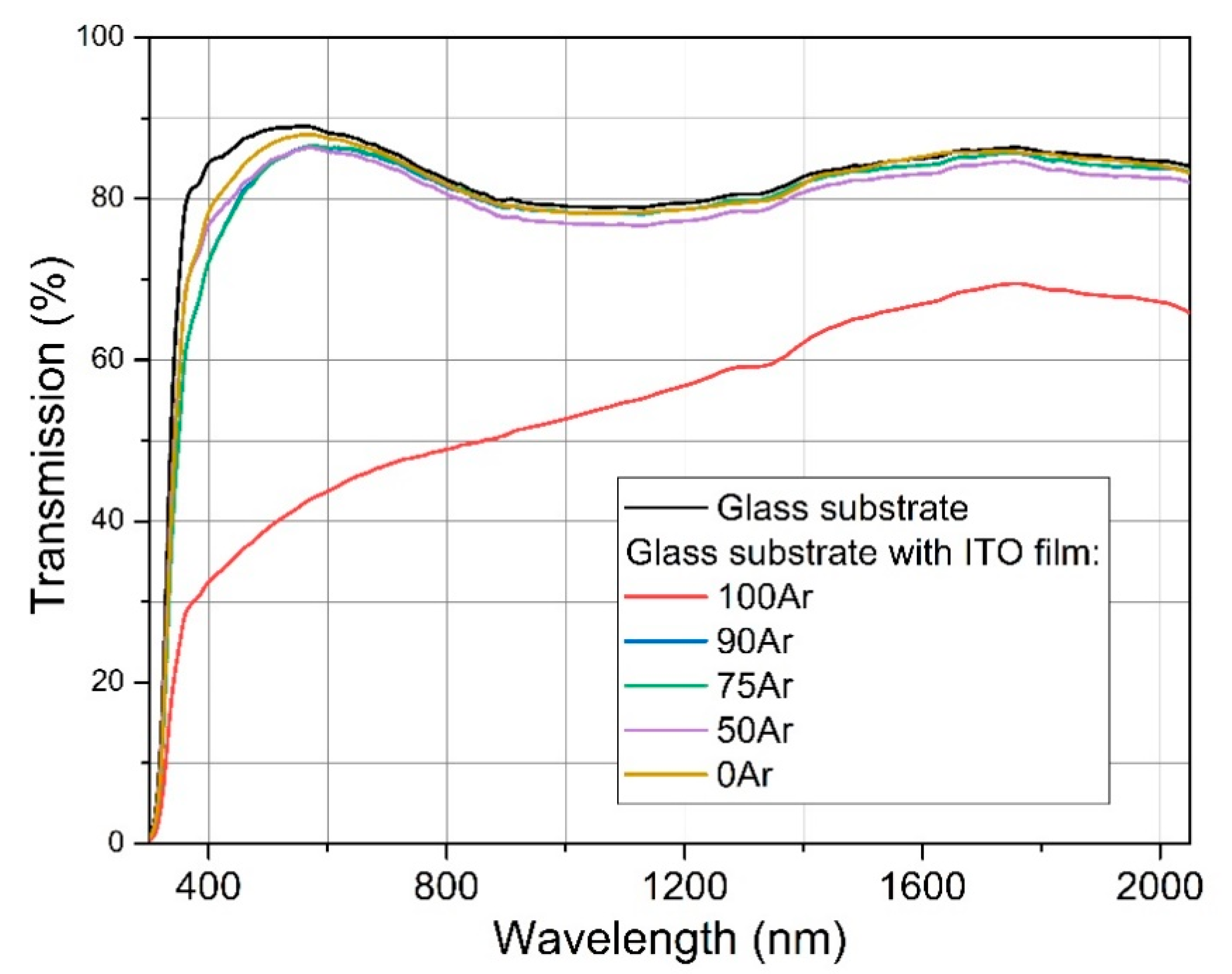

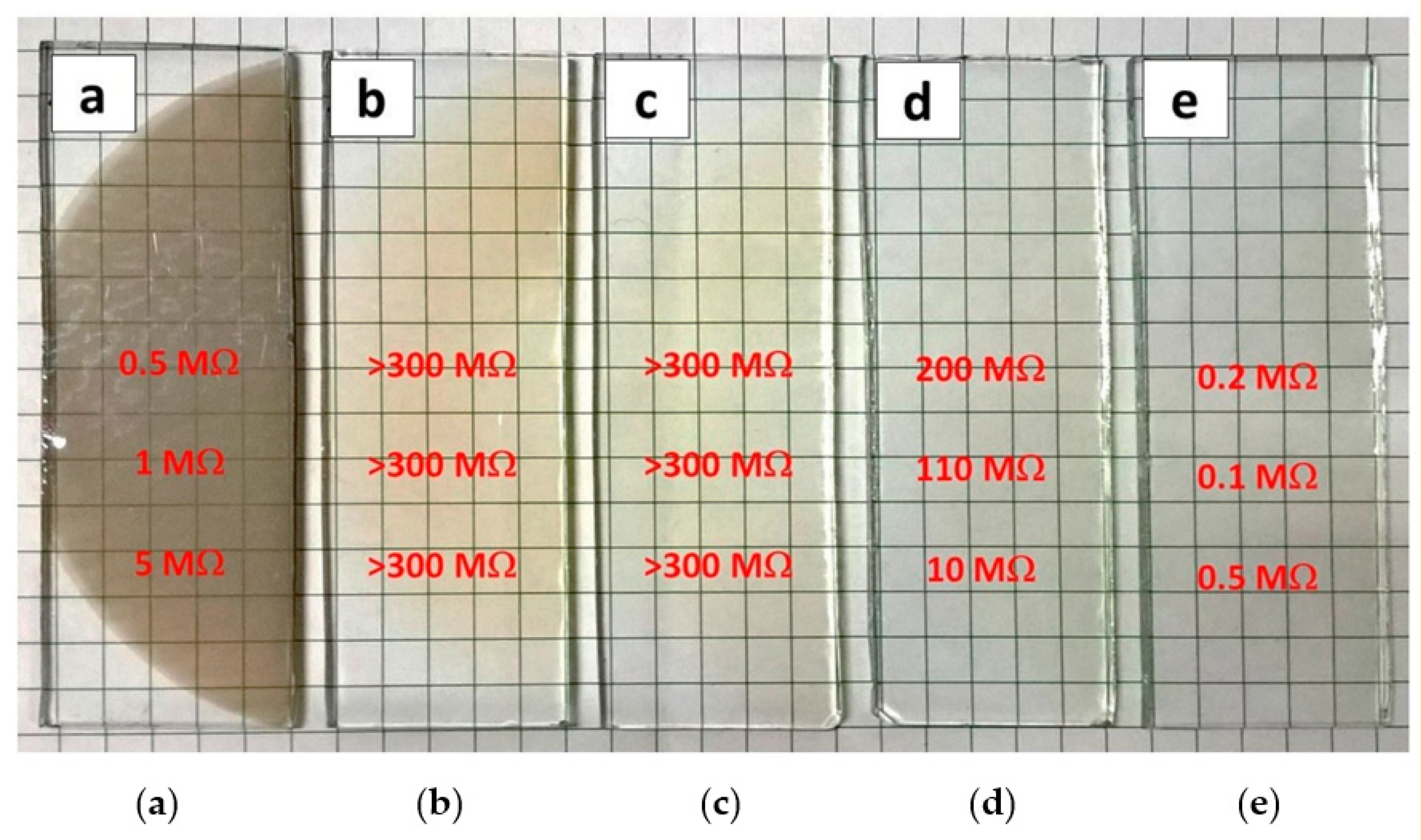

3.2. HiPIMS Deposition Process and ITO Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, Y.; Lieber, C.M. Functional Nanoscale Electronic Devices Assembled Using Silicon Nanowire Building Blocks. Science 2001, 291, 851–853. [Google Scholar] [CrossRef]

