On the Use of EBSD and Microhardness to Study the Microstructure Properties of Tungsten Samples Prepared by Selective Laser Melting

Abstract

1. Introduction

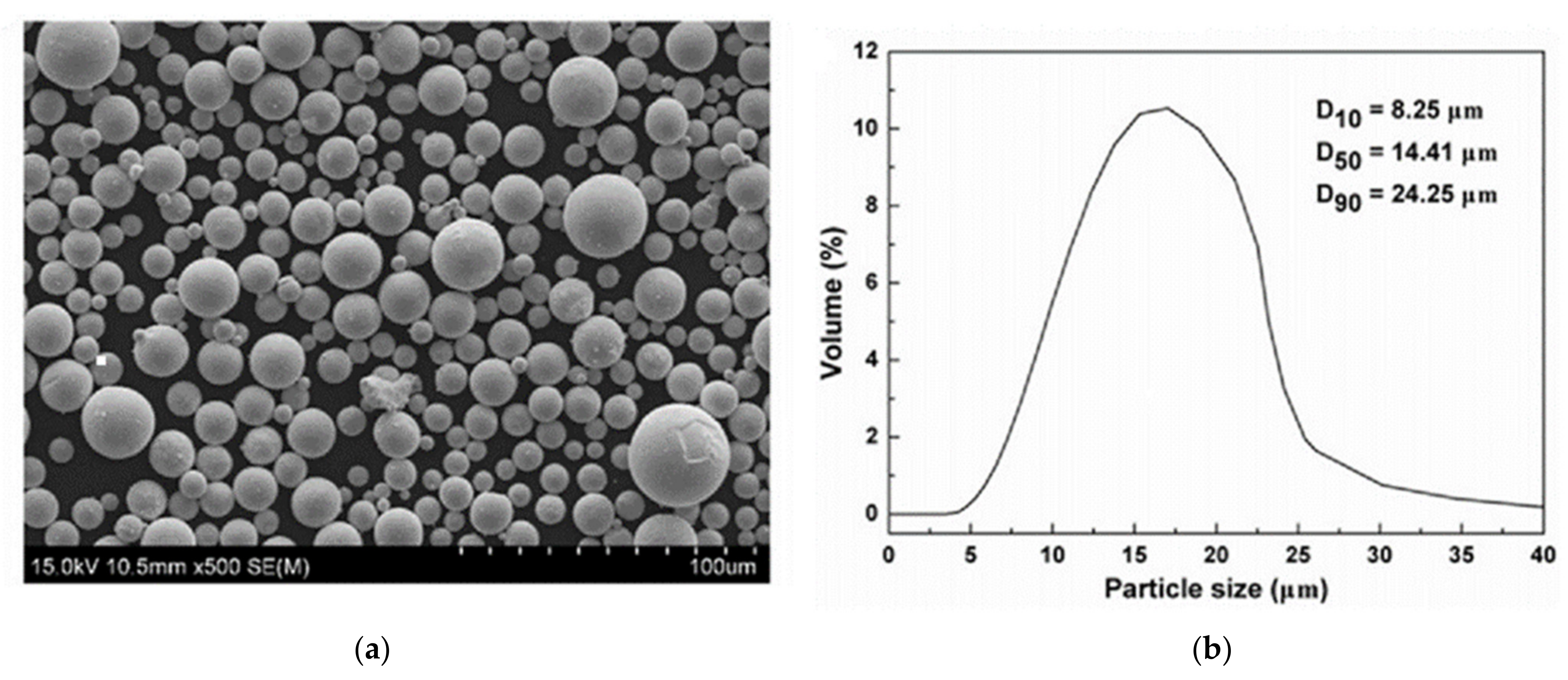

2. Materials and Methods

3. Results and Discussion

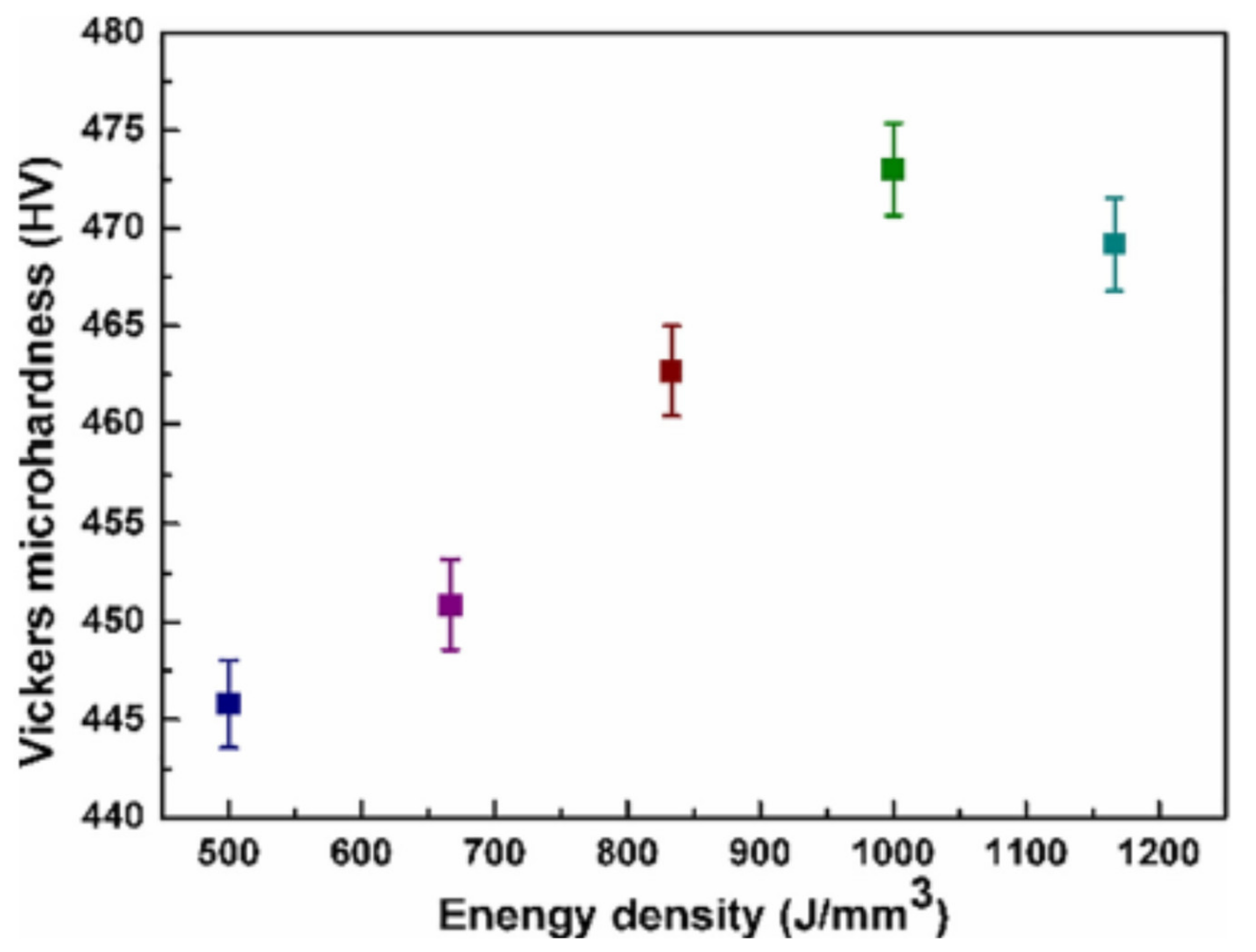

3.1. Microhardness

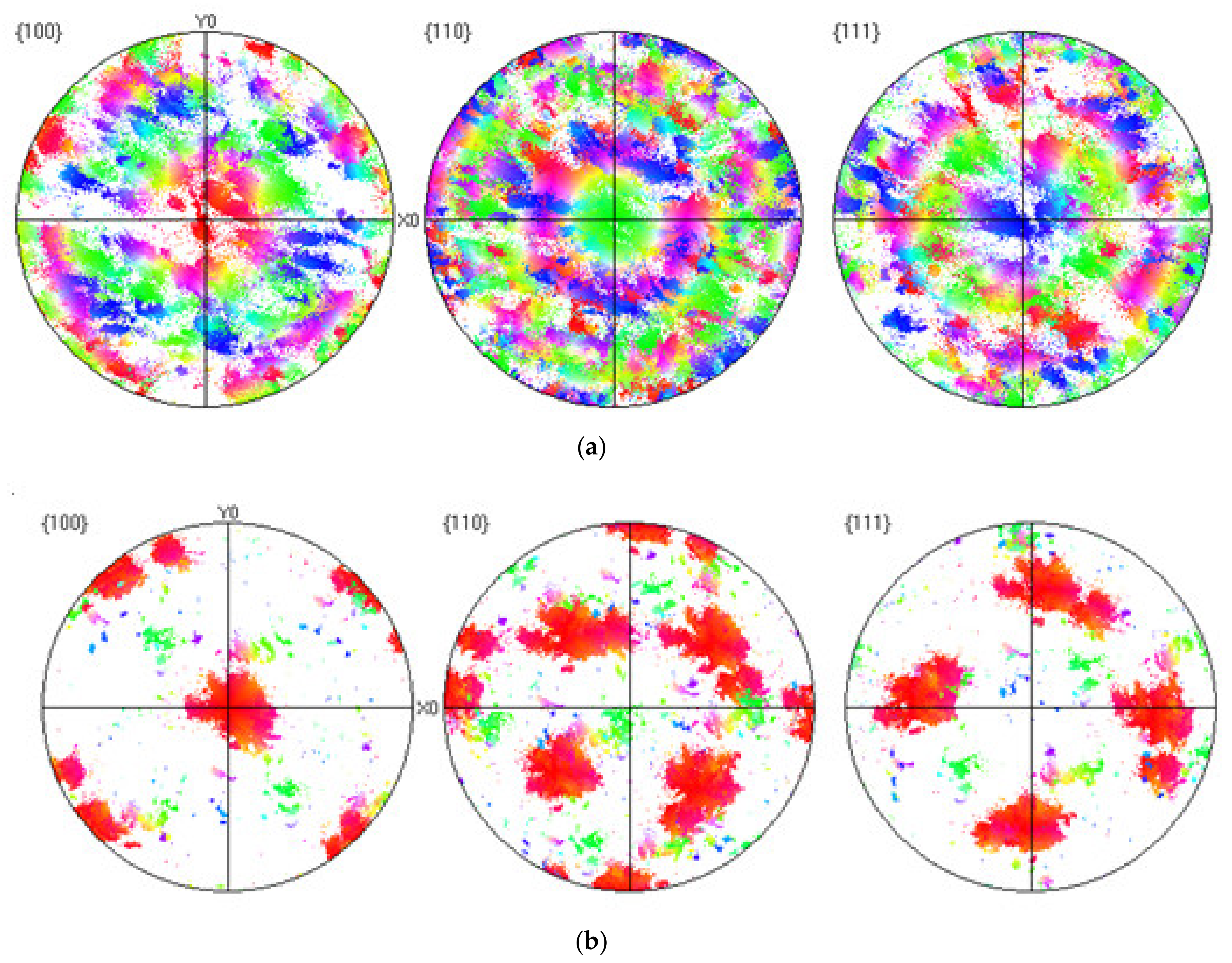

3.2. Crystallographic Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lassner, E.; Schubert, W.-D. Tungsten in Hardmetals; Springer International Publishing: New York, NY, USA, 1999; pp. 321–363. [Google Scholar]

- Philipps, V. Tungsten as material for plasma-facing components in fusion devices. J. Nucl. Mater. 2011, 415, S2–S9. [Google Scholar] [CrossRef]