- Duan, X.; Huang, Y.; Cui, Y.; Wang, J.; Lieber, C.M. Indium Phosphide Nanowires as Building Blocks for Nanoscale Electronic and Optoelectronic Devices. Nature 2001, 409, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Noh, M.; Seo, I.; Park, J.; Chung, J.-S.; Lee, Y.S.; Kim, H.J.; Chang, Y.J.; Park, J.-H.; Kang, M.G.; Kang, C.Y. Spectroscopic Ellipsometry Investigation on the Excimer Laser Annealed Indium Thin Oxide Sol–Gel Films. Curr. Appl. Phys. 2016, 16, 145–149. [Google Scholar] [CrossRef]

- Hong, S.-J.; Song, S.-H.; Kim, B.J.; Lee, J.-Y.; Kim, Y.-S. ITO Nanoparticles Reused from ITO Scraps and Their Applications to Sputtering Target for Transparent Conductive Electrode Layer. Nano Converg. 2017, 4, 23. [Google Scholar] [CrossRef] [PubMed]

- Gao, Q.; Li, E.; Wang, A.X. Ultra-Compact and Broadband Electro-Absorption Modulator Using an Epsilon-near-Zero Conductive Oxide. Photonics Res. 2018, 6, 277–281. [Google Scholar] [CrossRef]

- Ellmer, K. Past Achievements and Future Challenges in the Development of Optically Transparent Electrodes. Nat. Photonics 2012, 6, 809–817. [Google Scholar] [CrossRef]

- Li, Q.; Tian, Z.; Zhang, Y.; Wang, Z.; Li, Y.; Ding, W.; Wang, T.; Yun, F. 3D ITO-Nanowire Networks as Transparent Electrode for All-Terrain Substrate. Sci. Rep. 2019, 9, 4983. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.-S.; Hsieh, C.-Y.; Wu, Y.-J.; Wei, Y.-S.; Lee, P.-M.; Hsieh, H.-M.; Liu, C.-Y. Mechanism of Conductivity Degradation of AZO Thin Film in High Humidity Ambient. Appl. Surf. Sci. 2013, 282, 32–37. [Google Scholar] [CrossRef]

- Jin, E.M.; Park, J.-Y.; Gu, H.-B.; Jeong, S.M. Synthesis of SnO2 Hollow Fiber Using Kapok Biotemplate for Application in Dye-Sensitized Solar Cells. Mater. Lett. 2015, 159, 321–324. [Google Scholar] [CrossRef]

- Hadri, A.; Taibi, M.; Loghmarti, M.; Nassiri, C.; Tlemçani, T.S.; Mzerd, A. Development of Transparent Conductive Indium and Fluorine Co-Doped ZnO Thin Films: Effect of F Concentration and Post-Annealing Temperature. Thin Solid Film. 2016, 601, 7–12. [Google Scholar] [CrossRef]

- Ha, M.; Lim, S.; Park, J.; Um, D.-S.; Lee, Y.; Ko, H. Bioinspired Interlocked and Hierarchical Design of ZnO Nanowire Arrays for Static and Dynamic Pressure-Sensitive Electronic Skins. Adv. Funct. Mater. 2015, 25, 2841–2849. [Google Scholar] [CrossRef]

- Zhang, X.; Zhong, Y.; Yan, Y.; Huo, Z.; Hao, C.; Peng, J.; Zhang, G. Mechanical Performance of Indium Zinc Oxide Films Deposited on Coating-Treated PMMA Substrates. Surf. Coat. Technol. 2019, 358, 604–610. [Google Scholar] [CrossRef]

- Kim, S.; Hwang, B. Ag Nanowire Electrode with Patterned Dry Film Photoresist Insulator for Flexible Organic Light-Emitting Diode with Various Designs. Mater. Des. 2018, 160, 572–577. [Google Scholar] [CrossRef]

- Peiris, T.A.N.; Ghanizadeh, S.; Jayathilake, D.S.Y.; Hutt, D.A.; Wijayantha, K.G.U.; Conway, P.P.; Southee, D.J.; Parkin, I.P.; Marchand, P.; Darr, J.A.; et al. Aerosol-Assisted Fabrication of Tin-Doped Indium Oxide Ceramic Thin Films from Nanoparticle Suspensions. J. Mater. Chem. C 2016, 4, 5739–5746. [Google Scholar] [CrossRef]

- Hu, L.; Ren, X.; Liu, J.; Tian, A.; Jiang, L.; Huang, S.; Zhou, W.; Zhang, L.; Yang, H. High-Power Hybrid GaN-Based Green Laser Diodes with ITO Cladding Layer. Photonics Res. 2020, 8, 279–285. [Google Scholar] [CrossRef]

- Yarali, E.; Koutsiaki, C.; Faber, H.; Tetzner, K.; Yengel, E.; Patsalas, P.; Kalfagiannis, N.; Koutsogeorgis, D.C.; Anthopoulos, T.D. Recent Progress in Photonic Processing of Metal-Oxide Transistors. Adv. Funct. Mater. 2020, 30, 1906022. [Google Scholar] [CrossRef]

- Ali, A.H.; Hassan, Z.; Shuhaimi, A. Enhancement of Optical Transmittance and Electrical Resistivity of Post-Annealed ITO Thin Films RF Sputtered on Si. Appl. Surf. Sci. 2018, 443, 544–547. [Google Scholar] [CrossRef]

- Li, E.; Nia, B.A.; Zhou, B.; Wang, A.X. Transparent Conductive Oxide-Gated Silicon Microring with Extreme Resonance Wavelength Tunability. Photonics Res. 2019, 7, 473–477. [Google Scholar] [CrossRef]

- Wu, P.-C.; Wu, G.-W.; Timofeev, I.V.; Zyryanov, V.Y.; Lee, W. Electro-Thermally Tunable Reflective Colors in a Self-Organized Cholesteric Helical Superstructure. Photonics Res. 2018, 6, 1094–1100. [Google Scholar] [CrossRef]

- Awasthi, V.; Garg, V.; Sengar, B.S.; Pandey, S.K.; Aaryashree; Kumar, S.; Mukherjee, C.; Mukherjee, S. Impact of Sputter-Instigated Plasmonic Features in TCO Films: For Ultrathin Photovoltaic Applications. Appl. Phys. Lett. 2017, 110, 103903. [Google Scholar] [CrossRef]

- Shen, Y.; Feng, Z.; Zhang, H. Study of Indium Tin Oxide Films Deposited on Colorless Polyimide Film by Magnetron Sputtering. Mater. Des. 2020, 193, 108809. [Google Scholar] [CrossRef]

- Szkutnik, P.D.; Roussel, H.; Lahootun, V.; Mescot, X.; Weiss, F.; Jiménez, C. Study of the Functional Properties of ITO Grown by Metalorganic Chemical Vapor Deposition from Different Indium and Tin Precursors. J. Alloys Compd. 2014, 603, 268–273. [Google Scholar] [CrossRef]

- Mohammadi, S.; Abdizadeh, H.; Golobostanfard, M.R. Opto-Electronic Properties of Molybdenum Doped Indium Tin Oxide Nanostructured Thin Films Prepared via Sol–Gel Spin Coating. Ceram. Int. 2013, 39, 6953–6961. [Google Scholar] [CrossRef]

- Zhang, L.; Lan, J.; Yang, J.; Guo, S.; Peng, J.; Zhang, L.; Tian, S.; Ju, S.; Xie, W. Study on the Physical Properties of Indium Tin Oxide Thin Films Deposited by Microwave-Assisted Spray Pyrolysis. J. Alloys Compd. 2017, 728, 1338–1345. [Google Scholar] [CrossRef]

- van den Ham, E.J.; Elen, K.; Bonneux, G.; Maino, G.; Notten, P.H.L.; Van Bael, M.K.; Hardy, A. 3D Indium Tin Oxide Electrodes by Ultrasonic Spray Deposition for Current Collection Applications. J. Power Sources 2017, 348, 130–137. [Google Scholar] [CrossRef]