- Roth, J.; Sergienko, G.; Sips, A. The ASDEX upgrade team. Nucl. Fusion. 2005, 47, 12. [Google Scholar]

- Pitts, R.; Bardin, S.; Bazylev, B.; Berg, M.V.D.; Bunting, P.; Carpentier-Chouchana, S.; Coenen, J.; Corre, Y.; Dejarnac, R.; Escourbiac, F.; et al. Physics conclusions in support of ITER W divertor monoblock shaping. Nucl. Mater. Energy 2017, 12, 60–74. [Google Scholar] [CrossRef]

- Ongena, J.; Van Oost, G. Militaire School—Ecole Royale Militaire Association “EURATOM—Belgian State” B–BRUSSELS (Belgium) Partner in the Trilateral Euregio Cluster (TEC). Energy for future centuries: Prospects for fusion power as a future energy source. Fusion Sci. Technol. 2012, 61, 3–16. [Google Scholar] [CrossRef]

- Tabor, D. The Hardness of Metals; Oxford University Press: Oxford, UK, 2000. [Google Scholar]

- Standard, A. Standard Hardness Conversion Tables for Metals Relationship among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb Hardness; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Sidambe, A.; Fox, P. Interaction of pure tungsten powder with processing conditions in selective laser melting. In Proceedings of the 2017 International Conference on Powder Metallurgy and Particulate Materials, Las Vegas, NV, USA, 13–16 June 2017. [Google Scholar]