- Gao, M.; Wu, X.; Liu, J.; Liu, W. The Effect of Heating Rate on the Structural and Electrical Properties of Sol–Gel Derived Al-Doped ZnO Films. Appl. Surf. Sci. 2011, 257, 6919–6922. [Google Scholar] [CrossRef]

- Hagendorfer, H.; Lienau, K.; Nishiwaki, S.; Fella, C.M.; Kranz, L.; Uhl, A.R.; Jaeger, D.; Luo, L.; Gretener, C.; Buecheler, S.; et al. Highly Transparent and Conductive ZnO: Al Thin Films from a Low Temperature Aqueous Solution ApproaC. Adv. Mater. 2014, 26, 632–636. [Google Scholar] [CrossRef]

- Park, T.; Kim, D. Excimer Laser Sintering of Indium Tin Oxide Nanoparticles for Fabricating Thin Films of Variable Thickness on Flexible Substrates. Thin Solid Film. 2015, 578, 76–82. [Google Scholar] [CrossRef]

- Cheong, W.-S.; Hong, C.-H.; Shin, J.-H.; Kim, K.-H.; Park, N.-M.; You, S.-J.; Kim, J.-H.; Kim, Y.-S. Low Temperature Fabrication of Indium-Tin Oxide Film by Using Ionized Physical Vapor Deposition Method. Surf. Coat. Technol. 2015, 266, 10–13. [Google Scholar] [CrossRef]

- May, C.; Strümpfel, J. ITO coating by reactive magnetron sputtering-comparison of properties from DC and MF processing. Thin Solid Film. 1999, 351, 48–52. [Google Scholar] [CrossRef]

- del Rio, E.; Ivanov, E.; Omi, K.; Teraoka, H. High performance of high density and high transparency Indium Tin oxide(ITO) and Zinc Aluminum Oxide(ZAO). In Proceedings of the 56th Annual Technical Conference, Providence, RI, USA, 20–25 April 2013. [Google Scholar]

- Carter, D.C. Arc prevention in magnetron puttering process. In Proceedings of the 51st Annual Technical Conference, Chicago, IL, USA, 19–24 April 2008. [Google Scholar]

- Wang, H.; Xu, X.; Li, X.; Zhang, J.; Li, C. Synthesis and sintering of indium tin oxide nanoparticles by citrate-Nitrate combustion method. Rare Met. 2010, 29, 355–360. [Google Scholar] [CrossRef]

- Xu, J.; Yang, L.; Wang, H.; Zhu, G.; Xu, H.; Zhou, C.; Yuan, C.; Yang, Z. Sintering behavior and refining grains of high density tin doped indium oxide targets with low tin oxide content. J. Mater. Sci. Mater. Electron. 2016, 27, 3298–3304. [Google Scholar] [CrossRef]

- Chang, S.Y.; Tsao, L.C.; Chiang, M.J.; Chuang, T.H.; Tung, C.N.; Pan, G.H. Active Soldering of Indium Tin Oxide(ITO) with Cu in Air Using an Sn3.5Ag4Ti(Ce, Ga) Filler. J. Mater. Eng. Perform. 2003, 12, 383–389. [Google Scholar] [CrossRef]

- Winnicki, M.; Baszczuk, A.; Rutkowska-Gorczyca, M.; Jasiorski, M.; Małachowska, A.; Posadowski, W.; Znamirowski, Z.; Ambroziak, A. Microscopic Examination of Cold Spray Cermet Sn+In2O3 Coatings for Sputtering Target Materials. Scanning 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Pathak, S.; Saha, G.C. Cold Spray: Its Prominence as an Additive Manufacturing Technology. In Cold Spray in the Realm of Additive Manufacturing. Materials Forming, Machining and Tribology, 1st ed.; Pathak, S., Saha, G., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From particles acceleration to impact and bonding in cold spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Yan, X.; Ahmed, M.; Lupoi, R.; Wang, J.; Ren, Z.; Liao, H.; Yin, S. Tribological properties of Al/diamond composites produced by cold spray additive manufacturing. Addit. Manuf. 2020, 36, 101434. [Google Scholar] [CrossRef]

- Santiago, J.A.; Fernández-Martínez, I.; Wennberg, A.; Molina-Aldareguia, J.M.; Castillo-Rodríguez, M.; Rojas, T.C.; Sánchez-López, J.C.; González, M.U.; García-Martín, J.M.; Li, H.; et al. Adhesion Enhancement of DLC Hard Coatings by HiPIMS Metal Ion Etching Pretreatment. Surf. Coat. Technol. 2018, 349, 787–796. [Google Scholar] [CrossRef]

- Rezek, J.; Novák, P.; Houška, J.; Pajdarová, A.D.; Kozák, T. High-Rate Reactive High-Power Impulse Magnetron Sputtering of Transparent Conductive Al-Doped ZnO Thin Films Prepared at Ambient Temperature. Thin Solid Film. 2019, 679, 35–41. [Google Scholar] [CrossRef]

- Tamai, T.; Nabeta, Y.; Sawada, S.; Hattori, Y. Property of Tin Oxide Film Formed on Tin-Plated Connector Contacts. In Proceedings of the 56th IEEE Holm Conference on Electrical Contacts, Charleston, SC, USA, 4–7 October 2010. [Google Scholar] [CrossRef]

- Huh, M.-Y.; Kim, S.-H.; Ahn, J.-P.; Park, J.-K.; Kim, B.-K. Oxidation of nanophase tin particles. NanoStruct. Mater. 1999, 11, 211–220. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Kijaszek, W.; Posadowski, W.M.; Oleszkiewicz, W.; Jadczak, J.; Kunicki, P. Deposition of Diamond-like Carbon Thin Films by the High Power Impulse Magnetron Sputtering Method. Diam. Relat. Mater. 2017, 72, 71–76. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, E.E. X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, 2nd ed.; John Wiley and Sons: New York, NY, USA, 1974. [Google Scholar]

- Konyashin, I.; Lachmann, F.; Ries, B.; Mazilkin, A.A.; Straumal, B.B.; Kübel, C.; Llanes, L.; Baretzky, B. Strengthening zones in the Co matrix of WC–Co cemented carbides. Scr. Mater. 2014, 83, 17–20. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, X.; Lu, L.; Li, D.; Mohanty, P.; Wang, Y. Microstructure and properties of Ag/SnO2 coatings prepared by cold spraying. Surf. Coat. Technol. 2013, 236, 224–229. [Google Scholar] [CrossRef]

- Munday, G.; Hogan, J.; McDonald, A. On the Microstructure-Dependency of Mechanical Properties and Failure of Low-Pressure Cold-Sprayed Tungsten Carbide-Nickel Metal Matrix Composite Coatings. Surf. Coat. Technol. 2020, 396, 125947. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Xie, Y.; Sapanathan, T.; Planche, M.P.; Kromer, R.; Costil, S.; Langlade, C. Cold Gas Dynamic Spray Technology: A Comprehensive Review of Processing Conditions for Various Technological Developments till to Date. Addit. Manuf. 2018, 19, 134–159. [Google Scholar] [CrossRef]

- Ko, K.H.; Lee, H.; Choi, J.O. Effect of Sn Particle Size on the Intermetallic Compound Formations of Cold Sprayed Sn–Ni Coatings. Appl. Surf. Sci. 2011, 257, 2970–2977. [Google Scholar] [CrossRef]

- Hassani-Gangaraj, M.; Veysset, D.; Nelson, K.A.; Schuh, C.A. Impact-bonding with aluminum, silver, and gold microparticles: Toward understanding the role of native oxide layer. Appl. Surf. Sci. 2019, 476, 528–532. [Google Scholar] [CrossRef]

- Hemeda, A.A.; Zhang, C.; Hu, X.Y.; Fukuda, D.; Cote, D.; Nault, I.M.; Nardi, A.; Champagne, V.K.; Ma, Y.; Palko, J.W. Particle-based simulation of cold spray: Influence of oxide layer on impact process. Addit. Manuf. in press. [CrossRef]