- Sidambe, A.; Fox, P. Investigation of the selective laser melting process with tungsten metal powder. In Proceedings of the 19th Plansee Seminar, Reutte, Austria, 29 May–2 June 2017. [Google Scholar]

- Guo, M.; Gu, D.; Xi, L.; Zhang, H.; Zhang, J.; Yang, J.; Wang, R. Selective laser melting additive manufacturing of pure tungsten: Role of volumetric energy density on densification, microstructure and mechanical properties. Int. J. Refract. Met. Hard Mater. 2019, 84, 105025. [Google Scholar] [CrossRef]

- Kniepkamp, M.; Harbig, J.; Seyfert, C.; Abele, E. Towards High Build Rates: Combining Different Layer Thicknesses within One Part in Selective Laser Melting. In Proceedings of the SFF symposium proceedings, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Wang, D.Z.; Li, K.L.; Yu, C.F.; Ma, J.; Liu, W.; Shen, Z.J. Cracking behavior in additively manufactured pure tungsten. Acta Metall. Sin. 2019, 32, 127–135. [Google Scholar] [CrossRef]

- Zhang, D.; Cai, Q.; Liu, J. Formation of Nanocrystalline Tungsten by Selective Laser Melting of Tungsten Powder. Mater. Manuf. Process. 2012, 27, 1267–1270. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Q.; Lang, S.; Wang, Y.; Ge, C. Preparation of pure tungsten via various rolling methods and their influence on macro-texture and mechanical properties. Mater. Des. 2017, 126, 1–11. [Google Scholar] [CrossRef]

- Lennon, A.; Ramesh, K. The thermoviscoplastic response of polycrystalline tungsten in compression. Mater. Sci. Eng. A 2000, 276, 9–21. [Google Scholar] [CrossRef]

- Jin, J.-E.; Lee, Y.-K. Strain hardening behavior of a Fe–18Mn–0.6 C–1.5 Al TWIP steel. Mater. Sci. Eng. 2009, 527, 157–161. [Google Scholar] [CrossRef]

- Şahin, Y. Recent Progress in Processing of Tungsten Heavy Alloys. J. Powder Technol. 2014, 2014, 1–22. [Google Scholar] [CrossRef]

- Lee, J.-K.; Kim, S.-Y.; Ott, R.T.; Kim, J.-Y.; Eckert, J.; Lee, M.-H. Effect of reinforcement phase on the mechanical property of tungsten nanocomposite synthesized by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 54, 14–18. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, J.; Liu, W.; Shen, Z. Suppressing pore-boundary separation during spark plasma sintering of tungsten. J. Nucl. Mater. 2013, 438, 199–203. [Google Scholar] [CrossRef]

- Senthilnathan, N.; Annamalai, A.R.; Venkatachalam, G. Synthesis of tungsten through spark plasma and conventional sintering processes. Mater. Today Proc. 2018, 5, 7954–7959. [Google Scholar] [CrossRef]

- Yanwei, L.; Xiaodong, Y.; Chengwen, T.; Tiefeng, S.; Kunsong, M.; Hongnian, C. Effect of the β Phase on Compressive Mechanical Property of CVD Tungsten. Rare Met. Mater. Eng. 2011, 40, 1138–1140. [Google Scholar] [CrossRef]

- Gaganidze, E.; Rupp, D.; Aktaa, J. Fracture behaviour of polycrystalline tungsten. J. Nucl. Mater. 2014, 446, 240–245. [Google Scholar] [CrossRef]

- Antonysamy, A.A. Microstructure, Texture and Mechanical Property Evolution during Additive Manufacturing of Ti6Al4V Alloy for Aerospace Applications. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2012. [Google Scholar]

- Kruth, J.-P.; Kruth, J.P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Van Humbeeck, J. Part and material properties in selective laser melting of metals. Proceedings of the 16th International Symposium on Electromachining (ISEM XVI). Shanghai Jiao Tong; University Press: Cambridge, UK, 2010. [Google Scholar]

- Unnikrishnan, R.; Idury, K.S.; Ismail, T.; Bhadauria, A.; Shekhawat, S.; Khatirkar, R.K.; Sapate, S.G. Effect of heat input on the microstructure, residual stresses and corrosion resistance of 304L austenitic stainless steel weldments. Mater. Charact. 2014, 93, 10–23. [Google Scholar] [CrossRef]

- Thijs, L.; Sistiaga, M.L.M.; Wauthle, R.; Xie, Q.; Kruth, J.-P.; Van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef]

- Vickers, N.J. Animal Communication: When I’m Calling You, Will You Answer Too? Curr. Biol. 2017, 27, R713–R715. [Google Scholar] [CrossRef]

- Stojadinović, S.; Tadić, N.; Vasilić, R. Plasma electrolytic oxidation of hafnium. Int. J. Refract. Met. Hard Mater. 2017, 69, 153–157. [Google Scholar] [CrossRef]

- Upmanyu, M.; Hassold, G.; Kazaryan, A.; Holm, E.; Wang, Y.; Patton, B.; Srolovitz, D. Boundary Mobility and Energy Anisotropy Effects on Microstructural Evolution During Grain Growth. Interface Sci. 2002, 10, 201–216. [Google Scholar] [CrossRef]

- David, S.A.; Vitek, J.M. Correlation between solidification parameters and weld microstructures. Int. Mater. Rev. 1989, 34, 213–245. [Google Scholar] [CrossRef]

- Wei, H.L.; Mazumder, J.; Debroy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef]

- McAndrew, A.R.; Colegrove, P.A.; Bühr, C.; Flipo, B.C.; Vairis, A. A literature review of Ti-6Al-4V linear friction welding. Prog. Mater. Sci. 2018, 92, 225–257. [Google Scholar] [CrossRef]

| Element | Tungsten (W) | Oxygen (O) | Carbon (C) | Sulphur (S) |

|---|---|---|---|---|

| wt. % | Balance | 0.0016 | 0.0063 | 0.0022 |

| No. of OBS | Manufacturing Parameters | Dwell Time (s) | HV (Kgf) | HV (GPa) | ||

|---|---|---|---|---|---|---|

| Laser Power (watt) | Scan Speed (mm/s) | Hatch Spacing (mm) | Average Value | |||

| 1 | 130 | 500 | 0.03 | 10 | 506.9 | 4.97 |

| 2 | 150 | 500 | 0.03 | 10 | 438.0 | 4.23 |

| 3 | 150 | 500 | 0.04 | 10 | 458.7 | 4.45 |

| 4 | 150 | 400 | 0.08 | 10 | 451.7 | 4.42 |

| 5 | 150 | 500 | 0.08 | 10 | 436.2 | 4.27 |

| 6 | 170 | 500 | 0.03 | 10 | 762.7 | 7.47 |

| 7 | 170 | 400 | 0.04 | 10 | 484.5 | 4.75 |

| Manufacturing Technique | HV | Ultimate Compressive Stress (MPa) |

|---|---|---|

| SLM (selective laser melting) | 450–480 | 900–920 (This study) |

| CVD (Chemical vapor deposition) | 410–430 | 770–790 |

| PM (power metallurgy) | 430–450 | 1000–1150 ([15,16,17]) |

| SPS (spark plasma sintering) | 290–310 | 960–990 ([18,19,20,21] |

| No. of Observations | Scanning Speed (mm/s) | Laser Power (watt) | Hatch Spacing (mm) |

|---|---|---|---|

| Sample 1 | 300 | 150 | 0.08 |

| Sample 2 | 400 | 110 | 0.08 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, M.A.; Anru, Y.; Wang, Z.Y. On the Use of EBSD and Microhardness to Study the Microstructure Properties of Tungsten Samples Prepared by Selective Laser Melting. Materials 2021, 14, 1215. https://doi.org/10.3390/ma14051215

Abbas MA, Anru Y, Wang ZY. On the Use of EBSD and Microhardness to Study the Microstructure Properties of Tungsten Samples Prepared by Selective Laser Melting. Materials. 2021; 14(5):1215. https://doi.org/10.3390/ma14051215

Chicago/Turabian StyleAbbas, Mirza Atif, Yan Anru, and Zhi Yong Wang. 2021. "On the Use of EBSD and Microhardness to Study the Microstructure Properties of Tungsten Samples Prepared by Selective Laser Melting" Materials 14, no. 5: 1215. https://doi.org/10.3390/ma14051215

APA StyleAbbas, M. A., Anru, Y., & Wang, Z. Y. (2021). On the Use of EBSD and Microhardness to Study the Microstructure Properties of Tungsten Samples Prepared by Selective Laser Melting. Materials, 14(5), 1215. https://doi.org/10.3390/ma14051215