- Zhao, X.; Jin, J.; Cheng, J.-C.; Lee, J.-W.; Wu, K.-H.; Lin, K.-C.; Tsai, J.-R.; Liu, K.-C. Structural and Optical Properties of Zirconia Thin Films Deposited by Reactive High-Power Impulse Magnetron Sputtering. Thin Solid Film. 2014, 570, 404–411. [Google Scholar] [CrossRef]

- Wie, S.-M.; Hong, C.-H.; Oh, S.K.; Cheong, W.S.; Yoon, Y.J.; Kwak, J.S. Fully crystallized ultrathin ITO films deposited by sputtering with in-situ electron beam irradiation for touch-sensitive screens. Ceram. Int. 2014, 40, 11163–11169. [Google Scholar] [CrossRef]

- Guo, E.-J.; Guo, H.; Lua, H.; Jin, K.; He, M.; Yang, G. Structure and characteristics of ultrathin indium tin oxide films. Appl. Phys. Lett. 2011, 98, 011905. [Google Scholar] [CrossRef]

- Chu, J.; Huanga, S.M.; Zhua, H.B.; Xua, X.B.; Suna, Z.; Chena, Y.W.; Huang, F.Q. Preparation of indium tin oxide thin films without external heating for application in solar cells. J. Non-Cryst. Solids 2008, 354, 5480–5484. [Google Scholar] [CrossRef]

- Kim, J.; Shrestha, S.; Souri, M.; Connell, J.G.; Park, S.; Seo, A. High-temperature optical properties of indium tin oxide thin-films. Sci. Rep. 2020, 10, 12486. [Google Scholar] [CrossRef]

- Teixeira, V.; Cui, H.N.; Meng, L.J.; Fortunato, E.; Martins, R. Amorphous ITO thin films prepared by DC sputtering for electrochromic applications. Thin Solid Film. 2002, 420–421, 70–75. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, X.; Zhao, W.; Lu, K.; Ji, X.; Boukherroub, R. Preparation of Low-Resistance and Residue-free ITO Films for Large-scale 3D Displays. ACS Appl. Mater. Interfaces 2019, 11, 45903–45913. [Google Scholar] [CrossRef]

- Mohamed, S.; El-Hossary, F.; Gamal, G.; Kahlid, M. Properties of Indium Tin Oxide Thin Films Deposited on Polymer Substrates. Acta Phys. Pol. A 2009, 115, 704–708. [Google Scholar] [CrossRef]

- Powder Diffraction File. In Joint Committee on Powder Diffraction Standards; ASTM: Philadelphia, PA, USA, 1967.

- Zhang, H.; Cherng, J.-S.; Chen, Q. Recent Progress on High Power Impulse Magnetron Sputtering (HiPIMS): The Challenges and Applications in Fabricating VO2 Thin Film. AIP Adv. 2019, 9, 035242. [Google Scholar] [CrossRef]

- Stamate, E. Lowering the Resistivity of Aluminum Doped Zinc Oxide Thin Films by Controlling the Self-Bias during RF Magnetron Sputtering. Surf. Coat. Technol. 2020, 402, 126306. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winnicki, M.; Wiatrowski, A.; Mazur, M. High Power Impulse Magnetron Sputtering of In2O3/Sn Cold Sprayed Composite Target. Materials 2021, 14, 1228. https://doi.org/10.3390/ma14051228

Winnicki M, Wiatrowski A, Mazur M. High Power Impulse Magnetron Sputtering of In2O3/Sn Cold Sprayed Composite Target. Materials. 2021; 14(5):1228. https://doi.org/10.3390/ma14051228

Chicago/Turabian StyleWinnicki, Marcin, Artur Wiatrowski, and Michał Mazur. 2021. "High Power Impulse Magnetron Sputtering of In2O3/Sn Cold Sprayed Composite Target" Materials 14, no. 5: 1228. https://doi.org/10.3390/ma14051228

APA StyleWinnicki, M., Wiatrowski, A., & Mazur, M. (2021). High Power Impulse Magnetron Sputtering of In2O3/Sn Cold Sprayed Composite Target. Materials, 14(5), 1228. https://doi.org/10.3390/ma14051228